Influence of Acrylic Acid and Tert-Dodecyl Mercaptan in the Adhesive Performance of Water-Based Acrylic Pressure-Sensitive Adhesives

Abstract

:1. Introduction

2. Materials and Methods

2.1. Emulsion Polymerization

2.2. Latex Characterization

2.3. Adhesion Tests

3. Results and Discussion

3.1. Physico-Chemical Properties

3.2. Adhesive Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Platt, D. The Future of Labels and Release Liners to 2023; Smithers Pira: Leatherhead, UK, 2018. [Google Scholar]

- Creton, C. Pressure-sensitive adhesives: An introductory course. Mrs Bull. 2003, 28, 434–439. [Google Scholar] [CrossRef] [Green Version]

- Bilgin, E.T.; Turna, M.; Dülgar, C.A. Effect of the chain transfer agent on pressure-sensitive adhesive performance of butyl acrylate based latexes and determination of odor level caused by sulfur derivative compound. Aip Conf. Proc. 2020, 2205, 20048. [Google Scholar]

- Chauvet, J.; Asua, J.M.; Leiza, J.R. Independent control of sol molar mass and gel content in acrylate polymer/latexes. Polymer 2005, 46, 9555–9561. [Google Scholar] [CrossRef]

- Rajaram, S. Adhesives and Adhesive Applications: Technologies and Global Markets; BCC Research: Wellesley, MA, USA, 2013; ISBN 1569655219. [Google Scholar]

- Penzel, E.; Ballard, N.; Asua, J.M. Polyacrylates. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley Online Library: Hoboken, NJ, USA, 2018; pp. 7–9. [Google Scholar]

- Gower, M.D.; Shanks, R.A. The effect of varied monomer composition on adhesive performance and peeling master curves for acrylic pressure-sensitive adhesives. J. Appl. Polym. Sci. 2004, 93, 2909–2917. [Google Scholar] [CrossRef]

- Schultz, J.; Nardin, M. Theories and mechanisms of adhesion. In Handbook of Adhesive Technology; Pizzi, A., Mittal, K.L., Eds.; Taylor & Francis Group: New York, NY, USA, 2003; pp. 61–75. ISBN 0-8247-0986-1. [Google Scholar]

- Karyu, N.; Noda, M.; Fujii, S.; Nakamura, Y.; Urahama, Y. Effect of adhesive thickness on the wettability and deformability of polyacrylic pressure-sensitive adhesives during probe tack test. J. Appl. Polym. Sci. 2016, 133, 1–11. [Google Scholar] [CrossRef]

- Formulation, A.C. Classification of Adhesives and Compounds. In Adhesives Technology Handbook; Elsevier: Amsterdam, The Netherlands, 2009; pp. 47–62. [Google Scholar]

- Lee, J.H.; Lee, D.W. Contact-induced molecular rearrangement of acrylic acid-incorporated pressure sensitive adhesives. Appl. Surf. Sci. 2020, 500, 144246. [Google Scholar] [CrossRef]

- Gower, M.D.; Shanks, R.A. Acrylic Acid Level and Adhesive Performance and Peel Master-Curves of Acrylic Pressure- Sensitive Adhesives. J. Polym. Sci. 2006, 44, 1237–1252. [Google Scholar] [CrossRef]

- Aubrey, D.W.; Ginosatis, S. Peel Adhesion Behaviour of Carboxylic Elastomers. J. Adhes. 1981, 12, 189–198. [Google Scholar] [CrossRef]

- Chan, H.-K.; Howard, G. Structure-property relationships in acrylic adhesives. J. Adhes. 1978, 9, 279–304. [Google Scholar] [CrossRef]

- Vorwerg, L.; Gilbert, R.G. Electrosteric stabilization with poly(acrylic) acid in emulsion polymerization: Effect on kinetics and secondary particle formation. Macromolecules 2000, 33, 6693–6703. [Google Scholar] [CrossRef]

- Klein, A.S.; Daniels, E. Formulation components. In Emulsion Polymerization and Emulsion Polymers; Jonh Wiley & Sons: Bethlehem, PA, USA, 1997; pp. 228–229. [Google Scholar]

- Lena, J.B.; Deschamps, M.; Sciortino, N.F.; Masters, S.L.; Squire, M.A.; Russell, G.T. Effects of Chain Transfer Agent and Temperature on Branching and β-Scission in Radical Polymerization of 2-Ethylhexyl Acrylate. Macromol. Chem. Phys. 2018, 219, 1700579. [Google Scholar] [CrossRef]

- Lena, J.B.; Goroncy, A.K.; Thevarajah, J.J.; Maniego, A.R.; Russell, G.T.; Castignolles, P.; Gaborieau, M. Effect of transfer agent, temperature and initial monomer concentration on branching in poly(acrylic acid): A study by13C NMR spectroscopy and capillary electrophoresis. Polymer 2017, 114, 209–220. [Google Scholar] [CrossRef]

- Plessis, C.; Arzamendi, G.; Leiza, J.R.; Alberdi, J.M.; Schoonbrood, H.A.S.; Charmot, D.; Asua, J.M. Seeded semibatch emulsion polymerization of butyl acrylate: Effect of the chain-transfer agent on the kinetics and structural properties. J. Polym. Sci. Part A Polym. Chem. 2001, 39, 1106–1119. [Google Scholar] [CrossRef]

- Gower, M.D.; Shanks, R.A. The effect of chain transfer agent level on adhesive performance and peel master-curves for acrylic pressure sensitive adhesives. Macromol. Chem. Phys. 2004, 205, 2139–2150. [Google Scholar] [CrossRef]

- Carro, S.; Herrera-Ordonez, J.; Castillo-Tejas, J. On the mechanism of particle formation above the CMC in emulsion polymerization. Polym. Bull. 2018, 75, 1027–1035. [Google Scholar] [CrossRef]

- El-hoshoudy, A.N.M.B. Emulsion Polymerization Mechanism. In Recent Research in Polymerization; Çankaya, N., Ed.; InTech: Rijeka, Croatia, 2018; ISBN 978-953-51-3747-4. [Google Scholar]

- Lovell, P.A.; Schork, F.J. Fundamentals of Emulsion Polymerization. Biomacromolecules 2020, 21, 4396–4441. [Google Scholar] [CrossRef]

- Plessis, C.; Arzamendi, G.; Leiza, J.R.; Schoonbrood, H.A.S.; Charmot, D.; Asua, J.M. Decrease in effective acrylate propagation rate constants caused by intramolecular chain transfer. Macromolecules 2000, 33, 4–7. [Google Scholar] [CrossRef]

- Alarcia, F.; de la Cal, J.C.; Asua, J.M. Continuous production of specialty waterborne adhesives: Tuning the adhesive performance. Chem. Eng. J. 2006, 122, 117–126. [Google Scholar] [CrossRef]

- America Sociaty for Testing and Materials. Standard Test Method for Peel Adhesion of Pressure-Sensitive Tape; America Sociaty for Testing and Materials: West Conshohocken, PA, USA, 2003; Volume 4, pp. 1–6. [Google Scholar]

- FINAT Technical Committee FINAT Test Method No. 9 ‘Loop’ tack measurement. In FINAT Technical Handbook; FINAT: The Hague, The Netherlands, 2001; Volume 7, pp. 22–24.

- America Sociaty for Testing and Materials. Loop Tack Measurements. In Norm PSTC-16; America Sociaty for Testing and Materials: Oakbrook Terrace, IL, USA, 2007; pp. 1–8. [Google Scholar]

- FINAT Technical Committee FINAT Test method no. 8 Resistance to shear from a standard surface. In FINAT Technical Handbook; FINAT: The Hague, The Netherlands, 2001; Volume 7, pp. 20–21.

- FINAT Technical Committee FINAT Test Method No. 18 Dynamic Shear. In FINAT Technical Handbook; FINAT: The Hague, The Netherlands, 2001; Volume 11, pp. 42–44.

- Cohen-Addad, J.P.; Bogonuk, C. Gel-like Behavior of pH Dependent Latex Films. Macromolecules 1994, 27, 5032–5036. [Google Scholar] [CrossRef]

- Odian, G. Radical Chain Polymerization. In Principles of Polymerization; John Wiley & Sons: Hoboken, NJ, USA, 2004; pp. 252–253. ISBN 0-471-27400-3. [Google Scholar]

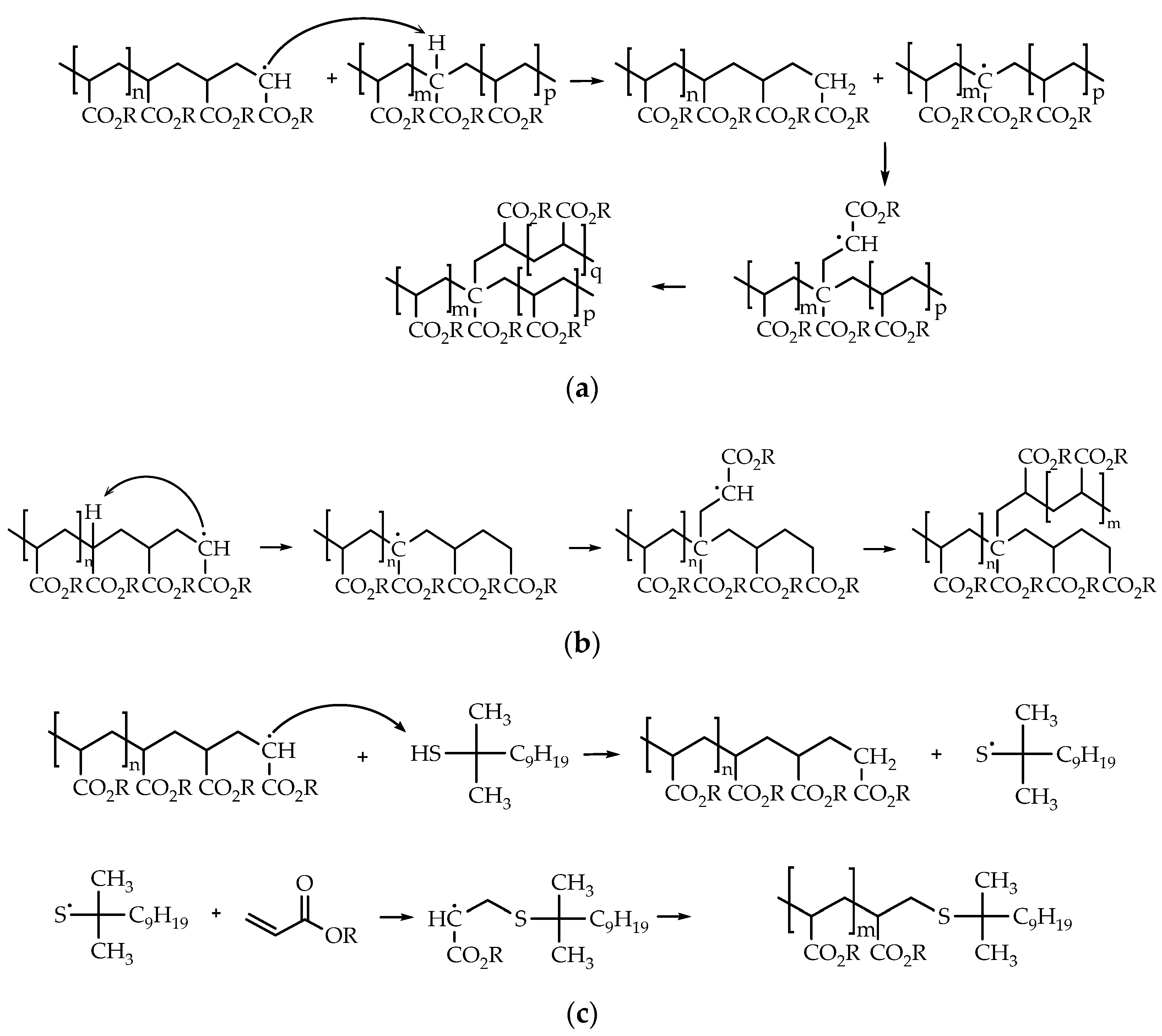

- Ballard, N.; Asua, J.M. Radical polymerization of acrylic monomers: An overview. Prog. Polym. Sci. 2018, 79, 40–60. [Google Scholar] [CrossRef]

- Ballard, N.; Hamzehlou, S.; Asua, J.M. Intermolecular Transfer to Polymer in the Radical Polymerization of n-Butyl Acrylate. Macromolecules 2016, 49, 5418–5426. [Google Scholar] [CrossRef]

- Moghadam, N.; Liu, S.; Srinivasan, S.; Grady, M.C.; Rappe, A.M.; Soroush, M. Theoretical study of intermolecular chain transfer to polymer reactions of alkyl acrylates. Ind. Eng. Chem. Res. 2015, 54, 4148–4165. [Google Scholar] [CrossRef]

- Plessis, C.; Arzamendi, G.; Leiza, J.R.; Schoonbrood, H.A.S.; Charmot, D.; Asua, J.M. Seeded semibatch emulsion polymerization of n-butyl acrylate. Kinetics and structural properties. Macromolecules 2000, 33, 5041–5047. [Google Scholar] [CrossRef]

- Treviño, M.E.; Dubé, M.A. Synthesis of Self-Crosslinkable Water-Borne Pressure Sensitive Adhesives. Macromol. React. Eng. 2013, 7, 484–492. [Google Scholar] [CrossRef]

- Fang, C.; Liu, Z.; Zhu, X.; Cao, Y.; Dong, X. Manipulation of chain transfer agent and cross-linker concentration to modify the performance of fluorinated acrylate latex pressure sensitive adhesive. J. Adhes. Sci. Technol. 2020, 34, 976–994. [Google Scholar] [CrossRef]

- Çetinkaya, O.; Demirci, G.; Mergo, P. Effect of the different chain transfer agents on molecular weight and optical properties of poly(methyl methacrylate). Opt. Mater. 2017, 70, 25–30. [Google Scholar] [CrossRef]

- Ballard, N.; De La Cal, J.C.; Asua, J.M. The role of chain transfer agent in reducing branching content in radical polymerization of Acrylates. Macromolecules 2015, 48, 987–993. [Google Scholar] [CrossRef]

- Furuncuoǧlu, T.; Uǧur, I.; Degirmenci, I.; Aviyente, V. Role of chain transfer agents in free radical polymerization kinetics. Macromolecules 2010, 43, 1823–1835. [Google Scholar] [CrossRef]

- Benedek, I. Converting properties of PSAs. In Pressure-Sensitive Adhesives and Applications; Marcel Dekker, Inc.: New York, NY, USA, 2004; p. 386. ISBN 0824750594. [Google Scholar]

- Ghim, D.; Kim, J.H. Effects of composition and layer thickness of a butyl acrylate/acrylic acid copolymer on the adhesion properties. Korean J. Chem. Eng. 2016, 33, 707–710. [Google Scholar] [CrossRef]

- Satas, D. Handbook of Pressure Sensitive Adhesive Technology, 2nd ed.; Van Nostrand Reinhold: New York, NY, USA, 1989; ISBN 978-1-4757-0868-4. [Google Scholar]

| Series | AA | n-BA | ACN | TDM |

|---|---|---|---|---|

| AA-0.5 | 0.5 | 93.0 | 6.0 | 0.00 |

| 0.05 | ||||

| 0.10 | ||||

| 0.20 | ||||

| AA-1.0 | 1.0 | 93.0 | 6.0 | 0.00 |

| 0.05 | ||||

| 0.10 | ||||

| 0.20 | ||||

| AA-1.5 | 1.5 | 92.5 | 6.0 | 0.00 |

| 0.05 | ||||

| 0.10 | ||||

| 0.20 | ||||

| AA-3.0 | 3.0 | 91.0 | 6.0 | 0.00 |

| 0.05 | ||||

| 0.10 | ||||

| 0.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Márquez, I.; Paredes, N.; Alarcia, F.; Velasco, J.I. Influence of Acrylic Acid and Tert-Dodecyl Mercaptan in the Adhesive Performance of Water-Based Acrylic Pressure-Sensitive Adhesives. Polymers 2020, 12, 2879. https://doi.org/10.3390/polym12122879

Márquez I, Paredes N, Alarcia F, Velasco JI. Influence of Acrylic Acid and Tert-Dodecyl Mercaptan in the Adhesive Performance of Water-Based Acrylic Pressure-Sensitive Adhesives. Polymers. 2020; 12(12):2879. https://doi.org/10.3390/polym12122879

Chicago/Turabian StyleMárquez, Irene, Núria Paredes, Felipe Alarcia, and José Ignacio Velasco. 2020. "Influence of Acrylic Acid and Tert-Dodecyl Mercaptan in the Adhesive Performance of Water-Based Acrylic Pressure-Sensitive Adhesives" Polymers 12, no. 12: 2879. https://doi.org/10.3390/polym12122879

APA StyleMárquez, I., Paredes, N., Alarcia, F., & Velasco, J. I. (2020). Influence of Acrylic Acid and Tert-Dodecyl Mercaptan in the Adhesive Performance of Water-Based Acrylic Pressure-Sensitive Adhesives. Polymers, 12(12), 2879. https://doi.org/10.3390/polym12122879