Effect of Plasma-Treatment of Interleaved Thermoplastic Films on Delamination in Interlayer Fibre Hybrid Composite Laminates

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials for Fibre-Hybrid Composites

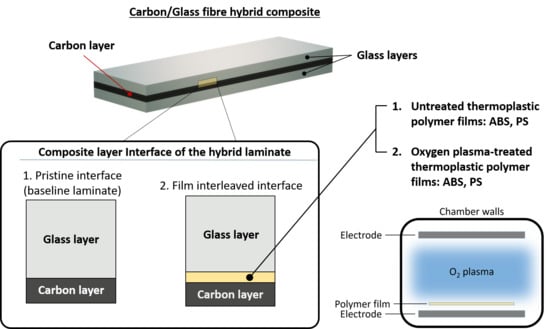

2.2. Intrerleaved Thermoplastic Films

2.3. Oxygen Plasma Treatment of Interleaf Films

2.4. Surface Analysis of Plasma-Treated Polymer Films by X-ray Photoelectron Spectroscopy

2.5. Contact Angle Measurements

2.6. Design and Manufacturing of Hybrid Composite Laminates

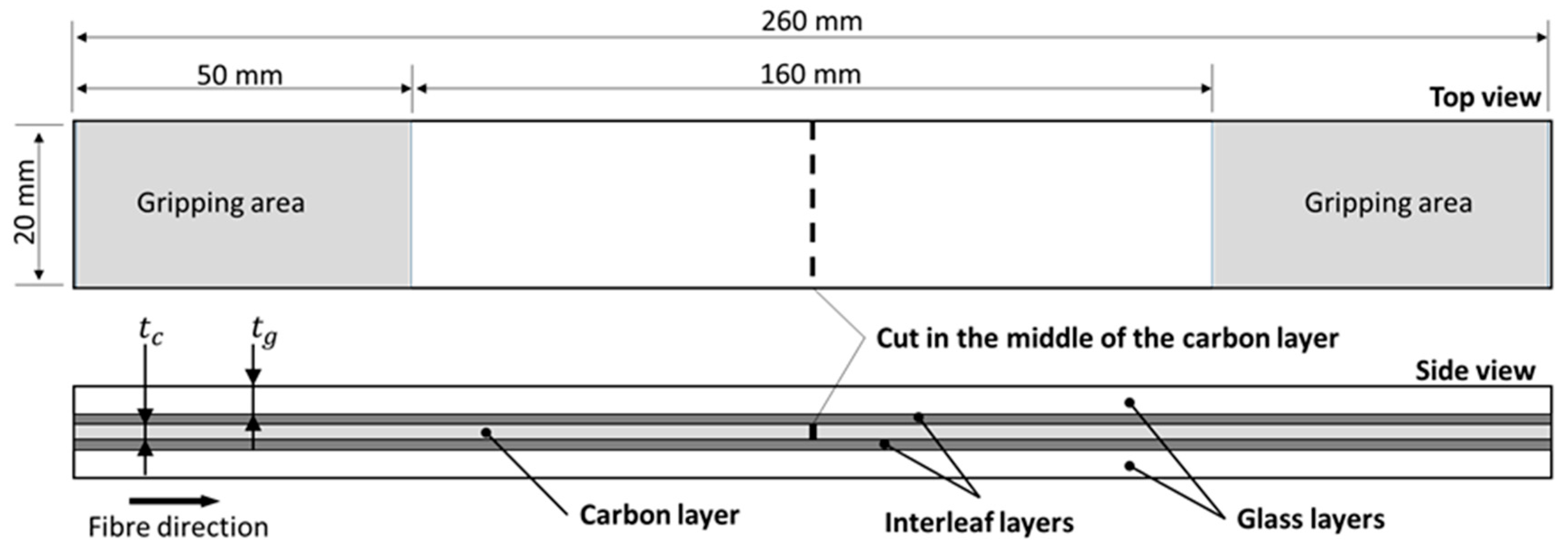

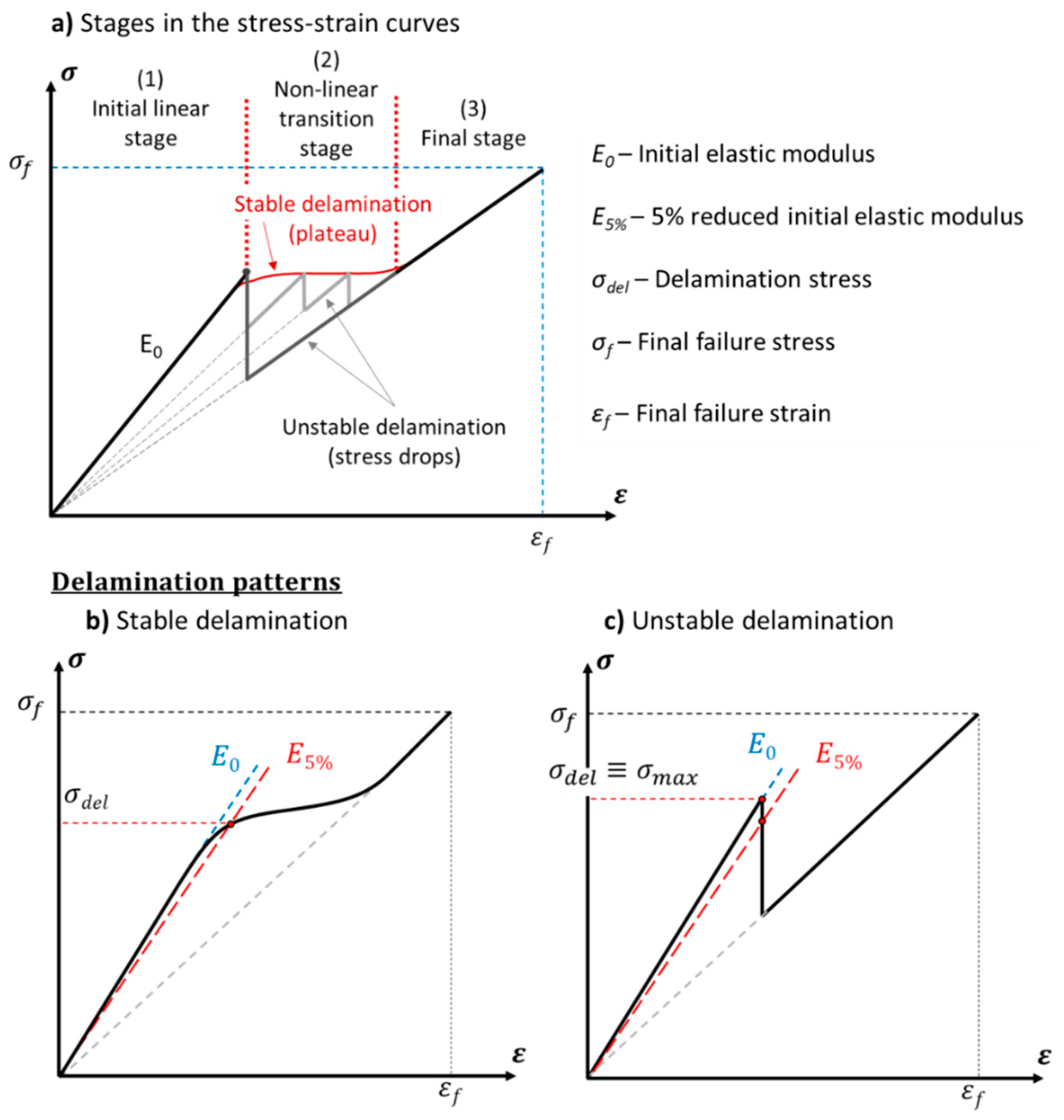

2.7. Mechanical Testing Methods and Calculation of the Parameters

2.8. Microscope Analysis

3. Results and Discussion

3.1. Effect of Plasma Treatment on the Wettability of the Applied Polymer Films

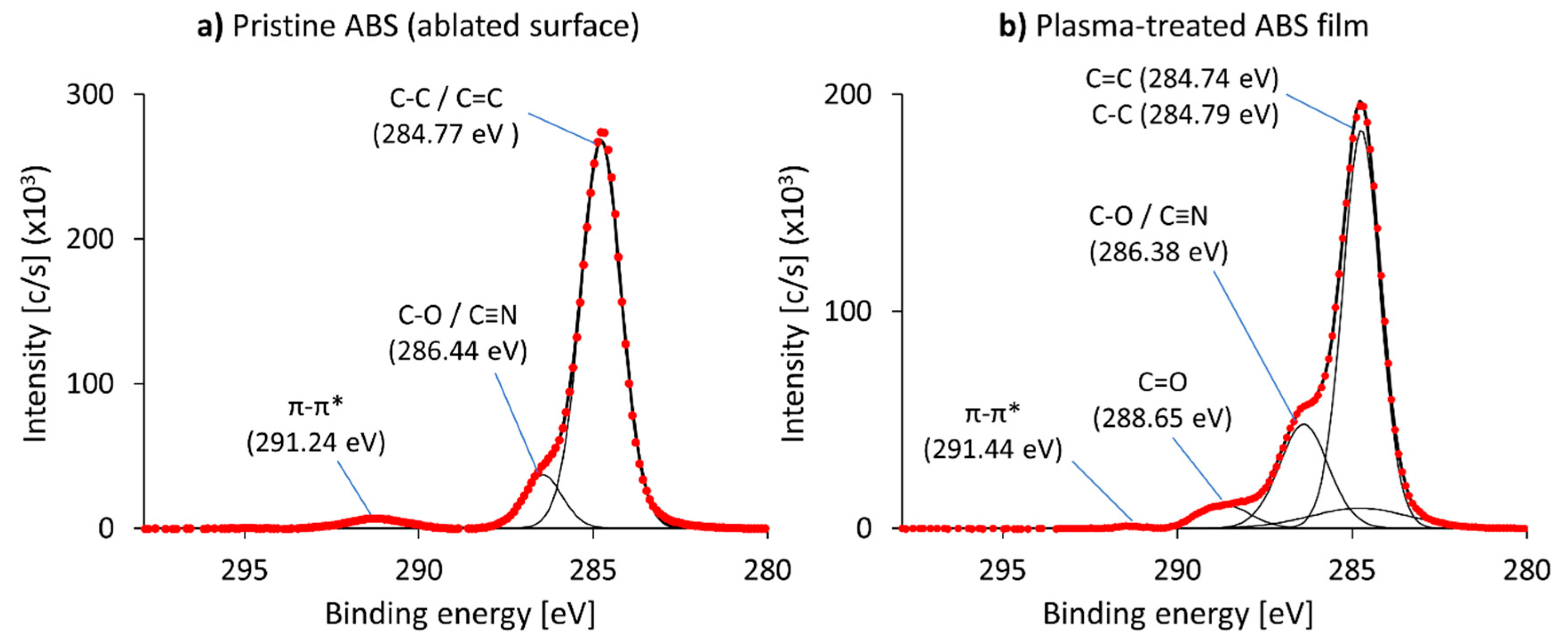

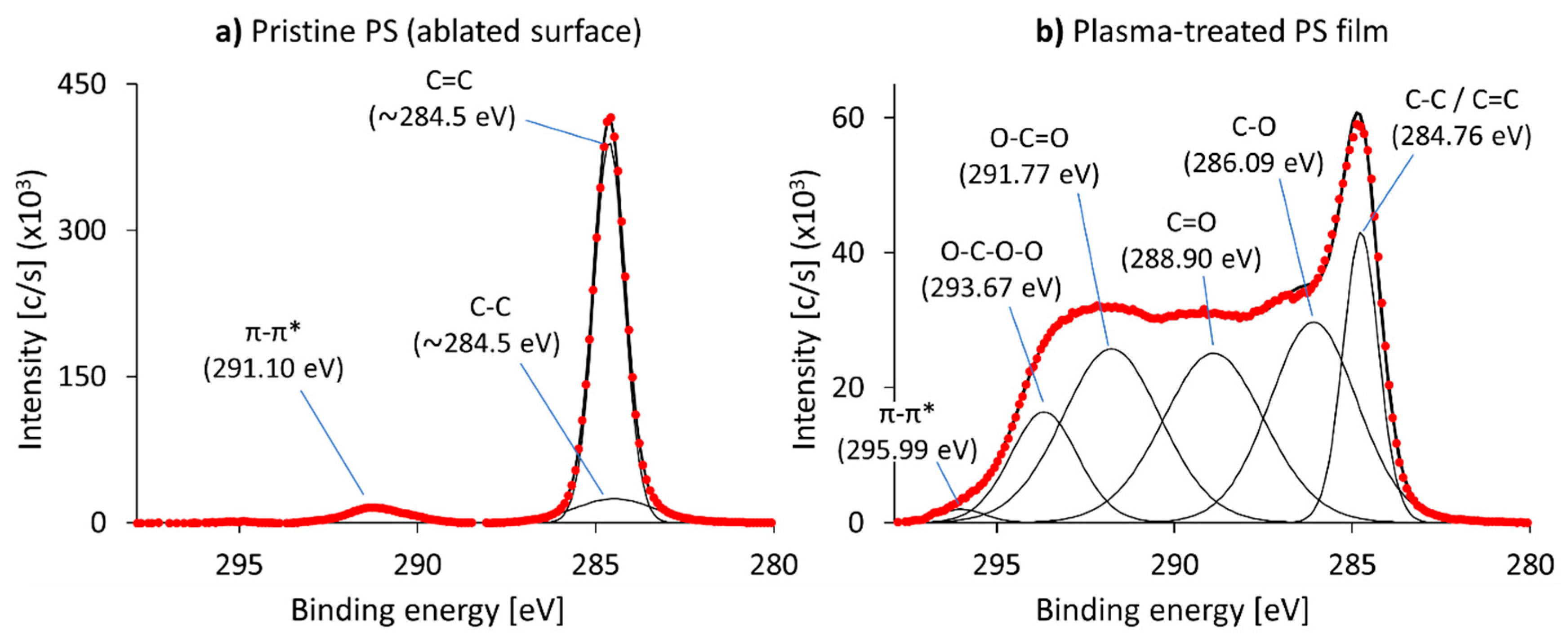

3.2. XPS Analysis

3.2.1. Determined Elemental Surface Composition

3.2.2. Analysis of the Bonding Mechanism of Oxygen on the Treated Polymer Surfaces

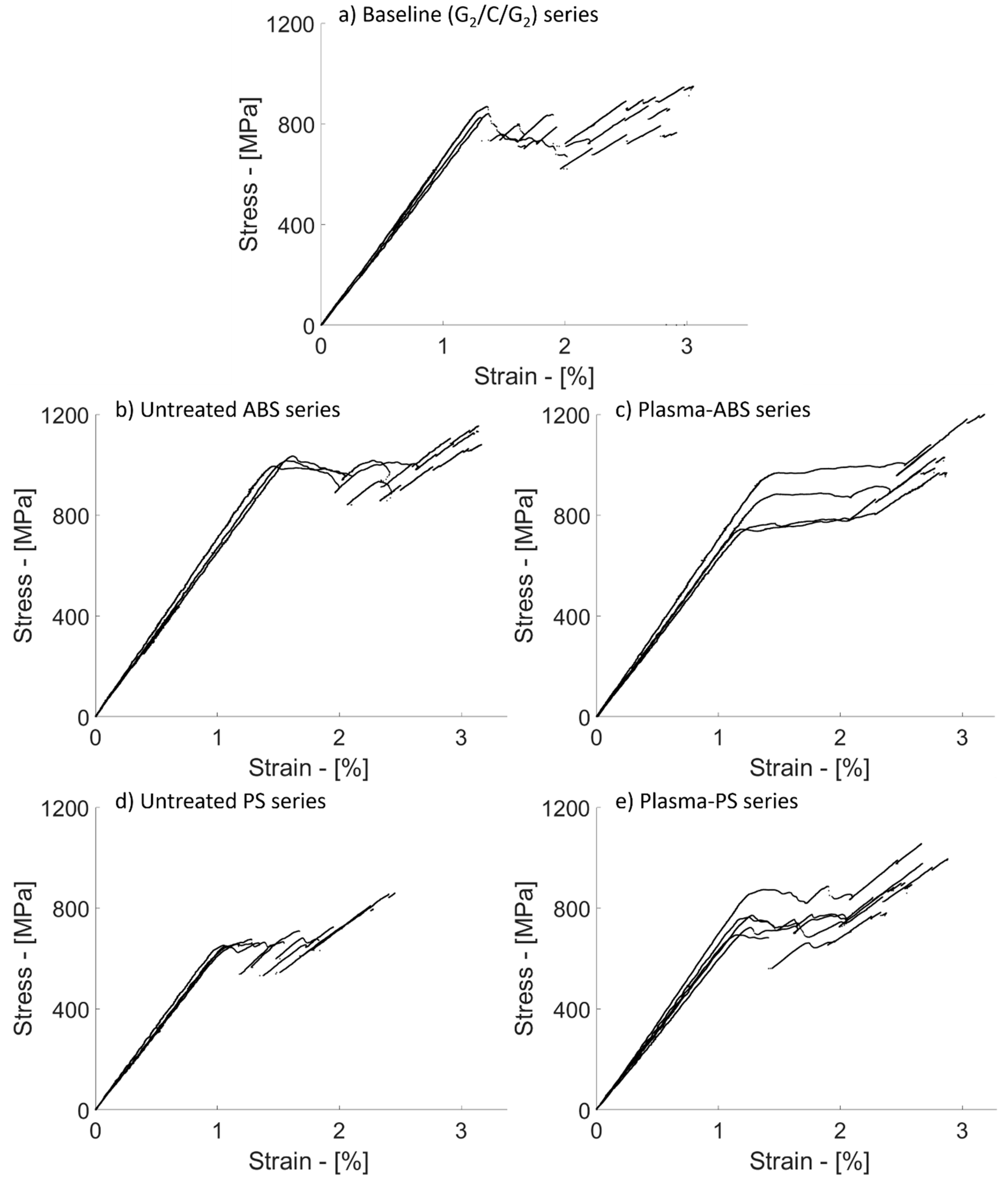

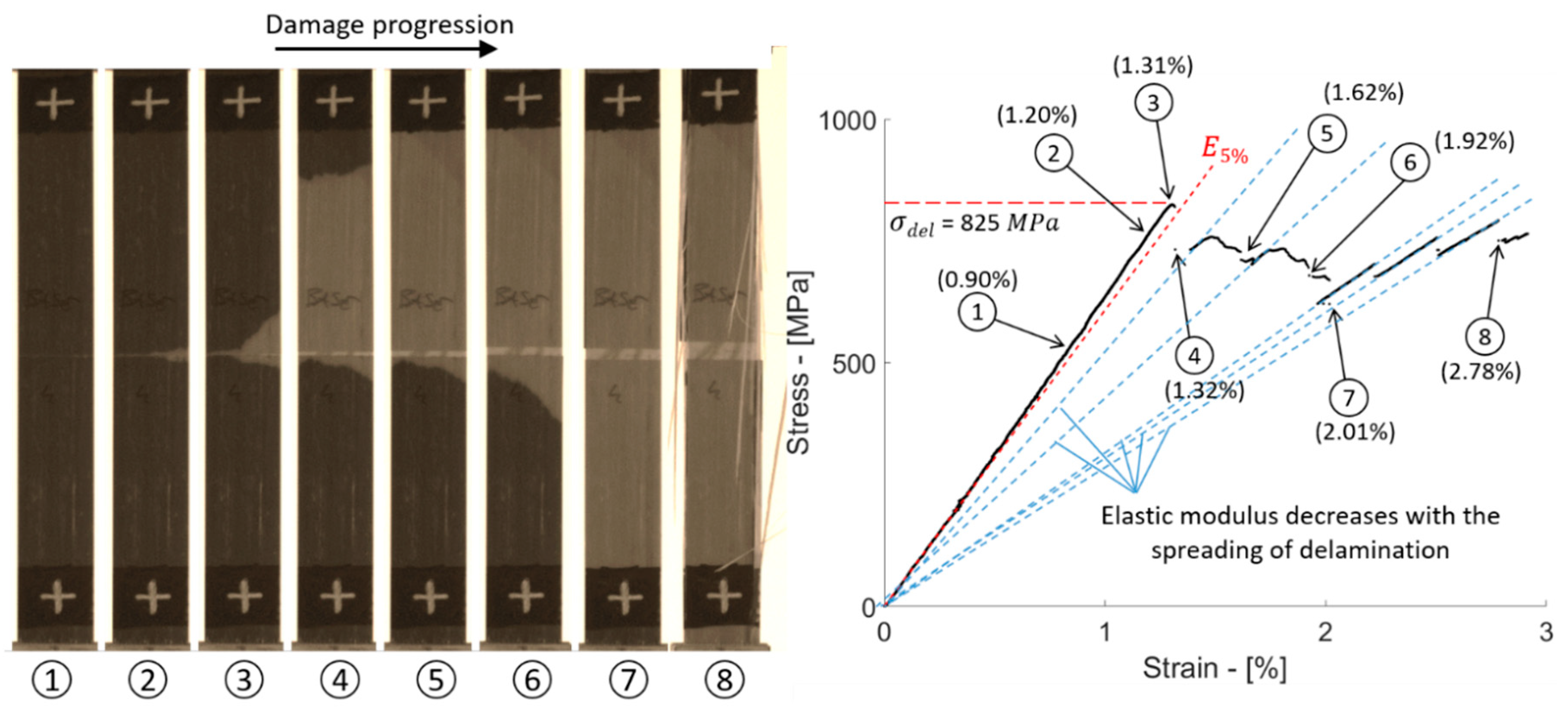

3.3. Discussion of the Mechanical Test Results

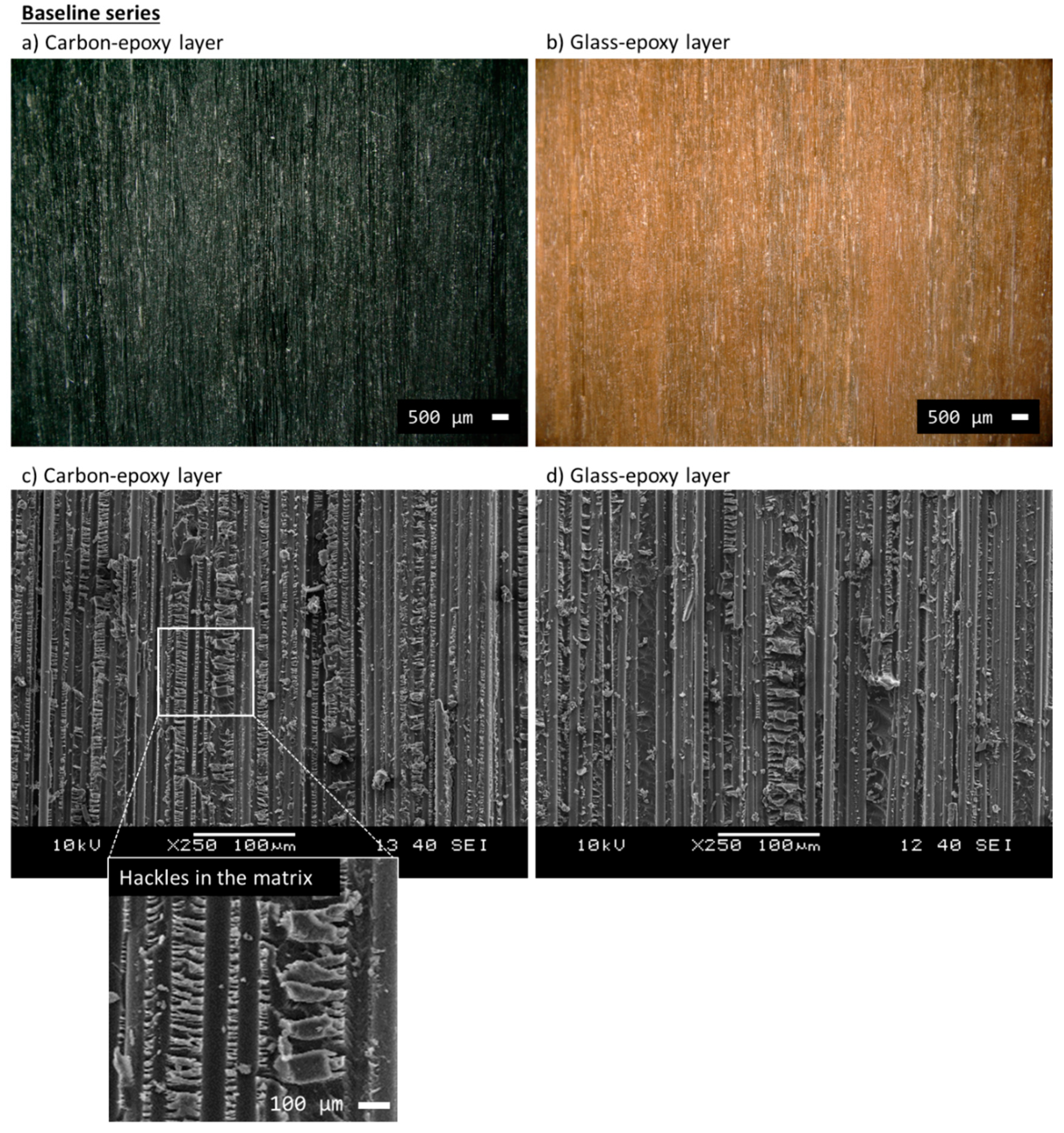

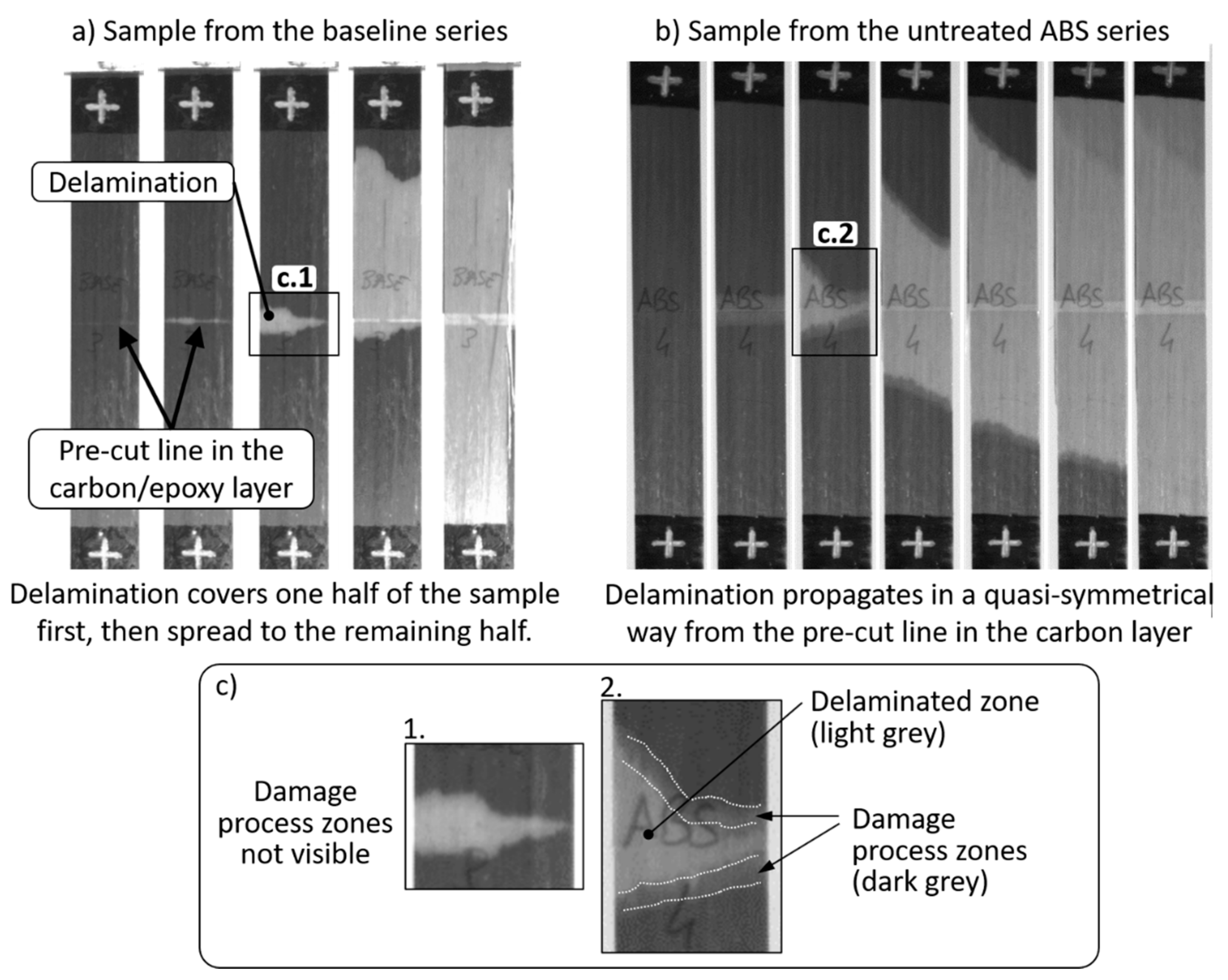

3.3.1. Delamination in the Baseline Hybrid Composites

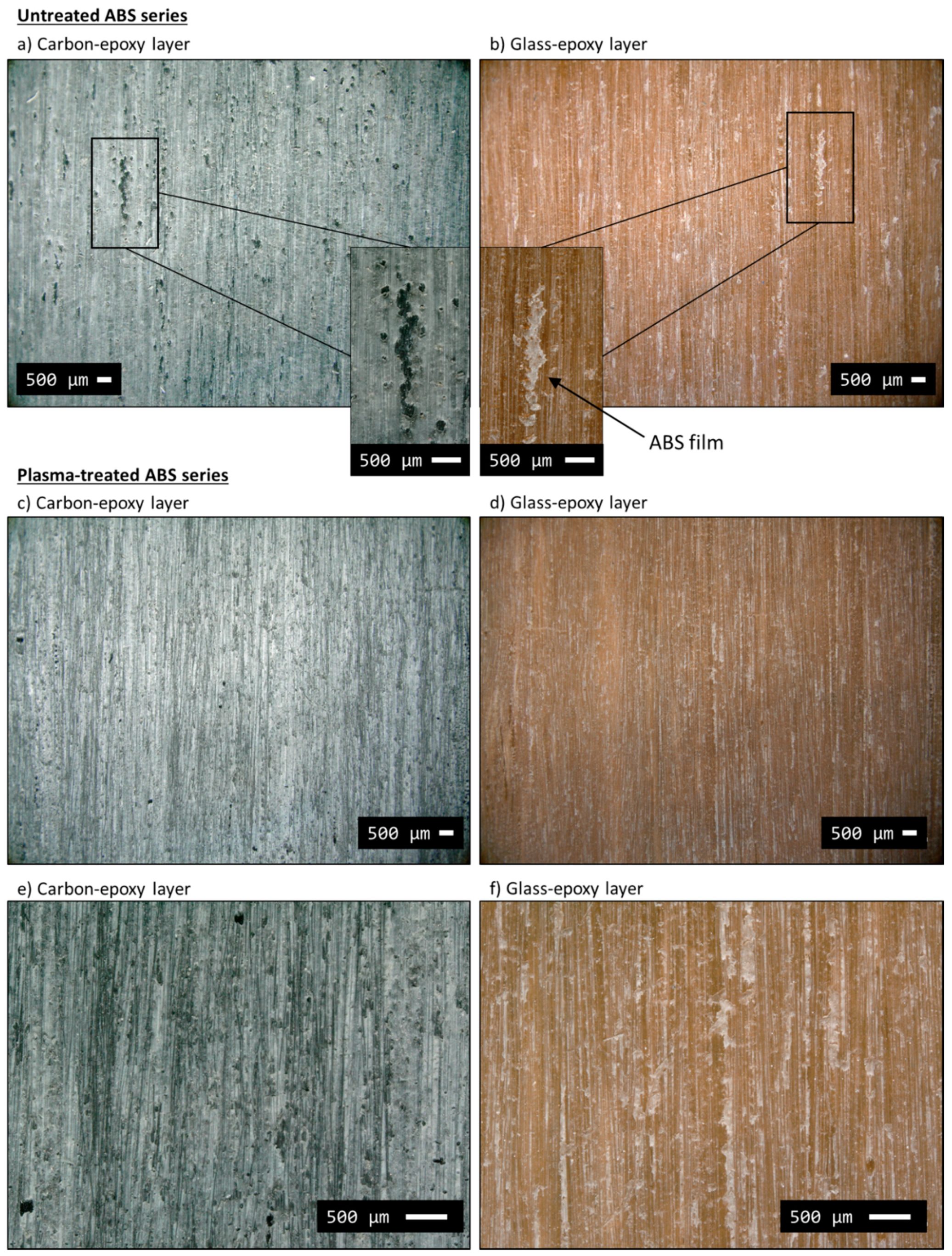

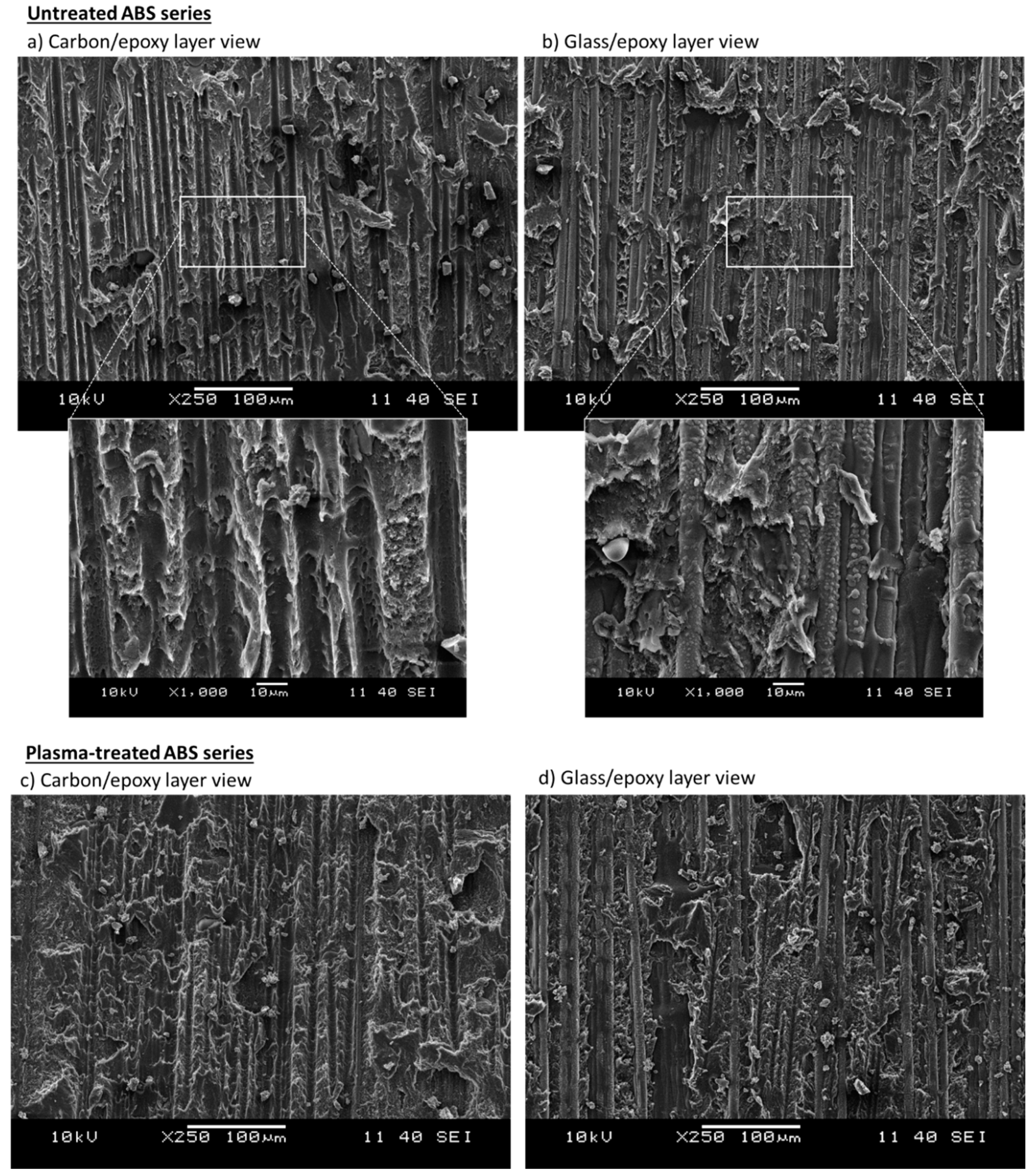

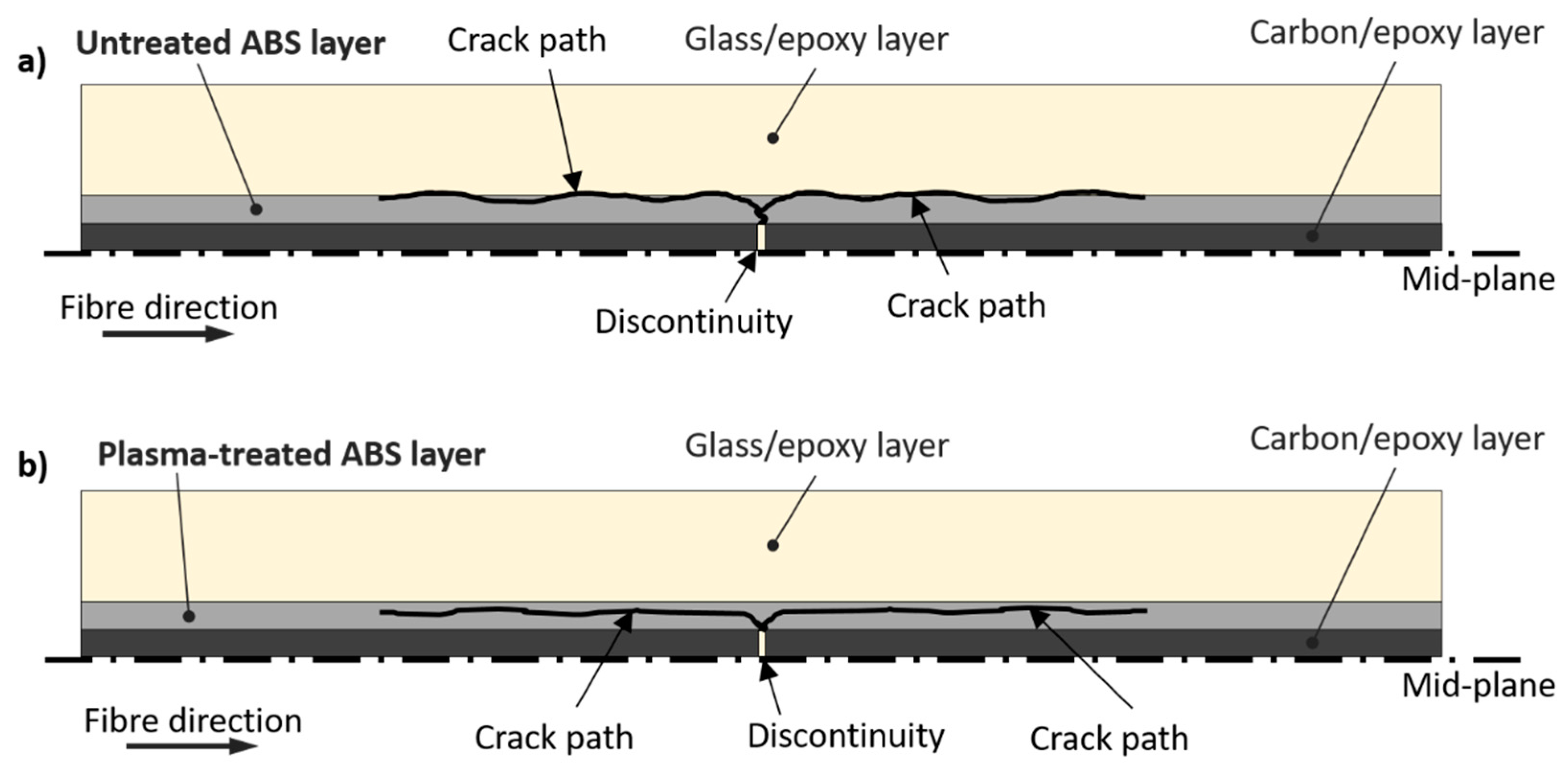

3.3.2. Hybrid Composites Containing ABS Film Interleaves

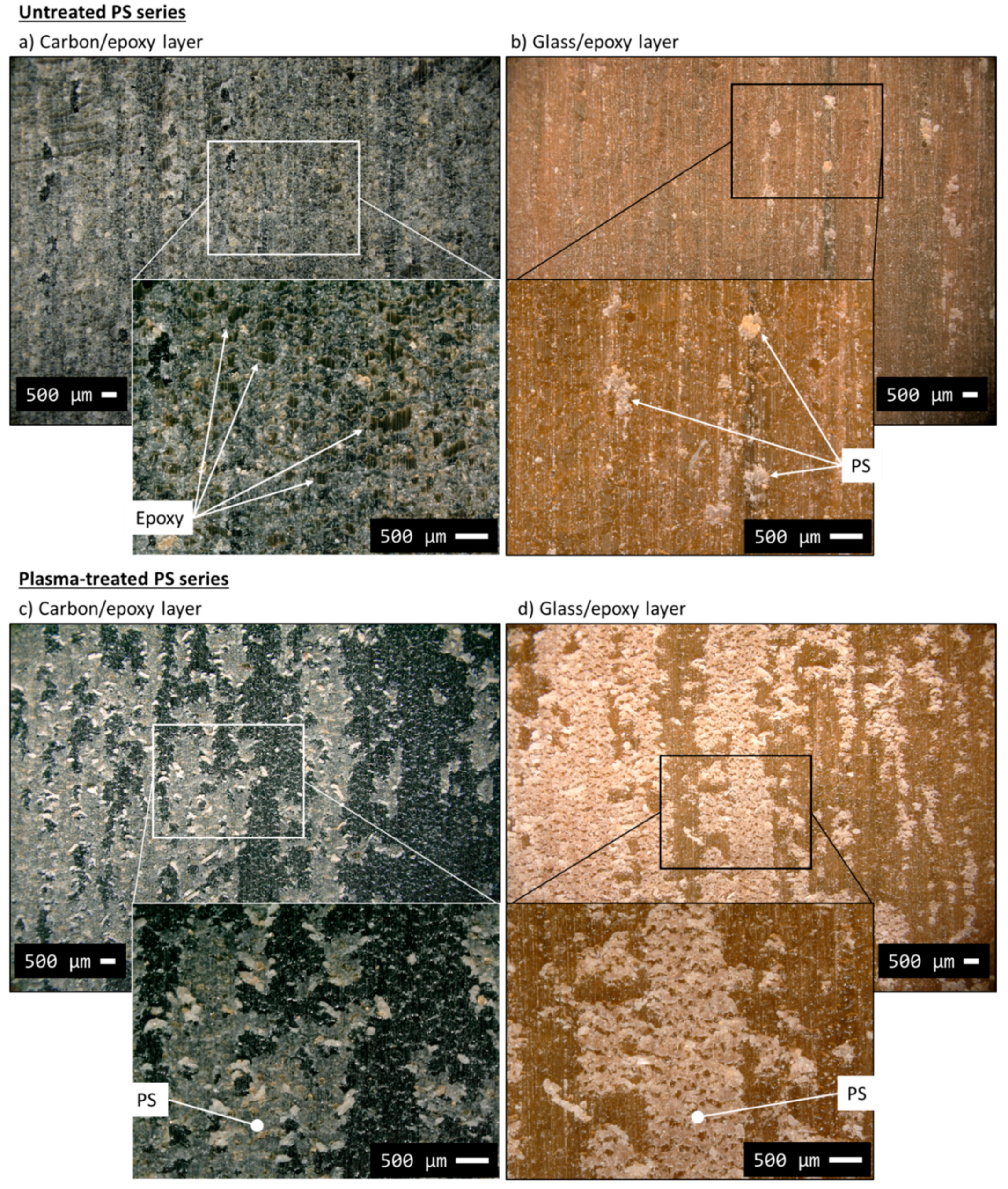

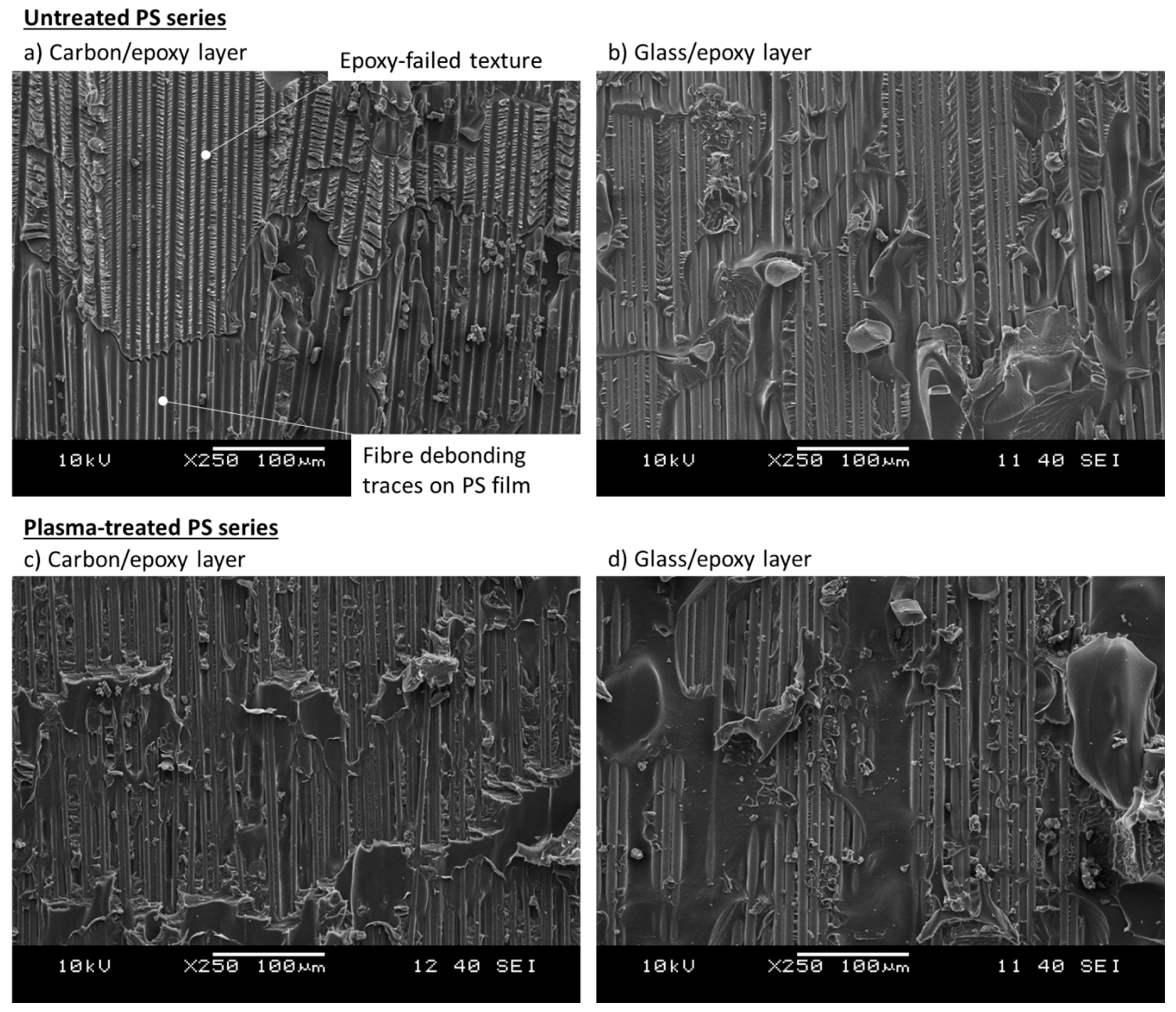

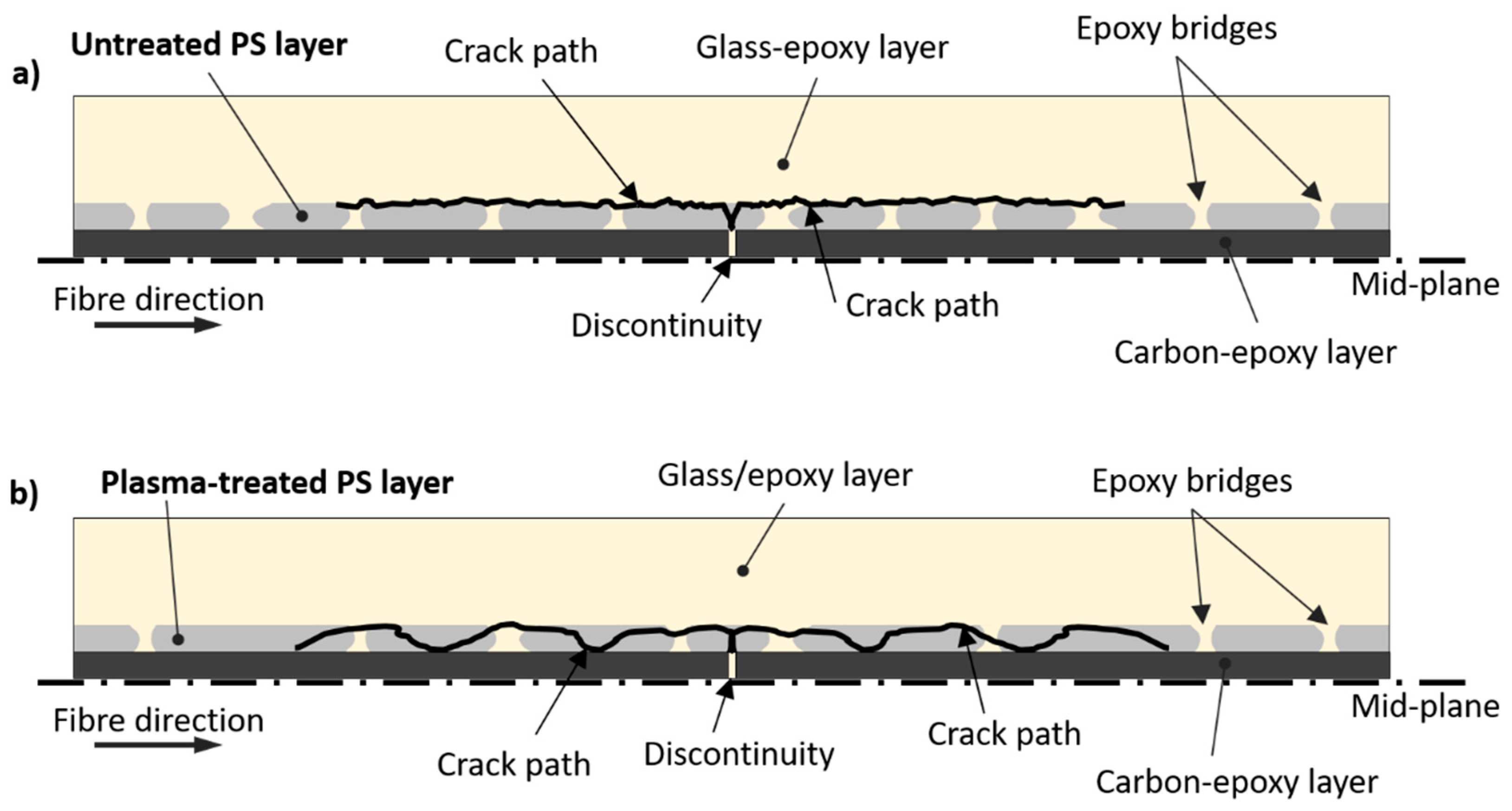

3.3.3. Hybrid Composites Containing PS Film Interleaves

4. Conclusions

- Interleaving ABS films in hybrid composites increased the delamination stress and the corresponding GIIC of the layer interfaces. The ABS films reduced the sudden delamination-induced stress drops in the tensile stress–strain curves of the samples.

- The more stable delamination patterns in the untreated ABS series compared to that of the baseline was attributed to the observed damage process zones at the delamination crack front, possibly due to plastic deformation of the interleaved ABS films, which reduced the stress concentration by blunting micro-cracks around the Mode II crack tips.

- The plasma-treated ABS series showed stable delamination without exhibiting stress drops in the stress–strain curves possibly due to reduced delamination stresses associated with an overall decrease of performance.

- Untreated PS films impaired the mechanical properties of the hybrid composites and promoted a sudden spread of delamination causing intense stress drops in the tensile stress–strain curves. It was related to the weak adhesion between PS and epoxy.

- The O-C=O and O-C-O-O functional groups, introduced by oxygen plasma treatment and detected by XPS analysis, promoted covalent bonds between the plasma-treated PS films and epoxy, leading to stronger interface adhesion. The better PS/epoxy bonding introduced energy absorption mechanisms, i.e., crack deflection, generating higher delamination stress and GIIC in comparison to the untreated PS film-interleaved configuration.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Safri, S.N.A.B.; Sultan, M.T.H. Damage analysis of glass fiber reinforced composites. Durab. Life Predict. Biocomposites Fibre-Reinf. Compos. Hybrid Compos. 2019, 133–147. [Google Scholar] [CrossRef]

- Pagano, N.J.; Schoeppner, G.A. 2.13—Delamination of Polymer Matrix Composites: Problems and Assessment. In Comprehensive Composite Materials; Kelly, A., Zweben, C.B.T.-C.C.M., Eds.; Pergamon: Oxford, UK, 2000; pp. 433–528. ISBN 978-0-08-042993-9. [Google Scholar]

- Ferreira De Moura, M.F.S. Interlaminar mode II fracture Characterization. In Delamination Behaviour of Composites: A Volume in Woodhead Publishing Series in Composites Science and Engineering; Elsevier: Amsterdam, The Netherlands, 2008; pp. 310–326. ISBN 9781845692445. [Google Scholar]

- Mochane, M.J.; Mokhena, T.C.; Mokhothu, T.H.; Mtibe, A.; Sadiku, E.R.; Ray, S.S.; Ibrahim, I.D.; Daramola, O.O. Recent progress on natural fiber hybrid composites for advanced applications: A review. Express Polym. Lett. 2019, 13, 159–198. [Google Scholar] [CrossRef]

- Swolfs, Y.; Verpoest, I.; Gorbatikh, L. Recent advances in fibre-hybrid composites: Materials selection, opportunities and applications. Int. Mater. Rev. 2019, 64, 181–215. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre hybridisation in polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Czél, G.; Wisnom, M.R. Demonstration of pseudo-ductility in high performance glass/epoxy composites by hybridisation with thin-ply carbon prepreg. Compos. Part A Appl. Sci. Manuf. 2013, 52, 23–30. [Google Scholar] [CrossRef] [Green Version]

- Bismarck, A.; Bacarreza, O.; Blaker, J.; Diao, H.; Grail, G.; Pimenta, S.; Robinson, P.; Shaffer, M. Exploring routes to create high performance pseudo-ductile fibre reinforced composites. In Proceedings of the ICCM International Conferences on Composite Materials, Copenhagen, Denmark, 19–24 July 2015. [Google Scholar]

- Czél, G.; Jalalvand, M.; Wisnom, M.R. Design and characterisation of advanced pseudo-ductile unidirectional thin-ply carbon/epoxy-glass/epoxy hybrid composites. Compos. Struct. 2016, 143, 362–370. [Google Scholar] [CrossRef] [Green Version]

- Di Boon, Y.; Joshi, S.C. A review of methods for improving interlaminar interfaces and fracture toughness of laminated composites. Mater. Today Commun. 2020, 22, 100830. [Google Scholar] [CrossRef]

- Sela, N.; Ishai, O. Interlaminar fracture toughness and toughening of laminated composite materials: A review. Composites 1989, 20, 423–435. [Google Scholar] [CrossRef]

- Salehi, M.M.; Hakkak, F.; Sadati Tilebon, S.M.; Ataeefard, M.; Rafizadeh, M. Intelligently optimized electrospun polyacrylonitrile/poly(vinylidene fluoride) nanofiber: Using artificial neural networks. Express Polym. Lett. 2020, 14, 1003–1017. [Google Scholar] [CrossRef]

- Koprivova, B.; Lisnenko, M.; Solarska-Sciuk, K.; Prochazkova, R.; Novotny, V.; Mullerova, J.; Mikes, P.; Jencova, V. Large-scale electrospinning of poly (Vinylalcohol) nanofibers incorporated with platelet-derived growth factors. Express Polym. Lett. 2020, 14, 987–1000. [Google Scholar] [CrossRef]

- Lomov, S.V.; Molnár, K. Compressibility of carbon fabrics with needleless electrospun PAN nanofibrous interleaves. Express Polym. Lett. 2016, 10, 25–35. [Google Scholar] [CrossRef] [Green Version]

- Hojo, M.; Matsuda, S.; Tanaka, M.; Ochiai, S.; Murakami, A. Mode I delamination fatigue properties of interlayer-toughened CF/epoxy laminates. Compos. Sci. Technol. 2006, 66, 665–675. [Google Scholar] [CrossRef]

- Zeng, Y.; Liu, H.Y.; Mai, Y.W.; Du, X.S. Improving interlaminar fracture toughness of carbon fibre/epoxy laminates by incorporation of nano-particles. Compos. Part B Eng. 2012, 43, 90–94. [Google Scholar] [CrossRef]

- Tsai, J.L.; Huang, B.H.; Cheng, Y.L. Enhancing fracture toughness of glass/epoxy composites for wind blades using silica nanoparticles and rubber particles. Procedia Eng. 2011, 14, 1982–1987. [Google Scholar] [CrossRef] [Green Version]

- Ozdemir, N.G.; Zhang, T.; Aspin, I.; Scarpa, F.; Hadavinia, H.; Song, Y. Toughening of carbon fibre reinforced polymer composites with rubber nanoparticles for advanced industrial applications. Express Polym. Lett. 2016, 10, 394–407. [Google Scholar] [CrossRef]

- Wang, C.; Sun, Q.; Lei, K.; Chen, C.; Yao, L.; Peng, Z. Effect of Toughening with Different Liquid Rubber on Dielectric Relaxation Properties of Epoxy Resin. Polymers 2020, 12, 433. [Google Scholar] [CrossRef] [Green Version]

- Hayes, B.S.; Seferis, J.C. Influence of Particle Size Distribution of Preformed Rubber on the Structure and Properties of Composite Systems. J. Compos. Mater. 2002, 36, 299–312. [Google Scholar] [CrossRef]

- van der Heijden, S.; Daelemans, L.; Meireman, T.; De Baere, I.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Interlaminar toughening of resin transfer molded laminates by electrospun polycaprolactone structures: Effect of the interleave morphology. Compos. Sci. Technol. 2016, 136, 10–17. [Google Scholar] [CrossRef] [Green Version]

- Qin, Q.; Ye, J. Toughening Mechanisms in Composite Materials; Woodhead Publishing: Cambridge, UK, 2015; ISBN 9781782422914. [Google Scholar]

- Molnár, K.; Košt’áková, E.; Mészáros, L. The effect of needleless electrospun nanofibrous interleaves on mechanical properties of carbon fabrics/epoxy laminates. Express Polym. Lett. 2014, 8, 62–72. [Google Scholar] [CrossRef] [Green Version]

- Gibson, A.G. Continuous Molding of Thermoplastic Composites. In Comprehensive Composite Materials; Elsevier: Amsterdam, The Netherlands, 2000; pp. 979–998. ISBN 9780080429939. [Google Scholar]

- Kishi, H.; Nakao, N.; Kuwashiro, S.; Matsuda, S. Carbon fiber reinforced thermoplastic composites from acrylic polymer matrices: Interfacial adhesion and physical properties. Express Polym. Lett. 2017, 11, 334–342. [Google Scholar] [CrossRef]

- Adeniyi, A.; Agboola, O.; Sadiku, E.R.; Durowoju, M.O.; Olubambi, P.A.; Babul Reddy, A.; Ibrahim, I.D.; Kupolati, W.K. Thermoplastic-Thermoset Nanostructured Polymer Blends. Des. Appl. Nanostructured Polym. Blends Nanocomposite Syst. 2016, 15–38. [Google Scholar] [CrossRef] [Green Version]

- Evans, R.; Masters, J.; RE Evans, J.E.M. A New Generation of Epoxy Composites for Primary Structural Applications: Materials and Mechanics. In Toughened Composites; Johnston, N.J., Ed.; ASTM International: West Conshohocken, PA, USA, 1987; pp. 413–424. ISBN 0803109342. [Google Scholar]

- Anthony, D.B.; Bacarreza Nogales, O.R.; Shaffer, M.S.P.; Bismarck, A.; Robinson, P.; Pimenta, S. Pseudo-ductile failure mechanism introduced into finger jointed thermoplastic PES interleaved CFRC. In Proceedings of the ECCM 2018—18th European Conference on Composite Materials, Athens, Greece, 24–28 June 2020. [Google Scholar]

- Yun, N.G.; Won, Y.G.; Kim, S.C. Toughening of carbon fiber/epoxy composite by inserting polysulfone film to form morphology spectrum. Polymer 2004, 45, 6953–6958. [Google Scholar] [CrossRef]

- Naffakh, M.; Dumon, M.; Gérard, J.F. Study of a reactive epoxy–amine resin enabling in situ dissolution of thermoplastic films during resin transfer moulding for toughening composites. Compos. Sci. Technol. 2006, 66, 1376–1384. [Google Scholar] [CrossRef]

- Shivakumar, K.; Panduranga, R. Interleaved polymer matrix composites—A review. In Proceedings of the 54th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Boston, MA, USA, 8–11 April 2013; American Institute of Aeronautics and Astronautics: Boston, MA, USA, 2013. [Google Scholar]

- Qian, X.; Kravchenko, O.G.; Pedrazzoli, D.; Manas-Zloczower, I. Effect of polycarbonate film surface morphology and oxygen plasma treatment on mode I and II fracture toughness of interleaved composite laminates. Compos. Part A Appl. Sci. Manuf. 2018, 105, 138–149. [Google Scholar] [CrossRef]

- Grail, G.; Pimenta, S.; Pinho, S.T.; Robinson, P. Exploring the potential of interleaving to delay catastrophic failure in unidirectional composites under tensile loading. Compos. Sci. Technol. 2015, 106, 100–109. [Google Scholar] [CrossRef]

- Bilge, K.; Papila, M. Interlayer toughening mechanisms of composite materials. In Toughening Mechanisms in Composite Materials; Elsevier: Amsterdam, The Netherlands, 2015; pp. 263–294. ISBN 9781782422914. [Google Scholar]

- Wolf, R.; Sparavigna, A.C. Role of Plasma Surface Treatments on Wetting and Adhesion. Engineering 2010, 02, 397–402. [Google Scholar] [CrossRef] [Green Version]

- Yasuda, H.; Iriyama, Y. Plasma Polymerization. Compr. Polym. Sci. Suppl. 1989, 357–375. [Google Scholar] [CrossRef]

- Hegemann, D.; Brunner, H.; Oehr, C. Plasma treatment of polymers for surface and adhesion improvement. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2003, 208, 281–286. [Google Scholar] [CrossRef]

- Bismarck, A. Springer Wettability: Plasma Treatment Effects. In Encyclopedia of Surface and Colloid Science, 3rd ed.; CRC Pess: Boca Raton, FL, USA, 2015; pp. 7666–7683. ISBN 1-4665-9045-9. [Google Scholar]

- Sim, K.-B.; Baek, D.; Shin, J.-H.; Shim, G.-S.; Jang, S.-W.; Kim, H.-J.; Hwang, J.-W.; Roh, J.U. Enhanced Surface Properties of Carbon Fiber Reinforced Plastic by Epoxy Modified Primer with Plasma for Automotive Applications. Polymers 2020, 12, 556. [Google Scholar] [CrossRef] [Green Version]

- Lu, C.; Qiu, S.; Lu, X.; Wang, J.; Xiao, L.; Zheng, T.; Wang, X.; Zhang, D. Enhancing the Interfacial Strength of Carbon Fiber/Poly(ether ether ketone) Hybrid Composites by Plasma Treatments. Polymers 2019, 11, 753. [Google Scholar] [CrossRef] [Green Version]

- Pegoretti, A.; Karger-Kocsis, J. Interleaving in structural composites: Adapting an old concept to new challenges. Express Polym. Lett. 2018, 12, 1025. [Google Scholar] [CrossRef]

- Zaplotnik, R.; Vesel, A. Effect of VUV radiation on surface modification of polystyrene exposed to atmospheric pressure plasma jet. Polymers 2020, 12, 1136. [Google Scholar] [CrossRef] [PubMed]

- Parameswaranpillai, J.; Hameed, N.; Pionteck, J.; Woo, E.M. (Eds.) Handbook of Epoxy Blends|Jyotishkumar Parameswaranpillai; Springer: Berlin/Heisenberg, Germany, 2017; ISBN 978-3-319-40042-6. [Google Scholar]

- Jalalvand, M.; Czél, G.; Wisnom, M.R. Damage analysis of pseudo-ductile thin-ply UD hybrid composites—A new analytical method. Compos. Part A Appl. Sci. Manuf. 2015, 69, 83–93. [Google Scholar] [CrossRef] [Green Version]

- Czél, G.; Jalalvand, M.; Wisnom, M.R.; Czigány, T. Design and characterisation of high performance, pseudo-ductile all-carbon/epoxy unidirectional hybrid composites. Compos. Part B Eng. 2017, 111, 348–356. [Google Scholar] [CrossRef]

- Wisnom, M.R. On the Increase in Fracture Energy with Thickness in Delamination of Unidirectional Glass Fibre-Epoxy with Cut Central Plies. J. Reinf. Plast. Compos. 1992, 11, 897–909. [Google Scholar] [CrossRef]

- Cui, W.; Wisnom, M.R.; Jones, M. An Experimental and Analytical Study of Delamination of Unidirectional Specimens with Cut Central Plies. J. Reinf. Plast. Compos. 1994, 13, 722–739. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Z.; He, Y.; Wang, Z. Study of an Environmentally Friendly Surface Etching System of ABS for Improving Adhesion of Electroless Cu film. J. Electrochem. Soc. 2011. [Google Scholar] [CrossRef]

- Paynter, R.W. XPS studies of the modification of polystyrene and polyethyleneterephthalate surfaces by oxygen and nitrogen plasmas. Surf. Interface Anal. 1998, 26, 674–681. [Google Scholar] [CrossRef]

- Wisnom, M.R.; Czél, G.; Swolfs, Y.; Jalalvand, M.; Gorbatikh, L.; Verpoest, I. Hybrid effects in thin ply carbon/glass unidirectional laminates: Accurate experimental determination and prediction. Compos. Part A Appl. Sci. Manuf. 2016, 88, 131–139. [Google Scholar] [CrossRef] [Green Version]

- Rev, T.; Jalalvand, M.; Fuller, J.; Wisnom, M.R.; Czél, G. A simple and robust approach for visual overload indication—UD thin-ply hybrid composite sensors. Compos. Part A Appl. Sci. Manuf. 2019, 121, 376–385. [Google Scholar] [CrossRef] [Green Version]

- Greenhalgh, E.S.; Hiley, M.J. Fractography of Polymer Composites: Current Status and Future Issues. In Proceedings of the 13th European Conference on Composite Materials, Stockholm, Sweden, 2–5 June 2008. [Google Scholar]

- Greenhalgh, E.S. (Ed.) Failure Analysis and Fractography of Polymer Composites; Woodhead Publishing: Cambridge, UK, 2009; ISBN 9781845692179. [Google Scholar]

| Dry Fibres | Tensile Modulus | Strain to Failure | Tensile Strength | Density |

|---|---|---|---|---|

| [GPa] | [%] | [MPa] | [kg/m3] | |

| AGY S-2 Glass | 89 | 5.7 | 4890 | 2470 |

| HexTow IM7 Carbon | 276 | 1.9 | 5516 | 1780 |

| Prepreg Plies | Nominal Fibre Areal Density | Fibre Volume Fraction | Ply Thickness | Strain to Failure | Elastic Modulus |

|---|---|---|---|---|---|

| [g/m2] | [-] | [µm] | [%] | [GPa] | |

| AGY S-2 Glass/913 epoxy | 190 | 0.49 | 153.8 | 3.1 | 45.6 |

| IM7 Carbon/913 epoxy | 134 | 0.58 | 128.4 | 1.68 | 163.2 |

| Thermoplastic Materials | Density | Tensile Stress at Break | Strain to Failure | Tensile Modulus | Glass Transition Temperature (a) |

|---|---|---|---|---|---|

| [g/cm3] | [MPa] | [%] | [GPa] | [°C] | |

| Starex® LX0981 ABS | 1.05 | 32.4 | 17 | 2.26 | 103 |

| Empera® 124N PS | 1.04 | 50 | 2 | 3.2 | 87 |

| Thermoplastic Films | Contact Angle in [deg] after the Indicated Time of Treatment in Oxygen Plasma | ||

|---|---|---|---|

| 0 min | 2 min | 4 min | |

| ABS | 93 | 35 | 33 |

| (8.3) | (18.8) | (15.8) | |

| PS | 85 | 22 | 0 |

| (25.6) | (17.5) | (-) | |

| Thermoplastic Materials | Elemental Composition [Atomic %] | |||||

|---|---|---|---|---|---|---|

| (before Argon Ablation) | (after Argon Ablation) | |||||

| C | O | N | C | O | N | |

| ABS | 90.8 | 5.3 | 3.9 | 94.1 | 0.9 | 5.1 |

| Plasma-treated ABS | 78.2 | 17.3 | 4.5 | 93.8 | 1.3 | 5 |

| PS | 94.2 | 5.8 | - | 99.6 | 0.4 | - |

| Plasma-treated PS | 78.7 | 21.3 | - | 99.9 | 0.2 | - |

| Material Configurations | Measured Thickness of the Samples | Measured Width of the Samples | Parameters Calculated with the Nominal Thickness (0.75 mm) | Parameters Calculated with the Measured Thickness | Mode II Fracture Toughness (GIIC) (a) | ||

|---|---|---|---|---|---|---|---|

| Initial Elastic Modulus (E0) | Delamination Stress (σdel) | Initial Elastic Modulus (E0) | Delamination Stress (σdel) | ||||

| [mm] | [mm] | [GPa] | [MPa] | [GPa] | [MPa] | [kJ/m2] | |

| Baseline [G2/C/G2] | 0.77 | 20.5 | 64.2 | 844.5 | 62.4 | 820.5 | 1.503 |

| (2.90) | (0.32) | (3.89) | (2.63) | (4.10) | (1.31) | (5.27) | |

| Untreated ABS [G2/ABS/C/ABS/G2] | 0.89 | 20.6 | 67.5 | 1014.9 | 57.0 | 857.7 | 2.170 |

| (3.20) | (0.17) | (3.36) | (1.99) | (0.31) | (5.15) | (3.97) | |

| Plasma-treated ABS [G2/P-ABS/C/P-ABS/G2] | 0.83 | 20.6 | 66.2 | 831.8 | 59.6 | 747.3 | 1.475 |

| (6.70) | (0.26) | (4.78) | (12.60) | (1.97) | (8.09) | (25.37) | |

| Untreated PS [G2/PS/C/PS/G2] | 0.84 | 20.3 | 63.5 | 646.0 | 56.4 | 574.0 | 0.879 |

| (1.85) | (0.08) | (3.00) | (0.67) | (1.30) | (1.71) | (1.35) | |

| Plasma-treated PS [G2/P-PS/C/P-PS/G2] | 0.86 | 20.5 | 64.1 | 761.5 | 55.9 | 663.9 | 1.228 |

| (4.32) | (0.13) | (6.53) | (8.36) | (3.16) | (5.34) | (17.04) | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marino, S.G.; Mayer, F.; Bismarck, A.; Czél, G. Effect of Plasma-Treatment of Interleaved Thermoplastic Films on Delamination in Interlayer Fibre Hybrid Composite Laminates. Polymers 2020, 12, 2834. https://doi.org/10.3390/polym12122834

Marino SG, Mayer F, Bismarck A, Czél G. Effect of Plasma-Treatment of Interleaved Thermoplastic Films on Delamination in Interlayer Fibre Hybrid Composite Laminates. Polymers. 2020; 12(12):2834. https://doi.org/10.3390/polym12122834

Chicago/Turabian StyleMarino, Salvatore Giacomo, Florian Mayer, Alexander Bismarck, and Gergely Czél. 2020. "Effect of Plasma-Treatment of Interleaved Thermoplastic Films on Delamination in Interlayer Fibre Hybrid Composite Laminates" Polymers 12, no. 12: 2834. https://doi.org/10.3390/polym12122834

APA StyleMarino, S. G., Mayer, F., Bismarck, A., & Czél, G. (2020). Effect of Plasma-Treatment of Interleaved Thermoplastic Films on Delamination in Interlayer Fibre Hybrid Composite Laminates. Polymers, 12(12), 2834. https://doi.org/10.3390/polym12122834