Study on the Microstructure of Polyether Ether Ketone Films Irradiated with 170 keV Protons by Grazing Incidence Small Angle X-ray Scattering (GISAXS) Technology

Abstract

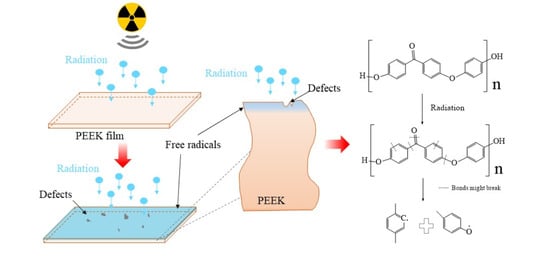

1. Introduction

2. Experimental Section

2.1. Materials and Equipment

2.2. Experimental Parameter

2.3. Microstructural and Mechanical Property Analysis

3. Results

3.1. SIRM Calculation

3.2. Surface Morphology and Roughness Analysis

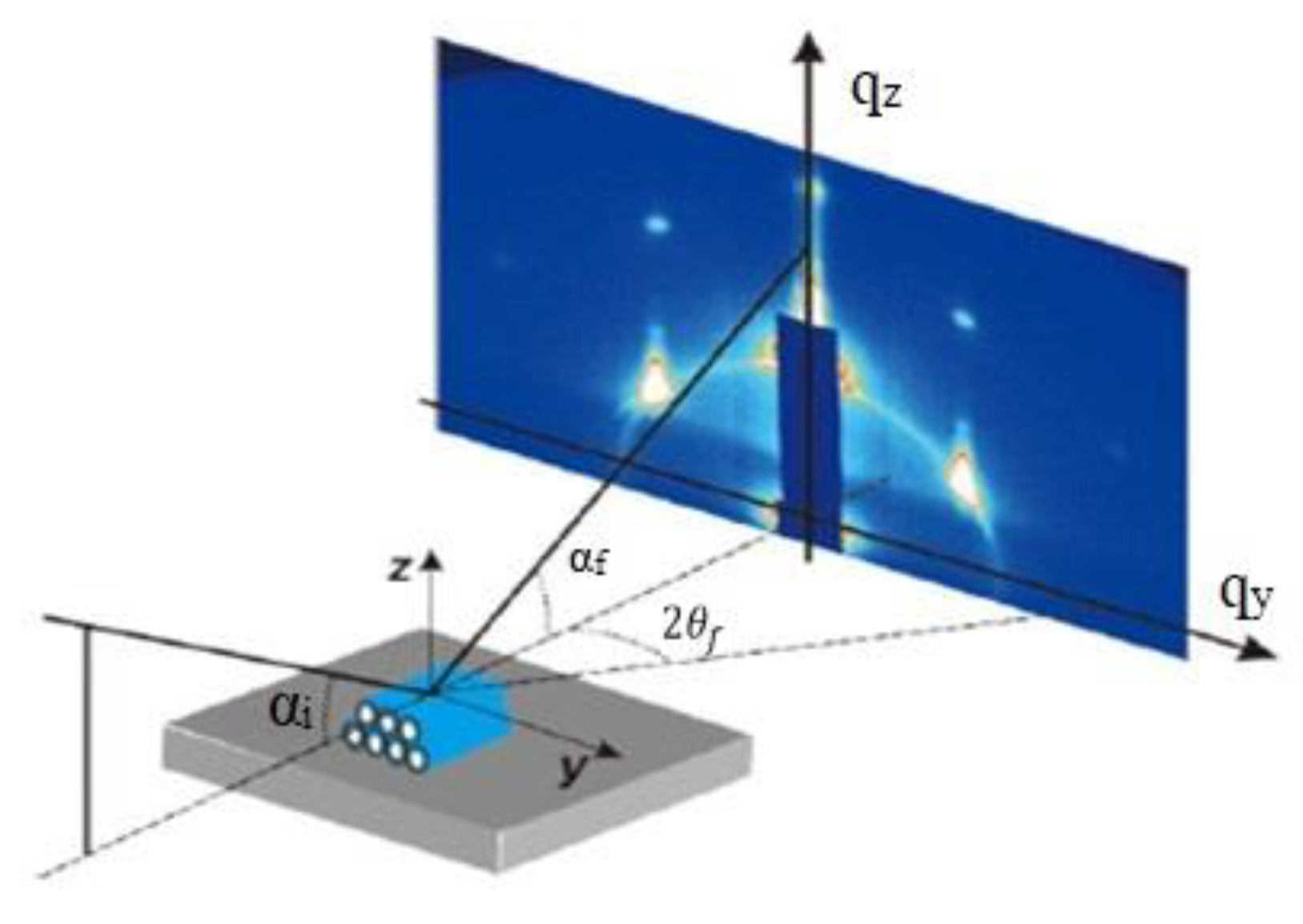

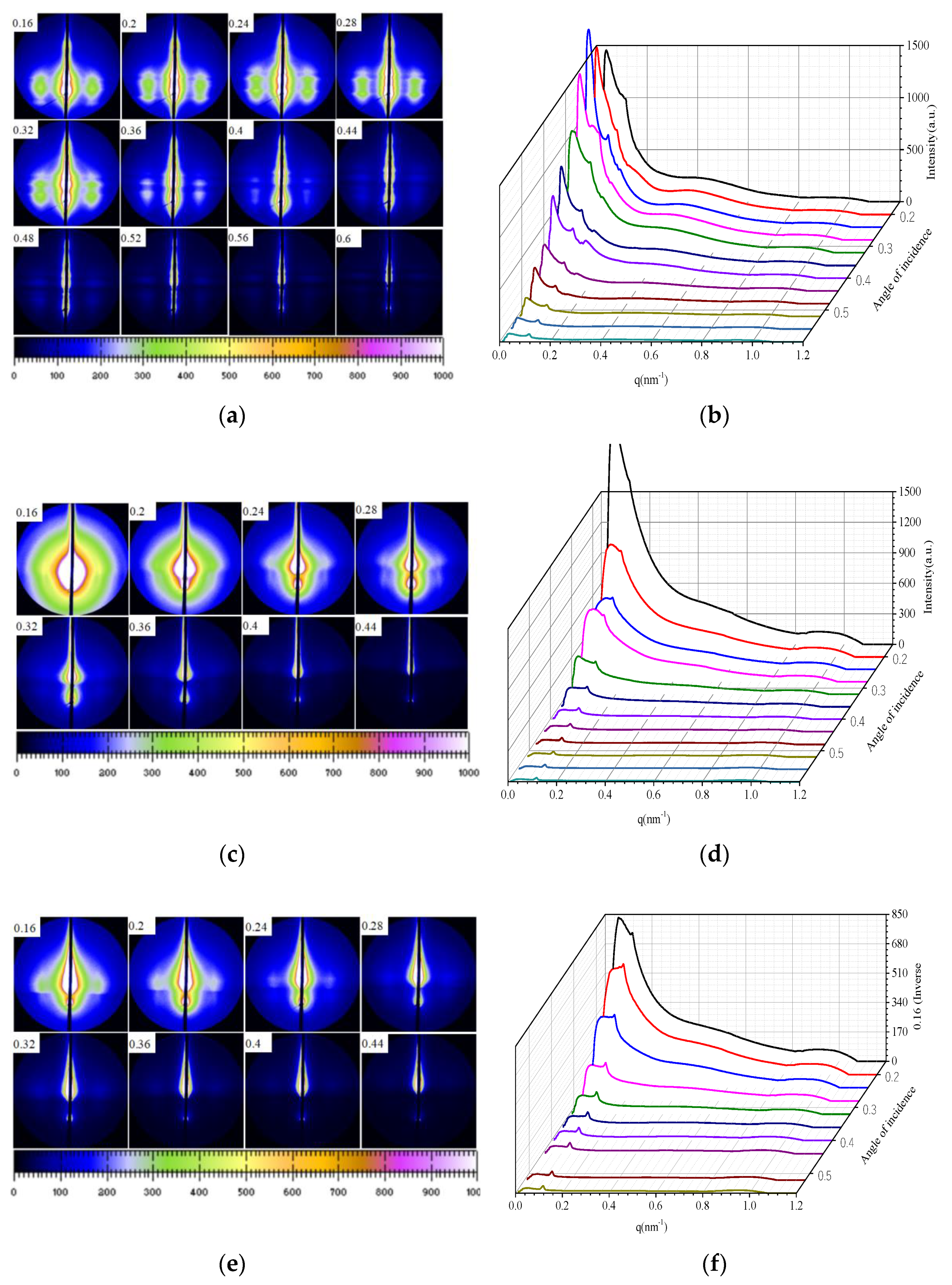

3.3. Micrstructure Analysis Based on GISAXS

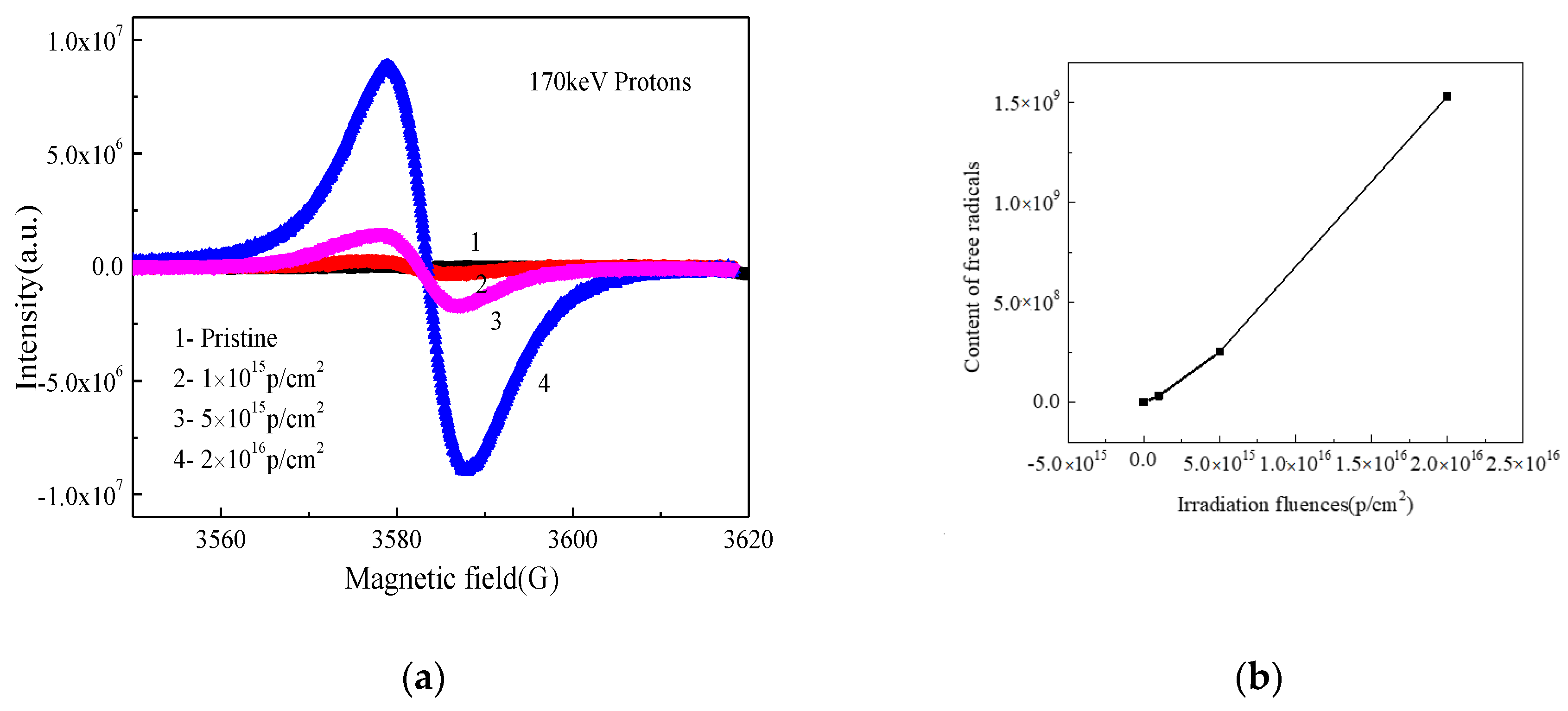

3.4. EPR Analysis

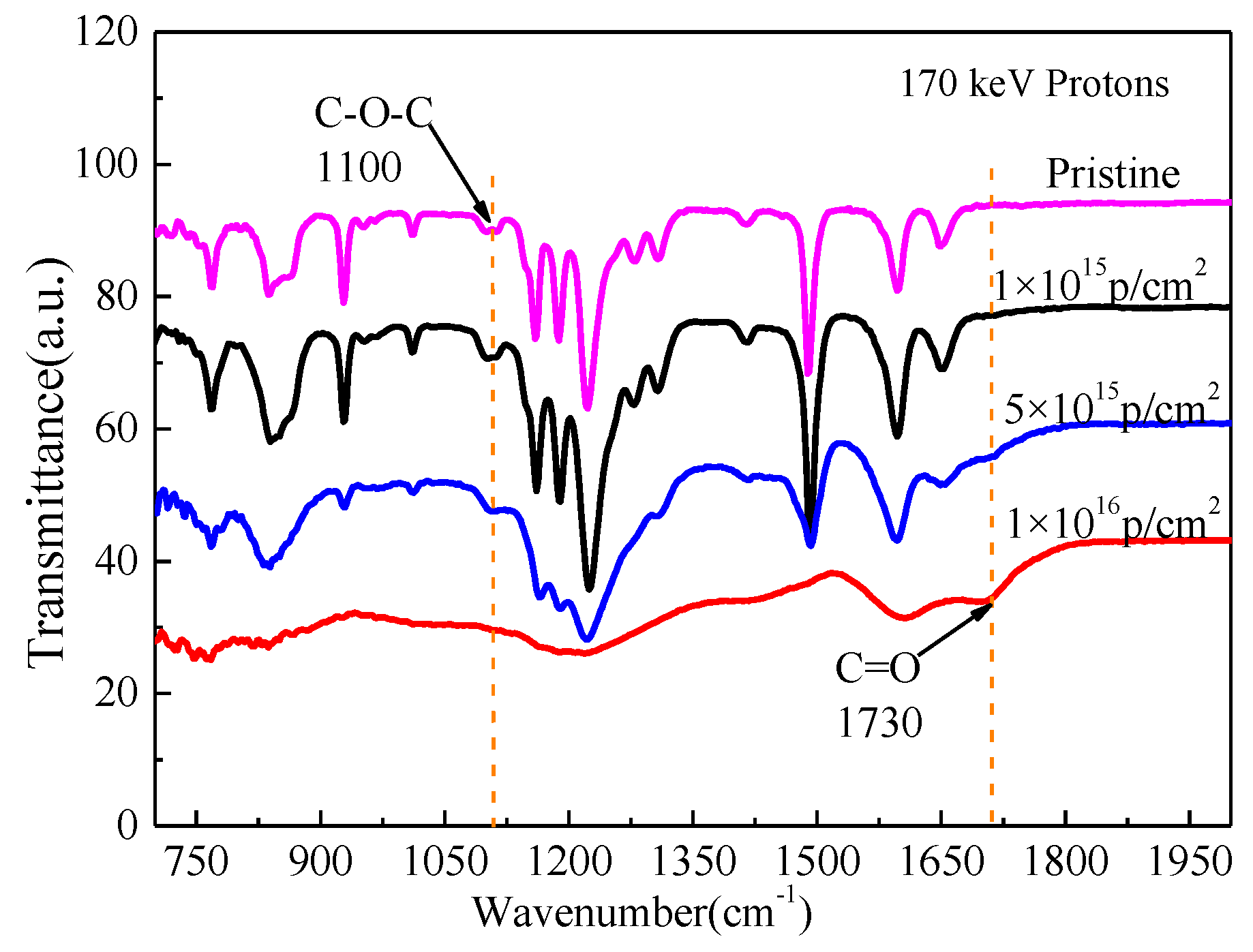

3.5. FTIR Analysis

3.6. DSC Analysis

3.7. Stress–Strain Curves Analysis

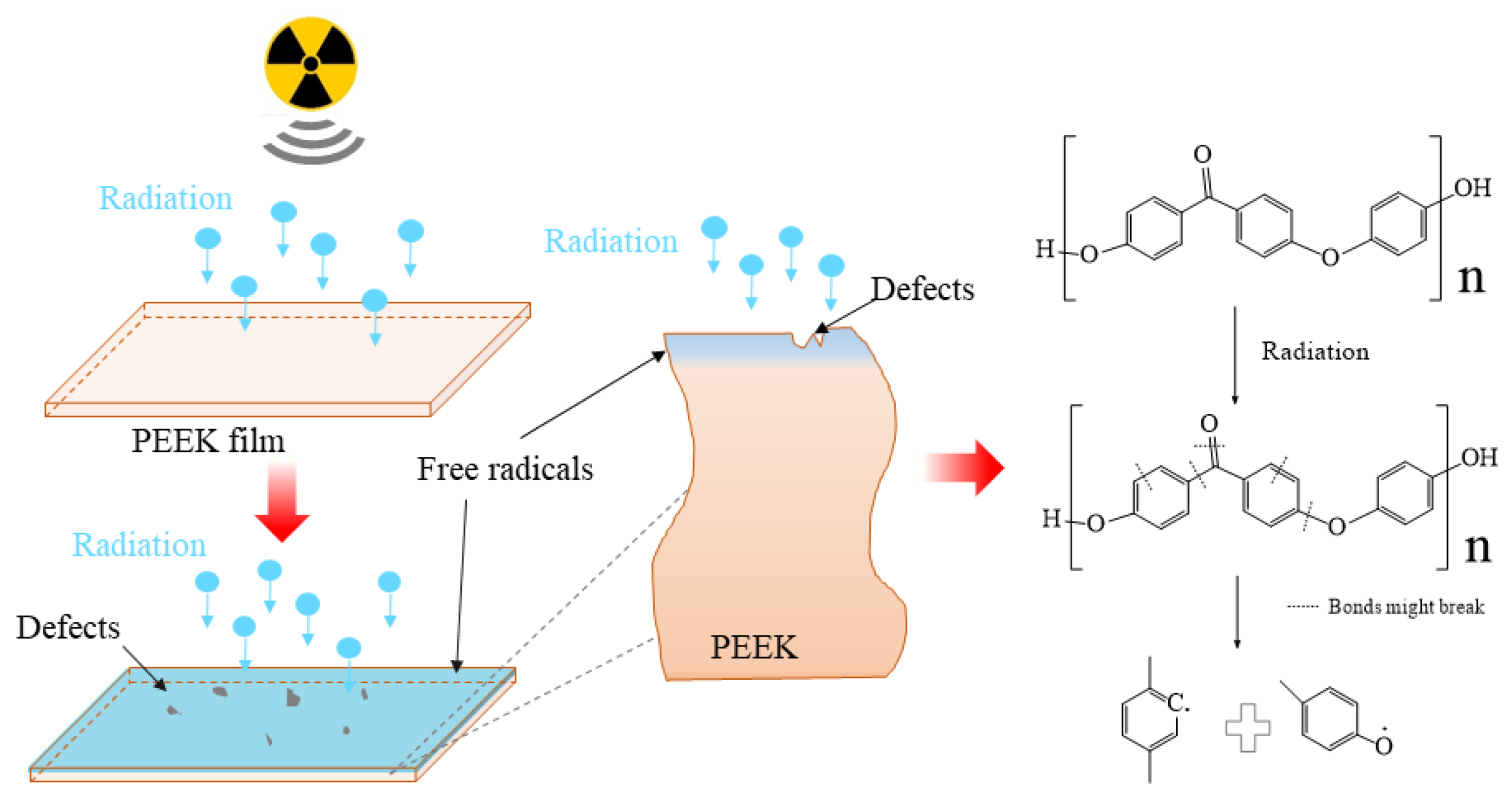

3.8. Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jung, H.; Bae, K.J.; Jin, J.-U.; Oh, Y.; Hong, H.; Youn, S.J.; You, N.-H.; Yu, J. The effect of aqueous polyimide sizing agent on PEEK based carbon fiber composites using experimental techniques and molecular dynamics simulations. Funct. Compos. Struct. 2020, 2, 025001. [Google Scholar] [CrossRef]

- Wu, Y.; Cao, Y.; Wu, Y.; Li, D. Neutron Shielding Performance of 3D-Printed Boron Carbide PEEK Composites. Materials 2020, 13, 2314. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Xie, F.; Dwyer-Joyce, R. PEEK Composites as Self-Lubricating Bush Materials for Articulating Revolute Pin Joints. Polymers 2020, 12, 665. [Google Scholar] [CrossRef] [PubMed]

- Laux, C.J.; Villefort, C.; Ehrbar, S.; Wilke, L.; Guckenberger, M.; Müller, D.A. Carbon Fiber/Polyether Ether Ketone (CF/PEEK) Implants Allow for More Effective Radiation in Long Bones. Materials 2020, 13, 1754. [Google Scholar] [CrossRef] [PubMed]

- Sehyun, K.; Ki-Jun, L.; Yongsok, S. Polyetheretherketone (PEEK) Surface Functionalization by Low-Energy Ion-Beam Irradiation under a Reactive O2 Environment and Its Effect on the PEEK/Copper Adhesives. Langmuir 2004, 20, 157–163. [Google Scholar]

- Li, H.; Yang, J.-Q.; Dong, S.; Tian, F.; Li, X. Low Dielectric Constant Polyimide Obtained by Four Kinds of Irradiation Sources. Polymers 2020, 12, 879. [Google Scholar] [CrossRef] [PubMed]

- Shyichuk, A.; Stavychna, D.; White, J. Effect of tensile stress on chain scission and crosslinking during photo-oxidation of polypropylene. Polym. Degrad. Stab. 2001, 72, 279–285. [Google Scholar] [CrossRef]

- Liu, B.-X.; Liang, J.; Peng, Z.-J.; Wang, X.-L. Proton irradiation effects on the structural and tribological properties of polytetrafluoroethylene. Chin. J. Polym. Sci. 2016, 34, 1448–1455. [Google Scholar] [CrossRef]

- Dong, L.; Liu, X.-D.; Xiong, Z.-R.; Sheng, D.; Zhou, Y.; Yang, Y. Preparation and Characterization of UV-absorbing PVDF Membranes via Pre-irradiation Induced Graft Polymerization. Chin. J. Polym. Sci. 2018, 37, 493–499. [Google Scholar] [CrossRef]

- Nakamura, T.; Nakamura, H.; Fujita, O.; Noguchi, T.; Imagawa, K. The Space Exposure Experiment of PEEK Sheets under Tensile Stress. JSME Int. J. Ser. A 2004, 47, 365–370. [Google Scholar] [CrossRef]

- Macková, A.; Havránek, V.; Svorcik, V.; Djourelov, N.; Suzuki, T. Degradation of PET, PEEK and PI induced by irradiation with 150keV Ar+ and 1.76MeV He+ ions. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2005, 240, 245–249. [Google Scholar] [CrossRef]

- Narasimha, P.; Sudhir, T.; Henry, C. Fabrication of Lightweight Radiation Shielding Composite Materials by Field Assisted Sintering Technique (FAST); NASA: Washington, DC, USA, 2017.

- Malinsky, P.A.; Mackova, V.; Hnatowicz, R.I.; Khaibullin, V.F. Properties of polyimide, polyetheretherketone and poly-ethyleneterephthalate implanted by Ni ions to high fluences. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2012, 272, 396–399. [Google Scholar] [CrossRef]

- Alnajrani, M.N.; Alosime, E.M.; Basfar, A.A. Influence of irradiation crosslinking on the flame-retardant properties of polyolefin blends. J. Appl. Polym. Sci. 2019, 137, 48649. [Google Scholar] [CrossRef]

- Jeun, J.P.; Nho, Y.C.; Kang, P.H. Enhancement of mechanical properties of PEEK using radiation process. Appl. Chem. 2008, 12, 245–248. [Google Scholar]

- Sasuga, T.; Kudoh, H. Ion irradiation effects on thermal and mechanical properties of poly(ether–ether–ketone) (PEEK). Polymer 2000, 41, 185–194. [Google Scholar] [CrossRef]

- Végsö, K.; Siffalovic, P.; Weis, M.; Jergel, M.; Benkovičová, M.; Majkova, E.; Chitu, L.; Halahovets, Y.; Luby, Š.; Capek, I.; et al. In Situ GISAXS monitoring of Langmuir nanoparticle multilayer degradation processes induced by UV photolysis. Phys. Status Solidi 2011, 208, 2629–2634. [Google Scholar]

- Dong, Q.; Brian, D.; Lorcán, B.; Gennaro, S. Rapid surface activation of carbon fibre reinforced PEEK and PPS composites by high-power UV-irradiation for the adhesive joining of dissimilar materials. Compos. Part A 2020, 137, 105976. [Google Scholar]

- Végsö, K.; Siffalovic, P.; Benkovicova, M.; Jergel, M.; Luby, S.; Majkova, E.; Capek, I.; Kocsis, T.; Perlich, J.; Roth, S.V. GISAXS analysis of 3D nanoparticle assemblies—Effect of vertical nanoparticle ordering. Nanotechnology 2012, 23, 45704–45711. [Google Scholar] [CrossRef]

- Xue, F.; Li, H.; You, J.; Lu, C.; Reiter, G.; Jiang, S. The crucial role of cadmium acetate-induced conformational restriction in microscopic structure and stability of polystyrene-block-polyvinyl pyridine thin films. Polymer 2014, 55, 5801–5810. [Google Scholar] [CrossRef]

- Yasin, S.; Shakeel, A.; Ahmad, M.; Ahmad, A.; Iqbal, T. Physico-chemical analysis of semi-crystalline PEEK in aliphatic and aromatic solvents. Soft Mater. 2019, 17, 143–149. [Google Scholar] [CrossRef]

- Susumu, T.; Toshiaki, E.; Hiroaki, I.; Yousuke, O.; Joji, O.; Takuji, K. Highly Efficient Singlet Oxygen Generation and High Oxidation Resistance Enhanced by Arsole-Polymer-Based Photosensitizer: Application as a Recyclable Photooxidation Catalyst. Macromolecules 2020, 53, 2006–2013. [Google Scholar]

- Shaimukhametova, I.F.; Shigabieva, Y.A.; Bogdanova, S.A.; Allayarov, S.R. Effect of γ-Irradiation on the Gel-Forming Capability of a Crosslinked Acrylic Polymer. High Energy Chem. 2020, 54, 111–114. [Google Scholar] [CrossRef]

- Lyu, J.-Z.; Laptev, R.S.; Dubrova, N. Positron Spectroscopy of Free Volume in Poly(vinylidene fluoride) after Helium Ions Irradiation. Chin. J. Polym. Sci. 2018, 37, 527–534. [Google Scholar] [CrossRef]

- Al Lafi, A.G.; Alzier, A.; Allaf, A.W. Two-dimensional FTIR spectroscopic analysis of crystallization in cross-linked poly(ether ether ketone). Int. J. Plast. Technol. 2020, 24, 1–8. [Google Scholar] [CrossRef]

- Kornacka, E.M.; Przybytniak, G.; Nowicki, A. Radical processes initiated by ionizing radiation in PEEK and their macroscopic consequences. Polym. Adv. Technol. 2018, 30, 79–85. [Google Scholar] [CrossRef]

- Claude, B.; Gonon, L.; Duchet, J.; Verney, V.; Gardette, J. Surface cross-linking of polycarbonate under irradiation at long wavelengths. Polym. Degrad. Stab. 2004, 83, 237–240. [Google Scholar] [CrossRef]

| Sample | Pristine | 5 × 1015 p/cm2 | 1 × 1016 p/cm2 |

|---|---|---|---|

| Ra(nm) | 18.8 | 20.8 | 17.5 |

| Rq(nm) | 23.4 | 26.1 | 22.3 |

| Sample | 0.16 | 0.2 | 0.24 | 0.28 | 0.32 | 0.36 | 0.4 | 0.44 | 0.48 |

|---|---|---|---|---|---|---|---|---|---|

| L(nm)/Pristine | 16.44 | 16.10 | 16.02 | 15.90 | 15.66 | 15.43 | 15.24 | 14.74 | 14.6 |

| L(nm)/5 × 1015 p/cm2 | 14.78 | 14.6 | 14.37 | 13.86 | 13.14 | 12.41 | |||

| L(nm)/1 × 1016 p/cm2 | 14.4 | 14.08 | 13.96 | 13.36 | 12.56 |

| Sample | Pristine | 5 × 1015 e/cm2 | 1 × 1016 e/cm2 |

|---|---|---|---|

| T1 (°C) | 301.8 ± 0.5 | 305.5 ± 0.5 | 309.2 ± 0.5 |

| T2 (°C) | 350.9 ± 0.5 | 351.3 ± 0.5 | 352.7 ± 0.5 |

| ΔHm (J/g) | 21.9 ± 5 | 20.4 ± 5 | 16.7 ± 5 |

| T3 (°C) | 301.4 ± 0.5 | 302.5 ± 0.5 | 303.4 ± 0.5 |

| T4 (°C) | 294.5 ± 0.5 | 296.7 ± 0.5 | 299.9 ± 0.5 |

| ΔHc (J/g) | 40.9 ± 5 | 43.0 ± 5 | 39.5 ± 5 |

| X (%) | 17 | 15.8 | 13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Yang, J.; Tian, F.; Li, X.; Dong, S. Study on the Microstructure of Polyether Ether Ketone Films Irradiated with 170 keV Protons by Grazing Incidence Small Angle X-ray Scattering (GISAXS) Technology. Polymers 2020, 12, 2717. https://doi.org/10.3390/polym12112717

Li H, Yang J, Tian F, Li X, Dong S. Study on the Microstructure of Polyether Ether Ketone Films Irradiated with 170 keV Protons by Grazing Incidence Small Angle X-ray Scattering (GISAXS) Technology. Polymers. 2020; 12(11):2717. https://doi.org/10.3390/polym12112717

Chicago/Turabian StyleLi, Hongxia, Jianqun Yang, Feng Tian, Xingji Li, and Shangli Dong. 2020. "Study on the Microstructure of Polyether Ether Ketone Films Irradiated with 170 keV Protons by Grazing Incidence Small Angle X-ray Scattering (GISAXS) Technology" Polymers 12, no. 11: 2717. https://doi.org/10.3390/polym12112717

APA StyleLi, H., Yang, J., Tian, F., Li, X., & Dong, S. (2020). Study on the Microstructure of Polyether Ether Ketone Films Irradiated with 170 keV Protons by Grazing Incidence Small Angle X-ray Scattering (GISAXS) Technology. Polymers, 12(11), 2717. https://doi.org/10.3390/polym12112717