Silanized Silica-Encapsulated Calcium Carbonate@Natural Rubber Composites Prepared by One-Pot Reaction

Abstract

1. Introduction

2. Experimental

2.1. Materials

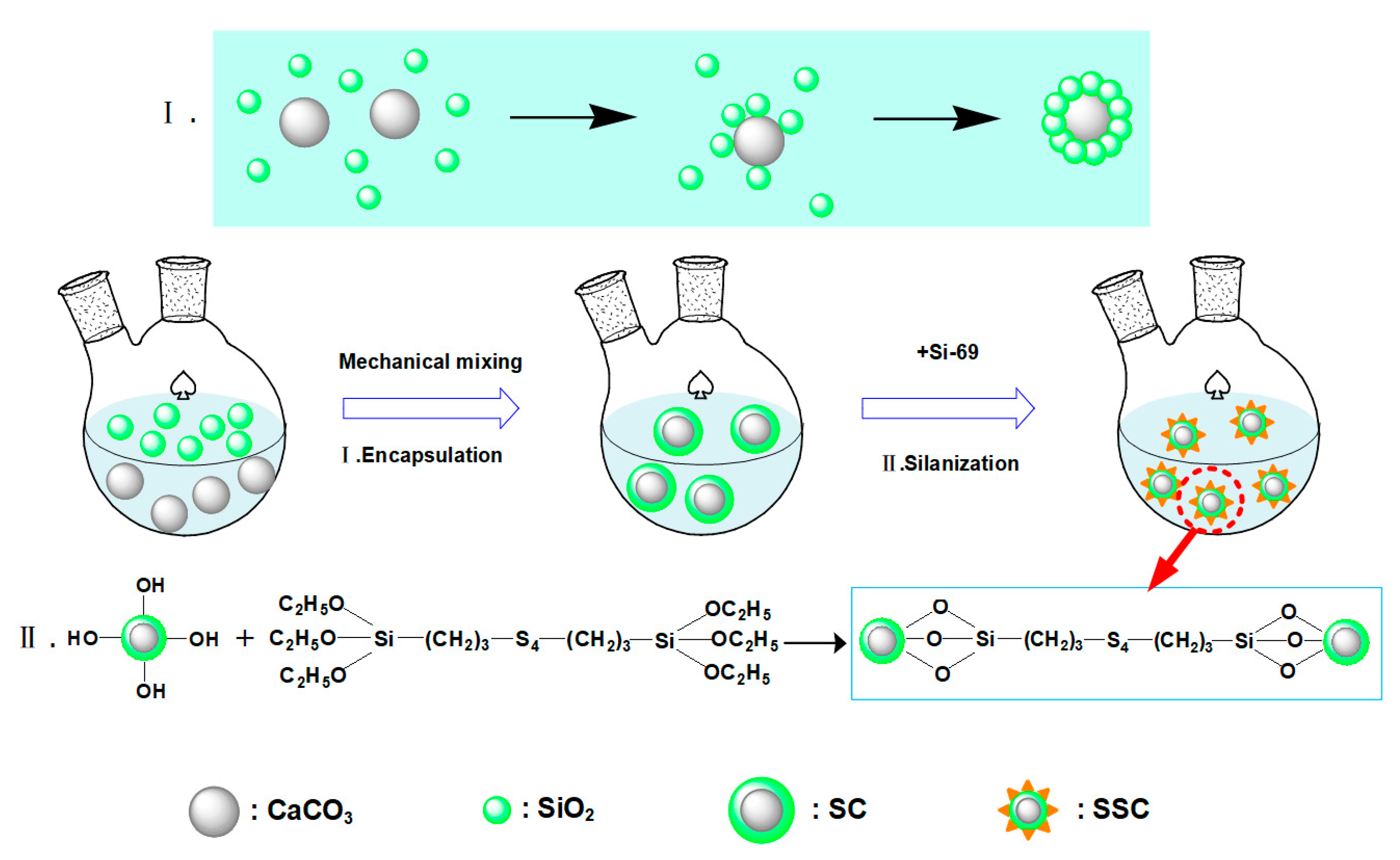

2.2. Preparation of the SSC@NR

2.3. Experimental Variables

2.4. Characterization and Testing

3. Results and Discussion

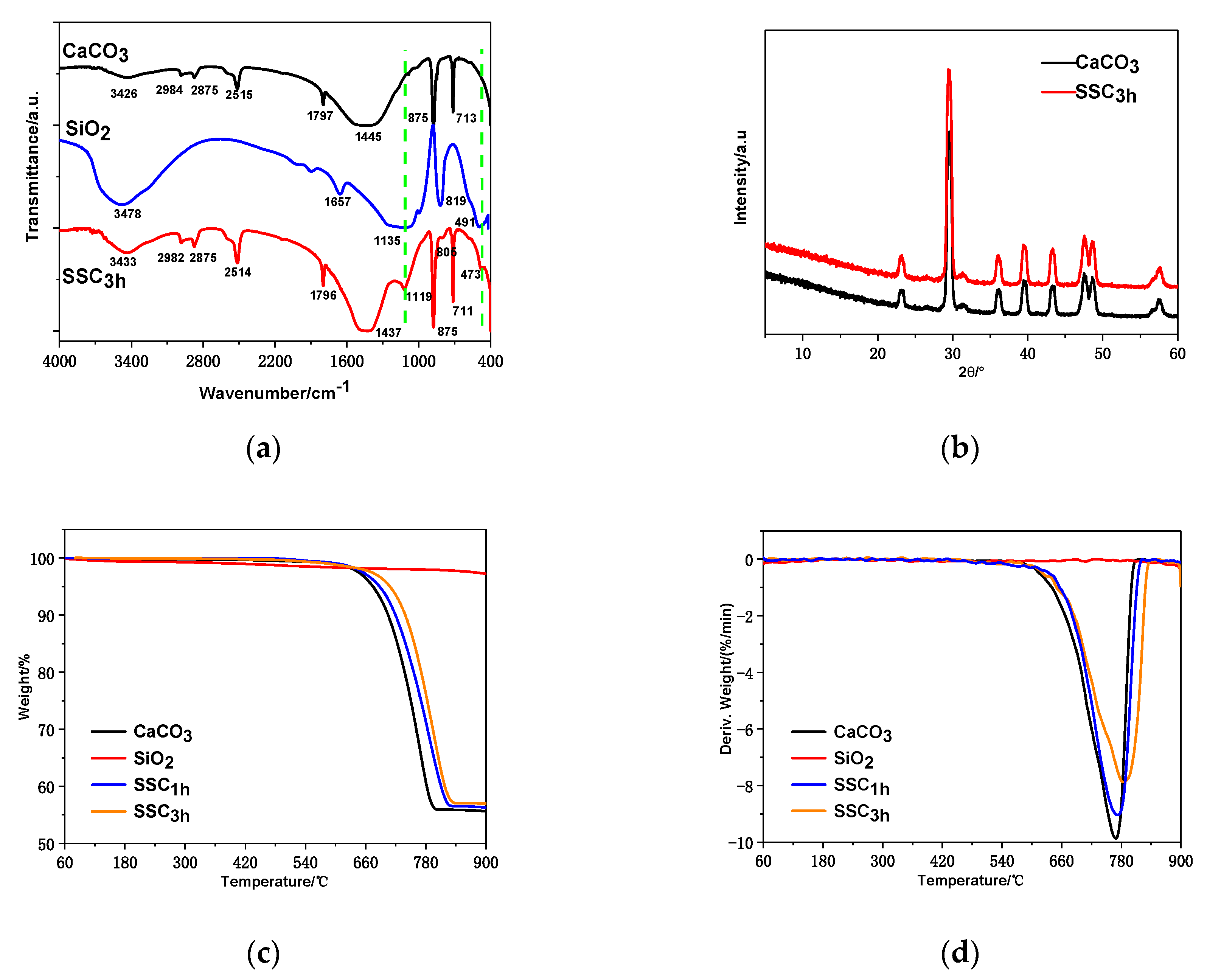

3.1. The Chemical Structure and Microstructure of SSC

3.2. The Comprehensive Properties of SSC@NR Composites

3.2.1. Mooney Viscosity of SSC@NR Compounds

3.2.2. Curing Characteristics of SSC@NR Composites

3.2.3. Physical and Mechanical Properties of SSC@NR Composites

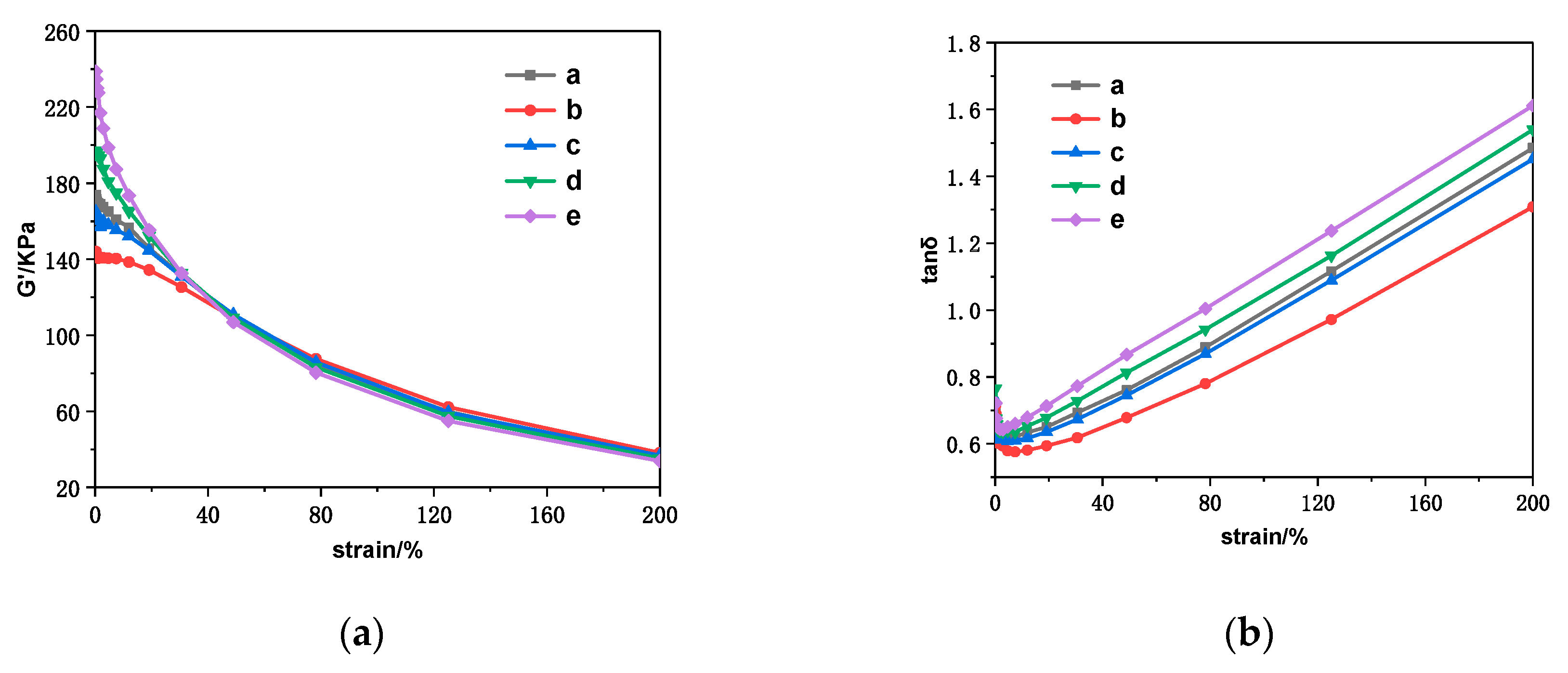

3.2.4. Dynamic Mechanical Properties of SSC@NR Composites

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shimpi, N.G.; Mishra, S. Synthesis of nanoparticles and its effect on properties of elastomeric nanocomposites. J. Nanoparticle Res. 2009, 12, 2093–2099. [Google Scholar] [CrossRef]

- Chan, C.-M.; Wu, J.; Li, J.-X.; Cheung, Y.-K. Polypropylene/calcium carbonate nanocomposites. Polymer 2002, 43, 2981–2992. [Google Scholar] [CrossRef]

- Zeng, X.F.; Wang, W.Y.; Wang, G.Q.; Chen, J.F. Influence of the diameter of CaCO3 particles on the mechanical and rheological properties of PVC composites. J. Mater. Sci. 2008, 43, 3505–3509. [Google Scholar] [CrossRef]

- Jin, F.-L.; Park, S.-J. Thermo-mechanical behaviors of butadiene rubber reinforced with nano-sized calcium carbonate. Mater. Sci. Eng. A 2008, 478, 406–408. [Google Scholar] [CrossRef]

- Wang, J.; Song, J.; Ji, Z.-Y.; Liu, J.; Guo, X.; Zhao, Y.-Y.; Yuan, J. The preparation of calcium carbonate with different morphologies under the effect of alkanolamide 6502. Colloids Surfaces A Physicochem. Eng. Asp. 2020, 588, 124392. [Google Scholar] [CrossRef]

- Zhang, W.; Hu, Y.; Xi, L.; Zhang, Y.; Gu, H.; Zhang, T. Preparation of Calcium Carbonate Superfine Powder by Calcium Carbide Residue. Energy Proc. 2012, 17, 1635–1640. [Google Scholar] [CrossRef]

- Jia, Z.; Chang, Q.; Qin, J.; Mamat, A. Preparation of Calcium Carbonate Nanoparticles with a Continuous Gas-liquid Membrane Contactor: Particles Morphology and Membrane Fouling. Chin. J. Chem. Eng. 2013, 21, 121–126. [Google Scholar] [CrossRef]

- Hassan, T.A.; Rangari, V.K.; Jeelani, S. Value-Added Biopolymer Nanocomposites from Waste Eggshell-Based CaCO3 Nanoparticles as Fillers. ACS Sustain. Chem. Eng. 2014, 2, 706–717. [Google Scholar] [CrossRef]

- Gabriel, D.; Karbach, A.; Drechsler, D.; Gutmann, J.S.; Graf, K.; Kheirandish, S. Bound rubber morphology and loss tangent properties of carbon-black-filled rubber compounds. Colloid Polym. Sci. 2015, 294, 501–511. [Google Scholar] [CrossRef]

- Chen, L.; Song, L.; Li, J.; Chen, P.; Huang, N.; Li, L. From the Volume-Filling Effect to the Stress-Bearing Network: The Reinforcement Mechanisms of Carbon Black Filler in Natural Rubber. Macromol. Mater. Eng. 2016, 301, 1390–1401. [Google Scholar] [CrossRef]

- Pedrosa, J.; Gamelas, J.A.; Lourenço, A.F.; Ferreira, P.J. Surface properties of calcium carbonate modified with silica by sol-gel method. Colloids Surfaces A Physicochem. Eng. Asp. 2016, 497, 1–7. [Google Scholar] [CrossRef]

- Fang, Q.; Song, B.; Tee, T.-T.; Sin, L.T.; Hui, D.; Bee, S.-T. Investigation of dynamic characteristics of nano-size calcium carbonate added in natural rubber vulcanizate. Compos. Part B Eng. 2014, 60, 561–567. [Google Scholar] [CrossRef]

- Cao, Z.; Daly, M.; Clémence, L.; Geever, L.M.; Major, I.; Higginbotham, C.L.; Devine, D.M. Chemical surface modification of calcium carbonate particles with stearic acid using different treating methods. Appl. Surf. Sci. 2016, 378, 320–329. [Google Scholar] [CrossRef]

- el Malti, W.; Laurencin, D.; Guerrero, G.; Smith, M.E.; Mutin, P.H. Surface modification of calcium carbonate with phosphonic acids. J. Mater. Chem. 2012, 22, 1212–1218. [Google Scholar] [CrossRef]

- Ippolito, F.; Hübner, G.; Claypole, T.; Gane, P. Influence of the Surface Modification of Calcium Carbonate on Polyamide 12 Composites. Polymers 2020, 12, 1295. [Google Scholar] [CrossRef]

- Zhang, A.; Zhao, G.; Guan, Y. Effect of surface modifiers and surface modification methods on properties of acrylonitrile-butadiene-styrene/poly(methyl methacrylate)/nano-calcium carbonate composites. J. Appl. Polym. Sci. 2012, 127, 2520–2528. [Google Scholar] [CrossRef]

- Kim, D.; Lee, J.; Lee, S.; Lim, J. Surface modification of calcium carbonate nanoparticles by fluorosurfactant. Colloids Surfaces A Physicochem. Eng. Asp. 2018, 536, 213–223. [Google Scholar] [CrossRef]

- Li, L.; Zou, H.; Shao, L.; Wang, G.; Chen, J. Study on mechanical property of epoxy composite filled with nano-sized calcium carbonate particles. J. Mater. Sci. 2005, 40, 1297–1299. [Google Scholar] [CrossRef]

- Jiang, Z.; Wang, J.-W.; Ge, R.; Wu, C. The effects of surface modification of ground calcium carbonate powdery fillers on the properties of PVC. Polym. Bull. 2017, 75, 1123–1139. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, S.; Zhang, Y.; Zhang, Y. Reinforcement effect of MAA on nano-CaCO3-filled EPDM vulcanizates and possible mechanism. J. Polym. Sci. Part B Polym. Phys. 2006, 44, 1226–1236. [Google Scholar] [CrossRef]

- Poompradub, S.; Luthikaviboon, T.; Linpoo, S.; Rojanathanes, R.; Prasassarakich, P. Improving oxidation stability and mechanical properties of natural rubber vulcanizates filled with calcium carbonate modified by gallic acid. Polym. Bull. 2010, 66, 965–977. [Google Scholar] [CrossRef]

- Kalkan, E.; Akbulut, S. The positive effects of silica fume on the permeability, swelling pressure and compressive strength of natural clay liners. Eng. Geol. 2004, 73, 145–156. [Google Scholar] [CrossRef]

- Park, J.T.; Seo, J.A.; Ahn, S.H.; Kim, J.H.; Kang, S.W. Surface modification of silica nanoparticles with hydrophilic polymers. J. Ind. Eng. Chem. 2010, 16, 517–522. [Google Scholar] [CrossRef]

- Li, Y.; Han, B.; Wen, S.; Lu, Y.; Yang, H.; Zhang, L.; Liu, L. Effect of the temperature on surface modification of silica and properties of modified silica filled rubber composites. Compos. Part A Appl. Sci. Manuf. 2014, 62, 52–59. [Google Scholar] [CrossRef]

- Min, K.; Hong, C.K.; Choe, S.; Shim, S.E. Synthesis of polystyrene/silica composite particles by soap-free emulsion polymerization using positively charged colloidal silica. J. Colloid Interface Sci. 2007, 310, 112–120. [Google Scholar] [CrossRef]

- Zou, H.; Wu, S.; Shen, J. Polymer/Silica Nanocomposites: Preparation, Characterization, Properties, and Applications. Chem. Rev. 2008, 108, 3893–3957. [Google Scholar] [CrossRef]

- Li, Y.; Han, B.; Liu, L.; Zhang, F.; Zhang, L.; Wen, S.; Lu, Y.; Yang, H.; Shen, J. Surface modification of silica by two-step method and properties of solution styrene butadiene rubber (SSBR) nanocomposites filled with modified silica. Compos. Sci. Technol. 2013, 88, 69–75. [Google Scholar] [CrossRef]

- Xiang, Y.; Shen, X.; Gao, J.; Asiri, A.M.; Marwani, H.M. Grafting polyisoprene onto surfaces of nanosilica via RAFT polymerization and modification of natural rubber. Polym. Eng. Sci. 2019, 59, 1167–1174. [Google Scholar] [CrossRef]

- Pan, Q.; Wang, B.; Chen, Z.; Zhao, J. Reinforcement and antioxidation effects of antioxidant functionalized silica in styrene–butadiene rubber. Mater. Des. 2013, 50, 558–565. [Google Scholar] [CrossRef]

- Luo, K.; Zheng, W.; Zhao, X.; Wang, X.; Wu, S. Effects of antioxidant functionalized silica on reinforcement and anti-aging for solution-polymerized styrene butadiene rubber: Experimental and molecular simulation study. Mater. Des. 2018, 154, 312–325. [Google Scholar] [CrossRef]

- Qu, L.; Yu, G.; Xie, X.; Wang, L.; Li, J.; Zhao, Q. Effect of silane coupling agent on filler and rubber interaction of silica reinforced solution styrene butadiene rubber. Polym. Compos. 2013, 34, 1575–1582. [Google Scholar] [CrossRef]

- Reculusa, S.; Mingotaud, C.; Bourgeat-Lami, E.; Duguet, A.E.; Ravaine, S. Synthesis of Daisy-Shaped and Multipod-like Silica/Polystyrene Nanocomposites. Nano Lett. 2004, 4, 1677–1682. [Google Scholar] [CrossRef]

- Zheng, J.; Han, D.; Ye, X.; Wu, X.; Wu, Y.; Wang, Y.; Zhang, L. Chemical and physical interaction between silane coupling agent with long arms and silica and its effect on silica/natural rubber composites. Polymers 2018, 135, 200–210. [Google Scholar] [CrossRef]

- Morsy, F.A.; El-Sheikh, S.M.; Barhoum, A. Nano-silica and SiO2/CaCO3 nanocomposite prepared from semi-burned rice straw ash as modified papermaking fillers. Arab. J. Chem. 2019, 12, 1186–1196. [Google Scholar] [CrossRef]

- Lu, G.-Q.; Hao, H.; Wang, F.-Y.; Zhang, X.-G. Preparation of closed-cell Mg foams using SiO2-coated CaCO3 as blowing agent in atmosphere. Trans. Nonferrous Met. Soc. China 2013, 23, 1832–1837. [Google Scholar] [CrossRef]

- Wen, X.; Liu, Y.; Xu, Z.; Yang, J.; Pi, P.; Cai, Z.; Cheng, J.; Yang, Z. Mechano-Chemical Preparation and Application of Mulberry-Like CaCO3/SiO2 Composite Particles in Superhydrophobic Films. Soft Mater. 2012, 10, 435–448. [Google Scholar] [CrossRef]

- Gamelas, J.A.F.; Lourenco, A.F.; Ferreira, P.J. New modified filler obtained by silica formed by sol–gel method on calcium carbonate. J. Sol-Gel Sci. Technol. 2011, 59, 25–31. [Google Scholar] [CrossRef]

- Jiang, L.; Pan, K.; Dan, Y. Synthesis and characterization of well-defined poly(methyl methacrylate)/CaCO3/SiO2 three-component composite particles via reverse atom transfer radical polymerization. Colloid Polym. Sci. 2006, 285, 65–74. [Google Scholar] [CrossRef]

- Zhang, S.; Li, X. Synthesis and characterization of CaCO3@SiO2 core–shell nanoparticles. Powder Technol. 2004, 141, 75–79. [Google Scholar] [CrossRef]

- Cui, C.; Ding, H.; Cao, L.; Chen, D. Preparation of CaCO3-SiO2 composite with core-shell structure and its application in silicone rubber. Pol. J. Chem. Technol. 2015, 17, 128–133. [Google Scholar] [CrossRef]

- Nyquist, R.A.; Putzig, C.L.; Leugers, M.A. The Handbook of Infrared and Raman Spectra of Inorganic Compounds and Organic Salts; Academic Press: San Diego, CA, USA, 1997; Volume 1, p. 4. [Google Scholar]

- Kamath, S.R.; Proctor, A. Silica Gel from Rice Hull Ash: Preparation and Characterization. Cereal Chem. J. 1998, 75, 484–487. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Raengthon, N.; Potiyaraj, P. Understanding the reinforcing efficiency of waste eggshell-derived nano calcium carbonate in natural rubber composites with maleated natural rubber as compatibilizer. Polym. Eng. Sci. 2019, 59, 1428–1436. [Google Scholar] [CrossRef]

- Pattanawanidchai, S.; Loykulnant, S.; Sae-Oui, P.; Maneevas, N.; Sirisinha, C. Development of eco-friendly coupling agent for precipitated silica filled natural rubber compounds. Polym. Test. 2014, 34, 58–63. [Google Scholar] [CrossRef]

- Chen, X.Z.; Chen, X.M.; Cheng, J.Z.; Wu, Q.F. Effect of nano-calcium carbonate/silica composite particles on mechanical properties of styrene-butadiene rubber. China Synth. Rubber Ind. 2012, 35, 229–233. (In Chinese) [Google Scholar]

- Sajjayanukul, T.; Saeoui, P.; Sirisinha, C. Experimental analysis of viscoelastic properties in carbon black-filled natural rubber compounds. J. Appl. Polym. Sci. 2005, 97, 2197–2203. [Google Scholar] [CrossRef]

| Samples | A 1 | B 2 | C 3 | D 4 | E 5 |

|---|---|---|---|---|---|

| NR/phr | 100 | 100 | 100 | 100 | 100 |

| Calcium carbonate/phr | 40 | 40 | 60 | 80 | 100 |

| Silica sol/phr | - | 5 | 7.5 | 10 | 12.5 |

| Si-69/phr | - | 2 | 3 | 4 | 5 |

| Modification time/h | - | 3 | 3 | 3 | 3 |

| Project | Sample | ||||

|---|---|---|---|---|---|

| a | b | c | d | e | |

| ML/dN·m | 0.356 | 0.533 | 0.873 | 0.892 | 1.010 |

| MH/dN·m | 22.091 | 23.061 | 29.920 | 33.195 | 37.334 |

| MH-ML/dN·m | 21.735 | 22.705 | 29.047 | 32.303 | 36.324 |

| Ts1/min | 1.63 | 1.75 | 1.57 | 1.53 | 1.48 |

| T10/min | 1.80 | 1.93 | 1.80 | 1.83 | 1.83 |

| T90/min | 6.22 | 6.90 | 7.38 | 7.70 | 7.88 |

| CRI/min−1 | 22.64 | 20.13 | 17.91 | 17.05 | 16.53 |

| Property | Sample | ||||

|---|---|---|---|---|---|

| a | b | c | d | e | |

| Tensile strength/MPa | 22.2 ± 1.1 | 25.6 ± 0.9 | 22.1 ± 1.2 | 20.2 ± 0.7 | 19.2 ± 1.0 |

| Elongation at break/% | 582 ± 38 | 629 ± 37 | 632 ± 41 | 556 ± 32 | 509 ± 35 |

| 100% Tensile modulus/MPa | 1.2 ± 0.1 | 1.2 ± 0.1 | 1.8 ± 0.2 | 2.1 ± 0.1 | 2.8 ± 0.2 |

| 300% Tensile modulus/MPa | 4.5 ± 0.2 | 4.3 ± 0.2 | 5.7 ± 0.4 | 6.9 ± 0.3 | 8.3 ± 0.4 |

| Tear strength/N·mm−1 | 35.4 ± 1.5 | 38.1 ± 2.1 | 44.0 ± 1.4 | 46.3 ± 1.9 | 46.8 ± 1.5 |

| Shore A hardness | 44 ± 1 | 46 ± 1 | 55 ± 1 | 61 ± 1 | 64 ± 1 |

| Compression permanent distortion/% | 3.5 ± 0.1 | 3.3 ± 0.2 | 4.1 ± 0.1 | 4.9 ± 0.2 | 5.7 ± 0.3 |

| Schopper abrasion/cm3 | 0.173 ± 0.012 | 0.163 ± 0.009 | 0.174 ± 0.010 | 0.177 ± 0.007 | 0.189 ± 0.013 |

| Polymer Matrix | Filler Materials | Tensile Strength/MPa | Elongation at Break/% | Reference |

|---|---|---|---|---|

| NR | 20 phr CaCO3 | 20.1 | 713 | [21] |

| NR | 5 phr WESNCC/MNR | 20.7 | 670 | [43] |

| NR | 70 phr SiO2 | 26.2 | 575 | [33] |

| NR | 50 phr SiO2 | 15.1 | 555 | [44] |

| SBR | 75 phr CaCO3/SiO2 75 phr CaCO3 | 14.1 8.1 | 1036 1291 | [45] |

| Silicone rubber | 45 phr CaCO3- SiO2 45 phr CaCO3 | 1.0 0.4 | 157 99 | [40] |

| NR | 40 phr SSC 40 phr CaCO3 | 25.6 22.2 | 629 582 | Our work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.; Zhang, J.; Wang, H.; Xin, Z. Silanized Silica-Encapsulated Calcium Carbonate@Natural Rubber Composites Prepared by One-Pot Reaction. Polymers 2020, 12, 2668. https://doi.org/10.3390/polym12112668

Yu Y, Zhang J, Wang H, Xin Z. Silanized Silica-Encapsulated Calcium Carbonate@Natural Rubber Composites Prepared by One-Pot Reaction. Polymers. 2020; 12(11):2668. https://doi.org/10.3390/polym12112668

Chicago/Turabian StyleYu, Yao, Junyi Zhang, Hongzhen Wang, and Zhenxiang Xin. 2020. "Silanized Silica-Encapsulated Calcium Carbonate@Natural Rubber Composites Prepared by One-Pot Reaction" Polymers 12, no. 11: 2668. https://doi.org/10.3390/polym12112668

APA StyleYu, Y., Zhang, J., Wang, H., & Xin, Z. (2020). Silanized Silica-Encapsulated Calcium Carbonate@Natural Rubber Composites Prepared by One-Pot Reaction. Polymers, 12(11), 2668. https://doi.org/10.3390/polym12112668