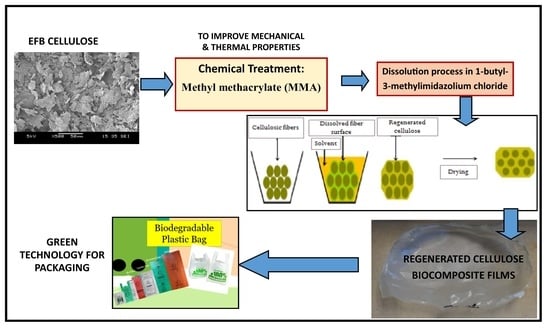

Methyl Methacrylate (MMA) Treatment of Empty Fruit Bunch (EFB) to Improve the Properties of Regenerated Cellulose Biocomposite Films

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Pre-Treatment of EFB

2.3. EFB Modification

2.4. Preparation of EFB Regenerated Cellulose (RC) Biocomposite Films

3. Texting and Characterization

3.1. Tensile Testing

3.2. Scanning Electron Microscopy (SEM)

3.3. X-Ray Diffraction (XRD)

3.4. Fourier Transform Infrared (FTIR)

3.5. Thermogravimetric Analysis (TGA)

4. Results and Discussion

4.1. Tensile Properties

4.2. X-Ray Diffraction (XRD)

4.3. Morphology Study

4.4. Thermal Gravimetric Analysis

4.5. Fourier Transform Infrared Spectroscopy Analysis (FTIR)

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Haider, T.P.; Völker, C.; Kramm, J.; Landfester, K.; Wurm, F.R. Plastics of the Future? The Impact of Biodegradable Polymers on the Environment and on Society. Angew. Chem. Int. Ed. 2019, 58, 50–62. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Balakrishnan, P.; Gopi, S.; Sreekala, M.S.; Thomas, S. UV resistant transparent bionanocomposite films based on potato starch/cellulose for sustainable packaging. Starch-Starke 2018, 70, 1700139. [Google Scholar] [CrossRef]

- Osman, A.F.; Ashafee, A.M.T.; Adnan, S.A.; Alakrach, A. Influence of Hybrid Cellulose/Bentonite Fillers on Structure, Ambient and Low Temperature Tensile Properties of Thermoplastic Starch Composites. Polym. Eng. Sci. 2020, 60, 810–822. [Google Scholar] [CrossRef]

- Syed Adam, S.N.S.; Osman, A.F.; Shamsudin, R. Tensile Properties, Biodegradability and Bioactivity of Thermoplastic Starch (TPS) / Bioglass Composites for Bone Tissue Engineering. Sains Malay. 2018, 47, 1303–1310. [Google Scholar] [CrossRef]

- Yang, Y.; Shen, H.; Wang, X.; Qiu, J. Preparation of Nanolignocellulose/Chitin Composites with Superior Mechanical Property and Thermal Stability. J. Bioresour. Bioprod. 2019, 4, 251–259. [Google Scholar]

- Hassan, M.; Bai, J.; Dou, D. Biopolymers; Definition, Classification and Applications. Egypt. J. Chem. 2019, 62, 1725–1737. [Google Scholar] [CrossRef]

- Miao, X.; Lin, J.; Bian, F. Utilization of discarded crop straw to produce cellulose nanofibrils and their assemblies. J. Bioresour. Bioprod. 2020, 5, 26–36. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Arpith, G.R.; Laxmana Naik, L.; Gopalakrishna, K.; Yogesha, B. Applications of Natural Fibers and Its Composites: An Overview. Nat. Resour. 2016, 7, 108–114. [Google Scholar] [CrossRef] [Green Version]

- Ismail, I.; Osman, A.F.; Ping, T.L. Effects of ultrasonication process on crystallinity and tear strength of thermoplastic starch/cellulose biocomposites. IOP Conf. Ser. Mat. Sci. Eng. 2019, 701, 012045. [Google Scholar]

- Zailuddin, N.L.I.; Osman, A.F.; Rahman, R. Morphology, Mechanical Properties and Biodegradability of All-Cellulose Composite Films from Oil Palm Empty Fruit Bunch. SPF Polymers 2020, 1, 4–14. [Google Scholar] [CrossRef]

- Huber, T.; Mussig, J.; Curnow, O.; Pang, S.; Bickerton, S.; Staiger, M.P. A Critical review of all-cellulose composites. J. Mater. Sci. 2012, 47, 1171–1186. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, H.; Li, Z.; Lu, X.; Zhang, X.; Zhang, S.; Zhou, K. Characterization of the regenerated cellulose films in ionic liquids and rheological properties of the solutions. Mater. Chem. Phys. 2011, 128, 220–227. [Google Scholar] [CrossRef]

- Jiang, G.; Huang, W.; Li, L.; Wang, X.; Pang, F.; Zhang, Y.; Wang, H. Structure and properties of regenerated cellulose fibers from different technology processes. Carbohydr. Polym. 2012, 87, 2012–2018. [Google Scholar] [CrossRef]

- Earle, M.J.; Seddon, K.R. Ionic liquids. Green solvents for the future. Pure Appl. Chem. 2000, 72, 1391–1398. [Google Scholar] [CrossRef] [Green Version]

- Xia, Z.; Li, J.; Zhang, J.; Zhang, X.; Zheng, X.; Zhang, J. Processing and Valorization of Cellulose, Lignin and Lignocellulose Using Ionic Liquids. J. Bioresour. Bioprod. 2020, 5, 79–95. [Google Scholar] [CrossRef]

- Zhu, S.; Wu, Y.; Chen, Q.; Yu, Z.; Wang, C.; Jin, S.; Ding, Y.; Wu, G. Dissolution of cellulose with ionic liquids and its application: A mini-review. Green Chem. 2006, 8, 325–327. [Google Scholar] [CrossRef]

- Biganska, O.; Navard, P. Kinetics of precipitation of cellulose from cellulose-NMMO-water solutions. Biomacromolecules 2005, 6, 1948–1953. [Google Scholar] [CrossRef] [PubMed]

- Soheilmoghaddam, M.; Wahit, M.U. Development of regenerated cellulose/halloysite nanotube bionanocomposite films with ionic liquid. Int. J. Biol. Macromol. 2013, 58, 133–139. [Google Scholar] [CrossRef]

- Pang, J.; Liu, X.; Zhang, X.; Wu, Y.; Sun, R. Fabrication of cellulose film with enhanced mechanical properties in ionic liquid 1-allyl-3-methylimidaxolium chloride (AmimCl). Materials 2013, 6, 1270–1284. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Pang, J.; Zhang, X.; Wu, Y.; Sun, R. Regenerated cellulose film with enhanced tensile strength prepared with ionic liquid 1-ethyl-3-methylimidazolium acetate (EMIMAc). Cellulose 2013, 20, 1391–1399. [Google Scholar] [CrossRef]

- Wang, L.; Gao, L.; Cheng, B.; Ji, X.; Song, J.; Lu, F. Rheological behaviors of cellulose in 1-ethyl-3-methylimidazolium chloride/ dimethylsulfoxide. Carbohydr. Polym. 2014, 110, 292–297. [Google Scholar] [CrossRef]

- Swatloski, R.P.; Spear, S.K.; Holbrey, J.D.; Rogers, R.D. Dissolution of cellose with ionic liquids. J. Am. Chem. Soc. 2002, 124, 4974–4975. [Google Scholar] [CrossRef]

- Ying, T.Y.; Teong, L.K.; Abdullah, W.N.W.; Peng, L.C. The effect of various pretreatment methods on oil palm empty fruit bunch (EFB) and kenaf core fibers for sugar production. Procedia Environ. Sci. 2014, 20, 328–335. [Google Scholar] [CrossRef] [Green Version]

- Nazir, M.S.; Wahjoedi, B.A.; Yussof, A.W.; Abdullah, M.A. Eco-friendly extraction and characterization of cellulose from oil palm empty fruit bunches. Bioresources 2013, 8, 2161–2172. [Google Scholar] [CrossRef] [Green Version]

- Zailuddin, N.L.I.; Osman, A.F.; Rozyanty Rahman, R. Effects of Formic Acid Treatment on Properties of Oil Palm Empty Fruit Bunch (OPEFB)-Based All Cellulose Composite (ACC) Films. J. Eng Sci. 2020, 16, 75–95. [Google Scholar]

- Kobayashi, H.; Ito, Y.; Komanoya, T.; Hosaka, Y.; Dhepe, P.L.; Kasai, K.; Hara, K.; Fukuoka, A. Synthesis of sugar alcohols by hydrolytic hydrogenation of cellulose over supported metal catalysts. Green Chem. 2011, 13, 326–333. [Google Scholar] [CrossRef] [Green Version]

- Tolonen, L.K.; Zuckerstätter, G.; Penttilä, P.A.; Milacher, W.; Habicht, W.; Serimaa, R.; Kruse, A.; Sixta, H. Structural changes in microcrystalline cellulose in subcritical water treatment. Biomacromolecules 2011, 12, 2544–2551. [Google Scholar] [CrossRef]

- Kim, J.W.; Kim, K.S.; Lee, J.S.; Park, S.M.; Cho, H.Y.; Park, J.C.; Kim, J.S. Two-stage pretreatment of rice straw using aqueous ammonia and dilute acid. Bioresource Technol. 2011, 102, 8992–8999. [Google Scholar] [CrossRef]

- Thakur, M.K.; Gupta, R.K.; Thakur, V.K. Surface modification of cellulose using silane coupling agent. Carbohydr. Polym. 2014, 111, 849–855. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Li, J.; Zhang, J.; Li, H.; Chen, P.; Gu, Q.; Wang, Z. Thermo-mechanical properties of the composite made of poly (3-hydroxybutyrate-co-3-hydroxyvalerate) and acetylated chitin nanocrystals. Carbohydr. Polym. 2013, 95, 100–106. [Google Scholar] [CrossRef]

- Yu, H.Y.; Qin, Z.Y. Surface grafting of cellulose nanocrystals with poly (3-hydroxybutyrate-co-3-hydroxyvalerate). Carbohydr. Polym. 2014, 101, 471–478. [Google Scholar] [CrossRef] [PubMed]

- Tanjung, F.A.; Husseinsyah, S.; Hussin, K.; Tahir, I. Chemically chitosan modified with methyl methacrylate and its effect on mechanical and thermal properties of polypropylene composites. Indones. J. Chem. 2013, 13, 114–121. [Google Scholar] [CrossRef]

- Rasidi, M.S.M.; Husseinsyah, S.; Leng, T.P. Chemical modification of Nypa fruticans filled polylactic acid/recycled low-density polyethylene biocomposites. Bioresources 2014, 9, 2033–2050. [Google Scholar]

- Segal, L.G.J.M.A.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, J.; Zhang, J.; He, J. 1-Allyl-3-methylimidazolium chloride room temperature ionic liquid: A new and powerful nonderivatizing solvent for cellulose. Macromolecules 2005, 38, 8272–8277. [Google Scholar] [CrossRef]

- Reddy, K.O.; Zhang, J.; Zhang, J.; Rajulu, A.V. Preparation and properties of self-reinforced cellulose composite films from Agave microfibrils using an ionic liquid. Carbohydr. Polym. 2014, 114, 537–545. [Google Scholar]

- Chen, X.; Yu, J.; Zhang, Z.; Lu, C. Study on structure and thermal stability properties of cellulose fibers from rice straw. Carbohydr. Polym. 2011, 85, 245–250. [Google Scholar] [CrossRef]

- Chen, Y.; Pang, L.; Li, Y.; Luo, H.; Duan, G.; Mei, C.; Xu, W.; Zhou, W.; Liu, K.; Jiang, S. Ultra-thin and highly flexible cellulose nanofiber/silver nanowire conductive paper for effective electromagnetic interference shielding. Compos. Part A-Appl. Sci.Manuf. 2020, 135, 105960. [Google Scholar] [CrossRef]

| Biocomposite Films | Untreated | Treated |

|---|---|---|

| CrI (%) | CrI (%) | |

| 2 wt% EFB RC | 41.9 | 45.0 |

| 4 wt% EFB RC | 38.5 | 40.7 |

| Biocomposite Films | Tdmax (°C) | Weight Loss (%) | |

|---|---|---|---|

| 300 °C | 600 °C | ||

| 2 wt% untreated EFB RC | 293 | 65.1 | 81.6 |

| 2 wt% treated EFB RC | 295 | 59.3 | 78.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Husseinsyah, S.; Zailuddin, N.L.I.; Osman, A.F.; Li Li, C.; Alrashdi, A.A.; Alakrach, A. Methyl Methacrylate (MMA) Treatment of Empty Fruit Bunch (EFB) to Improve the Properties of Regenerated Cellulose Biocomposite Films. Polymers 2020, 12, 2618. https://doi.org/10.3390/polym12112618

Husseinsyah S, Zailuddin NLI, Osman AF, Li Li C, Alrashdi AA, Alakrach A. Methyl Methacrylate (MMA) Treatment of Empty Fruit Bunch (EFB) to Improve the Properties of Regenerated Cellulose Biocomposite Films. Polymers. 2020; 12(11):2618. https://doi.org/10.3390/polym12112618

Chicago/Turabian StyleHusseinsyah, Salmah, Nur Liyana Izyan Zailuddin, Azlin Fazlina Osman, Chew Li Li, Awad A. Alrashdi, and Abdulkader Alakrach. 2020. "Methyl Methacrylate (MMA) Treatment of Empty Fruit Bunch (EFB) to Improve the Properties of Regenerated Cellulose Biocomposite Films" Polymers 12, no. 11: 2618. https://doi.org/10.3390/polym12112618

APA StyleHusseinsyah, S., Zailuddin, N. L. I., Osman, A. F., Li Li, C., Alrashdi, A. A., & Alakrach, A. (2020). Methyl Methacrylate (MMA) Treatment of Empty Fruit Bunch (EFB) to Improve the Properties of Regenerated Cellulose Biocomposite Films. Polymers, 12(11), 2618. https://doi.org/10.3390/polym12112618