High-Performance Polyacrylic Acid-Grafted PVDF Nanofiltration Membrane with Good Antifouling Property for the Textile Industry

Abstract

1. Introduction

2. Material and Methods

2.1. Materials

2.2. NF Membrane Fabrication

2.3. Characterization of NF Membranes

2.4. Performance of the NF Membranes

2.5. Fluorescent BSA Attachment and Lysozyme Adsorption Test

3. Results and Discussion

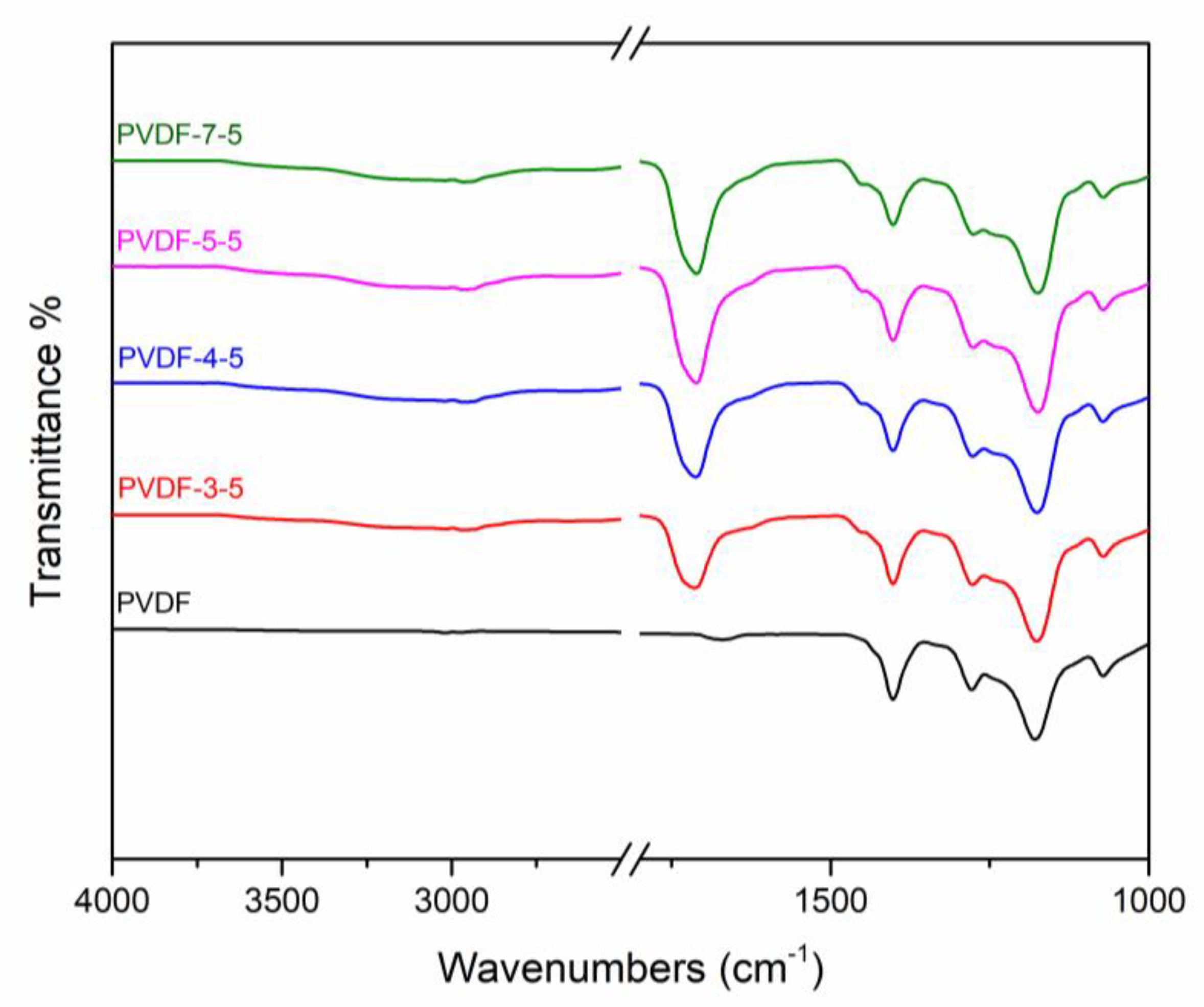

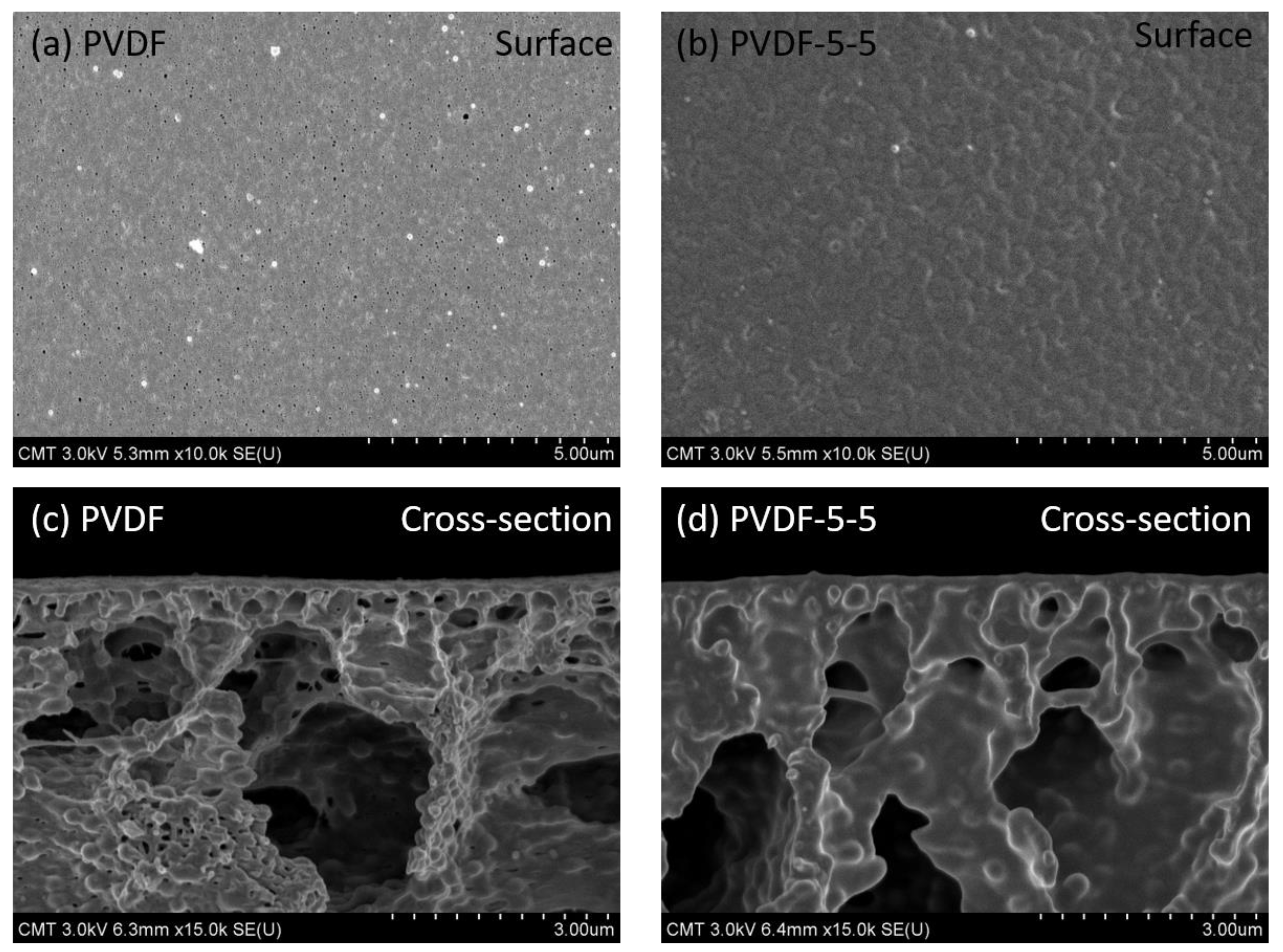

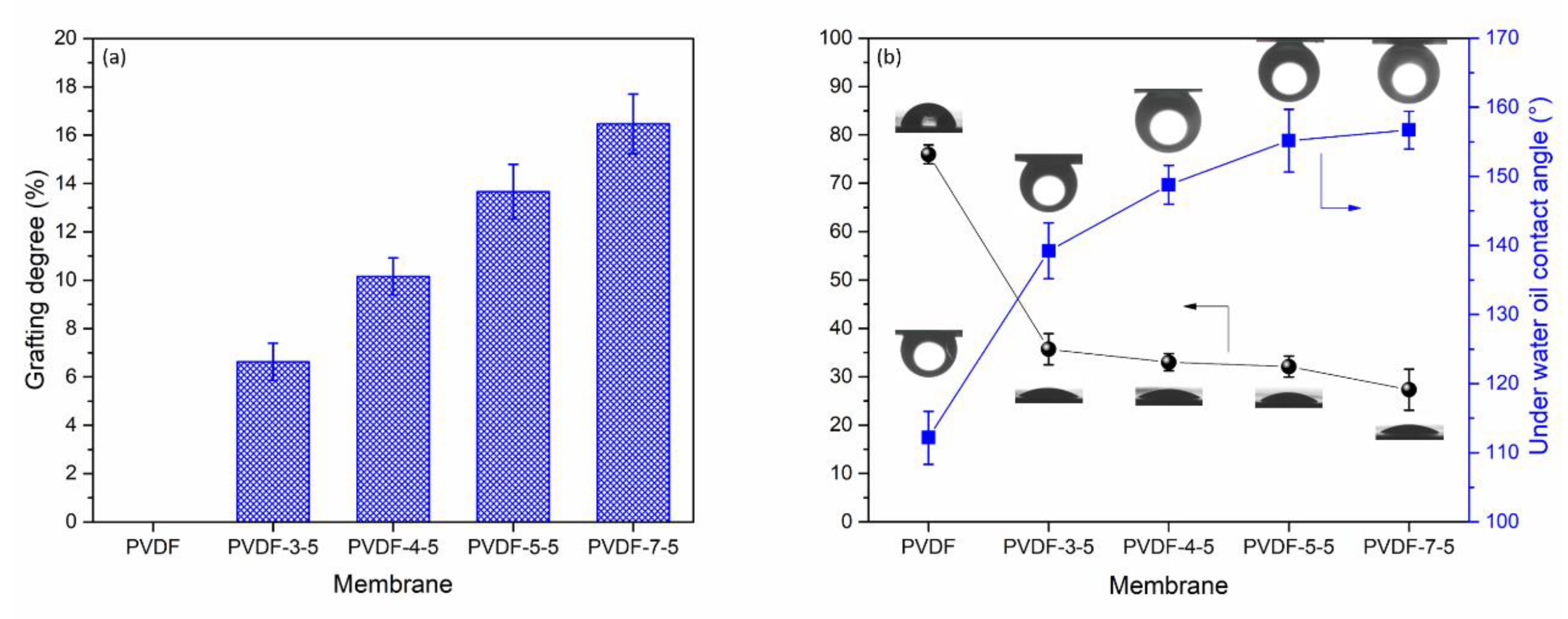

3.1. Physicochemical Properties Characterization of the Loose NF Membranes

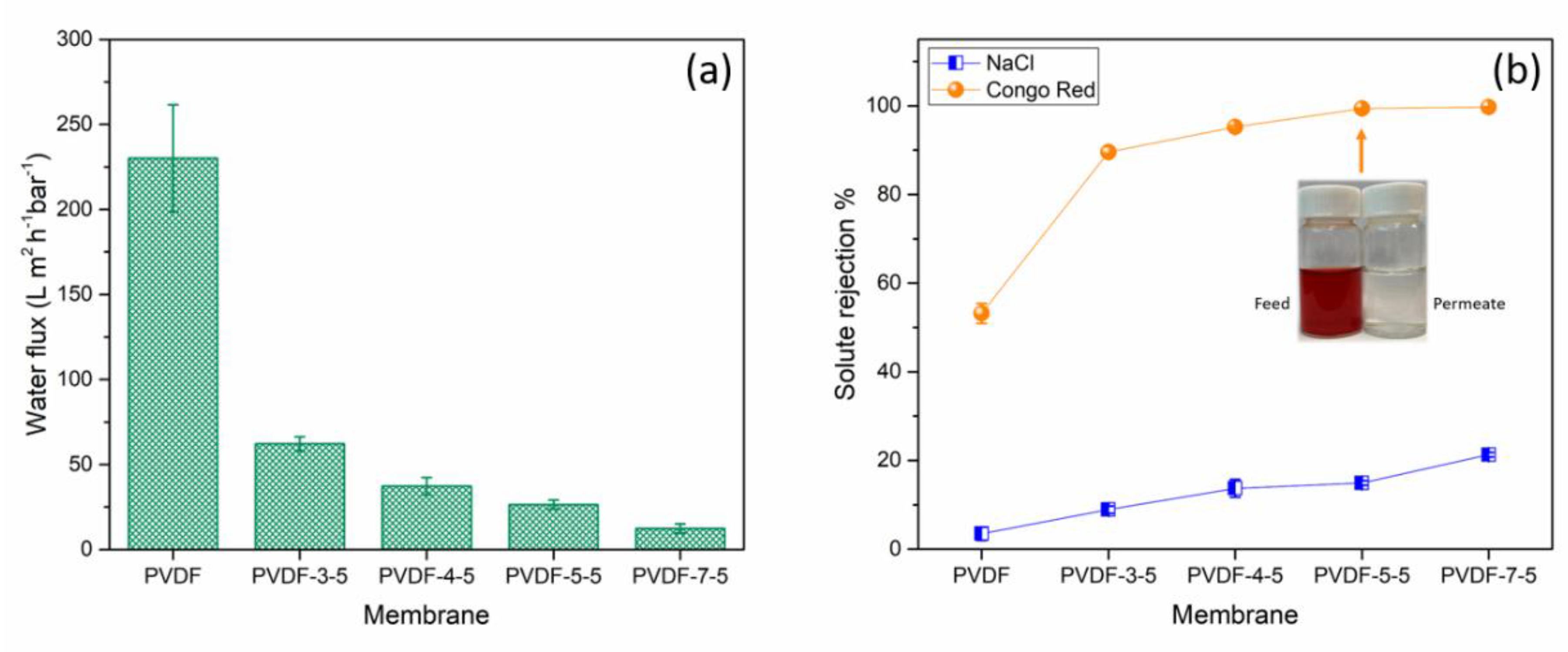

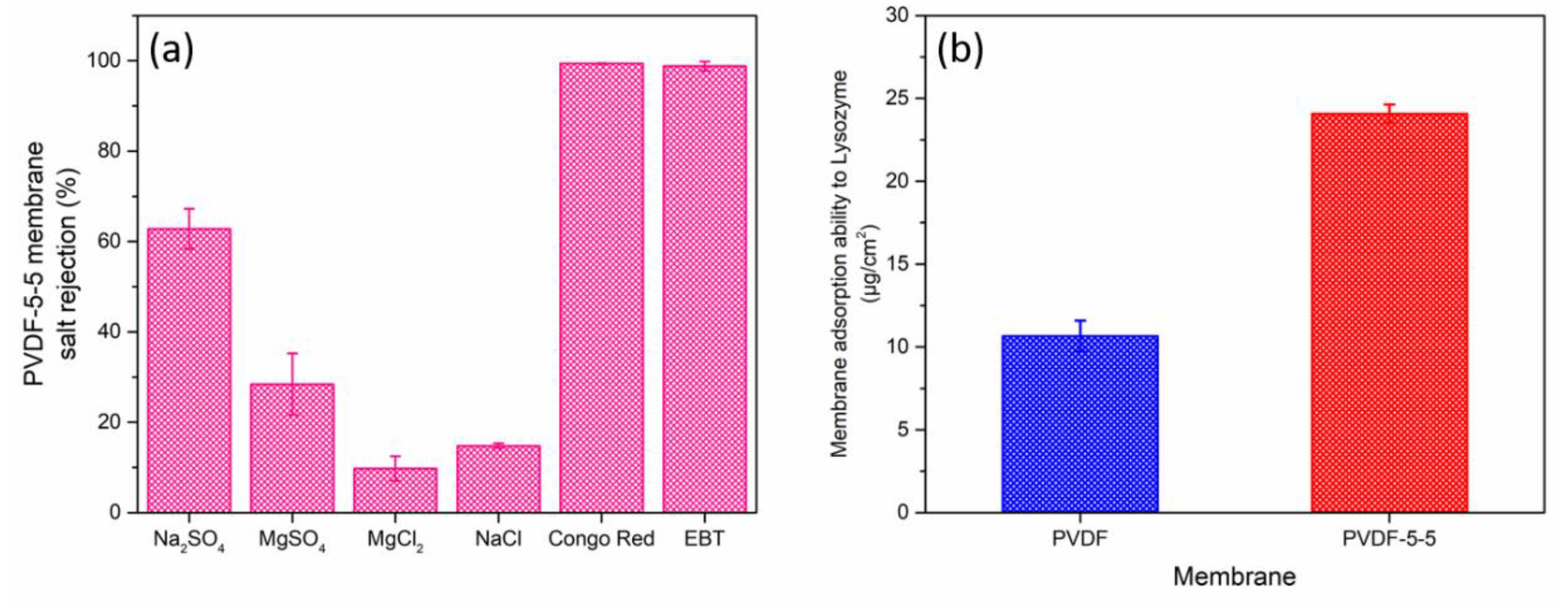

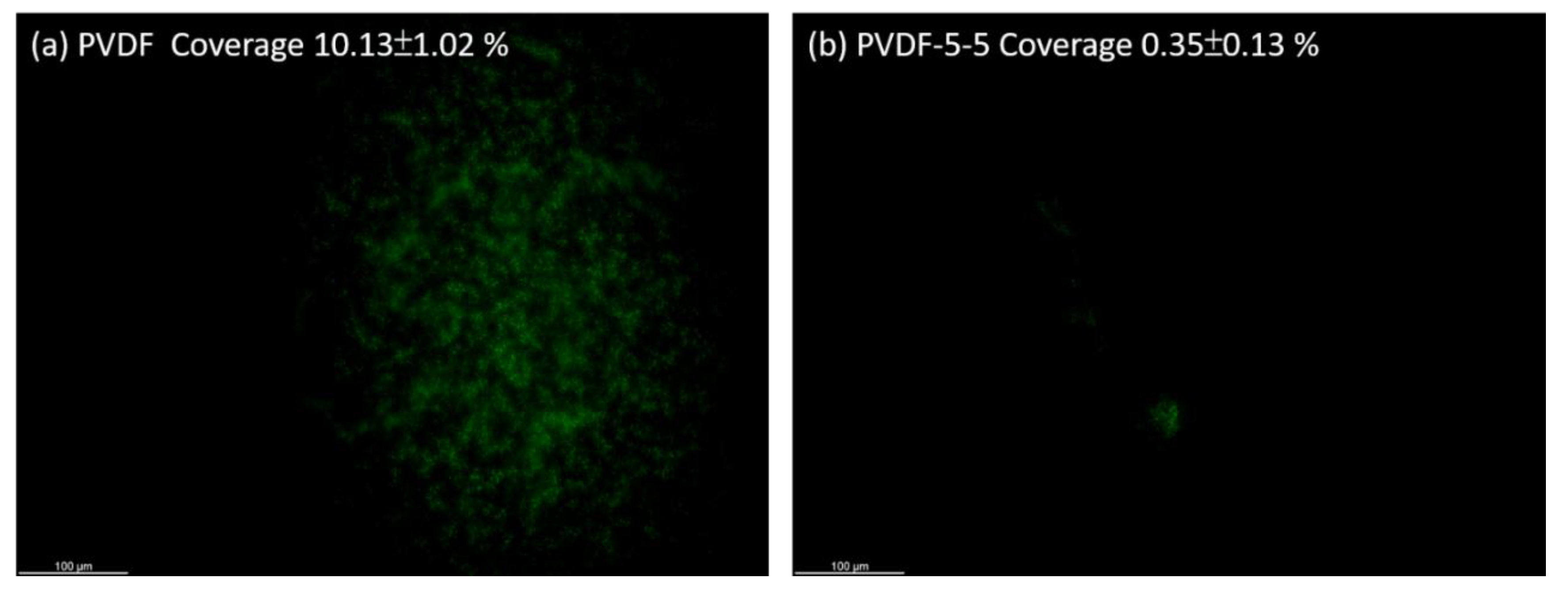

3.2. Membrane Separation Performance and Fluorescent-BSA Attachment of NF

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gao, Y.; Deng, S.-Q.; Jin, X.; Cai, S.-L.; Zheng, S.-R.; Zhang, W.-G. The construction of amorphous metal-organic cage-based solid for rapid dye adsorption and time-dependent dye separation from water. Chem. Eng. J. 2019, 357, 129–139. [Google Scholar] [CrossRef]

- De Luna, L.A.; da Silva, T.H.; Nogueira, R.F.; Kummrow, F.; Umbuzeiro, G.A. Aquatic toxicity of dyes before and after photo-fenton treatment. J. Hazard. Mater. 2014, 276, 332–338. [Google Scholar] [CrossRef] [PubMed]

- Akyol, A. Treatment of paint manufacturing wastewater by electrocoagulation. Desalination 2012, 285, 91–99. [Google Scholar] [CrossRef]

- Lin, J.; Ye, W.; Baltaru, M.-C.; Tang, Y.P.; Bernstein, N.J.; Gao, P.; Balta, S.; Vlad, M.; Volodin, A.; Sotto, A. Tight ultrafiltration membranes for enhanced separation of dyes and na 2 so 4 during textile wastewater treatment. J. Membr. Sci. 2016, 514, 217–228. [Google Scholar] [CrossRef]

- Van der Bruggen, B.; De Vreese, I.; Vandecasteele, C. Water reclamation in the textile industry: Nanofiltration of dye baths for wool dyeing. Ind. Eng. Chem. Res. 2001, 40, 3973–3978. [Google Scholar] [CrossRef]

- Hayat, H.; Mahmood, Q.; Pervez, A.; Bhatti, Z.A.; Baig, S.A. Comparative decolorization of dyes in textile wastewater using biological and chemical treatment. Sep. Purif. Technol. 2015, 154, 149–153. [Google Scholar] [CrossRef]

- Liu, M.; Chen, Q.; Lu, K.; Huang, W.; Lü, Z.; Zhou, C.; Yu, S.; Gao, C. High efficient removal of dyes from aqueous solution through nanofiltration using diethanolamine-modified polyamide thin-film composite membrane. Sep. Purif. Technol. 2017, 173, 135–143. [Google Scholar] [CrossRef]

- Chiao, Y.H.; Patra, T.; Ang, M.B.M.Y.; Chen, S.T.; Almodovar, J.; Qian, X.; Wickramasinghe, R.; Hung, W.S.; Huang, S.H.; Chang, Y.; et al. Zwitterion co-polymer pei-sbma nanofiltration membrane modified by fast second interfacial polymerization. Polymers 2020, 12, 269. [Google Scholar] [CrossRef]

- Liu, S.; Fang, F.; Wu, J.; Zhang, K. The anti-biofouling properties of thin-film composite nanofiltration membranes grafted with biogenic silver nanoparticles. Desalination 2015, 375, 121–128. [Google Scholar] [CrossRef]

- Ba, C.; Langer, J.; Economy, J. Chemical modification of p84 copolyimide membranes by polyethylenimine for nanofiltration. J. Membr. Sci. 2009, 327, 49–58. [Google Scholar] [CrossRef]

- Jimenez-Solomon, M.F.; Bhole, Y.; Livingston, A.G. High flux membranes for organic solvent nanofiltration (osn)—Interfacial polymerization with solvent activation. J. Membr. Sci. 2012, 423–424, 371–382. [Google Scholar] [CrossRef]

- Mohammad, A.W.; Teow, Y.H.; Ang, W.L.; Chung, Y.T.; Oatley-Radcliffe, D.L.; Hilal, N. Nanofiltration membranes review: Recent advances and future prospects. Desalination 2015, 356, 226–254. [Google Scholar] [CrossRef]

- Hung, W.-S.; Lin, T.-J.; Chiao, Y.-H.; Sengupta, A.; Hsiao, Y.-C.; Wickramasinghe, S.R.; Hu, C.-C.; Lee, K.-R.; Lai, J.-Y. Graphene-induced tuning of the d-spacing of graphene oxide composite nanofiltration membranes for frictionless capillary action-induced enhancement of water permeability. J. Mater. Chem. A 2018, 6, 19445–19454. [Google Scholar] [CrossRef]

- Ang, M.B.M.Y.; Maganto, H.L.C.; Macni, C.R.M.; Caparanga, A.R.; Huang, S.H.; Lee, K.R.; Lai, J.Y. Effect of introducing varying amounts of polydopamine particles into different concentrations of polyethersulfone solution on the performance of resultant mixed-matrix membranes intended for dye separation. J. Polym. Res. 2020, 27, 196. [Google Scholar] [CrossRef]

- Ji, Y.-L.; Gu, B.-X.; An, Q.-F.; Gao, C.-J. Recent advances in the fabrication of membranes containing “ion pairs” for nanofiltration processes. Polymers 2017, 9, 715. [Google Scholar] [CrossRef] [PubMed]

- Ang, M.B.M.Y.; Huang, S.-H.; Wei, S.-W.; Chiao, Y.-H.; Aquino, R.R.; Hung, W.-S.; Tsai, H.-A.; Lee, K.-R.; Lai, J.-Y. Surface Properties, Free Volume, and Performance for Thin-Film Composite Pervaporation Membranes Fabricated through Interfacial Polymerization Involving Different Organic Solvents. Polymers 2020, 12, 2326. [Google Scholar] [CrossRef]

- Guo, W.; Ngo, H.H.; Li, J. A mini-review on membrane fouling. Bioresour. Technol. 2012, 122, 27–34. [Google Scholar] [CrossRef]

- Yu, H.Q. Molecular insights into extracellular polymeric substances in activated sludge. Environ. Sci. Technol. 2020, 54, 7742–7750. [Google Scholar] [CrossRef]

- Meng, S.; Meng, X.; Fan, W.; Liang, D.; Wang, L.; Zhang, W.; Liu, Y. The role of transparent exopolymer particles (tep) in membrane fouling: A critical review. Water Res. 2020, 181, 115930. [Google Scholar] [CrossRef]

- Ang, M.B.M.Y.; Ji, Y.L.; Huang, S.H.; Tsai, H.A.; Hung, W.S.; Hu, C.C.; Lee, K.R.; Lai, J.Y. Incorporation of carboxylic monoamines into thin-film composite polyamide membranes to enhance nanofiltration performance. J. Membr. Sci. 2017, 539, 52–64. [Google Scholar] [CrossRef]

- Avram, A.M.; Ahmadiannamini, P.; Vu, A.; Qian, X.; Sengupta, A.; Wickramasinghe, S.R. Polyelectrolyte multilayer modified nanofiltration membranes for the recovery of ionic liquid from dilute aqueous solutions. J. Appl. Polym. Sci. 2017, 134, 45349. [Google Scholar] [CrossRef]

- Huang, R.; Chen, G.; Yang, B.; Gao, C. Positively charged composite nanofiltration membrane from quaternized chitosan by toluene diisocyanate cross-linking. Sep. Purif. Technol. 2008, 61, 424–429. [Google Scholar] [CrossRef]

- Zhong, P.S.; Widjojo, N.; Chung, T.-S.; Weber, M.; Maletzko, C. Positively charged nanofiltration (nf) membranes via uv grafting on sulfonated polyphenylenesulfone (sppsu) for effective removal of textile dyes from wastewater. J. Membr. Sci. 2012, 417–418, 52–60. [Google Scholar] [CrossRef]

- Kamaz, M.; Sengupta, A.; Gutierrez, A.; Chiao, Y.-H.; Wickramasinghe, R. Surface modification of PVDF membranes for treating produced waters by direct contact membrane distillation. Int. J. Environ. Res. Public Health 2019, 16, 685. [Google Scholar] [CrossRef]

- Ang, M.B.M.Y.; Huang, S.H.; Chang, M.W.; Lai, C.L.; Tsai, H.A.; Hung, W.S.; Hu, C.C.; Lee, K.R. Ultraviolet-initiated graft polymerization of acrylic acid onto thin-film polyamide surface for improved ethanol dehydration performance of pervaporation membranes. Sep. Purif. Technol. 2020, 235, 116155. [Google Scholar] [CrossRef]

- Yang, X.; Ku, T.-H.; Biswas, S.K.; Yano, H.; Abe, K. Uv grafting: Surface modification of cellulose nanofibers without the use of organic solvents. Green Chem. 2019, 21, 4619–4624. [Google Scholar] [CrossRef]

- Chiao, Y.H.; Chen, S.T.; Sivakumar, M.; Ang, M.B.M.Y.; Patra, T.; Almodovar, J.; Wickramasinghe, S.R.; Hung, W.S.; Lai, J.Y. Zwitterionic polymer brush grafted on polyvinylidene difluoride membrane promoting enhanced ultrafiltration performance with augmented antifouling property. Polymers 2020, 12, 1303. [Google Scholar] [CrossRef]

- Xueli, G.; Haizeng, W.; Jian, W.; Xing, H.; Congjie, G. Surface-modified psf uf membrane by uv-assisted graft polymerization of capsaicin derivative moiety for fouling and bacterial resistance. J. Membr. Sci. 2013, 445, 146–155. [Google Scholar] [CrossRef]

- Rahimpour, A. Uv photo-grafting of hydrophilic monomers onto the surface of nano-porous pes membranes for improving surface properties. Desalination 2011, 265, 93–101. [Google Scholar] [CrossRef]

- Chen, S.T.; Wickramasinghe, S.R.; Qian, X. Electrospun weak anion-exchange fibrous membranes for protein purification. Membranes 2020, 10, 39. [Google Scholar] [CrossRef]

- Lin, H.-T.; Venault, A.; Chang, Y. Zwitterionized chitosan based soft membranes for diabetic wound healing. J. Membr. Sci. 2019, 591, 117319. [Google Scholar] [CrossRef]

- Chiao, Y.-H.; Sengupta, A.; Chen, S.-T.; Huang, S.-H.; Hu, C.-C.; Hung, W.-S.; Chang, Y.; Qian, X.; Wickramasinghe, S.R.; Lee, K.-R.; et al. Zwitterion augmented polyamide membrane for improved forward osmosis performance with significant antifouling characteristics. Sep. Purif. Technol. 2019, 212, 316–325. [Google Scholar] [CrossRef]

- Lin, J.; Ye, W.; Zeng, H.; Yang, H.; Shen, J.; Darvishmanesh, S.; Luis, P.; Sotto, A.; Van der Bruggen, B. Fractionation of direct dyes and salts in aqueous solution using loose nanofiltration membranes. J. Membr. Sci. 2015, 477, 183–193. [Google Scholar] [CrossRef]

- Zhang, Q.; Fan, L.; Yang, Z.; Zhang, R.; Liu, Y.-N.; He, M.; Su, Y.; Jiang, Z. Loose nanofiltration membrane for dye/salt separation through interfacial polymerization with in-situ generated tio2 nanoparticles. Appl. Surf. Sci. 2017, 410, 494–504. [Google Scholar] [CrossRef]

- Zeng, Z.; Yu, D.; He, Z.; Liu, J.; Xiao, F.X.; Zhang, Y.; Wang, R.; Bhattacharyya, D.; Tan, T.T. Graphene oxide quantum dots covalently functionalized pvdf membrane with significantly-enhanced bactericidal and antibiofouling performances. Sci. Rep. 2016, 6, 20142. [Google Scholar] [CrossRef]

- Lu, X.; Peng, Y.; Qiu, H.; Liu, X.; Ge, L. Anti-fouling membranes by manipulating surface wettability and their anti-fouling mechanism. Desalination 2017, 413, 127–135. [Google Scholar] [CrossRef]

- Abu Seman, M.N.; Khayet, M.; Bin Ali, Z.I.; Hilal, N. Reduction of nanofiltration membrane fouling by uv-initiated graft polymerization technique. J. Membr. Sci. 2010, 355, 133–141. [Google Scholar] [CrossRef]

- Zeng, G.; Wei, K.; Yang, D.; Yan, J.; Zhou, K.; Patra, T.; Sengupta, A.; Chiao, Y.-H. Improvement in performance of pvdf ultrafiltration membranes by co-incorporation of dopamine and halloysite nanotubes. Colloids Surf. A 2020, 586, 124142. [Google Scholar] [CrossRef]

- Chiao, Y.-H.; Chen, S.-T.; Patra, T.; Hsu, C.-H.; Sengupta, A.; Hung, W.-S.; Huang, S.-H.; Qian, X.; Wickramasinghe, R.; Chang, Y. Zwitterionic forward osmosis membrane modified by fast second interfacial polymerization with enhanced antifouling and antimicrobial properties for produced water pretreatment. Desalination 2019, 469, 114090. [Google Scholar] [CrossRef]

- Zhang, H.; Li, B.; Pan, J.; Qi, Y.; Shen, J.; Gao, C.; Van der Bruggen, B. Carboxyl-functionalized graphene oxide polyamide nanofiltration membrane for desalination of dye solutions containing monovalent salt. J. Membr. Sci. 2017, 539, 128–137. [Google Scholar] [CrossRef]

- Van Chung, C.; Quoc Buu, N.; Hoai Chau, N. Influence of surface charge and solution ph on the performance characteristics of a nanofiltration membrane. Sci. Technol. Adv. Mater. 2005, 6, 246–250. [Google Scholar] [CrossRef]

- Yu, L.; Zhang, Y.; Wang, Y.; Zhang, H.; Liu, J. High flux, positively charged loose nanofiltration membrane by blending with poly (ionic liquid) brushes grafted silica spheres. J. Hazard. Mater. 2015, 287, 373–383. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Wang, Z. A loose nano-filtration membrane prepared by coating hpan uf membrane with modified pei for dye reuse and desalination. J. Membr. Sci. 2017, 524, 214–224. [Google Scholar] [CrossRef]

- Chiao, Y.-H.; Sengupta, A.; Chen, S.-T.; Hung, W.-S.; Lai, J.-Y.; Upadhyaya, L.; Qian, X.; Wickramasinghe, S.R. Novel thin-film composite forward osmosis membrane using polyethylenimine and its impact on membrane performance. Sep. Sci. Technol. 2020, 55, 590–600. [Google Scholar] [CrossRef]

- Peng, Z.G.; Hidajat, K.; Uddin, M.S. Adsorption and desorption of lysozyme on nano-sized magnetic particles and its conformational changes. Colloids Surf. B 2004, 35, 169–174. [Google Scholar] [CrossRef]

| PVDF | PVDF-3-5 | PVDF-4-5 | PVDF-5-5 | PVDF-7-5 | |

|---|---|---|---|---|---|

| C1s | 55.17 | 63.44 | 62.89 | 63.02 | 63.77 |

| F1s | 44.83 | - | - | - | - |

| O1s | - | 36.56 | 37.11 | 36.98 | 36.23 |

| Membrane | Modified Method | Water Permeability (L∙m⁻2∙h⁻1∙bar⁻1) | Dye Type | Dye Concentration (mg/L) | Dyes Rejection (%) | NaCl Concentration (mg/L) | NaCl Rejection (%) | Reference |

|---|---|---|---|---|---|---|---|---|

| PVDF-PAA d | UV | 26.42 | CR | 100 | 99.38 | 1000 | 14.92 | This work |

| NF270 a | IP | 11.32 | CR | 100 | 99.76 | 1000 | 47.8 | This work |

| NF90 a | IP | 10.49 | CR | 100 | 99.94 | 1000 | 66.49 | This work |

| NF245 a | IP | 5.15 | CR | 100 | 99.81 | 1000 | 24.93 | This work |

| DEA-PA | IP | 17 | CR | 100 | 99.6 | 500 | 50.6 | [7] |

| NFM-PIL | MMM | ~15 | RR | 500 | 85 | 1000 | 7 | [42] |

| NF-B c | UV | 9 | SO | - | 99.98 | - | 75 | [23] |

| TiO2@PES | IP | 18.1 | CR | 100 | 98 | - | - | [34] |

| PEI-GA | Condensation b | 25.5 | CR | 100 | 97.1 | 1000 | ~10 | [43] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiao, Y.-H.; Chen, S.-T.; Yap Ang, M.B.M.; Patra, T.; Castilla-Casadiego, D.A.; Fan, R.; Almodovar, J.; Hung, W.-S.; Wickramasinghe, S.R. High-Performance Polyacrylic Acid-Grafted PVDF Nanofiltration Membrane with Good Antifouling Property for the Textile Industry. Polymers 2020, 12, 2443. https://doi.org/10.3390/polym12112443

Chiao Y-H, Chen S-T, Yap Ang MBM, Patra T, Castilla-Casadiego DA, Fan R, Almodovar J, Hung W-S, Wickramasinghe SR. High-Performance Polyacrylic Acid-Grafted PVDF Nanofiltration Membrane with Good Antifouling Property for the Textile Industry. Polymers. 2020; 12(11):2443. https://doi.org/10.3390/polym12112443

Chicago/Turabian StyleChiao, Yu-Hsuan, Shu-Ting Chen, Micah Belle Marie Yap Ang, Tanmoy Patra, David Alfonso Castilla-Casadiego, Rong Fan, Jorge Almodovar, Wei-Song Hung, and S. Ranil Wickramasinghe. 2020. "High-Performance Polyacrylic Acid-Grafted PVDF Nanofiltration Membrane with Good Antifouling Property for the Textile Industry" Polymers 12, no. 11: 2443. https://doi.org/10.3390/polym12112443

APA StyleChiao, Y.-H., Chen, S.-T., Yap Ang, M. B. M., Patra, T., Castilla-Casadiego, D. A., Fan, R., Almodovar, J., Hung, W.-S., & Wickramasinghe, S. R. (2020). High-Performance Polyacrylic Acid-Grafted PVDF Nanofiltration Membrane with Good Antifouling Property for the Textile Industry. Polymers, 12(11), 2443. https://doi.org/10.3390/polym12112443