Experimental Study on the Effectiveness of Polyurethane Flexible Adhesive in Reduction of Structural Vibrations

Abstract

1. Introduction

2. Investigation on Plain and Composite Aluminium Beams with Polymer Layer

2.1. Experimental Study—Part 1

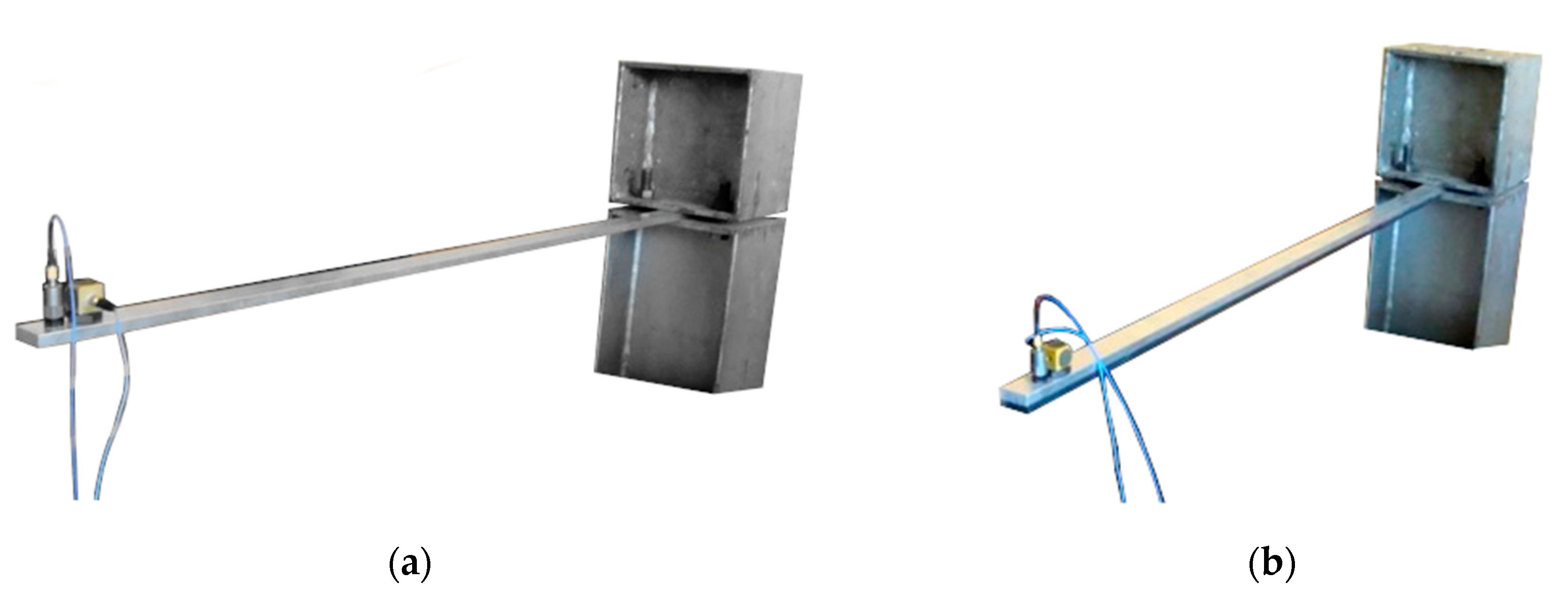

2.1.1. Experimental Setup

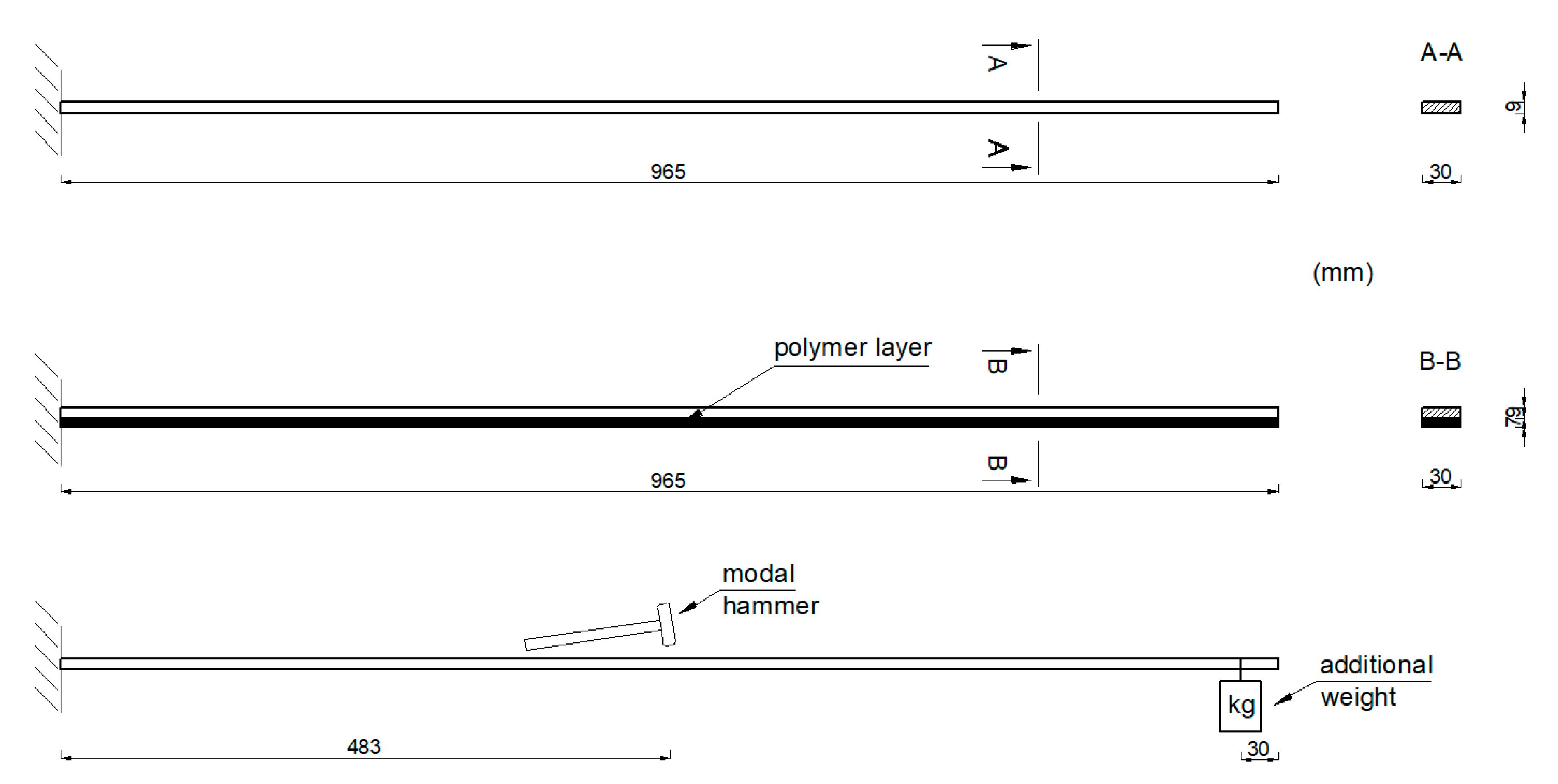

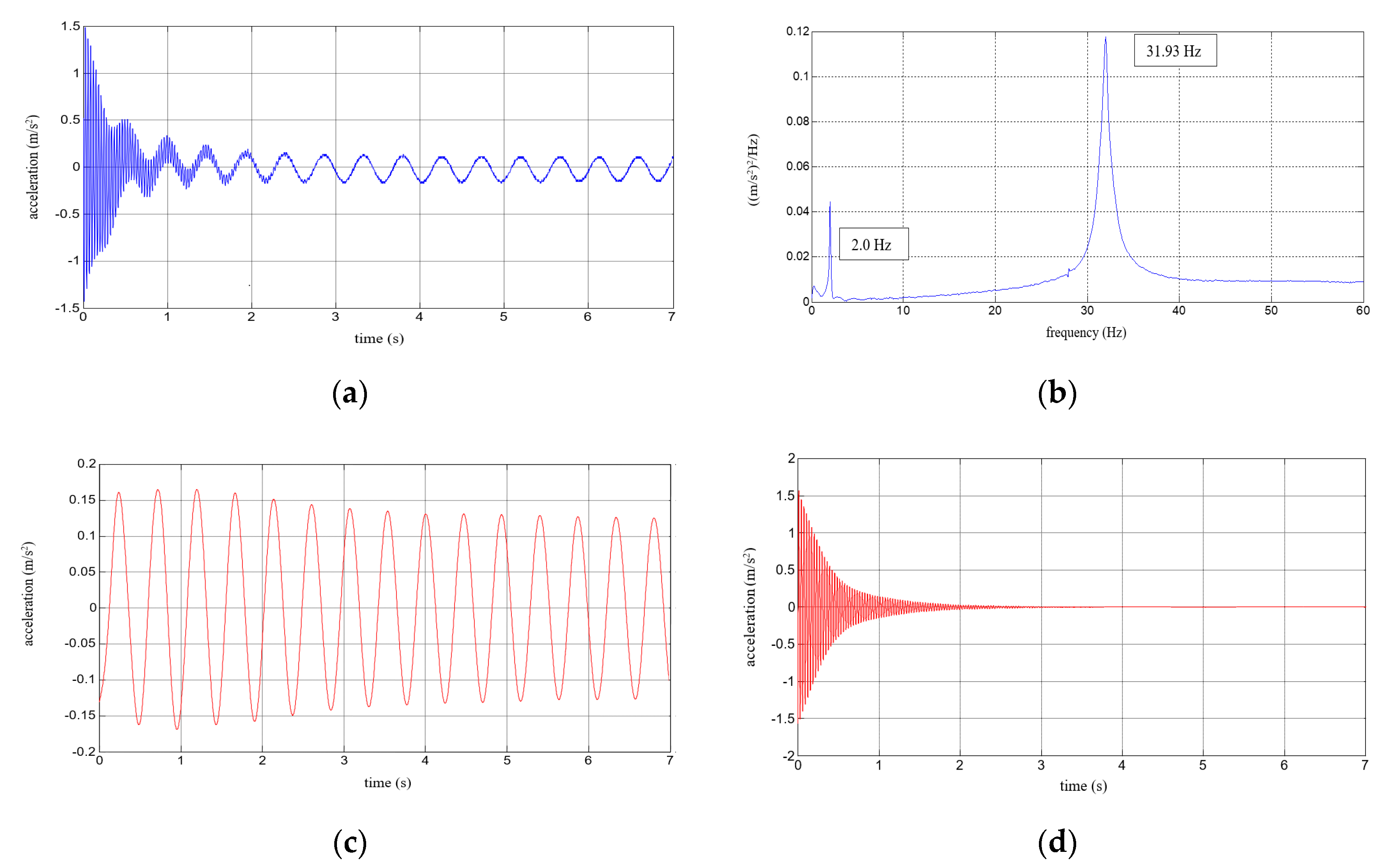

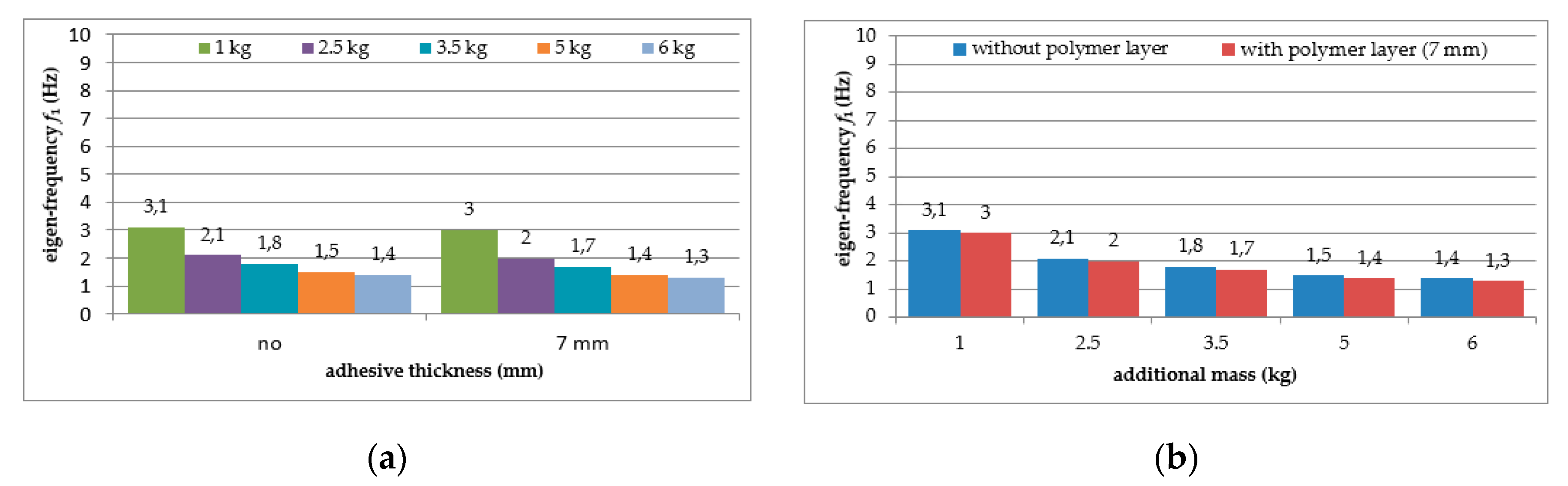

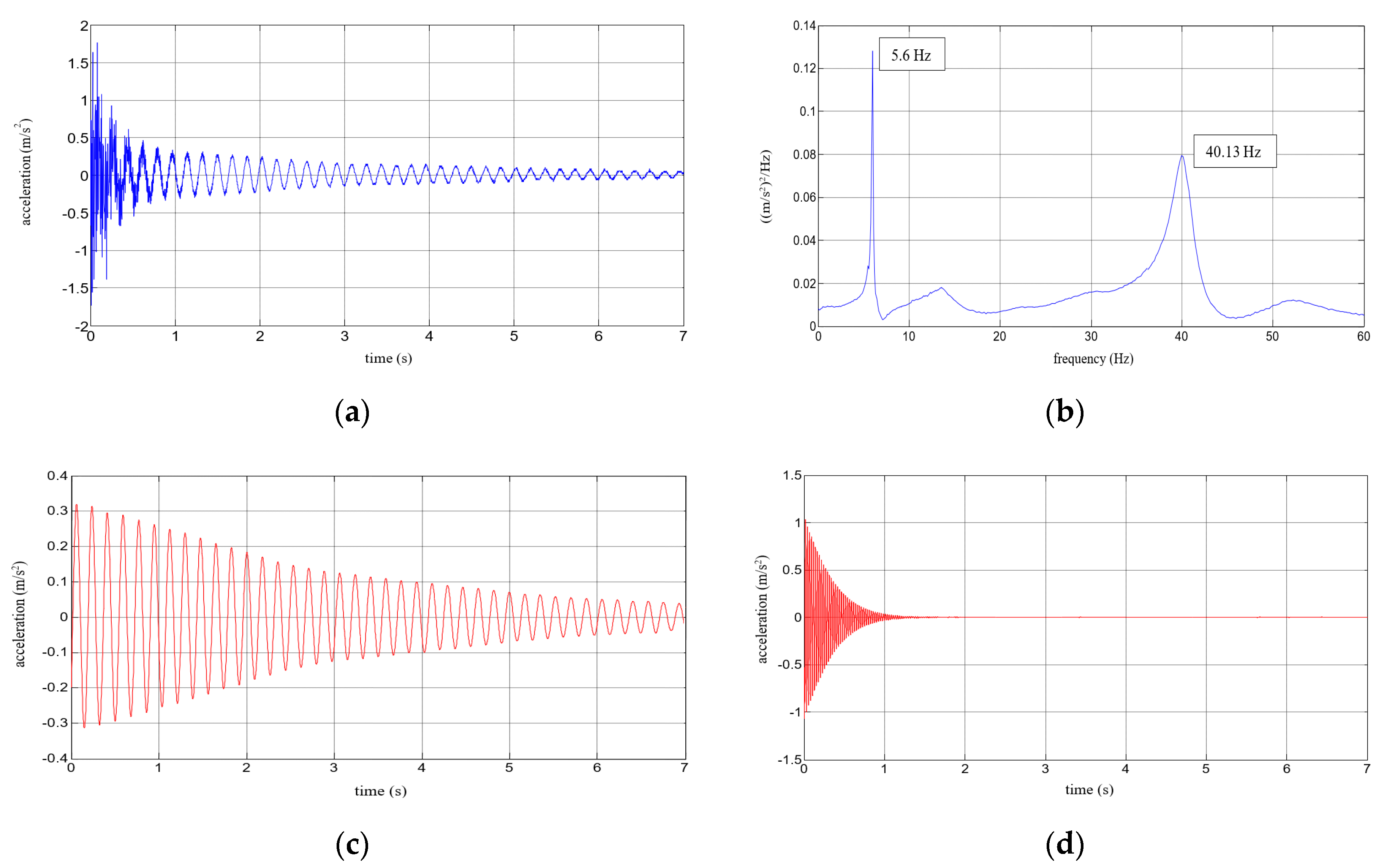

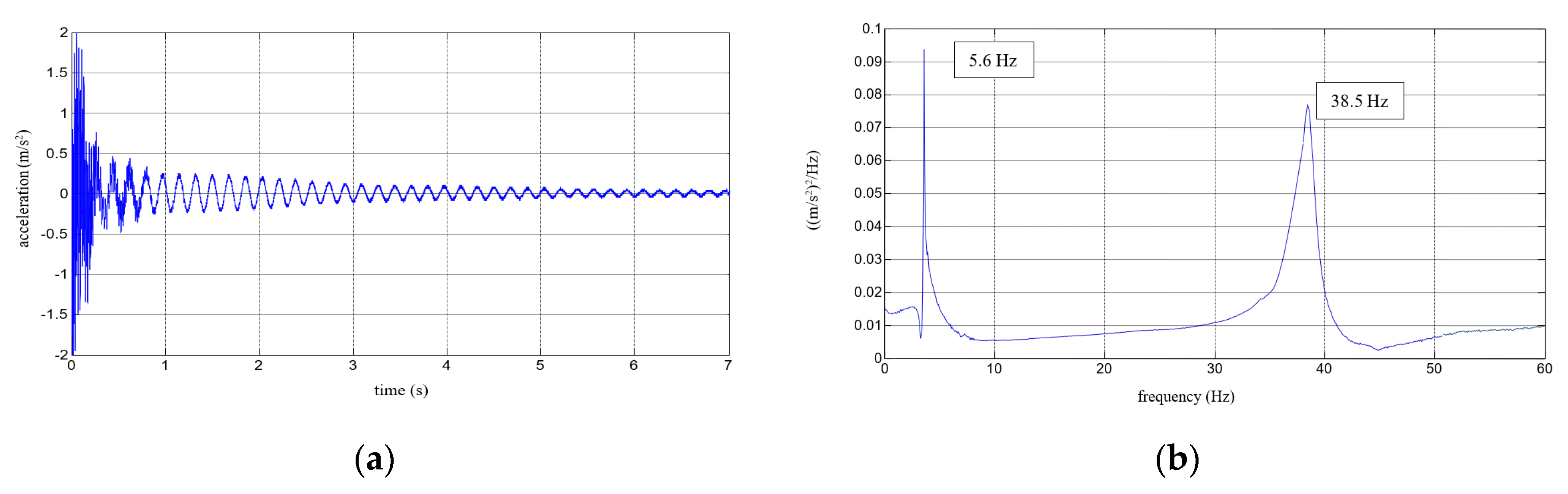

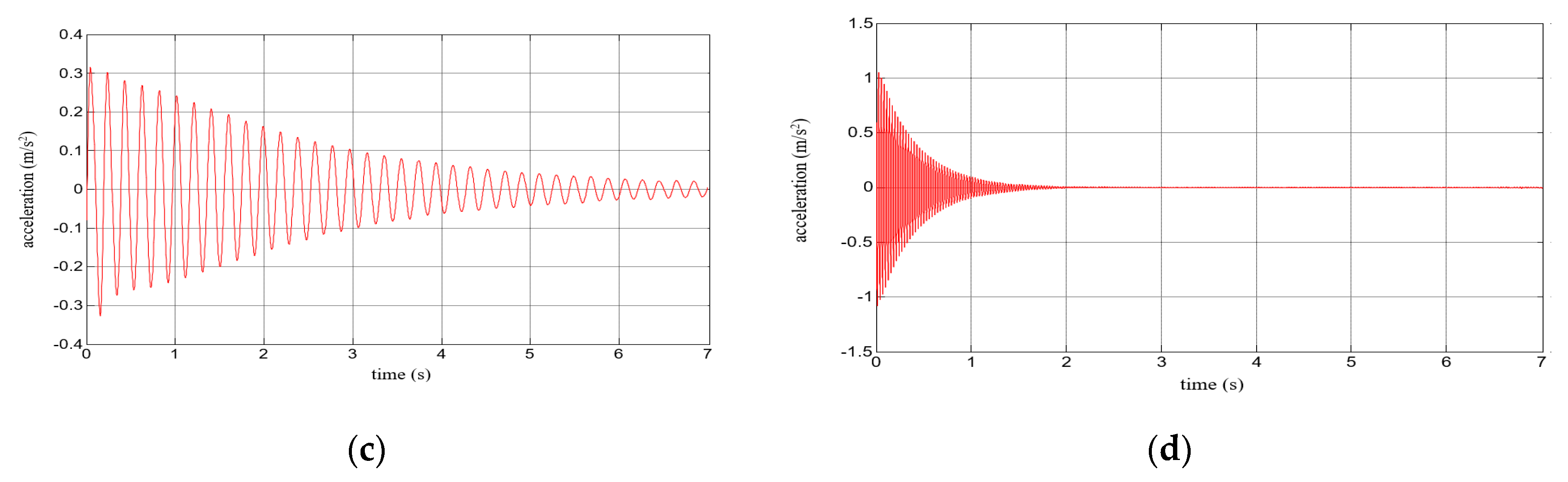

2.1.2. Experimental Results

2.1.3. Discussion of Results Obtained

2.2. Experimental Study—Part 2

2.2.1. Experimental Setup

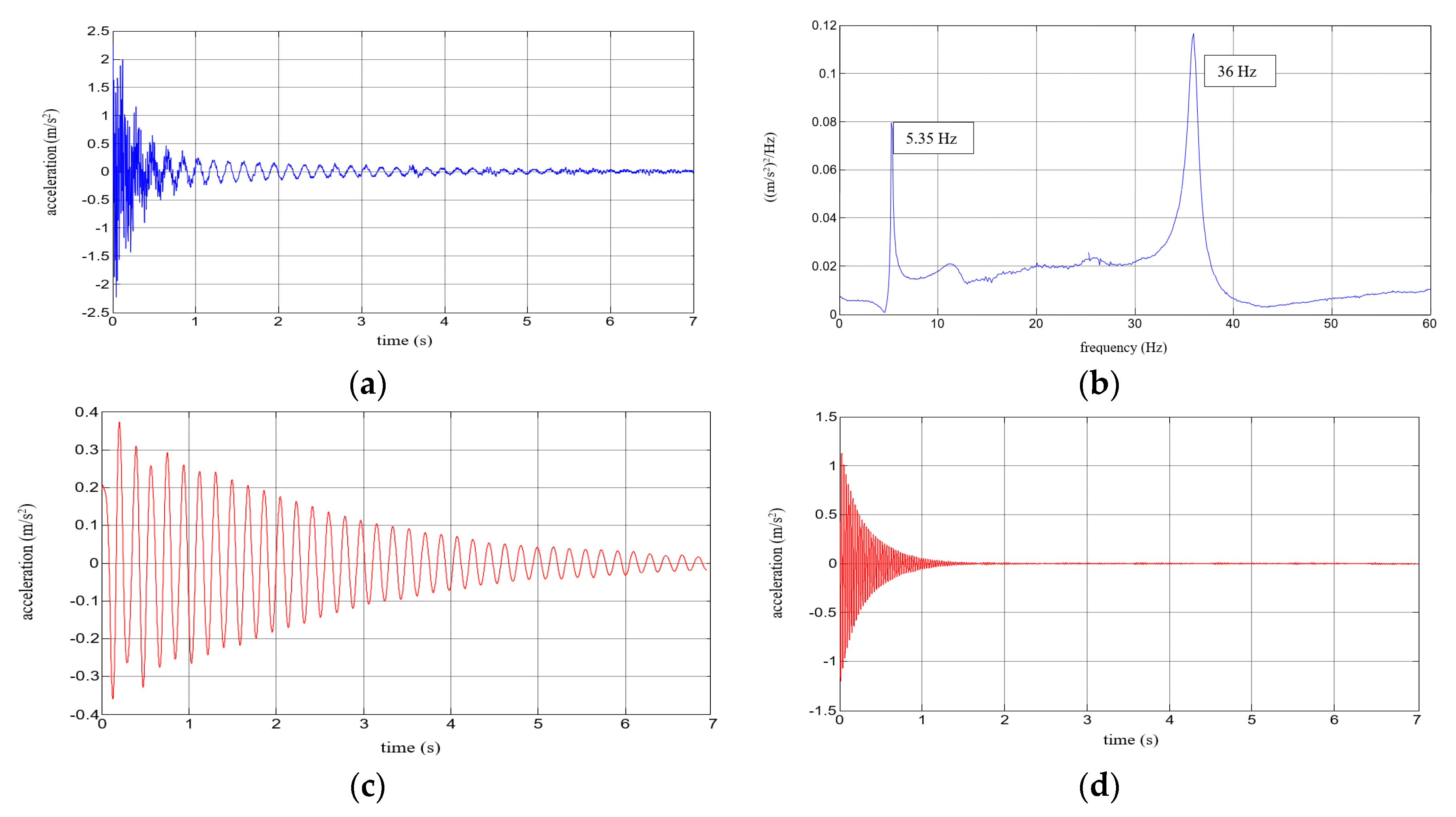

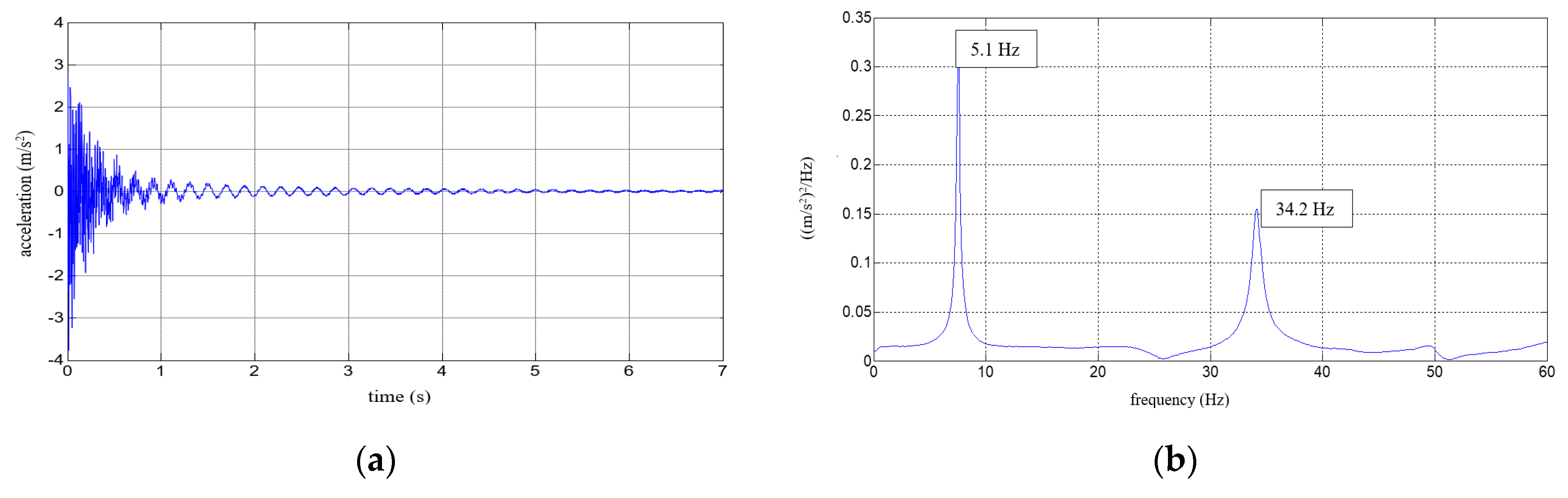

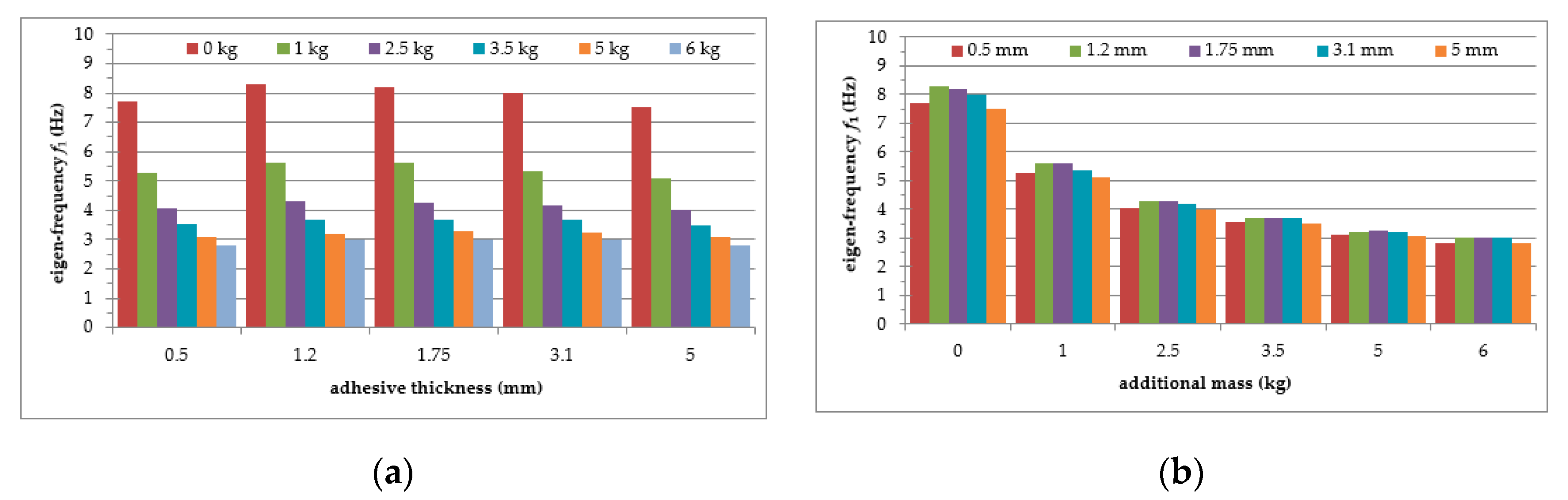

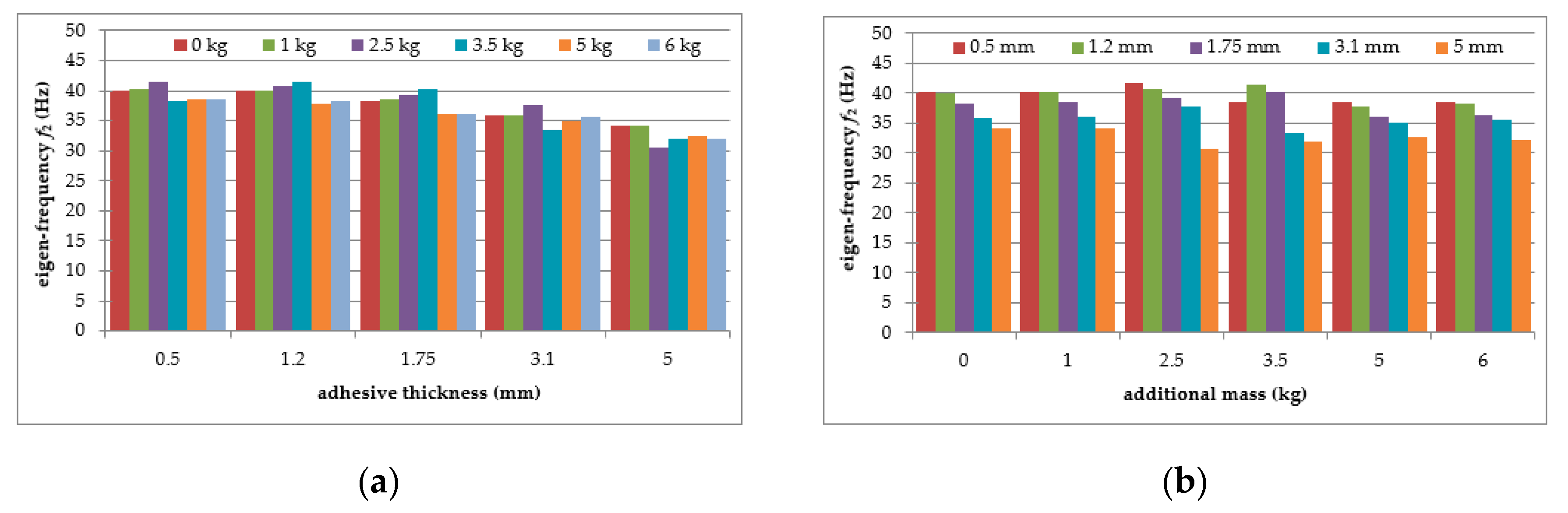

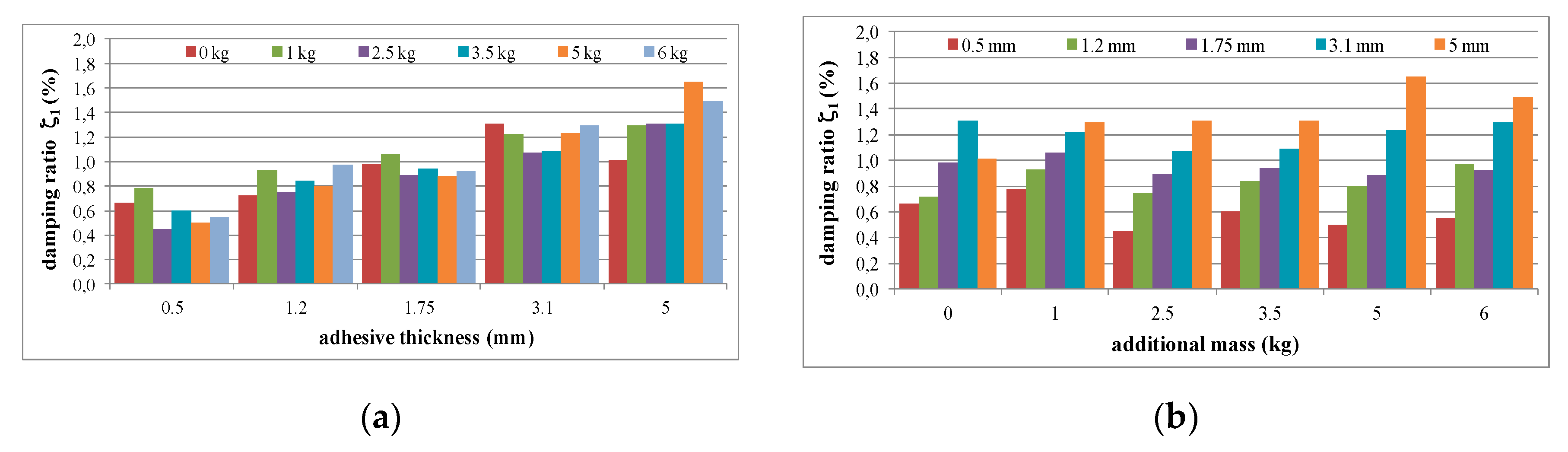

2.2.2. Experimental Results

2.2.3. Discussion of the Results Obtained

3. Approach for Correction of Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chopra, A.K. Dynamics of Structures: Theory and Applications to Earthquake Engineering; Englewood Cliffs: Prentice-Hall, NJ, USA, 1995. [Google Scholar]

- Miari, M.; Choong, K.K.; Jankowski, R. Seismic pounding between adjacent buildings: Identification of parameters, soil interaction issues and mitigation measures. Soil Dyn. Earthq. Eng. 2019, 121, 135–150. [Google Scholar] [CrossRef]

- Elwardany, H.; Seleemah, A.; Jankowski, R.; El-Khoriby, S. Influence of soil–structure interaction on seismic pounding between steel frame buildings considering the effect of infill panels. Bull. Earthq. Eng. 2019, 17, 6165–6202. [Google Scholar] [CrossRef]

- Simiu, E.; Scanlan, R.H. Wind Effects on Structures, 3rd ed.; John Wiley and Sons: New York, NY, USA, 1996. [Google Scholar]

- Sołtysik, B.; Jankowski, R. Non-linear strain rate analysis of earthquake-induced pounding between steel buildings. Int. J. Earth Sci. Eng. 2013, 6, 429–433. [Google Scholar]

- Lasowicz, N.; Jankowski, R. The Effectiveness of Polymer Damper in Damage Reduction of Temporary Steel Grandstand. Key Eng. Mater. 2016, 713, 171–174. [Google Scholar] [CrossRef]

- Almusallam, T.H.; Al-Salloum, Y.A. Behavior of FRP Strengthened Infill Walls under In-Plane Seismic Loading. J. Compos. Constr. 2007, 11, 308–318. [Google Scholar] [CrossRef]

- Altin, S.; Anıl, Ö.; Kara, M.E.; Kaya, M. An experimental study on strengthening of masonry infilled RC frames using diagonal CFRP strips. Compos. Part B Eng. 2008, 39, 680–693. [Google Scholar] [CrossRef]

- Ozden, S.; Akguzel, U.; Ozturan, T. Seismic Strengthening of Infilled Reinforced Concrete Frames with Composite Materials. ACI Struct. J. 2011, 108, 414–422. [Google Scholar]

- Koutas, L.; Bousias, S.N.; Triantafillou, T.C. Seismic Strengthening of Masonry-Infilled RC Frames with TRM: Experimental Study. J. Compos. Constr. 2015, 19, 04014048. [Google Scholar] [CrossRef]

- Koutas, L.N.; Triantafillou, T.; Bousias, S.N. Analytical Modeling of Masonry-Infilled RC Frames Retrofitted with Textile-Reinforced Mortar. J. Compos. Constr. 2015, 19, 04014082. [Google Scholar] [CrossRef]

- Gams, M.; Tomaževič, M.; Berset, T. Seismic strengthening of brick masonry by composite coatings: An experimental study. Bull. Earthq. Eng. 2017, 15, 4269–4298. [Google Scholar] [CrossRef]

- Ghiassi, B.; Xavier, J.; Oliveira, D.; Kwiecień, A.; Lourenço, P.B.; Zając, B. Evaluation of the bond performance in FRP–brick components re-bonded after initial delamination. Compos. Struct. 2015, 123, 271–281. [Google Scholar] [CrossRef]

- Kwiecień, A. Stiff and flexible adhesives bonding CFRP to masonry substrates—Investigated in pull-off test and Single-Lap test. Arch. Civ. Mech. Eng. 2012, 12, 228–239. [Google Scholar] [CrossRef]

- Tedeschi, C.; Kwiecień, A.; Valluzzi, M.; Zając, B.; Garbin, E.; Binda, L. Effect of thermal ageing and salt decay on bond between FRP and masonry. Mater. Struct. 2014, 47, 2051–2065. [Google Scholar] [CrossRef]

- Kwiecień, A.; Gruszczynski, M.; Zając, B. Tests of Flexible Polymer Joints Repairing of Concrete Pavements and of Polymer Modified Concretes Influenced by High Deformations. Key Eng. Mater. 2011, 466, 225–239. [Google Scholar] [CrossRef]

- Kwiecien, A.; Krajewski, P.; Hojdys, Ł.; Tekieli, M.; Słoński, M. Flexible Adhesive in Composite-to-Brick Strengthening-Experimental and Numerical Study. Polymers 2018, 10, 356. [Google Scholar] [CrossRef] [PubMed]

- Rousakis, T.; Papadouli, E.; Sapalidis, A.; Vanian, V.; Ilki, A.; Halici, O.F.; Kwiecień, A.; Zając, B.; Hojdys, Ł.; Krajewski, P.; et al. Flexible joints between RC frames and masonry infill for improved seismic performance—Shake table test. In Brick and Block Masonry—From Historical to Sustainable Masonry; Kubica, J., Kwiecień, A., Bednarz, L., Eds.; Taylor & Francis Group: London, UK, 2020; pp. 499–507. [Google Scholar]

- Akyildiz, A.; Kwiecień, A.; Zając, B.; Triller, P.; Bohinc, U.; Rousakis, T.; Viskovic, A. Preliminary in-plane shear test of infills protected by PUFJ interfaces. In Brick and Block Masonry—From Historical to Sustainable Masonry; Kubica, J., Kwiecień, A., Bednarz, L., Eds.; Taylor & Francis Group: London, UK, 2020; pp. 968–975. [Google Scholar]

- Schommer, S.; Nguyen, V.H.; Maas, S.; Zürbes, A. Model updating for structural health monitoring using static and dynamic measurements. Procedia Eng. 2017, 199, 2146–2153. [Google Scholar] [CrossRef]

- Wesołowski, M.; Barszcz, P.; Blacha, K. Influence of the condition of the airfield pavement structures on the operation safety of aircraft. J. KONBIN 2017, 42, 305–328. [Google Scholar] [CrossRef]

- Wesołowski, M.; Blacha, K. Assessment of Load Capacity of the Airport Pavement Structure With the Use of the Acn-Pcn Method. Res. Work. Air Force Inst. Technol. 2014, 35, 23–38. [Google Scholar] [CrossRef]

- Foraboschi, P. Effectiveness of novel methods to increase the FRP-masonry bond capacity. Compos. Part B: Eng. 2016, 107, 214–232. [Google Scholar] [CrossRef]

- Kwiecień, A.; Kuboń, P. Dynamic Analysis of Damaged Masonry Building Repaired with the Flexible Joint Method. Arch. Civ. Eng. 2012, 58, 39–55. [Google Scholar] [CrossRef][Green Version]

- Kwiecień, A.; Gams, M.; Rousakis, T.; Viskovic, A.; Korelc, J. Validation of a new hyperviscoelastic model for deformable polymers used for joints between RC frames and masonry infills. Eng. Trans. 2017, 65, 113–121. [Google Scholar]

- Szeptyński, P. Comparison and experimental verification of simplified one-dimensional linear elastic models of multilayer sandwich beams. Compos. Struct. 2020, 241, 112088. [Google Scholar] [CrossRef]

- Blasi, C.; Foraboschi, P. Analytical Approach to Collapse Mechanisms of Circular Masonry Arch. J. Struct. Eng. ASCE 1994, 120, 2288–2309. [Google Scholar] [CrossRef]

- Housner, G.W.; Bergman, L.A.; Caughey, T.K.; Chassiakos, A.G.; Claus, R.O.; Masri, S.F.; Skelton, R.E.; Soong, T.T.; Spencer, B.F.; Yao, J.T.P. Structural Control: Past, Present, and Future. J. Eng. Mech. 1997, 123, 897–971. [Google Scholar] [CrossRef]

- Lewandowski, R.; Pawlak, Z. Dynamic analysis of frames with viscoelastic dampers modeled by rheological models with fractional derivatives. J. Sound Vib. 2011, 330, 923–936. [Google Scholar] [CrossRef]

- Weber, F.; Maslanka, M. Frequency and damping adaptation of a TMD with controlled MR damper. Smart Mater. Struct. 2012, 21, 55011. [Google Scholar] [CrossRef]

- Naderpour, H.; Naji, N.; Burkacki, D.; Jankowski, R. Seismic Response of High-Rise Buildings Equipped with Base Isolation and Non-Traditional Tuned Mass Dampers. Appl. Sci. 2019, 9, 1201. [Google Scholar] [CrossRef]

- Kwiecień, A.; Kuboń, P.; Zając, B. Numerical analysis of cracked masonry building excited by an earthquake after repair using polymer flexible joint. In Recent Advances in Civil Engineering: Structural Mechanics; Stypuła, K., Ed.; Wydawnictwo Politechniki Krakowskiej: Cracow, Poland, 2015; Volume 482, pp. 63–79. [Google Scholar]

- Falborski, T.; Jankowski, R. Polymeric Bearings—A New Base Isolation System to Reduce Structural Damage during Earthquakes. Key Eng. Mater. 2013, 569–570, 143–150. [Google Scholar] [CrossRef]

- Falborski, T.; Jankowski, R.; Kwiecień, A. Experimental Study on Polymer Mass Used to Repair Damaged Structures. Key Eng. Mater. 2012, 488–489, 347–350. [Google Scholar] [CrossRef]

- Falborski, T.; Jankowski, R. Experimental Study on Effectiveness of a Prototype Seismic Isolation System Made of Polymeric Bearings. Appl. Sci. 2017, 7, 808. [Google Scholar] [CrossRef]

- Falborski, T.; Jankowski, R. Advanced Hysteretic Model of a Prototype Seismic Isolation System Made of Polymeric Bearings. Appl. Sci. 2018, 8, 400. [Google Scholar] [CrossRef]

- Lasowicz, N.; Kwiecień, A.; Jankowski, R. Enhancing the Seismic Resistance of Columns by GFRP Confinement Using Flexible Adhesive - Experimental Study. Key Eng. Mater. 2015, 624, 478–485. [Google Scholar] [CrossRef]

- Zając, B. Experimentally-analytical determination of material effort of polymer adhesive layer applied in compound beams. Ph.D. Thesis, Cracow University of Technology, Cracow, Poland, 2008. [Google Scholar]

- Foraboschi, P. Laminated glass columns. Struct. Eng. 2009, 87, 20–26. [Google Scholar]

- Furtak, K.; Rodacki, K. Experimental investigations of load-bearing capacity of composite timber-glass I-beams. Arch. Civ. Mech. Eng. 2018, 18, 956–964. [Google Scholar] [CrossRef]

- Piekarczyk, M.; Grec, R. Application of Adhesive Bonding in Steel and Aluminium Structures. Arch. Civ. Eng. 2012, 58, 309–329. [Google Scholar] [CrossRef]

- Schmidt, L.C. Vibration theory. In Analysis and Design of Foundations for Vibrations; Moore, P.J., Ed.; A.A. BALKEMA: Rotterdam, The Netherlands; Boston, MA, USA, 1985. [Google Scholar]

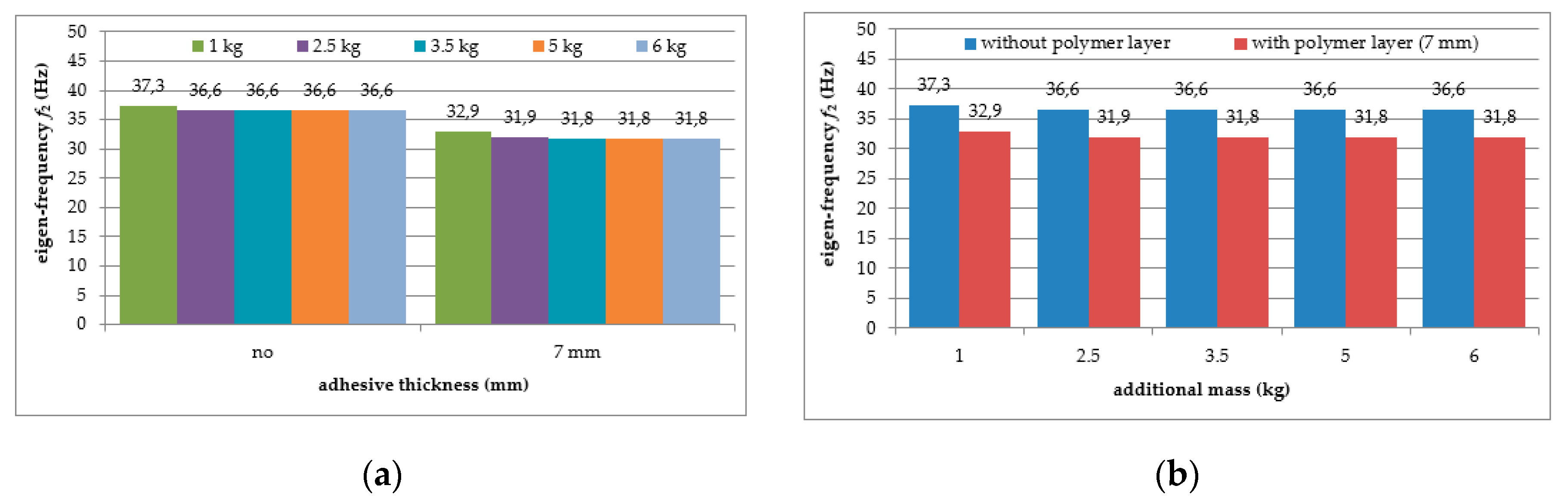

| Aluminium Beam | Aluminium Beam with Polymer Layer (7 mm) | |||

|---|---|---|---|---|

| Mass of Weight (kg) | f1 * (Hz) | f2 ** (Hz) | f1 * (Hz) | f2 ** (Hz) |

| 1 | 3.1 (1.00) | 37.3 (1.00) | 3.0 (0.97) | 32.9 (0.88) |

| 2.5 | 2.1 (0.68) | 36.6 (0.98) | 2.0 (0.64) | 31.9 (0.86) |

| 3.5 | 1.8 (0.58) | 36.6 (0.98) | 1.7 (0.55) | 31.8 (0.85) |

| 5 | 1.5 (0.48) | 36.6 (0.98) | 1.4 (0.45) | 31.8 (0.85) |

| 6 | 1.4 (0.45) | 36.6 (0.98) | 1.3 (0.42) | 31.8 (0.85) |

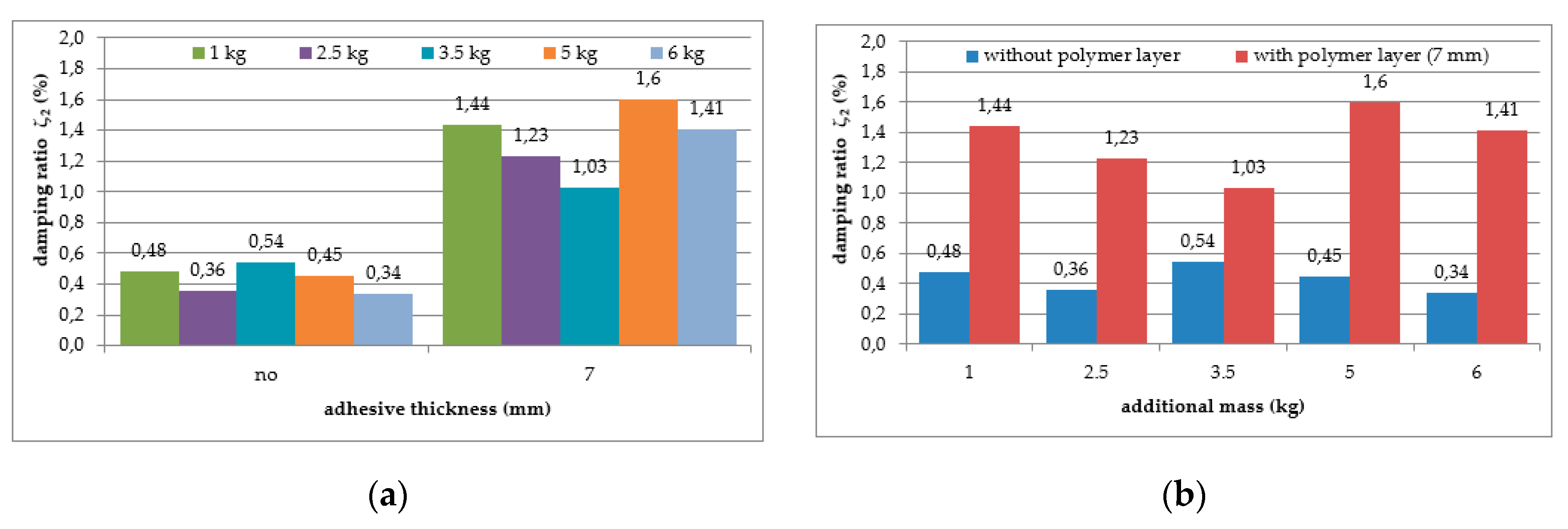

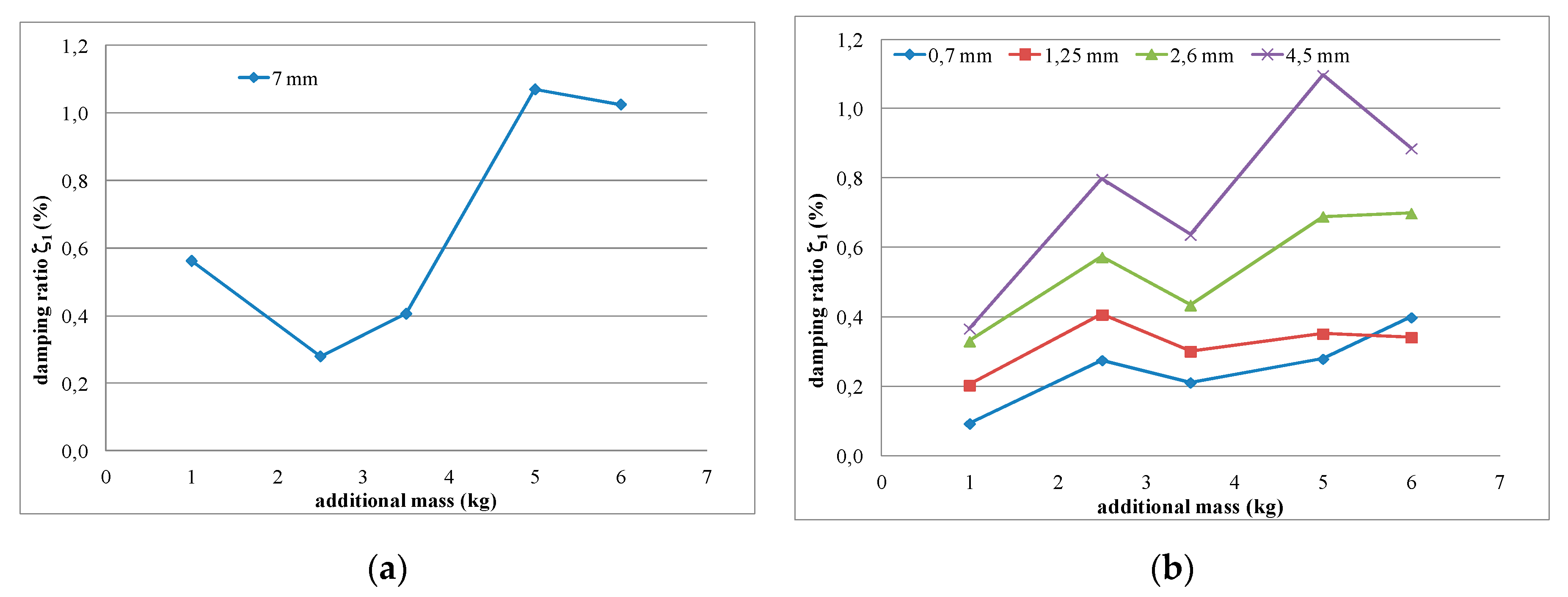

| Aluminium Beam | Aluminium Beam with Polymer Layer (7 mm) | |||

|---|---|---|---|---|

| Mass of Weight (kg) | ζ1 * (%) | ζ2 ** (%) | ζ1 * (%) | ζ2 ** (%) |

| 1 | 0.27 (1.00) | 0.48 (1.00) | 0.92 (3.41) | 1.44 (3.00) |

| 2.5 | 0.33 (1.22) | 0.36 (0.75) | 0.69 (2.55) | 1.23 (2.56) |

| 3.5 | 0.30 (1.11) | 0.54 (1.12) | 0.77 (2.85) | 1.03 (2.14) |

| 5 | 0.38 (1.41) | 0.45 (0.94) | 1.52 (5.63) | 1.60 (3.33) |

| 6 | 0.38 (1.41) | 0.34 (0.71) | 1.47 (5.44) | 1.41 (2.94) |

| Aluminium Beam with Polymer Adhesive | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mass of Weight (kg) | 0.5 mm | 1.2 mm | 1.75 mm | 3.1 mm | 5 mm | |||||

| f1 * (Hz) | f2 ** (Hz) | f1 * (Hz) | f2 ** (Hz) | f1 * (Hz) | f2 ** (Hz) | f1 * (Hz) | f2 ** (Hz) | f1 * (Hz) | f2 ** (Hz) | |

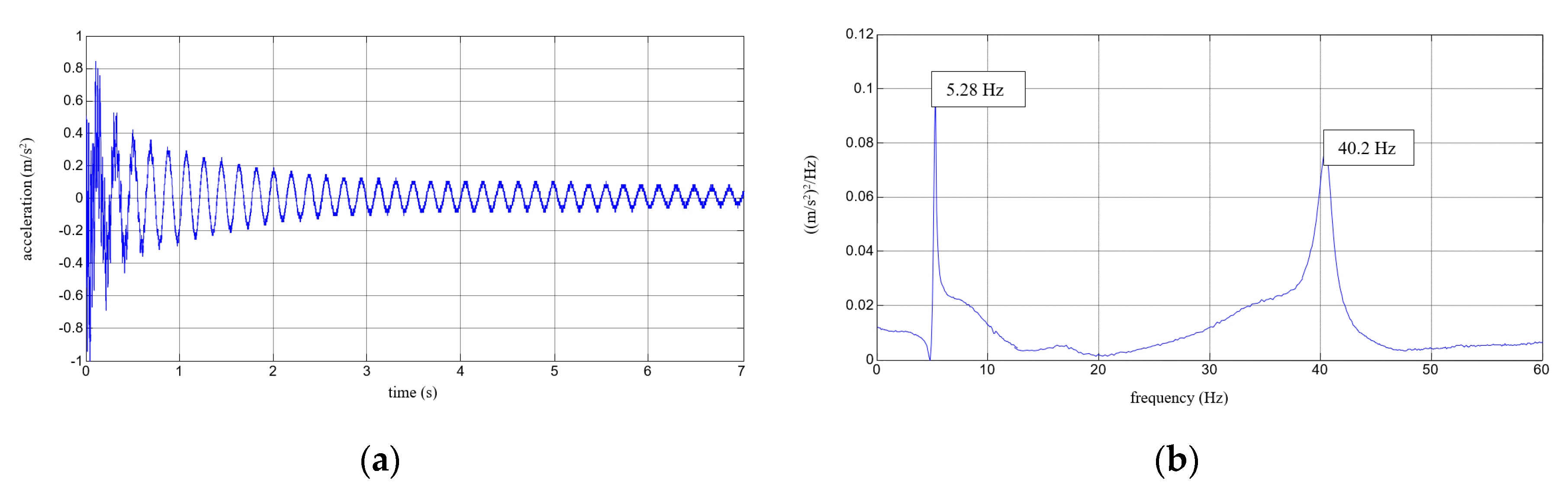

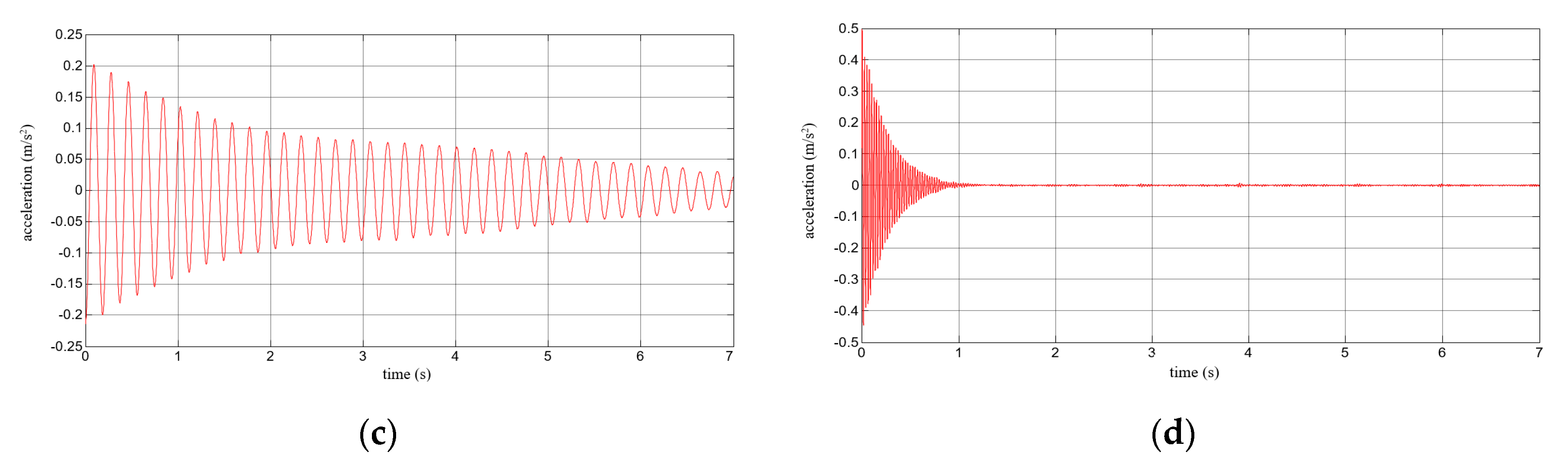

| 0 | 7.7 | 40.1 | 8.3 | 39.9 | 8.2 | 38.3 | 8.0 | 35.9 | 7.5 | 34.1 |

| 1 | 5.3 | 40.2 | 5.6 | 40.1 | 5.6 | 38.5 | 5.3 | 36.0 | 5.1 | 34.2 |

| 2.5 | 4.0 | 41.6 | 4.3 | 40.7 | 4.3 | 39.2 | 4.2 | 37.7 | 4.0 | 30.6 |

| 3.5 | 3.5 | 38.4 | 3.7 | 41.4 | 3.7 | 40.2 | 3.7 | 33.5 | 3.5 | 31.9 |

| 5 | 3.1 | 38.6 | 3.2 | 37.8 | 3.3 | 36.1 | 3.2 | 35.0 | 3.1 | 32.5 |

| 6 | 2.8 | 38.6 | 3.0 | 38.3 | 3.0 | 36.2 | 3.0 | 35.6 | 2.8 | 32.1 |

| Aluminium Beam with Polymer Adhesive | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mass of Weight (kg) | 0.5 mm | 1.2 mm | 1.75 mm | 3.1 mm | 5 mm | |||||

| ζ1 * (%) | ζ2 ** (%) | ζ1 * (%) | ζ2 ** (%) | ζ1 * (%) | ζ2 ** (%) | ζ1 * (%) | ζ2 ** (%) | ζ1 * (%) | ζ2 ** (%) | |

| 0 | 0.66 | 1.37 | 0.72 | 1.29 | 0.98 | 1.30 | 1.31 | 1.11 | 1.01 | 1.01 |

| 1 | 0.78 | 1.43 | 0.93 | 1.27 | 1.06 | 1.39 | 1.22 | 1.28 | 1.29 | 1.06 |

| 2.5 | 0.45 | 2.39 | 0.75 | 1.78 | 0.89 | 1.41 | 1.07 | 2.45 | 1.31 | 2.27 |

| 3.5 | 0.60 | 1.98 | 0.84 | 2.97 | 0.94 | 2.77 | 1.09 | 2.11 | 1.31 | 1.68 |

| 5 | 0.50 | 1.52 | 0.80 | 2.80 | 0.88 | 2.65 | 1.23 | 2.03 | 1.65 | 1.48 |

| 6 | 0.55 | 1.36 | 0.97 | 2.23 | 0.92 | 1.91 | 1.29 | 1.62 | 1.49 | 1.17 |

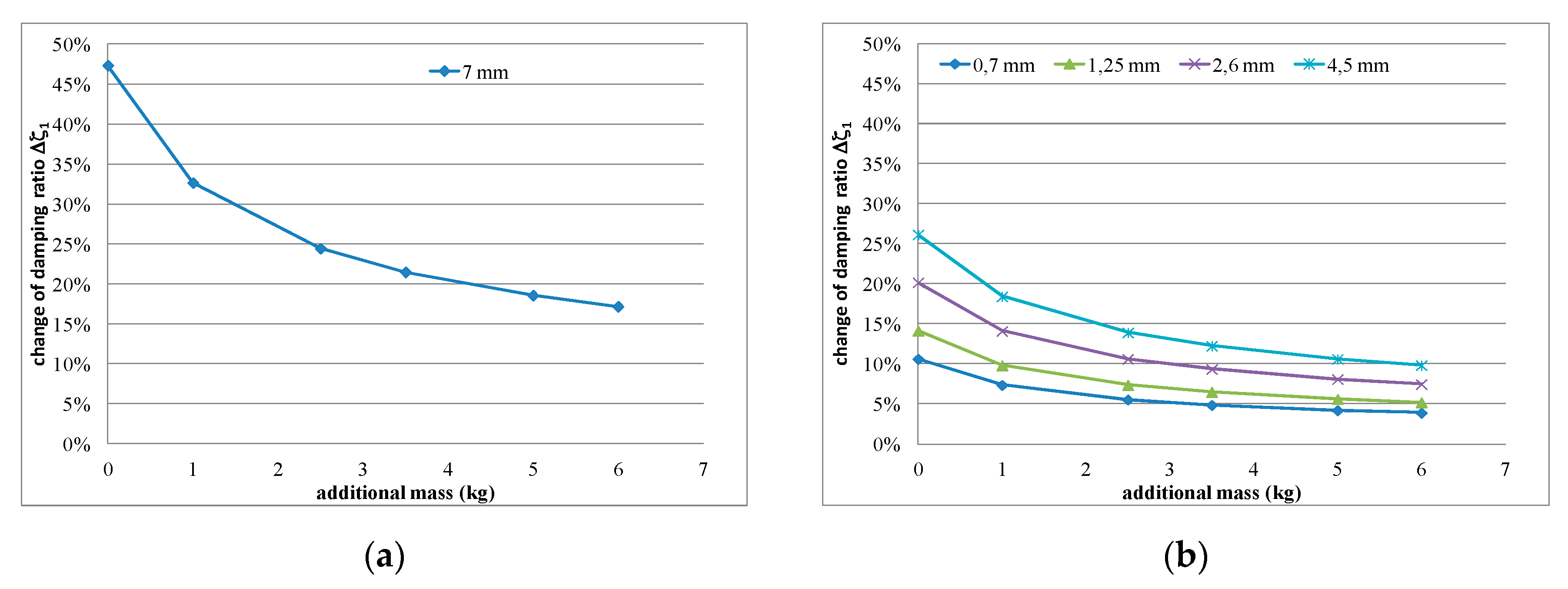

| Change in Mass from Aluminium Beam to Aluminium Beam with Polymer Adhesive for Thickness Increment from 0 mm to 7 mm | ||

|---|---|---|

| Mass of Weight (kg) | 7 mm | |

| α (-) | Δζ * (-) | |

| 0 | 1.288 | 0.473 |

| 1 | 1.119 | 0.326 |

| 2.5 | 1.063 | 0.244 |

| 3.5 | 1.048 | 0.214 |

| 5 | 1.036 | 0.185 |

| 6 | 1.030 | 0.171 |

| Change in Mass for Aluminium Beam with Polymer Adhesive for Thickness Increment from 0.7 mm to 4.5 mm | ||||||||

|---|---|---|---|---|---|---|---|---|

| Mass of Weight (kg) | 0.7 mm | 1.25 mm | 2.6 mm | 4.5 mm | ||||

| α (-) | Δζ * (-) | α (-) | Δζ * (-) | α (-) | Δζ * (-) | α (-) | Δζ * (-) | |

| 0 | 1.011 | 0.106 | 1.020 | 0.141 | 1.042 | 0.202 | 1.073 | 0.262 |

| 1 | 1.005 | 0.074 | 1.010 | 0.098 | 1.020 | 0.141 | 1.035 | 0.184 |

| 2.5 | 1.003 | 0.055 | 1.005 | 0.074 | 1.011 | 0.106 | 1.020 | 0.139 |

| 3.5 | 1.002 | 0.049 | 1.004 | 0.065 | 1.009 | 0.094 | 1.015 | 0.123 |

| 5 | 1.002 | 0.042 | 1.003 | 0.056 | 1.007 | 0.081 | 1.011 | 0.106 |

| 6 | 1.002 | 0.039 | 1.003 | 0.052 | 1.006 | 0.075 | 1.010 | 0.098 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lasowicz, N.; Kwiecień, A.; Jankowski, R. Experimental Study on the Effectiveness of Polyurethane Flexible Adhesive in Reduction of Structural Vibrations. Polymers 2020, 12, 2364. https://doi.org/10.3390/polym12102364

Lasowicz N, Kwiecień A, Jankowski R. Experimental Study on the Effectiveness of Polyurethane Flexible Adhesive in Reduction of Structural Vibrations. Polymers. 2020; 12(10):2364. https://doi.org/10.3390/polym12102364

Chicago/Turabian StyleLasowicz, Natalia, Arkadiusz Kwiecień, and Robert Jankowski. 2020. "Experimental Study on the Effectiveness of Polyurethane Flexible Adhesive in Reduction of Structural Vibrations" Polymers 12, no. 10: 2364. https://doi.org/10.3390/polym12102364

APA StyleLasowicz, N., Kwiecień, A., & Jankowski, R. (2020). Experimental Study on the Effectiveness of Polyurethane Flexible Adhesive in Reduction of Structural Vibrations. Polymers, 12(10), 2364. https://doi.org/10.3390/polym12102364