Recent Advances in the Application of Functionalized Lignin in Value-Added Polymeric Materials

Abstract

1. Introduction

2. Covalent Incorporation of Functionalized Lignin

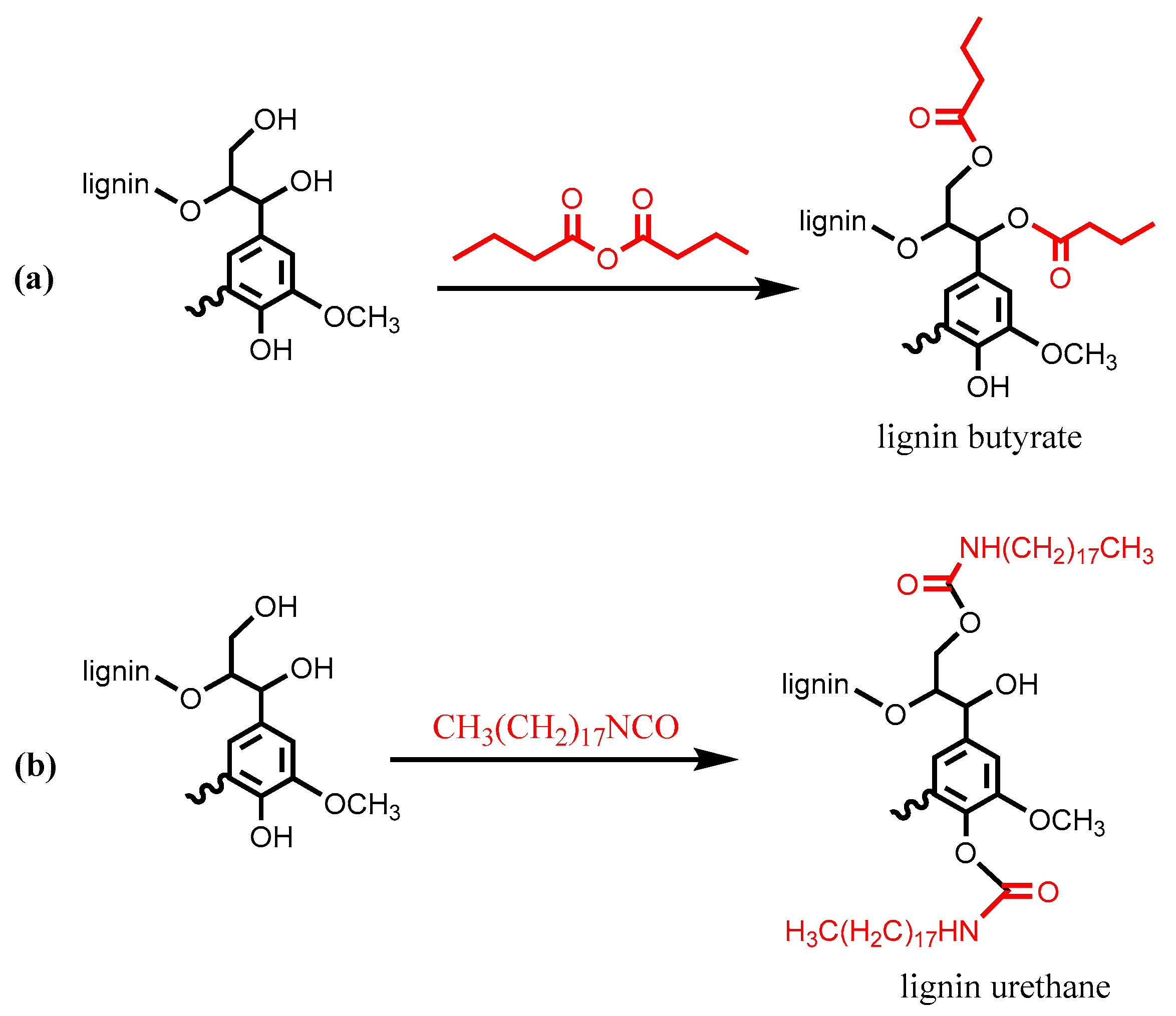

2.1. Polyurethanes

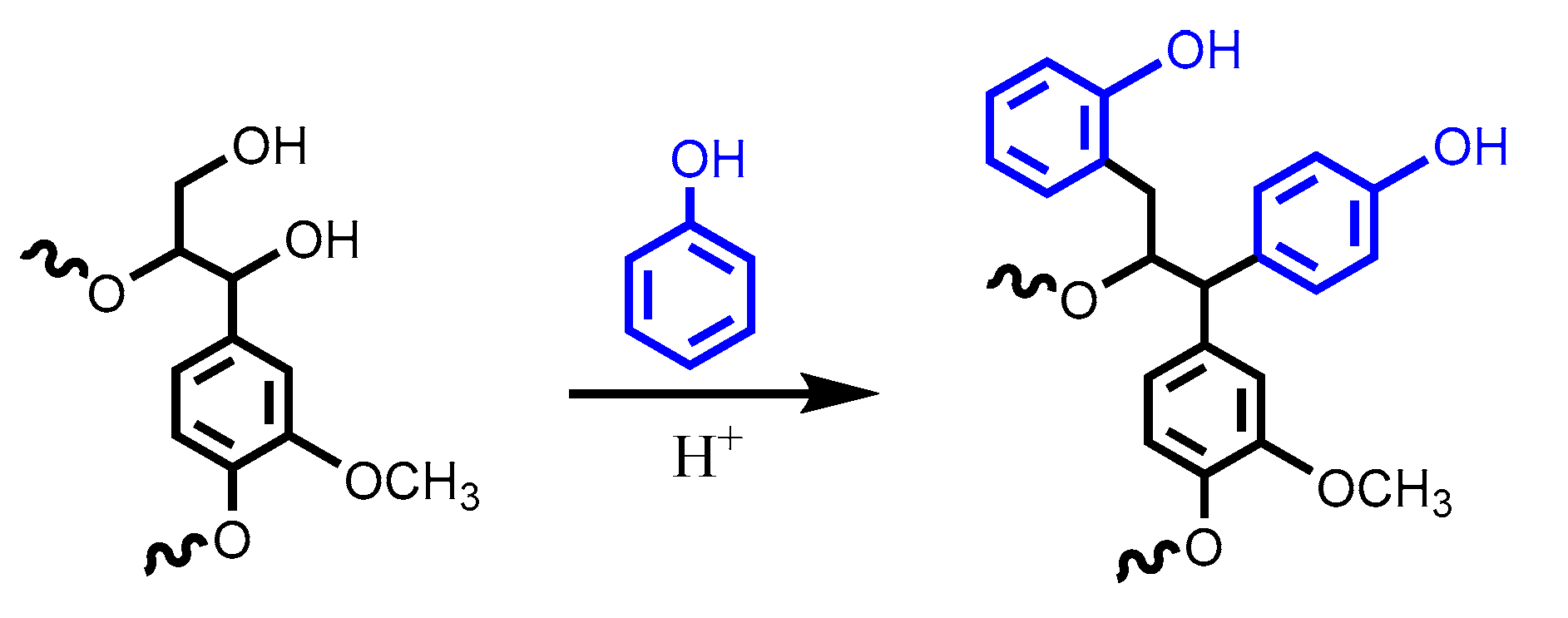

2.2. Lignin-Phenol-Formaldehyde (LPF)

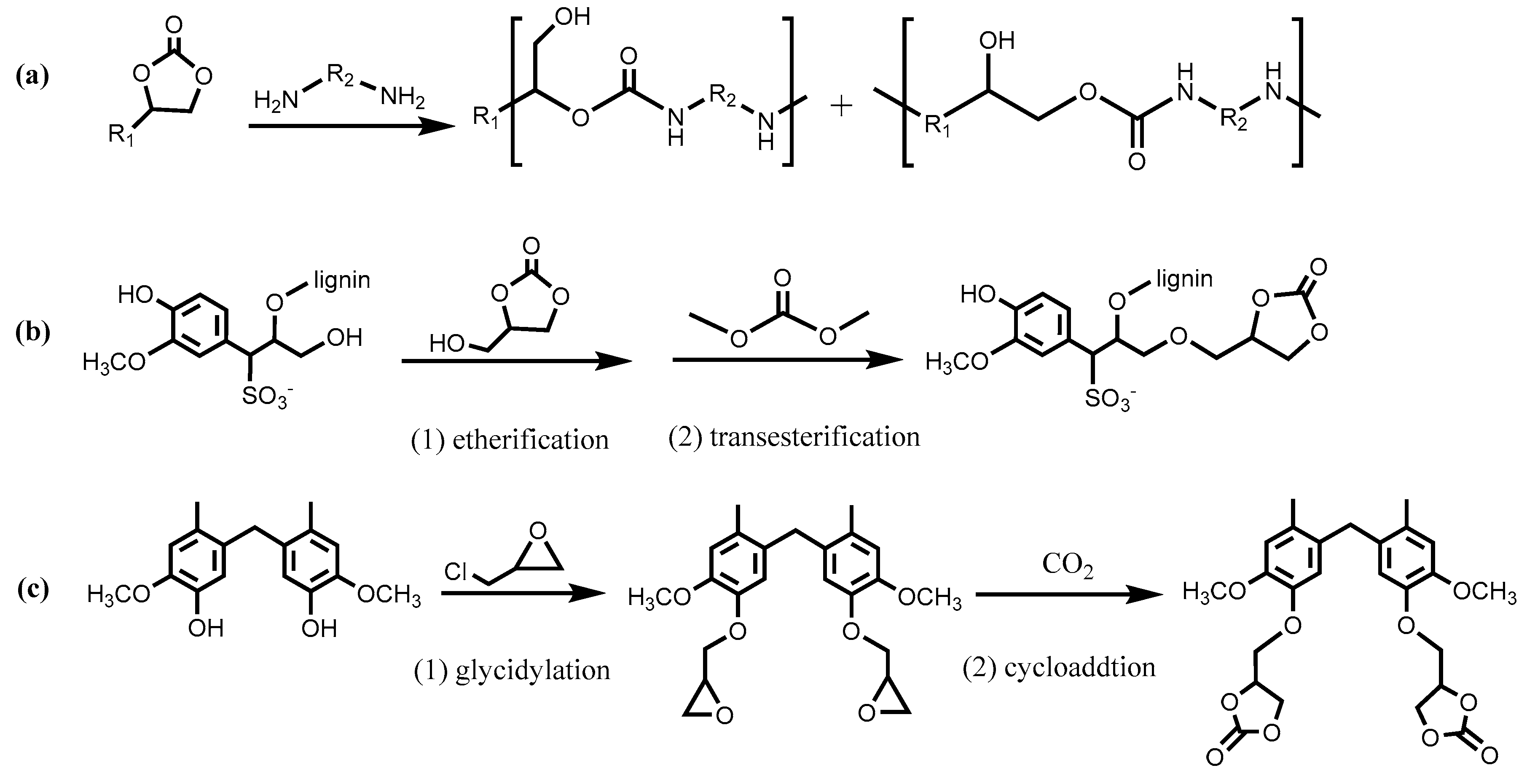

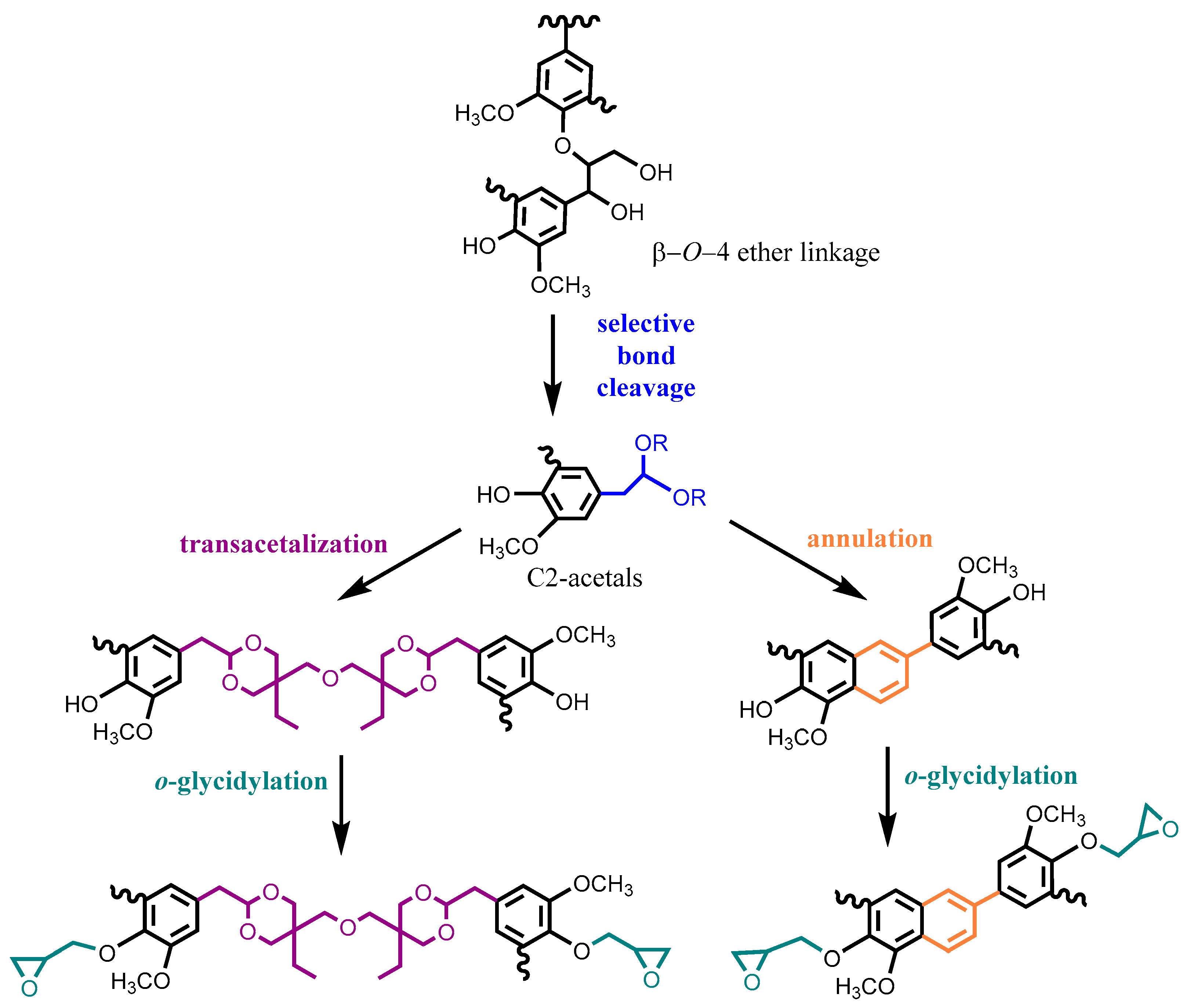

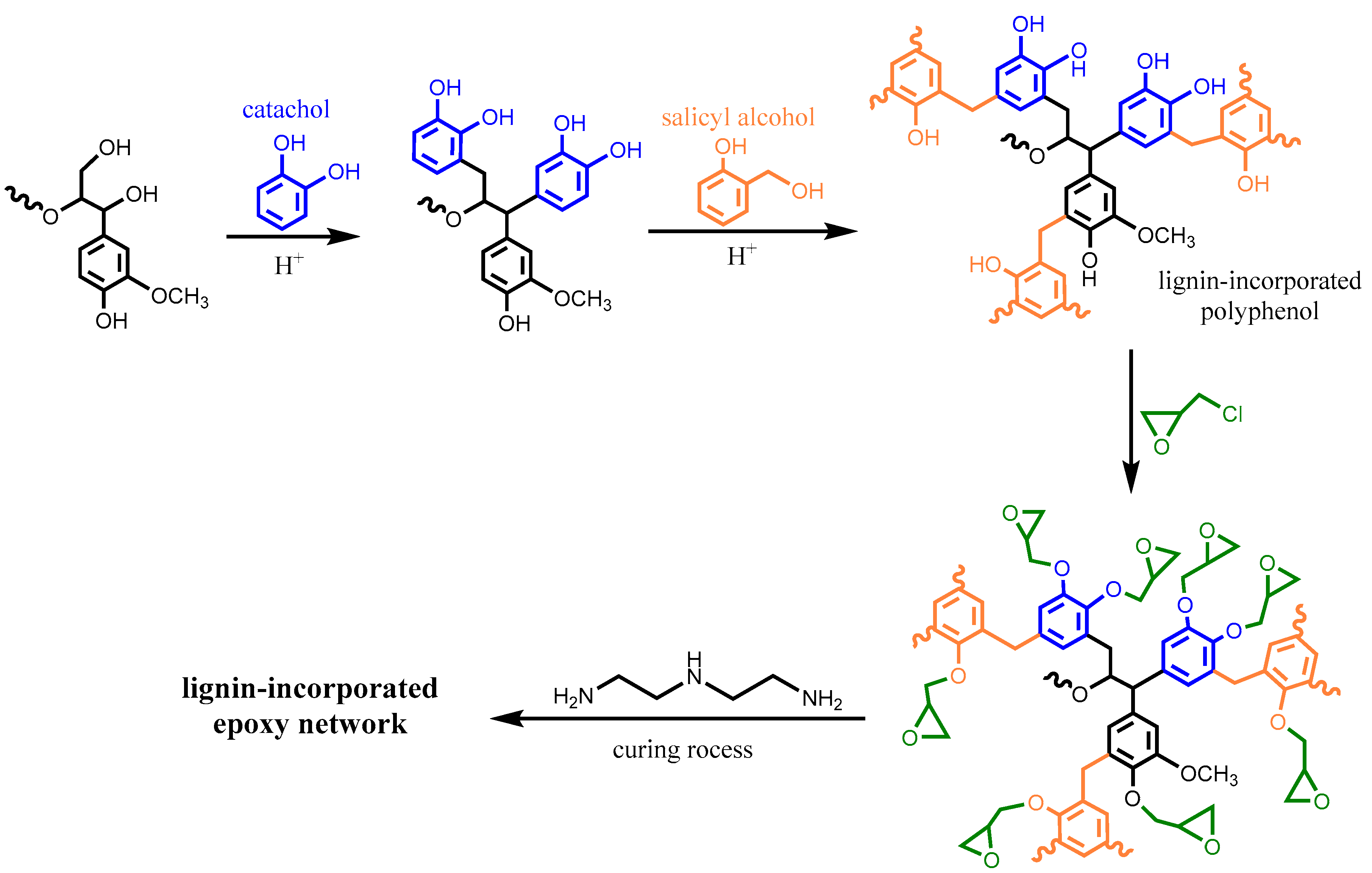

2.3. Epoxy

2.4. Lignin-Based Copolymers

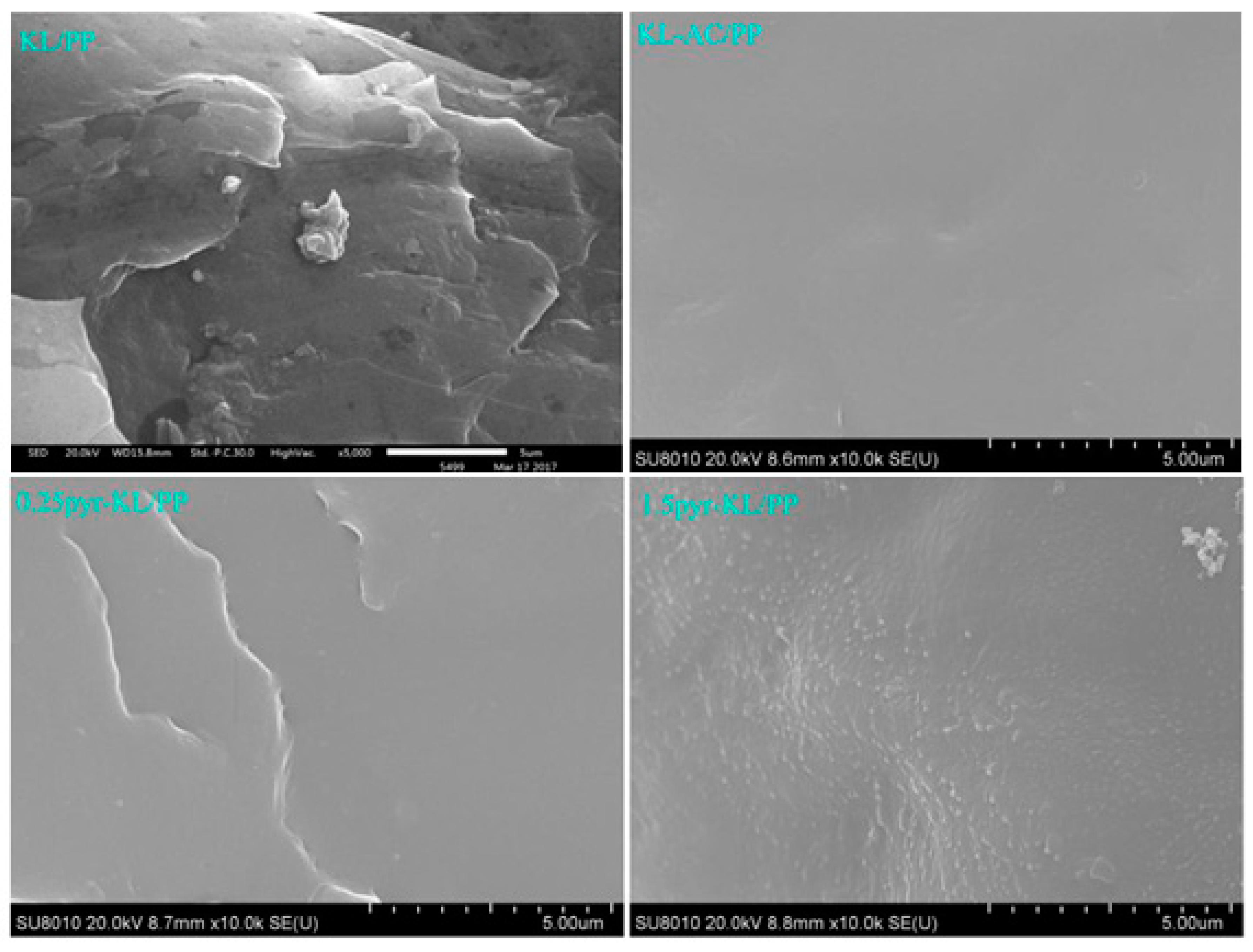

3. Functionalized Lignin-Based/Containing Blends, Composites

4. Lignin as Carbon Fiber Precursors

5. Lignin and Its Derivatives for Heavy Metal Adsorbent

6. Preparation of Lignin Nanoparticles and Their Applications

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Notice

References

- Cheng, C.; Shen, D.; Gu, S.; Luo, K.H. State-of-the-art catalytic hydrogenolysis of lignin for the production of aromatic chemicals. Catal. Sci. Technol. 2018, 8, 6275–6296. [Google Scholar] [CrossRef]

- Ragauskas, A.J.; Beckham, G.T.; Biddy, M.J.; Chandra, R.; Chen, F.; Davis, M.F.; Davison, B.H.; Dixon, R.A.; Gilna, P.; Keller, M.; et al. Lignin Valorization: Improving Lignin Processing in the Biorefinery. Science 2014, 344, 1246843. [Google Scholar] [CrossRef] [PubMed]

- Shuai, L.; Saha, B. Towards high-yield lignin monomer production. Green Chem. 2017, 19, 3752–3758. [Google Scholar] [CrossRef]

- Li, M.; Pu, Y.; Ragauskas, A.J. Current Understanding of the Correlation of Lignin Structure with Biomass Recalcitrance. Front. Chem. 2016, 4. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Harrison, M.D.; Rackemann, D.W.; Doherty, W.O.S.; O’Hara, I.M. Organosolv pretreatment of plant biomass for enhanced enzymatic saccharification. Green Chem. 2016, 18, 360–381. [Google Scholar] [CrossRef]

- Li, T.; Takkellapati, S. The current and emerging sources of technical lignins and their applications. Biofuel. Bioprod. Biorefin. 2018, 12, 756–787. [Google Scholar] [CrossRef]

- Upton, B.M.; Kasko, A.M. Strategies for the Conversion of Lignin to High-Value Polymeric Materials: Review and Perspective. Chem. Rev. 2016, 116, 2275–2306. [Google Scholar] [CrossRef]

- Wang, C.; Kelley, S.S.; Venditti, R.A. Lignin-Based Thermoplastic Materials. ChemSusChem 2016, 9, 770–783. [Google Scholar] [CrossRef]

- Laurichesse, S.; Avérous, L. Chemical modification of lignins: Towards biobased polymers. Prog. Polym. Sci. 2014, 39, 1266–1290. [Google Scholar] [CrossRef]

- Crestini, C.; Lange, H.; Sette, M.; Argyropoulos, D.S. On the structure of softwood kraft lignin. Green Chem. 2017, 19, 4104–4121. [Google Scholar] [CrossRef]

- Evdokimov, A.N.; Kurzin, A.V.; Fedorova, O.V.; Lukanin, P.V.; Kazakov, V.G.; Trifonova, A.D. Desulfurization of kraft lignin. Wood Sci. Technol. 2018, 52, 1165–1174. [Google Scholar] [CrossRef]

- Kai, D.; Tan, M.J.; Chee, P.L.; Chua, Y.K.; Yap, Y.L.; Loh, X.J. Towards lignin-based functional materials in a sustainable world. Green Chem. 2016, 18, 1175–1200. [Google Scholar] [CrossRef]

- Shuai, L.; Questell-Santiago, Y.M.; Luterbacher, J.S. A mild biomass pretreatment using γ-valerolactone for concentrated sugar production. Green Chem. 2016, 18, 937–943. [Google Scholar] [CrossRef]

- Cai, C.M.; Zhang, T.; Kumar, R.; Wyman, C.E. THF co-solvent enhances hydrocarbon fuel precursor yields from lignocellulosic biomass. Green Chem. 2013, 15, 3140–3145. [Google Scholar] [CrossRef]

- Li, S.-X.; Li, M.-F.; Bian, J.; Sun, S.-N.; Peng, F.; Xue, Z.-M. Biphasic 2-methyltetrahydrofuran/oxalic acid/water pretreatment to enhance cellulose enzymatic hydrolysis and lignin valorization. Bioresour. Technol. 2017, 243, 1105–1111. [Google Scholar] [CrossRef]

- Meng, X.; Pu, Y.; Li, M.; Ragauskas, A.J. A biomass pretreatment using cellulose-derived solvent Cyrene. Green Chem. 2020, 22, 2862–2872. [Google Scholar] [CrossRef]

- Cornille, A.; Auvergne, R.; Figovsky, O.; Boutevin, B.; Caillol, S. A perspective approach to sustainable routes for non-isocyanate polyurethanes. Eur. Polym. J. 2017, 87, 535–552. [Google Scholar] [CrossRef]

- Wang, Y.-Y.; Cai, C.M.; Ragauskas, A.J. Recent advances in lignin-based polyurethanes. Tappi J. 2017, 16, 203–207. [Google Scholar] [CrossRef]

- Bayer, O. Das Di-Isocyanat-Polyadditionsverfahren (Polyurethane). Angew. Chem. 1947, 59, 257–272. [Google Scholar] [CrossRef]

- Jaunzems, V.; Mozheiko, L.N.; Sergeeva, V.N. Nitrogen-containing lignin derivatives. III. Reaction of lignin with tolylene diisocyanate. Khimiya Drev. 1968, 2, 107–114. [Google Scholar]

- Glasser, W.G. About Making Lignin Great Again—Some Lessons from the Past. Front. Chem. 2019, 7, 565. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Wu, H.; Kessler, M.R. High bio-content polyurethane composites with urethane modified lignin as filler. Polymer 2015, 69, 52–57. [Google Scholar] [CrossRef]

- Jang, S.-H.; Kim, D.-H.; Park, D.H.; Kim, O.Y.; Hwang, S.-H. Construction of sustainable polyurethane-based gel-coats containing poly(ε-caprolactone)-grafted lignin and their coating performance. Progr. Organ. Coat. 2018, 120, 234–239. [Google Scholar] [CrossRef]

- Vebi, M.; Hassan, A.; Hubert, H.; Markus, B.; Ireen, G.; Robert, B.; Karin, F.; Antje, P.; Thomas, R. Lignosulfonate-based polyurethane materials via cyclic carbonates: Preparation and characterization. Holzforschung 2020, 74, 203–211. [Google Scholar] [CrossRef]

- Chen, Q.; Gao, K.; Peng, C.; Xie, H.; Zhao, Z.K.; Bao, M. Preparation of lignin/glycerol-based bis(cyclic carbonate) for the synthesis of polyurethanes. Green Chem. 2015, 17, 4546–4551. [Google Scholar] [CrossRef]

- Tejado, A.; Kortaberria, G.; Labidi, J.; Echeverria, J.M.; Mondragon, I. Isoconversional kinetic analysis of novolac-type lignophenolic resins cure. Thermochim. Acta 2008, 471, 80–85. [Google Scholar] [CrossRef]

- Xu, C.; Ferdosian, F. Conversion of Lignin into Bio-Based Chemicals and Materials; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Podschun, J.; Stücker, A.; Saake, B.; Lehnen, R. Structure–Function Relationships in the Phenolation of Lignins from Different Sources. ACS Sustain. Chem. Eng. 2015, 3, 2526–2532. [Google Scholar] [CrossRef]

- Yang, S.; Wen, J.-L.; Yuan, T.-Q.; Sun, R.-C. Characterization and phenolation of biorefinery technical lignins for lignin–phenol–formaldehyde resin adhesive synthesis. RSC Adv. 2014, 4, 57996–58004. [Google Scholar] [CrossRef]

- Pang, B.; Cao, X.-F.; Sun, S.-N.; Wang, X.-L.; Wen, J.-L.; Lam, S.S.; Yuan, T.-Q.; Sun, R.-C. The direct transformation of bioethanol fermentation residues for production of high-quality resins. Green Chem. 2020, 22, 439–447. [Google Scholar] [CrossRef]

- Pang, B.; Yang, S.; Fang, W.; Yuan, T.-Q.; Argyropoulos, D.S.; Sun, R.-C. Structure-property relationships for technical lignins for the production of lignin-phenol-formaldehyde resins. Ind. Crops Prod. 2017, 108, 316–326. [Google Scholar] [CrossRef]

- Gan, L.; Pan, X. Phenol-Enhanced Depolymerization and Activation of Kraft Lignin in Alkaline Medium. Ind. Eng. Chem. Res. 2019, 58, 7794–7800. [Google Scholar] [CrossRef]

- Li, J.; Wang, W.; Zhang, S.; Gao, Q.; Zhang, W.; Li, J. Preparation and characterization of lignin demethylated at atmospheric pressure and its application in fast curing biobased phenolic resins. RSC Adv. 2016, 6, 67435–67443. [Google Scholar] [CrossRef]

- Song, Y.; Wang, Z.; Yan, N.; Zhang, R.; Li, J. Demethylation of Wheat Straw Alkali Lignin for Application in Phenol Formaldehyde Adhesives. Polymers 2016, 8, 209. [Google Scholar] [CrossRef]

- Zhang, Y.; Pang, H.; Wei, D.; Li, J.; Li, S.; Lin, X.; Wang, F.; Liao, B. Preparation and characterization of chemical grouting derived from lignin epoxy resin. Eur. Polym. J. 2019, 118, 290–305. [Google Scholar] [CrossRef]

- Kaiho, A.; Mazzarella, D.; Satake, M.; Kogo, M.; Sakai, R.; Watanabe, T. Construction of the di(trimethylolpropane) cross linkage and the phenylnaphthalene structure coupled with selective β-O-4 bond cleavage for synthesizing lignin-based epoxy resins with a controlled glass transition temperature. Green Chem. 2016, 18, 6526–6535. [Google Scholar] [CrossRef]

- Zhao, S.; Abu-Omar, M.M. Synthesis of Renewable Thermoset Polymers through Successive Lignin Modification Using Lignin-Derived Phenols. ACS Sustain. Chem. Eng. 2017, 5, 5059–5066. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, X.; Whelton, A.J.; Abu-Omar, M.M. Formaldehyde-Free Method for Incorporating Lignin into Epoxy Thermosets. ACS Sustain. Chem. Eng. 2018, 6, 10628–10636. [Google Scholar] [CrossRef]

- Nikafshar, S.; Zabihi, O.; Moradi, Y.; Ahmadi, M.; Amiri, S.; Naebe, M. Catalyzed Synthesis and Characterization of a Novel Lignin-Based Curing Agent for the Curing of High-Performance Epoxy Resin. Polymers 2017, 9, 266. [Google Scholar] [CrossRef]

- Mendis, G.P.; Hua, I.; Youngblood, J.P.; Howarter, J.A. Enhanced dispersion of lignin in epoxy composites through hydration and mannich functionalization. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Sun, J.; Wang, C.; Stubbs, L.P.; He, C. Carboxylated Lignin as an Effective Cohardener for Enhancing Strength and Toughness of Epoxy. Macromol. Mater. Eng. 2017, 302, 1700341. [Google Scholar] [CrossRef]

- Guo, X.; Xin, J.; Huang, J.; Wolcott, M.P.; Zhang, J. Preparation and toughening of mechanochemically modified lignin-based epoxy. Polymer 2019, 183, 121859. [Google Scholar] [CrossRef]

- Ganewatta, M.S.; Lokupitiya, H.N.; Tang, C. Lignin Biopolymers in the Age of Controlled Polymerization. Polymers 2019, 11, 1176. [Google Scholar] [CrossRef] [PubMed]

- Kong, F.; Wang, S.; Price, J.T.; Konduri, M.K.R.; Fatehi, P. Water soluble kraft lignin–acrylic acid copolymer: Synthesis and characterization. Green Chem. 2015, 17, 4355–4366. [Google Scholar] [CrossRef]

- Kai, D.; Zhang, K.; Jiang, L.; Wong, H.Z.; Li, Z.; Zhang, Z.; Loh, X.J. Sustainable and Antioxidant Lignin–Polyester Copolymers and Nanofibers for Potential Healthcare Applications. ACS Sustain. Chem. Eng. 2017, 5, 6016–6025. [Google Scholar] [CrossRef]

- Kai, D.; Jiang, S.; Low, Z.W.; Loh, X.J. Engineering highly stretchable lignin-based electrospun nanofibers for potential biomedical applications. J. Mater. Chem. B 2015, 3, 6194–6204. [Google Scholar] [CrossRef] [PubMed]

- Kai, D.; Zhang, K.; Liow, S.S.; Loh, X.J. New Dual Functional PHB-Grafted Lignin Copolymer: Synthesis, Mechanical Properties, and Biocompatibility Studies. ACS Appl. Bio Mater. 2019, 2, 127–134. [Google Scholar] [CrossRef]

- Sivasankarapillai, G.; Li, H.; McDonald, A.G. Lignin-Based Triple Shape Memory Polymers. Biomacromolecules 2015, 16, 2735–2742. [Google Scholar] [CrossRef]

- Kim, Y.S.; Youe, W.-J.; Kim, S.J.; Lee, O.-K.; Lee, S.-S. Preparation of a Thermoplastic Lignin-Based Biomaterial through Atom Transfer Radical Polymerization. J. Wood Chem. Technol. 2015, 35, 251–259. [Google Scholar] [CrossRef]

- Kai, D.; Chua, Y.K.; Jiang, L.; Owh, C.; Chan, S.Y.; Loh, X.J. Dual functional anti-oxidant and SPF enhancing lignin-based copolymers as additives for personal and healthcare products. RSC Adv. 2016, 6, 86420–86427. [Google Scholar] [CrossRef]

- Atz Dick, T.; Couve, J.; Gimello, O.; Mas, A.; Robin, J.-J. Chemical modification and plasma-induced grafting of pyrolitic lignin. Evaluation of the reinforcing effect on lignin/poly(l-lactide) composites. Polymer 2017, 118, 280–296. [Google Scholar] [CrossRef]

- Price, J.T.; Gao, W.; Fatehi, P. Lignin-g-poly(acrylamide)-g-poly(diallyldimethyl- ammonium chloride): Synthesis, Characterization and Applications. ChemistryOpen 2018, 7, 645–658. [Google Scholar] [CrossRef]

- Abdollahi, M.; Bairami Habashi, R.; Mohsenpour, M. Poly(ε-caprolactone) chains grafted from lignin, hydroxymethylated lignin and silica/lignin hybrid macroinitiators: Synthesis and characterization of lignin- based thermoplastic copolymers. Ind. Crops Prod. 2019, 130, 547–557. [Google Scholar] [CrossRef]

- Feldman, D. Lignin and Its Polyblends—A Review. In Chemical Modification, Properties, and Usage of Lignin; Hu, T.Q., Ed.; Springer: Boston, MA, USA, 2002; pp. 81–99. [Google Scholar] [CrossRef]

- Li, Y.; Sarkanen, S. Alkylated Kraft Lignin-Based Thermoplastic Blends with Aliphatic Polyesters. Macromolecules 2002, 35, 9707–9715. [Google Scholar] [CrossRef]

- Li, Y.; Sarkanen, S. Miscible Blends of Kraft Lignin Derivatives with Low-Tg Polymers. Macromolecules 2005, 38, 2296–2306. [Google Scholar] [CrossRef]

- Zhao, W.; Simmons, B.; Singh, S.; Ragauskas, A.; Cheng, G. From lignin association to nano-/micro-particle preparation: Extracting higher value of lignin. Green Chem. 2016, 18, 5693–5700. [Google Scholar] [CrossRef]

- Pucciariello, R.; Villani, V.; Bonini, C.; D’Auria, M.; Vetere, T. Physical properties of straw lignin-based polymer blends. Polymer 2004, 45, 4159–4169. [Google Scholar] [CrossRef]

- Duval, A.; Lawoko, M. A review on lignin-based polymeric, micro- and nano-structured materials. React. Funct. Polym. 2014, 85, 78–96. [Google Scholar] [CrossRef]

- Dehne, L.; Vila Babarro, C.; Saake, B.; Schwarz, K.U. Influence of lignin source and esterification on properties of lignin-polyethylene blends. Ind. Crops Prod. 2016, 86, 320–328. [Google Scholar] [CrossRef]

- Ye, D.; Kong, J.; Gu, S.; Zhou, Y.; Huang, C.; Xu, W.; Zhang, X. Selective aminolysis of acetylated lignin: Toward simultaneously improving thermal-oxidative stability and maintaining mechanical properties of polypropylene. Int. J. Biol. Macromol. 2018, 108, 775–781. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S. An overview of polylactides as packaging materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef]

- Kun, D.; Pukánszky, B. Polymer/lignin blends: Interactions, properties, applications. Eur. Polym. J. 2017, 93, 618–641. [Google Scholar] [CrossRef]

- Guo, X.; Junna, X.; Wolcott, M.P.; Zhang, J. Mechanochemical Oleation of Lignin Through Ball Milling and Properties of its Blends with PLA. ChemistrySelect 2016, 1, 3449–3454. [Google Scholar] [CrossRef]

- Vila, C.; Santos, V.; Saake, B.; Parajó, J.C. Manufacture, Characterization, and Properties of Poly-(lactic acid) and its Blends with Esterified Pine Lignin. BioResources 2016, 11, 5322–5332. [Google Scholar] [CrossRef]

- Gordobil, O.; Delucis, R.; Egüés, I.; Labidi, J. Kraft lignin as filler in PLA to improve ductility and thermal properties. Ind. Crops Prod. 2015, 72, 46–53. [Google Scholar] [CrossRef]

- Xiong, S.-J.; Pang, B.; Zhou, S.-J.; Li, M.-K.; Yang, S.; Wang, Y.-Y.; Shi, Q.; Wang, S.-F.; Yuan, T.-Q.; Sun, R.-C. Economically Competitive Biodegradable PBAT/Lignin Composites: Effect of Lignin Methylation and Compatibilizer. ACS Sustain. Chem. Eng. 2020, 8, 5338–5346. [Google Scholar] [CrossRef]

- Li, Y.; Mlynár, J.; Sarkanen, S. The first 85% kraft lignin-based thermoplastics. J. Polym. Sci. Part B Polym. Phys. 1998, 35, 1899–1910. [Google Scholar] [CrossRef]

- Wang, Y.-Y.; Chen, Y.-R.; Sarkanen, S. Blend configuration in functional polymeric materials with a high lignin content. Faraday Discuss. 2017, 202, 43–59. [Google Scholar] [CrossRef]

- Wang, Y.-Y.; Chen, Y.-R.; Sarkanen, S. Path to plastics composed of ligninsulphonates (lignosulfonates). Green Chem. 2015, 17, 5069–5078. [Google Scholar] [CrossRef]

- Li, Q.; Li, M.; Lin, H.-S.; Hu, C.; Truong, P.; Zhang, T.; Sue, H.-J.; Pu, Y.; Ragauskas, A.J.; Yuan, J.S. Non-Solvent Fractionation of Lignin Enhances Carbon Fiber Performance. ChemSusChem 2019, 12, 3249–3256. [Google Scholar] [CrossRef]

- Aslanzadeh, S.; Ahvazi, B.; Boluk, Y.; Ayranci, C. Carbon Fiber Production from Electrospun Sulfur Free Softwood Lignin Precursors. J. Eng. Fibers Fabr. 2017, 12, 155892501701200405. [Google Scholar] [CrossRef]

- Mainka, H.; Hilfert, L.; Busse, S.; Edelmann, F.; Haak, E.; Herrmann, A.S. Characterization of the major reactions during conversion of lignin to carbon fiber. J. Mater. Res. Technol. 2015, 4, 377–391. [Google Scholar] [CrossRef]

- Baker, D.A.; Rials, T.G. Recent advances in low-cost carbon fiber manufacture from lignin. J. Appl. Polym. Sci. 2013, 130, 713–728. [Google Scholar] [CrossRef]

- Hosseinaei, O.; Harper, D.P.; Bozell, J.J.; Rials, T.G. Role of Physicochemical Structure of Organosolv Hardwood and Herbaceous Lignins on Carbon Fiber Performance. ACS Sustain. Chem. Eng. 2016, 4, 5785–5798. [Google Scholar] [CrossRef]

- Imel, A.E.; Naskar, A.K.; Dadmun, M.D. Understanding the Impact of Poly(ethylene oxide) on the Assembly of Lignin in Solution toward Improved Carbon Fiber Production. ACS Appl. Mate. Interfaces 2016, 8, 3200–3207. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.C.; Luo, J.; Chang, H.; Bakhtiary Davijani, A.A.; Wang, P.-H.; Kumar, S. Polyacrylonitrile sheath and polyacrylonitrile/lignin core bi-component carbon fibers. Carbon 2019, 149, 165–172. [Google Scholar] [CrossRef]

- Dai, Z.; Shi, X.; Liu, H.; Li, H.; Han, Y.; Zhou, J. High-strength lignin-based carbon fibers via a low-energy method. RSC Adv. 2018, 8, 1218–1224. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, H.; Shen, F.; Wan, J.; Han, X.; Dai, J.; Dai, H.; Hu, L. Highly Conductive Microfiber of Graphene Oxide Templated Carbonization of Nanofibrillated Cellulose. Adv. Funct. Mater. 2014, 24, 7366–7372. [Google Scholar] [CrossRef]

- Krishnan, D.; Raidongia, K.; Shao, J.; Huang, J. Graphene Oxide Assisted Hydrothermal Carbonization of Carbon Hydrates. ACS Nano 2014, 8, 449–457. [Google Scholar] [CrossRef]

- Torres-Canas, F.; Bentaleb, A.; Föllmer, M.; Roman, J.; Neri, W.; Ly, I.; Derré, A.; Poulin, P. Improved structure and highly conductive lignin-carbon fibers through graphene oxide liquid crystal. Carbon 2020, 163, 120–127. [Google Scholar] [CrossRef]

- Newcomb, B.A.; Giannuzzi, L.A.; Lyons, K.M.; Gulgunje, P.V.; Gupta, K.; Liu, Y.; Kamath, M.; McDonald, K.; Moon, J.; Feng, B.; et al. High resolution transmission electron microscopy study on polyacrylonitrile/carbon nanotube based carbon fibers and the effect of structure development on the thermal and electrical conductivities. Carbon 2015, 93, 502–514. [Google Scholar] [CrossRef]

- Foston, M.; Nunnery, G.A.; Meng, X.; Sun, Q.; Baker, F.S.; Ragauskas, A. NMR a critical tool to study the production of carbon fiber from lignin. Carbon 2013, 52, 65–73. [Google Scholar] [CrossRef]

- Sun, Q.; Khunsupat, R.; Akato, K.; Tao, J.; Labbé, N.; Gallego, N.C.; Bozell, J.J.; Rials, T.G.; Tuskan, G.A.; Tschaplinski, T.J.; et al. A study of poplar organosolv lignin after melt rheology treatment as carbon fiber precursors. Green Chem. 2016, 18, 5015–5024. [Google Scholar] [CrossRef]

- Abdelhamid, H.N.; Zou, X. Template-free and room temperature synthesis of hierarchical porous zeolitic imidazolate framework nanoparticles and their dye and CO2 sorption. Green Chem. 2018, 20, 1074–1084. [Google Scholar] [CrossRef]

- Olivo-Alanis, D.; Garcia-Reyes, R.B.; Alvarez, L.H.; Garcia-Gonzalez, A. Mechanism of anaerobic bio-reduction of azo dye assisted with lawsone-immobilized activated carbon. J. Hazard. Mater. 2018, 347, 423–430. [Google Scholar] [CrossRef]

- Konicki, W.; Aleksandrzak, M.; Moszyński, D.; Mijowska, E. Adsorption of anionic azo-dyes from aqueous solutions onto graphene oxide: Equilibrium, kinetic and thermodynamic studies. J. Colloid Interface Sci. 2017, 496, 188–200. [Google Scholar] [CrossRef]

- Vahidhabanu, S.; Adeogun, A.I.; Babu, B.R. Biopolymer-Grafted, Magnetically Tuned Halloysite Nanotubes as Efficient and Recyclable Spongelike Adsorbents for Anionic Azo Dye Removal. ACS Omega 2019, 4, 2425–2436. [Google Scholar] [CrossRef]

- Todorciuc, T.; Bulgariu, L.; Popa, V.I. Adsorption of Cu(II) from aqueous solution on wheat straw lignin: Equilibrium and kinetic studies. Cellul. Chem. Technol. 2015, 49, 439–447. [Google Scholar]

- Albadarin, A.B.; Al-Muhtaseb, A.a.H.; Al-laqtah, N.A.; Walker, G.M.; Allen, S.J.; Ahmad, M.N.M. Biosorption of toxic chromium from aqueous phase by lignin: Mechanism, effect of other metal ions and salts. Chem. Eng. J. 2011, 169, 20–30. [Google Scholar] [CrossRef]

- Demirbas, A. Adsorption of lead and cadmium ions in aqueous solutions onto modified lignin from alkali glycerol delignication. J. Hazard. Mater. 2004, 109, 221–226. [Google Scholar] [CrossRef]

- Harmita, H.; Karthikeyan, K.G.; Pan, X. Copper and cadmium sorption onto kraft and organosolv lignins. Bioresour. Technol. 2009, 100, 6183–6191. [Google Scholar] [CrossRef]

- Bartczak, P.; Klapiszewski, Ł.; Wysokowski, M.; Majchrzak, I.; Czernicka, W.; Piasecki, A.; Ehrlich, H.; Jesionowski, T. Treatment of model solutions and wastewater containing selected hazardous metal ions using a chitin/lignin hybrid material as an effective sorbent. J. Environ. Manag. 2017, 204, 300–310. [Google Scholar] [CrossRef] [PubMed]

- Nair, V.; Panigrahy, A.; Vinu, R. Development of novel chitosan–lignin composites for adsorption of dyes and metal ions from wastewater. Chem. Eng. J. 2014, 254, 491–502. [Google Scholar] [CrossRef]

- Song, Z.; Li, W.; Liu, W.; Yang, Y.; Wang, N.; Wang, H.; Gao, H. Novel magnetic lignin composite sorbent for chromium(vi) adsorption. RSC Adv. 2015, 5, 13028–13035. [Google Scholar] [CrossRef]

- Li, Z.; Chen, J.; Ge, Y. Removal of lead ion and oil droplet from aqueous solution by lignin-grafted carbon nanotubes. Chem. Eng. J. 2017, 308, 809–817. [Google Scholar] [CrossRef]

- Okoronkwo, A.E.; Adebayo, A.O.; Omotunde, O.I. Sorptive removal of cadmium from aqueous solutions by Delonix regia derived lignin: Effect of amination. Desalin. Water Treat. 2013, 51, 5026–5034. [Google Scholar] [CrossRef]

- Xu, J.; Zhu, S.; Liu, P.; Gao, W.; Li, J.; Mo, L. Adsorption of Cu(ii) ions in aqueous solution by aminated lignin from enzymatic hydrolysis residues. RSC Adv. 2017, 7, 44751–44758. [Google Scholar] [CrossRef]

- Huang, C.; Shi, X.; Wang, C.; Guo, L.; Dong, M.; Hu, G.; Lin, J.; Ding, T.; Guo, Z. Boosted selectivity and enhanced capacity of As(V) removal from polluted water by triethylenetetramine activated lignin-based adsorbents. Int. J. Biol. Macromol. 2019, 140, 1167–1174. [Google Scholar] [CrossRef]

- Li, Z.; Xiao, D.; Kong, Y.; Ge, Y. Enhancing lead adsorption capacity by controlling the chain length of alkyl amine grafted lignin. BioResources 2015, 10, 2425–2432. [Google Scholar] [CrossRef][Green Version]

- Jin, C.; Zhang, X.; Xin, J.; Liu, G.; Wu, G.; Kong, Z.; Zhang, J. Clickable Synthesis of 1,2,4-Triazole Modified Lignin-Based Adsorbent for the Selective Removal of Cd(II). ACS Sustain. Chem. Eng. 2017, 5, 4086–4093. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, J.; Luo, X.; Lin, X. Adsorption of Hg(II) in aqueous solutions using mercapto-functionalized alkali lignin. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Ogunsile, B.O.; Bamgboye, M.O. Biosorption of Lead (II) onto soda lignin gels extracted from Nypa fruiticans. J. Environ. Chem. Eng. 2017, 5, 2708–2717. [Google Scholar] [CrossRef]

- Liu, C.; Li, Y.; Hou, Y. Preparation of a Novel Lignin Nanosphere Adsorbent for Enhancing Adsorption of Lead. Molecules 2019, 24, 2704. [Google Scholar] [CrossRef] [PubMed]

- Dizhbite, T.; Jashina, L.; Dobele, G.; Andersone, A.; Evtuguin, D.; Bikovens, O.; Telysheva, G. Polyoxometalate (POM)-aided modification of lignin from wheat straw biorefinery. Holzforschung 2013, 67, 539–547. [Google Scholar] [CrossRef]

- Ge, Y.; Li, Z.; Kong, Y.; Song, Q.; Wang, K. Heavy metal ions retention by bi-functionalized lignin: Synthesis, applications, and adsorption mechanisms. J. Ind. Eng. Chem. 2014, 20, 4429–4436. [Google Scholar] [CrossRef]

- Duan, Y.; Freyburger, A.; Kunz, W.; Zollfrank, C. Lignin/Chitin Films and Their Adsorption Characteristics for Heavy Metal Ions. ACS Sustain. Chem. Eng. 2018, 6, 6965–6973. [Google Scholar] [CrossRef]

- Pang, Y.; Wang, S.; Qiu, X.; Luo, Y.; Lou, H.; Huang, J. Preparation of Lignin/Sodium Dodecyl Sulfate Composite Nanoparticles and Their Application in Pickering Emulsion Template-Based Microencapsulation. J. Agric. Food. Chem. 2017, 65, 11011–11019. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Sun, D.; Wang, H.-M.; Yuan, T.-Q.; Sun, R.-C. Green and Facile Preparation of Regular Lignin Nanoparticles with High Yield and Their Natural Broad-Spectrum Sunscreens. ACS Sustain. Chem. Eng. 2019, 7, 2658–2666. [Google Scholar] [CrossRef]

- Abbati de Assis, C.; Greca, L.G.; Ago, M.; Balakshin, M.Y.; Jameel, H.; Gonzalez, R.; Rojas, O.J. Techno-Economic Assessment, Scalability, and Applications of Aerosol Lignin Micro- and Nanoparticles. ACS Sustain. Chem. Eng. 2018, 6, 11853–11868. [Google Scholar] [CrossRef]

- Nair, S.S.; Sharma, S.; Pu, Y.; Sun, Q.; Pan, S.; Zhu, J.Y.; Deng, Y.; Ragauskas, A.J. High Shear Homogenization of Lignin to Nanolignin and Thermal Stability of Nanolignin-Polyvinyl Alcohol Blends. ChemSusChem 2014, 7, 3513–3520. [Google Scholar] [CrossRef]

- Siddiqui, L.; Bag, J.; Seetha; Mittal, D.; Leekha, A.; Mishra, H.; Mishra, M.; Verma, A.K.; Mishra, P.K.; Ekielski, A.; et al. Assessing the potential of lignin nanoparticles as drug carrier: Synthesis, cytotoxicity and genotoxicity studies. Int. J. Biol. Macromol. 2020, 152, 786–802. [Google Scholar] [CrossRef]

- Österberg, M.; Sipponen, M.H.; Mattos, B.D.; Rojas, O.J. Spherical lignin particles: A review on their sustainability and applications. Green Chem. 2020, 22, 2712–2733. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, M.; Yuan, Q.; Cheng, G. Controlled Preparation of Corncob Lignin Nanoparticles and their Size-Dependent Antioxidant Properties: Toward High Value Utilization of Lignin. ACS Sustain. Chem. Eng. 2019, 7, 17166–17174. [Google Scholar] [CrossRef]

- Agustin, M.B.; Penttilä, P.A.; Lahtinen, M.; Mikkonen, K.S. Rapid and Direct Preparation of Lignin Nanoparticles from Alkaline Pulping Liquor by Mild Ultrasonication. ACS Sustain. Chem. Eng. 2019, 7, 19925–19934. [Google Scholar] [CrossRef]

- Liu, Z.-H.; Hao, N.; Shinde, S.; Pu, Y.; Kang, X.; Ragauskas, A.J.; Yuan, J.S. Defining lignin nanoparticle properties through tailored lignin reactivity by sequential organosolv fragmentation approach (SOFA). Green Chem. 2019, 21, 245–260. [Google Scholar] [CrossRef]

- Xiong, F.; Han, Y.; Wang, S.; Li, G.; Qin, T.; Chen, Y.; Chu, F. Preparation and Formation Mechanism of Renewable Lignin Hollow Nanospheres with a Single Hole by Self-Assembly. ACS Sustain. Chem. Eng. 2017, 5, 2273–2281. [Google Scholar] [CrossRef]

- Ma, M.; Dai, L.; Xu, J.; Liu, Z.; Ni, Y. A simple and effective approach to fabricate lignin nanoparticles with tunable sizes based on lignin fractionation. Green Chem. 2020, 22, 2011–2017. [Google Scholar] [CrossRef]

- Iravani, S.; Varma, R.S. Greener synthesis of lignin nanoparticles and their applications. Green Chem. 2020, 22, 612–636. [Google Scholar] [CrossRef]

- Figueiredo, P.; Lintinen, K.; Hirvonen, J.T.; Kostiainen, M.A.; Santos, H.A. Properties and chemical modifications of lignin: Towards lignin-based nanomaterials for biomedical applications. Prog. Mater Sci. 2018, 93, 233–269. [Google Scholar] [CrossRef]

- Shikinaka, K.; Nakamura, M.; Otsuka, Y. Strong UV absorption by nanoparticulated lignin in polymer films with reinforcement of mechanical properties. Polymer 2020, 190, 122254. [Google Scholar] [CrossRef]

- Chen, L.; Shi, Y.; Gao, B.; Zhao, Y.; Jiang, Y.; Zha, Z.; Xue, W.; Gong, L. Lignin Nanoparticles: Green Synthesis in a γ-Valerolactone/Water Binary Solvent and Application to Enhance Antimicrobial Activity of Essential Oils. ACS Sustain. Chem. Eng. 2020, 8, 714–722. [Google Scholar] [CrossRef]

- Hrůzová, K.; Matsakas, L.; Sand, A.; Rova, U.; Christakopoulos, P. Organosolv lignin hydrophobic micro- and nanoparticles as a low-carbon footprint biodegradable flotation collector in mineral flotation. Bioresour. Technol. 2020, 306, 123235. [Google Scholar] [CrossRef]

- Rahman, O.u.; Shi, S.; Ding, J.; Wang, D.; Ahmad, S.; Yu, H. Lignin nanoparticles: Synthesis, characterization and corrosion protection performance. New J. Chem. 2018, 42, 3415–3425. [Google Scholar] [CrossRef]

- Dai, L.; Liu, R.; Hu, L.-Q.; Zou, Z.-F.; Si, C.-L. Lignin Nanoparticle as a Novel Green Carrier for the Efficient Delivery of Resveratrol. ACS Sustain. Chem. Eng. 2017, 5, 8241–8249. [Google Scholar] [CrossRef]

- Tian, D.; Hu, J.; Bao, J.; Chandra, R.P.; Saddler, J.N.; Lu, C. Lignin valorization: Lignin nanoparticles as high-value bio-additive for multifunctional nanocomposites. Biotechnol. Biofuels 2017, 10, 192. [Google Scholar] [CrossRef]

- Yang, W.; Owczarek, J.S.; Fortunati, E.; Kozanecki, M.; Mazzaglia, A.; Balestra, G.M.; Kenny, J.M.; Torre, L.; Puglia, D. Antioxidant and antibacterial lignin nanoparticles in polyvinyl alcohol/chitosan films for active packaging. Ind. Crops Prod. 2016, 94, 800–811. [Google Scholar] [CrossRef]

| Lignin | Monomer/Prepolymer | Copolymer | Application | Ref. |

|---|---|---|---|---|

| Kraft lignin | methyl methacrylate | lignin-PMMA | nanofiber | [46] |

| Kraft lignin | Styrene | lignin-PS | thermoplastics | [49] |

| soda lignin | hyperbranched poly(ester-amine-amide) | lignin-HBPEAA | memory polymer | [48] |

| Kraft lignin | acrylic acid (AA) | lignin-PAA | dispersant, flocculant | [44] |

| alkali lignin | poly(ethylene glycol) methacrylate (PEGMA) | lignin-PEGMA | UV-blocker | [50] |

| alkali lignin | ε-caprolatone, L-lactide | lignin-PCLLA | nanofiber | [45] |

| pyrolytic lignin | L-lactide | lignin-PLA | composites | [51] |

| Kraft lignin | acrylamide, diallyldimethylammonium chloride | lignin-PAM-PDADMAC | flocculant | [52] |

| Kraft lignin | ε-caprolatone | lignin-PCL | thermoplastics | [53] |

| alkali lignin | β-butyrolactone | lignin-PHB | nanofiber | [47] |

| Adsorbent | Heavy Metal | Adsorption Capacity (mg/g) | pH | T (°C) | Ref. |

|---|---|---|---|---|---|

| Alkaline lignin | Cd (II) | 63.6 | 5 | 28 | [97] |

| Alkaline lignin | Cu (II) | 26.0 | 6 | 20 | [89] |

| Organosolv lignin (softwood) | Cu (II) | 1.38 | 5.3 | 24 | [92] |

| Organosolv lignin (softwood) | Cd (II) | 0.92 | 6.5 | 24 | [92] |

| Organosolv lignin (hardwood) | Cu (II) | 2.56 | 5.3 | 24 | [92] |

| Organosolv lignin (hardwood) | Cd (II) | 2.06 | 6.5 | 24 | [92] |

| Lignin/chitin film | Cu (II) | 0.28 | 3–4 | R.T | [107] |

| Lignin/chitin film | Fe (III) | 1.21 | 3–4 | R.T | [107] |

| Lignin/chitin hybrid material | Ni (II) | 70.4 | 5 | 25 | [93] |

| Lignin/chitin hybrid material | Cu (II) | 75.7 | 5 | 25 | [93] |

| Lignin/chitin hybrid material | Zn (II) | 82.4 | 5 | 25 | [93] |

| Lignin/chitin hybrid material | Pb (II) | 91.7 | 5 | 25 | [93] |

| Aminated lignin | Cd (II) | 43.2 | 5 | 28 | [97] |

| Aminated lignin | Cu (II) | 37.1 | 5.5 | 40 | [98] |

| Aminated lignin | As (V) | 62.5 | 9 | 25 | [99] |

| Triazole modifed lignin | Cd (II) | 87.4 | 6 | 25 | [101] |

| Mercapto modified alkali lignin | Hg (II) | 101.2 | 4 | 20 | [102] |

| Carboxymethyl lignin | Pb (II) | 333.3 | 6 | 30 | [104] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.-Y.; Meng, X.; Pu, Y.; J. Ragauskas, A. Recent Advances in the Application of Functionalized Lignin in Value-Added Polymeric Materials. Polymers 2020, 12, 2277. https://doi.org/10.3390/polym12102277

Wang Y-Y, Meng X, Pu Y, J. Ragauskas A. Recent Advances in the Application of Functionalized Lignin in Value-Added Polymeric Materials. Polymers. 2020; 12(10):2277. https://doi.org/10.3390/polym12102277

Chicago/Turabian StyleWang, Yun-Yan, Xianzhi Meng, Yunqiao Pu, and Arthur J. Ragauskas. 2020. "Recent Advances in the Application of Functionalized Lignin in Value-Added Polymeric Materials" Polymers 12, no. 10: 2277. https://doi.org/10.3390/polym12102277

APA StyleWang, Y.-Y., Meng, X., Pu, Y., & J. Ragauskas, A. (2020). Recent Advances in the Application of Functionalized Lignin in Value-Added Polymeric Materials. Polymers, 12(10), 2277. https://doi.org/10.3390/polym12102277