Tribological Performance of Nylon Composites with Nanoadditives for Self-Lubrication Purposes

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Specimen Preparation

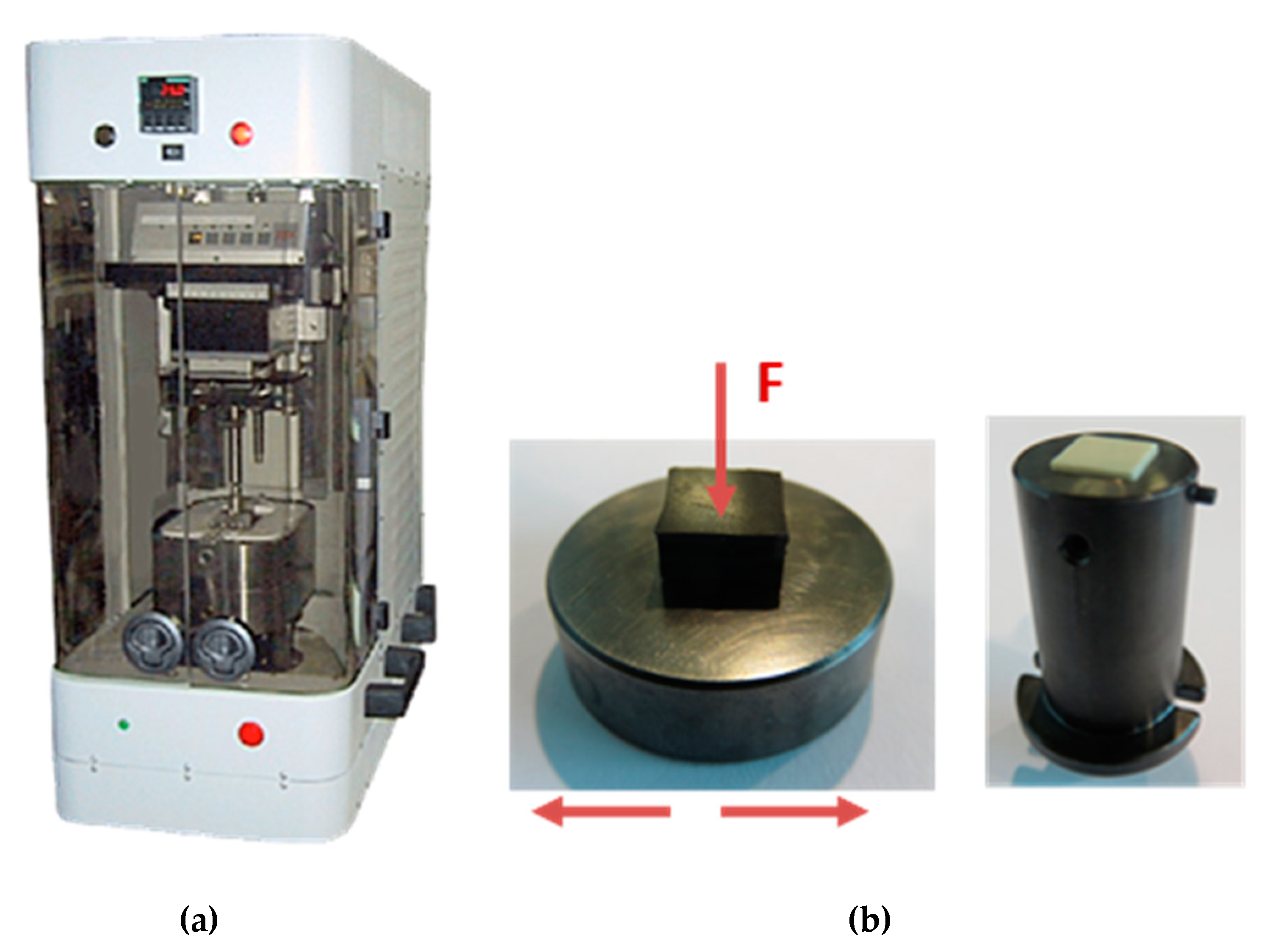

2.3. Pin on Disc Tests

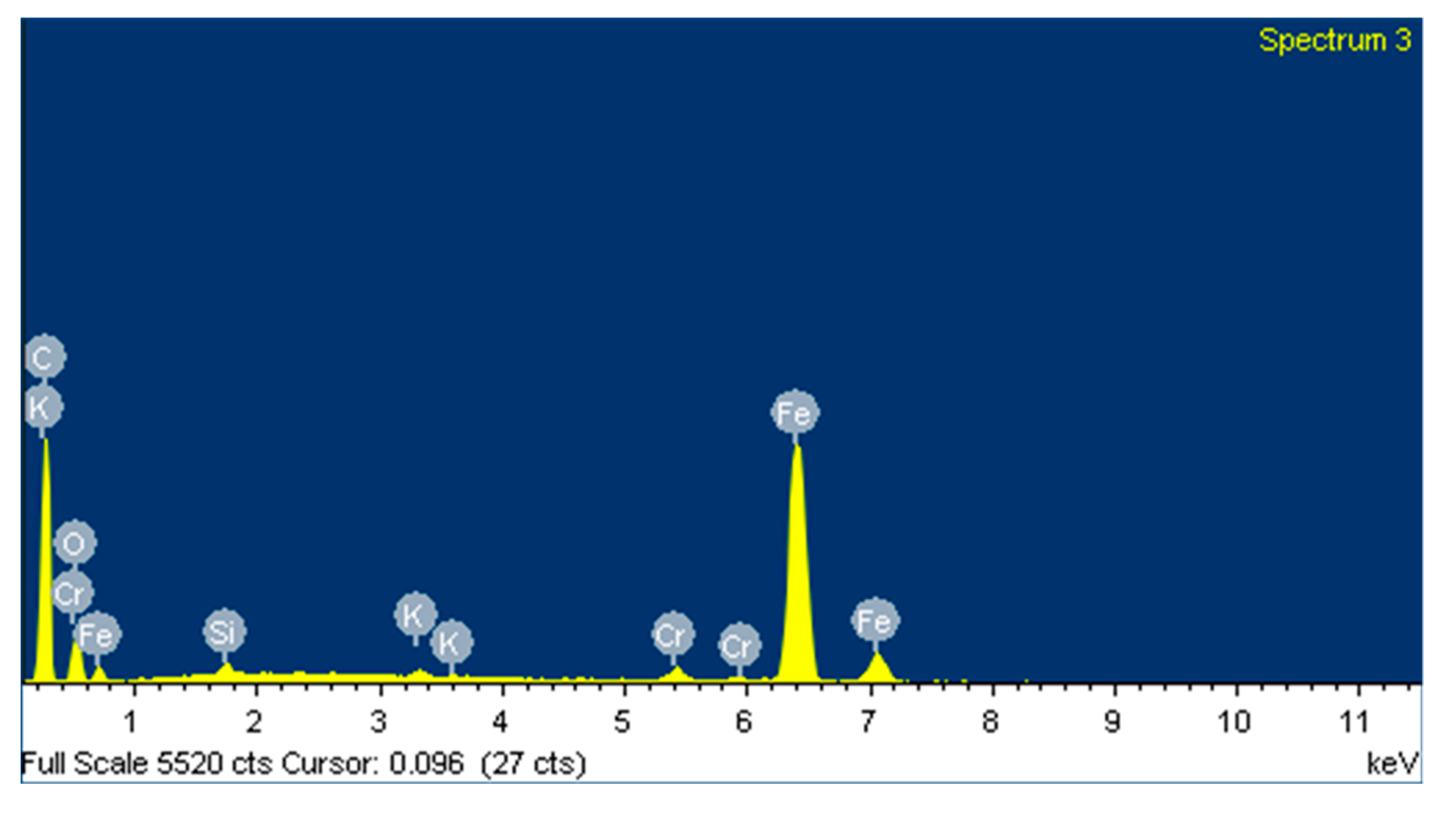

2.4. SEM and EDS Analysis

3. Results and Discussion

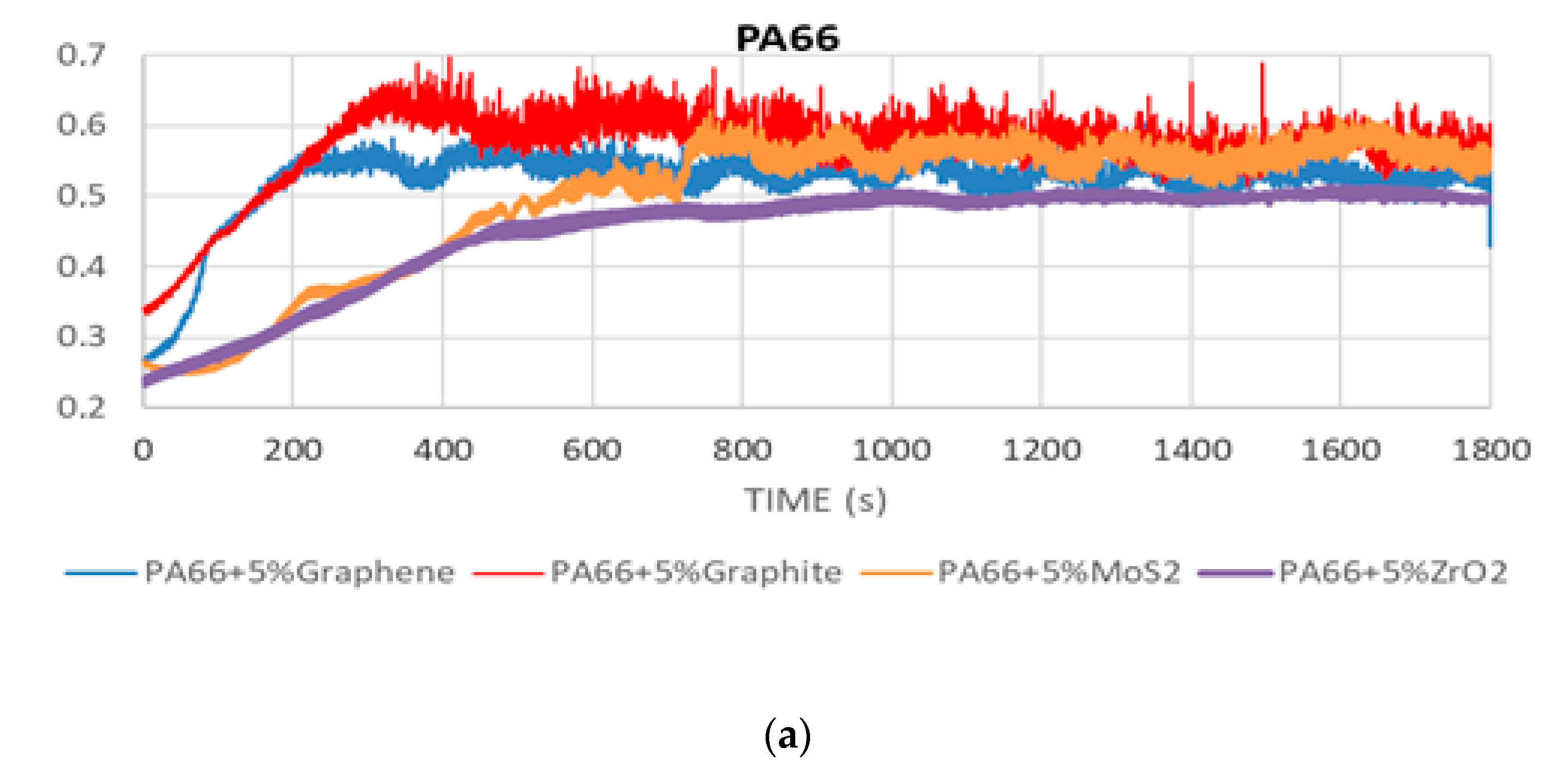

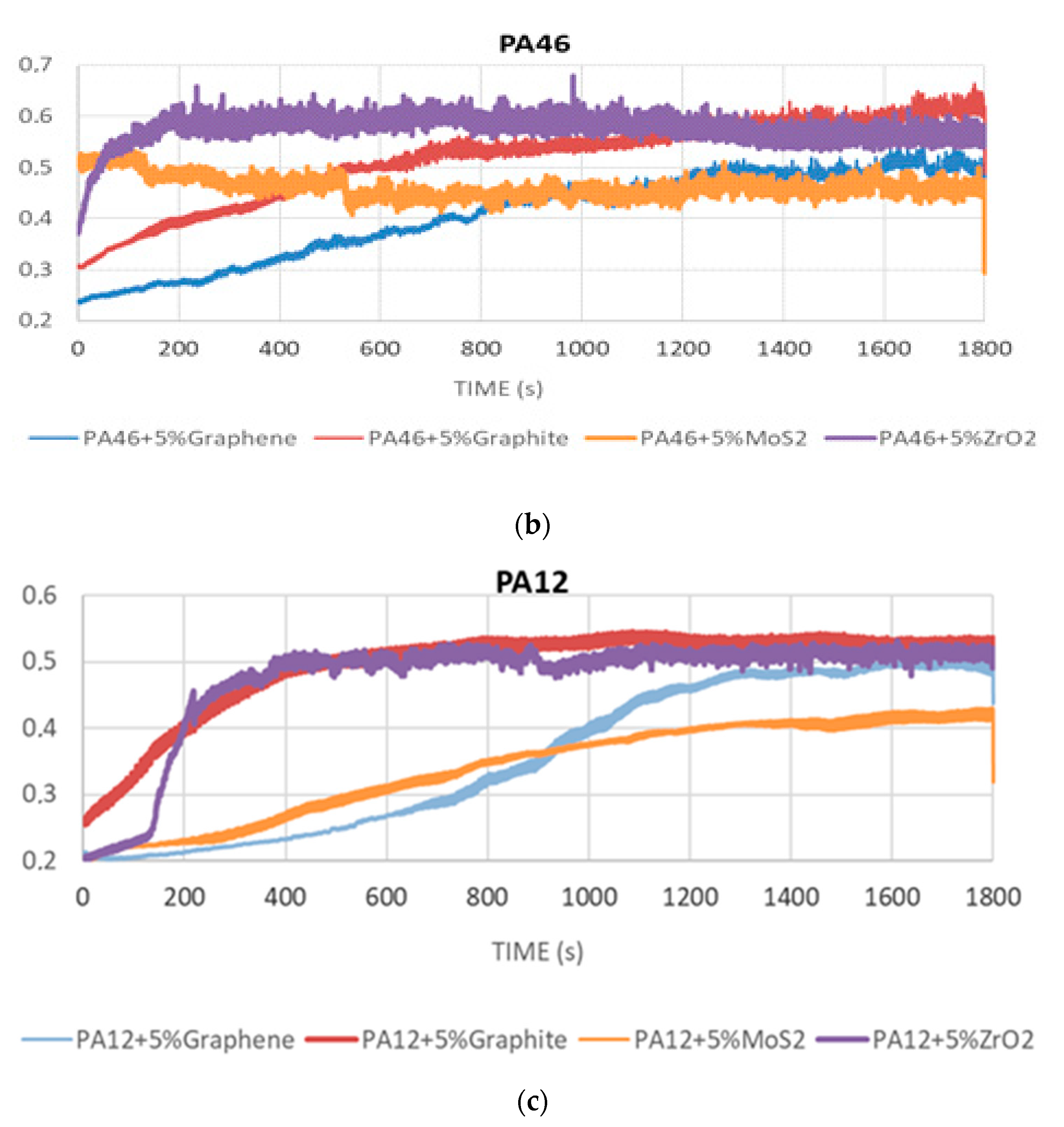

3.1. Coefficient of Friction and Wear

3.2. Influence of Nanoadditives

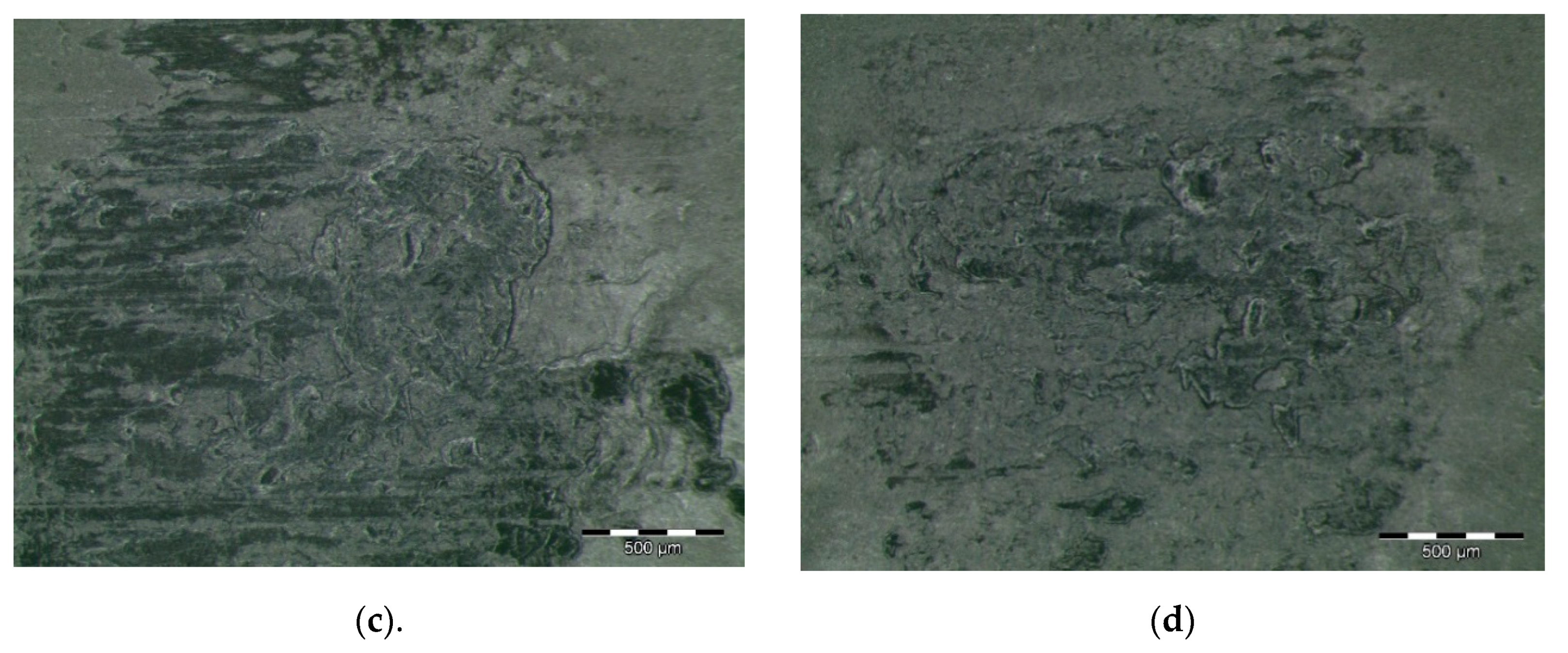

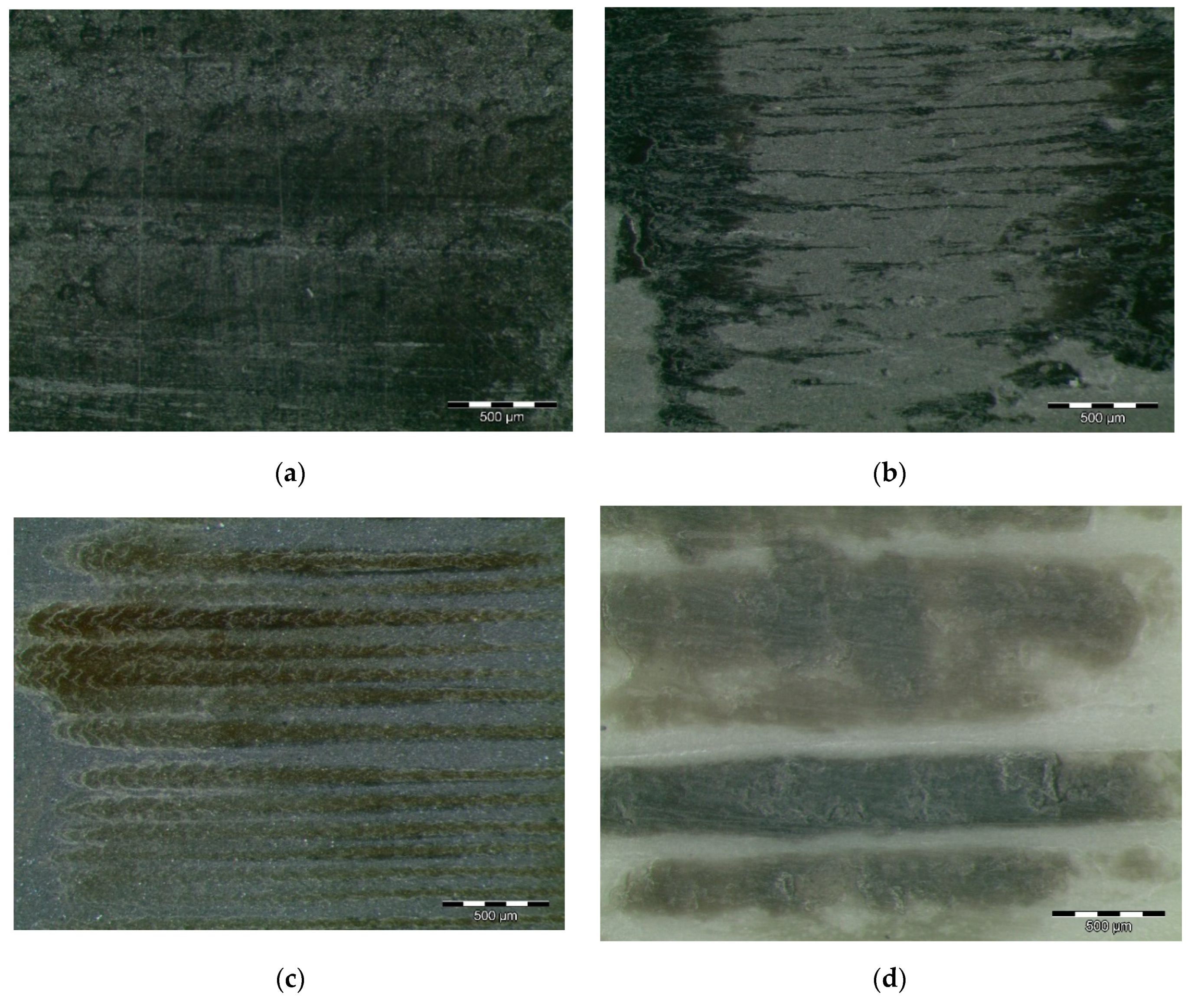

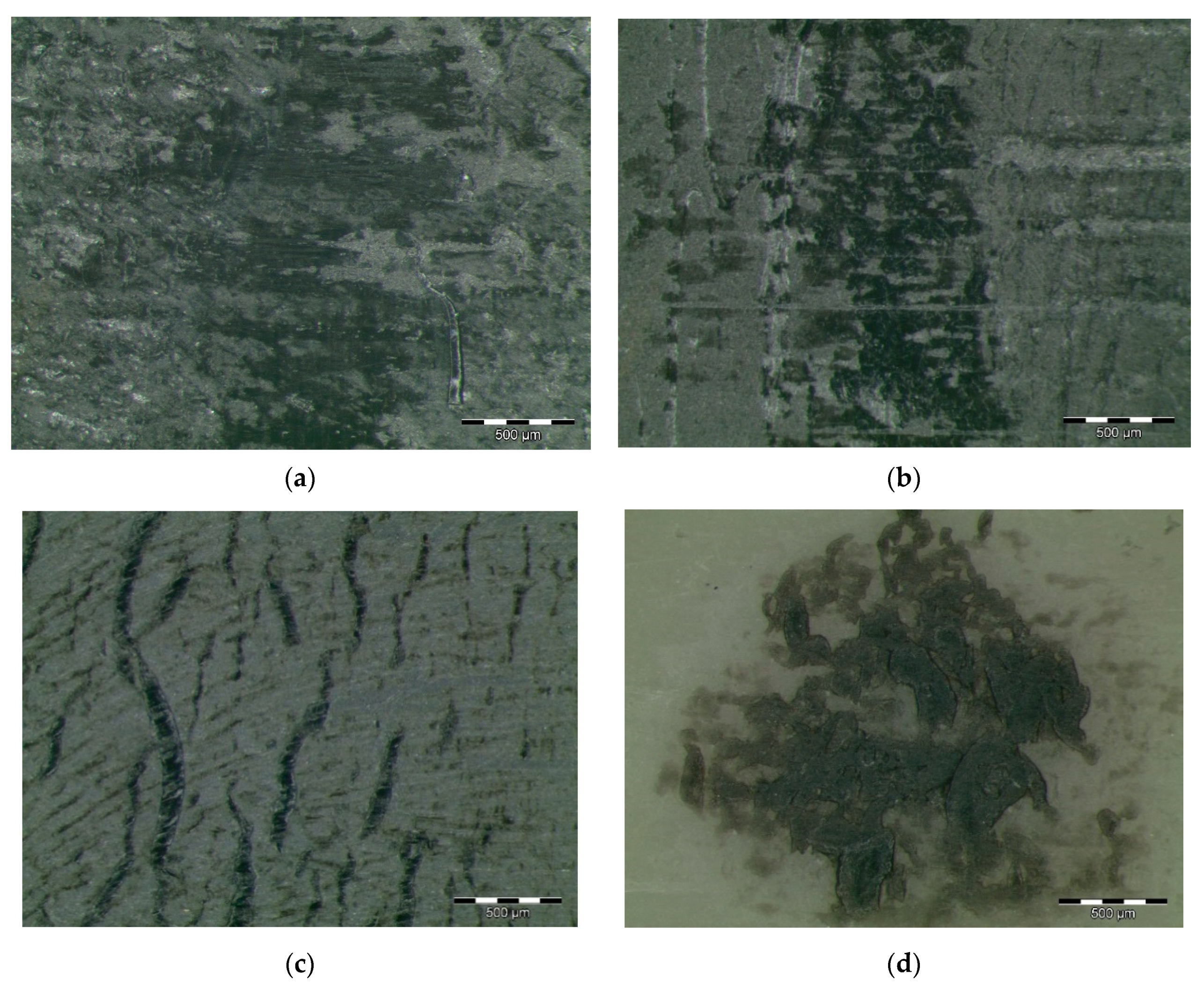

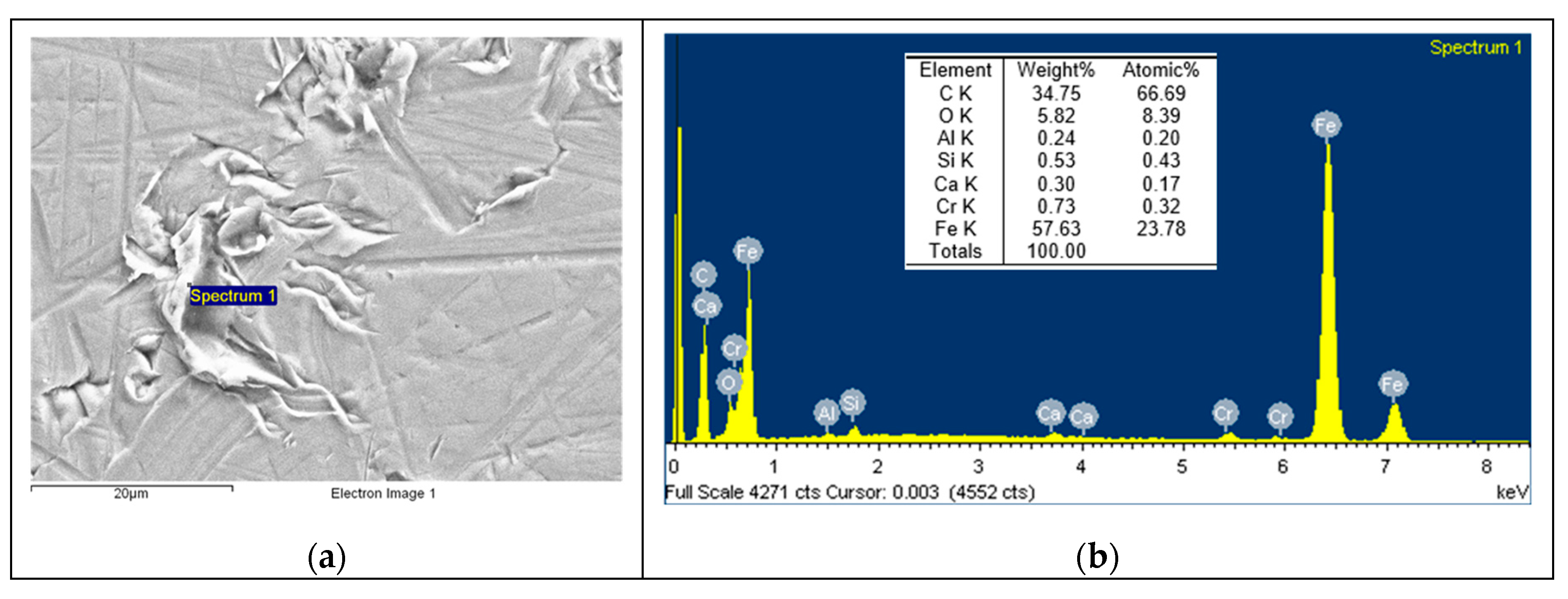

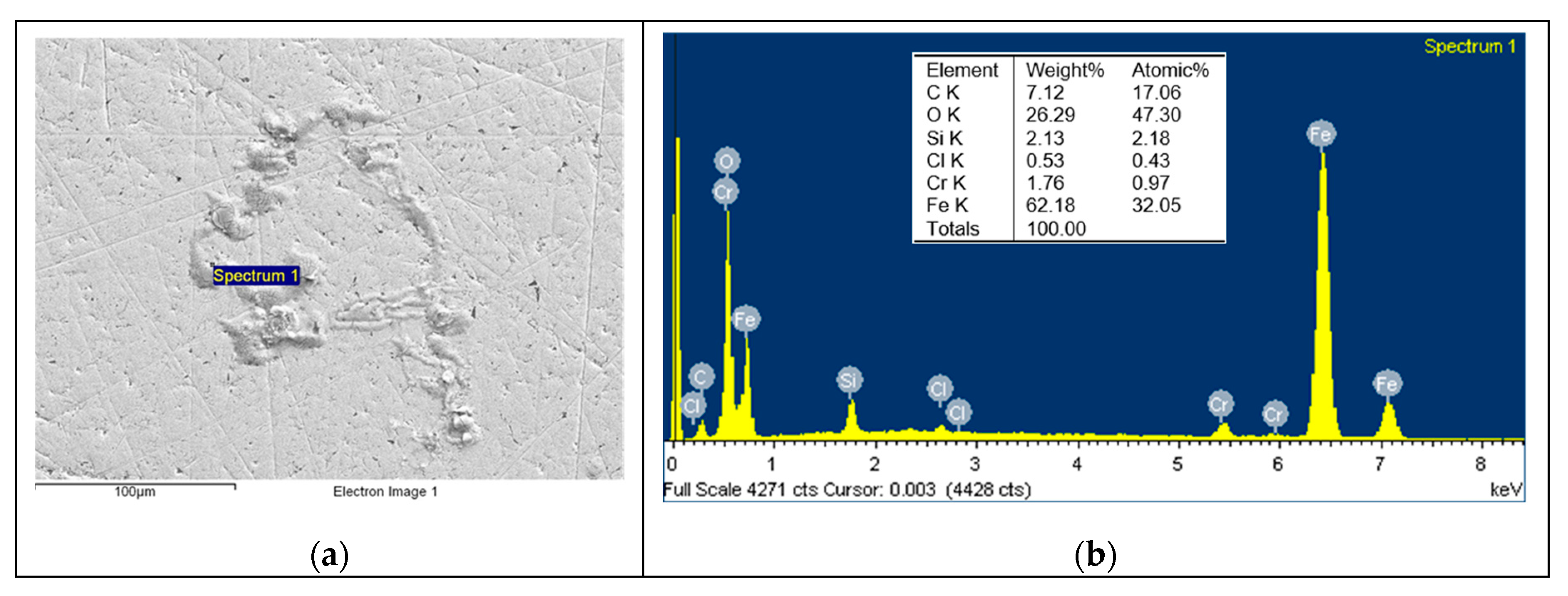

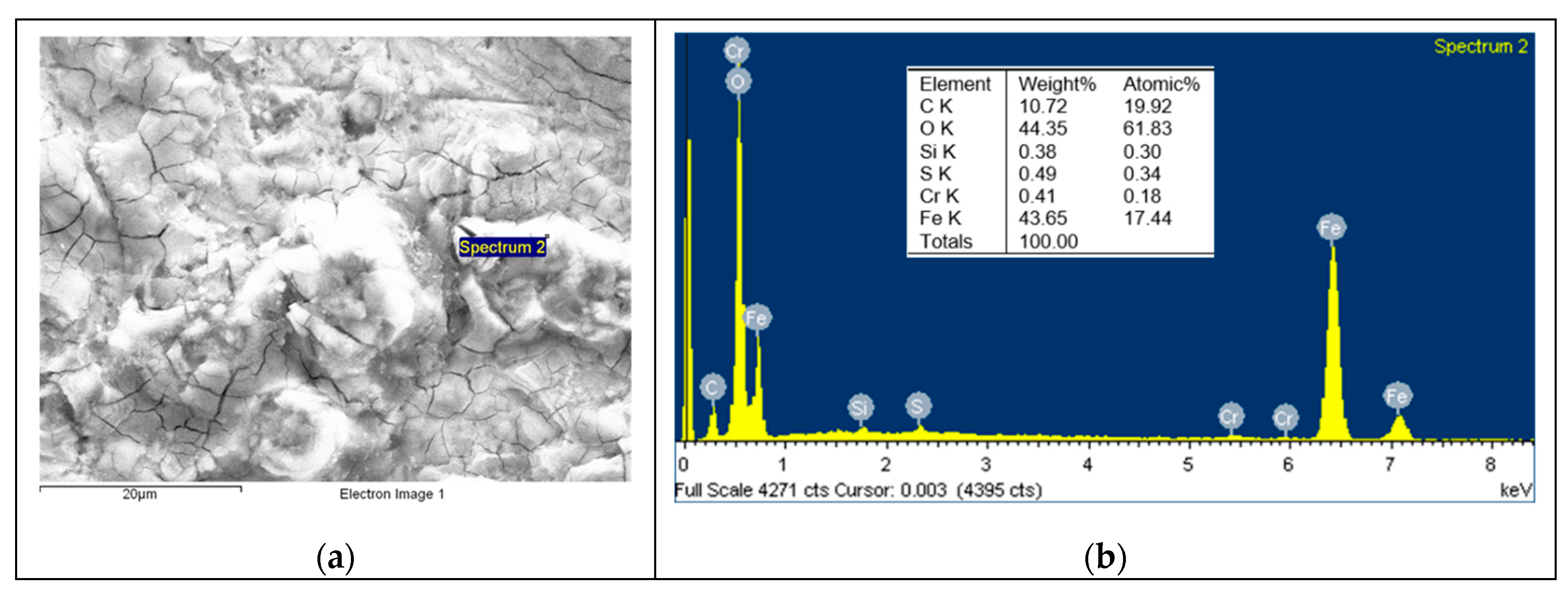

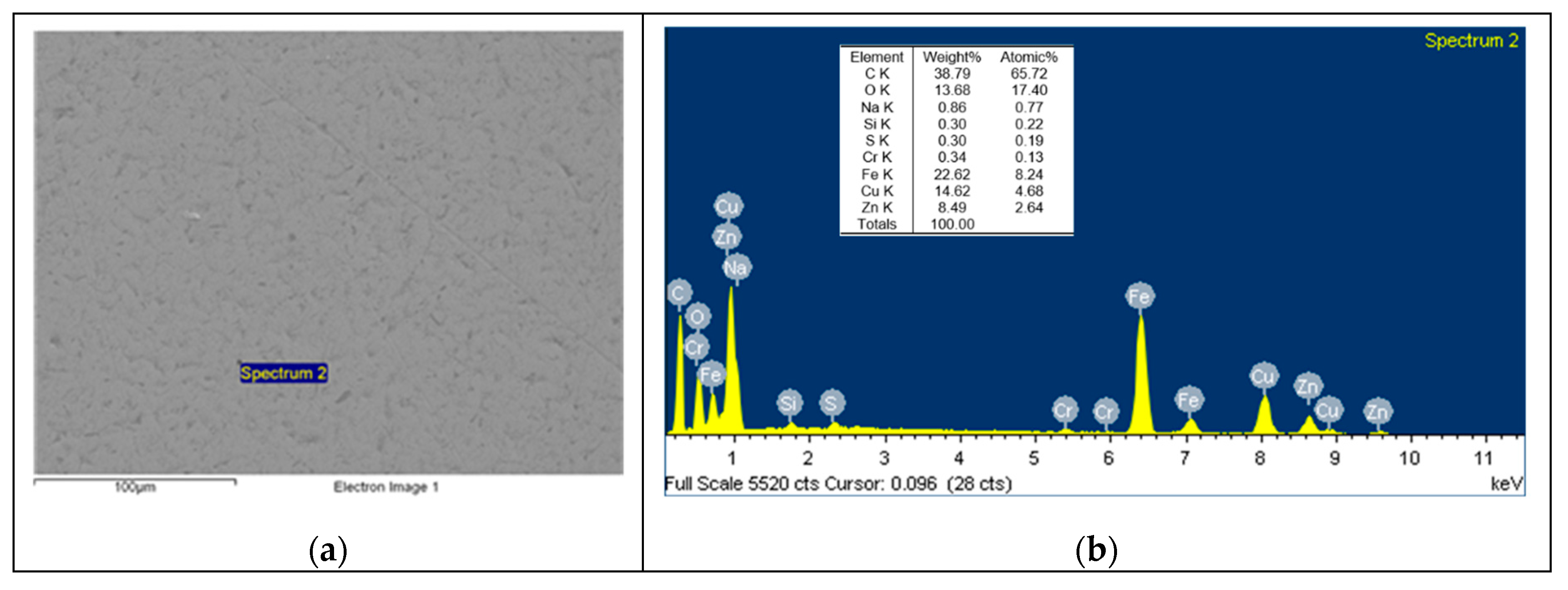

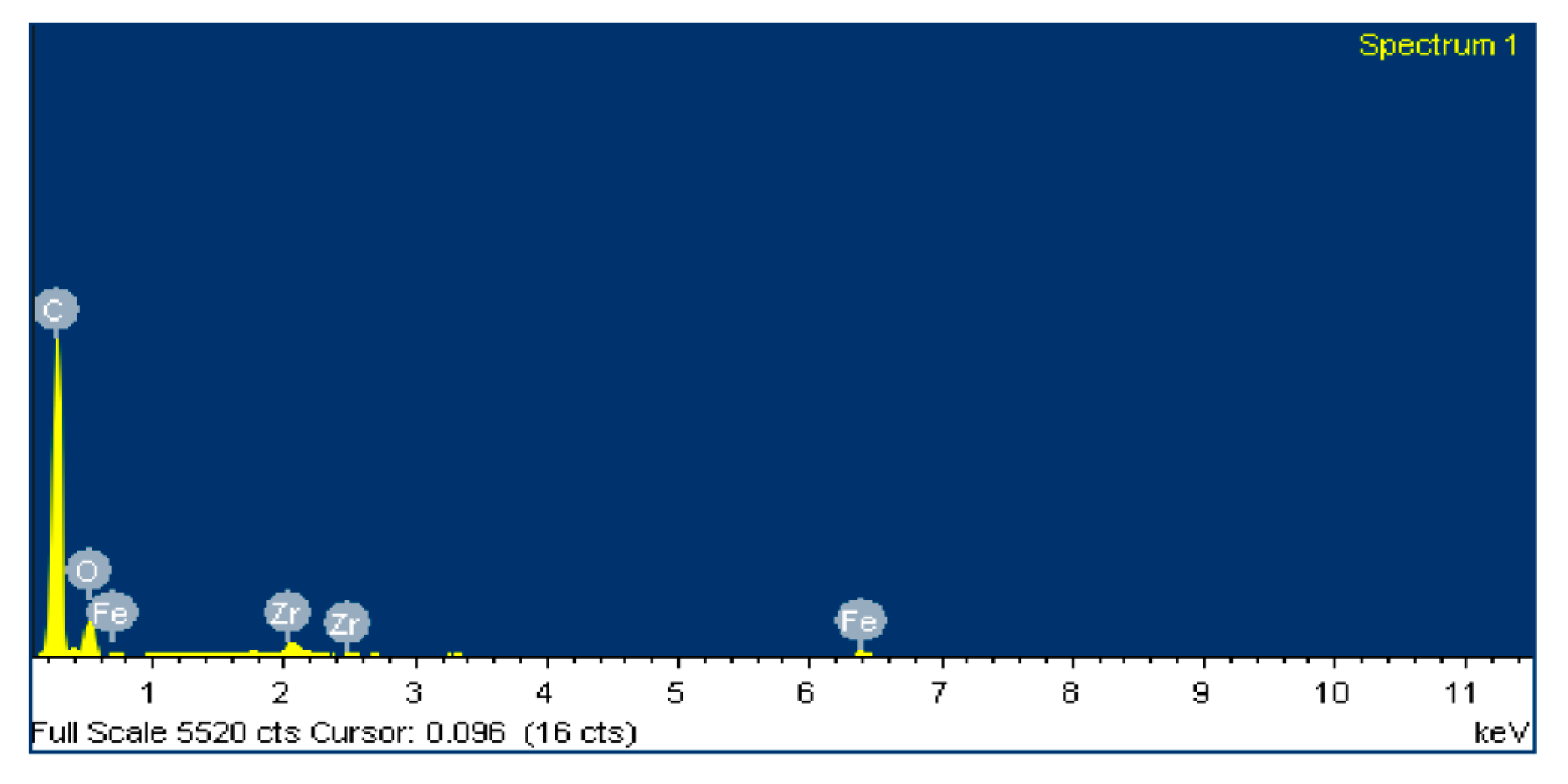

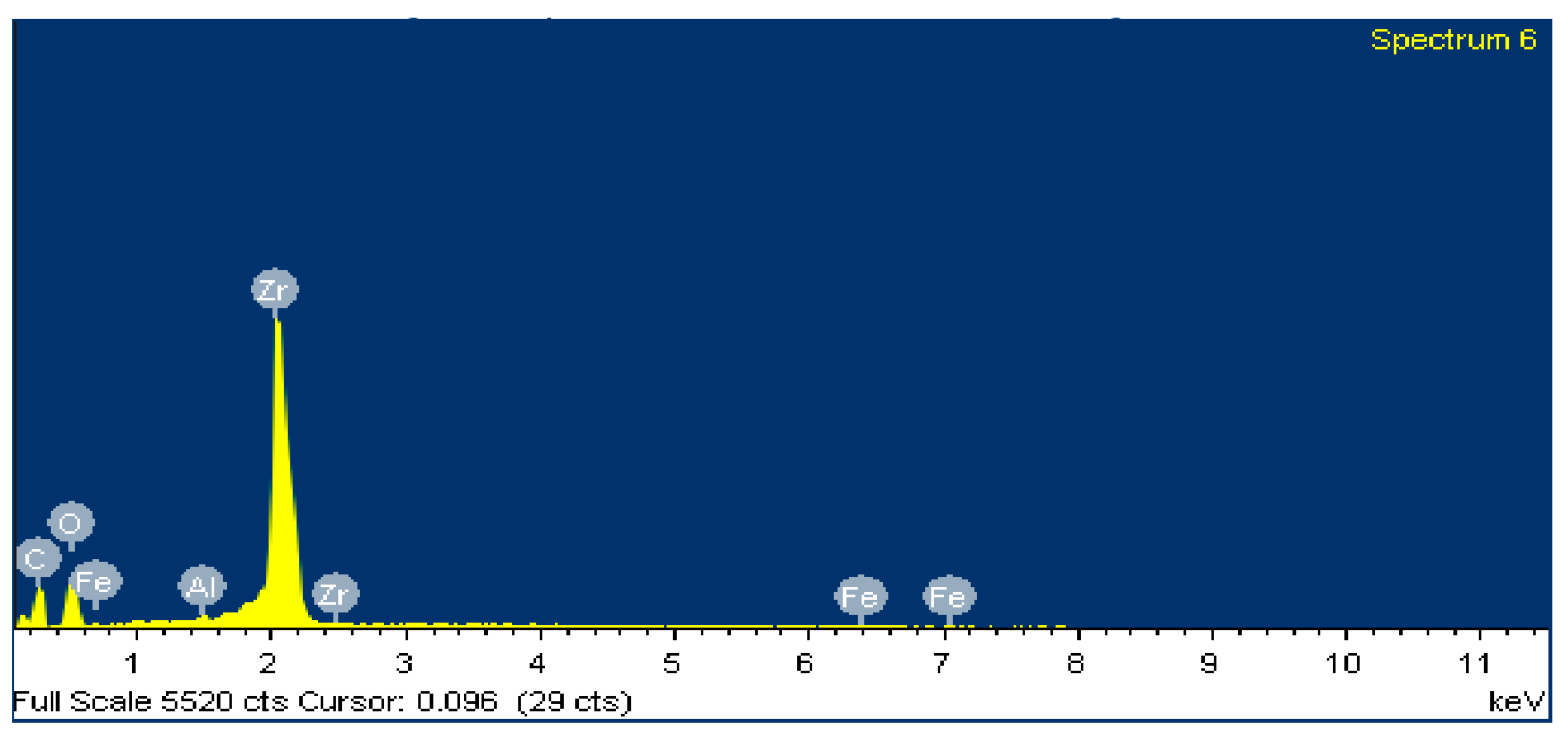

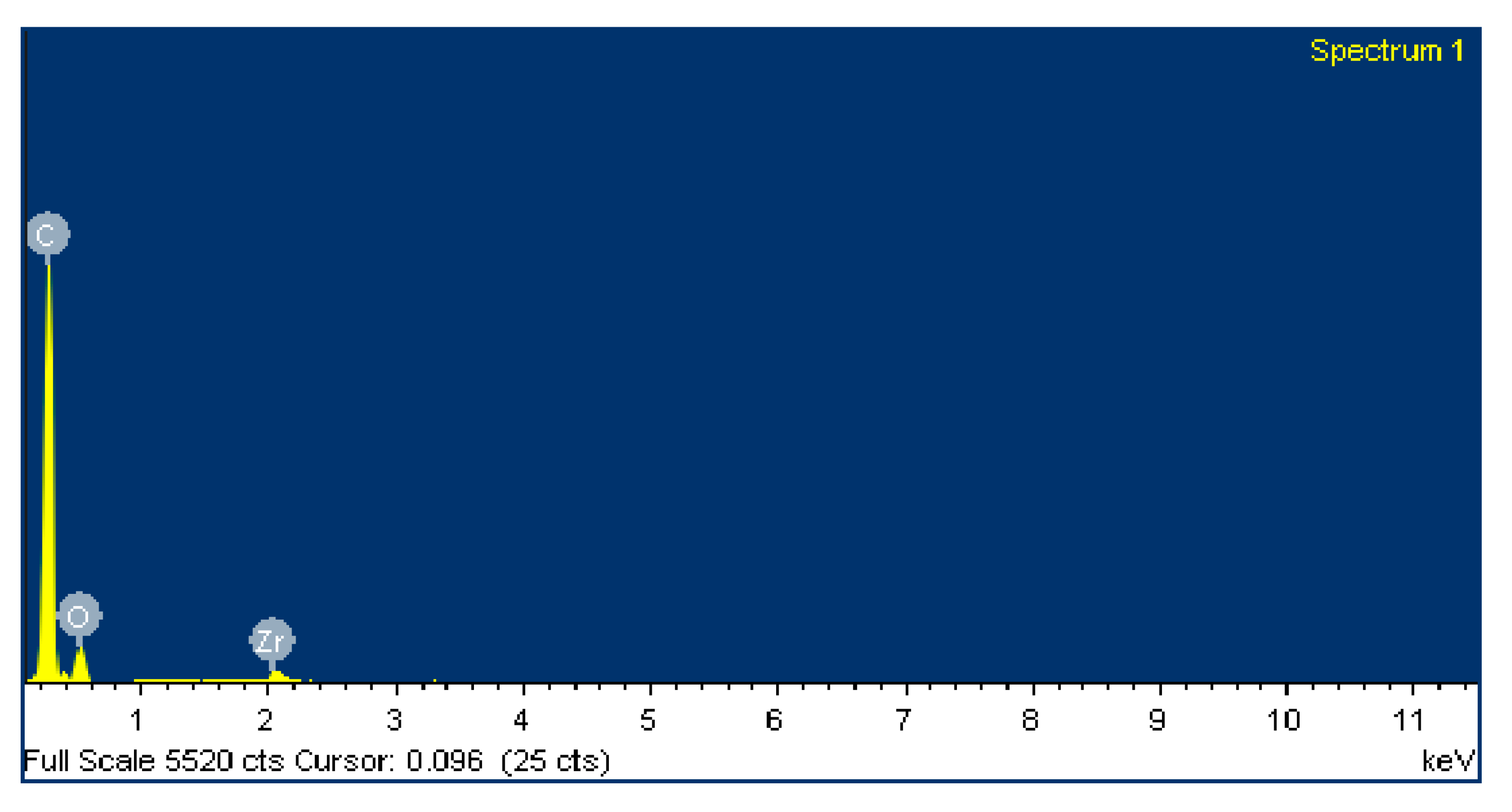

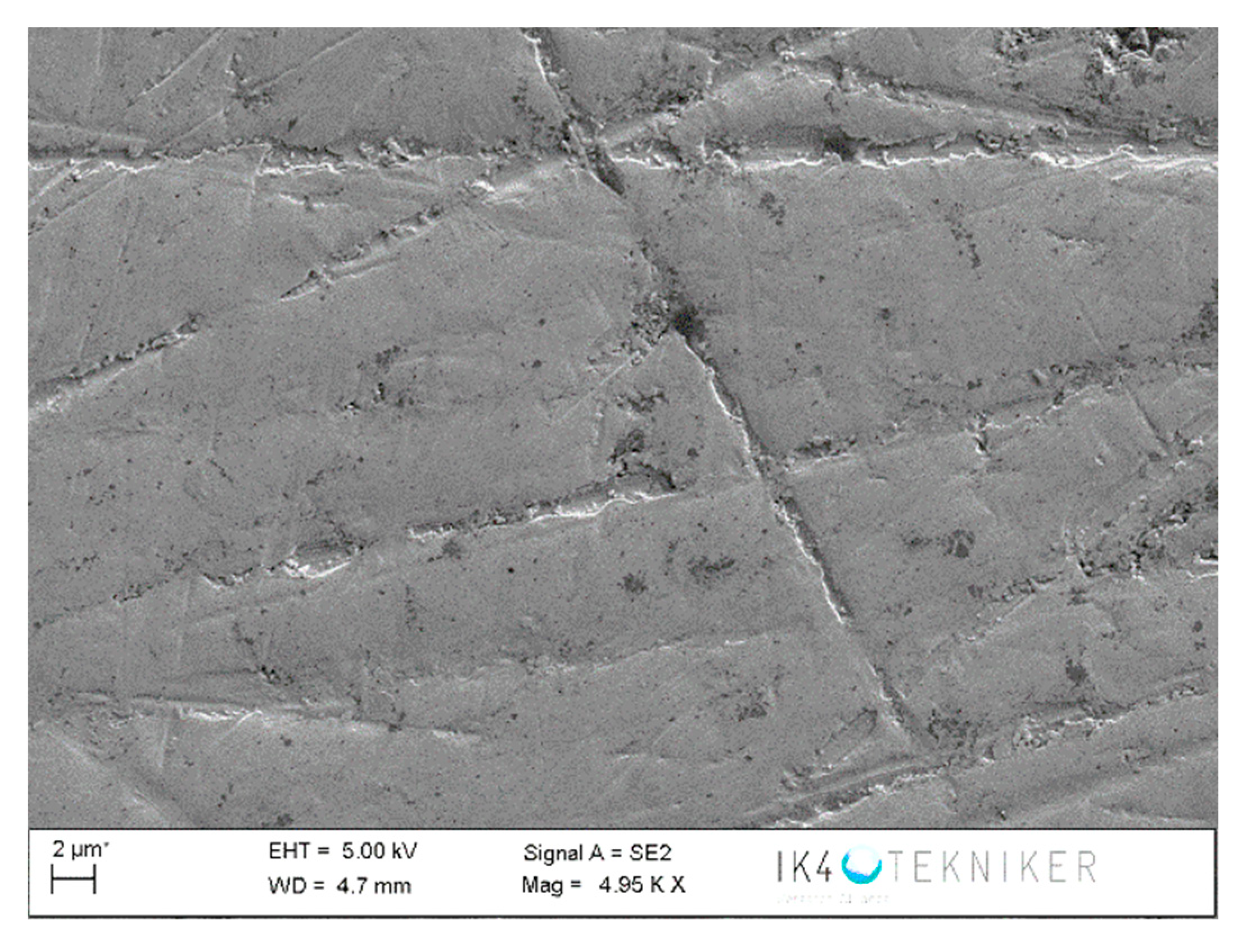

3.3. Characterisation of the Worn Surface

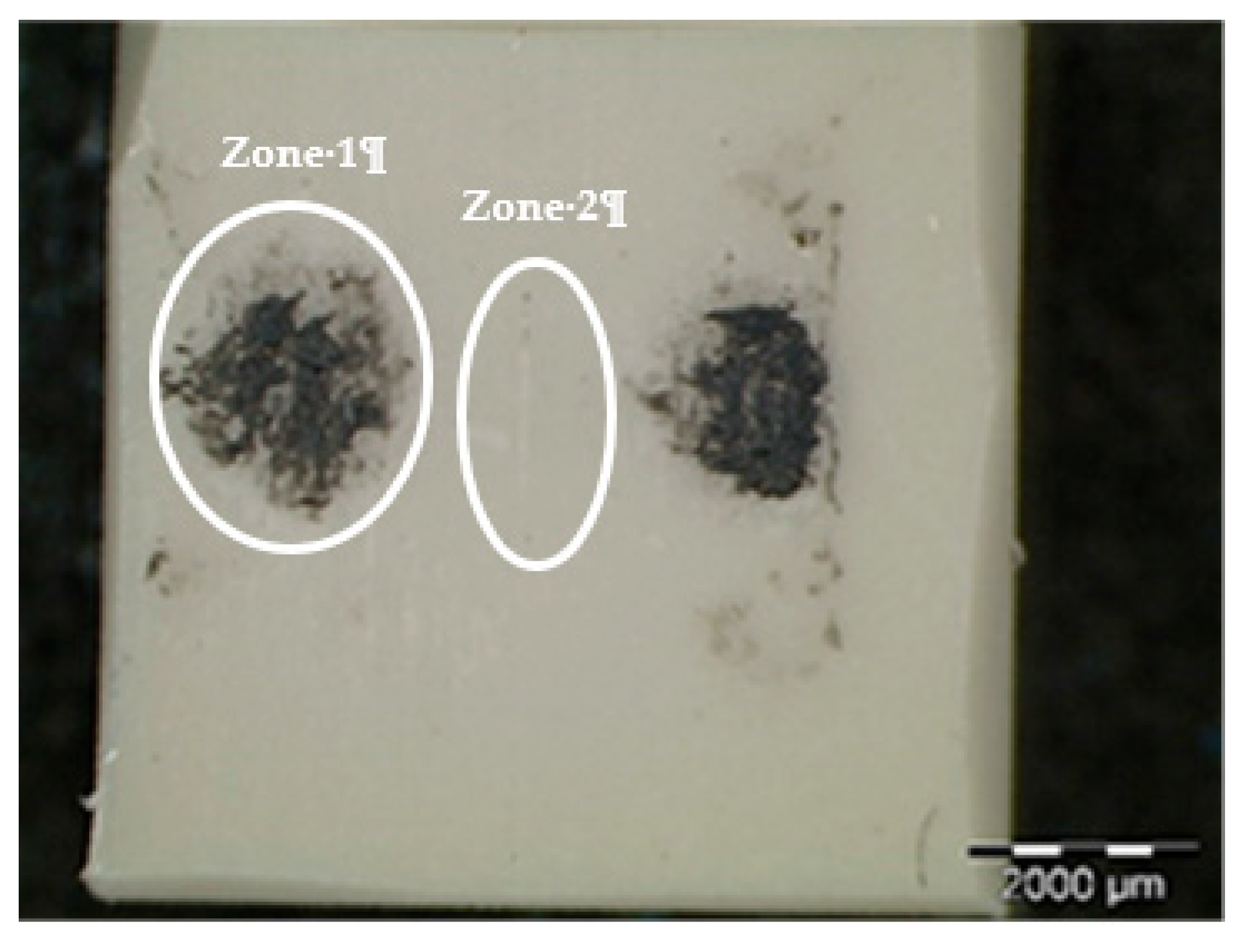

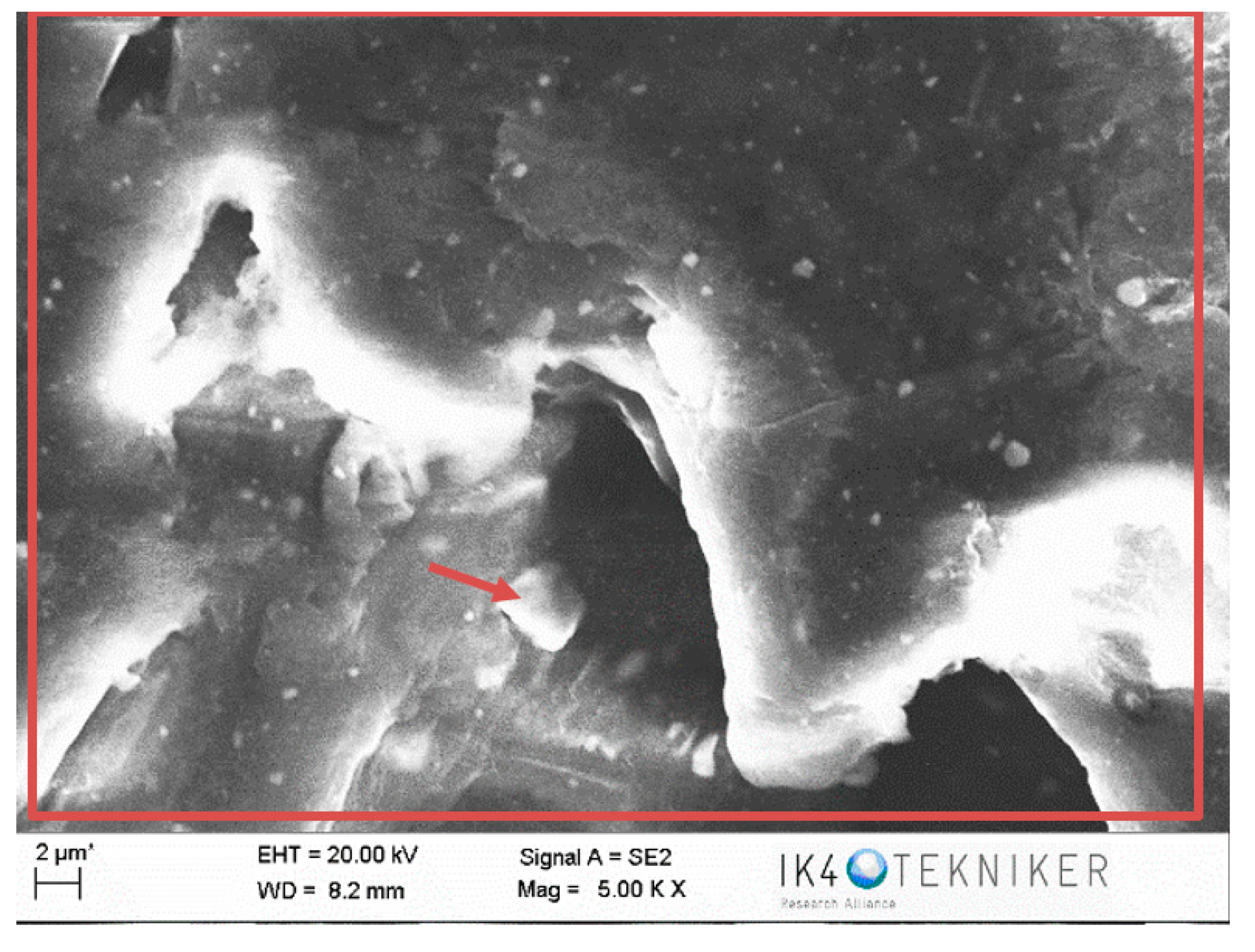

3.4. Analysis of Wear in ZrO2 Composites

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Holmberg, K.; Andersson, P.; Nylund, N.-O.; Mäkelä, K.; Erdemir, A. Global energy consumption due to friction in trucks and buses. Tribol. Int. 2014, 78, 94–114. [Google Scholar] [CrossRef]

- Jost, H.P. Tribology: Origin and future. Wear 1990, 136, 1–17. [Google Scholar] [CrossRef]

- Morita, T.; Andatsu, K.; Hirota, S.; Kumakiri, T.; Ikenaga, M.; Kagaya, C. Effect of Hybrid Surface Treatment Composed of Plasma Nitriding and DLC Coating on Friction Coefficient and Fatigue Strength of Stainless Steel. Mater. Trans. 2013, 54, 732–735. [Google Scholar] [CrossRef] [Green Version]

- Ceschini, L.; Chiavari, C.; Marconi, A.; Martini, C. Influence of the countermaterial on the dry sliding friction and wear behaviour of low temperature carburised AISI316L Steel. Tribol. Int. 2013, 67, 36–37. [Google Scholar] [CrossRef]

- Clavería, I.; Lostalé, A.; Fernández, A.; Castell, P.; Elduque, D.; Mendoza, G.; Zubizarreta, C. Enhancement of tribological behaviour of rolling bearings by applying a multilayer ZrN/ZrCN coating. Coatings 2019, 9, 434. [Google Scholar] [CrossRef] [Green Version]

- Lin, Z.; Sun, F.; Shen, B. Friction properties of polished CVD diamond films sliding against different metals. Surf. Rev. Lett. 2016, 23, 1550096. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, H.; Dong, J. Tribological Properties of Magnesium Ion-exchanged α-Zirconium Phosphate as a Solid Lubricant Additive in Lithium Grease. J. Wuham Univ. Tech. Mater. Sci. 2019, 34, 47–54. [Google Scholar] [CrossRef]

- Holmberg, K.; Ronkainen, H.; Matthews, A. Tribology of thin coatings. Ceram. Int. 2000, 26, 787–795. [Google Scholar] [CrossRef]

- Clavería, I.; Elduque, D.; Lostalé, A.; Fernández, A.; Castell, P. Analysis of self-lubrication enhancement via PA66 strategies: Texturing and nano-reinforcement with ZrO2 and graphene. Tribol. Int. 2019, 131, 332–342. [Google Scholar] [CrossRef]

- Ai, S.; Wang, W.; Wang, Y.; Zhao, Z. Temperature rise of double-row tapered roller bearings analysed with thermal network method. Tribol. Int. 2015, 87, 11–22. [Google Scholar] [CrossRef]

- Zhao, X.; Liang, L.; Liu, Z. Tapered Roller Bearings Cage to Improvement Design. Indones. J. Electr. Eng. 2014, 12, 1855–1859. [Google Scholar]

- Neis, P.D.; Ferreira, N.F.; Poletto, J.C.; Sukumaran, J.; Ando, M.; Zhang, Y. Tribological behavior of polyamide-6 plastics and their potential use in industrial applications. Wear 2017, 376, 1391–1398. [Google Scholar] [CrossRef]

- Kastan, A.; Unal, H. Abrasive wear behaviour of polyamide 6/polypropylene/nanoclay composites. Rom. J. Mater. 2018, 48, 185–190. [Google Scholar]

- Blanchet, T.A.; Kennedy, F.E. Sliding wear mechanism of polytetrafluoroethylene (PTFE) and PTFE composites. Wear 1992, 153, 229–243. [Google Scholar] [CrossRef]

- Seo, W.S.; Choe, B.; Lee, Y.; Lee, J.K. Wear of Polymer Composite Solid Lubricants for Cryogenic Ball Bearing Cages. In Proceedings of the Asia International Conference on Tribology 2018, Kuching, Sarawak, 17–20 September 2018; pp. 271–272. [Google Scholar]

- Gu, D.; Zhang, L.; Chen, S.; Song, K.; Liu, S. Significant Reduction of the Friction and Wear of PMMA Based Composite by Filling with PTFE. Polymers 2018, 10, 966. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, J. The effect of PTFE on the mechanical and friction and wear properties of GF/PA6 composites. Adv. Mater. Res. 2011, 284–286, 2370–2373. [Google Scholar] [CrossRef]

- Moder, J.; Grun, F.; Summer, F.; Kohlhauser, M.; Wohlfahrt, M. Application of high performance composite polymers with steel counterparts in dry rolling/sliding contacts. Polym. Test. 2018, 66, 371–382. [Google Scholar] [CrossRef]

- Song, J.F.; Zhao, G.; Ding, Q.J.; Qiu, J.H. Reciprocating friction and wear of polyimide composites filled with solid lubricants. J. Polym. Eng. 2018, 38, 363–370. [Google Scholar] [CrossRef]

- Xibata, K.; Fukuda, M.; Yamaguchi, T. Relationship between sliding induced wear and severity of sliding contact for polyamide66 filled with hard filler. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2017, 231, 783–790. [Google Scholar] [CrossRef]

- Pogacnik, A.; Kupec, A.; Kalin, M. Tribological properties of polyamide (PA6) in self-mated contacts and against steel as a stationary and moving body. Wear 2017, 378–379, 17–26. [Google Scholar] [CrossRef]

- Lenfeld, P.; Bĕhálek, L.; Boruvka, M.; Prusek, J. Dynamic-Mechanical Properties of Polymer Composites with the Short and Long Glass Fibers. Mater. Sci. Forum 2016, 862, 166–173. [Google Scholar] [CrossRef]

- Huynh, D.S.T.; Le, H.G.; Nguyen, T.N.H.; Pham, S.M. Enhancing the Fatigue Property of Nylon 6 by Using Glass-Fiber Reinforcement and Injection Molding. Mater. Sci. Forum 2019, 971, 85–90. [Google Scholar] [CrossRef]

- Gordon, D.H.; Kukureka, S.N. The wear and friction of polyamide 46 and polyamide 46/aramid-fibre Kumar, S.S.; Kanagaraj, J. Investigation on Mechanical and Tribological Behaviours of PA6 and Graphite-Reinforced PA6 Polymer Composites. Arab. J. Sci. Eng. 2016, 41, 4347–4357. [Google Scholar]

- Rajamani, G.; Paulraj, J.; Krishnan, K. Analysis of wear behaviour of graphene oxide—Polyamide gears for engineering applications. Surf. Rev. Lett. 2019, 24, 1850018. [Google Scholar] [CrossRef]

- Hassan, A.E.M.; Eid, A.I.; El-Sheikh, M.; Ali, W.Y. Mechanical and tribological performance of polyamide 12 reinforced with graphene nanoplatelets and paraffin oil nanocomposites. Mater. Werkst. 2019, 50, 74–85. [Google Scholar] [CrossRef] [Green Version]

- Karami, P.; Shojaei, A. Improvement of dry sliding tribological properties of polyamide 6 using diamond nanoparticles. Tribol. Int. 2017, 115, 370–377. [Google Scholar] [CrossRef]

- Khandanur, S.S.; Rafiee, M.A.; Yavari, F.; Schrameyer, M.; Yu, Z.; Blanchet, T.A.; Koratkar, N. Suppression of wear in graphene polymer composites. Carbon 2012, 50, 3178–3183. [Google Scholar] [CrossRef]

- Kalin, M.; Zalaznik, M.; Novak, S. Wear and friction behaviour of poly-ether-ether-ketone (PEEK) filled with graphene, WS2 and CNT nanoparticles. Wear 2015, 332–333, 855–863. [Google Scholar] [CrossRef]

- Yan, S.; Yang, Y.; Song, L.; Qi, X.; Xue, Y.; Duan, C. Tribological Behaviour of Graphite Oxide Reinforced Polyethersulfone Composite Under Drying Sliding Condition. Polym. Compos. 2018, 39, 2320–2335. [Google Scholar] [CrossRef]

- Quiang, L.; Xu, F.; Voisey, K.T.; Nekouie, W.; Zhou, Z.; Silberschmidt, V.V.; Hou, X. Incorporation and evolution of ZrO2 nanoparticles in Pt-modified aluminide coating for high-temperature applications. Surf. Coat. Technol. 2017, 31, 238–247. [Google Scholar] [CrossRef]

- Ma, J.; Xu, C.H.; Yi, M.D.; Xiao, G.C.; Wang, X.H. Friction and wear property of Ti(C, N)/ ZrO2/WC nano-composite cermet die material. Adv. Mater. Res. 2013, 834–836, 23–28. [Google Scholar] [CrossRef]

- Song, J.; Liu, Y.; Liao, Z.; Wang, S.; Tyagi, R.; Liu, W. Wear studies on ZrO2-filled PEEK as coating bearing materials for artificial cervical discs of Ti6Al4V. Mater. Sci. Eng. C 2016, 69, 985–994. [Google Scholar] [CrossRef] [PubMed]

- Mordina, B.; Tiwari, R.K. A comparative study of mechanical and tribological properties of poly (ether ether ketone) composites filled by micro- and nano-Ni and ZrO2 fillers. J. Compos. Mater. 2013, 47, 2835–2845. [Google Scholar] [CrossRef]

- Cao, W.; Gong, J.; Qi, Y.; Yang, D.; Gao, G.; Wang, H.; Ren, J.; Chen, S. Tribological Behaviour of Nano-ZrO2 Reinforced PTFE-PPS Composites. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2019, 34, 527–533. [Google Scholar] [CrossRef]

- Vazirisereshk, M.R.; Martini, A.; Strubbe, D.A.; Mehmet, Z.; Baykara, M.Z. Solid Lubrication with MoS2: A Review. Lubricants 2019, 7, 57. [Google Scholar] [CrossRef] [Green Version]

- Zalaznik, M.; Novak, S.; Huskic, M.; Kalin, M. Tribological behaviour of a PEEK polymer-containing solid MoS2 lubricants. Lubr. Sci. 2016, 28, 27–42. [Google Scholar] [CrossRef]

- Theiler, G.; Gradt, T. Friction and wear of PEEK composites in vacuum environment. Wear 2010, 269, 278–284. [Google Scholar] [CrossRef]

- Wang, L.; Shi, B.; Hu, E.; Hu, K.; Hu, X. Reuse of spent bleaching clay for supporting MoS2 nanoparticles as a lubricating filler in ABS plastics. Tribol. Int. 2019, 131, 415–423. [Google Scholar] [CrossRef]

- Xin, Y.; Li, T.; Gong, D.; Xu, F.; Wang, M. Preparation and tribological properties of graphene oxide/nano-MoS2 hybrid as multidimensional assembly used in the polyimide nanocomposites. RSC Adv. 2017, 7, 6323–6335. [Google Scholar] [CrossRef] [Green Version]

- You, Y.; Li, D.; Si, G.; Deng, X. Investigation of the influence of solid lubricants on the tribological properties of polyamide 6 composite. Wear 2014, 311, 57–64. [Google Scholar] [CrossRef]

- Basavaraj, E.; Ramaraj, B.; Lee, J.; Siddaramaiah. Microstructure, Thermal, Physico–Mechanical and Tribological Characteristics of Molybdenum Disulphide-Filled Polyamide 66/Carbon Black Composites. Polym. Eng. Sci. 2013, 53, 1676–1686. [Google Scholar] [CrossRef]

- Horovistiz, A.; Laranjeira, S.; Davim, J.P. Influence of sliding velocity on the tribological behaviour of PA66GF30 and PA66 + MoS2: An analysis of morphology of sliding surface by digital image processing. Polym. Bull. 2018, 75, 5113–5131. [Google Scholar] [CrossRef]

- Bai, J.; Song, J.; Wei, J. Tribological and mechanical properties of MoS2 enhanced polyamide 12 for selective laser sintering. J. Mater. Process. Technol. 2019, 264, 382–388. [Google Scholar] [CrossRef]

- Sahoo, R.R.; Biswas, S.K. Deformation and friction of MoS2 particles in liquid suspensions used to lubricate sliding contact. Thin Solid Films 2010, 518, 5995–6005. [Google Scholar] [CrossRef]

- Zhu, G.P.; Sun, J.L.; Wang, B.; Wang, Y.Z. Study on Tribological Properties of the Rolling Fluid Containing Nano-MoS2 for Cold Rolling of Steel Strip. China Pet. Process. Petrochem. Technol. 2011, 13, 64–69. [Google Scholar]

- Singh, K.K.; Prabhu, B.R.; Choudhary, S.; Pramanik, C. Effect of Graphene and MoS2 Flakes in Industrial Oils to Enhance Lubrication. ACS Omega 2019, 4, 14569–14578. [Google Scholar] [CrossRef] [Green Version]

- Sahoo, R.R.; Biswas, S.K. Microtribology and Friction-Induced Material Transfer in Layered MoS2 Nanoparticles Sprayed on a Steel Surface. Tribol. Lett. 2010, 37, 313–326. [Google Scholar] [CrossRef]

- Han, H.L.; Qian, Z.Y. Tribological performances of graphite-MoS2 coating at various high temperatures. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2019, 233, 1888–1902. [Google Scholar] [CrossRef]

- Mutyala, K.C.; Wu, Y.M.A.; Erdemir, A.; Sumant, A.V. Graphene—MoS2 ensembles to reduce friction and wear in DLC-Steel contacts. Carbon 2019, 146, 524–527. [Google Scholar] [CrossRef]

- Zhang, X.; Liao, G.; Jin, Q.; Feng, X.; Jian, X. On dry sliding friction and wear behaviour of PPESK filled with PTFE and graphite. Tribol. Int. 2008, 41, 195–201. [Google Scholar] [CrossRef]

- BADAMID A70 S Technical Datasheet. 2008. Available online: http://www.performance-plastics.co.uk/wp-content/uploads/TD_Badamid_A70_S.pdf (accessed on 17 January 2020).

- Stanyl® TW341 Technical Datasheet. 2018. Available online: https://plasticsfinder.com/en/datasheet/Stanyl%C2%AE+TW341/V67x4 (accessed on 17 January 2020).

- BADAMID® PA12H Technical Datasheet. 2011. Available online: http://www.performance-plastics.co.uk/wp-content/uploads/PA12-TDS.pdf (accessed on 17 January 2020).

- MICROZIR® ULTRAFINE Technical DATA SHEET. 2018. Available online: http://www.chilchesmaterials.com/producto/microzir-ultrafine-2/ (accessed on 17 January 2020).

- Brugarolas, S.L. 2020. Available online: https://brugarolas.com (accessed on 17 January 2020).

- Graphene Tech S.L. 2016. Available online: http://www.graphene-tech.net/ (accessed on 17 January 2020).

- Blanco, M.; Sarasua, J.A.; López, M.; Gonzalo, O.; Marcaide, A.; Muniesa, M.; Fernández, A. Ultrasound Assisted Extrusion of Polyamide 6 Nanocomposites Based on Carbon Nanotubes. Macromol. Symp. 2012, 321–322, 80–83. [Google Scholar] [CrossRef]

- Muniesa, M.; Fernández, A.; Clavería, I.; Javierre, C.; Sarasua, J.A.; Blanco, M. A new extrusion head with integrated ultrasonic device and online process parameters measurements system—Design and testing. Polimery 2015, 60, 209–216. [Google Scholar] [CrossRef]

- Bahadur, S. The development of transfer layers and their role in polymer tribology. Wear 2000, 245, 92–99. [Google Scholar] [CrossRef]

- Quaglini, V.; Dubini, P.; Ferroni, D.; Poggi, C. Influence of counterface roughness on friction properties of engineering plastics for bearing applications. Mater. Des. 2009, 30, 1650–1658. [Google Scholar] [CrossRef]

- Meng, H.; Sui, G.X.; Sie, G.Y.; Yang, R. Friction and wear behaviour of carbon nanotubes reinforced polyamide 6 composites under dry sliding and water-lubricated condition. Compos. Sci. Technol. 2009, 69, 606–611. [Google Scholar] [CrossRef]

- PA46 Technical Data. 2020. Available online: https://www.designerdata.nl/kunststoffen/thermoplasten/PA46?cookie=YES (accessed on 17 January 2020).

- Boric, A.; Kalendová, A.; Urbanek, M.; Pepelnjak, T. Characterisation of Polyamide (PA) 12 Nanocomposites with Montmorillonite (MMT) Filler Clay Used for the Incremental Forming of Sheets. Polymers 2019, 11, 1248. [Google Scholar] [CrossRef]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior Thermal Conductivity of Single-Layer Graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef]

- Li, Z.; Sun, W.G.; Wang, G.; Wu, Z.G. Experimental and numerical study on the effective thermal conductivity of paraffin/expanded graphite composite. Sol. Energy Mater. Solar Cells 2014, 128, 447–455. [Google Scholar] [CrossRef]

- Aiyiti, A.; Bai, X.; Wu, J.; Xu, X.; Li, B. Measuring the thermal conductivity and interfacial thermal resistance of suspended MoS2 using electron beam self-heating technique. Sci. Bull. 2018, 63, 452–458. [Google Scholar] [CrossRef] [Green Version]

- Orain, S.; Scudeller, Y.; Brousse, T. Thermal conductivity of ZrO2 thin films. Int. J. Therm. Sci. 2000, 39, 537–543. [Google Scholar] [CrossRef]

- Yan, S.; Yan, Y.; Song, L.; Qi, X.; Zuo, Z.; Xue, Y. Tribological property of 3-aminopropyltriethoxysilane-graphite oxide nanosheets reinforced polyethersulfone composite under drying sliding condition. Tribol. Int. 2016, 103, 316–330. [Google Scholar] [CrossRef]

- Yu, L.; Yang, S.; Liu, W.; Xue, Q. An investigation of the friction and wear behaviours of polyphenylene sulfide filled with solid lubricants. Polym. Eng. Sci. 2010, 40, 1825–1832. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, X.; Pei, X. Study on the synergistic effect of carbon fibre and graphite and nanoparticle on the friction and wear behaviour of polyimide composites. Mater. Des. 2010, 31, 3761–3768. [Google Scholar] [CrossRef]

- Suresha, B.; Chandramohan, G.; Renukappa, M.N.; Siddaramaiah. Mechanical and Tribological Properties of Glass–Epoxy Composites with and Without Graphite Particulate Filler. J. Appl. Polym. Sci. 2007, 103, 2472–2480. [Google Scholar] [CrossRef]

- Kim, S.S.; Shin, M.W.; Jang, H. Tribological properties of short glass fibre reinforced polyamide 12 sliding on medium carbon steel. Wear 2012, 274–275, 34–42. [Google Scholar] [CrossRef]

- Yamada, Y.; Kurobe, T.; Toyooka, Y. XPS study of transfer films of MoS2 filled nylon-46 composites sliding against steel counterfaces. J. Mater. Sci. Lett. 2001, 20, 577–579. [Google Scholar] [CrossRef]

- Cong, P.; Xiang, F.; Liu, X.; Li, T. Morphology and microstructure of polyamide 46 wear debris and transfer film: In relation to wear mechanisms. Wear 2008, 265, 1100–1105. [Google Scholar] [CrossRef]

| Composite Name | Base Polymer | Additive (by Weight) | Additive (by Volume) |

|---|---|---|---|

| PA66GN | PA66 | 5% graphene | 4.10% graphene |

| PA66GT | PA66 | 5% graphite | 4.20% graphite |

| PA66M | PA66 | 5% MoS2 | 1.75% MoS2 |

| PA66Z | PA66 | 5% ZrO2 | 3.60% ZrO2 |

| PA46GN | PA46 | 5% graphene | 4.10% graphene |

| PA46GT | PA46 | 5% graphite | 4.20% graphite |

| PA46M | PA46 | 5% MoS2 | 1.75% MoS2 |

| PA46Z | PA46 | 5% ZrO2 | 3.60% ZrO2 |

| PA12GN | PA12 | 5% graphene | 4.10% graphene |

| PA12GT | PA12 | 5% graphite | 4.20% graphite |

| PA12M | PA12 | 5% MoS2 | 1.75% MoS2 |

| PA12Z | PA12 | 5% ZrO2 | 3.60% ZrO2 |

| Material | μ | Δm (mg) | ws 10−3 (mm3/Nm) | |

|---|---|---|---|---|

| Average | Standard Deviation | |||

| PA66GN | 0.52 | 0.018 | 0.35 | 0.010 |

| PA66GT | 0.59 | 0.027 | 0.25 | 0.007 |

| PA66M | 0.53 | 0.051 | 0.24 | 0.006 |

| PA66Z | 0.49 | 0.011 | 0.000 * | - |

| PA46GN | 0.51 | 0.063 | 0.11 | 0.003 |

| PA46GT | 0.57 | 0.030 | 0.02 | 0.001 |

| PA46M | 0.45 | 0.014 | 0.25 | 0.006 |

| PA46Z | 0.58 | 0.019 | −0.06 * | - |

| PA12GN | 0.48 | 0.010 | 0.07 | 0.002 |

| PA12GT | 0.52 | 0.011 | 0.10 | 0.003 |

| PA12M | 0.41 | 0.008 | 0.03 | 0.001 |

| PA12Z | 0.50 | 0.009 | −0.09 * | - |

| Element | Weight (%) | |||||

|---|---|---|---|---|---|---|

| Non-Tested Disc | PA46 | PA46GT | PA46GN | PA46M | PA46Z | |

| C K | 4.49% | 34.75% | 10.56% | 7.12% | 10.72% | 38.79% |

| Cr K | 1.49% | 0.73% | 3.48% | 1.76% | 0.41% | 0.34% |

| Fe K | 93.24% | 57.63% | 50.67% | 62.18% | 43.65% | 22.62% |

| Si K | 0.77% | 0.53% | 2.02% | 2.13% | 0.38% | 0.30% |

| O K | 5.82% | 32.88% | 26.29% | 44.35% | 13.68% | |

| Ca K | 0.30% | 0.38% | ||||

| S K | 0.49% | 0.30% | ||||

| Al K | 0.24% | |||||

| Cl K | 0.53% | |||||

| Na K | 0.86% | |||||

| Cu K | 14.62% | |||||

| Zn K | 8.49% | |||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Clavería, I.; Gimeno, S.; Miguel, I.; Mendoza, G.; Lostalé, A.; Fernández, Á.; Castell, P.; Elduque, D. Tribological Performance of Nylon Composites with Nanoadditives for Self-Lubrication Purposes. Polymers 2020, 12, 2253. https://doi.org/10.3390/polym12102253

Clavería I, Gimeno S, Miguel I, Mendoza G, Lostalé A, Fernández Á, Castell P, Elduque D. Tribological Performance of Nylon Composites with Nanoadditives for Self-Lubrication Purposes. Polymers. 2020; 12(10):2253. https://doi.org/10.3390/polym12102253

Chicago/Turabian StyleClavería, Isabel, Sofía Gimeno, Ignacio Miguel, Gemma Mendoza, Aleida Lostalé, Ángel Fernández, Pere Castell, and Daniel Elduque. 2020. "Tribological Performance of Nylon Composites with Nanoadditives for Self-Lubrication Purposes" Polymers 12, no. 10: 2253. https://doi.org/10.3390/polym12102253

APA StyleClavería, I., Gimeno, S., Miguel, I., Mendoza, G., Lostalé, A., Fernández, Á., Castell, P., & Elduque, D. (2020). Tribological Performance of Nylon Composites with Nanoadditives for Self-Lubrication Purposes. Polymers, 12(10), 2253. https://doi.org/10.3390/polym12102253