Enhanced Protein Immobilization on Polymers—A Plasma Surface Activation Study

Abstract

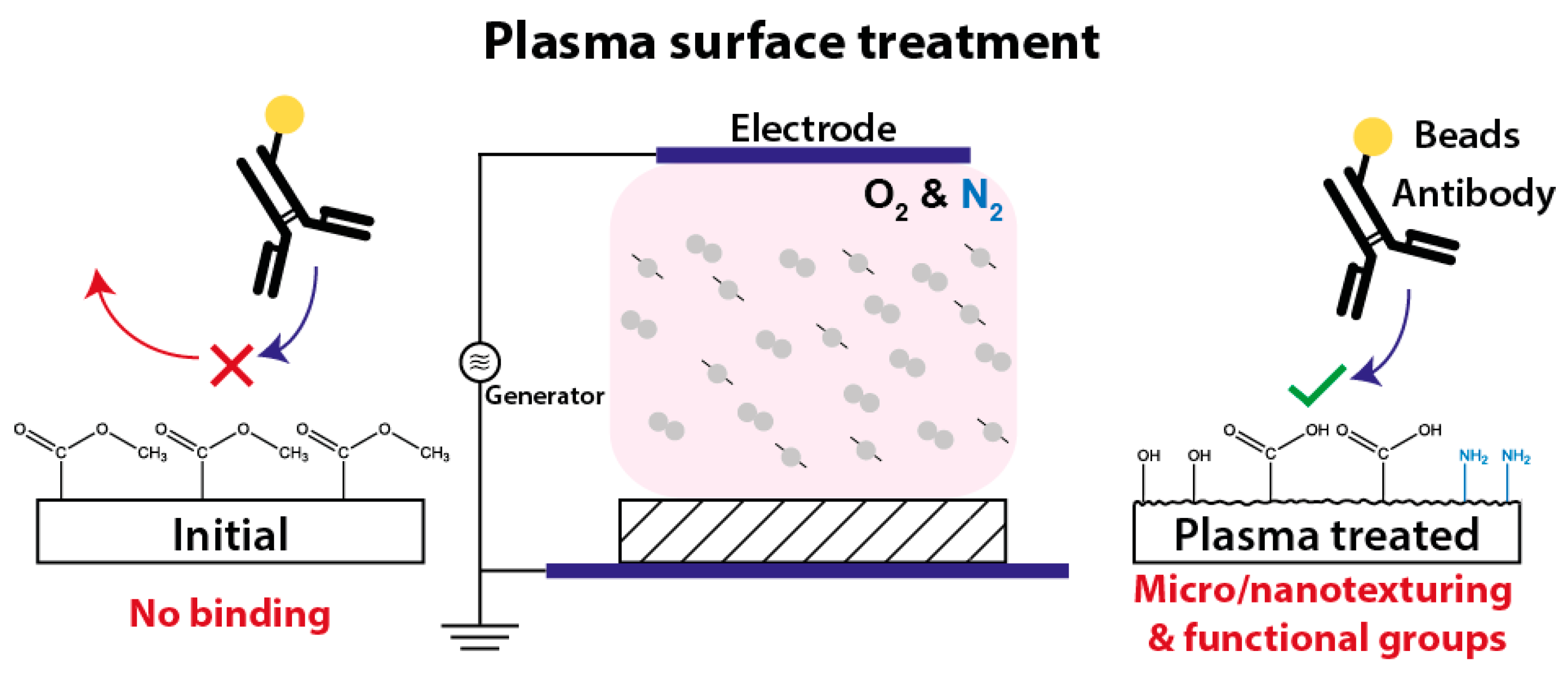

1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Substrate Preparation

2.3. Biomolecule Preparation and Incubation Procedure

2.4. Plasma Activation

2.5. Surface Characterization

3. Results

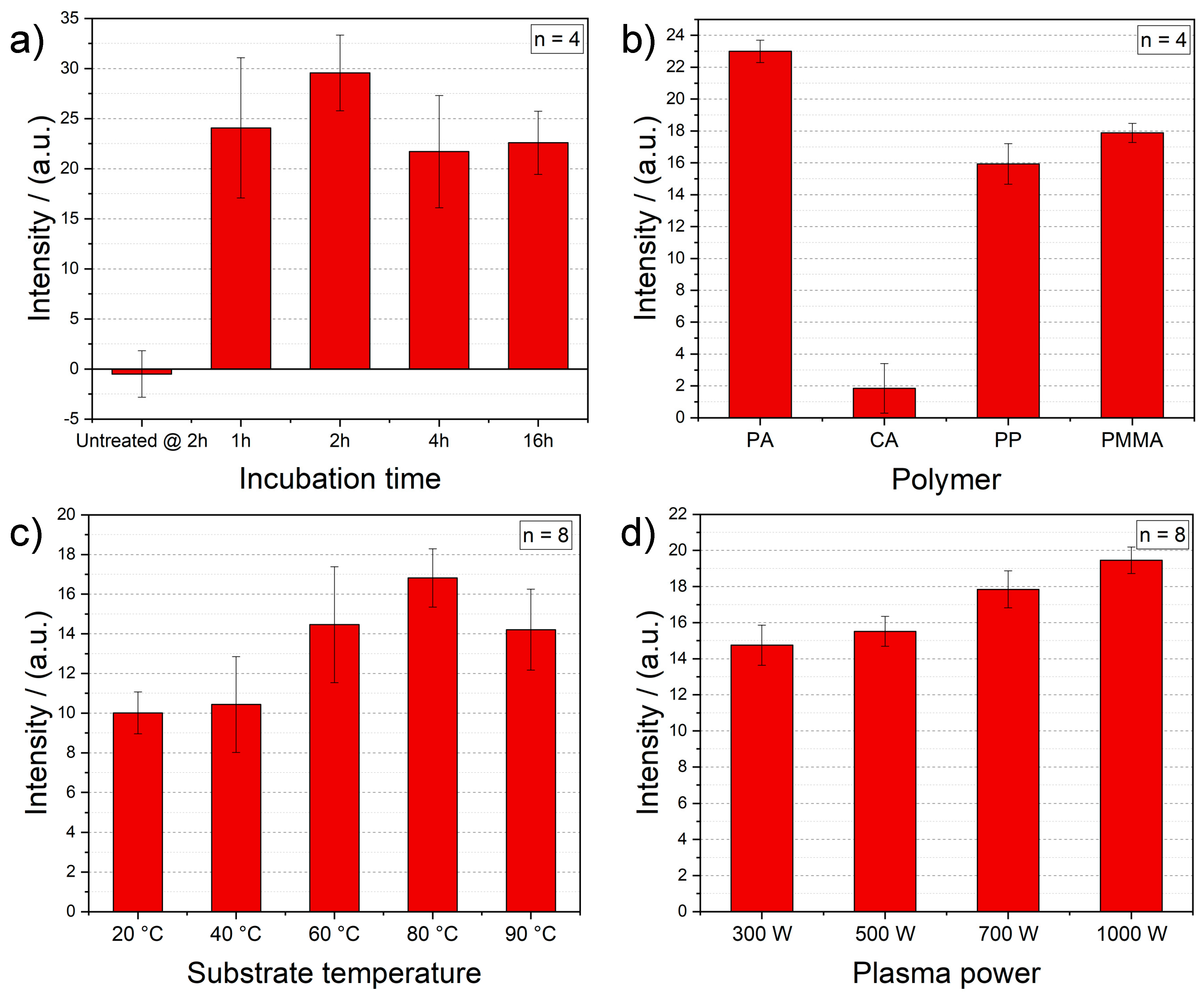

3.1. Initial Tests

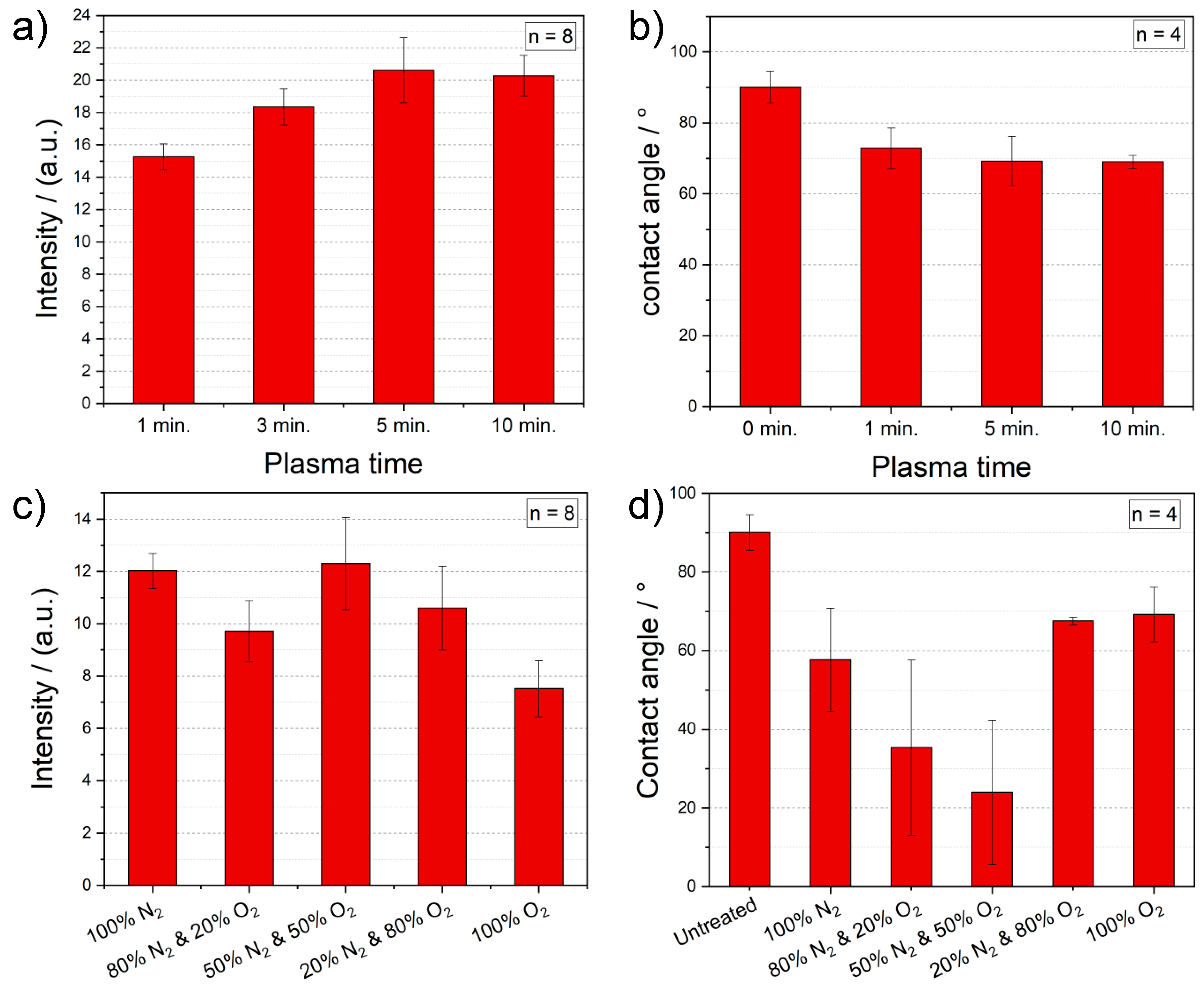

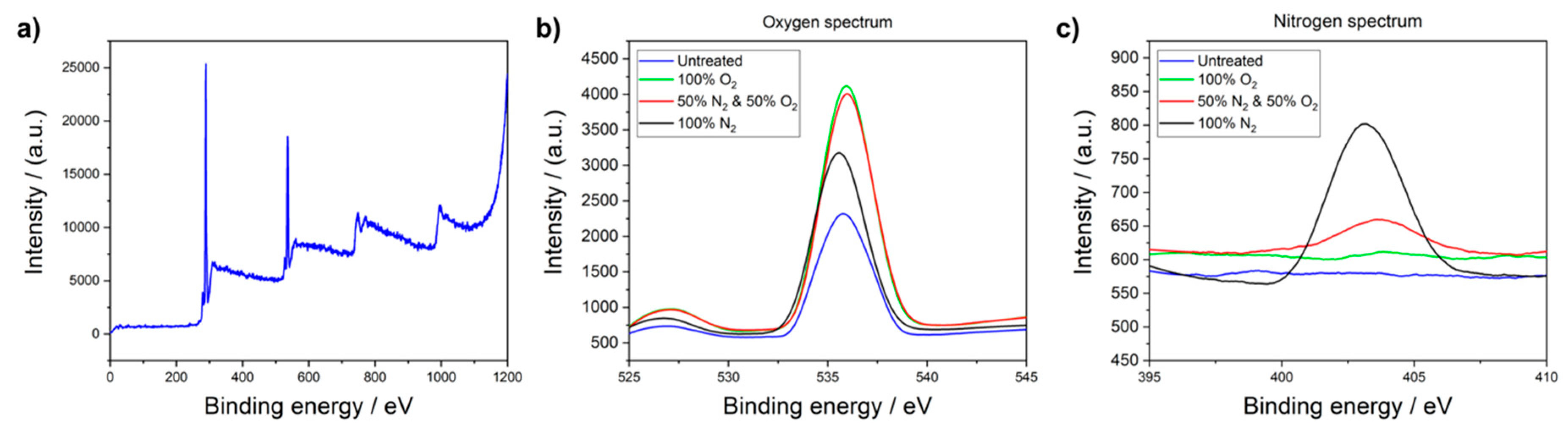

3.2. Optimization of Plasma Process Parameters

3.3. Comparison of Different Immobilization Techniques

3.4. Estimation of the Immobilized Antibody Density

4. Discussion

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Luppa, P.B.; Müller, C.; Schlichtiger, A.; Schlebusch, H. Point-of-care testing (POCT): Current techniques and future perspectives. TrAC Trends Anal. Chem. 2011, 30, 887–898. [Google Scholar] [CrossRef]

- Dincer, C.; Bruch, R.; Kling, A.; Dittrich, P.S.; Urban, G.A. Multiplexed Point-of-Care Testing–xPOCT. Trends Biotechnol. 2017, 35, 728–742. [Google Scholar] [CrossRef] [PubMed]

- Vashist, S.K.; Luppa, P.B.; Yeo, L.Y.; Ozcan, A.; Luong, J.H.T. Emerging Technologies for Next-Generation Point-of-Care Testing. Trends Biotechnol. 2015, 33, 692–705. [Google Scholar] [CrossRef] [PubMed]

- Dincer, C.; Bruch, R.; Costa-Rama, E.; Fernández-Abedul, M.T.; Merkoçi, A.; Manz, A.; Urban, G.A.; Güder, F. Disposable Sensors in Diagnostics, Food, and Environmental Monitoring. Adv. Mater. 2019, 31, 1806739. [Google Scholar] [CrossRef] [PubMed]

- Rim, Y.S.; Bae, S.-H.; Chen, H.; De Marco, N.; Yang, Y. Recent Progress in Materials and Devices toward Printable and Flexible Sensors. Adv. Mater. 2016, 28, 4415–4440. [Google Scholar] [CrossRef] [PubMed]

- Hou, X.; Zhang, Y.S.; Santiago, G.T.; Alvarez, M.M.; Ribas, J.; Jonas, S.J.; Weiss, P.S.; Andrews, A.M.; Aizenberg, J.; Khademhosseini, A. Interplay between materials and microfluidics. Nat. Rev. Mater. 2017, 2, 17016. [Google Scholar] [CrossRef]

- Ali, U.; Karim, K.J.B.A.; Buang, N.A. A Review of the Properties and Applications of Poly (Methyl Methacrylate) (PMMA). Polym. Rev. 2015, 55, 678–705. [Google Scholar] [CrossRef]

- Fixe, F.; Dufva, M.; Telleman, P.; Christensen, C.B. Functionalization of poly(methyl methacrylate) (PMMA) as a substrate for DNA microarrays. Nucleic Acids Res. 2004, 32, e9. [Google Scholar] [CrossRef] [PubMed]

- Feyssa, B.; Liedert, C.; Kivimaki, L.; Johansson, L.-S.; Jantunen, H.; Hakalahti, L. Patterned Immobilization of Antibodies within Roll-to-Roll Hot Embossed Polymeric Microfluidic Channels. PLoS ONE 2013, 8, e68918. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Yan, Q.; Liu, H.-B.; Zhou, X.-H.; Xiao, S.-J. Different EDC/NHS Activation Mechanisms between PAA and PMAA Brushes and the Following Amidation Reactions. Langmuir 2011, 27, 12058–12068. [Google Scholar] [CrossRef] [PubMed]

- Hetemi, D.; Pinson, J. Surface functionalisation of polymers. Chem. Soc. Rev. 2017, 46, 5701–5713. [Google Scholar] [CrossRef] [PubMed]

- Inagaki, N. Plasma Surface Modification and Plasma Polymerization, 1st ed.; CRC Press: Boca Raton, FL, USA, 1996; ISBN 9781566763370. [Google Scholar]

- Černák, M.; Kormunda, M.; Homola, T.; Matoušek, J.; Hergelová, B.; Wu, L.Y.L. Activation of poly(methyl methacrylate) surfaces by atmospheric pressure plasma. Polym. Degrad. Stab. 2012, 97, 886–892. [Google Scholar]

- Tsougeni, K.; Petrou, P.S.; Awsiuk, K.; Marzec, M.M.; Ioannidis, N.; Petrouleas, V.; Tserepi, A.; Kakabakos, S.E.; Gogolides, E. Direct Covalent Biomolecule Immobilization on Plasma-Nanotextured Chemically Stable Substrates. ACS Appl. Mater. Interfaces 2015, 7, 14670–14681. [Google Scholar] [CrossRef] [PubMed]

- Vesel, A.; Elersic, K.; Mozetic, M. Immobilization of protein streptavidin to the surface of PMMA polymer. Vacuum 2012, 86, 773–775. [Google Scholar] [CrossRef]

- Tsougeni, K.; Petrou, P.S.; Tserepi, A.; Kakabakos, S.E.; Gogolides, E. Nano-texturing of poly(methyl methacrylate) polymer using plasma processes and applications in wetting control and protein adsorption. Microelectron. Eng. 2009, 86, 1424–1427. [Google Scholar] [CrossRef]

- Sankaran, R.M. Plasma Processing of Nanomaterials, 1st ed.; CRC Press: Boca Raton, FL, USA, 2017; ISBN 9781138077430. [Google Scholar]

- Plasmatechnik. Product Data Sheet; Diener Electronic GmbH + Co. KG: Ebhausen, Germany, 2011. [Google Scholar]

- Abcam Gold Conjugation Kit. Instructions for Use; Abcam Gold Conjugation Kit: Cambridge, UK, 2018. [Google Scholar]

- Expedeon Protocol. Latex Conjugation Kit; Expedeon Protocol: San Diego, CA, USA, 2018. [Google Scholar]

- PLEXIGLAS® Film 99524. Product Data Sheet; PLEXIGLAS® Film 99524: Essen, Germany, 2014. [Google Scholar]

- Rieß, K. Plasmamodifizierung von Polyethylen. Ph.D. Thesis, Martin-Luther-Universität Halle Wittenberg, Halle Wittenberg, Germany, 2001. [Google Scholar]

- Kim, D.; Herr, A.E. Protein immobilization techniques for microfluidic assays. Biomicrofluidics 2013, 7, 041501. [Google Scholar] [CrossRef] [PubMed]

- Haken, H.; Wolf, H.C. Molecular Physics and Elements of Quantum Chemistry; Advanced Texts in Physics; Springer: Berlin/Heidelberg, Germany, 2004; ISBN 978-3-642-07400-4. [Google Scholar]

- Van der Heide, P. X-ray Photoelectron Spectroscopy: An introduction to Principles and Practices; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; ISBN 978-1-118-06253-1. [Google Scholar]

- Van Vrekhem, S.; Morent, R.; De Geyter, N. Deposition of a PMMA coating with an atmospheric pressure plasma jet. J. Coat. Technol. Res. 2018, 15, 679–690. [Google Scholar] [CrossRef]

- Rusmini, F.; Zhong, Z.; Feijen, J. Protein Immobilization Strategies for Protein Biochips. Biomacromolecules 2007, 8, 1775–1789. [Google Scholar] [CrossRef] [PubMed]

- Sam, S.; Touahir, L.; Andresa, J.S.; Allongue, P.; Chazalviel, J.-N.; Gouget-Laemmel, A.C.; Henry de Villeneuve, C.; Moraillon, A.; Ozanam, F.; Gabouze, N.; et al. Semiquantitative study of the EDC/NHS activation of acid terminal groups at modified porous silicon surfaces. Langmuir 2009, 26, 809–814. [Google Scholar] [CrossRef] [PubMed]

- Staros, J.V.; Wright, R.W.; Swingle, D.M. ESemiquantitative Study of the EDC/NHS Activation of Acid Terminal Groups at Modified Porous Silicon Surfaces. Lanhancement by N-hydroxysulfosuccinimide of water-soluble carbodiimide-mediated coupling reactions. Anal. Biochem. 1986, 156, 220–222. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wieland, F.; Bruch, R.; Bergmann, M.; Partel, S.; Urban, G.A.; Dincer, C. Enhanced Protein Immobilization on Polymers—A Plasma Surface Activation Study. Polymers 2020, 12, 104. https://doi.org/10.3390/polym12010104

Wieland F, Bruch R, Bergmann M, Partel S, Urban GA, Dincer C. Enhanced Protein Immobilization on Polymers—A Plasma Surface Activation Study. Polymers. 2020; 12(1):104. https://doi.org/10.3390/polym12010104

Chicago/Turabian StyleWieland, Felicia, Richard Bruch, Michael Bergmann, Stefan Partel, Gerald A. Urban, and Can Dincer. 2020. "Enhanced Protein Immobilization on Polymers—A Plasma Surface Activation Study" Polymers 12, no. 1: 104. https://doi.org/10.3390/polym12010104

APA StyleWieland, F., Bruch, R., Bergmann, M., Partel, S., Urban, G. A., & Dincer, C. (2020). Enhanced Protein Immobilization on Polymers—A Plasma Surface Activation Study. Polymers, 12(1), 104. https://doi.org/10.3390/polym12010104