Evaluation of the Mechanical and Thermal Properties Decay of PHBV/Sisal and PLA/Sisal Biocomposites at Different Recycle Steps

Abstract

1. Introduction

2. Materials and Methods

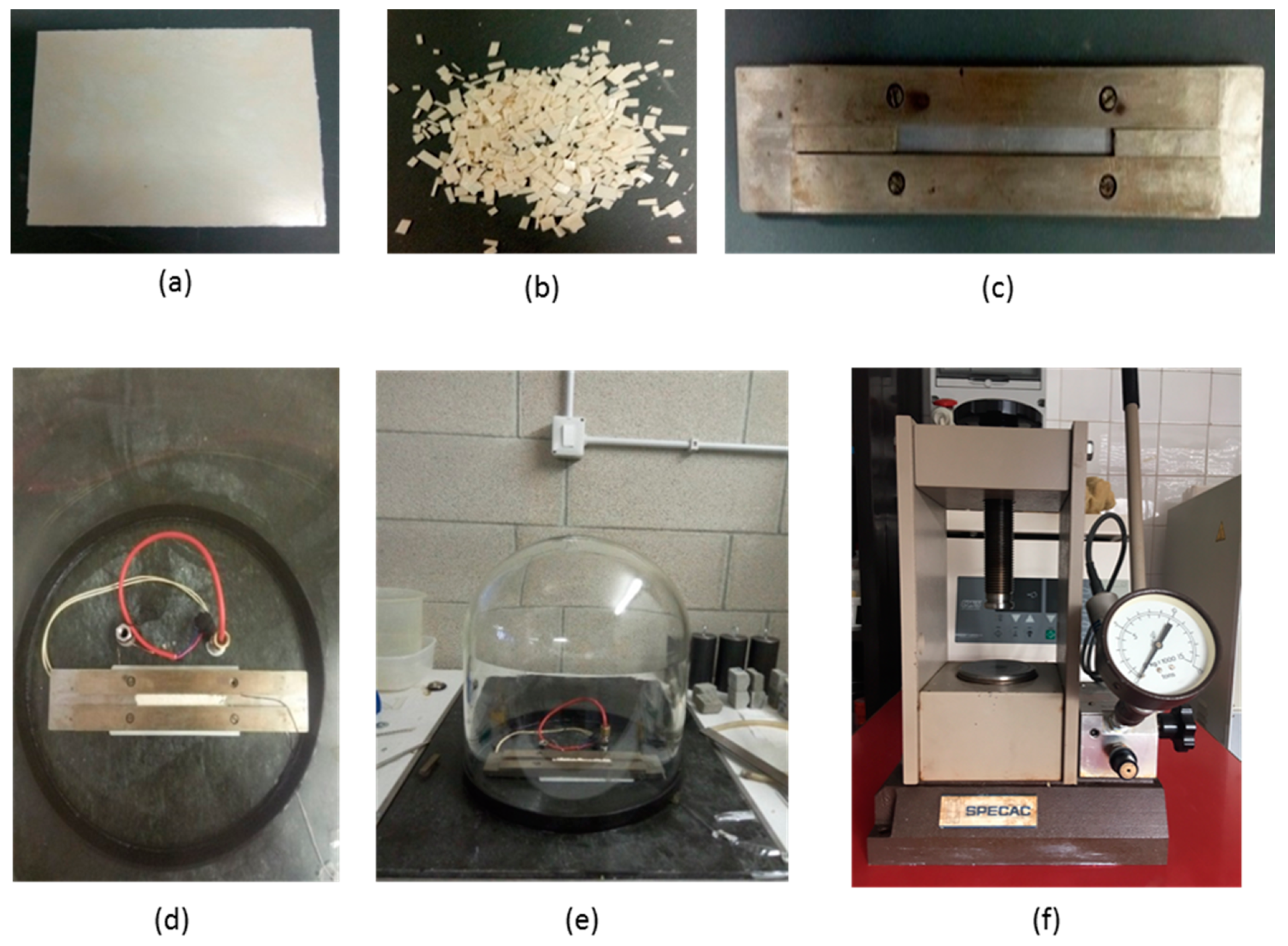

2.1. Materials and Sample Preparation

2.1.1. Raw Materials

2.1.2. Recycled Materials

2.2. Mechanical Analysis

2.2.1. Static Measurements

2.2.2. Dynamic Measurements

2.3. Thermal Analysis

Calorimetric Analysis

3. Results

3.1. Evaluation of Initial Biocomposites Properties

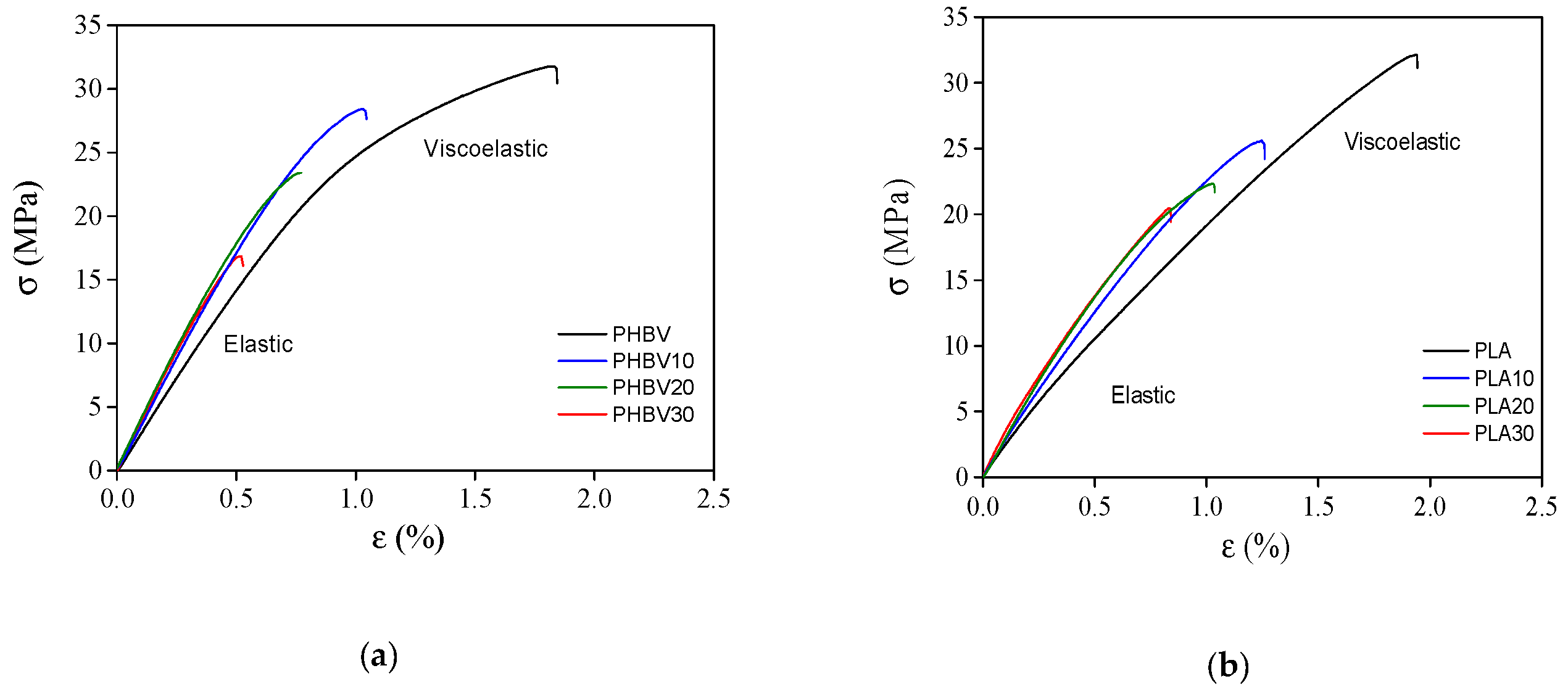

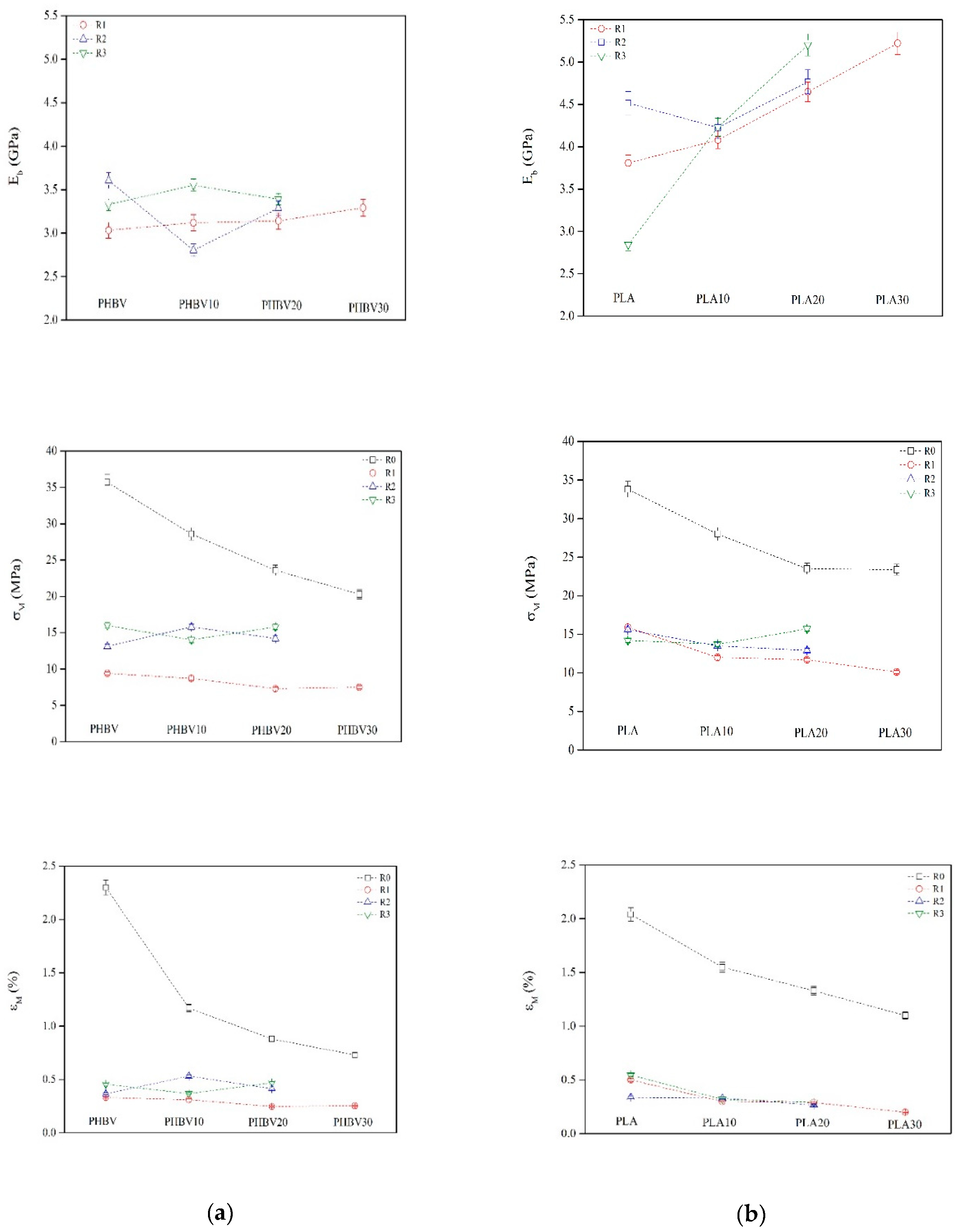

3.1.1. Tensile Tests

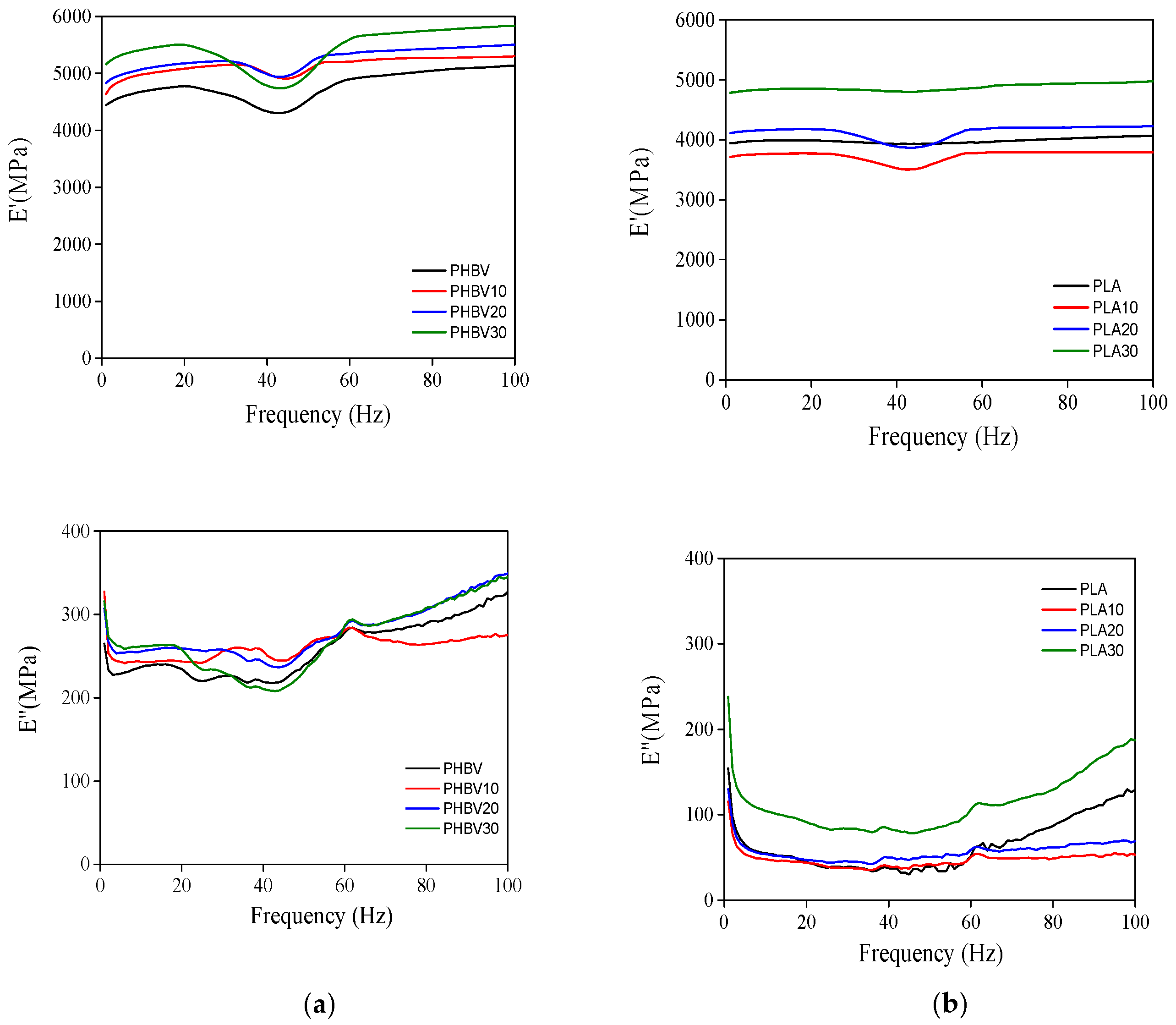

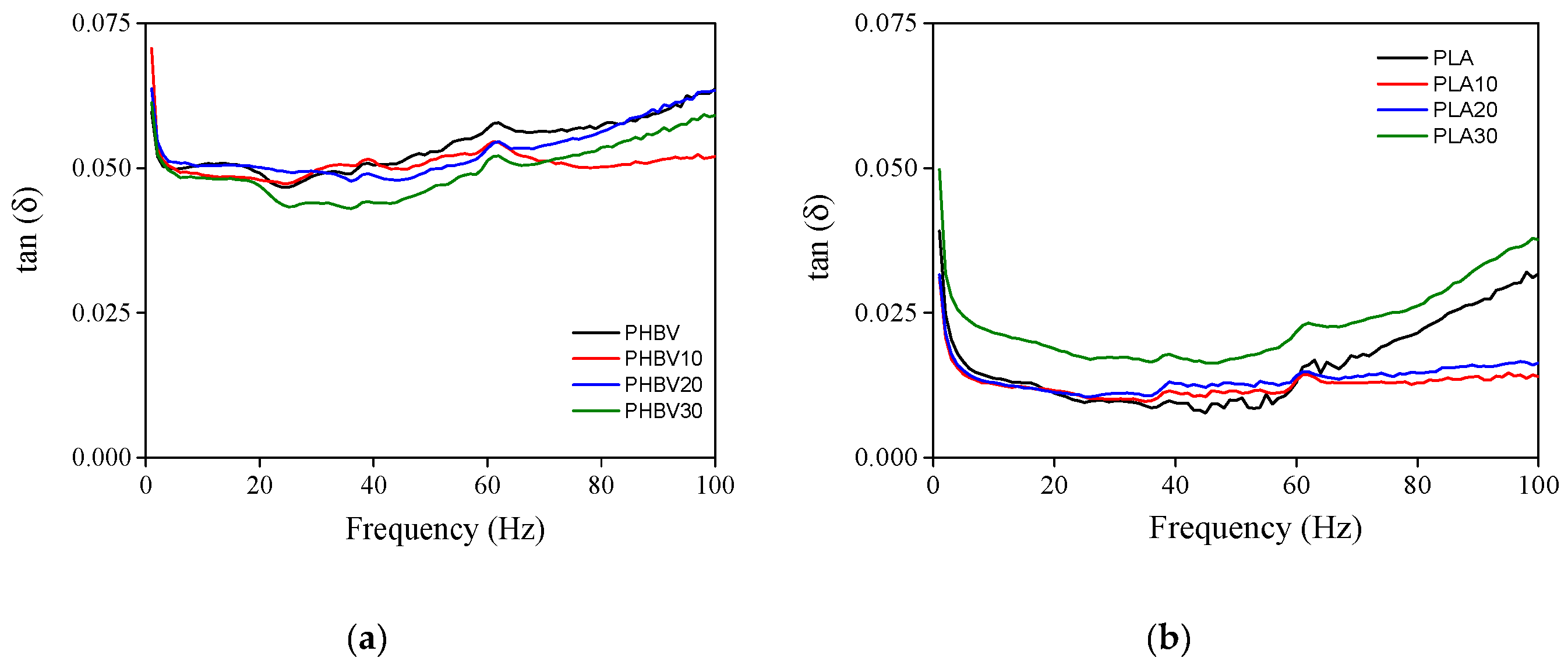

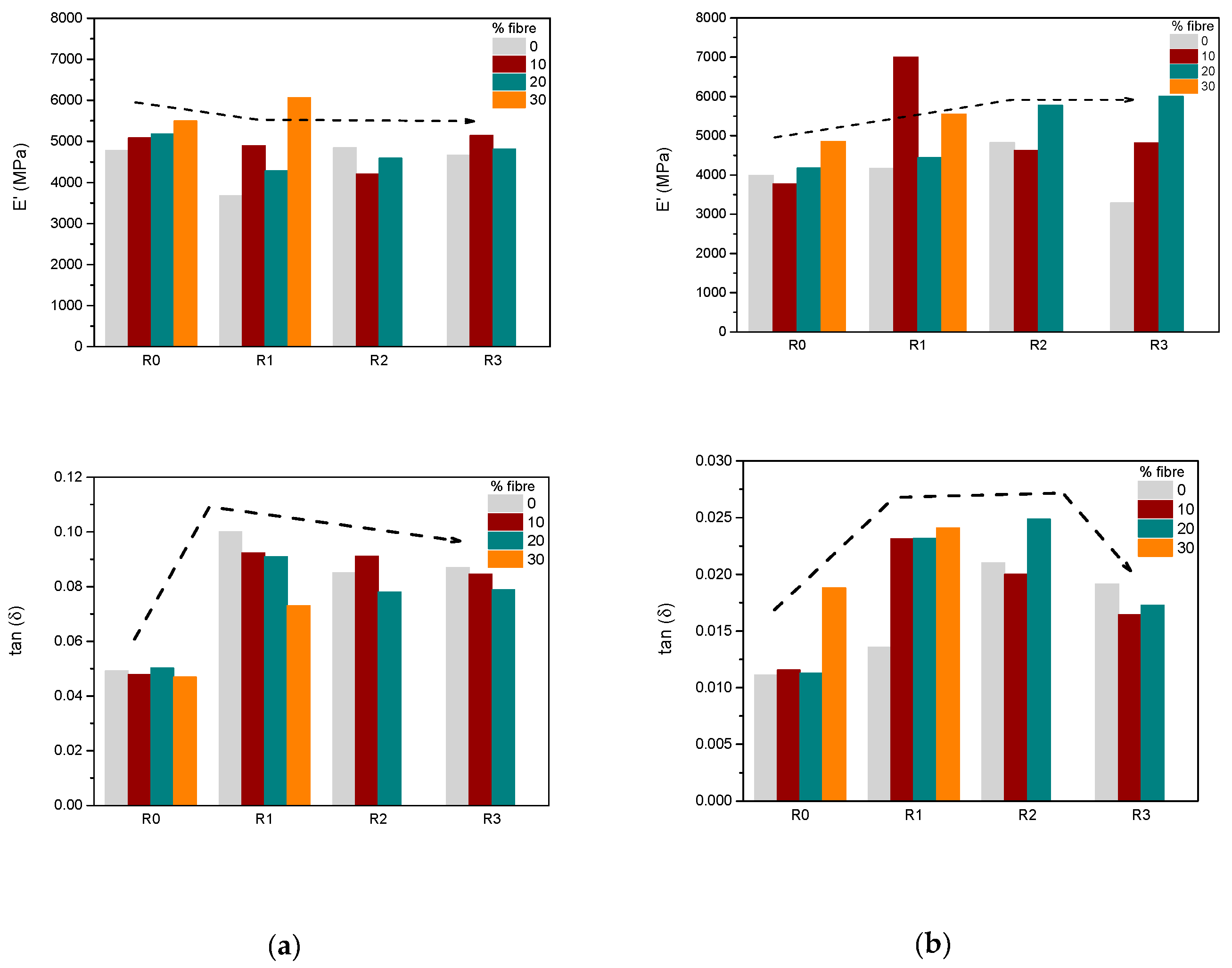

3.1.2. Dynamic Tests

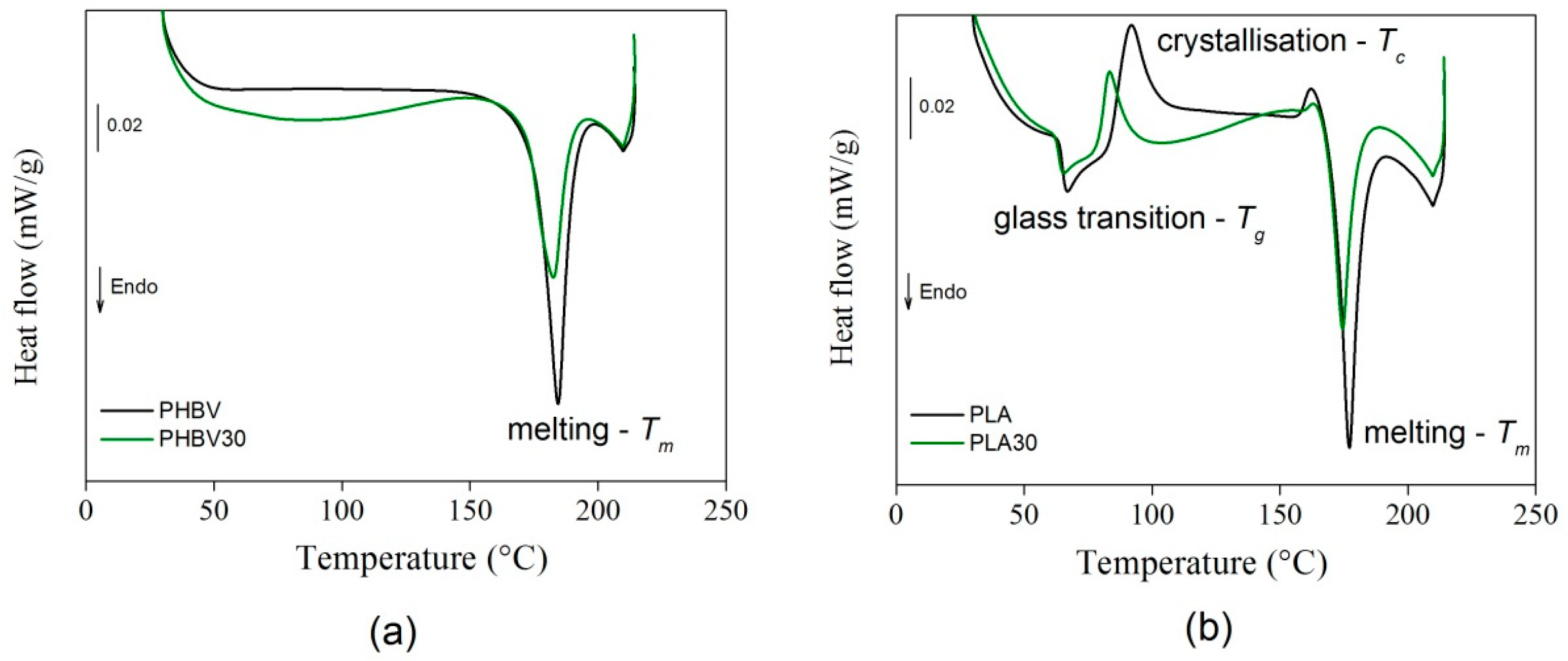

3.1.3. Thermal Tests

3.2. Evaluation of Recycled Biocomposites Properties

3.2.1. Tensile Tests

3.2.2. Dynamic Tests

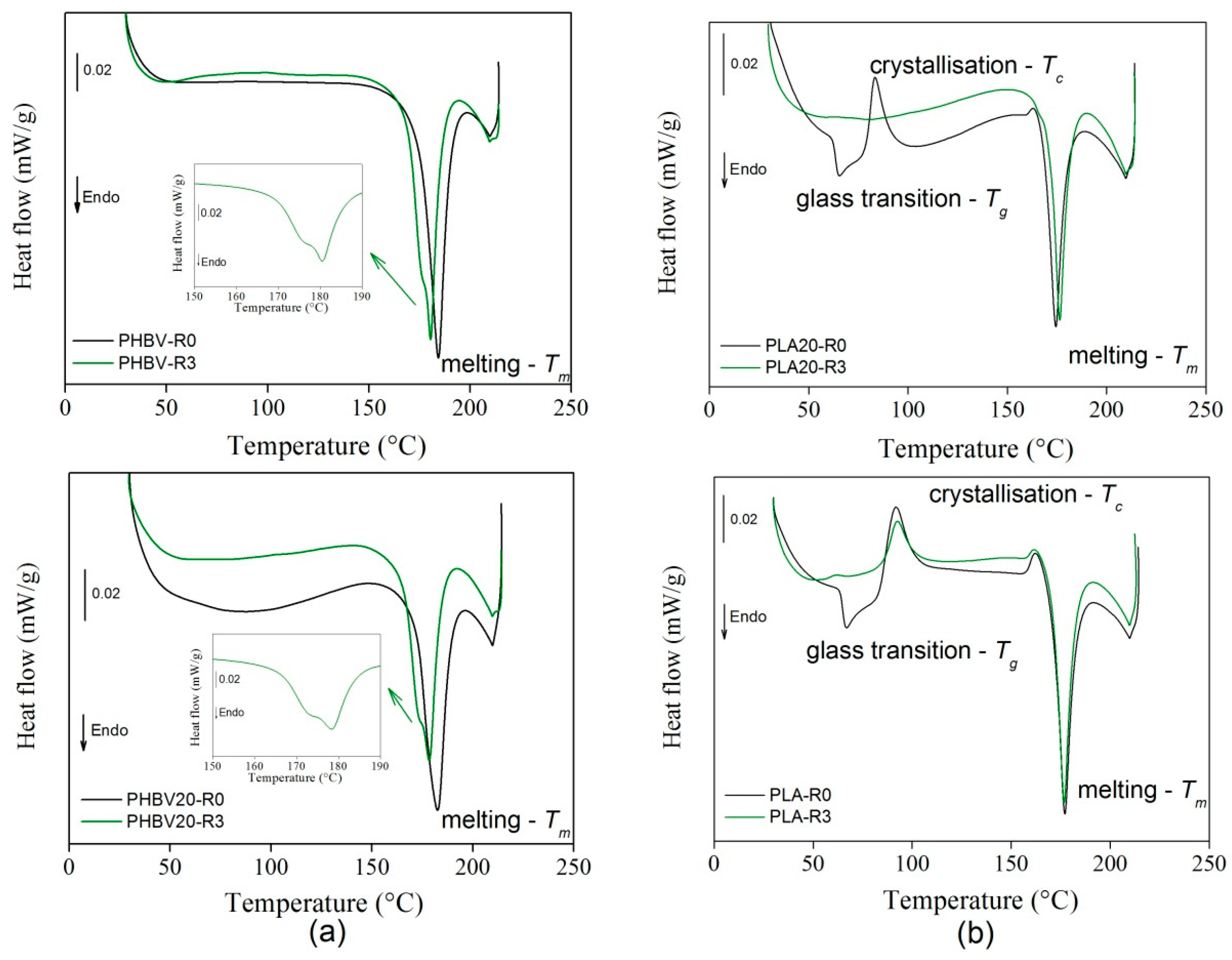

3.2.3. Thermal Tests

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| PHBV | Poly (3-hydroxybutyrate-co-3-hydroxyvalerate) |

| PLA | Polylactide acid |

| R0 | Unrecycled samples |

| Ri (i = 1, 2 and 3) | Recycling steps |

Symbols

| Crystallization temperature | Tc – °C |

| Crystallization enthaply | ΔHc – J/g |

| Deformation at break | εM – % |

| Degree of crystallization | Xc – % |

| Elastic modulus | Et – Gpa |

| Elastic flexural modulus | Eb – GPa |

| Glass transition temperature | Tg – °C |

| Loss factor | tan (δ) – / |

| Loss modulus | E″ – Mpa |

| Melting temperature | Tm – °C |

| Melting enthalpy | ΔHm – J/g |

| Storage modulus | E′ – MPa |

| Tensile strength | σM – MPa |

References

- Alaerts, L.; Augustinus, M.; Van Acker, K. Impact of bio-based plastics on current recycling of plastics. Sustainability 2018, 10, 1487. [Google Scholar] [CrossRef]

- Weng, Y.X.; Wang, Y.; Wang, X.L.; Wang, Y.Z. Biodegradation behavior of PHBV films in a pilot-scale composting condition. Polym. Test. 2010, 29, 579–587. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Jaszkiewicz, A. Mechanical performance of biocomposites based on PLA and PHBV reinforced with natural fibres-A comparative study to PP. Compos. Sci. Technol. 2010, 70, 1687–1696. [Google Scholar] [CrossRef]

- Rivera-Briso, A.L.; Serrano-Aroca, Á. Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate): Enhancement strategies for advanced applications. Polymers 2018, 10, 732. [Google Scholar] [CrossRef] [PubMed]

- Gatenholm, P.; Mathiasson, A. Biodegradable natural composites. II. Synergistic effects of processing cellulose with PHB. J. Appl. Polym. Sci. 1994, 51, 1231–1237. [Google Scholar] [CrossRef]

- Corre, Y.M.; Bruzaud, S.; Audic, J.L.; Grohens, Y. Morphology and functional properties of commercial polyhydroxyalkanoates: A comprehensive and comparative study. Polym. Test. 2012, 31, 226–235. [Google Scholar] [CrossRef]

- Hartmann, M.H. High molecular weight polylactic acid polymers. In Biopolymers from Renewable Resources; Springer, Ed.; Springer: Berlin/Heidelberg, Germany, 1998. [Google Scholar]

- Henton, P.D.E.; Gruber, J.; Lunt, J.R. Natural Fibers, Biopolymers and Biocomposites; Mohan, A.K., Ed.; Taylor & Francis: Abingdon-on-Thames, UK, 2005. [Google Scholar]

- Sawyer, D.J. Bioprocessing-No Longer a Field of Dreams. Macromol. Symp. 2003, 201, 271–281. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S. An overview of polylactides as packaging materials. Macromol. Biosci. 2004, 16, 835–864. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Joseph, K.; Toledo Filho, R.D.; James, B.; Thomas, S.; de Carvalho, L.H. A review on sisal fiber reinforced polymer. Rev. Bras. Eng. Agríc. Ambient. 1999, 3, 367–379. [Google Scholar] [CrossRef]

- Pavithran, C.; Mukherjee, P.S.; Brahmakumar, M.; Damodaran, A.D. Impact performance of sisal-polyester composites. J. Mater. Sci. Lett. 1988, 7, 825–826. [Google Scholar] [CrossRef]

- Zhao, X.; Li, R.K.Y.; Bai, S.L. Mechanical properties of sisal fiber reinforced high density polyethylene composites: Effect of fiber content, interfacial compatibilization, and manufacturing process. Compos. Part A Appl. Sci. Manuf. 2014, 65, 169–174. [Google Scholar] [CrossRef]

- Fung, K.L.; Xing, X.S.; Li, R.K.Y.; Tjong, S.C.; Mai, Y.W. An investigation on the processing of sisal fibre reinforced polypropylene composites. Compos. Sci. Technol. 2003, 63, 1255–1258. [Google Scholar] [CrossRef]

- Prasad, G.L.E.; Gowda, B.S.K.; Velmurugan, R. Comparative Study of Impact Strength Characteristics of Treated and Untreated Sisal Polyester Composites. Procedia Eng. 2017, 173, 778–785. [Google Scholar] [CrossRef]

- Thielen, M. Plants and Crops Raw Materials Products. In Bioplastics Magazine; GmbH: Mönchengladbach, Germany, 2014. [Google Scholar]

- Madhavan Nampoothiri, K.; Nair, N.R.; John, R.P. An overview of the recent developments in polylactide (PLA) research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef]

- Badia, J.D.; Gil-Castell, O.; Ribes-Greus, A. Long-term properties and end-of-life of polymers from renewable resources. Polym. Degrad. Stab. 2017, 137, 35–57. [Google Scholar] [CrossRef]

- Moliner, C.; Badia, J.D.; Bosio, B.; Arato, E.; Lagazzo, A.; Capurro, M.; Ribes-Greus, A. Mechanical and thermal performance of PLA and PHBV-based biopolymers as potential alternatives to PET. In Chemical Engineering Transactions; AIDIC Servizi S.r.l.: Milano, Italy, 2017; Volume 57, ISBN 9788895608488. [Google Scholar]

- Moraczewski, K. Influence of multiple processing on selected properties of poly(3-hydroxybutyrate- co -4-hydroxybutyrate). Polym. Adv. Technol. 2016, 27, 733–739. [Google Scholar] [CrossRef]

- Moraczewski, K. Characterization of multi-injected poly(e-caprolactone). Polym. Test. 2014, 33, 116–120. [Google Scholar] [CrossRef]

- Pillin, I.; Montrelay, N.; Bourmaud, A.; Grohens, Y. Effect of thermo-mechanical cycles on the physico-chemical properties of poly(lactic acid). Polym. Degrad. Stab. 2008, 93, 321–328. [Google Scholar] [CrossRef]

- Badia, J.D.; Ribes-Greus, A. Mechanical recycling of polylactide, upgrading trends and combination of valorization techniques. Eur. Polym. J. 2016, 84, 22–39. [Google Scholar] [CrossRef]

- Yarahmadi, N.; Jakubowicz, I.; Enebro, J. Polylactic acid and its blends with petroleum-based resins: Effects of reprocessing and recycling on properties. J. Appl. Polym. Sci. 2016, 133, 43916. [Google Scholar] [CrossRef]

- Celik, H.; Tuna, B.; Ozkoc, G. The effects of thermomechanical cycles on the properties of PLA/TPS blends. Adv. Polym. Technol. 2014, 33, 1–9. [Google Scholar]

- Zaverl, M.; Seydibeyoğlu, M.Ö.; Misra, M.; Mohanty, A. Studies on recyclability of polyhydroxybutyrate-co-valerate bioplastic: Multiple melt processing and performance evaluations. J. Appl. Polym. Sci. 2012, 125, E324–E331. [Google Scholar] [CrossRef]

- Le Duigou, A.; Pillin, I.; Bourmaud, A.; Davies, P.; Baley, C. Effect of recycling on mechanical behaviour of biocompostable flax/poly(l-lactide) composites. Compos. Part Appl. Sci. Manuf. 2008, 39, 1471–1478. [Google Scholar] [CrossRef]

- Zembouai, I.; Bruzaud, S.; Kaci, M.; Benhamida, A.; Corre, Y.M.; Grohens, Y. Mechanical Recycling of Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate)/Polylactide Based Blends. J. Polym. Environ. 2014, 22, 449–459. [Google Scholar] [CrossRef]

- Moliner, C.; Badia, J.D.; Bosio, B.; Arato, E.; Teruel-Juanes, R.; Kittikorn, T.; Strömberg, E.; Ek, M.; Karlsson, S.; Ribes-Greus, A. Thermal kinetics for the energy valorisation of polylactide/sisal biocomposites. Thermochim. Acta 2018, 670, 169–177. [Google Scholar] [CrossRef]

- Moliner, C.; Badia, J.D.; Bosio, B.; Arato, E.; Kittikorn, T.; Strömberg, E.; Teruel-Juanes, R.; Ek, M.; Karlsson, S.; Ribes-Greus, A. Thermal and thermo-oxidative stability and kinetics of decomposition of PHBV/sisal composites. Chem. Eng. Commun. 2018, 205, 226–237. [Google Scholar] [CrossRef]

- Dabiri, S.; Lagazzo, A.; Barberis, F.; Farokhi, M.; Finochio, E.; Pastorino, L. Characterization of alginate-brushite in-situ hydrogel composites. Mater. Sci. Eng. C Mater. Biol. Appl. 2016, 67, 502–510. [Google Scholar] [CrossRef] [PubMed]

- Menini, M.; Pesce, P.; Pera, F.; Barberis, F.; Lagazzo, A.; Bertola, L.; Pera, P. Biological and mechanical characterization of carbon fiber frameworks for dental implant applications. Mater. Sci. Eng. C Mater. Biol. Appl. 2017, 70, 646–655. [Google Scholar] [CrossRef] [PubMed]

- Gil-Castell, O.; Badia, J.D.; Kittikorn, T.; Strömberg, E.; Ek, M.; Karlsson, S.; Ribes-Greus, A. Impact of hydrothermal ageing on the thermal stability, morphology and viscoelastic performance of PLA/sisal biocomposites. Polym. Degrad. Stab. 2016, 132, 87–96. [Google Scholar] [CrossRef]

- Yu, H.; Sun, B.; Zhang, D.; Chen, G.; Yang, X.; Yao, J. Reinforcement of biodegradable poly(3-hydroxybutyrate-co-3-hydroxyvalerate) with cellulose nanocrystal/silver nanohybrids as bifunctional nanofillers. J. Mater. Chem. B 2014, 2, 8479–8489. [Google Scholar] [CrossRef]

- Singh, S.; Mohanty, A.K.; Sugie, T.; Takai, Y.; Hamada, H. Renewable resource based biocomposites from natural fiber and polyhydroxybutyrate-co-valerate (PHBV) bioplastic. Compos. Part A Appl. Sci. Manuf. 2008, 39, 875–886. [Google Scholar] [CrossRef]

- Albinante, S.R.; Pacheco, E.; Visconte, L.L.Y.; Platenik, G.; Batista, L.N. Modification of Brazilian Natural Fibers from Banana’s Tree to Apply as Fillers into Polymers Composites. Chem. Eng. Trans. 2014, 37, 715–720. [Google Scholar]

- Jang, J.Y.; Jeong, T.K.; Oh, H.J.; Youn, J.R.; Song, Y.S. Thermal stability and flammability of coconut fiber reinforced poly(lactic acid) composites. Compos. Part B Eng. 2012, 43, 2434–2438. [Google Scholar] [CrossRef]

- Sahari, J.; Sapuan, S.M. Natural fibre reinforced biodegradable polymer composites. Rev. Adv. Mater. Sci. 2011, 30, 166–174. [Google Scholar]

- Sudesh, K.; Abe, H.; Doi, Y. Synthesis, structure and properties of polyhydroxyalkanoates: Biological polyesters. Prog. Polym. Sci. 2000, 25, 1503–1555. [Google Scholar] [CrossRef]

- Clarinval, A.M.; Halleux, J. Classification of Biodegradable Polymers; Woodhead Publishing Ltd.: Cambridge, UK, 2005. [Google Scholar]

- Menard, K.P.; Menard, N.R. Dynamic Mechanical Analysis in the Analysis of Polymers and Rubbers. Encycl. Polym. Sci. Technol. 2015. [Google Scholar] [CrossRef]

- Modi, S.; Koelling, K.; Vodovotz, Y. Assessment of PHB with varying hydroxyvalerate content for potential packaging applications. Eur. Polym. J. 2011, 47, 179–186. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

- Requena, R.; Jiménez, A.; Vargas, M.; Chiralt, A. Effect of plasticizers on thermal and physical properties of compression-moulded poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] films. Polym. Test. 2016, 56, 45–53. [Google Scholar] [CrossRef]

- Cai, L.; Dou, Q. Investigation on the melting and crystallization behaviors, mechanical properties and morphologies of polypropylene/sericite composites. J. Mater. Sci. 2019, 54, 3600–3618. [Google Scholar] [CrossRef]

- Fischer, E.W.; Sterzel, H.J.; Wegner, G. Investigation of structure of solution grown crystals of lactide copolymers by means of chemical-reactions. Colloid Polym. Sci. 1973, 251, 980–990. [Google Scholar]

- Deroiné, M.; Le Duigou, A.; Corre, Y.M.; Le Gac, P.Y.; Davies, P.; César, G.; Bruzaud, S. Seawater accelerated ageing of poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Polym. Degrad. Stab. 2014, 105, 237–247. [Google Scholar] [CrossRef]

- Mieck, K.P.; Reußmann, T.; Hauspurg, C. Correlations for the fracture work and falling weight impact properties of thermoplastic natural/long fibre composites. Mater. Werkst. 2000, 31, 169–174. [Google Scholar] [CrossRef]

- Graupner, N.; Müssig, J. A comparison of the mechanical characteristics of kenaf and lyocell fibre reinforced poly(lactic acid) (PLA) and poly(3-hydroxybutyrate) (PHB) composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 2010–2019. [Google Scholar] [CrossRef]

- Beltrán, F.R.; Lorenzo, V.; Acosta, J.; de la Orden, M.U.; Martínez Urreaga, J. Effect of simulated mechanical recycling processes on the structure and properties of poly(lactic acid). J. Environ. Manag. 2018, 216, 25–31. [Google Scholar] [CrossRef] [PubMed]

- Kittikorn, T.; Malakul, R.; Stromberg, E.; Ek, M.; Karlsson, S. Enhancement of mechanical, thermal and antibacterial properties of sisal/ polyhydroxybutyrate-co-valerate biodegradable composite. J. Met. Mater. Miner. 2018, 28, 52–61. [Google Scholar]

- Luo, H.; Xiong, G.; Ma, C.; Chang, P.; Yao, F.; Zhu, Y.; Zhang, C.; Wan, Y. Mechanical and thermo-mechanical behaviors of sizing-treated corn fiber/polylactide composites. Polym. Test. 2014, 39, 45–52. [Google Scholar] [CrossRef]

| Sample | Et (GPa) | σM (MPa) | εM (%) |

|---|---|---|---|

| PHBV | 3.1 (±0.01) | 35.7 (±0.11) | 2.3 (±0.21) |

| PHBV10 | 3.4 (±0.05) | 28.6 (±0.01) | 1.2 (±0.11) |

| PHBV20 | 3.6 (±0.07) | 23.6 (±0.03) | 0.9 (±0.09) |

| PHBV30 | 3.8 (±0.02) | 20.3 (±0.17) | 0.7 (±0.29) |

| PLA | 2.5 (±0.09) | 33.8 (±0.09) | 2.0 (±0.11) |

| PLA10 | 3.0 (±0.02) | 28.0 (±0.04) | 1.5 (±0.07) |

| PLA20 | 3.1 (±0.05) | 23.5 (±0.07) | 1.3 (±0.06) |

| PLA30 | 3.6 (±0.04) | 23.4 (±0.12) | 1.1 (±0.24) |

| Sample | Tg (°C) | Tc (°C) | ΔHc (J/g) | Tm (° C) | ΔHm (J/g) | Xc (%) |

|---|---|---|---|---|---|---|

| PHBV | - | - | - | 184 | 94.4 | 64.7 |

| PHBV30 | - | - | - | 182 | 66.3 | 64.9 |

| PLA | 67 | 92 | −29.3 | 177 | 64 | 68.7 |

| PLA30 | 65 | 83 | −13.7 | 174 | 37.3 | 57.2 |

| Sample | Tg (°C) | Tc (°C) | ΔHc (J/g) | Tm (°C) | ΔHm (J/g) | Xc (%) |

|---|---|---|---|---|---|---|

| PHBV-R0 | - | - | - | 184 | 94.4 | 64.4 |

| PHBV-R1 | - | - | - | 178 | 97.7 | 66.6 |

| PHBV-R3 | - | - | - | 180 | 94.9 | 64.7 |

| PHBV20-R0 | - | - | - | 182 | 66.3 | 56.5 |

| PHBV20-R1 | - | - | - | 179 | 77.1 | 65.7 |

| PHBV20-R3 | - | - | - | 178 | 79.6 | 67.9 |

| PLA-R0 | 66 | 92 | −29.3 | 177 | 64 | 68.7 |

| PLA-R1 | - | - | - | 176 | 37.9 | 40.7 |

| PLA-R3 | - | - | - | 176 | 39 | 41.9 |

| PLA20-R0 | 65 | 99 | −25.9 | 177 | 64.8 | 87 |

| PLA20-R1 | - | 91 | −22.2 | 177 | 64.8 | 87 |

| PLA20-R3 | - | 92 | −13.7 | 177 | 57.5 | 77.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lagazzo, A.; Moliner, C.; Bosio, B.; Botter, R.; Arato, E. Evaluation of the Mechanical and Thermal Properties Decay of PHBV/Sisal and PLA/Sisal Biocomposites at Different Recycle Steps. Polymers 2019, 11, 1477. https://doi.org/10.3390/polym11091477

Lagazzo A, Moliner C, Bosio B, Botter R, Arato E. Evaluation of the Mechanical and Thermal Properties Decay of PHBV/Sisal and PLA/Sisal Biocomposites at Different Recycle Steps. Polymers. 2019; 11(9):1477. https://doi.org/10.3390/polym11091477

Chicago/Turabian StyleLagazzo, Alberto, Cristina Moliner, Barbara Bosio, Rodolfo Botter, and Elisabetta Arato. 2019. "Evaluation of the Mechanical and Thermal Properties Decay of PHBV/Sisal and PLA/Sisal Biocomposites at Different Recycle Steps" Polymers 11, no. 9: 1477. https://doi.org/10.3390/polym11091477

APA StyleLagazzo, A., Moliner, C., Bosio, B., Botter, R., & Arato, E. (2019). Evaluation of the Mechanical and Thermal Properties Decay of PHBV/Sisal and PLA/Sisal Biocomposites at Different Recycle Steps. Polymers, 11(9), 1477. https://doi.org/10.3390/polym11091477