Characterization of Double-Doped Polymer Optical Fibers as Luminescent Solar Concentrators

Abstract

1. Introduction

2. Materials and Methods

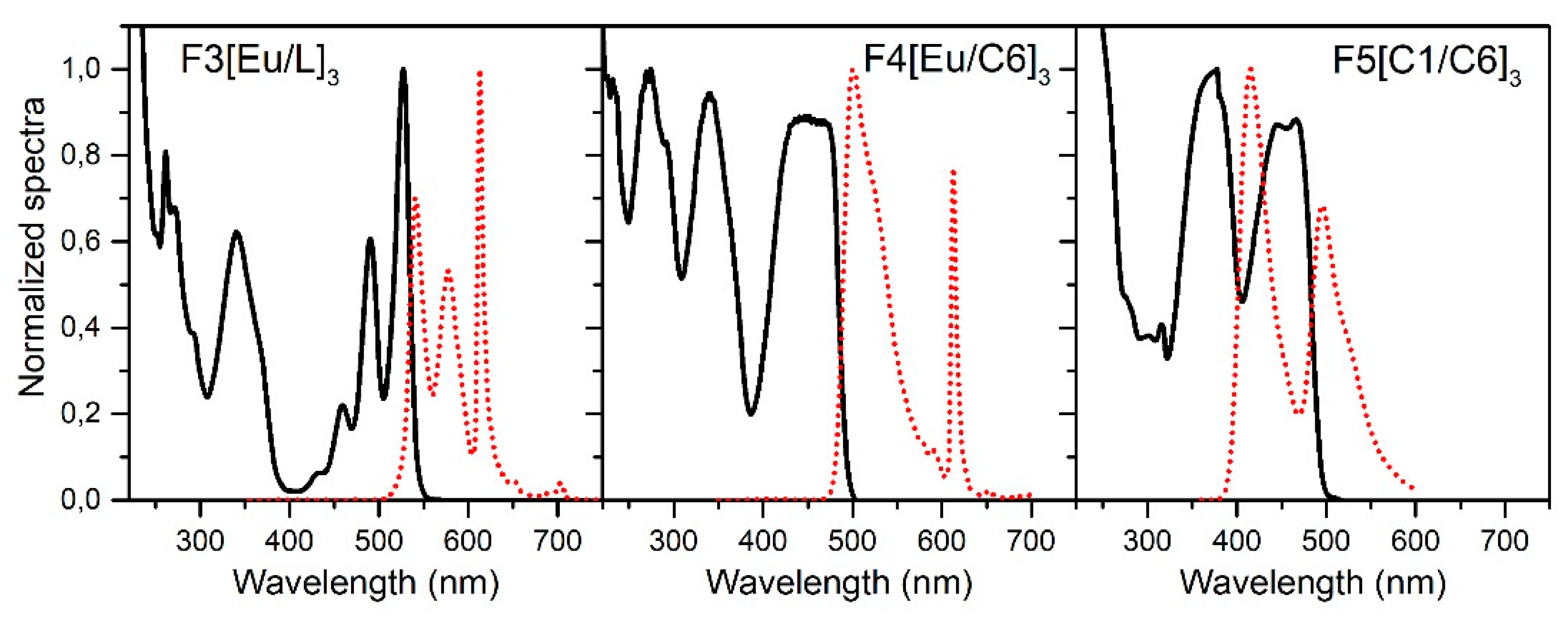

3. Results and Discussion

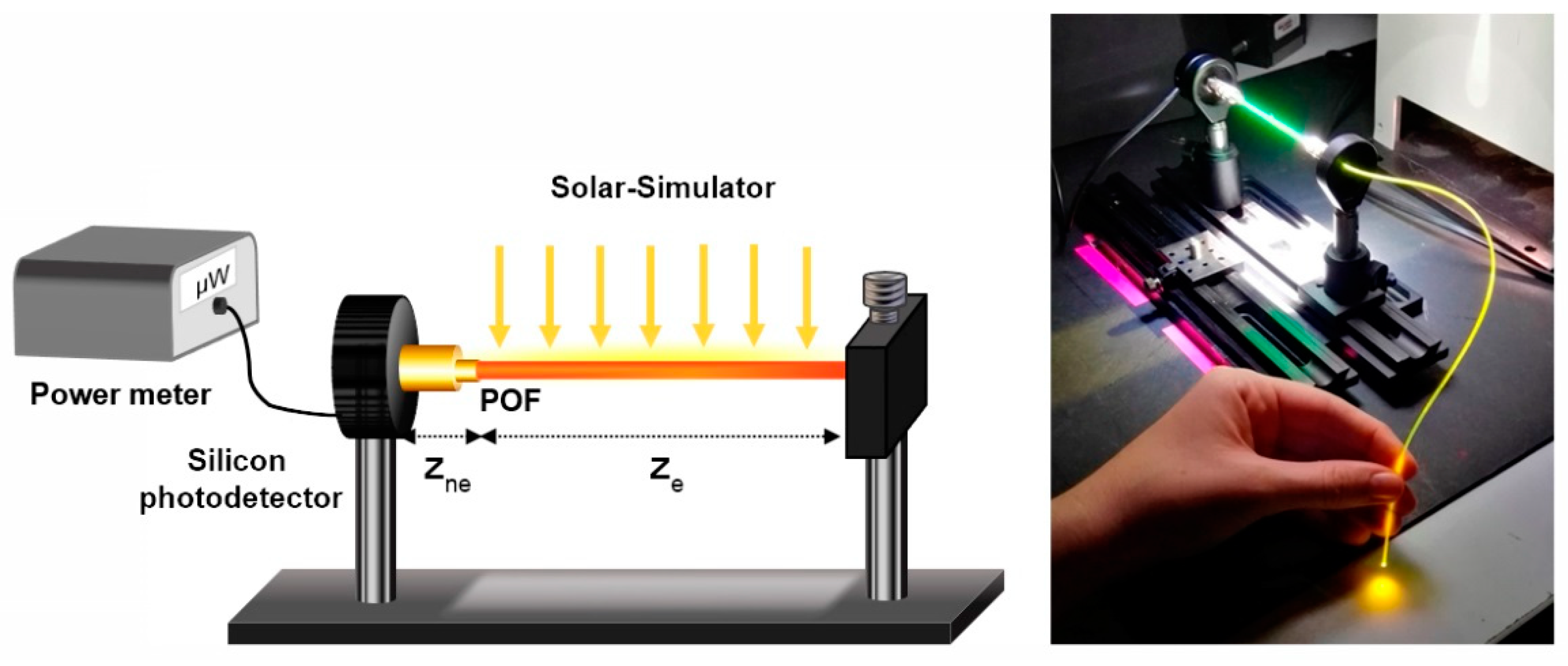

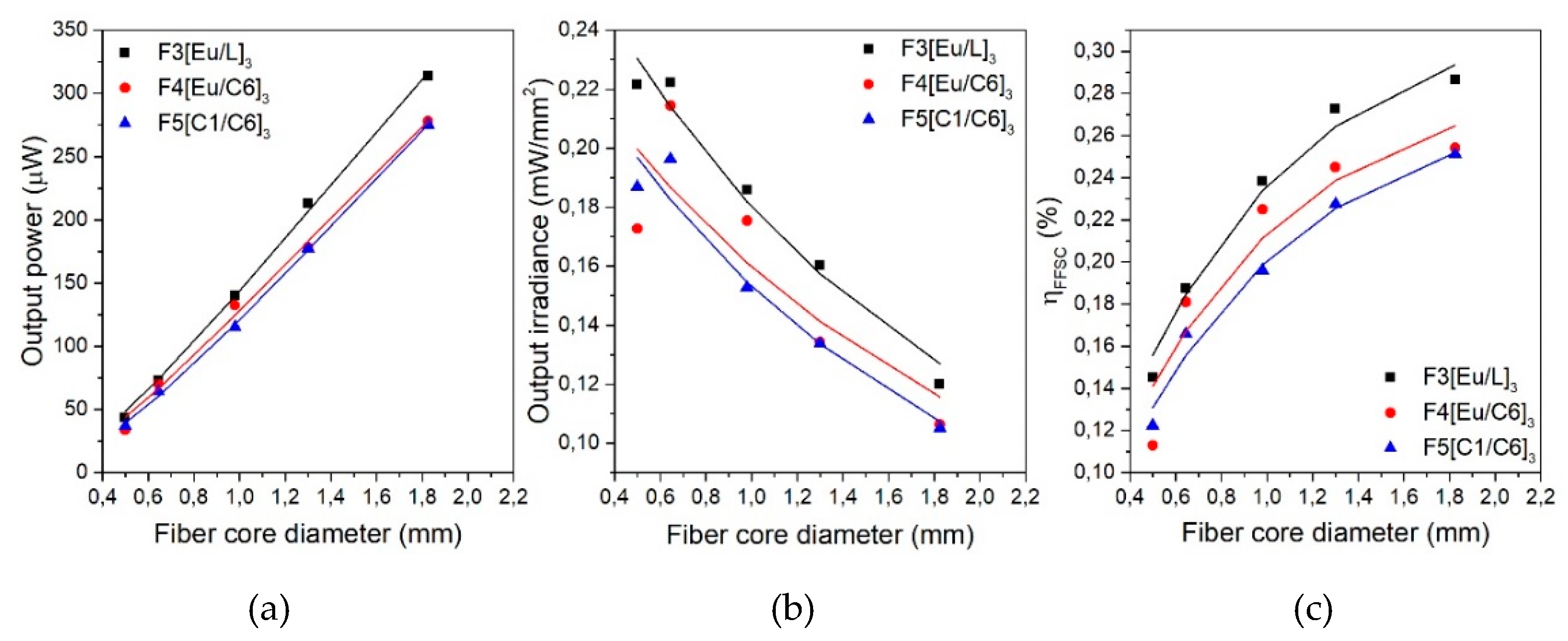

3.1. Output Power, Output Irradiance, and FFSC Efficiency

3.2. Performance under Different Lighting Conditions

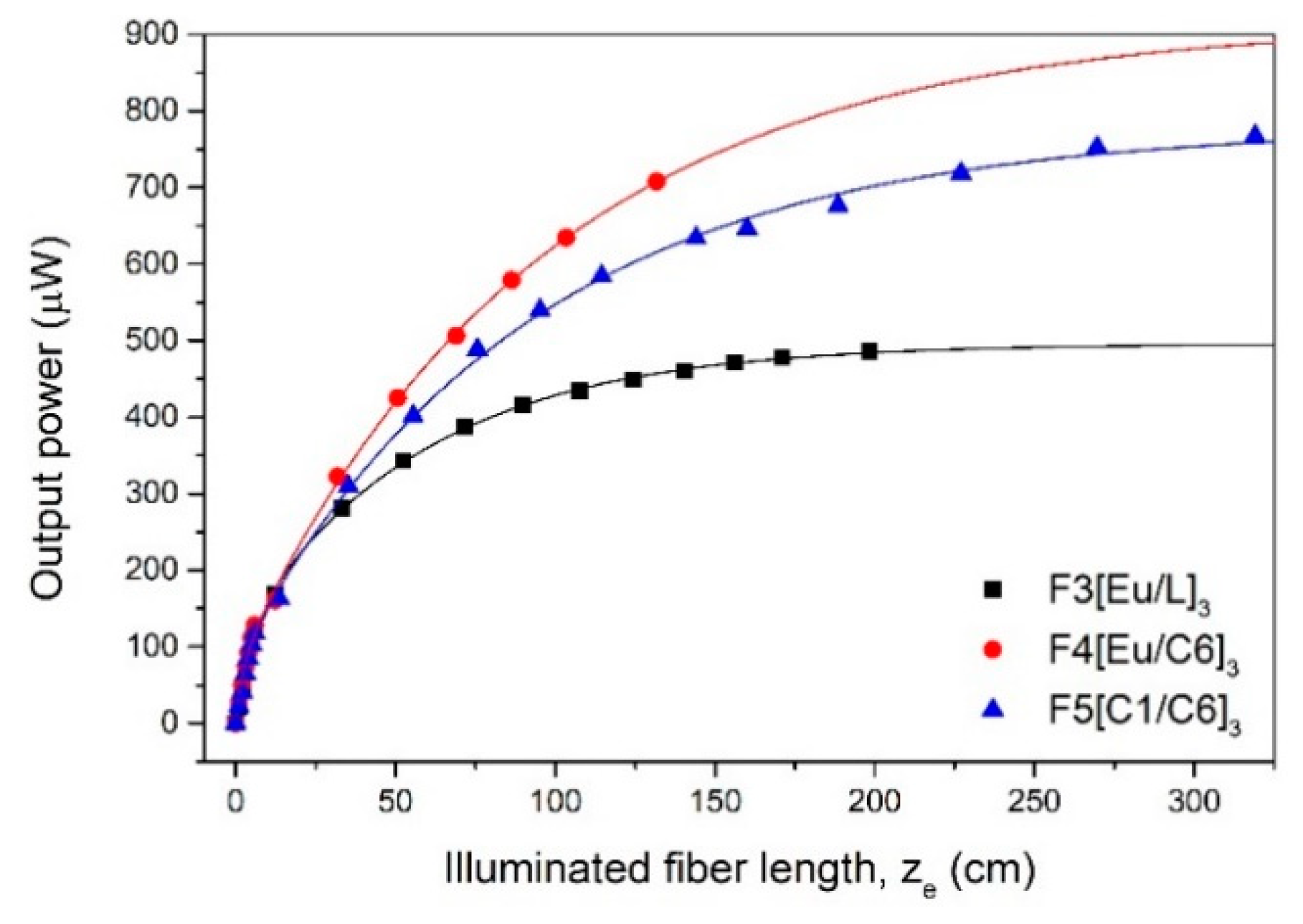

3.3. Power-Saturation Fiber Length

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- BP Statistical Review of World Energy 2017. Available online: https://www.bp.com/content/dam/bp/en/corporate/pdf/energy-economics/statistical-review-2017/bp-statistical-review-of-world-energy-2017-full-report.pdf (accessed on 12 December 2017).

- Green, M.A. The path to 25% silicon solar cell efficiency: history of silicon cell evolution. Prog. Photovolt. 2009, 17, 183–189. [Google Scholar] [CrossRef]

- Weber, W.H.; Lambe, J. Luminescent greenhouse collector for solar radiation. Appl. Opt. 1976, 15, 2299–2300. [Google Scholar] [CrossRef] [PubMed]

- BASF Lumogen F Colorants and Graphic Systems. Available online: http://www2.basf.us/additives/pdfs/p3201e.pdf (accessed on 5 February 2018).

- Currie, M.J.; Mapel, J.K.; Heidel, T.D.; Goffri, S.; Baldo, M.A. High-efficiency organic solar concentrators for photovoltaics. Science (80-) 2008, 321, 226–228. [Google Scholar] [CrossRef]

- Rowan, B.C.; Wilson, L.R.; Richards, B.S. Advanced material concepts for luminescent solar concentrators. IEEE J. Sel. Top. Quantum Electron. 2008, 14, 1312–1322. [Google Scholar] [CrossRef]

- Maggioni, G.; Campagnaro, A.; Carturan, S.; Quaranta, A. Dye-doped parylene-based thin film materials: Application to luminescent solar concentrators. Sol. Energy Mater. Sol. Cells 2013, 108, 27–37. [Google Scholar] [CrossRef]

- Kaysir, R.; Fleming, S.; Macqueen, R.W.; Schmidt, T.W.; Argyros, A. Luminescent solar concentrators utilizing stimulated emission. Opt. Express 2016, 24, A497. [Google Scholar] [CrossRef] [PubMed]

- Waldron, D.L.; Preske, A.; Zawodny, J.M.; Krauss, T.D.; Gupta, M.C. PbSe quantum dot based luminescent solar concentrators. Nanotechnology 2017, 28, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Debije, M.G.; Verbunt, P.P.C. Thirty Years of Luminescent Solar Concentrator Research: Solar Energy for the Built Environment. Adv. Energy Mater. 2012, 2, 12–35. [Google Scholar] [CrossRef]

- Edelenbosch, O.Y.; Fisher, M.; Patrignani, L.; van Sark, W.G.J.H.M.; Chatten, A.J. Luminescent solar concentrators with fiber geometry. Opt. Express 2013, 21, A503. [Google Scholar] [CrossRef]

- Banaei, E.-H.; Abouraddy, A.F. Design of a polymer optical fiber luminescent solar concentrator. Prog. Photovolt. Res. Appl. 2015, 23, 403–416. [Google Scholar] [CrossRef]

- Correia, S.F.H.; Lima, P.P.; André, P.S.; Ferreira, M.R.S.; Carlos, L.A.D. High-efficiency luminescent solar concentrators for flexible waveguiding photovoltaics. Sol. Energy Mater. Sol. Cells 2015, 138, 51–57. [Google Scholar] [CrossRef]

- Videira, J.J.H.; Bilotti, E.; Chatten, A.J. Cylindrical array luminescent solar concentrators: performance boosts by geometric effects. Opt. Express 2016, 24, A1188–A1200. [Google Scholar] [CrossRef] [PubMed]

- Mateen, F.; Oh, H.; Kang, J.; Lee, S.Y.; Hong, S.-K. Improvement in the performance of luminescent solar concentrator using array of cylindrical optical fibers. Renew. Energy 2019, 138, 691–696. [Google Scholar] [CrossRef]

- McIntosh, K.R.; Yamada, N.; Richards, B.S. Theoretical comparison of cylindrical and square-planar luminescent solar concentrators. Appl. Phys. B 2007, 88, 285–290. [Google Scholar] [CrossRef]

- Colantuono, G.; Buckley, A.; Erdelyi, R. Ray-Optics Modelling of Rectangular and Cylindrical 2-Layer Solar Concentrators. J. Light. Technol. 2013, 31, 1033–1044. [Google Scholar] [CrossRef]

- Videira, J.J.H.; Bilotti, E.; Chatten, A.J. Cylindrical and square fibre luminescent solar concentrators: Experimental and simulation comparisons. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; pp. 2280–2285. [Google Scholar]

- Verbunt, P.P.C.; Debije, M.G. Progress in luminescent solar concentrator research: solar energy for the built environment. In Proceedings of the World Renewable Energy Congress, Linköping, Sweden, 8–13 May 2011; pp. 2751–2758. [Google Scholar]

- Meinardi, F.; Ehrenberg, S.; Dhamo, L.; Carulli, F.; Mauri, M.; Bruni, F.; Simonutti, R.; Kortshagen, U.; Brovelli, S. Highly efficient luminescent solar concentrators based on earth-Abundant indirect-bandgap silicon quantum dots. Nat. Photonics 2017, 11, 177–185. [Google Scholar] [CrossRef]

- European Commission-Energy. Performance of Buildings Directive Nearly Zero-Energy Buildings. Available online: https://ec.europa.eu/energy/en/topics/energy-efficiency/buildings/nearly-zero-energy-buildings (accessed on 5 February 2018).

- van Sark, W.G.J.H.M.; Barnham, K.W.J.; Slooff, L.H.; Chatten, A.J.; Buechtemann, A.; Meyer, A.; McCormack, S.J.; Koole, R.; Farrell, D.J.; Bose, R.; et al. Luminescent Solar Concentrators - A review of recent results. Opt. Express 2008, 16, 21773–21792. [Google Scholar] [CrossRef]

- Cerdán, L.; Costela, A.; Durán-Sampedro, G.; García-Moreno, I.; Calle, M.; Juan-y-Seva, M.; de Abajo, J.; Turnbull, G.A. New perylene-doped polymeric thin films for efficient and long-lasting lasers. J. Mater. Chem. 2012, 22, 8938. [Google Scholar] [CrossRef]

- Parola, I.; Arrospide, E.; Recart, F.; Illarramendi, M.A.; Durana, G.; Guarrotxena, N.; García, O.; Zubia, J. Fabrication and characterization of polymer optical fibers doped with perylene-derivatives for fluorescent lighting applications. Fibers 2017, 5, 28. [Google Scholar] [CrossRef]

- Ayesta, I.; Illarramendi, M.A.; Arrue, J.; Parola, I.; Jiménez, F.; Zubia, J.; Tagaya, A.; Koike, Y. Optical characterization of doped thermoplastic and thermosetting polymer-Optical-Fibers. Polymers (Basel) 2017, 9, 90. [Google Scholar] [CrossRef]

- Illarramendi, M.A.; Zubia, J.; Bazzana, L.; Durana, G.; Aldabaldetreku, G.; Sarasua, J.R. Spectroscopic characterization of plastic optical fibers doped with fluorene oligomers. J. Light. Technol. 2009, 27, 3220–3226. [Google Scholar] [CrossRef]

- Parola, I.; Zaremba, D.; Evert, R.; Kielhorn, J.; Jakobs, F.; Illarramendi, M.A.; Zubia, J.; Kowalsky, W.; Johannes, H.-H. High performance fluorescent fiber solar concentrators employing double-doped polymer optical fibers. Sol. Energy Mater. Sol. Cells 2018, 178, 20–28. [Google Scholar] [CrossRef]

- Internatonal, A. ASTM G173-03(2012)-Standard Tables for Reference Solar Spectral Irradiances: Direct Normal and Hemispherical on 37° Tilted Surface. Available online: https://www.astm.org/Standards/G173.htm (accessed on 12 December 2017).

- Arrue, J.; Illarramendi, M.A.; Ayesta, I.; Jiménez, F.; Zubia, J.; Tagaya, A.; Koike, Y. Laser-like performance of side-pumped dye-doped polymer optical fibers. IEEE Photonics J. 2015, 7, 1–10. [Google Scholar] [CrossRef]

- Parola, I.; Illarramendi, M.A.; Arrue, J.; Ayesta, I.; Jiménez, F.; Zubia, J.; Tagaya, A.; Koike, Y. Characterization of the optical gain in doped polymer optical fibres. J. Lumin. 2016, 177, 1–8. [Google Scholar] [CrossRef]

- Illarramendi, M.A.; Arrue, J.; Ayesta, I.; Jiménez, F.; Zubia, J.; Bikandi, I.; Tagaya, A.; Koike, Y. Amplified spontaneous emission in graded-index polymer optical fibers: theory and experiment. Opt. Express 2013, 21, 24254–24266. [Google Scholar] [CrossRef] [PubMed]

- Arrue, J.; Jiménez, F.; Ayesta, I.; Illarramendi, M.A.; Zubia, J. Polymer-optical-fiber lasers and amplifiers doped with organic dyes. Polymers (Basel) 2011, 3, 1162–1180. [Google Scholar] [CrossRef]

| Total Fiber Diameter (μm) | Active Core Diameter (μm) | Cladding Thickness (μm) |

|---|---|---|

| 600 | 500 | 50 |

| 750 | 645 | 47 |

| 1000 | 980 | 10 |

| 1500 | 1300 | 100 |

| 2000 | 1825 | 87 |

| Diameter (mm) | F3[Eu/L]3 | F4[Eu/C6]3 | F3[C1/C6]3 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pout | ηFFSC | Iout | Pout | ηFFSC | Iout | Pout | ηFFSC | Iout | ||

| Without Reflective Layer | 0.6 | 44 | 0.15 | 0.22 | 34 | 0.11 | 0.17 | 37 | 0.12 | 0.19 |

| 0.75 | 73 | 0.19 | 0.22 | 70 | 0.18 | 0.21 | 64 | 0.17 | 0.20 | |

| 1.0 | 140 | 0.24 | 0.19 | 132 | 0.22 | 0.18 | 115 | 0.2 | 0.15 | |

| 1.5 | 213 | 0.21 | 0.16 | 178 | 0.23 | 0.13 | 177 | 0.23 | 0.13 | |

| 2.0 | 314 | 0.29 | 0.12 | 278 | 0.25 | 0.11 | 275 | 0.25 | 0.11 | |

| With Reflective Layer | 0.6 | 87 | 0.29 | 0.44 | 66 | 0.22 | 0.34 | 72 | 0.24 | 0.37 |

| 0.75 | 135 | 0.35 | 0.42 | 133 | 0.34 | 0.41 | 124 | 0.32 | 0.38 | |

| 1.0 | 265 | 0.46 | 0.36 | 238 | 0.40 | 0.32 | 217 | 0.37 | 0.29 | |

| 1.5 | 374 | 0.48 | 0.28 | 320 | 0.41 | 0.24 | 308 | 0.40 | 0.24 | |

| 2.0 | 540 | 0.50 | 0.21 | 462 | 0.42 | 0.18 | 465 | 0.43 | 0.18 | |

| Fiber Ø (mm) | F3[Eu/L]3 | F4[Eu/C6]3 | F5[C1/C6]3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Lsat | Psat | Isat | Lsat | Psat | Isat | Lsat | Psat | Isat | |

| 0.6 | 138 | 140 | 0.71 | 288 | 158 | 0.80 | 235 | 203 | 1.04 |

| 0.75 | 203 | 256 | 0.78 | 458 | 380 | 1.16 | 496 | 430 | 1.32 |

| 1.0 | 240 | 563 | 0.75 | 647 | 1005 | 1.33 | 624 | 890 | 1.18 |

| 1.5 | 173 | 615 | 0.66 | 308 | 876 | 0.66 | 203 | 895 | 0.67 |

| 2.0 | 301 | 1041 | 0.40 | 280 | 935 | 0.36 | 213 | 1022 | 0.39 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parola, I.; Illarramendi, M.A.; Jakobs, F.; Kielhorn, J.; Zaremba, D.; Johannes, H.-H.; Zubia, J. Characterization of Double-Doped Polymer Optical Fibers as Luminescent Solar Concentrators. Polymers 2019, 11, 1187. https://doi.org/10.3390/polym11071187

Parola I, Illarramendi MA, Jakobs F, Kielhorn J, Zaremba D, Johannes H-H, Zubia J. Characterization of Double-Doped Polymer Optical Fibers as Luminescent Solar Concentrators. Polymers. 2019; 11(7):1187. https://doi.org/10.3390/polym11071187

Chicago/Turabian StyleParola, Itxaso, M. Asuncion Illarramendi, Florian Jakobs, Jana Kielhorn, Daniel Zaremba, Hans-Hermann Johannes, and Joseba Zubia. 2019. "Characterization of Double-Doped Polymer Optical Fibers as Luminescent Solar Concentrators" Polymers 11, no. 7: 1187. https://doi.org/10.3390/polym11071187

APA StyleParola, I., Illarramendi, M. A., Jakobs, F., Kielhorn, J., Zaremba, D., Johannes, H.-H., & Zubia, J. (2019). Characterization of Double-Doped Polymer Optical Fibers as Luminescent Solar Concentrators. Polymers, 11(7), 1187. https://doi.org/10.3390/polym11071187