How does Pickering Emulsion Pre-treatment Influence the Properties of Wood Flour and its Composites with High-Density Polyethylene?

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

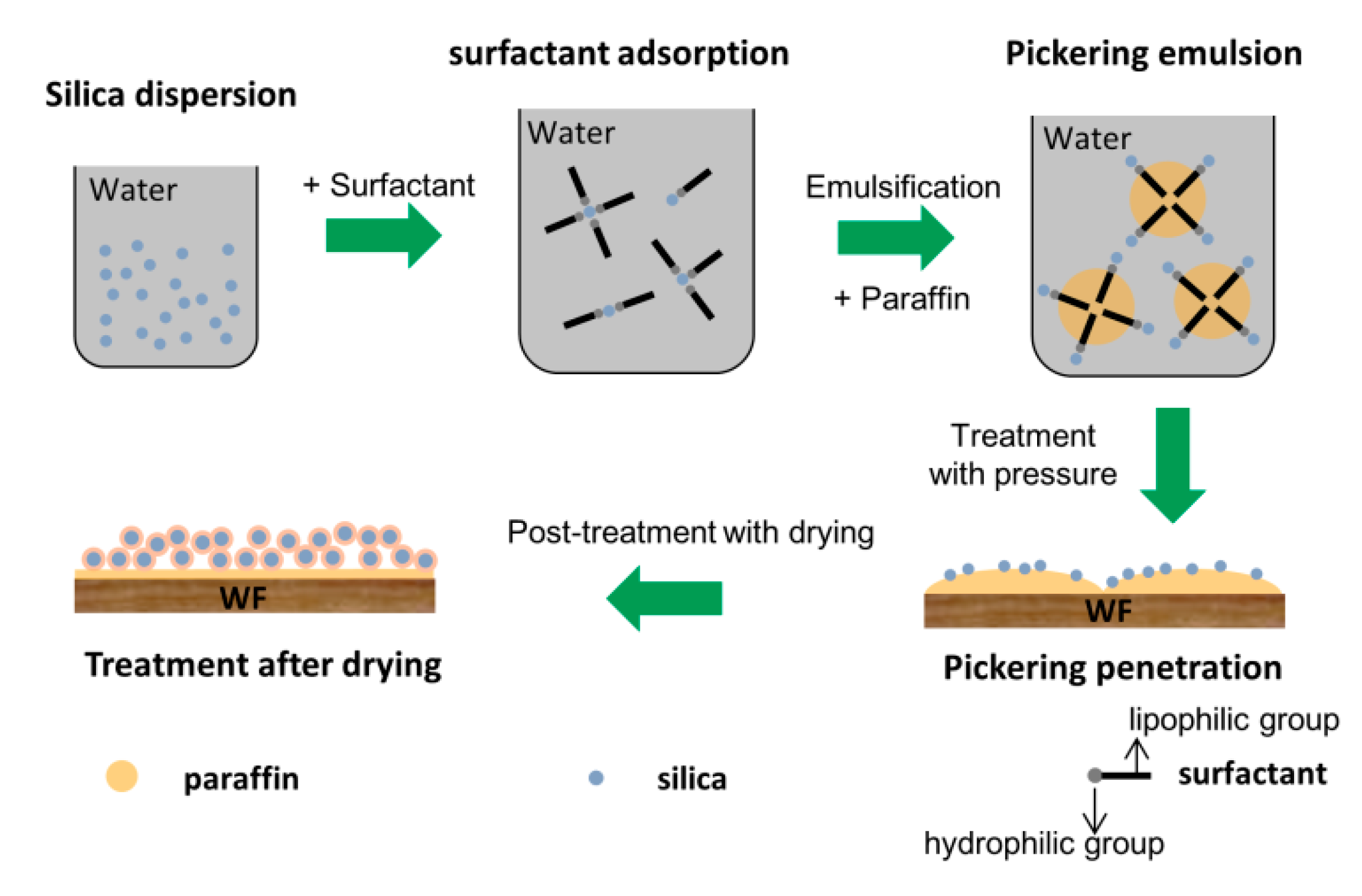

2.2. Pickering Emulsion Preparation and WFs Treatment

2.3. WF/HDPE Composites Fabrication

2.4. Analytical Methods Applied

3. Results and Discussion

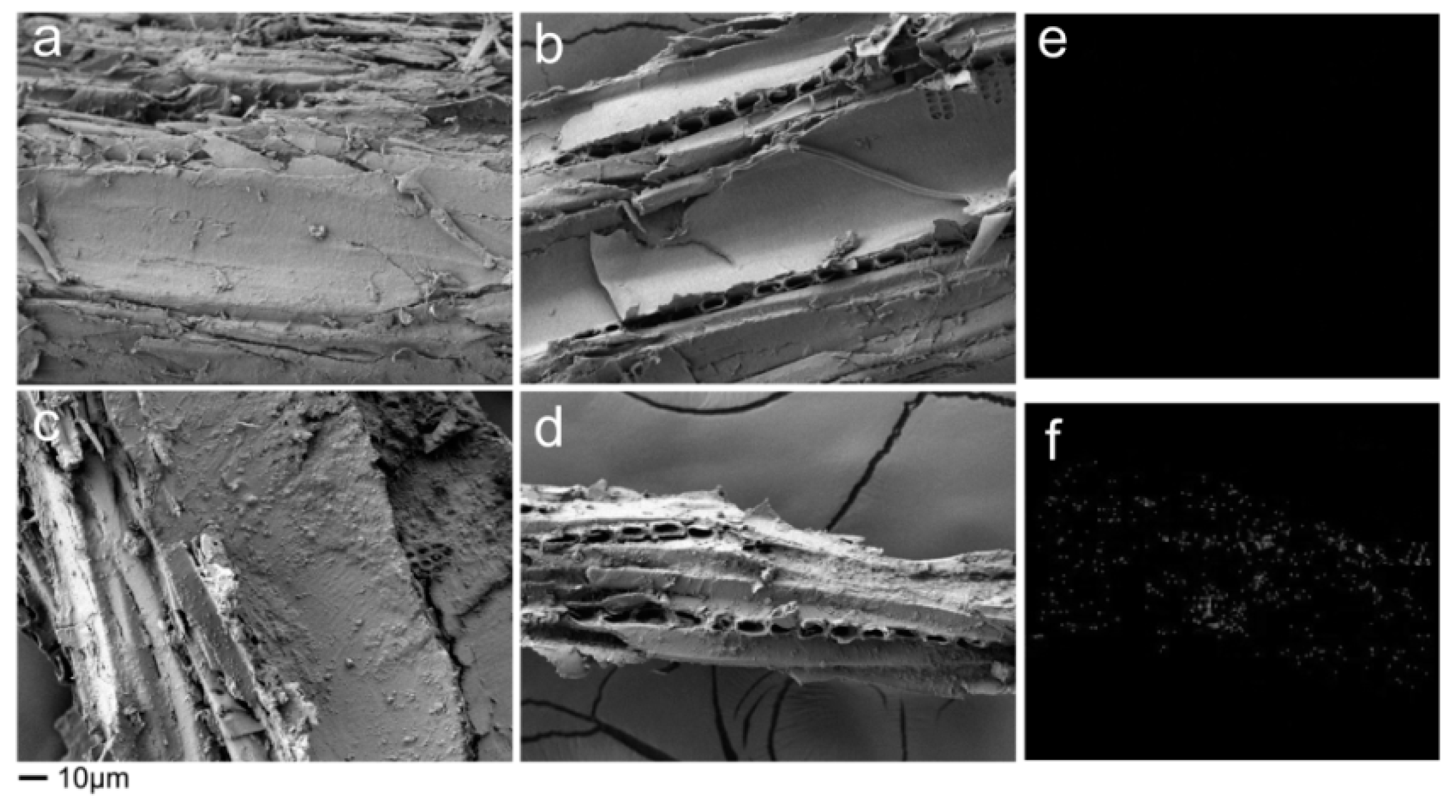

3.1. Microstructure of WFs

3.2. FTIR Characterization

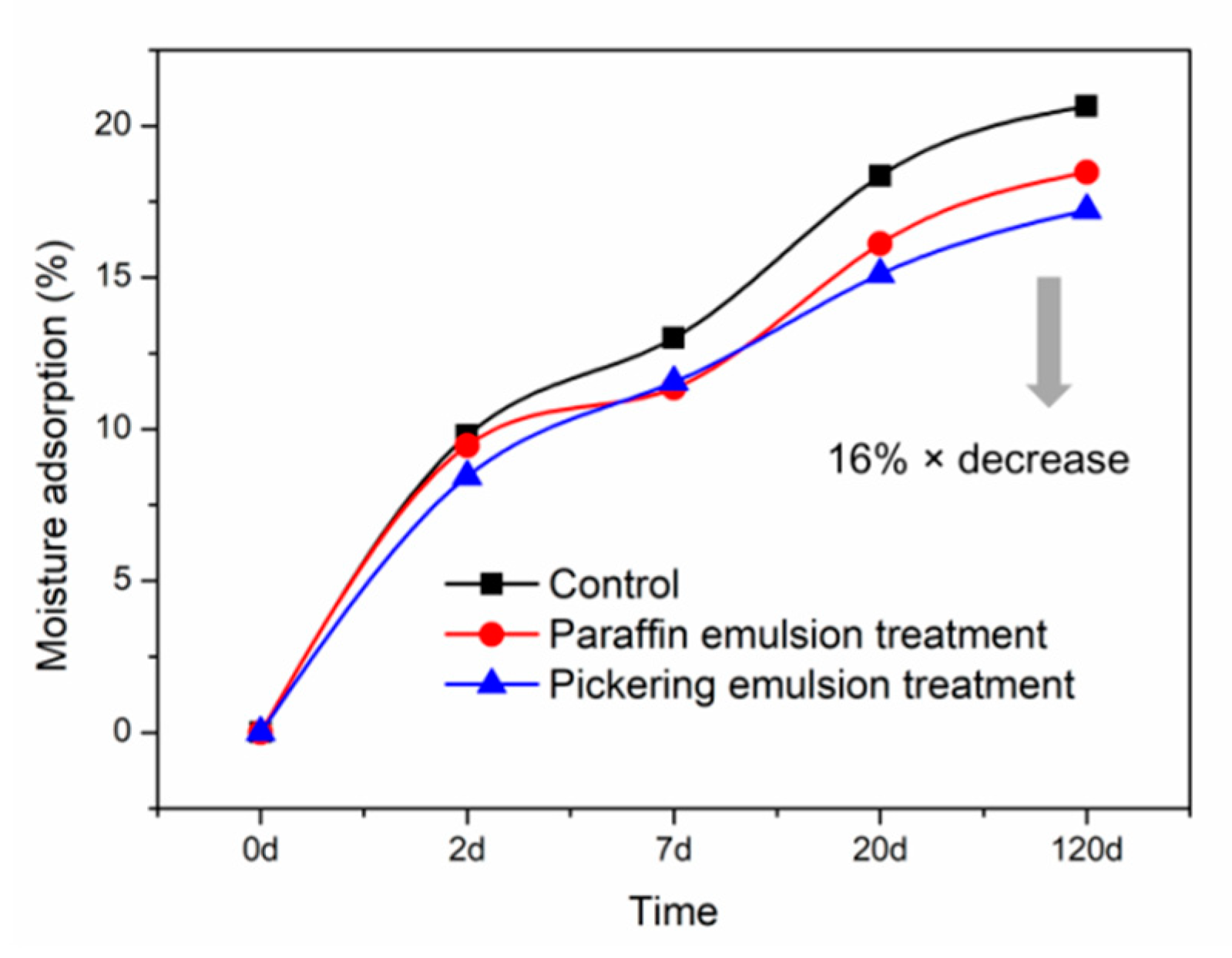

3.3. Moisture Adsorption of WFs

3.4. MFI Analysis

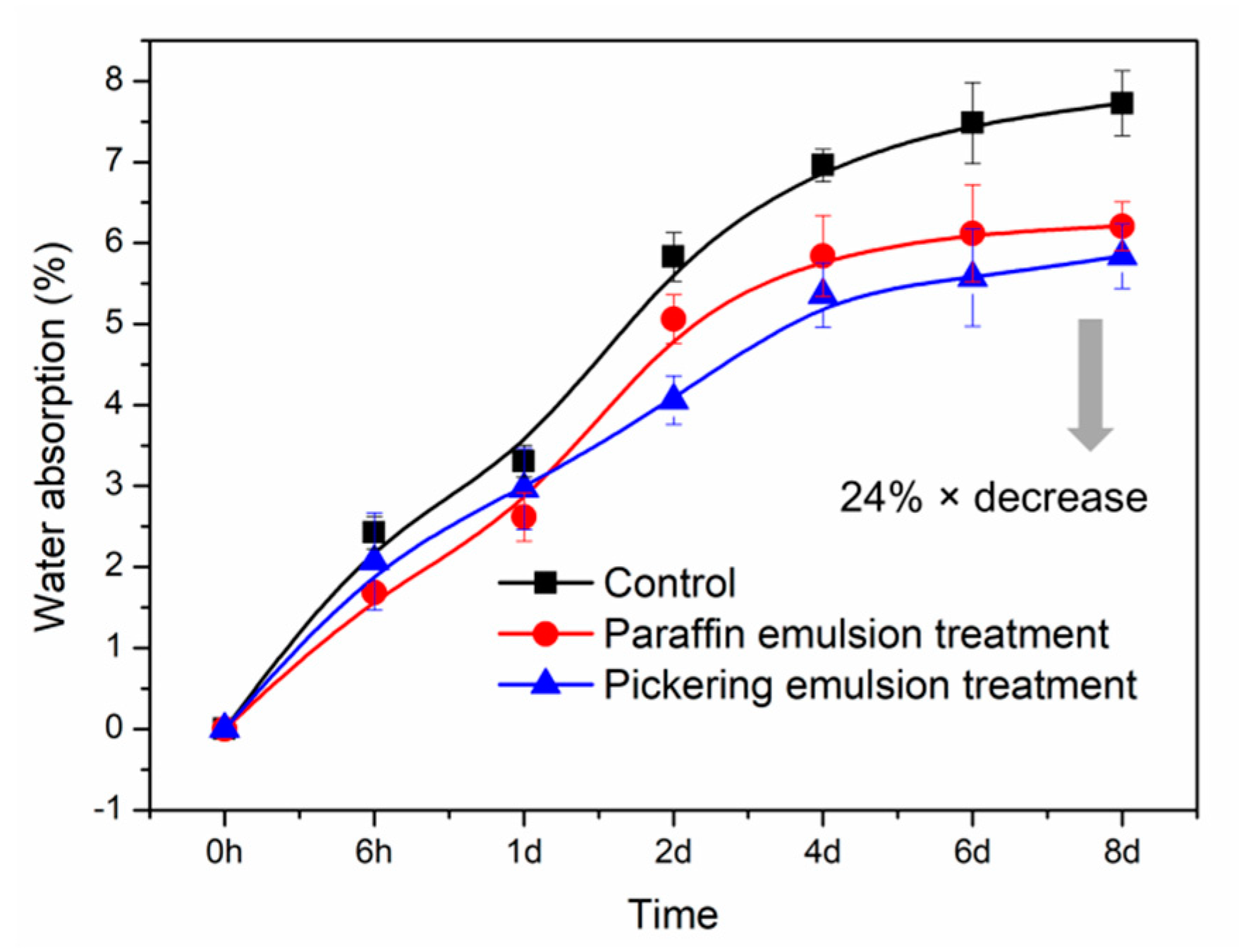

3.5. WA of Composites

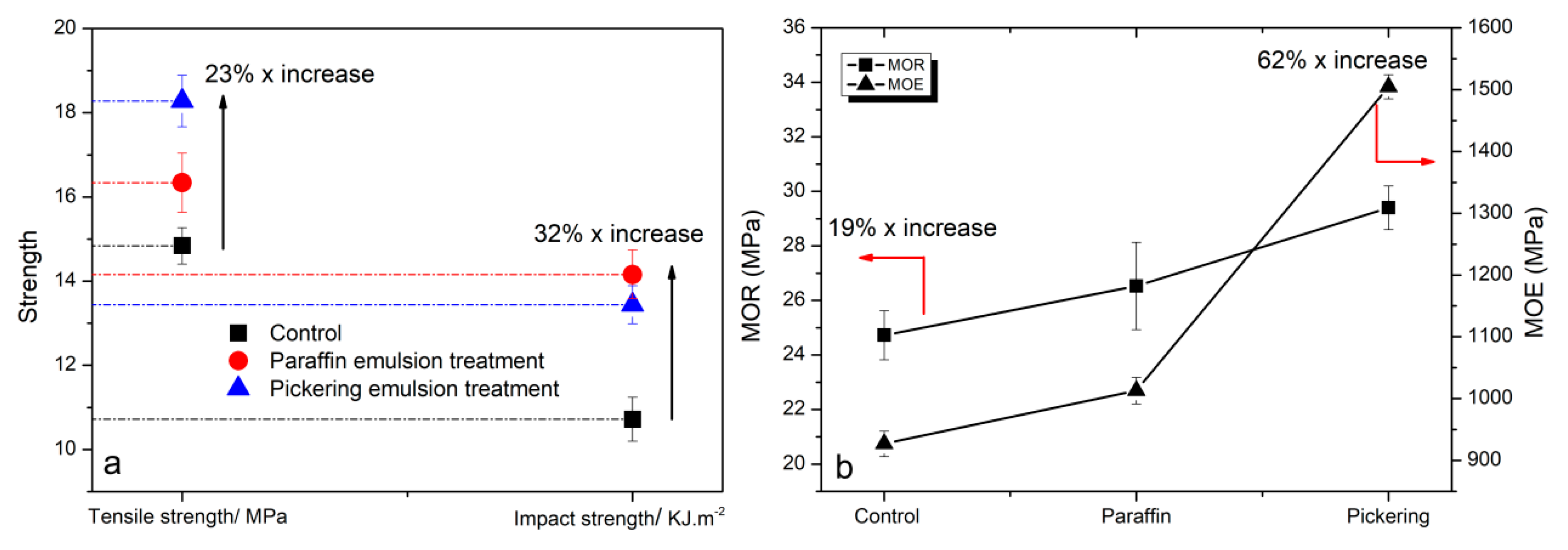

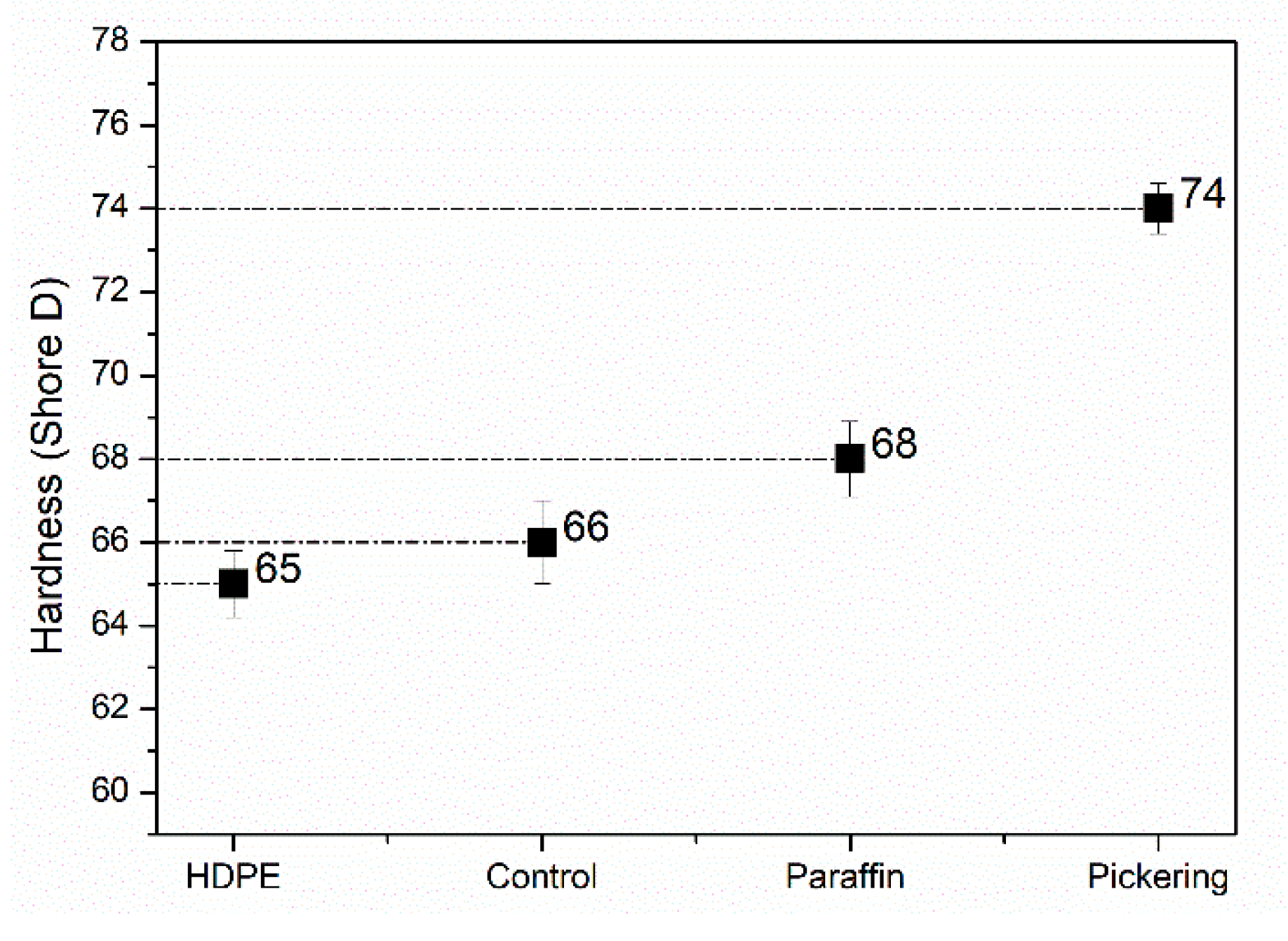

3.6. Mechanical Properties and Surface Hardness

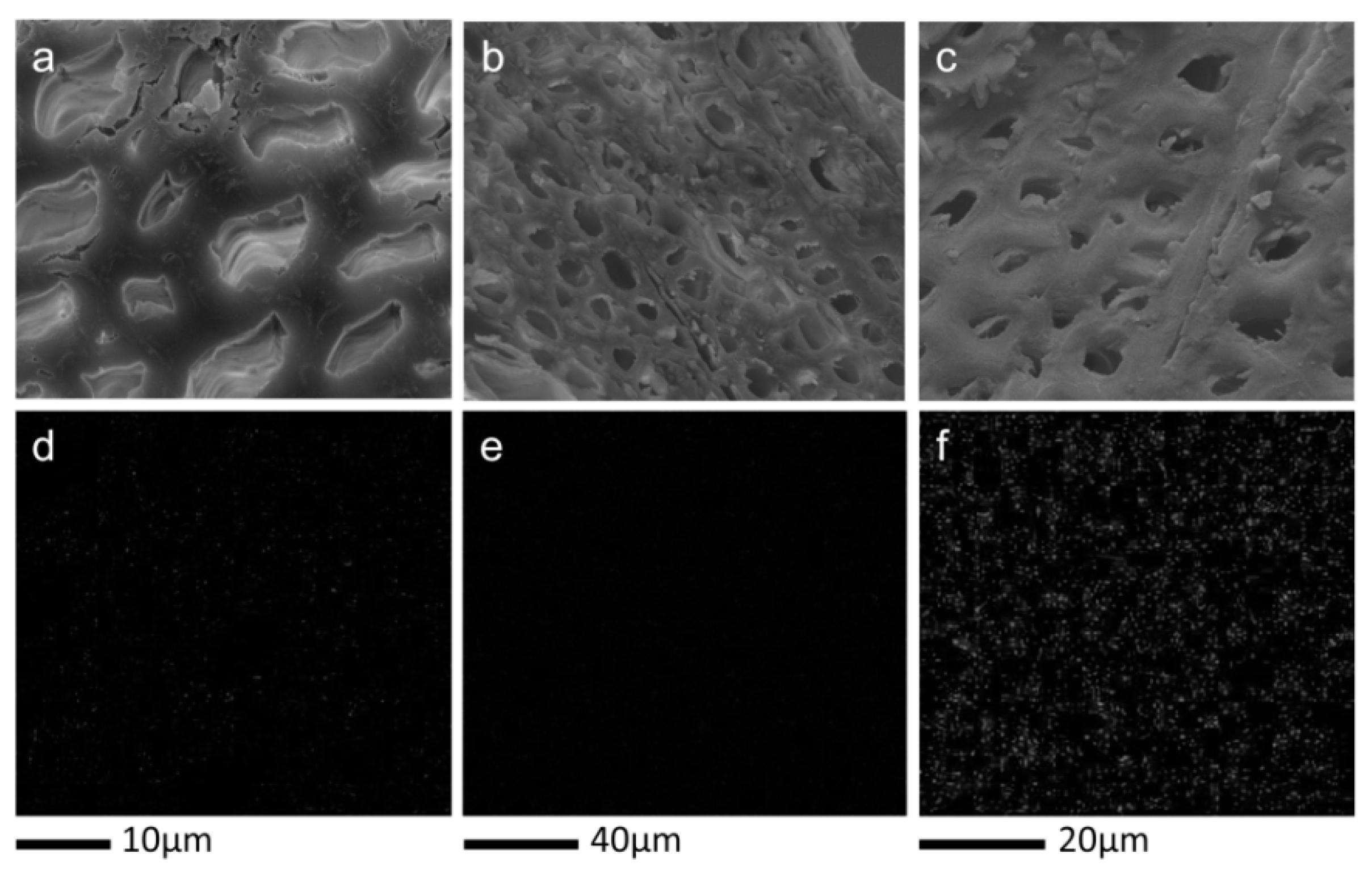

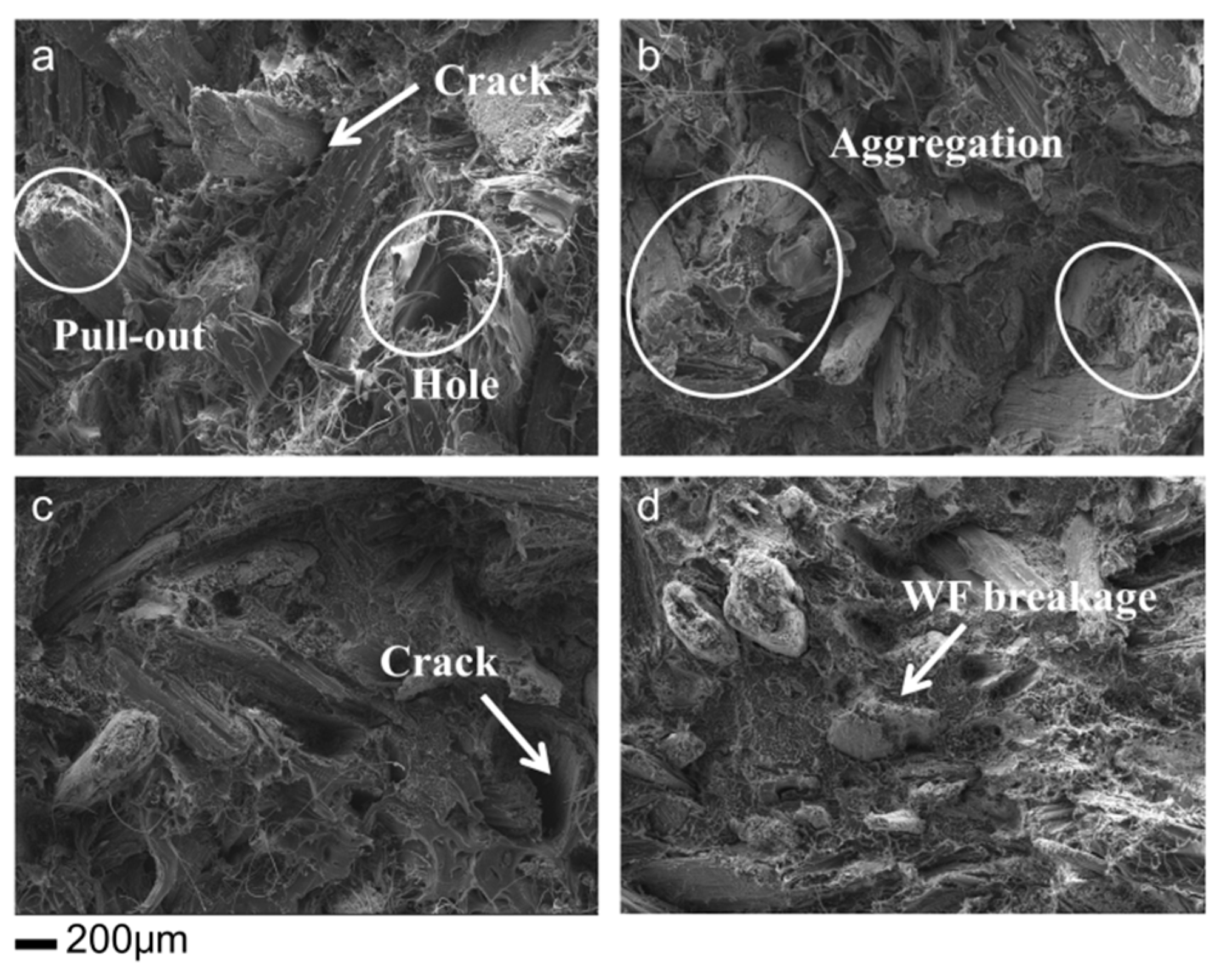

3.7. Microstructure of Impact Fracture Surface

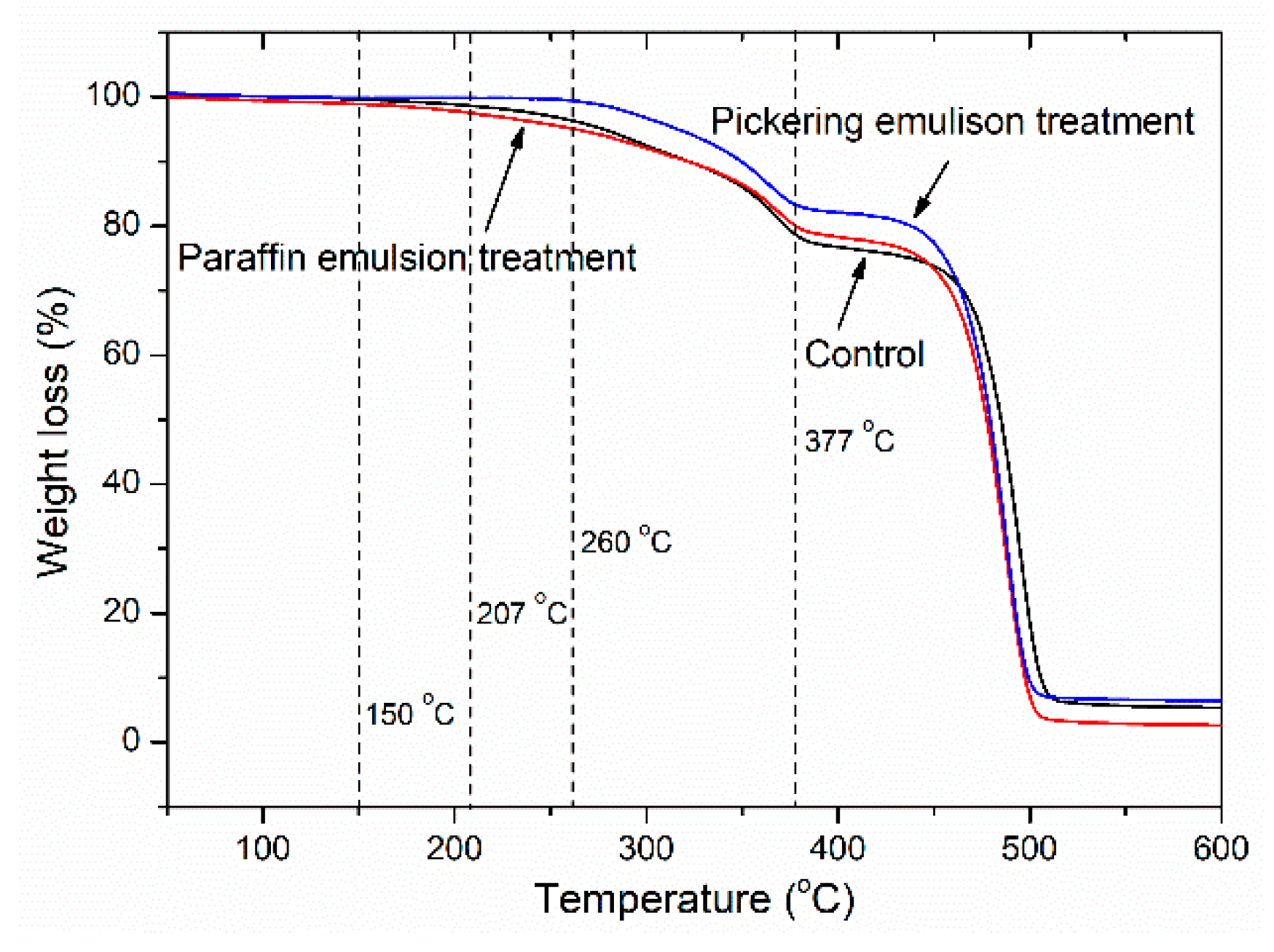

3.8. Thermal Stability

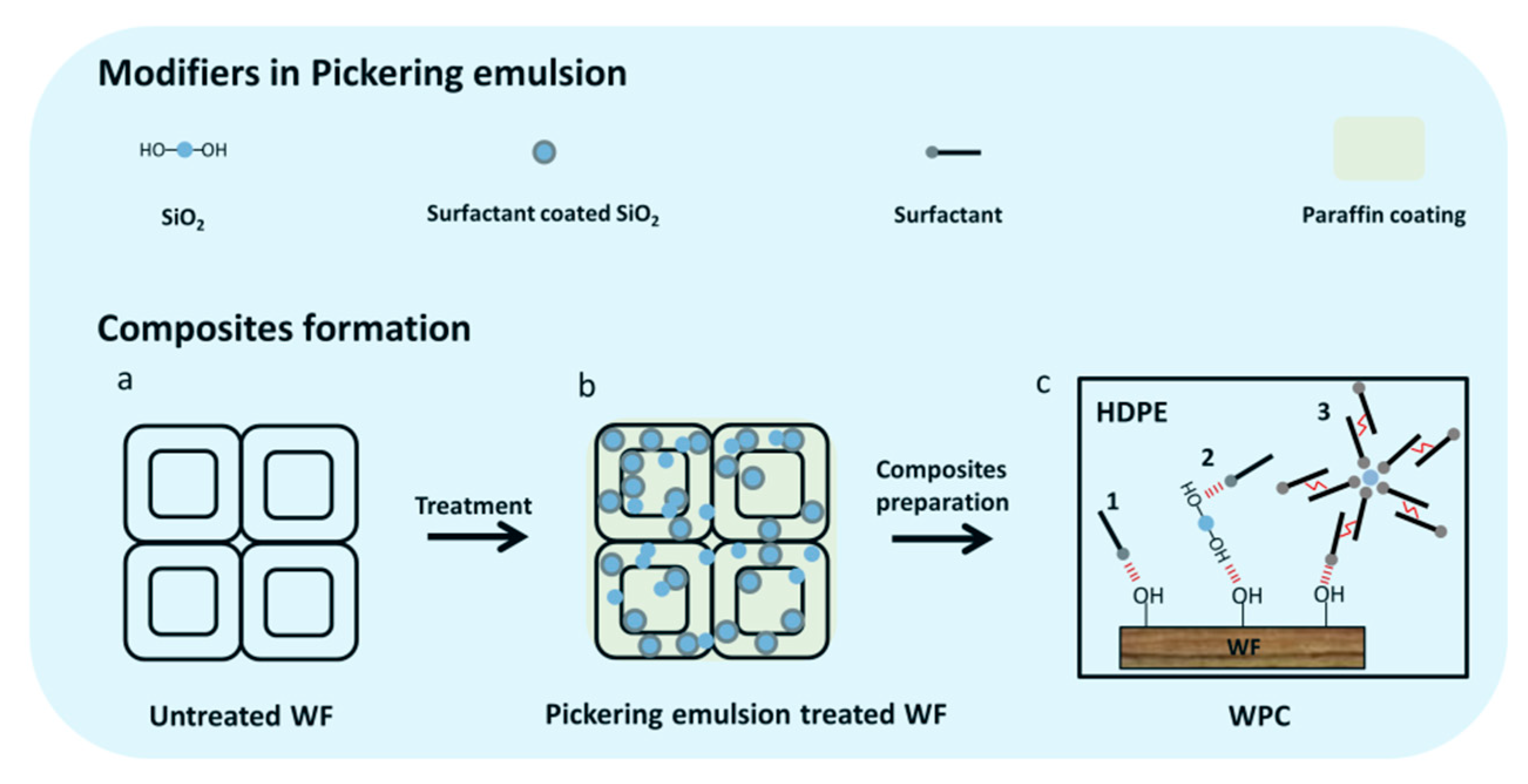

3.9. Model for Composites Formation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sharma, P.R.; Joshi, R.; Sharma, S.K.; Hsiao, B.S. A simple approach to prepare carboxycellulose nanofibers from untreated biomass. Biomacromolecules 2017, 18, 2333–2342. [Google Scholar] [CrossRef] [PubMed]

- Klemm, D.; Cranston, E.D.; Fischer, D.; Gama, M.; Kedzior, S.A.; Kralisch, D.; Petzold-Welcke, K. Nanocellulose as a natural source for groundbreaking applications in materials science: Today’s state. Mater. Today 2018, 21, 720–748. [Google Scholar] [CrossRef]

- Sharma, P.R.; Chattopadhyay, A.; Sharma, S.K.; Geng, L.; Amiralian, N.; Martin, D.; Hsiao, B.S. Nanocellulose from spinifex as an effective adsorbent to remove cadmium (II) from water. ACS Sustain. Chem. Eng. 2018, 6, 3279–3290. [Google Scholar] [CrossRef]

- Sharma, P.R.; Zheng, B.; Sharma, S.K.; Zhan, C.; Wang, R.; Bhatia, S.R.; Hsiao, B.S. High Aspect Ratio Carboxycellulose Nanofibers Prepared by Nitro-Oxidation Method and Their Nanopaper Properties. ACS Appl. Nano Mater. 2018, 1, 3969–3980. [Google Scholar] [CrossRef]

- Hosseinmardi, A.; Annamalai, P.K.; Wang, L.; Martin, D.; Amiralian, N. Reinforcement of natural rubber latex using lignocellulosic nanofibers isolated from spinifex grass. Nanoscale 2017, 9, 9510–9519. [Google Scholar] [CrossRef]

- Guo, Y.; Zhu, S.; Chen, Y.; Liu, D.; Li, D. Acoustic Emission-Based Study to Characterize the Crack Initiation Point of Wood Fiber/HDPE Composites. Polymers 2019, 11, 701. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, V.; Hao, J.; Wang, W. Ultraviolet weathering performance of high-density polyethylene/wood-flour composites with a basalt-fiber-included shell. Polymers 2018, 10, 831. [Google Scholar] [CrossRef]

- Tian, S.; He, H.; Yu, P.; Zhou, L.; Luo, Y.; Jia, D. Sustainable utilization of waste printed circuit boards powders in HDPE-wood composites: Synergistic effects of multicomponents on structure and properties. J. Clean. Prod. 2017, 164, 840–847. [Google Scholar] [CrossRef]

- Jiang, J.; Mei, C.; Pan, M.; Lu, F. Effects of hybridization and interface modification on mechanical properties of wood flour/polymer composites reinforced by glass fibers. Polym. Compos. 2019. [Google Scholar] [CrossRef]

- Liu, R.; Chen, Y.; Cao, J. Effects of modifier type on properties of in situ organo-montmorillonite modified wood flour/poly (lactic acid) composites. ACS Appl. Mater. Interfaces 2015, 8, 161–168. [Google Scholar] [CrossRef]

- Wu, J.; Yu, D.; Chan, C.M.; Kim, J.; Mai, Y.W. Effect of fiber pretreatment condition on the interfacial strength and mechanical properties of wood fiber/PP composites. J. Appl. Polym. Sci. 2000, 76, 1000–1010. [Google Scholar] [CrossRef]

- Liu, R.; Luo, S.; Cao, J.; Peng, Y. Characterization of organo-montmorillonite (OMMT) modified wood flour and properties of its composites with poly (lactic acid). Compos. Part A: Appl. Sci. Manuf. 2013, 51, 33–42. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Liu, R.; Sun, W.; Cao, J.; Wang, J. Surface properties of in situ organo-montmorillonite modified wood flour and the influence on mechanical properties of composites with polypropylene. Appl. Surf. Sci. 2016, 361, 234–241. [Google Scholar] [CrossRef]

- Wang, Y.; Qi, R.; Xiong, C.; Huang, M. Effects of coupling agent and interfacial modifiers on mechanical properties of poly (lactic acid) and wood flour biocomposites. Iranian Polym. J. 2011, 20, 281–294. [Google Scholar]

- Luo, S.; Cao, J.; Peng, Y. Properties of glycerin-thermally modified wood flour/polypropylene composites. Polym. Compos. 2014, 35, 201–207. [Google Scholar] [CrossRef]

- Csizmadia, R.; Faludi, G.; Renner, K.; Móczó, J.; Pukánszky, B. PLA/wood biocomposites: Improving composite strength by chemical treatment of the fibers. Compos. Part A: Appl. Sci. Manuf. 2013, 53, 46–53. [Google Scholar] [CrossRef]

- Klyosov, A.A. Wood-Plastic Composites; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Viksne, A.; Rence, L.; Kalnins, M.; Bledzki, A.K. The effect of paraffin on fiber dispersion and mechanical properties of polyolefin–sawdust composites. J. Appl. Polym. Sci. 2004, 93, 2385–2393. [Google Scholar] [CrossRef]

- Pan, Y.; Liu, Y.; Cheng, Q.; Celikbag, Y.; Via, B.K.; Wang, X.; Sun, R. Surface coating of microcrystalline cellulose with surfactants and paraffin wax. Eur. J. Wood Wood Prod. 2016, 74, 763–765. [Google Scholar] [CrossRef]

- Viksne, A.; Rence, L.; Berzina, R. Influence of modifiers on the physicomechanical properties of sawdust-polyethylene composites. Mech. Compos. Mater. 2004, 40, 169–178. [Google Scholar] [CrossRef]

- Shahnazar, S.; Bagheri, S.; Hamid, S.B.A. Enhancing lubricant properties by nanoparticle additives. Int. J. Hydrogen Energ. 2016, 41, 3153–3170. [Google Scholar] [CrossRef]

- Li, X.; Cao, Z.; Zhang, Z.; Dang, H. Surface-modification in situ of nano-SiO2 and its structure and tribological properties. Appl. Surf. Sci. 2006, 252, 7856–7861. [Google Scholar] [CrossRef]

- Peng, D.X.; Kang, Y.; Hwang, R.M.; Shyr, S.S.; Chang, Y.P. Tribological properties of diamond and SiO2 nanoparticles added in paraffin. Tribol. Int. 2009, 42, 911–917. [Google Scholar] [CrossRef]

- Jiang, J.; Cao, J.; Wang, W.; Shen, H. Preparation of a synergistically stabilized oil-in-water paraffin Pickering emulsion for potential application in wood treatment. Holzforschung 2018, 72, 489–497. [Google Scholar] [CrossRef]

- Aveyard, R.; Binks, B.P.; Clint, J.H. Emulsions stabilised solely by colloidal particles. Adv. Colloid Interface Sci. 2003, 100, 503–546. [Google Scholar] [CrossRef]

- Binks, B.P. Particles as surfactants-similarities and differences. Curr. Opin. Colloid Interf. Sci. 2002, 7, 21–41. [Google Scholar] [CrossRef]

- Jiang, J.; Cao, J.; Wang, W. Characteristics of wood-silica composites influenced by the pH value of silica sols. Holzforschung 2018, 72, 311–319. [Google Scholar] [CrossRef]

- Zhou, H.; Hao, X.; Wang, H.; Wang, X.; Liu, T.; Xie, Y.; Wang, Q. The reinforcement efficacy of nano-and microscale silica for extruded wood flour/HDPE composites: the effects of dispersion patterns and interfacial modification. J. Mater. Sci. 2018, 53, 1899–1910. [Google Scholar] [CrossRef]

- Pries, M.; Mai, C. Treatment of wood with silica sols against attack by wood-decaying fungi and blue stain. Holzforschung 2013, 67, 697–705. [Google Scholar] [CrossRef]

- Najafi, A.; Golestani-Fard, F.; Rezaie, H.R.; Ehsani, N. A study on sol–gel synthesis and characterization of SiC nano powder. J. Sol-Gel Sci. Technol. 2011, 59, 205–214. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Y.; Li, X.; Luo, J.; Gao, Q.; Li, J. “Green” bio-thermoset resins derived from soy protein isolate and condensed tannins. Ind. Crops Prod. 2017, 108, 363–370. [Google Scholar] [CrossRef]

- Farooq, A.; Shafaghat, H.; Jae, J.; Jung, S.C.; Park, Y.K. Enhanced stability of bio-oil and diesel fuel emulsion using Span 80 and Tween 60 emulsifiers. J. Eeviorn. Manage. 2019, 231, 694–700. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Cao, J.; Wang, W.; Mei, C. Analysis on the Influence of Component Ratio on Properties of Silica/Montmorillonite Nanocomposites. Materials 2018, 11, 2074. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Zhu, Y.; Cao, J.; Guo, X. Thermal modification of Southern pine combined with wax emulsion preimpregnation: Effect on hydrophobicity and dimensional stability. Holzforschung 2015, 69, 405–413. [Google Scholar] [CrossRef]

- Benavente, V.; Fullana, A. Torrefaction of olive mill waste. Biomass & Bioenergy 2015, 73, 186–194. [Google Scholar]

- Lu, Y.; Feng, M.; Zhan, H. Preparation of SiO2-wood composites by an ultrasonic-assisted sol-gel technique. Cellulose 2014, 21, 4393–4403. [Google Scholar] [CrossRef]

- Balasuriya, P.W.; Ye, L.; Mai, Y.W. Mechanical properties of wood flake–polyethylene composites. Part I: effects of processing methods and matrix melt flow behaviour. Compos. Part A: Appl. Sci. Manuf. 2001, 32, 619–629. [Google Scholar] [CrossRef]

- Liu, W.; Chen, S. An investigation of the tribological behaviour of surface-modified ZnS nanoparticles in liquid paraffin. Wear 2000, 238, 120–124. [Google Scholar] [CrossRef]

- Messersmith, P.B.; Giannelis, E.P. Synthesis and barrier properties of poly (ε-caprolactone)-layered silicate nanocomposites. J. Polym. Sci. Polym. Chem. 1995, 33, 1047–1057. [Google Scholar] [CrossRef]

- Phillips, D.C.; Harris, B. The Strength, Toughness and Fatigue Properties of Polymer Composites. In Polymer Engineering Composites; Richardson, M.O.R., Ed.; Applied Science Publishers: London, UK, 1977; pp. 197–235. [Google Scholar]

- Jiang, J.; Wang, W.; Shen, H.; Wang, J.; Cao, J. Characterization of silica particles modified with γ-methacryloxypropyltrimethoxysilane. Appl. Surf. Sci. 2017, 397, 104–111. [Google Scholar] [CrossRef]

- Esteves, B.; Nunes, L.; Domingos, I.; Pereira, H. Improvement of termite resistance, dimensional stability and mechanical properties of pine wood by paraffin impregnation. Eur. J. Wood Wood Prod. 2014, 72, 609–615. [Google Scholar] [CrossRef]

- Koohestani, B.; Ganetri, I.; Yilmaz, E. Effects of silane modified minerals on mechanical, microstructural, thermal, and rheological properties of wood plastic composites. Compos. Part B-eng. 2017, 111, 103–111. [Google Scholar] [CrossRef]

- Deka, B.K.; Maji, T.K. Effect of silica nanopowder on the properties of wood flour/polymer composite. Polym. Eng. Sci. 2012, 52, 1516–1523. [Google Scholar] [CrossRef]

- Pries, M.; Mai, C. Fire resistance of wood treated with a cationic silica sol. Eur. J. Wood Wood Prod. 2013, 2, 237–244. [Google Scholar] [CrossRef]

- Sun, L.; Yang, J.T.; Lin, G.Y.; Zhong, M.Q. Crystallization and thermal properties of polyamide 6 composites filled with different nanofillers. Mater. Lett. 2007, 18, 3963–3966. [Google Scholar] [CrossRef]

- Lee, J.; Zhou, Z.L.; Behrens, S.H. Interfaces Charged by a Nonionic Surfactant. J. Phys. Chem. B. 2018, 22, 6101–6106. [Google Scholar] [CrossRef]

- Li, L.; Zhang, J.; Sun, H.; Xu, J.; Sun, D. Dispersion stability of organoclay in octane improved by adding nonionic surfactants. Colloids Surf. A: Physicochem. Eng. Aspects 2012, 415, 180–186. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, J.; Mei, C.; Pan, M.; Cao, J. How does Pickering Emulsion Pre-treatment Influence the Properties of Wood Flour and its Composites with High-Density Polyethylene? Polymers 2019, 11, 1115. https://doi.org/10.3390/polym11071115

Jiang J, Mei C, Pan M, Cao J. How does Pickering Emulsion Pre-treatment Influence the Properties of Wood Flour and its Composites with High-Density Polyethylene? Polymers. 2019; 11(7):1115. https://doi.org/10.3390/polym11071115

Chicago/Turabian StyleJiang, Jun, Changtong Mei, Mingzhu Pan, and Jinzhen Cao. 2019. "How does Pickering Emulsion Pre-treatment Influence the Properties of Wood Flour and its Composites with High-Density Polyethylene?" Polymers 11, no. 7: 1115. https://doi.org/10.3390/polym11071115

APA StyleJiang, J., Mei, C., Pan, M., & Cao, J. (2019). How does Pickering Emulsion Pre-treatment Influence the Properties of Wood Flour and its Composites with High-Density Polyethylene? Polymers, 11(7), 1115. https://doi.org/10.3390/polym11071115