Structural and Thermo-Mechanical Properties of Poly(ε-Caprolactone) Modified by Various Peroxide Initiators

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Modified PCL Samples

2.3. Characterization of PCL Samples

2.3.1. Mechanical Properties

2.3.2. Dynamic Mechanical Analysis

2.3.3. Hardness

2.3.4. Fourier Infrared Spectroscopy

2.3.5. Gel Content

2.3.6. Differential Scanning Calorimetry Analysis

2.3.7. Thermogravimetric Analysis

2.3.8. Emission of Volatile Organic Compounds

3. Results and Discussion

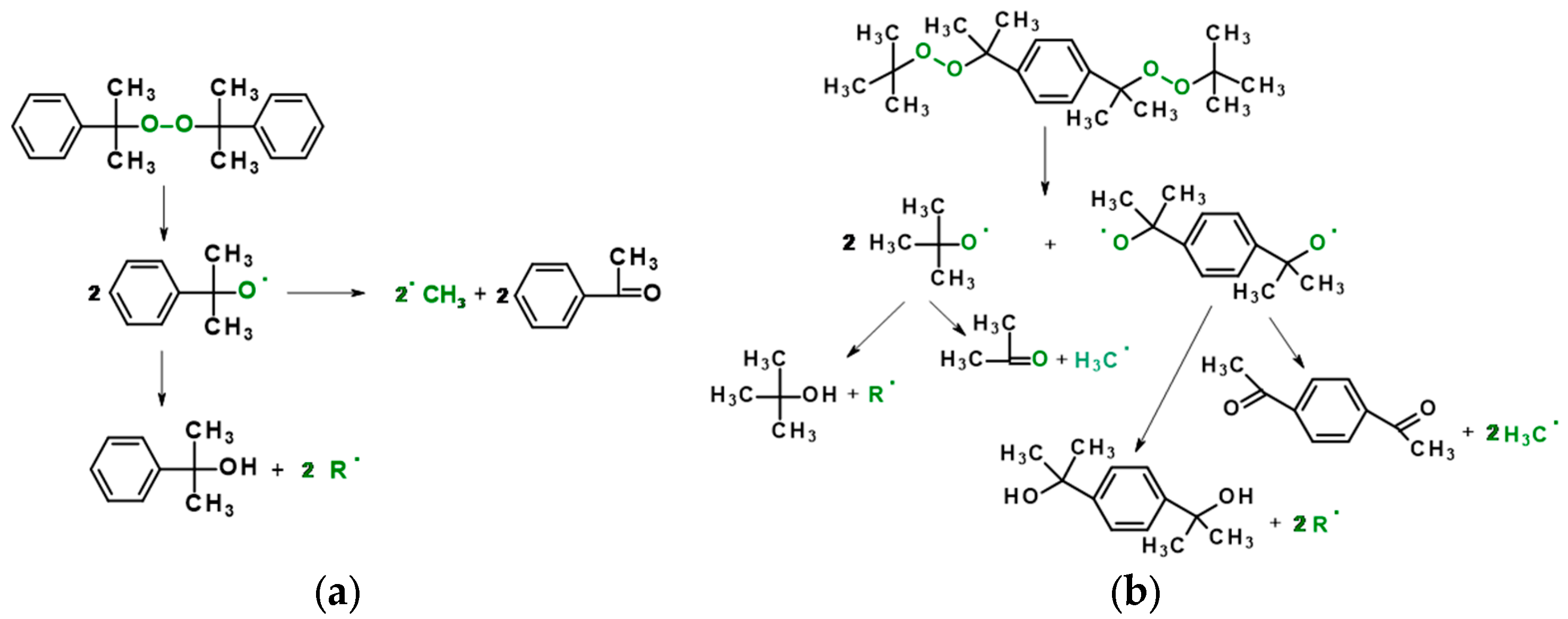

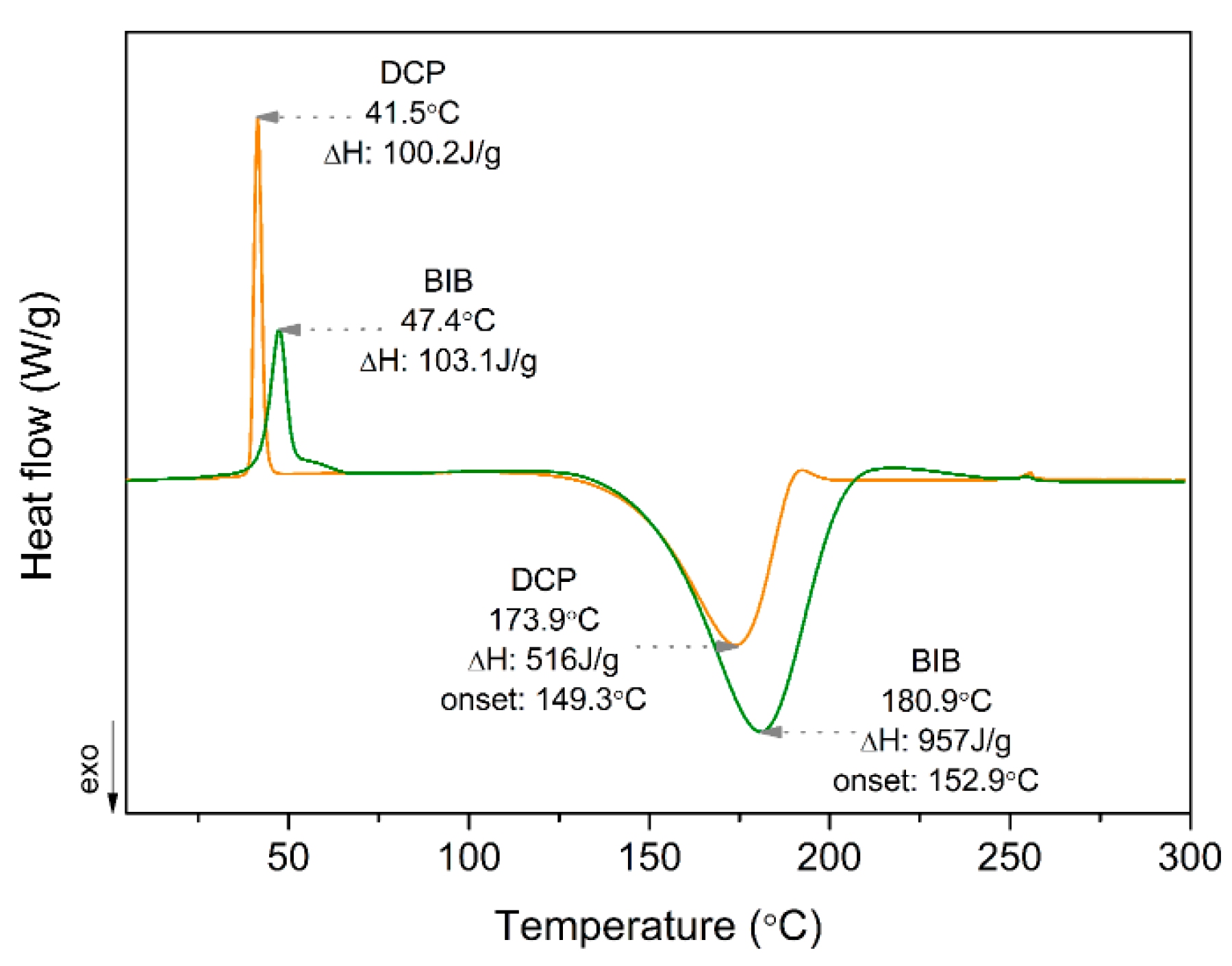

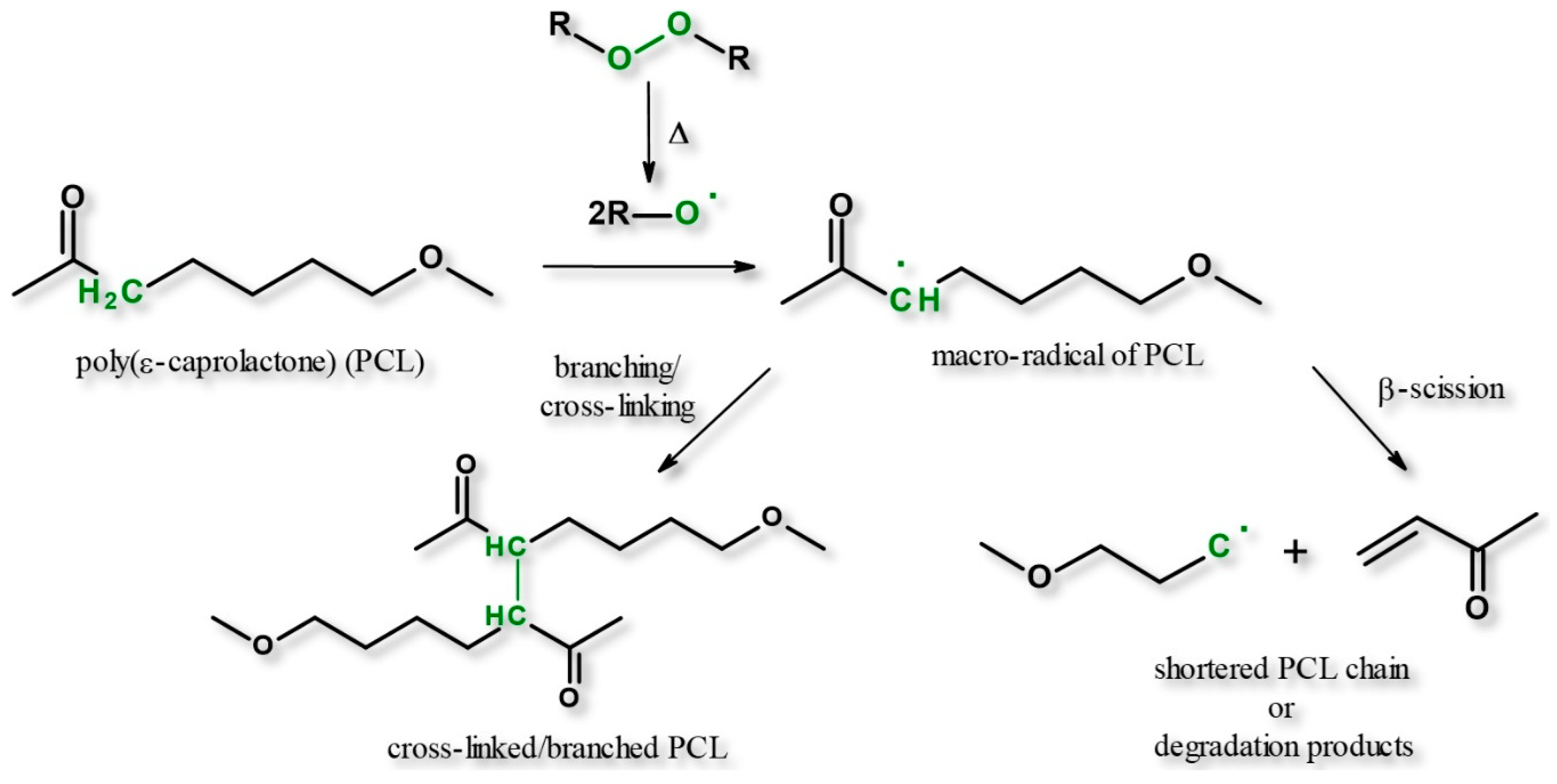

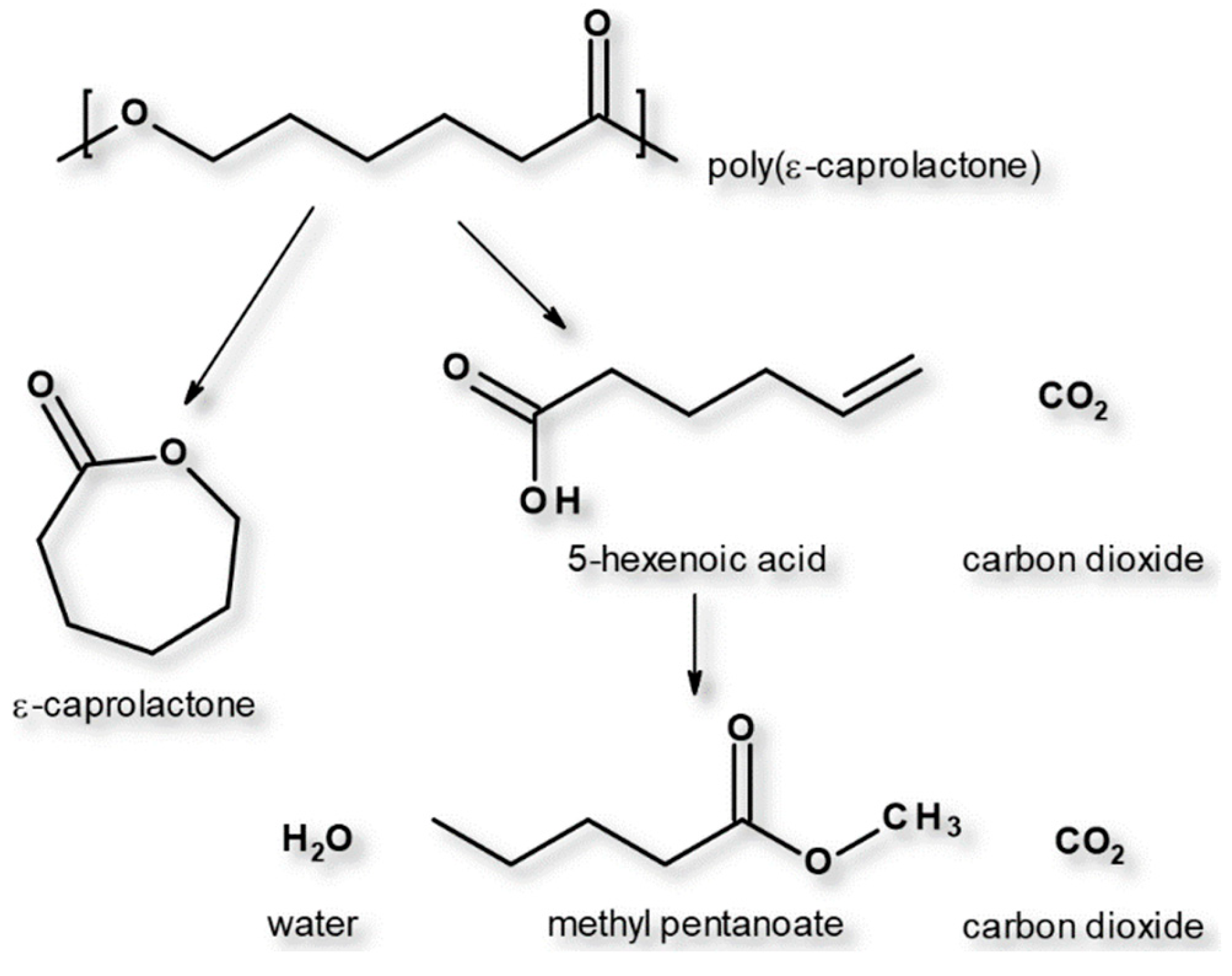

3.1. Modification of the PCL Structure by Organic Peroxides

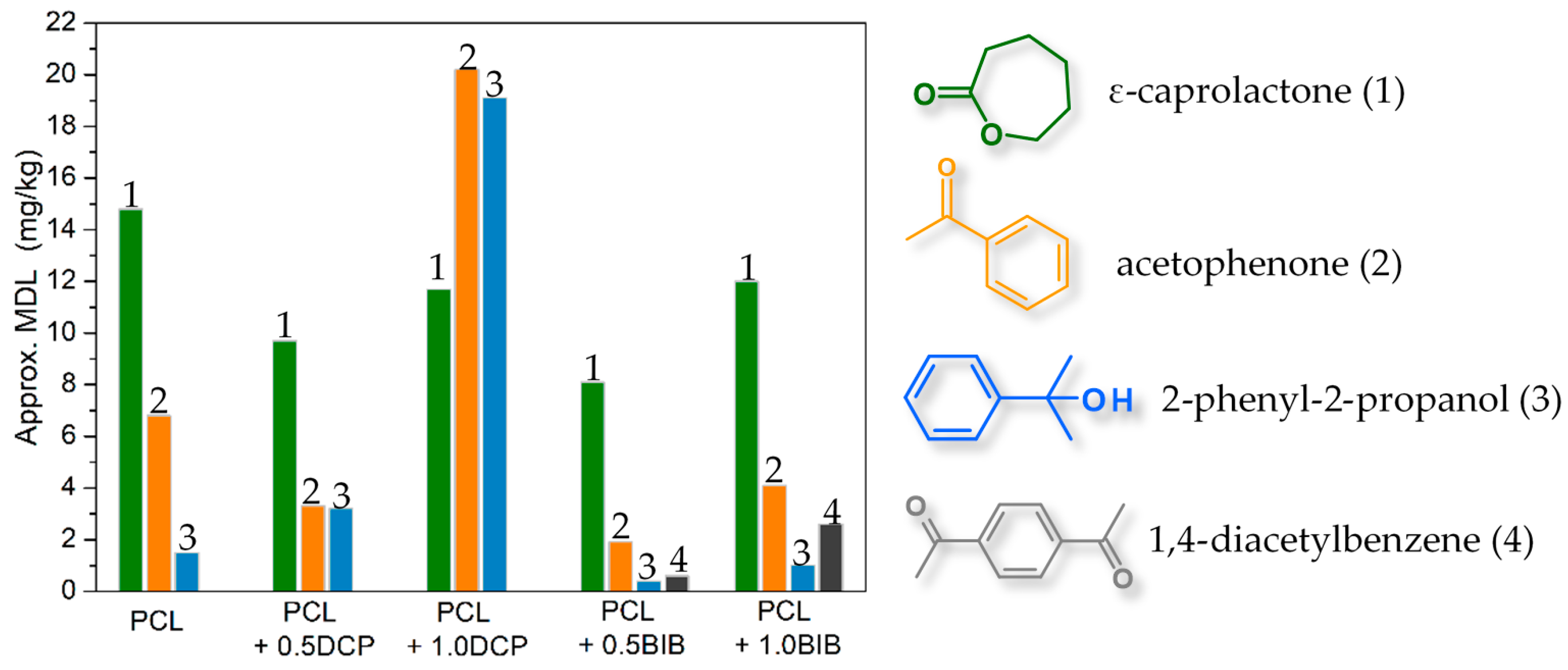

3.2. Volatile Organic Compounds Emission

3.3. Thermal Stability

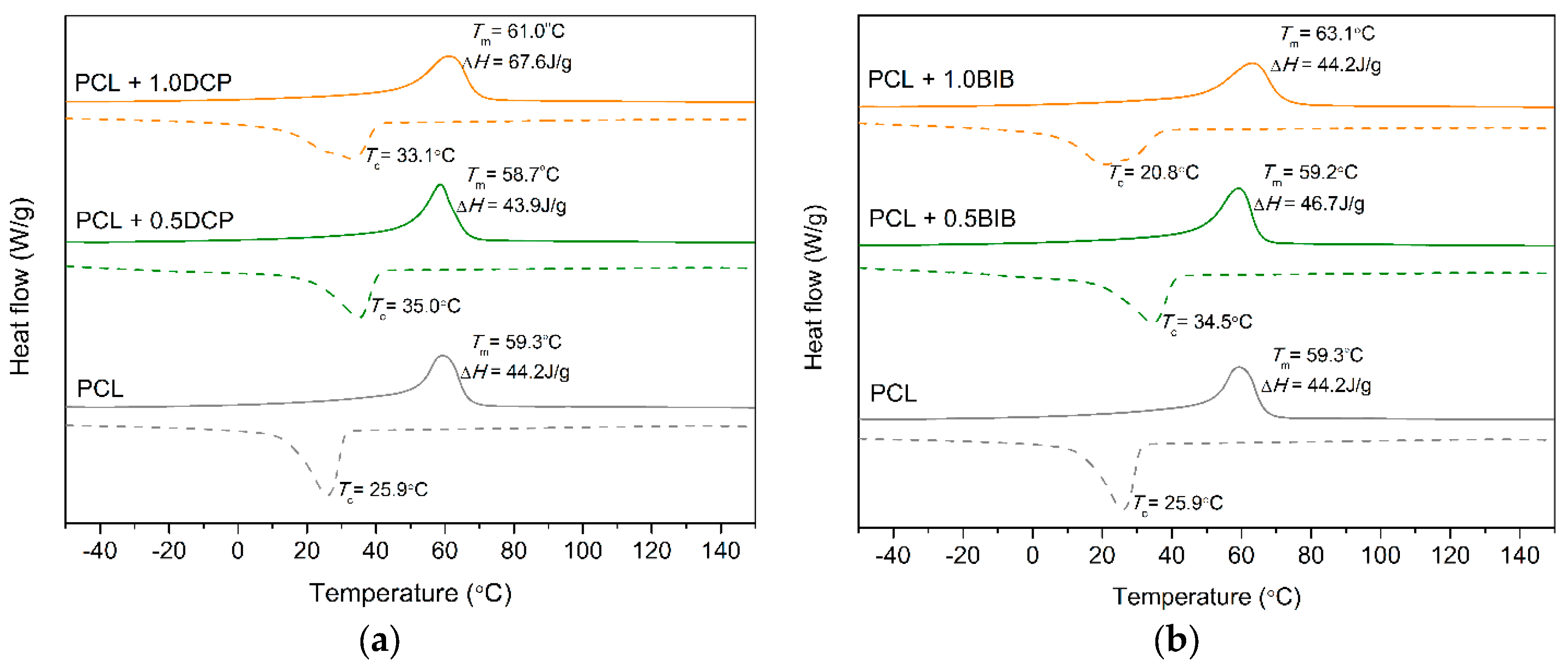

3.4. Thermal Properties

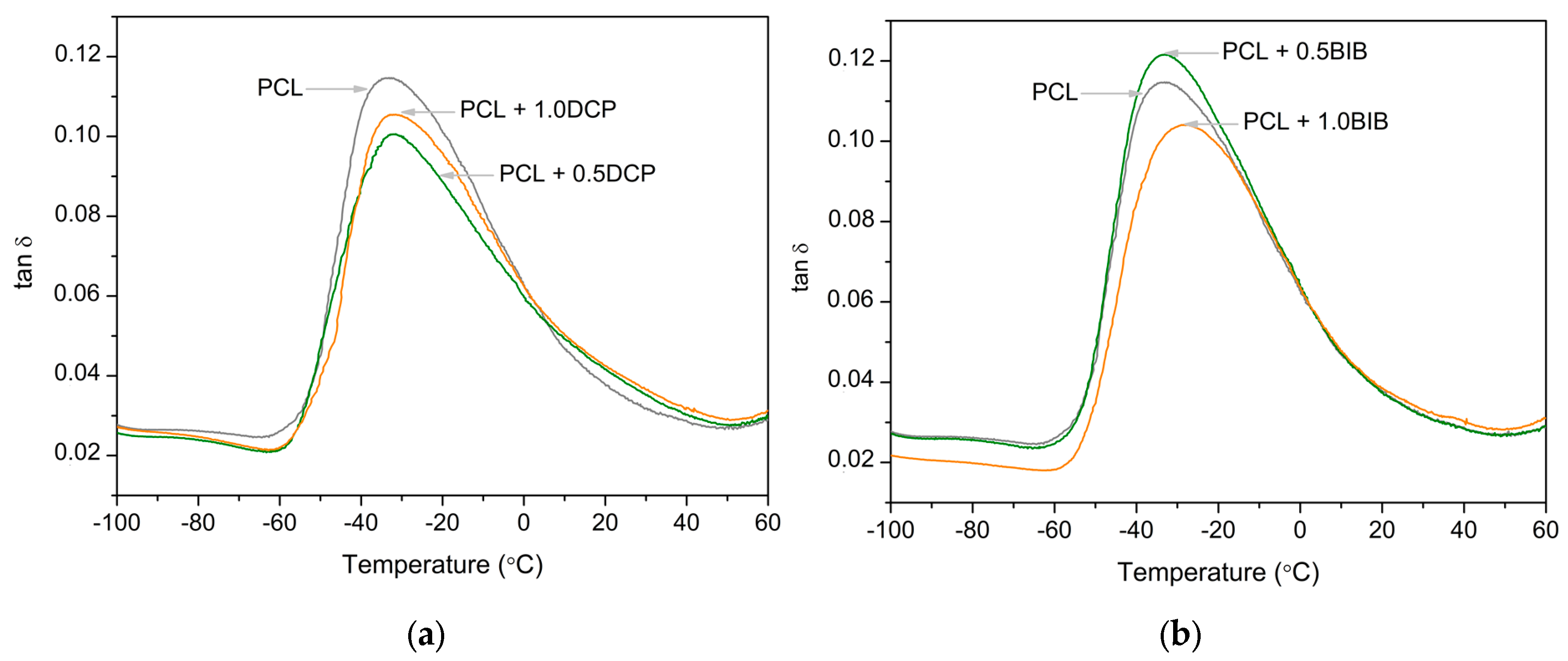

3.5. Dynamic Mechanical Analysis

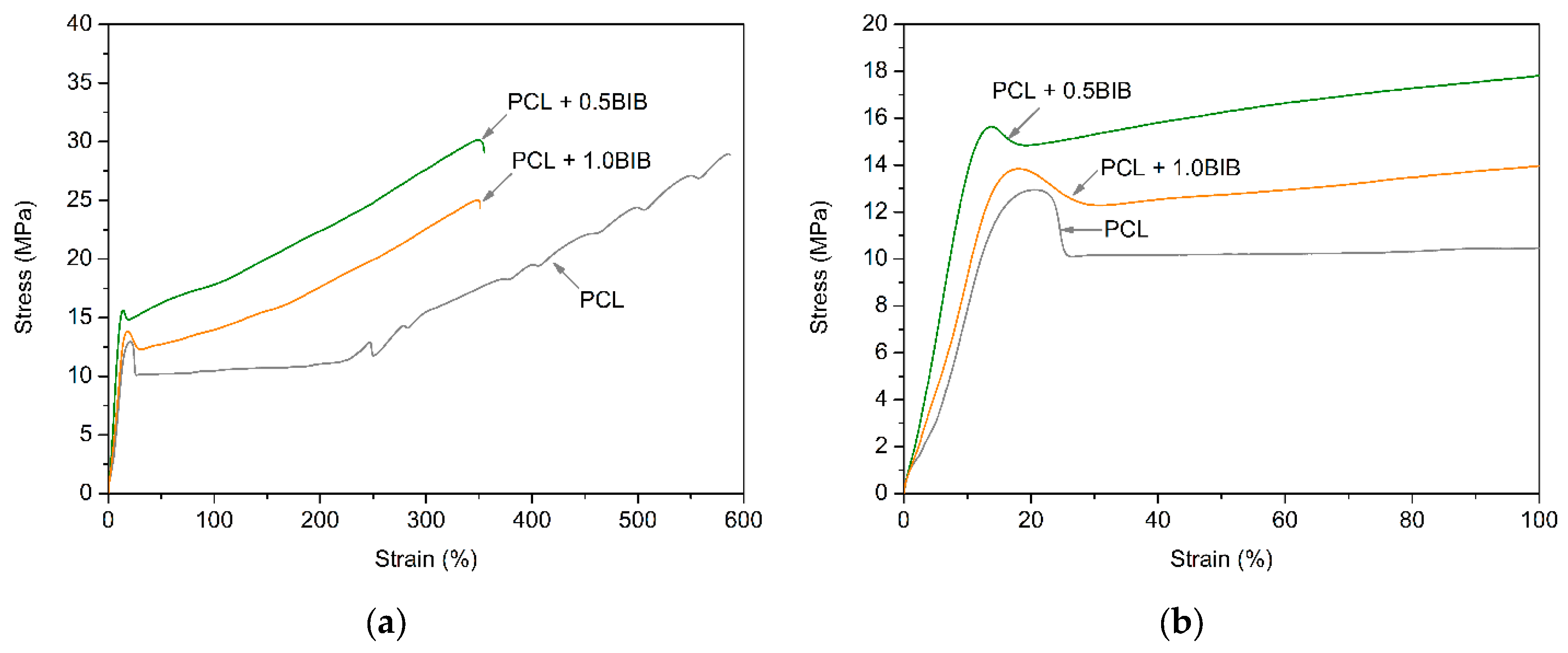

3.6. Static Mechanical Properties

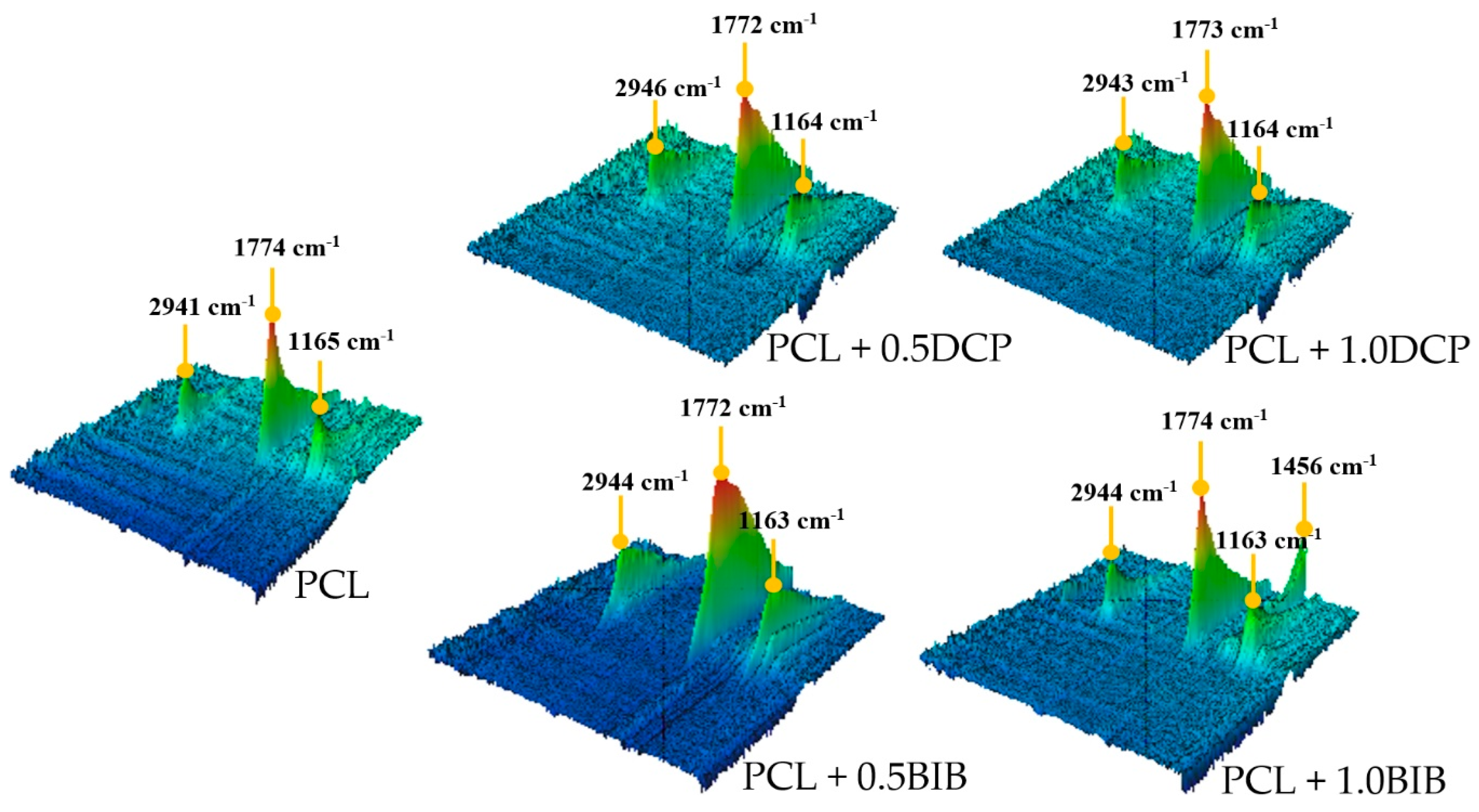

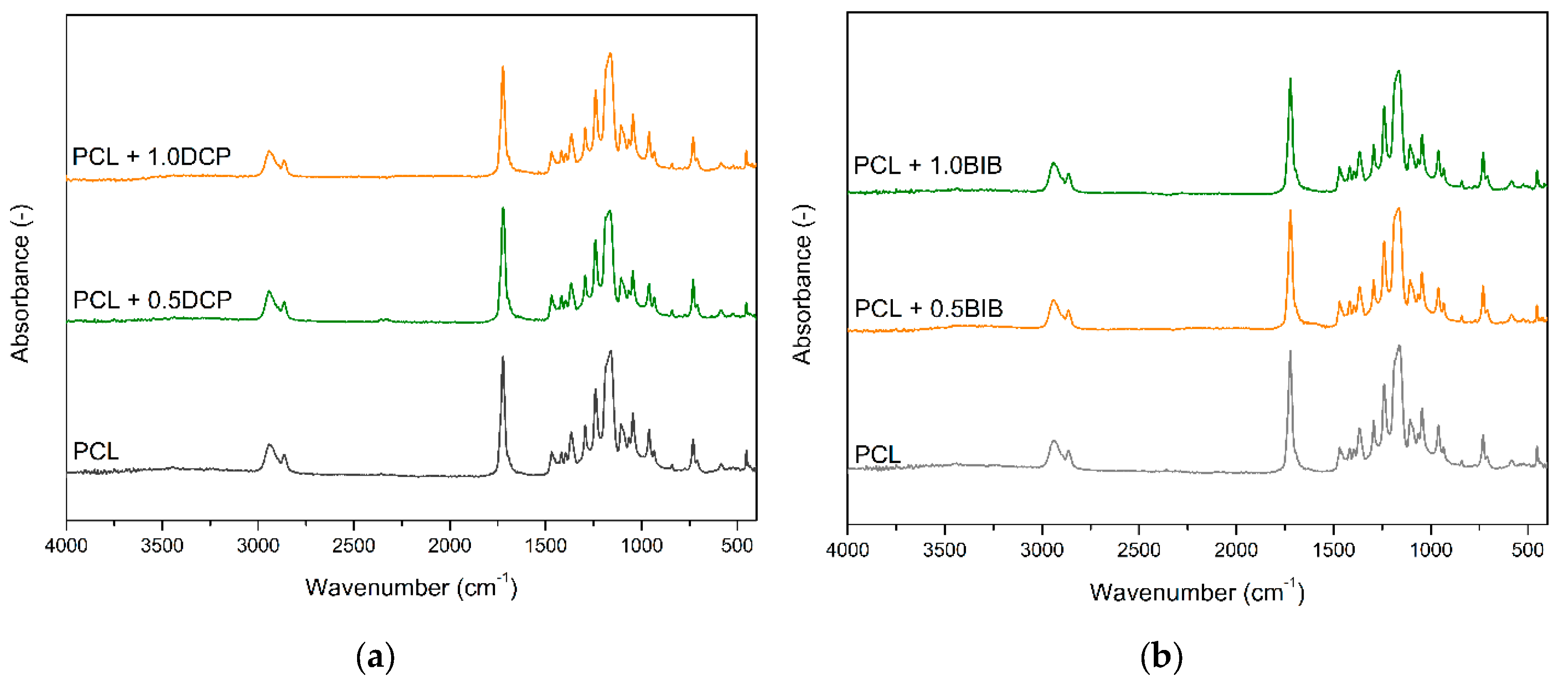

3.7. Fourier-Transform Infrared Analysis

3.8. Gel Fraction

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Rydz, J.; Sikorska, W.; Kyulavska, M.; Christova, D. Polyester-based (bio)degradable polymers as environmentally friendly materials for sustainable development. Int. J. Mol. Sci. 2014, 16, 564–596. [Google Scholar] [CrossRef] [PubMed]

- Tabone, M.D.; Cregg, J.J.; Beckman, E.J.; Landis, A.E. Sustainability metrics: Life cycle assessment and green design in polymers. Environ. Sci. Technol. 2010, 44, 8264–8269. [Google Scholar] [CrossRef] [PubMed]

- Lambert, S.; Wagner, M. Environmental performance of bio-based and biodegradable plastics: The road ahead. Chem. Soc. Rev. 2017, 46, 6855–6871. [Google Scholar] [CrossRef] [PubMed]

- Hou, A.L.; Qu, J.P. Super-toughened poly(lactic acid) with poly(ε-caprolactone) and ethylene-methylacrylate-glycidyl methacrylate by reactive melt blending. Polymers 2019, 11, 771. [Google Scholar] [CrossRef] [PubMed]

- Wisam, H.H.; Mansor, B.A.; Emad, A.J.A.M.; Nor, A.B.I. Preparation and characterization of polylactic acid/polycaprolactone clay nanocomposites. J. Appl. Sci. 2010, 10, 97–106. [Google Scholar]

- Dawidziuk, K.; Simmons, H.; Kontopoulou, M.; ScottParent, J. Peroxide-initiated graft modification of thermoplastic BioPolyesters: Introduction of long-chain branching. Polymer 2018, 158, 254–261. [Google Scholar] [CrossRef]

- Mangeon, C.; Renard, E.; Thevenieau, F.; Langlois, V. Networks based on biodegradable polyesters: An overview of the chemical ways of crosslinking. J. Mater. Sci. Eng. C 2017, 80, 760–770. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.L.; Wu, Z.H.; Yang, W.; Yang, M.B. Thermal and mechanical properties of chemical crosslinked polylactide (PLA). Polymer. Test. 2008, 27, 957–963. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Luyt, A.S. Dynamic mechanical properties of PLA/PHBV, PLA/PCL, PHBV/PCL blends and their nanocomposites with TiO2 as nanofiller. Thermochim. Acta 2015, 613, 41–53. [Google Scholar] [CrossRef]

- Ke, Y.; Zhang, X.Y.; Ramakrishna, S.; He, L.M.; Wu, G. Reactive blends based on polyhydroxyalkanoates: Preparation and biomedical application. J. Mater. Sci. Eng. C. 2017, 70, 1107–1119. [Google Scholar] [CrossRef]

- Göttermann, S.; Standau, T.; Weinmann, S.; Altstädt, V.; Bonten, C. Effect of chemical modification on the thermal and rheological properties of polylactide. Polym. Eng. Sci. 2017, 57, 1242–1251. [Google Scholar] [CrossRef]

- Niaounakis, M. Biopolymers: Processing and Products; William Andrew/Elsevier: Kidlington, UK, 2014. [Google Scholar]

- Cailloux, J. Sheets of branched poly(lactic acid) obtained by one step reactive extrusion calendering process: Melt rheology analysis. Express Polym. Lett. 2013, 7, 304–318. [Google Scholar] [CrossRef]

- Wang, Y.; Chiao, S.M.; Hung, T.-F.; Yang, S.-Y. Improvement in toughness and heat resistance of poly(lactic acid)/polycarbonate blend through twin-screw blending: Influence of compatibilizer type. J. Appl. Polym. Sci. 2012, 125, 402–412. [Google Scholar] [CrossRef]

- Carlson, D.; Dubois, P.; Nie, L.; Narayan, R. Free radical branching of polylactide by reactive extrusion. Polym. Eng. Sci. 1998, 38, 311–321. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, J. Research progress in toughening modification of poly(lactic acid). J. Polym. Sci. Part B Polym. Phys. 2011, 49, 1051–1083. [Google Scholar] [CrossRef]

- Takamura, M.; Nakamura, T.; Takahashi, T.; Koyama, K. Effect of type of peroxide on cross-linking of poly(l-lactide). Polym. Degrad. Stab. 2008, 93, 1909–1916. [Google Scholar] [CrossRef]

- Meng, Q.; Heuzey, M.-C.; Carreau, P.J. Control of thermal degradation of polylactide/clay nanocomposites during melt processing by chain extension reaction. Polym. Degrad. Stab. 2012, 97, 2010–2020. [Google Scholar] [CrossRef]

- Wei, L.; Mcdonald, A.G. Peroxide induced cross-linking by reactive melt processing of two biopolyesters: Poly(3-hydroxybutyrate) and poly(l-lactic acid) to improve their melting processability. J. Appl. Polym. Sci. 2015, 41724, 1–15. [Google Scholar] [CrossRef]

- Jin, F.; Hyon, S.H.; Iwata, H.; Tsutsumi, S. Crosslinking of poly(l-lactic acid) by γ-irradiation. Macromol. Rapid Commun. 2002, 23, 909–912. [Google Scholar] [CrossRef]

- Malinowski, R. Mechanical properties of PLA/PCL blends crosslinked by electron beam and TAIC additive. Chem. Phys. Lett. 2016, 662, 91–96. [Google Scholar] [CrossRef]

- Narkis, M.; Sibony-Chaouat, S.; Siegmann, A.; Shkolnik, S.; Bell, J.P. Irradiation effects on polycaprolactone. Polymer 1985, 26, 50–54. [Google Scholar] [CrossRef]

- Ai, X.; Wang, D.; Li, X.; Pan, H.; Kong, J.; Yang, H.; Zhang, H.; Dong, L. The properties of chemical cross-linked poly(lactic acid) by bis(tert-butyl dioxy isopropyl) benzene. Polym. Bull. 2018, 76, 575–594. [Google Scholar] [CrossRef]

- Liu, L.; Hou, J.; Wang, L.; Zhang, J.; Duan, Y. Role of dicumyl peroxide on toughening PLLA via dynamic vulcanization role of dicumyl peroxide on toughening PLLA via dynamic vulcanization. Ind. Eng. Chem. Res. 2016, 55, 9907–9914. [Google Scholar] [CrossRef]

- Rytlewski, P.; Żenkiewicz, M.; Malinowski, R. Influence of dicumyl peroxide content on thermal and mechanical properties of polylactide. Int. Polym. Process. 2011, 16, 580–586. [Google Scholar] [CrossRef]

- Fei, B.; Chen, C.; Chen, S.; Peng, S.W.; Zhuang, Y.G.; An, Y.X.; Dong, L.S. Crosslinking of poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] using dicumyl peroxide as initiator. Polym. Int. 2004, 53, 937–943. [Google Scholar] [CrossRef]

- You, J.; Lou, L.; Yu, W.; Zhou, C. The preparation and crystallization of long chain branching polylactide made by melt radicals reaction. J. Appl. Polym. Sci. 2013, 129, 1959–1970. [Google Scholar] [CrossRef]

- Signori, F.; Boggioni, A.; Righetti, M.C.; Rondán, C.E.; Bronco, S.; Ciardelli, F. Evidences of transesterification, chain branching and cross-linking in a biopolyester commercial blend upon reaction with dicumyl peroxide in the melt. Macromol. Mater. Eng. 2015, 300, 153–160. [Google Scholar] [CrossRef]

- Sipaut, C.S.; Mansa, R.F.; Yugis, A.R.; Ibrahim, M.N.M.; Ariff, Z.M.; Abdullah, A.A. The effect of different peroxide on LDPE foam properties in the presence of polyfunctional monomers. Cell. Polym. 2012, 31, 145–164. [Google Scholar] [CrossRef]

- Narkis, M.; Wallerstein, R. Crosslinking of polycaprolactone with peroxides. Polym. Commun. 1986, 27, 314–317. [Google Scholar]

- Di, Y.W.; Iannace, S.; Di Maio, E.; Nicolais, L. Reactively modified poly(lactic acid): Properties and foam processing. Macromol. Mater. Eng. 2005, 290, 1083. [Google Scholar] [CrossRef]

- Li, B.H.; Yang, M.C. Improvement of thermal and mechanical properties of poly(L-lactic acid) with 4,4-methylene diphenyl diisocyanate. Polym. Adv. Technol. 2006, 17, 439. [Google Scholar] [CrossRef]

- Zhou, Z.F.; Huang, G.Q.; Xu, W.B.; Ren, F.M. Chain extension and branching of poly(l-lactic acid) produced by reaction with a DGEBA-based epoxy resin. Express Polym. Lett. 2007, 1, 734–739. [Google Scholar] [CrossRef]

- Zhong, W.; Ge, J.; Gu, Z.; Li, W.; Chen, X.; Zang, Y.; Yang, Y. Study on biodegradable polymer materials based on poly(lactic acid). I. Chain extending of low molecular weight poly(lactic acid) with methylenediphenyl diisocyanate. J. Appl. Polym. Sci. 1999, 74, 2546–2551. [Google Scholar] [CrossRef]

- Liu, J.; Lou, L.; Yu, W.; Liao, R.; Li, R.; Zhou, C. Long chain branching polylactide: Structures and properties. Polymer 2010, 51, 5186–5197. [Google Scholar] [CrossRef]

- Gu, L.; Xu, Y.; Fahnhorst, G.W.; Macosko, C.W. Star vs long chain branching of poly(lactic acid) with multifunctional aziridine. J. Rheol. 2017, 61, 785–796. [Google Scholar] [CrossRef]

- Kim, C.-H.; Cho, K.Y.; Park, J.-K. Grafting of glycidyl methacrylate onto polycaprolactone: Preparation and characterization. Polymer 2001, 42, 5135–5142. [Google Scholar] [CrossRef]

- Yoshii, F.; Darwis, D.; Mitomo, H.; Makuuchi, K. Crosslinking of poly(ε-caprolactone) by radiation technique and its biodegradability. Radiat. Phys. Chem. 2000, 57, 417–420. [Google Scholar] [CrossRef]

- Abdel-Rehim, H.A.; Yoshii, F.; Kume, T. Modification of polycaprolactone in the presence of polyfunctional monomers by radiation and its biodegradability. Polym. Degrad. Stab. 2004, 85, 689–695. [Google Scholar] [CrossRef]

- Gandhi, K.; Kriz, D.; Salovey, M.; Narkis, M.; Wallerstein, R. Crosslinking of polycaprolactone in the pre-gelation region. Polym. Eng. Sci. 1988, 28, 1484–1490. [Google Scholar] [CrossRef]

- Han, C.; Ran, X.; Su, X.; Zhang, K.; Liu, N. Effect of peroxide crosslinking on thermal and mechanical properties of poly(ε-caprolactone). Polym. Int. 2007, 56, 593–600. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Sammon, C.; Balart, R.; Torres-Giner, S. Compatibilization of highly sustainable polylactide/almond shell flour composites by reactive extrusion with maleinized linseed oil. Ind. Crop. Prod. 2018, 111, 878–888. [Google Scholar] [CrossRef]

- Xu, Y.Q.; Qu, J.P. Mechanical and rheological properties of epoxidized soybean oil plasticized poly(lactic acid). J. Appl. Polym. Sci. 2009, 112, 3185–3191. [Google Scholar] [CrossRef]

- Chieng, B.W.; Ibrahim, N.A.; Then, Y.Y.; Loo, Y.Y. Epoxidized vegetable oils plasticized poly(lactic acid) biocomposites: Mechanical, thermal and morphology properties. Molecules 2014, 19, 16024–16038. [Google Scholar] [CrossRef] [PubMed]

- Quiles-Carrillo, L.; Blanes-Martínez, M.M.; Montanes, N.; Fenollar, O.; Torres-Giner, S.; Balart, R. Reactive toughening of injection-molded polylactide pieces using maleinized hemp seed oil. Eur. Polym. J. 2018, 98, 402–410. [Google Scholar] [CrossRef]

- Montava-Jordà, S.; Quiles-Carrillo, L.; Richart, N.; Torres-Giner, S.; Montanes, N. Enhanced interfacial adhesion of polylactide/poly(ε-caprolactone)/walnut shell flour composites by reactive extrusion with maleinized linseed oil. Polymers 2019, 11, 758. [Google Scholar] [CrossRef] [PubMed]

- Ferri, J.M.; Samper, M.D.; Garcia-Sanoguera, D.; Reig, M.J.; Fenollar, O.; Balart, R. Plasticizing effect of biobased epoxidized fatty acid esters on mechanical and thermal properties of poly(lactic acid). J. Mater. Sci. 2016, 51, 5356–5366. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Ferri, J.M.; Montanes, N.; Lopez-Martinez, J.; Balart, R. Plasticization effects of epoxidized vegetable oils on mechanical properties of poly(3-hydroxybutyrate). Polym. Int. 2016, 65, 1157–1164. [Google Scholar] [CrossRef]

- Crescenzi, V.; Manzini, G.; Calzolari, G.; Borri, C. Thermodynamics of fusion of poly-β-propiolactone and poly-ϵ-caprolactone comparative analysis of the melting of aliphatic polylactone and polyester chains. Eur. Polym. J. 1972, 8, 449–463. [Google Scholar] [CrossRef]

- Kruželák, J.; Sýkora, R.; Hudec, I. Vulcanization of rubber compounds with peroxide curing systems. Rubber Chem. Technol. 2017, 90, 60–88. [Google Scholar] [CrossRef]

- Xie, W.; Gan, Z. Thermal degradation of star-shaped poly(ε-caprolactone). Polym. Degrad. Stab. 2009, 94, 1040–1046. [Google Scholar] [CrossRef]

- Persenaire, O.; Alexandre, M.; Degée, P.; Dubois, P. Mechanisms and kinetics of thermal degradation of poly(ε-caprolactone). Biomacromolecules 2001, 2, 288–294. [Google Scholar] [CrossRef] [PubMed]

- Vogel, C.; Siesler, H.W. Thermal degradation of poly(ε-caprolactone), poly(l-lactic acid) and their blends with poly(3-hydroxy-butyrate) studied by TGA/FT-IR spectroscopy. Macromol. Symp. 2008, 265, 183–194. [Google Scholar] [CrossRef]

- Su, T.-T.; Jiang, H.; Gong, H. Thermal stability and thermal degradation kinetics of poly(ε-caprolactone). Polym. Plast. Technol. Eng. 2008, 47, 398–403. [Google Scholar] [CrossRef]

- Herrera-Kao, W.A.; Loría-Bastarrachea, M.I.; Pérez-Padilla, Y.; Cauich-Rodríguez, J.V.; Vázquez-Torres, H.; Cervantes-Uc, J.M. Thermal degradation of poly(caprolactone), poly(lactic acid), and poly(hydroxybutyrate) studied by TGA/FTIR and other analytical techniques. Polym. Bull. 2018, 75, 4191–4205. [Google Scholar] [CrossRef]

- Elzein, T.; Nasser-Eddine, M.; Delaite, C.; Bistac, S.; Dumas, P. FTIR study of polycaprolactone chain organization at interfaces. J. Colloid Interface Sci. 2004, 273, 381–387. [Google Scholar] [CrossRef] [PubMed]

- Unger, M.; Bogel, C.; Siesler, H.W. Molecular weight dependence of the thermal degradation of poly(ε-caprolactone): A thermogravimetric differential thermal fourier transform infrared spectroscopy study. Appl. Spectrosc. 2010, 64, 805–809. [Google Scholar] [CrossRef] [PubMed]

| Samples | Weight Ratios | T–2% (°C) | T–5% (°C) | T–10% (°C) | T–50% (°C) | R700°C (%) |

|---|---|---|---|---|---|---|

| PCL | 100 | 375 | 390 | 398 | 422 | 0.7 |

| PCL/DCP | 100/0.5 | 359 | 378 | 390 | 420 | 1.6 |

| 100/1.0 | 367 | 387 | 397 | 421 | 1.4 | |

| PCL/BIB | 100/0.5 | 364 | 383 | 395 | 429 | 2.0 |

| 100/1.0 | 321 | 363 | 381 | 415 | 1.0 |

| Samples | Weight Ratios | Tm(PCL) (°C) | ΔHm(PCL) (J/g) | Tc(PCL) (°C) | ΔHc(PCL) (J/g) | Xc(PCL) (%) |

|---|---|---|---|---|---|---|

| PCL | 100/0 | 59.3 | 44.2 | 25.9 | 54.7 | 32.5 |

| PCL/DCP | 100/0.5 | 58.7 | 43.9 | 35.0 | 45.5 | 32.3 |

| 100/1.0 | 61.0 | 67.6 | 33.1 | 50.0 | 49.7 | |

| PCL/BIB | 100/0.5 | 59.2 | 46.7 | 34.5 | 48.3 | 34.3 |

| 100/1.0 | 63.1 | 44.2 | 20.8 | 56.0 | 32.5 |

| Samples | Weight Ratios | tan δmax (°C) | E’25°C (MPa) |

|---|---|---|---|

| PCL | 100/0 | −33.5 | 512 |

| PCL/DCP | 100/0.5 | −32.2 | 599 |

| 100/1.0 | −31.2 | 563 | |

| PCL/BIB | 100/0.5 | −33.0 | 507 |

| 100/1.0 | −28.5 | 517 |

| Samples | Weight Ratios | Young’s Modulus (MPa) | Stress of Yield (MPa) | Stress at Break (MPa) | Elongation at Break (%) | Hardness (°Sh D) |

|---|---|---|---|---|---|---|

| PCL | 100 | 149 ± 25 | 13.1 ± 0.2 | 30.0 ± 1.2 | 611 ± 25 | 51.6 ± 0.7 |

| PCL/DCP | 100/0.5 | 183 ± 16 | 15.0 ± 0.8 | 35.7 ± 1.9 | 521 ± 23 | 53.0 ± 0.5 |

| 100/1.0 | 169 ± 11 | 14.6 ± 0.5 | 29.1 ±1.7 | 430 ± 9 | 53.3 ± 0.4 | |

| PCL/BIB | 100/0.5 | 143 ± 12 | 15.4 ± 0.5 | 36.7 ± 2.2 | 471 ± 18 | 52.9 ± 0.9 |

| 100/1.0 | 160 ± 13 | 13.4 ± 0.6 | 23.1 ± 1.4 | 372 ± 47 | 52.1 ± 0.2 |

| Wavenumber Assignments | Neat PCL | PCL + DCP | PCL + BIB | ||

|---|---|---|---|---|---|

| 0.5 | 1.0 | 0.5 | 1.0 | ||

| asymmetric CH2 stretching νas(CH2) | 2942 | 2944 | 2941 | 2941 | 2942 |

| symmetric CH2 stretching νs(CH2) | 2863 | 2863 | 2862 | 2863 | 2863 |

| carbonyl stretching ν(C=O) | 1722 | 1722 | 1721 | 1722 | 1722 |

| asymmetric COC stretching νas(COC) | 1240 | 1239 | 1238 | 1240 | 1240 |

| OC-O stretching ν(OC-O) | 1187 | 1184 | 1184 | 1187 | 1187 |

| symmetric COC stretching νs(COC) | 1160 | 1166 | 1162 | 1164 | 1165 |

| Samples Code | PCL100 | PCL + 0.5DCP | PCL + 1.0DCP | PCL + 0.5BIB (%) | PCL + 1.0BIB (%) | |

|---|---|---|---|---|---|---|

| Solvent | ||||||

| toluene | soluble | soluble | partially soluble | 37.9 ± 0.8 | 53.5 ± 0.9 | |

| dichloromethane | soluble | soluble | partially soluble | 37.7 ± 0.3 | 53.0 ± 0.4 | |

| chloroform | soluble | soluble | partially soluble | 41.1 ± 0.6 | 50.0 ± 0.7 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Przybysz, M.; Hejna, A.; Haponiuk, J.; Formela, K. Structural and Thermo-Mechanical Properties of Poly(ε-Caprolactone) Modified by Various Peroxide Initiators. Polymers 2019, 11, 1101. https://doi.org/10.3390/polym11071101

Przybysz M, Hejna A, Haponiuk J, Formela K. Structural and Thermo-Mechanical Properties of Poly(ε-Caprolactone) Modified by Various Peroxide Initiators. Polymers. 2019; 11(7):1101. https://doi.org/10.3390/polym11071101

Chicago/Turabian StylePrzybysz, Marta, Aleksander Hejna, Józef Haponiuk, and Krzysztof Formela. 2019. "Structural and Thermo-Mechanical Properties of Poly(ε-Caprolactone) Modified by Various Peroxide Initiators" Polymers 11, no. 7: 1101. https://doi.org/10.3390/polym11071101

APA StylePrzybysz, M., Hejna, A., Haponiuk, J., & Formela, K. (2019). Structural and Thermo-Mechanical Properties of Poly(ε-Caprolactone) Modified by Various Peroxide Initiators. Polymers, 11(7), 1101. https://doi.org/10.3390/polym11071101