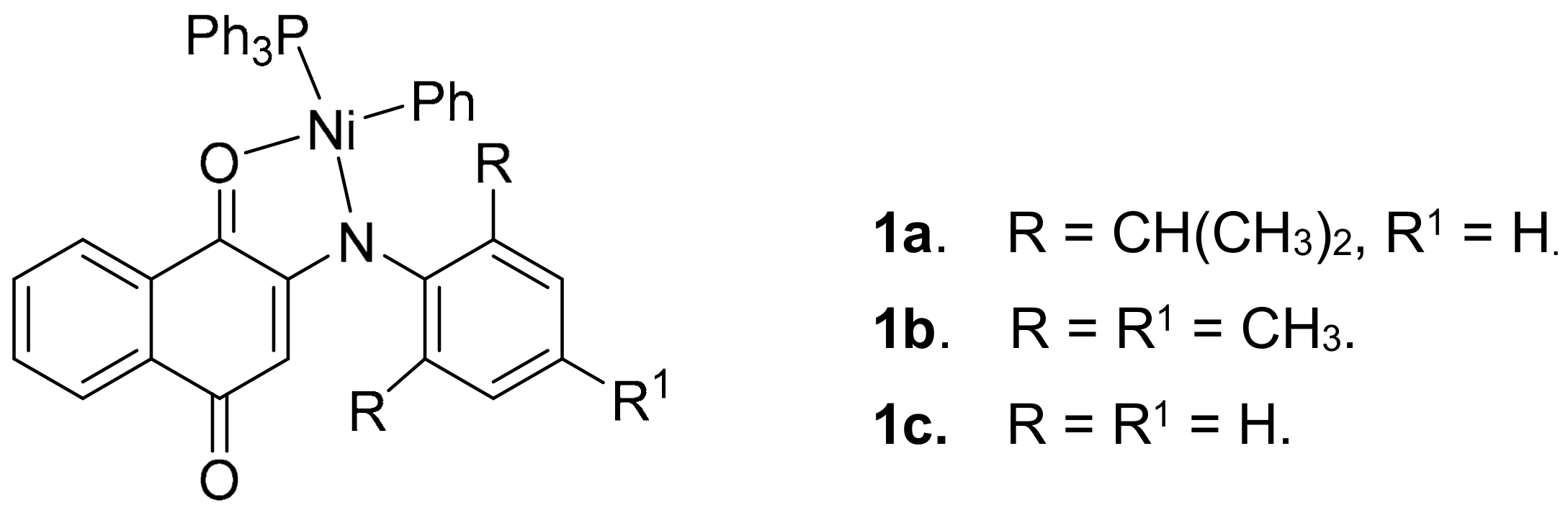

Copolymerization of Norbornene and Styrene with Anilinonaphthoquinone-Ligated Nickel Complexes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Analytical Procedure

2.3. Copolymerization of N and S

3. Results and Discussion

3.1. Homopolymerization of N and S

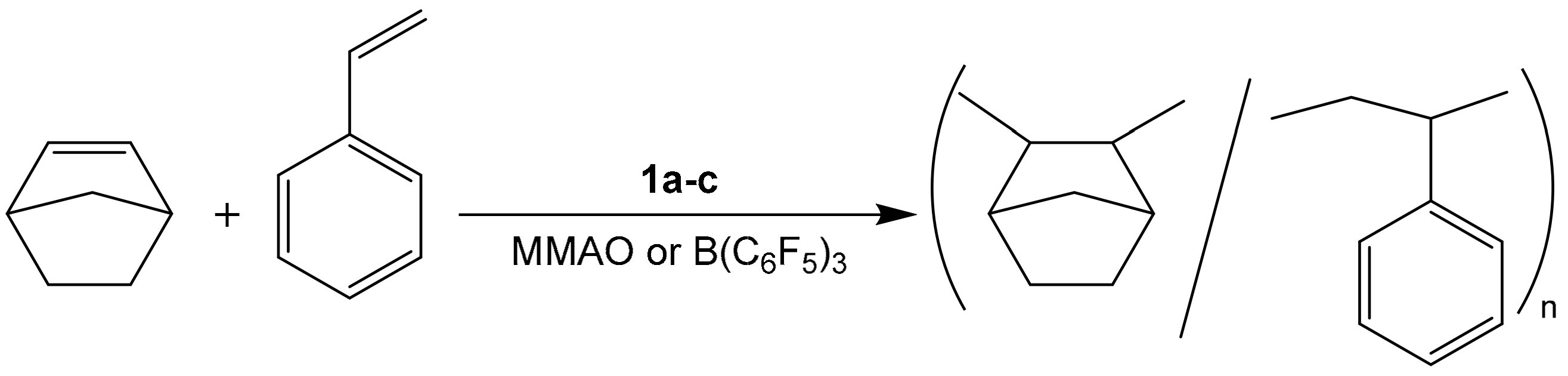

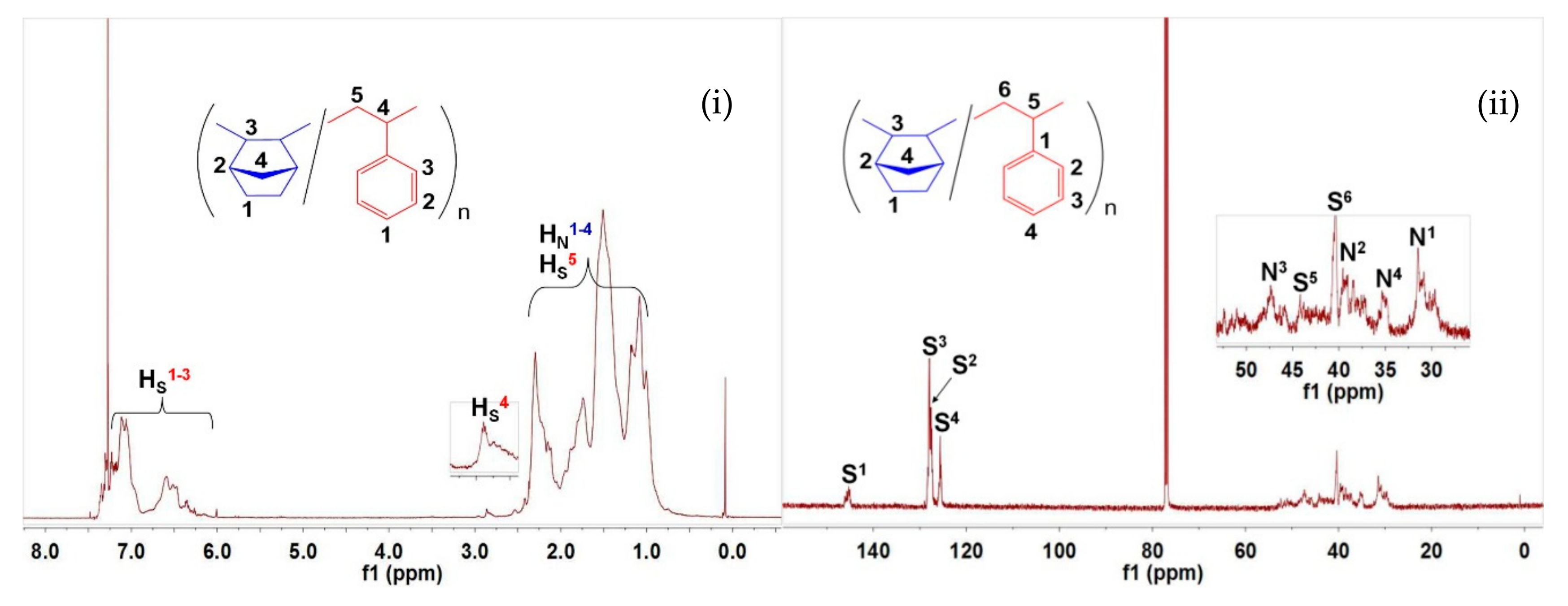

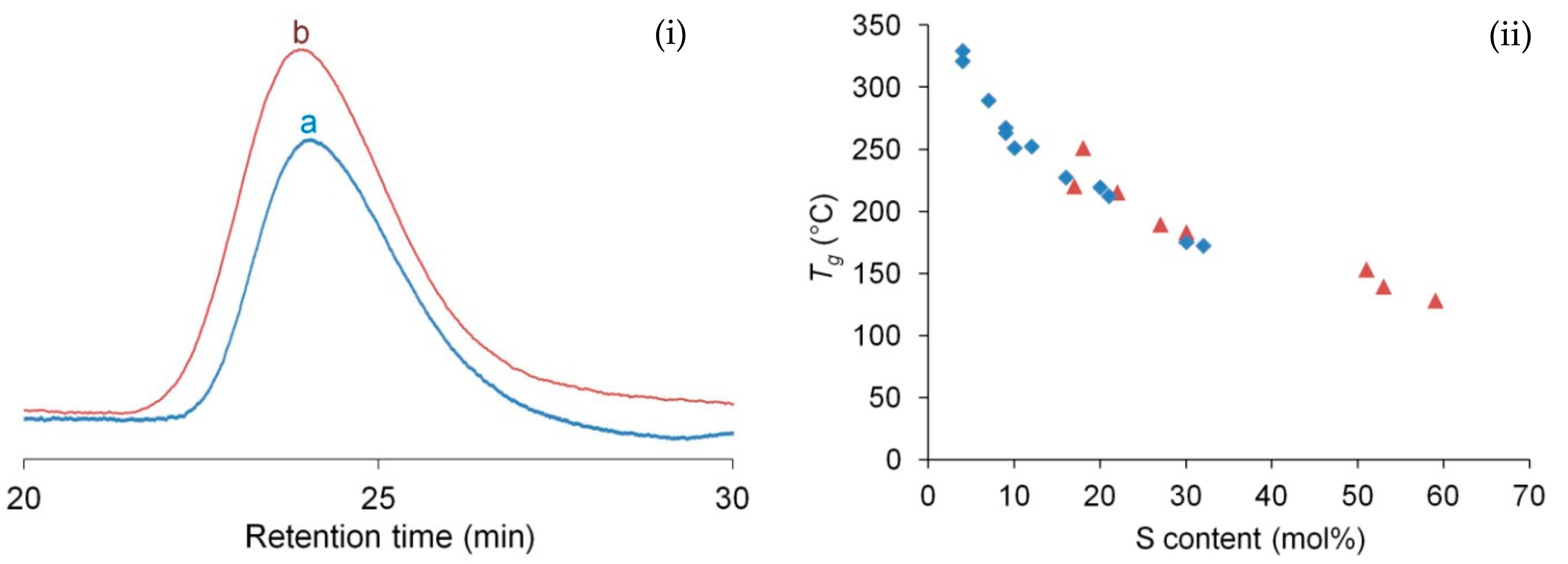

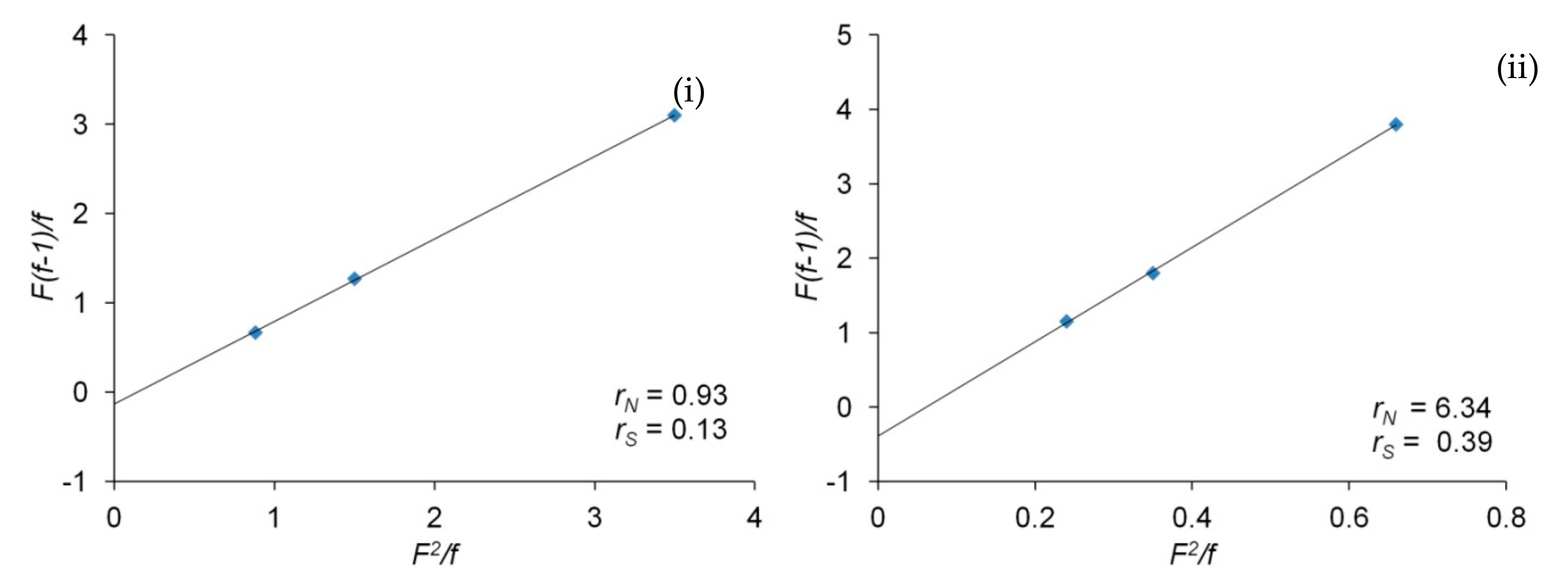

3.2. Copolymerization of N and S

3.3. Effect of Polymerization Temperature on N/S Copolymerization:

3.4. N/S Copolymerization by 1-B(C6F5)3:

3.5. Optical Property of the N/S Copolymer

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, M.; Zou, W.P.; Cai, Z.G.; Chen, C.L. Norbornene homopolymerization and copolymerization with ethylene by phosphine- sulfonate nickel catalysts. Polym. Chem. 2015, 6, 2669–2676. [Google Scholar] [CrossRef]

- Pei, L.X.; Tang, Y.; Gao, H.Y. Homo- and Copolymerization of Ethylene and Norbornene with Anilido–Imine Chromium Catalysts. Polymers 2016, 8, 69. [Google Scholar] [CrossRef] [PubMed]

- Meng, J.F.; Li, X.; Ni, X.F.; Shen, Z.Q. High transparent alternate copolymer of norbornene with isoprene catalyzed by bis(phenoxy–imine) titanium complex. RSC Adv. 2016, 6, 19351–19356. [Google Scholar] [CrossRef]

- Gilliom, L.R.; Grubbs, R.H. Titanacyclobutanes derived from strained, cyclic olefins: The living polymerization of norbornene. J. Am. Chem. Soc. 1986, 108, 733–742. [Google Scholar] [CrossRef]

- Nguyen, S.T.; Johnson, L.K.; Grubbs, R.H.; Ziller, J.W. Ring-opening metathesis polymerization (ROMP) of norbornene by a Group VIII carbene complex in protic media. J. Am. Chem. Soc. 1992, 114, 3974–3975. [Google Scholar] [CrossRef]

- Kennedy, J.P.; Makowski, H.S. Carbonium Ion Polymerization of Norbornene and Its Derivatives. J. Macromol. Sci. Chem. 1967, A1, 345–370. [Google Scholar] [CrossRef]

- Gaylord, N.G.; Mandal, B.M.; Martan, M. Peroxide-induced polymerization of norbornene. J. Polym. Sci. Polym. Lett. Ed. 1976, 14, 555–559. [Google Scholar] [CrossRef]

- Gaylord, N.G.; Deshpande, A.B. Structure of “vinyl-type” polynorbornenes prepared with ziegler-natta catalysts. J. Polym. Sci. Polym. Lett. Ed. 1976, 14, 613–617. [Google Scholar] [CrossRef]

- Gaylord, N.G.; Deshpande, A.B.; Mandal, B.M.; Martan, M. Poly-2,3- and 2,7-Bicyclo[2.2.1]hept-2-enes: Preparation and Structures of Polynorbornenes. J. Macromol. Sci. Chem. 1977, A11, 1053–1070. [Google Scholar] [CrossRef]

- Rush, S.; Reinmuth, A.; Risse, W. Palladium(II)-Catalyzed Olefin Addition Polymerizations of 3,3-Dialkyl-Substituted Cyclopropenes. Macromolecules 1997, 30, 7375–7385. [Google Scholar] [CrossRef]

- Goodall, L.; McIntosh III, L.H.; Rhodes, L.F. New catalysts for the polymerization of cyclic olefins. Macromol. Symp. 1995, 89, 421–432. [Google Scholar] [CrossRef]

- Seehof, N.; Mehler, C.; Breunig, S.; Risse, W. Pd2+ catalyzed addition polymerizations of norbornene and norbornene derivatives. J. Mol. Catal. 1992, 76, 219–228. [Google Scholar] [CrossRef]

- Grove, N.R.; Kohl, P.A.; Allen, S.A.B.; Jayaraman, S.; Shick, R. Functionalized Polynorbornene Dielectric Polymers: Adhesion and Mechanical Properties. J. Polym. Sci. Part. B Polym. Phys. 1999, 37, 3003–3010. [Google Scholar] [CrossRef]

- Janiak, C.P.; Lassahn, G. The Vinyl Homopolymerization of Norbornene. Macromol. Rapid Commun. 2001, 22, 479–492. [Google Scholar] [CrossRef]

- Boggioni, L.; Tritto, I. State of the art of cyclic olefin polymers. MRS Bull. 2013, 38, 245–251. [Google Scholar] [CrossRef]

- He, X.; Deng, Y.; Jiang, X.; Wang, Z.; Yang, Y.; Han, Z.; Chen, D. Copolymerization of norbornene and butyl methacrylate at elevated temperatures by a single centre nickel catalyst bearing bulky bis(α-diimine) ligand with strong electron-withdrawing groups. Polym. Chem. 2017, 8, 2390–2396. [Google Scholar] [CrossRef]

- Shiono, T.; Sugimoto, M.; Hasan, T.; Cai, Z.; Ikeda, T. Random Copolymerization of Norbornene with Higher 1-Alkene with ansa-Fluorenylamidodimethyltitanium Catalyst. Macromolecules 2008, 41, 8292–8294. [Google Scholar] [CrossRef]

- Cai, Z.; Harada, R.; Nakayama, Y.; Shiono, T. Highly Active Living Random Copolymerization of Norbornene and 1-Alkene with ansa-Fluorenylamidodimethyltitanium Derivative: Substituent Effects on Fluorenyl Ligand. Macromolecules 2010, 43, 4527–4531. [Google Scholar] [CrossRef]

- Xing, Y.; Chen, Y.; He, X.; Nie, H. Nickel(II) complexes bearing the bis(β-ketoamino) ligand for the copolymerization of norbornene with a higher 1-alkene. J. Appl. Polym. Sci. 2012, 124, 1323–1332. [Google Scholar] [CrossRef]

- Liu, Y.M.; Ouyang, M.; He, X.H.; Chen, Y.W.; Wang, K.T. Novel Ni and Pd(benzocyclohexan-ketonaphthylimino)2 complexes for copolymerization of norbornene with octane. J. Appl. Polym. Sci. 2013, 128, 216–223. [Google Scholar] [CrossRef]

- Zhao, W.; Nomura, K. Copolymerizations of Norbornene and Tetracyclododecene with α-Olefins by Half-Titanocene Catalysts: Efficient Synthesis of Highly Transparent, Thermal Resistance Polymers. Macromolecules 2016, 49, 59–70. [Google Scholar] [CrossRef]

- Zhao, W.; Nomura, K. Design of Efficient Molecular Catalysts for Synthesis of Cyclic Olefin Copolymers (COC) by Copolymerization of Ethylene and α-Olefins with Norbornene or Tetracyclododecene. Catalysts 2016, 6, 175. [Google Scholar] [CrossRef]

- He, X.; Deng, Y.; Han, Z.; Yang, Y.; Chen, D. Highly symmetric single nickel catalysts bearing bulky bis(α-diimine) ligand: Synthesis, characterization, and electron-effects on copolymerization of norbornene with 1-alkene at elevated temperarure. J. Polym. Sci: Part. A Polym. Chem. 2016, 54, 3495–3505. [Google Scholar] [CrossRef]

- Hasan, T.; Ikeda, T.; Shiono, T. Ethene−Norbornene Copolymer with High Norbornene Content Produced by ansa-Fluorenylamidodimethyltitanium Complex Using a Suitable Activator. Macromolecules 2004, 37, 8503–8509. [Google Scholar] [CrossRef]

- Ban, H.; Hagihara, H.; Tsunogae, Y.; Cai, Z.; Shiono, T. Highly thermostable and low birefringent norbornene-styrene copolymers with advanced optical properties: A potential plastic substrate for flexible displays. J. Polym. Sci. Part. A Polym. Chem. 2011, 49, 65–71. [Google Scholar] [CrossRef]

- Peruch, F.; Cramail, H.; Deffieux, A. Homopolymerization and copolymerization of styrene and norbornene with Ni-based/MAO catalysts. Macromol. Chem. Phys. 1998, 199, 2221–2227. [Google Scholar] [CrossRef]

- Zhao, C.T.; Ribeiro, M.D.R.; Portela, M.F.; Pereira Nunes, S.T. Homo- and copolymerisation of norbornene and styrene with nickel bis(acetyl acetonate)/methylaluminoxane system. Eur. Polym. J. 2001, 37, 45–54. [Google Scholar] [CrossRef]

- Mi, X.; Ma, Z.; Wang, L.; Ke, Y.; Hu, Y. Homo- and Copolymerization of Norbornene and Styrene with Pd- and Ni-Based Novel Bridged Dinuclear Diimine Complexes and MAO. Macromol. Chem. Phys. 2003, 204, 868–876. [Google Scholar] [CrossRef]

- Suzuki, H.; Matsumura, S.; Satoh, Y.; Sogoh, K.; Yasuda, H. Random copolymerizations of norbornene with other monomers catalyzed by novel Ni compounds involving N- or O-donated ligands. React. Funct. Polym. 2004, 58, 77–91. [Google Scholar] [CrossRef]

- Gao, H.; Chen, Y.; Zhu, F.; Wu, Q. Copolymerization of norbornene and styrene catalyzed by a novel anilido–imino nickel complex/methylaluminoxane system. J. Polym. Sci. Part. A Polym. Chem. 2006, 44, 5237–5246. [Google Scholar] [CrossRef]

- Bao, F.; Ma, R.; Jiao, Y. Homo- and copolymerization of norbornene with styrene catalyzed by a series of copper(II) complexes in the presence of methylaluminoxane. Appl. Organomet. Chem. 2006, 20, 368–374. [Google Scholar] [CrossRef]

- Bao, F.; Lu, X.; Chen, Y. Copolymerization of Norbornene and Styrene Catalyzed by a Series of Bis(β-ketoamine) Nickel(II) Complexes in the Presence of Methylaluminoxane. Polym. Bull. 2007, 58, 495–502. [Google Scholar] [CrossRef]

- Ogata, K.; Nishimura, N.; Yunokuchi, T.; Toyota, A. Copolymerization of tetracyclododecene or norbornene with styrene in the presence of Ni(II) complex/MAO catalytic system: First example for transition metal catalyzed copolymerization of tetracyclododecene with styrene. J. Appl. Polym. Sci. 2008, 108, 1562–1565. [Google Scholar] [CrossRef]

- Li, Y.; Wu, Q.; Shan, M.; Gao, M. Copolymerization of styrene and norbornene with β-diketiminato nickel/methylaluminoxane catalytic system. Appl. Organomet. Chem. 2012, 26, 225–229. [Google Scholar] [CrossRef]

- Feng, Q.; Chen, D.; Feng, D.; Jiao, L.; Peng, Z.; Pei, L. Synthesis of poly(norbornene-co-styrene) copolymers containing high styrene incorporation using bis(β-ketoamino) copper catalysts. J. Polym. Res. 2014, 21, 497. [Google Scholar] [CrossRef]

- Ban, H.T.; Nishii, K.; Tsunogae, Y.; Shiono, T. Synthesis and characterization of norbornene–ethylene–styrene terpolymers with a substituted ansa-fluorenylamidodimethyltitanium-based catalyst. J. Polym. Sci. Part A Polym. Chem. 2007, 45, 2765–2773. [Google Scholar] [CrossRef]

- Okada, M.; Nakayama, Y.; Shiono, T. Highly soluble polynorbornene prepared by an anilinonaphthoquinone-ligated nickel complex via coordination-insertion polymerization. J. Organomet. Chem. 2015, 384–387. [Google Scholar] [CrossRef]

- Okada, M.; Nakayama, Y.; Ikeda, T.; Shiono, T. Synthesis of Uniquely Branched Polyethylene by Anilinonaphthoquinone Ligated Nickel Complex Activated with Tris(pentafluorophenyl)borane. Macromol. Rapid Commun. 2006, 27, 1418–1423. [Google Scholar] [CrossRef]

- Okada, M.; Nakayama, Y.; Shiono, T. Synthesis of anilinonaphthoquinone-based nickel complexes and their application for olefin polymerization. J. Organomet. Chem. 2007, 692, 5183–5189. [Google Scholar] [CrossRef]

- Ivin, K.J.; Mol, J.C. Olefin Metathesis and Metathesis Polymerization; Academic Press: San Diego, CA, USA, 1997; p. 407. [Google Scholar]

- Benedikt, G.M.; Elce, E.; Goodall, B.L.; Kalamarides, H.A.; McIntosh, L.H.; Rhodes, L.F.; Selvy, K.T.; Andes, C.; Oyler, K.; Sen, A. Copolymerization of Ethene with Norbornene Derivatives Using Neutral Nickel Catalysts. Macromolecules 2002, 35, 8978–8988. [Google Scholar] [CrossRef]

| Run | N/S a (mmol/mmol) | Complex | Yield (g) | Act. b | fSc (mol%) | Mn (103) | Mw/Mnd | Ne (µmol) |

|---|---|---|---|---|---|---|---|---|

| 1 | 40/00 | 1a | 1.10 | 220 | 0 | 470 | 1.9 | 2.3 |

| 2 | 40/10 | 1a | 0.36 | 72 | 4 | 19 | 2.4 | 18.9 |

| 3 | 40/40 | 1a | 0.65 | 130 | 16 | 6 | 2.5 | 108.3 |

| 4 | 00/40 | 1a | 0.52 | 104 | 100 | 11 | 1.5 | 47.2 |

| 5 | 40/00 | 1b | 0.54 | 107 | 0 | 266 | 2.2 | 2.0 |

| 6 | 40/10 | 1b | 0.37 | 74 | 4 | 19 | 2.7 | 19.5 |

| 7 | 40/20 | 1b | 0.31 | 62 | 8 | 12 | 1.7 | 25.8 |

| 8 | 40/30 | 1b | 0.30 | 60 | 12 | 9 | 3.0 | 33.3 |

| 9 | 40/40 | 1b | 0.44 | 88 | 19 | 8 | 2.9 | 55.0 |

| 10 | 00/40 | 1b | 0.65 | 130 | 100 | 12 | 1.6 | 54.2 |

| 11 | 40/00 | 1c | 0.58 | 115 | 0 | 309 | 1.6 | 1.9 |

| 12 | 40/10 | 1c | 0.36 | 72 | 10 | 13 | 2.0 | 27.7 |

| 13 | 40/20 | 1c | 0.32 | 64 | 16 | 10 | 1.5 | 32.0 |

| 14 | 40/30 | 1c | 0.31 | 62 | 19 | 8 | 1.9 | 38.6 |

| 15 | 40/40 | 1c | 0.40 | 80 | 36 | 7 | 3.0 | 57.1 |

| 16 | 00/40 | 1c | 0.65 | 130 | 100 | 14 | 1.7 | 46.4 |

| Run | Complex | Temperature (°C) | Yield (g) | Activity a | fSb (mol%) | Mnc (103) | Mw/Mnc | Tgd |

|---|---|---|---|---|---|---|---|---|

| 2 | 1a | 70 | 0.36 | 72 | 4 | 19 | 2.4 | 321 |

| 17 | 1a | 50 | 0.27 | 54 | 7 | 26 | 2.2 | 289 |

| 18 | 1a | 30 | 0.14 | 28 | 9 | 27 | 2.0 | 267 |

| 19 | 1a | 0 | 0.13 | 26 | 20 | 55 | 2.1 | 219 |

| 6 | 1b | 70 | 0.37 | 74 | 4 | 19 | 2.7 | 329 |

| 20 | 1b | 50 | 0.27 | 54 | 9 | 24 | 2.2 | 263 |

| 21 | 1b | 30 | 0.20 | 40 | 12 | 27 | 2.3 | 252 |

| 22 | 1b | 0 | 0.11 | 22 | 30 | 57 | 1.5 | 175 |

| 12 | 1c | 70 | 0.36 | 72 | 10 | 13 | 2.0 | 251 |

| 23 | 1c | 50 | 0.29 | 58 | 16 | 18 | 2.2 | 227 |

| 24 | 1c | 30 | 0.24 | 48 | 21 | 54 | 1.5 | 212 |

| 25 | 1c | 0 | 0.14 | 27 | 32 | 61 | 1.5 | 172 |

| Run | Complex | Temperature (°C) | Yield (g) | Activity a | fSb (mol%) | Mnc (103) | Mw/Mnc | Tgd |

|---|---|---|---|---|---|---|---|---|

| 26 | 1a | 70 | 0.126 | 26 | 17 | 36 | 1.9 | 220 |

| 27 | 1a | 50 | 0.072 | 15 | 22 | 40 | 1.7 | 215 |

| 28 | 1a | 30 | 0.053 | 11 | 51 | 43 | 1.9 | 153 |

| 29 | 1b | 70 | 0.088 | 18 | 18 | 38 | 2.0 | 251 |

| 30 | 1b | 50 | 0.067 | 14 | 30 | 55 | 1.6 | 183 |

| 31 | 1b | 30 | 0.033 | 7 | 59 | 78 | 1.9 | 128 |

| 32 | 1c | 70 | 0.082 | 17 | 27 | 38 | 2.5 | 189 |

| 33 | 1c | 50 | 0.034 | 7 | 30 | 39 | 2.1 | 180 |

| 34 | 1c | 30 | 0.030 | 6 | 53 | 46 | 2.0 | 139 |

| 35[e] | 1a | 70 | 0.330 | 66 | 17 | 103 | 1.4 | 232 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chowdhury, S.I.; Tanaka, R.; Nakayama, Y.; Shiono, T. Copolymerization of Norbornene and Styrene with Anilinonaphthoquinone-Ligated Nickel Complexes. Polymers 2019, 11, 1100. https://doi.org/10.3390/polym11071100

Chowdhury SI, Tanaka R, Nakayama Y, Shiono T. Copolymerization of Norbornene and Styrene with Anilinonaphthoquinone-Ligated Nickel Complexes. Polymers. 2019; 11(7):1100. https://doi.org/10.3390/polym11071100

Chicago/Turabian StyleChowdhury, Samiul Islam, Ryo Tanaka, Yuushou Nakayama, and Takeshi Shiono. 2019. "Copolymerization of Norbornene and Styrene with Anilinonaphthoquinone-Ligated Nickel Complexes" Polymers 11, no. 7: 1100. https://doi.org/10.3390/polym11071100

APA StyleChowdhury, S. I., Tanaka, R., Nakayama, Y., & Shiono, T. (2019). Copolymerization of Norbornene and Styrene with Anilinonaphthoquinone-Ligated Nickel Complexes. Polymers, 11(7), 1100. https://doi.org/10.3390/polym11071100