Recent Trends of Foaming in Polymer Processing: A Review

Abstract

1. Introduction

2. Polymer Foaming and Processing

2.1. Classification of Polymer Foams

2.1.1. Hardness Classification

2.1.2. Density Classification

2.1.3. Classification of Bubble Structure

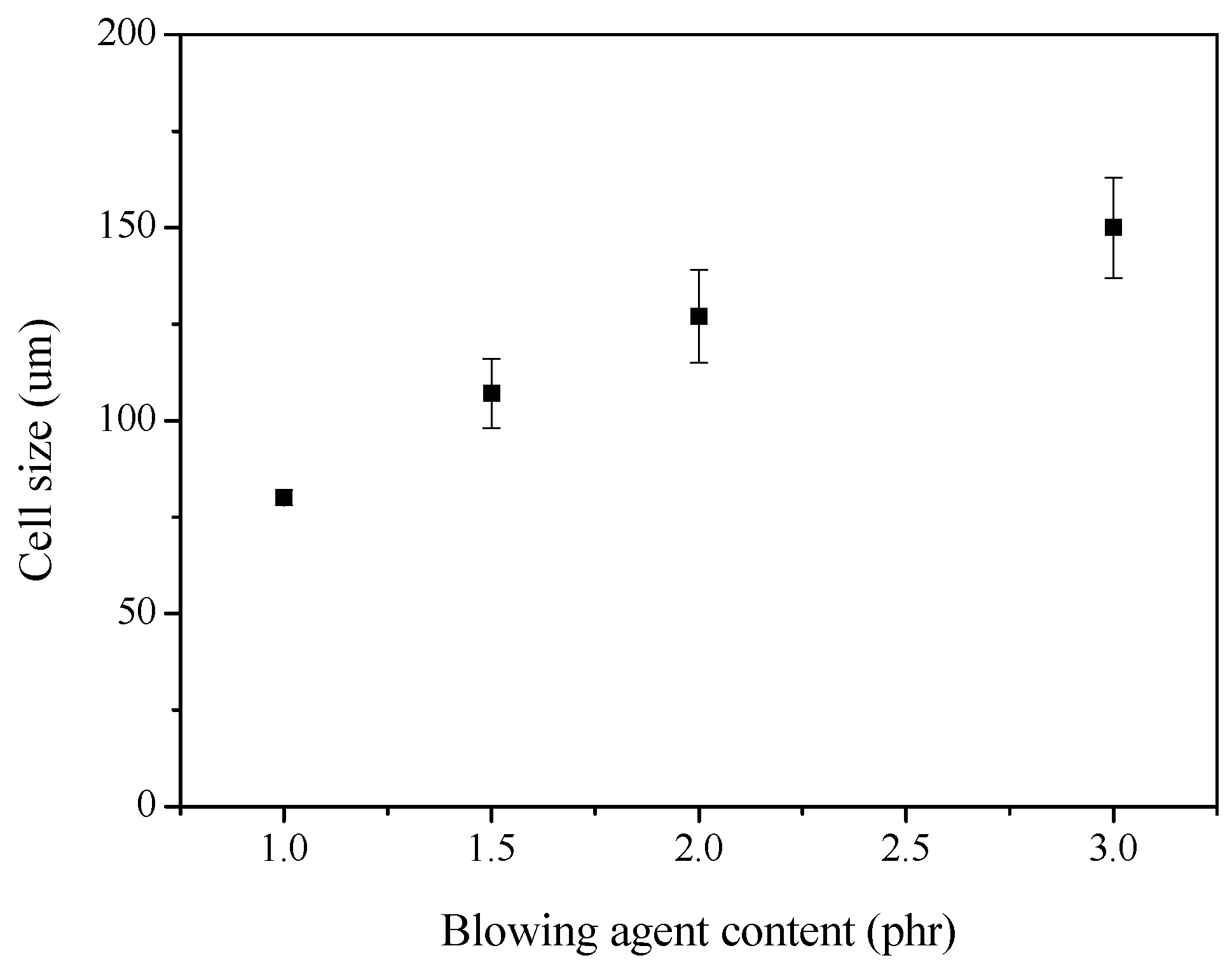

2.2. Blowing Agents

2.2.1. Physical Blowing Agent

2.2.2. Chemical Blowing Agent

2.2.3. Expandable Bead

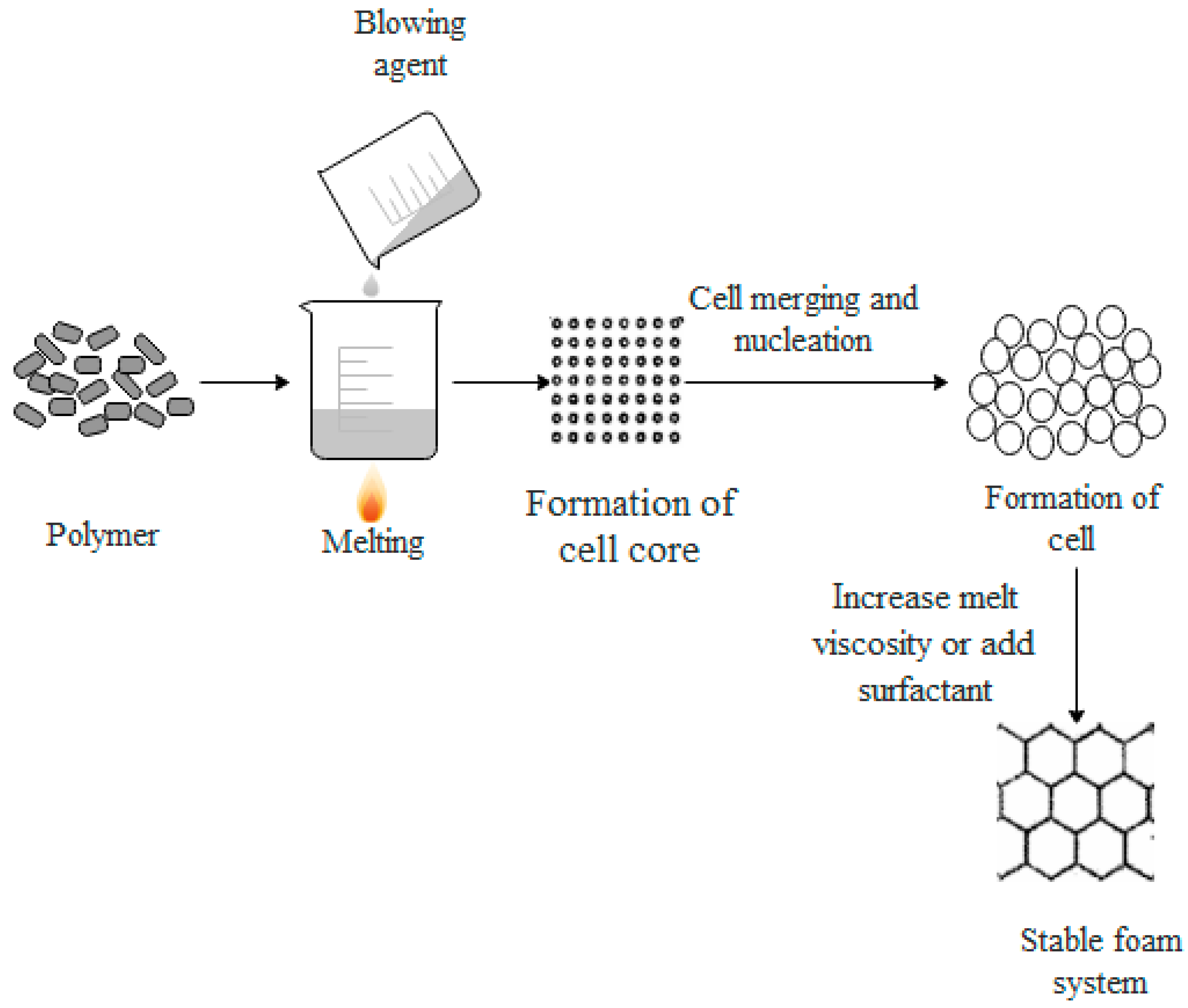

2.3. Principle of Foaming Process

2.3.1. Cell Formation

2.3.2. Cell Growth

2.3.3. Cell Stabilization

2.4. Foaming Methods

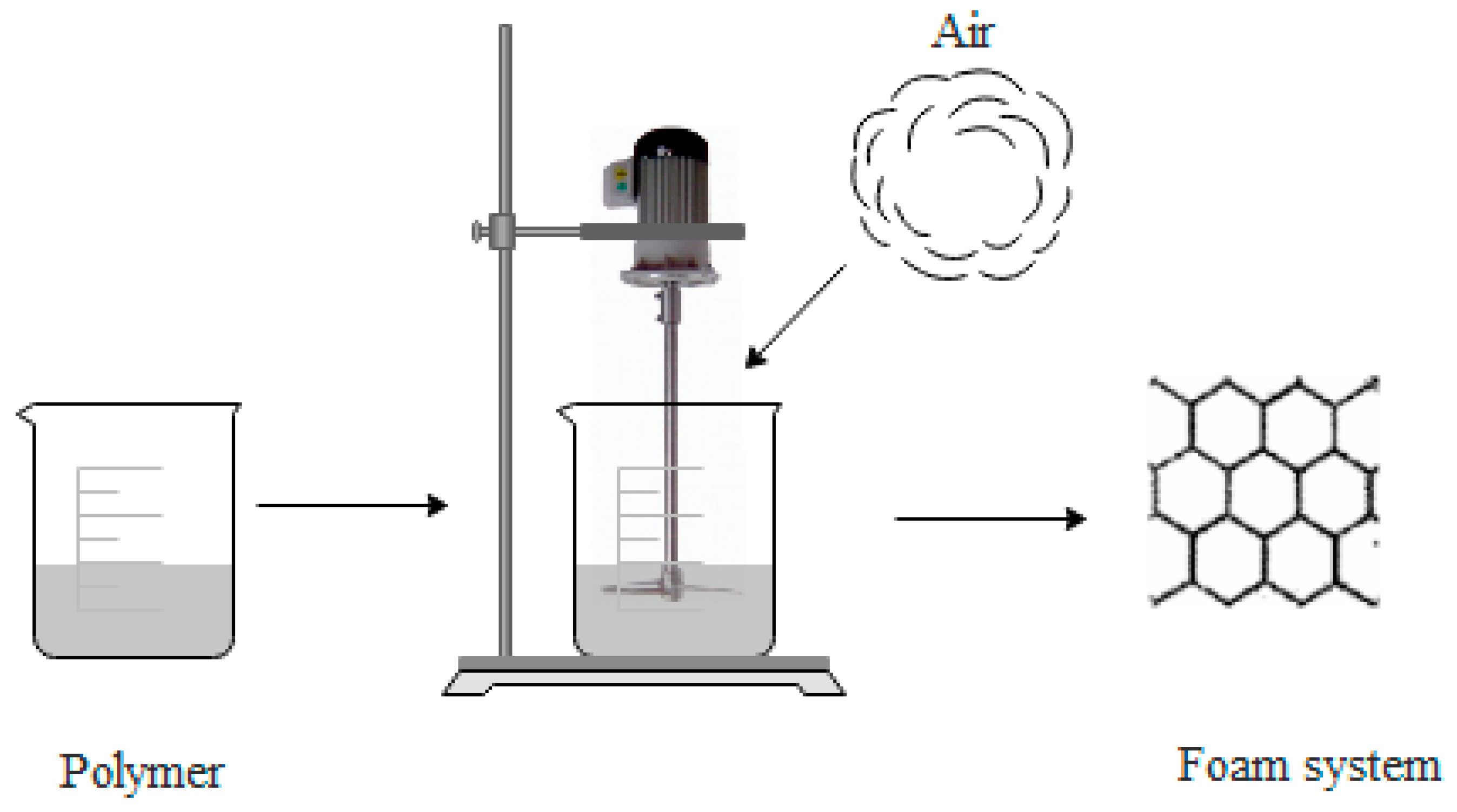

2.4.1. Mechanical Foaming

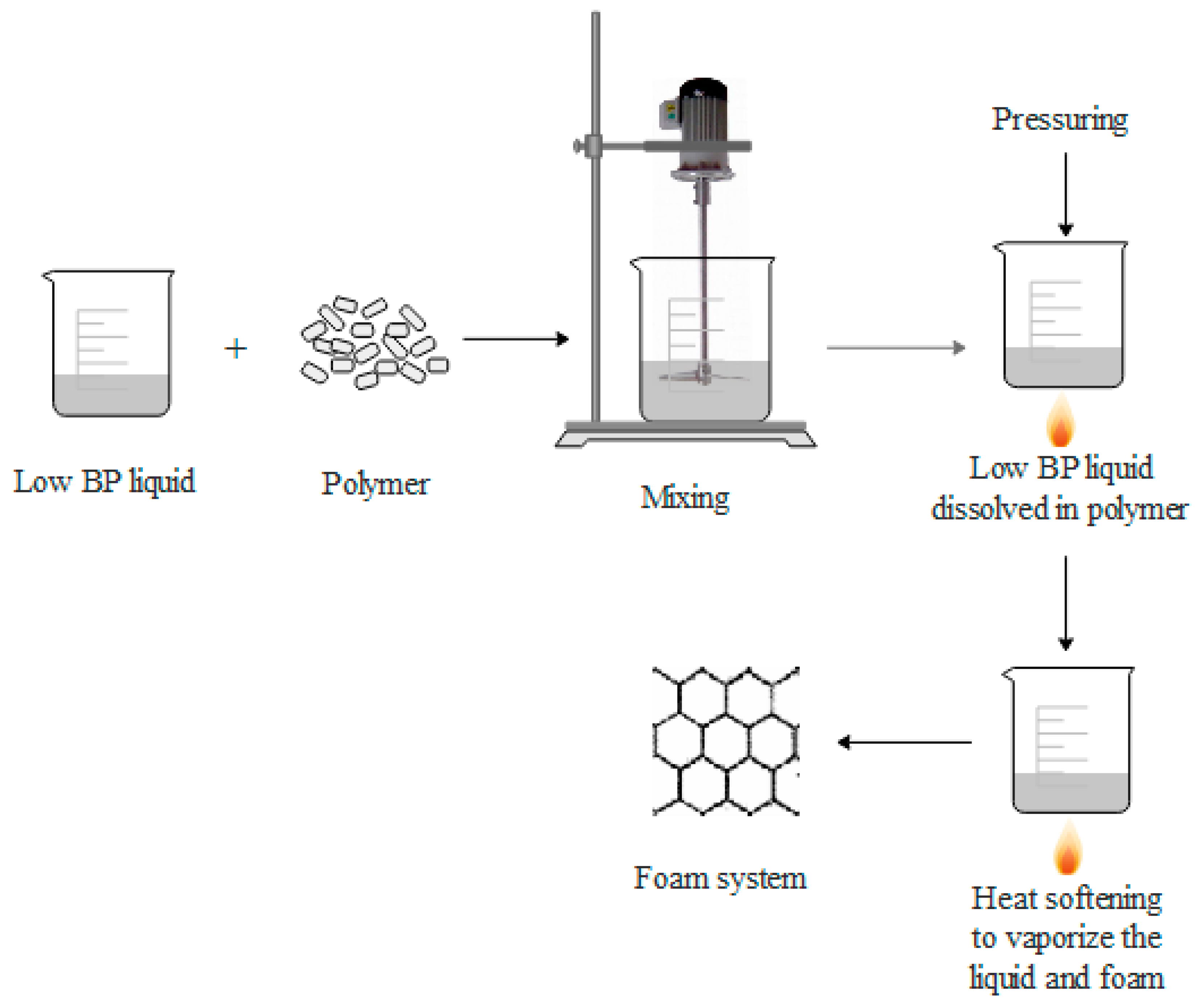

2.4.2. Physical Foaming

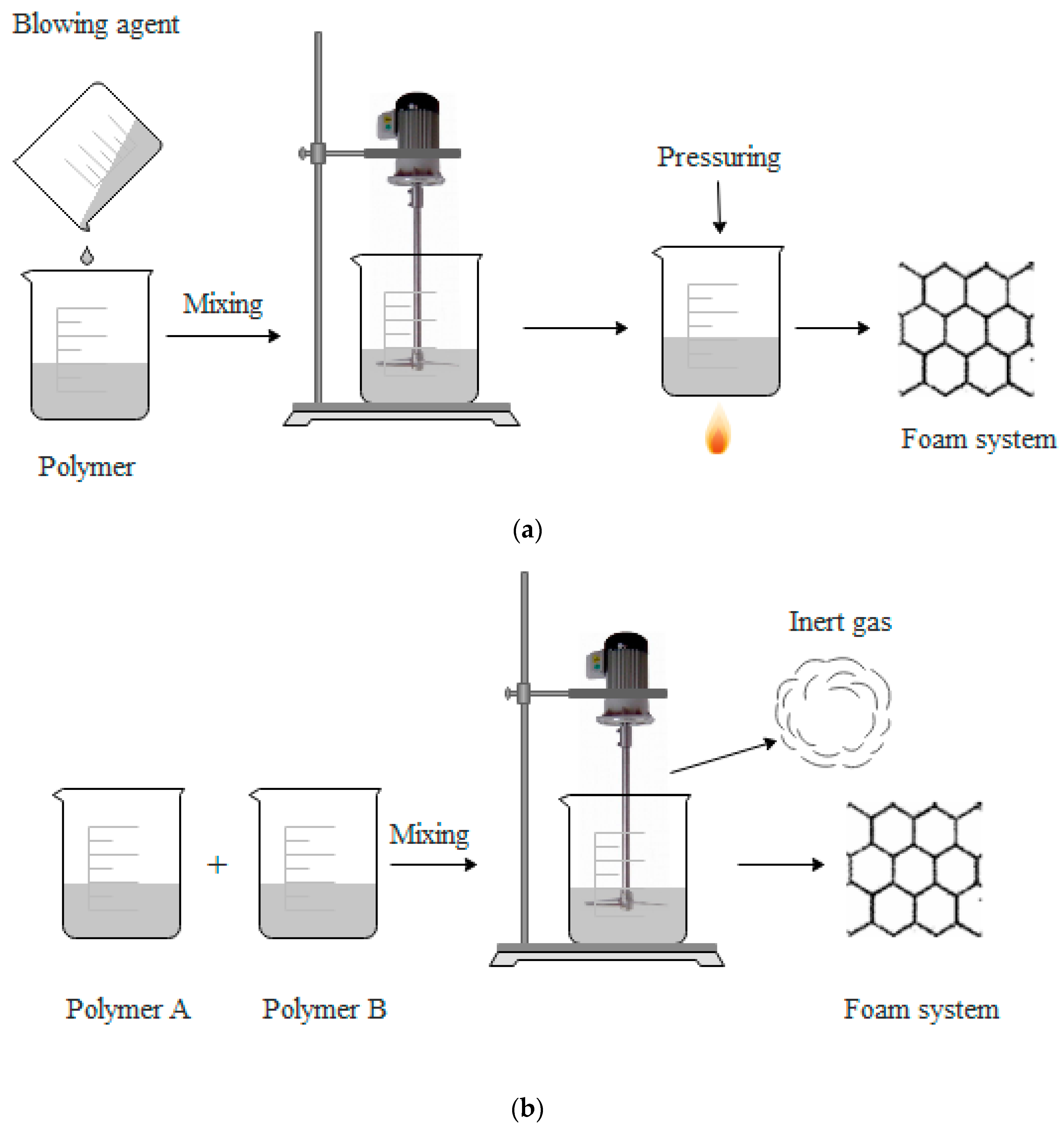

2.4.3. Chemical Foaming

2.5. Processing Techniques

2.5.1. Foam Extrusion Molding

2.5.2. Foam Injection Molding

2.6. Raw Materials of Polymer Foams

2.6.1. Plastics

Thermosetting Resins

Thermoplastics

2.6.2. Rubbers

3. Research Progress of Various Foaming Methods

3.1. Mechanical Foaming

3.2. Physical Foaming

3.3. Chemical Foaming

4. Current Problems and Possible Solutions

4.1. Current Problems

4.2. Possible Solutions

4.2.1. Environmental Pollution

4.2.2. Flame Retardancy

4.2.3. Fracture Toughness

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, S.; Lin, Y.; Ye, L.; Gu, Y.; Qiu, J.; Tang, T.; Li, M. Unexpected foaming behavior of heterografted comb-like PS-g-(PS/PE) copolymers with high branching density at semi-solid state under CO2 batching foam. Polymer 2018, 146, 304–311. [Google Scholar] [CrossRef]

- Li, R.; Lin, H.; Lan, P.; Gao, J.; Huang, Y.; Wen, Y.; Yang, W. Lightweight cellulose/carbon fiber composite foam for electromagnetic interference (EMI) shielding. Polymers 2018, 10, 1319. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Wu, Y.K.; Ai, F.F.; Fan, J.; Xia, Z.P.; Liu, Y. Hierarchical porous polyamide 6 by solution foaming: Synthesis, characterization and properties. Polymers 2018, 10, 1310. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Zhao, J.; Yu, K.; Mark, L.H.; Wang, G.; Gong, P.; Park, C.B.; Zhao, G. Role of elastic strain energy in cell nucleation of polymer foaming and its application for fabricating sub-microcellular TPU microfilms. Polymer 2017, 119, 28–39. [Google Scholar] [CrossRef]

- Li, M.; Qiu, J.; Xing, H.; Fan, D.; Wang, S.; Li, S.; Jiang, Z.; Tang, T. In-situ cooling of adsorbed water to control cellular structure of polypropylene composite foam during CO2 batch foaming process. Polymer 2018, 155, 116–128. [Google Scholar] [CrossRef]

- Tromm, M.; Shaayegan, V.; Wang, C.; Heim, H.P.; Park, C.B. Investigation of the mold-filling phenomenon in high-pressure foam injection molding and its effects on the cellular structure in expanded foams. Polymer 2019, 160, 43–52. [Google Scholar] [CrossRef]

- Lu, P.; Guo, M.; Yang, Y.; Wu, M. Nanocellulose stabilized pickering emulsion templating for thermosetting AESO nanocomposite foams. Polymers 2018, 10, 1111. [Google Scholar] [CrossRef]

- Pinto, J.; Morselli, D.; Bernardo, V.; Notario, B.; Fragouli, D.; Rodriguez-Perez, M.A.; Athanassiou, A. Nanoporous PMMA foams with templated pore size obtained by localized in situ synthesis of nanoparticles and CO2 foaming. Polymer 2017, 124, 176–185. [Google Scholar] [CrossRef]

- Gong, W.; Fu, H.; Zhang, C.; Ban, D.; Yin, X.; He, Y.; He, L.; Pei, X. Study on foaming quality and impact property of foamed polypropylene composites. Polymers 2018, 10, 1375. [Google Scholar] [CrossRef]

- Zhou, D.; Xiong, Y.; Yuan, H.; Luo, G.; Zhang, J.; Shen, Q.; Zhang, L. Synthesis and compressive behaviors of PMMA microporous foam with multi-layer cell structure. Compos. Part B Eng. 2019, 165, 272–278. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Zhang, L.; Mu, Y.; Park, C.B. Lightweight and tough nanocellular PP/PTFE nanocomposite foams with defect-free surfaces obtained using in situ nanofibrillation and nanocellular injection molding. Chem. Eng. J. 2018, 350, 1–11. [Google Scholar] [CrossRef]

- Pérez-Tamarit, S.; Solórzano, E.; Hilger, A.; Manke, I.; Rodríguez-Pérez, M.A. Multi-scale tomographic analysis of polymeric foams: A detailed study of the cellular structure. Eur. Polym. J. 2018, 109, 169–178. [Google Scholar] [CrossRef]

- Gerges, I.; Tamplenizza, M.; Martello, F.; Recordati, C.; Martelli, C.; Ottobrini, L.; Tamplenizza, M.; Guelcher, S.A.; Tocchio, A.; Lenardi, C. Exploring the potential of polyurethane-based soft foam as cell-free scaffold for soft tissue regeneration. Acta Biomater. 2018, 73, 141–153. [Google Scholar] [CrossRef] [PubMed]

- Paciorek-Sadowska, J.; Borowicz, M.; Czupryński, B.; Isbrandt, M. Effect of evening primrose oil-based polyol on the properties of rigid polyurethane–polyisocyanurate foams for thermal insulation. Polymers 2018, 10, 1334. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Tu, R.; Cheng, X.; Zhu, S.; Ma, J.; Fang, T. Experimental study of thermal behavior of insulation material rigid polyurethane in parallel, symmetric, and adjacent building façade constructions. Polymers 2018, 10, 1104. [Google Scholar] [CrossRef] [PubMed]

- Hou, J.; Zhao, G.; Wang, G.; Zhang, L.; Dong, G.; Li, B. Ultra-high expansion linear polypropylene foams prepared in a semi-molten state under supercritical CO2. J. Supercrit. Fluids 2019, 145, 140–150. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Dong, G.; Mu, Y.; Park, C.B. Lightweight and strong microcellular injection molded PP/talc nanocomposite. Compos. Sci. Technol. 2018, 168, 38–46. [Google Scholar] [CrossRef]

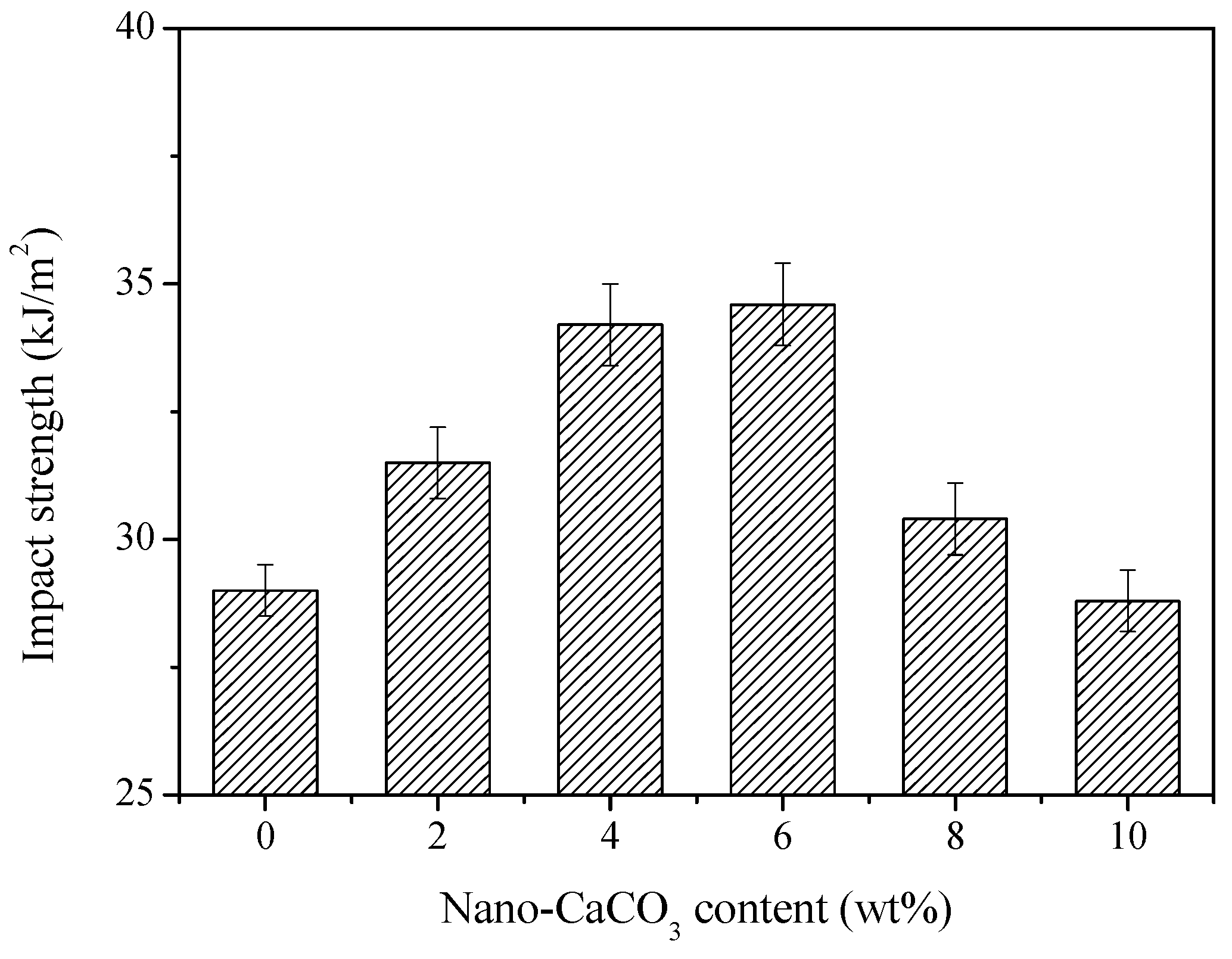

- Mao, H.; He, B.; Guo, W.; Hua, L.; Yang, Q. Effects of nano-CaCO3 content on the crystallization, mechanical properties, and cell structure of PP nanocomposites in microcellular injection molding. Polymers 2018, 10, 1160. [Google Scholar] [CrossRef]

- Li, J.; Zhang, A.; Zhang, S.; Gao, Q.; Zhang, W.; Li, J. Larch tannin-based rigid phenolic foam with high compressive strength, low friability, and low thermal conductivity reinforced by cork powder. Compos. Part B Eng. 2019, 156, 368–377. [Google Scholar] [CrossRef]

- Wang, G.; Liu, X.; Zhang, J.; Sui, W.; Jang, J.; Si, C. One-pot lignin depolymerization and activation by solid acid catalytic phenolation for lightweight phenolic foam preparation. Ind. Crop. Prod. 2018, 124, 216–225. [Google Scholar] [CrossRef]

- Ge, T.; Tang, K.; Yu, Y.; Tan, X. Preparation and properties of the 3-pentadecyl-phenol in situ modified foamable phenolic resin. Polymers 2018, 10, 1124. [Google Scholar] [CrossRef]

- Ma, Y.; Gong, X.; Liao, C.; Geng, X.; Wang, C.; Chu, F. Preparation and characterization of DOPO-ITA modified ethyl cellulose and its application in phenolic foams. Polymers 2018, 10, 1049. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Ye, Y.; Li, X.; Lü, X.; Chen, R. Flexible, conductive, and highly pressure-sensitive graphene-polyimide foam for pressure sensor application. Compos. Sci. Technol. 2018, 164, 187–194. [Google Scholar] [CrossRef]

- Ramya, G.; Crittenden, B.; Smith, M.; Camus, O.; Chew, Y.M.J.; Perera, S. Synthesis of novel regenerable 13X zeolite-polyimide adsorbent foams. Chem. Eng. J. 2019, 361, 736–750. [Google Scholar] [CrossRef]

- Sun, G.; Wang, W.; Zhang, C.; Liu, L.; Wei, H.; Han, S. Fabrication of isocyanate-based polyimide foam by a postgrafting method. J. Appl. Polym. Sci. 2017, 134, 44240. [Google Scholar] [CrossRef]

- Li, J.; Zhang, G.; Li, J.; Zhou, L.; Jing, Z.; Ma, Z. Preparation and properties of polyimide/chopped carbon fiber composite foams. Polym. Adv. Technol. 2017, 28, 28–34. [Google Scholar] [CrossRef]

- Sun, G.; Wang, W.; Wang, L.; Yang, Z.; Liu, L.; Wang, J.; Ma, N.; Wei, H.; Han, S. Effects of aramid honeycomb core on the flame retardance and mechanical property for isocyanate-based polyimide foams. J. Appl. Polym. Sci. 2017, 134, 45041. [Google Scholar] [CrossRef]

- Abbasi, H.; Antunes, M.; Velasco, J.I. Effects of carbon nanotubes/graphene nanoplatelets hybrid systems on the structure and properties of polyetherimide-based foams. Polymers 2018, 10, 348. [Google Scholar] [CrossRef]

- Taghizadeh, S.A.; Farrokhabadi, A.; Liaghat, G.; Pedram, E.; Malekinejad, H.; Mohammadi, S.F.; Ahmadi, H. Characterization of compressive behavior of PVC foam infilled composite sandwich panels with different corrugated core shapes. Thin Wall. Struct. 2019, 135, 160–172. [Google Scholar] [CrossRef]

- Wang, Y.; Zheng, Y.; He, W.; Wang, C.; Sun, Y.; Qiao, K.; Wang, X.; Gao, L. Reprint of: Preparation of a novel sodium alginate/polyvinyl formal composite with a double crosslinking interpenetrating network for multifunctional biomedical application. Compos. Part B Eng. 2017, 121, 9–22. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, Q.; Wang, C.; Guo, B.; Park, C.B.; Wang, G. High thermal insulation and compressive strength polypropylene foams fabricated by high-pressure foam injection molding and mold opening of nano-fibrillar composites. Mater. Des. 2017, 131, 1–11. [Google Scholar] [CrossRef]

- Linul, E.; Vălean, C.; Linul, P.A. Compressive behavior of aluminum microfibers reinforced semi-rigid polyurethane foams. Polymers 2018, 10, 1298. [Google Scholar] [CrossRef] [PubMed]

- Prociak, A.; Malewska, E.; Kurańska, M.; Bąk, S.; Budny, P. Flexible polyurethane foams synthesized with palm oil-based bio-polyols obtained with the use of different oxirane ring opener. Ind. Crop. Prod. 2018, 115, 69–77. [Google Scholar] [CrossRef]

- Carosio, F.; Ghanadpour, M.; Alongi, J.; Wågberg, L. Layer-by-layer- assembled chitosan/phosphorylated cellulose nanofibrils as a bio-based and flame protecting nano-exoskeleton on PU foams. Carbohydr. Polym. 2018, 202, 479–487. [Google Scholar] [CrossRef] [PubMed]

- Sun, B.; Kulinsky, L. Fabrication of regular polystyrene foam structures with selective laser sintering. Mater. Today Commun. 2017, 13, 346–353. [Google Scholar] [CrossRef]

- Alander, B.; Capezza, A.J.; Wu, Q.; Johansson, E.; Olsson, R.T.; Hedenqvist, M.S. A facile way of making inexpensive rigid and soft protein biofoams with rapid liquid absorption. Ind. Crop. Prod. 2018, 119, 41–48. [Google Scholar] [CrossRef]

- Laguna-Gutierrez, E.; Escudero, J.; Rodriguez-Perez, M.A. Analysis of the mechanical properties and effective diffusion coefficient under static creep loading of low-density foams based on polyethylene/clays nanocomposites. Compos. Part B Eng. 2018, 148, 156–165. [Google Scholar] [CrossRef]

- Liu, H.; Yang, J.; Liu, H. Impact response of low-density foam impinging onto viscoelastic bar: A theoretical analysis. Compos. Struct. 2018, 200, 47–58. [Google Scholar] [CrossRef]

- Park, J.H.; Minn, K.S.; Lee, H.R.; Yang, S.H.; Yu, C.B.; Pak, S.Y.; Oh, C.S.; Song, Y.S.; Kang, Y.J.; Youn, J.R. Cell openness manipulation of low density polyurethane foam for efficient sound absorption. J. Sound Vib. 2017, 406, 224–236. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Z.; Liu, H.; Yang, J.; Lin, H. Theoretical investigation on impact resistance and energy absorption of foams with nonlinearly varying density. Compos. Part B Eng. 2017, 116, 76–88. [Google Scholar] [CrossRef]

- Rizvi, A.; Tabatabaei, A.; Vahedi, P.; Mahmood, S.H.; Park, C.B. Non-crosslinked thermoplastic reticulated polymer foams from crystallization-induced structural heterogeneities. Polymer 2018, 135, 185–192. [Google Scholar] [CrossRef]

- Fazekas, B.; Goda, T.J. Determination of the hyper-viscoelastic model parameters of open-cell polymer foams and rubber-like materials with high accuracy. Mater. Des. 2018, 156, 596–608. [Google Scholar] [CrossRef]

- Schulze, M.; Handge, U.A.; Abetz, V. Preparation and characterisation of open-celled foams using polystyrene-b-poly(4-vinylpyridine) and poly(4-methylstyrene)-bpoly(4-vinylpyridine) diblock copolymers. Polymer 2017, 108, 400–412. [Google Scholar] [CrossRef]

- Smorygo, O.; Mikutski, V.; Marukovich, A.; Sadykov, V.; Bespalko, Y.; Stefan, A.; Pelin, C.E. Preparation and characterization of open-cell epoxy foams modified with carbon fibers and aluminum powder. Compos. Struct. 2018, 202, 917–923. [Google Scholar] [CrossRef]

- Kim, H.; Ahn, K.H.; Lee, S.J. Conductive poly(high internal phase emulsion) foams incorporated with polydopamine-coated carbon nanotubes. Polymer 2017, 110, 187–195. [Google Scholar] [CrossRef]

- Koohbor, B.; Ravindran, S.; Kidane, A. Effects of cell-wall instability and local failure on the response of closed-cell polymeric foams subjected to dynamic loading. Mech. Mater. 2018, 116, 67–76. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Ngamkhanong, C.; Papaelias, M.; Roberts, C. Wet/dry influence on behaviors of closed-cell polymeric cross-linked foams under static, dynamic and impact loads. Constr. Build. Mater. 2018, 187, 1092–1102. [Google Scholar] [CrossRef]

- Xie, P.; Wu, G.; Cao, Z.; Han, Z.; Zhang, Y.; An, Y.; Yang, W. Effect of mold opening process on microporous structure and properties of microcellular polylactide–polylactide nanocomposites. Polymers 2018, 18, 554. [Google Scholar] [CrossRef]

- Pinto, J.; Notario, B.; Verdejo, R.; Dumon, M.; Costeux, S.; Rodriguez-Perez, M.A. Molecular confinement of solid and gaseous phases of self-standing bulk nanoporous polymers inducing enhanced and unexpected physical properties. Polymer 2017, 113, 27–33. [Google Scholar] [CrossRef]

- Jahwari, F.A.; Huang, Y.; Naguib, H.E.; Lo, J. Relation of impact strength to the microstructure of functionally graded porous structures of acrylonitrile butadiene styrene (ABS) foamed by thermally activated microspheres. Polymer 2016, 98, 270–281. [Google Scholar] [CrossRef]

- Peng, J.; Wals, P.J.; Sabo, R.C.; Turng, L.S.; Clemons, C.M. Water-assisted compounding of cellulose nanocrystals into polyamide 6 for use as a nucleating agent for microcellular foaming. Polymer 2016, 84, 158–166. [Google Scholar] [CrossRef]

- Song, W.; Barber, K.; Lee, K.Y. Heat-induced bubble expansion as a route to increase the porosity of foam-templated bio-based macroporous polymers. Polymer 2017, 118, 97–106. [Google Scholar] [CrossRef]

- Sadik, T.; Pillon, C.; Carrot, C.; Ruiz, J.A.R. Dsc studies on the decomposition of chemical blowing agents based on citric acid and sodium bicarbonate. Thermochim. Acta 2018, 659, 74–81. [Google Scholar] [CrossRef]

- Petlitckaia, S.; Poulesquen, A. Design of lightweight metakaolin based geopolymer foamed with hydrogen peroxide. Ceram. Int. 2019, 45, 1322–1330. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, G.; Wang, G.; Zhang, W.; Li, Y. A new core-back foam injection molding method with chemical blowing agents. Mater. Des. 2018, 144, 331–342. [Google Scholar] [CrossRef]

- Michałowski, S.; Prociak, A.; Zajchowski, S.; Tomaszewska, J.; Mirowski, J. Porous product with reduced apparent density keeps good mechanical properties. Extruded composites of poly(vinyl chloride) blown under microwave irradiation. Polym. Test. 2017, 64, 229–234. [Google Scholar] [CrossRef]

- Liu, C.; Long, Y.; Xie, J.; Xie, X. Towards green polyurethane foams via renewable castor oil-derived polyol and carbon dioxide releasing blowing agents from alkylated polyethylenimines. Polymer 2017, 116, 240–250. [Google Scholar] [CrossRef]

- Long, Y.; An, J.; Xie, X. CO2-releasing blowing agents from modified polyethylenimines slightly consume isocyanate groups while foaming polyurethanes. Arab. J. Chem. 2019, in press. [Google Scholar] [CrossRef]

- Raps, D.; Hossieny, N.; Park, C.B.; Altsädt, V. Past and present developments in polymer bead foams and bead foaming technology. Polymer 2015, 56, 5–19. [Google Scholar] [CrossRef]

- Kakumanu, V.; Sundarram, S.S. Dual pore network polymer foams for biomedical applications via combined solid state foaming and additive manufacturing. Mater. Lett. 2018, 213, 366–369. [Google Scholar] [CrossRef]

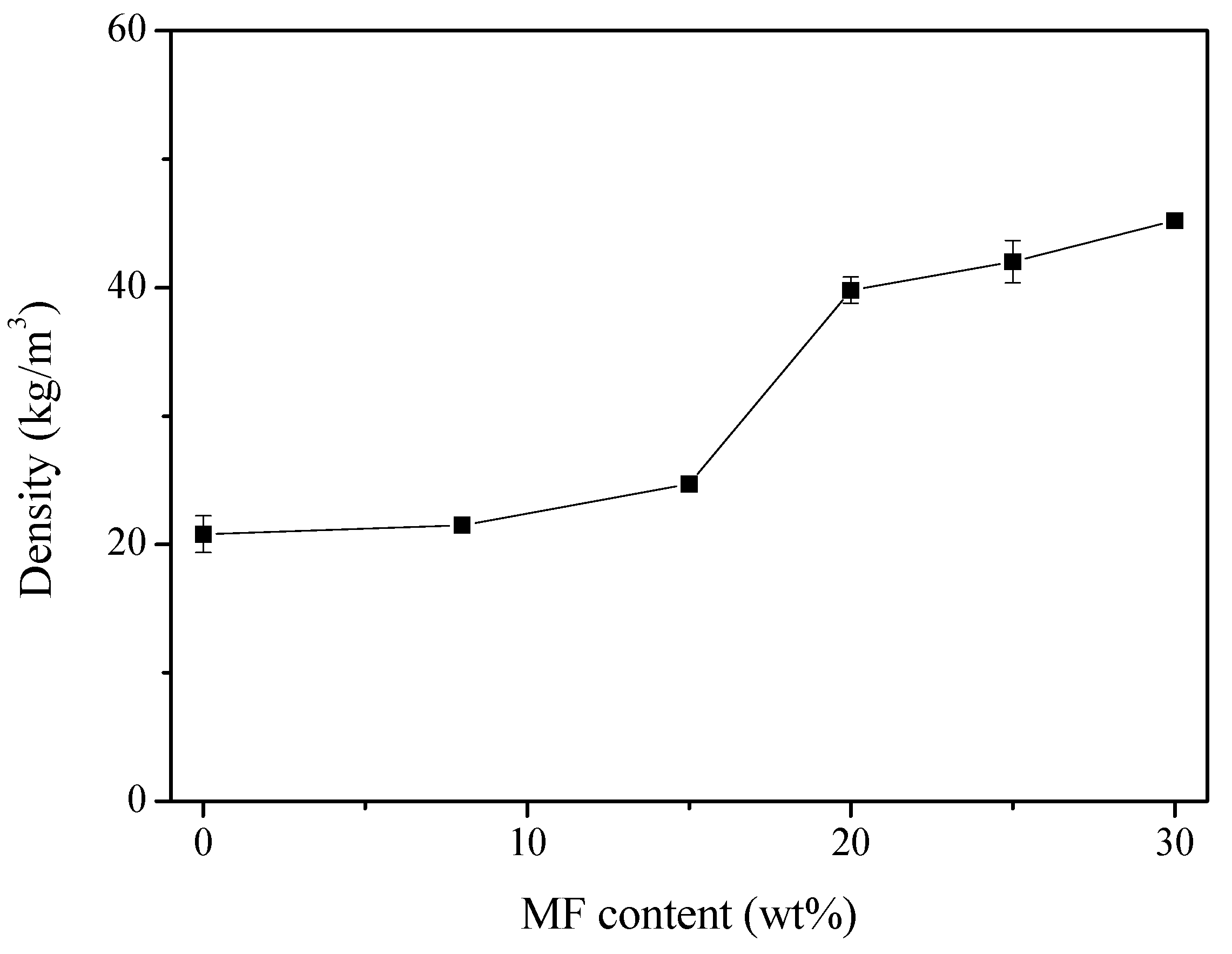

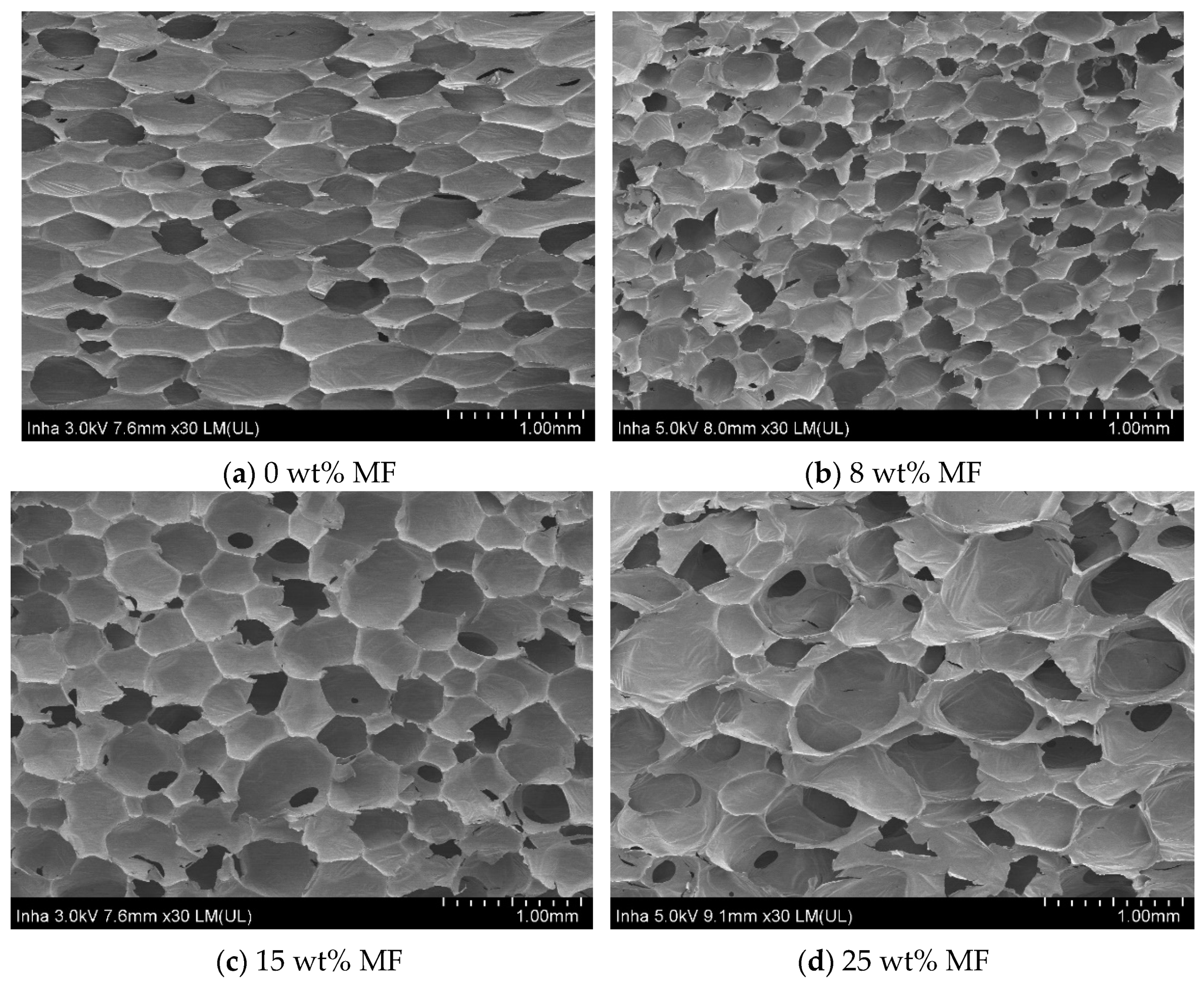

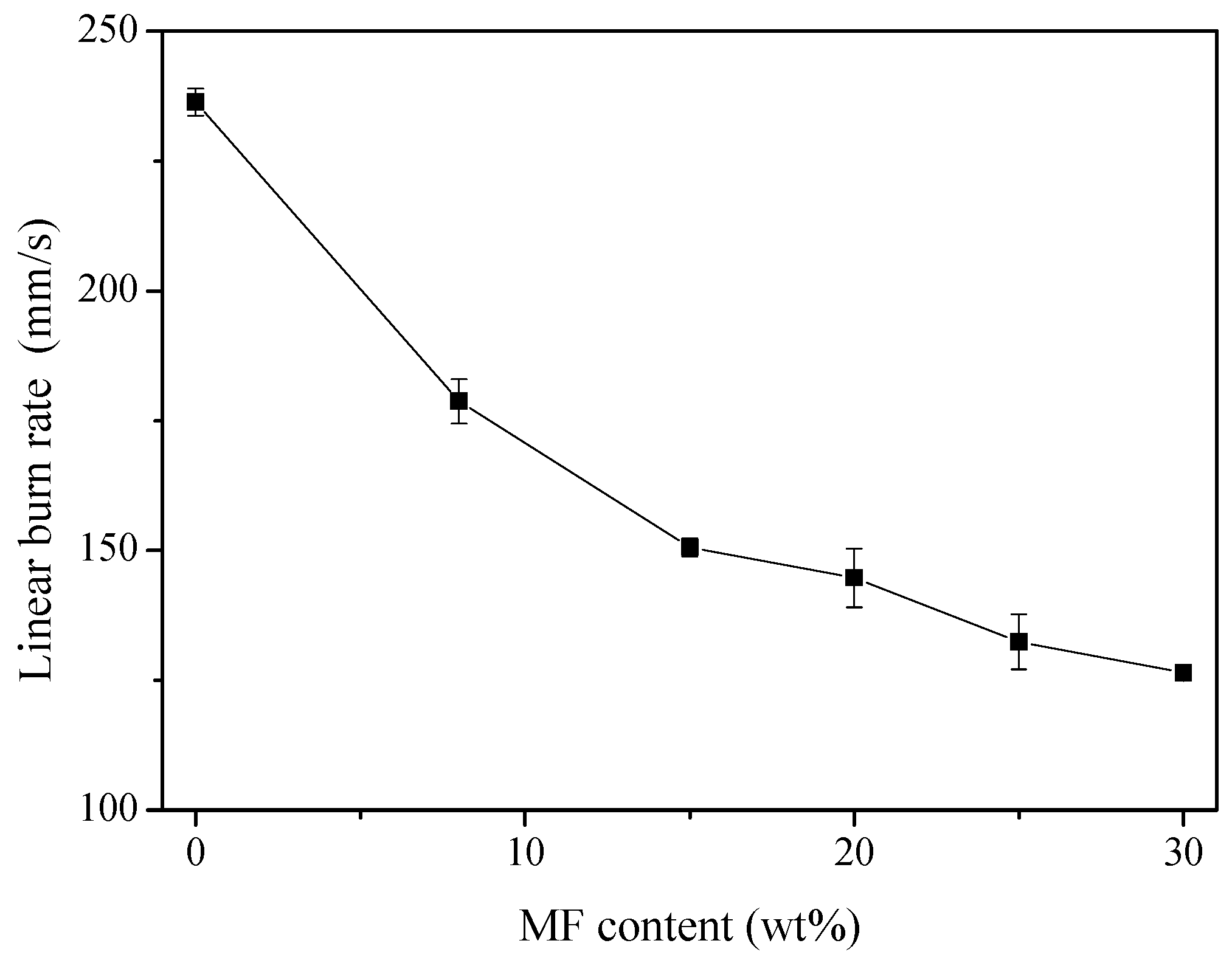

- Liu, Y.; Ye, L.; Shu, Y.; Zhao, X. In situ preparation of intrinsic flame retardant urea formaldehyde/aramid fiber composite foam: Structure, property and reinforcing mechanism. Compos. Part A Appl. Sci. Manuf. 2018, 115, 274–282. [Google Scholar] [CrossRef]

- Kuska, R.; Milovanovic, S.; Frerich, S.; Ivanovic, J. Thermal analysis of polylactic acid under high CO2 pressure applied in supercritical impregnation and foaming process design. J. Supercrit. Fluids 2019, 144, 71–80. [Google Scholar] [CrossRef]

- Wang, S.; Ameli, A.; Shaayegan, V.; Kazemi, Y.; Huang, Y.; Naguib, H.E.; Park, C.B. Modelling of rod-like fillers’ rotation and translation near two growing cells in conductive polymer composite foam processing. Polymers 2018, 10, 261. [Google Scholar] [CrossRef] [PubMed]

- Barmouz, M.; Behravesh, A.H. The role of foaming process on shape memory behavior of polylactic acidthermoplastic polyurethane-nano cellulose bio-nanocomposites. J. Mech. Behav. Biomed. 2019, 91, 266–277. [Google Scholar] [CrossRef] [PubMed]

- Heimann, J.; Matz, A.M.; Matz, B.S.; Jost, N. Processing of open-pore silicon foams using graphite composite as space holder. Sci. Technol. Mater. 2018, 30, 23–26. [Google Scholar] [CrossRef]

- Chen, S.; Zhu, W.; Cheng, Y. Multi-objective optimization of acoustic performances of polyurethane foam composites. Polymers 2018, 10, 788. [Google Scholar] [CrossRef] [PubMed]

- Keshtkar, M.; Nofar, M.; Park, C.B.; Carreau, P.J. Extruded PLA/clay nanocomposite foams blown with supercritical CO2. Polymer 2014, 55, 4077–4090. [Google Scholar] [CrossRef]

- Ellingham, T.; Duddleston, L.; Turng, L.S. Sub-critical gas-assisted processing using CO2 foaming to enhance the exfoliation of grapheme in polypropylene + grapheme nanocomposites. Polymer 2017, 117, 132–139. [Google Scholar] [CrossRef]

- Wang, L.; Hikima, Y.; Ishihara, S.; Ohshima, M. Fabrication of lightweight microcellular foams in injection-molded polypropylene using the synergy of long-chain branches and crystal nucleating agents. Polymer 2017, 128, 119–127. [Google Scholar] [CrossRef]

- Barbosa, R.C.N.; Campilho, R.D.S.G.; Silva, F.J.G. Injection mold design for a plastic component with blowing agent. Procedia Manuf. 2018, 17, 774–782. [Google Scholar] [CrossRef]

- Lionetto, F.; Timo, A.; Frigione, M. Cold-cured epoxy-based organic– inorganic hybrid resins containing deep eutectic solvents. Polymers 2019, 11, 14. [Google Scholar] [CrossRef] [PubMed]

- Esmaeili, N.; Salimi, A.; Zohuriaan-Mehr, M.J.; Vafayan, M.; Meyer, W. Bio-based thermosetting epoxy foam: Tannic acid valorization toward dyedecontaminating and thermo-protecting applications. J. Hazard. Mater. 2018, 357, 30–39. [Google Scholar] [CrossRef] [PubMed]

- Sousa, A.F.; Ferreira, S.; Lopez, A.; Borges, I.; Pinto, R.J.B.; Silvestre, A.J.D.; Freire, C.S.R. Thermosetting AESO-bacterial cellulose nanocomposite foams with tailored mechanical properties obtained by pickering emulsion templating. Polymer 2017, 118, 127–134. [Google Scholar] [CrossRef]

- Li, B.; Yuan, Z.; Schmidt, J.; Xu, C. New foaming formulations for production of bio-phenol formaldehyde foams using raw kraft lignin. Eur. Polym. J. 2019, 111, 1–10. [Google Scholar] [CrossRef]

- Caprio, M.R.D.; Tammaro, D.; Maio, E.D.; Cavalca, S.; Parenti, V.; Fangareggi, A.; Iannace, S. A pressure vessel for studying gas foaming of thermosetting polymers: Sorption, synthesis and processing. Polym. Test. 2017, 62, 137–142. [Google Scholar] [CrossRef]

- Bakir, M.; Henderson, C.N.; Meyer, J.L.; Oh, J.; Miljkovic, N.; Kumosa, M.; Economy, J.; Jasiuk, I. Effects of environmental aging on physical properties of aromatic thermosetting copolyester matrix neat and nanocomposite foams. Polym. Degrad. Stab. 2018, 147, 49–56. [Google Scholar] [CrossRef]

- Bakir, M.; Meyer, J.L.; Economy, J.; Jasiuk, I. Aromatic thermosetting copolyester nanocomposite foams: High thermal and mechanical performance lightweight structural materials. Polymer 2017, 123, 311–320. [Google Scholar] [CrossRef]

- Santiago-Calvo, M.; Pérez-Tamarit, S.; Tirado-Mediavilla, J.; Villafañe, F.; Rodríguez-Pérez, M.A. Infrared expandometry: A novel methodology to monitor the expansion kinetics of cellular materials produced with exothermic foaming mechanisms. Polym. Test. 2018, 66, 383–393. [Google Scholar] [CrossRef]

- Wu, S.; He, L.; Zhang, C.; Gong, W.; He, Y.; Luo, Y. Visualization observation of cells growth in low-density polyethylene foaming processes. Polym. Test. 2017, 63, 367–374. [Google Scholar] [CrossRef]

- Bernardo, V.; Laguna-Gutierrez, E.; Lopez-Gil, A.; Rodriguez-Perez, M.A. Highly anisotropic crosslinked HDPE foams with a controlled anisotropy ratio: Production and characterization of the cellular structure and mechanical properties. Mater. Des. 2017, 114, 83–91. [Google Scholar] [CrossRef]

- Wang, J.; Chen, D. Flexural properties and morphology of microcellular-insert injection molded all-polypropylene composite foams. Compos. Struct. 2018, 187, 403–410. [Google Scholar] [CrossRef]

- Pleşa, I.; Noţingher, P.V.; Stancu, C.; Wiesbrock, F.; Schlögl, S. Polyethylene nanocomposites for power cable insulations. Polymers 2019, 11, 24. [Google Scholar] [CrossRef] [PubMed]

- Albooyeh, A.R. The effect of addition of Multiwall Carbon Nanotubes on the vibration properties of Short Glass Fiber reinforced polypropylene and polypropylene foam composites. Polym. Test. 2019, 74, 86–98. [Google Scholar] [CrossRef]

- Tang, N.; Lei, D.; Huang, D.; Xiao, R. Mechanical performance of polystyrene foam (EPS): Experimental and numerical analysis. Polym. Test. 2019, 73, 359–365. [Google Scholar] [CrossRef]

- Coquard, R.; Baillis, D.; Quenard, D. Numerical and experimental study of the IR opacification of polystyrene foams for thermal insulation enhancement. Energy. Build. 2019, 183, 54–63. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, Y.; Xiang, L. Post-curing effect on the chemical structure and its relationship with heat resistance and thermal-mechanical properties of crosslinked PVC foams. Polym. Test. 2019, 73, 418–424. [Google Scholar] [CrossRef]

- Senol, K.; Shukla, A. Underwater mechanical behavior of closed cell PVC foams under hydrostatic loading through 3D DIC technique. Polym. Test. 2019, 73, 72–81. [Google Scholar] [CrossRef]

- León, J.M.; Bernardo, V.; Rodríguez-Pérez, M.Á. Low density nanocellular polymers based on PMMA produced by gas dissolution foaming: Fabrication and cellular structure characterization. Polymers 2016, 8, 265. [Google Scholar] [CrossRef] [PubMed]

- Notario, B.; Pinto, J.; Verdejo, R.; Rodríguez-Perez, M.A. Dielectric behavior of porous PMMA: From the micrometer to the nanometer scale. Polymer 2016, 107, 302–305. [Google Scholar] [CrossRef]

- Huang, D.; Zhang, M.; Guo, C.; Shi, L.; Lin, P. Experimental investigations on the effects of bottom ventilation on the fire behavior of natural rubber latex foam. Appl. Therm. Eng. 2018, 133, 201–210. [Google Scholar] [CrossRef]

- Tang, W.; Bai, J.; Liao, X.; Xiao, W.; Luo, Y.; Yang, Q.; Li, G. Carbon nanotube-reinforced silicone rubber nanocomposites and the foaming behavior in supercritical carbon dioxide. J. Supercrit. Fluids 2018, 141, 78–87. [Google Scholar] [CrossRef]

- Bai, J.; Liao, X.; Huang, E.; Luo, Y.; Yang, Q.; Li, G. Control of the cell structure of microcellular silicone rubber/nanographite foam for enhanced mechanical performance. Mater. Des. 2017, 133, 288–298. [Google Scholar] [CrossRef]

- Wang, H.; Hu, W.; Zhao, F. Numerical simulation of quasi-static compression on a complex rubber foam. Acta Mech. Solida Sin. 2017, 30, 285–290. [Google Scholar] [CrossRef]

- Liu, H.; Kang, Y. Superhydrophobic and superoleophilic modified EPDM foam rubber fabricated by a facile approach for oil/water separation. Appl. Surf. Sci. 2018, 451, 223–231. [Google Scholar] [CrossRef]

- He, W.; Zhou, Y.; Chen, X.; Guo, J.; Zhou, D.; Chen, S.; Wang, M.; Li, L. Novel intumescent flame retardant masterbatch prepared through different processes and its application in EPDM/PP thermoplastic elastomer: Thermal stability, flame retardancy, and mechanical properties. Polymers 2019, 11, 50. [Google Scholar] [CrossRef]

- Ji, Z.; Ma, J.; Qin, X.; Wu, Y.; Xu, R.; Ma, Z.; Xue, C.; Qin, J.; Shao, L. Improved dimensional stability of styrene butadiene rubber/ethylene vinyl acetate composite foams with skeleton support structure based on alternately cross-linking process. Polymer 2018, 157, 103–110. [Google Scholar] [CrossRef]

- Jin, F.L.; Feng, L.; Shi, Q.B.; Park, S.J. Physico-mechanical and fire properties of polyurethane/melamine-formaldehyde interpenetrating polymer network foams. Macromol. Res. 2016, 24, 773–776. [Google Scholar] [CrossRef]

- Pradeep, S.A.; Kharbas, H.; Turng, L.S.; Avalos, A.; Lawrence, J.G.; Pilla, S. Investigation of thermal and thermomechanical properties of biodegradable PLA/PBSA composites processed via supercritical fluid-assisted foam injection molding. Polymers 2017, 9, 22. [Google Scholar] [CrossRef]

- Gazzani, S.E.; Nassiet, V.; Habas, J.P.; Freydier, C.; Hilleshein, A. High temperature epoxy foam: Optimization of process parameters. Polymers 2016, 8, 215. [Google Scholar] [CrossRef]

- Mantaranon, N.; Chirachanchai, S. Polyoxymethylene foam: From an investigation of key factors related to porous morphologies and microstructure to the optimization of foam properties. Polymer 2016, 96, 54–62. [Google Scholar] [CrossRef]

- Chen, Y.C.; Tai, W. Castor oil-based polyurethane resin for low-density composites with bamboo charcoal. Polymers 2018, 10, 1100. [Google Scholar] [CrossRef] [PubMed]

- Park, S.J.; Jin, F.L.; Lee, J.R. Synthesis and thermal properties of epoxidized vegetable oil. Macromol. Rapid Commun. 2004, 25, 724–727. [Google Scholar] [CrossRef]

- Park, S.J.; Jin, F.L.; Lee, J.R.; Shin, J.S. Cationic polymerization and physicochemical properties of a biobased epoxy resin initiated by thermally latent catalysts. Eur. Polym. J. 2005, 41, 231–237. [Google Scholar] [CrossRef]

- Park, S.J.; Jin, F.L.; Lee, J.R. Effect of biodegradable epoxidized castor oil on physicochemical and mechanical properties of epoxy resins. Macromol. Chem. Phys. 2004, 205, 2048–2054. [Google Scholar] [CrossRef]

- Park, S.J.; Jin, F.L.; Lee, J.R. Thermal and mechanical properties of tetrafunctional epoxy resin toughened with epoxidized soybean oil. Mater. Sci. Eng. A Struct. 2004, 374, 109–114. [Google Scholar] [CrossRef]

- Mokhena, T.C.; Sefadi, J.S.; Sadiku, E.R.; John, M.J.; Mochane, M.J.; Mtibe, A. Thermoplastic processing of PLA/cellulose nanomaterials composites. Polymers 2018, 10, 1363. [Google Scholar] [CrossRef] [PubMed]

- Jiang, W.; Jin, F.L.; Park, S.J. Synthesis of a novel phosphorus-nitrogen- containing intumescent flame retardant and its application to fabrics. J. Ind. Eng. Chem. 2015, 27, 40–43. [Google Scholar] [CrossRef]

- Xu, H.J.; Jin, F.L.; Park, S.J. Synthesis of a novel phosphorus-containing flame retardant for epoxy resins. Bull. Korean Chem. Soc. 2009, 30, 2643–2646. [Google Scholar]

- Yang, G.; Wu, W.H.; Wang, Y.H.; Jiao, Y.H.; Lu, L.Y.; Qu, H.Q.; Qin, X.Y. Synthesis of a novel phosphazene-based flame retardant with active amine groups and its application in reducing the fire hazard of epoxy resin. J. Hazard. Mater. 2019, 366, 78–87. [Google Scholar] [CrossRef]

- Günther, M.; Lorenzetti, A.; Schartel, B. Fire phenomena of rigid polyurethane foams. Polymers 2018, 10, 1166. [Google Scholar] [CrossRef]

- Jin, H.; Yang, B.; Jin, F.L.; Park, S.J. Fracture toughness and surface morphology of polysulfone-modified epoxy resin. J. Ind. Eng. Chem. 2015, 25, 9–11. [Google Scholar] [CrossRef]

- Jin, F.L.; Liu, H.C.; Yang, B.; Park, S.J. Synthesis and thermal properties of urethane-containing epoxy resin. J. Ind. Eng. Chem. 2015, 24, 20–23. [Google Scholar] [CrossRef]

- Realinho, V.; Arencón, D.; Antunes, M.; Velasco, J.I. Effects of a phosphorus flame retardant system on the mechanical and fire behavior of microcellular ABS. Polymers 2019, 11, 30. [Google Scholar] [CrossRef] [PubMed]

- Dong, W.; Jin, F.L.; Park, S.J. Fracture toughness improvement of epoxy resins with short carbon fibers. J. Ind. Eng. Chem. 2014, 20, 1220–1222. [Google Scholar] [CrossRef]

- Yue, J.F.; Gan, L.; Liu, C.H.; Ma, X.Z.; Wang, D.; Huang, J. Heat-counteracted strategy for tailng the cell structure and properties of sustainable poly(butylene succinate) foamsori. Polymer 2018, 155, 50–57. [Google Scholar] [CrossRef]

- Stanzione, M.; Russo, V.; Oliviero, M.; Verdolotti, L.; Sorrentino, A.; Serio, M.D.; Tesser, R.; Iannace, S.; Lavorgna, M. Synthesis and characterization of sustainable polyurethane foams based on polyhydroxyls with different terminal groups. Polymer 2018, 149, 134–145. [Google Scholar] [CrossRef]

- Önder, O.C.; Yilgör, E.; Yilgor, I. Preparation of monolithic polycaprolactone foams with controlled morphology. Polymer 2018, 136, 166–178. [Google Scholar] [CrossRef]

- Önder, O.C.; Yilgör, E.; Yilgör, I. Fabrication of rigid poly(lactic acid) foams via thermally induced phase separation. Polymer 2016, 107, 240–248. [Google Scholar] [CrossRef]

- Andrieux, S.; Drenckhan, W.; Stubenrauch, C. Highly ordered biobased scaffolds: From liquid to solid foams. Polymer 2017, 126, 425–431. [Google Scholar] [CrossRef]

- Członka, S.; Sienkiewicz, N.; Strąkowska, A.; Strzelec, K. Keratin feathers as a filler for rigid polyurethane foams on the basis of soybean oil polyol. Polym. Test. 2018, 72, 32–45. [Google Scholar] [CrossRef]

- Prociak, A.; Kurańska, M.; Cabulis, U.; Ryszkowska, J.; Leszczyńska, M.; Uram, K.; Kirpluks, M. Effect of bio-polyols with different chemical structures on foaming of polyurethane systems and foam properties. Ind. Crop. Prod. 2018, 120, 262–270. [Google Scholar] [CrossRef]

- Ronkay, F.; Molnar, B.; Dogossy, G. The effect of mold temperature on chemical foaming of injection molded recycled polyethylene-terephthalate. Thermochim. Acta 2017, 651, 65–72. [Google Scholar] [CrossRef]

- Bedell, M.; Brown, M.; Kiziltas, A.; Mielewski, D.; Mukerjee, S.; Tabor, R. A case for closed-loop recycling of post-consumer PET for automotive foams. Waste Manag. 2018, 71, 97–108. [Google Scholar] [CrossRef] [PubMed]

- Gaidukova, G.; Ivdre, A.; Fridrihsone, A.; Verovkins, A.; Cabulis, U.; Gaidukovs, S. Polyurethane rigid foams obtained from polyols containing bio-based and recycled components and functional additives. Ind. Crop. Prod. 2017, 102, 133–143. [Google Scholar] [CrossRef]

- Lai, C.C.; Yu, C.T.; Wang, F.M.; Hsiao, H.T.; Liang, W.C.; Ho, Y.H.; Teng, W.F.; Liu, L.C.; Chen, C.M. Preparation of recycled polyethylene terephthalate composite foams and their feasible evaluation for electronic packages. Polym. Test. 2019, 74, 1–6. [Google Scholar] [CrossRef]

- Zhang, L.; Liang, S.; Chen, Z. Influence of particle size and addition of recycling phenolic foam on mechanical and flame retardant properties of wood-phenolic composites. Constr. Build. Mater. 2018, 168, 1–10. [Google Scholar] [CrossRef]

- Laur, V.; Benzerga, R.; Lebullenger, R.; Gendre, L.L.; Lanoë, G.; Sharaiha, A.; Queffelec, P. Green foams for microwave absorbing applications: Synthesis and characterization. Mater. Res. Bull. 2017, 96, 100–106. [Google Scholar] [CrossRef]

- Modesti, M.; Costantini, F.; Lago, E.; Piovesan, F.; Roso, M.; Boaretti, C.; Lorenzetti, A. Valuable secondary raw material by chemical recycling of polyisocyanurate foams. Polym. Degrad. Stab. 2018, 156, 151–160. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, F.; Dong, Q.; Xie, M.; Liu, P.; Ding, Y.; Zhang, S.; Yang, M.; Zheng, G. Core-shell expandable graphite @ aluminum hydroxide as a flame-retardant for rigid polyurethane foams. Polym. Degrad. Stab. 2017, 146, 267–276. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Z. Facile synthesis of a novel magnesium amino-tris- (methylenephosphonate)-reduced graphene oxide hybrid and its high performance in mechanical strength, thermal stability, smoke suppression and flame retardancy in phenolic foam. J. Hazard. Mater. 2018, 357, 89–99. [Google Scholar] [CrossRef]

- Yuan, Y.; Ma, C.; Shi, Y.; Song, L.; Hu, Y.; Hu, W. Highly-efficient reinforcement and flame retardancy of rigid polyurethane foam with phosphorus-containing additive and nitrogen-containing compound. Mater. Chem. Phys. 2018, 211, 42–53. [Google Scholar] [CrossRef]

- Vadas, D.; Igricz, T.; Sarazin, J.; Bourbigot, S.; Marosi, G.; Bczo, K. Flame retardancy of microcellular poly(lactic acid) foams prepared by supercritical CO2-assisted extrusion. Polym. Degrad. Stab. 2018, 153, 100–108. [Google Scholar] [CrossRef]

- Huang, P.; Wu, M.; Pang, Y.; Shen, B.; Wu, F.; Lan, X.; Luo, H.; Zheng, W. Ultrastrong, flexible and lightweight anisotropic polypropylene foams with superior flame retardancy. Compos. Part A Appl. Sci. 2019, 116, 180–186. [Google Scholar] [CrossRef]

- Salmeia, K.A.; Flaig, F.; Rentsch, D.; Gaan, S. One-pot synthesis of P(O)-N containing compounds using N-chlorosuccinimide and their influence in thermal decomposition of PU foams. Polymers 2018, 10, 740. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.X.; Zhao, H.B.; Rao, W.H.; Huang, S.C.; Wang, T.; Liao, W.; Wang, Y.Z. Inherently flame-retardant rigid polyurethane foams with excellent thermal insulation and mechanical properties. Polymer 2018, 153, 616–625. [Google Scholar] [CrossRef]

- Rao, W.H.; Liao, W.; Wang, H.; Zhao, H.B.; Wang, Y.Z. Flame-retardant and smoke-suppressant flexible polyurethane foams based on reactive phosphorus-containing polyol and expandable graphite. J. Hazard. Mater. 2018, 360, 651–660. [Google Scholar] [CrossRef]

- Chen, K.; Tian, C.; Liang, S.; Zhao, X.; Wang, X. Effect of stoichiometry on the thermal stability and flame retardation of polyisocyanurate foams modified with epoxy resin. Polym. Degrad. Stab. 2018, 150, 105–113. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Z. High performance nano-zinc amino-tris-(methylenephosphonate) in rigid polyurethane foam with improved mechanical strength, thermal stability and flame retardancy. Polym. Degrad. Stab. 2018, 154, 62–72. [Google Scholar] [CrossRef]

- Delgado-Sanchez, C.; Sarazin, J.; Santiago-Medina, F.J.; Fierro, V.; Pizzi, A.; Bourbigot, S.; Celzard, A. Impact of the formulation of biosourced phenolic foams on their fire properties. Polym. Degrad. Stab. 2018, 153, 1–14. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Linul, E.; Bahmani, A.; Marsavina, L. Experimental and theoretical fracture toughness investigation of PUR foams under mixed mode I+III loading. Polym. Test. 2018, 67, 75–83. [Google Scholar] [CrossRef]

- Linul, E.; Marşavina, L.; Vălean, C.; Bănică, R. Static and dynamic mode I fracture toughness of rigid PUR foams under room and cryogenic temperatures. Eng. Fract. Mech 2019, in press. [Google Scholar] [CrossRef]

- Jin, F.L.; Ma, C.J.; Park, S.J. Thermal and mechanical interfacial properties of epoxy composites based on functionalized carbon nanotubes. Mater. Sci. Eng. A Struct. 2011, 528, 8517–8522. [Google Scholar] [CrossRef]

- Jin, F.L.; Park, S.J. Interfacial toughness properties of trifunctional epoxy resins/calcium carbonate nanocomposites. Mater. Sci. Eng. A Struct. 2008, 475, 190–193. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, T.Y.; Jin, F.L.; Park, S.J. Fracture toughness improvement of poly(lactic acid) reinforced with poly(ε-caprolactone) and surface-modified silicon carbide. Adv. Mater. Sci. Eng. 2018, 2018. [Google Scholar] [CrossRef]

- Jin, F.L.; Pang, Q.Q.; Zhang, T.Y.; Park, S.J. Synergistic reinforcing of poly(lactic acid)-based systems by polybutylene succinate and nano-calcium carbonate. J. Ind. Eng. Chem. 2015, 32, 77–84. [Google Scholar] [CrossRef]

- Jin, F.L.; Park, S.J. Thermal properties and toughness performance of hyperbranched-polyimide-modified epoxy resins. J. Polym. Sci. Polym. Phys. 2006, 44, 3348–3356. [Google Scholar] [CrossRef]

- Kang, M.J.; Jin, F.L.; Park, S.J. Effect of ozone treatment on fracture toughness of single-walled carbon nanotubes-reinforced epoxy resin initiated by a thermal latent catalyst. Macromol. Res. 2018, 26, 1048–1051. [Google Scholar] [CrossRef]

- Jin, F.L.; Zhang, H.; Yao, S.S.; Park, S.J. Effect of surface modification on impact strength and flexural strength of poly(lactic acid)/silicon carbide nanocomposites. Macromol. Res. 2018, 26, 211–214. [Google Scholar] [CrossRef]

- Yao, S.S.; Pang, Q.Q.; Song, R.; Jin, F.L.; Park, S.J. Fracture toughness iprovement of poly(lactic acid) with silicon carbide whiskers. Macromol. Res. 2016, 24, 961–964. [Google Scholar] [CrossRef]

- Liu, Y.; Kong, S.; Xiao, H.; Bai, C.Y.; Lu, P.; Wang, S.F. Comparative study of ultra-lightweight pulp foams obtained from various fibers and reinforced by MFC. Carbohydr. Polym. 2018, 182, 92–97. [Google Scholar] [CrossRef]

- Ghanbari, A.; Tabarsa, T.; Ashori, A.; Shakeri, A.; Mashkour, M. Thermoplastic starch foamed composites reinforced with cellulose nanofibers: Thermal and mechanical properties. Carbohydr. Polym. 2018, 197, 305–311. [Google Scholar] [CrossRef] [PubMed]

- Członka, S.; Bertino, M.F.; Kośny, J.; Strąkowska, A.; Masłowski, M.; Strzelec, K. Linseed oil as a natural modifier of rigid polyurethane foams. Ind. Crop. Prod. 2018, 115, 40–51. [Google Scholar] [CrossRef]

| Temperature | 160 °C | 170 °C | 180 °C | 190 °C | 200 °C |

|---|---|---|---|---|---|

| Density (kg⋅m−3) | 909 ± 14 | 797 ± 22 | 676 ± 27 | 495 ± 38 | 462 ± 42 |

| Samples | Density (g/cm3) | Compressive Moduli (MPa) | Highest Compressive Stress (MPa) |

|---|---|---|---|

| 1 | 0.096 ± 0.002 | 1.38 ± 0.15 | 1.08 ± 0.05 |

| 2 | 0.095 ± 0.002 | 1.33 ± 0.10 | 1.23 ± 0.06 |

| 3 | 0.092 ± 0.002 | 1.29 ± 0.07 | 1.12 ± 0.03 |

| 4 | 0.090 ± 0.001 | 1.05 ± 0.06 | 0.96 ± 0.06 |

| 5 | 0.066 ± <0.001 | 1.02 ± 0.04 | 0.92 ± 0.07 |

| 6 | 0.082 ± 0.001 | 1.14 ± 0.04 | 1.21 ± 0.04 |

| 7 | 0.101 ± <0.001 | 4.74 ± 0.08 | 1.53 ± 0.05 |

| Material | Tensile Strength (MPa) | Elongation at Break (%) | Apparent Density (kg/m3) |

|---|---|---|---|

| PVC + CB + AC | 30.8 ± 2.6 | 3.82 ± 0.41 | 896 ± 52 |

| PVC + CB + AC + Talc | 29.9 ± 1.0 | 4.21 ± 0.27 | 892 ± 24 |

| PVC + CB + AC + MMT | 29.6 ± 0.4 | 3.73 ± 0.69 | 811 ± 34 |

| PVC + CB + AC + TiO2 | 27.5 ± 0.3 | 3.78 ± 0.22 | 838 ± 18 |

| Samples | LOI (%) | UL 94 Rating |

|---|---|---|

| Untreated phenolic foam | 38.0 | V0 |

| phenolic foam/1Mg-rGO | 38.5 | V0 |

| phenolic foam/2Mg-rGO | 39.5 | V0 |

| phenolic foam/3Mg-rGO | 40.5 | V0 |

| phenolic foam/4Mg-rGO | 41.5 | V0 |

| phenolic foam/5Mg-rGO | 41.0 | V0 |

| phenolic foam/4Mg-AMP | 40.0 | V0 |

| phenolic foam/4GO | 39.5 | V0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, F.-L.; Zhao, M.; Park, M.; Park, S.-J. Recent Trends of Foaming in Polymer Processing: A Review. Polymers 2019, 11, 953. https://doi.org/10.3390/polym11060953

Jin F-L, Zhao M, Park M, Park S-J. Recent Trends of Foaming in Polymer Processing: A Review. Polymers. 2019; 11(6):953. https://doi.org/10.3390/polym11060953

Chicago/Turabian StyleJin, Fan-Long, Miao Zhao, Mira Park, and Soo-Jin Park. 2019. "Recent Trends of Foaming in Polymer Processing: A Review" Polymers 11, no. 6: 953. https://doi.org/10.3390/polym11060953

APA StyleJin, F.-L., Zhao, M., Park, M., & Park, S.-J. (2019). Recent Trends of Foaming in Polymer Processing: A Review. Polymers, 11(6), 953. https://doi.org/10.3390/polym11060953