Fabrication of Graphene-Metal Transparent Conductive Nanocomposite Layers for Photoluminescence Enhancement

Abstract

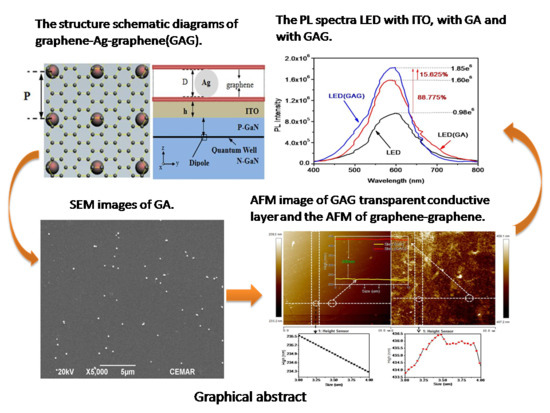

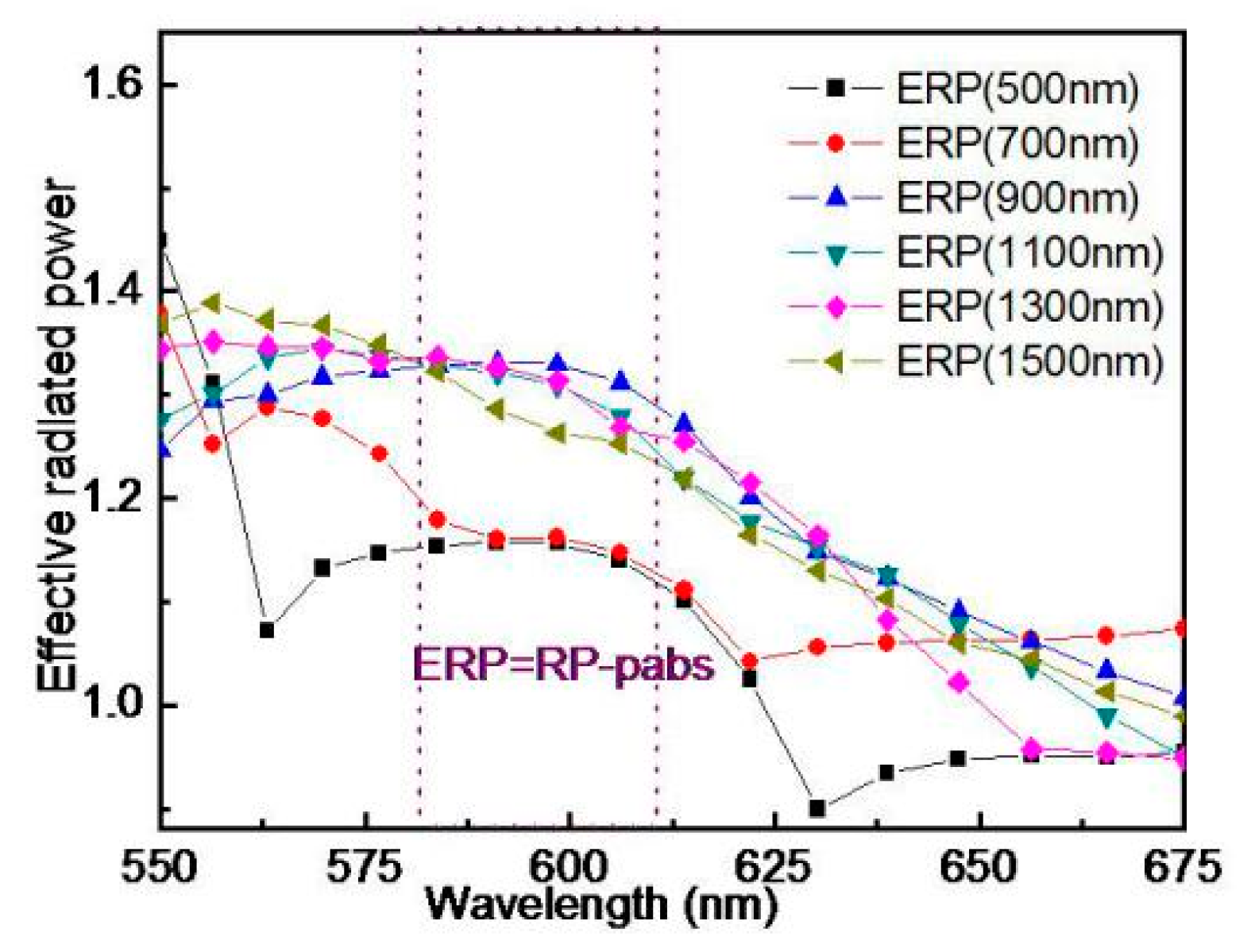

1. Introduction

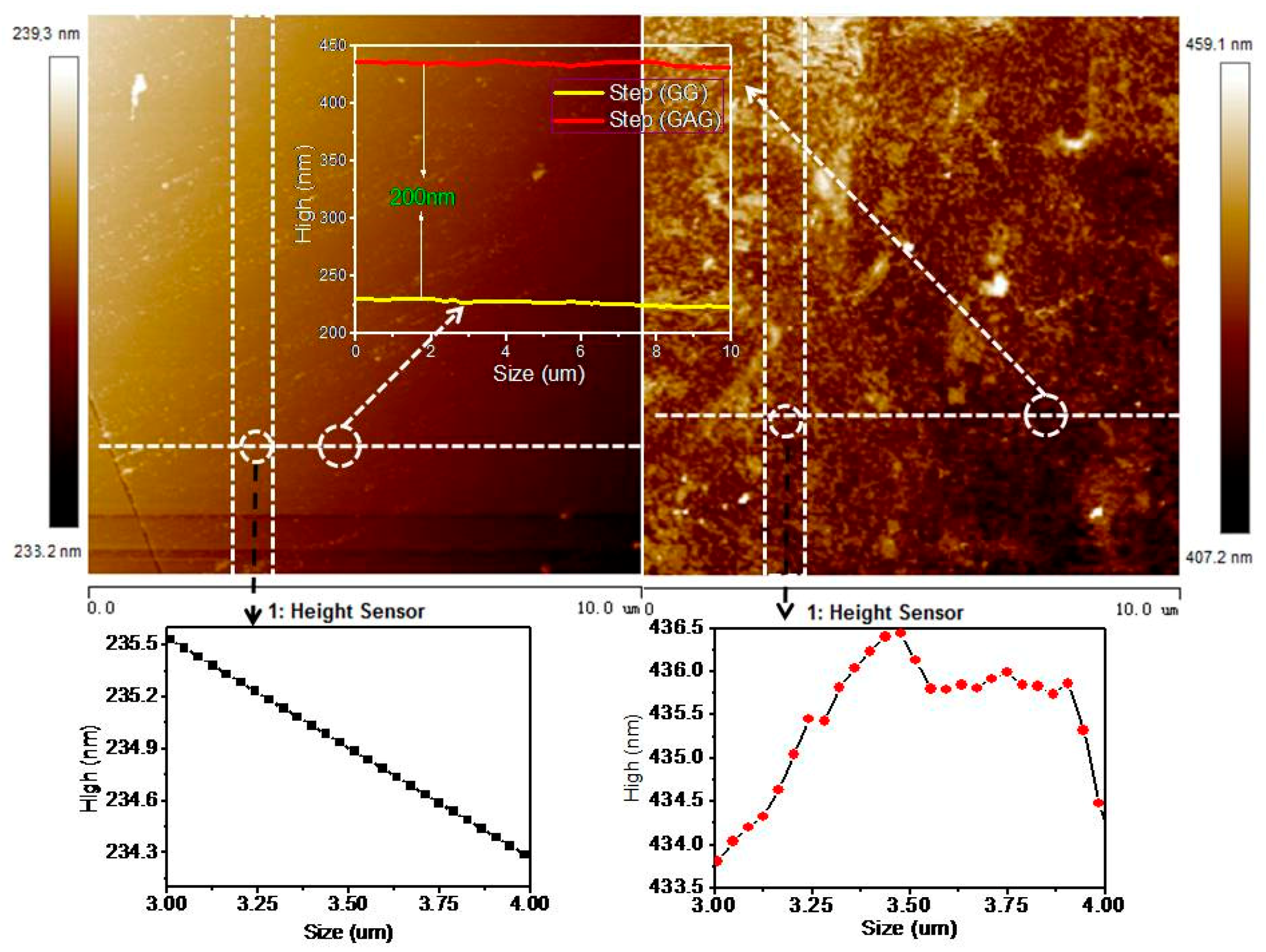

2. Experimental Section

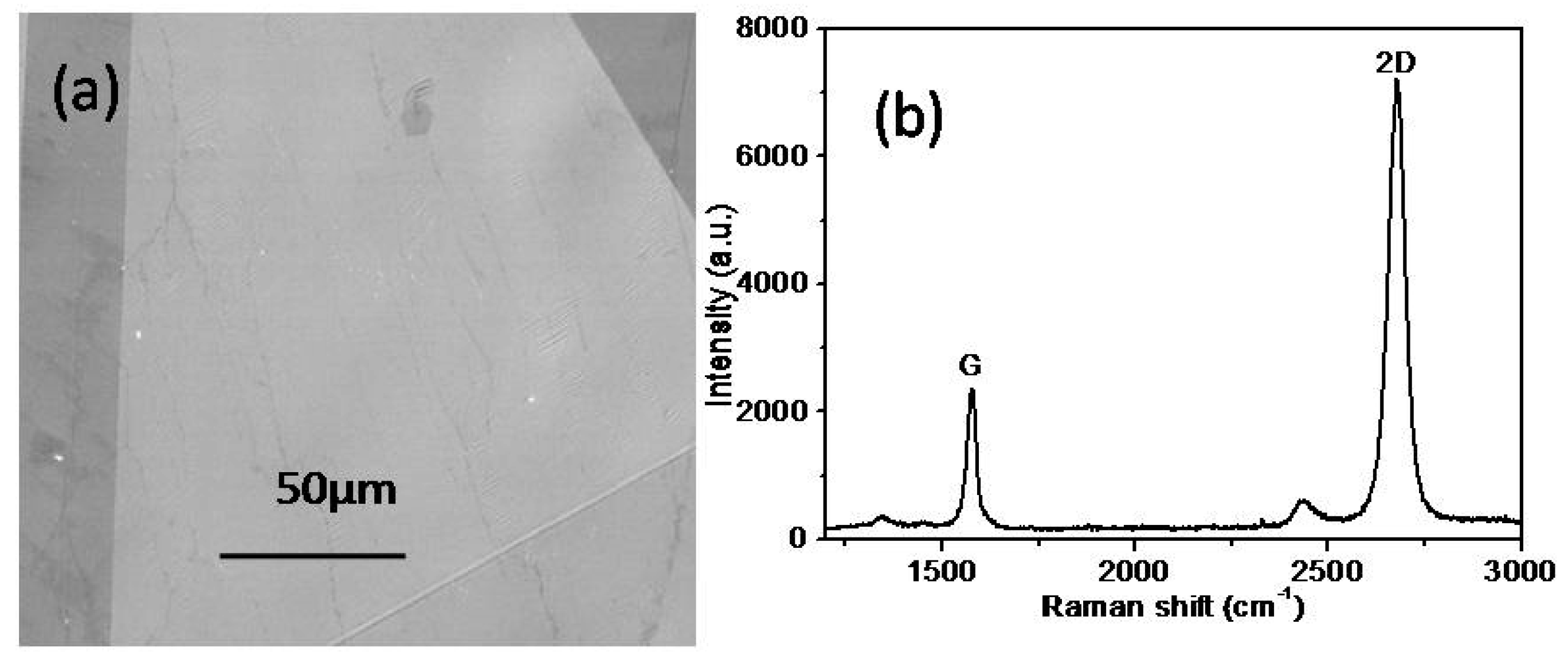

2.1. The Growth of Graphene Sheet Layer

2.2. Transfer Graphene Layer to Target Substrate

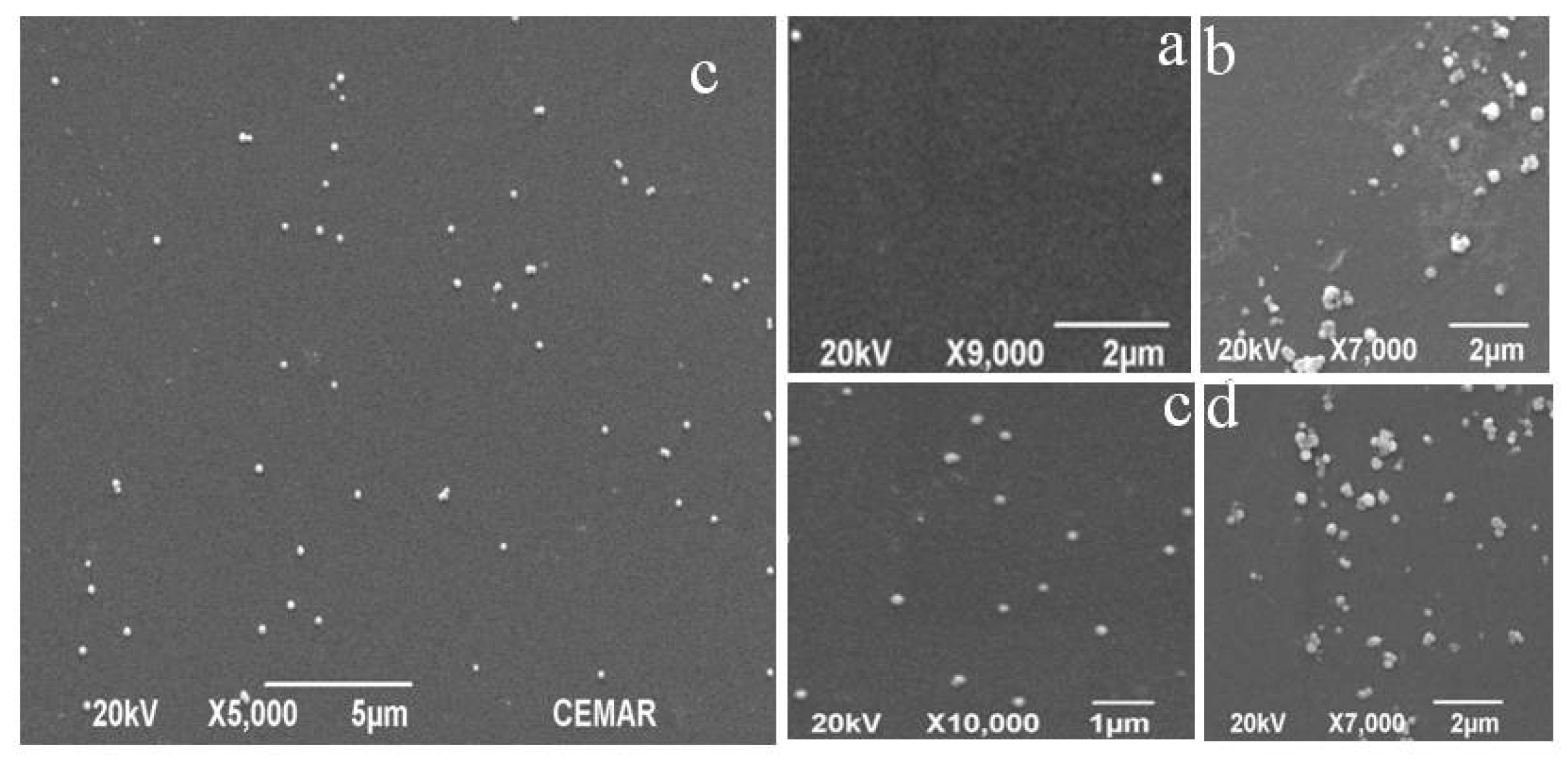

2.3. Preparation of GA (Graphene/Ag) Hybrid Sample

2.4. Transfer Second Layer Graphene to GA

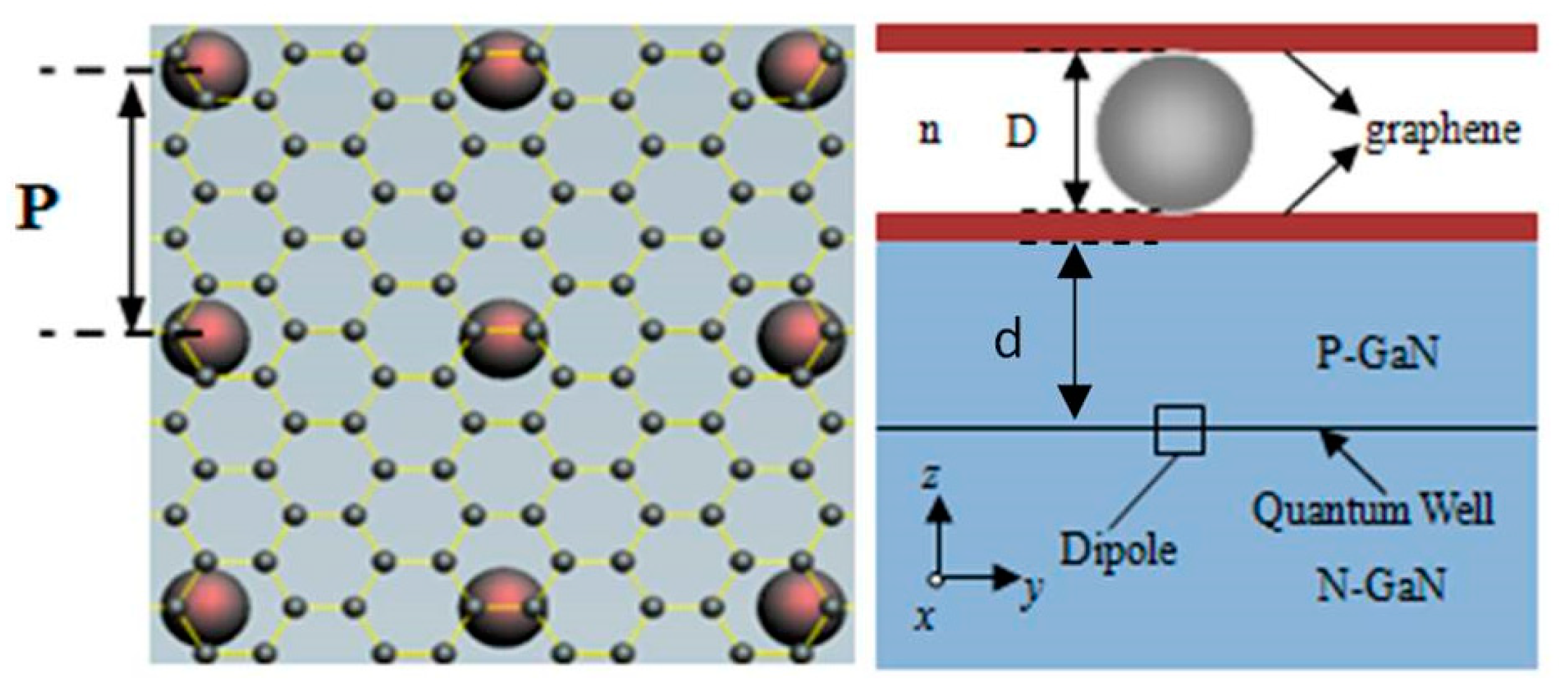

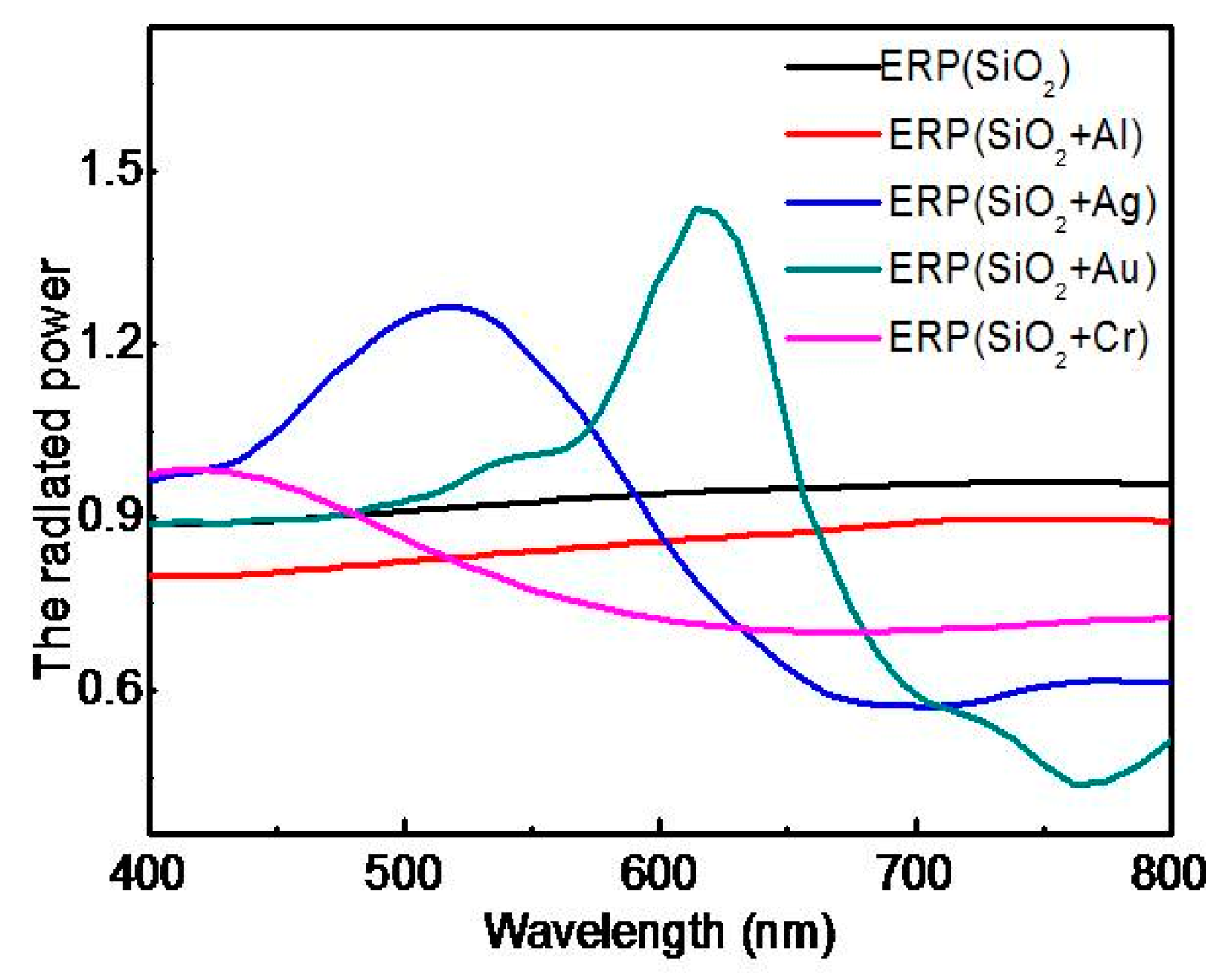

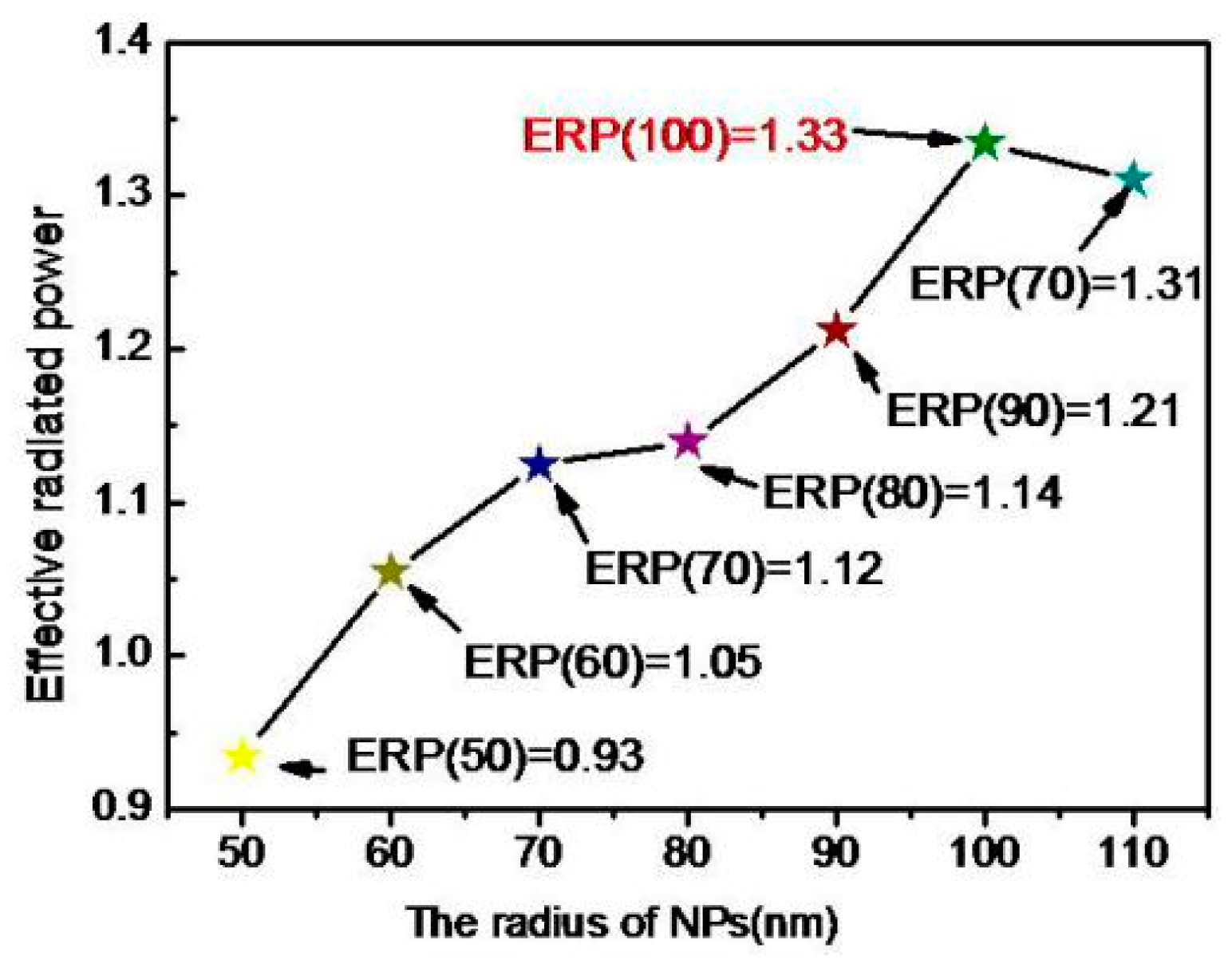

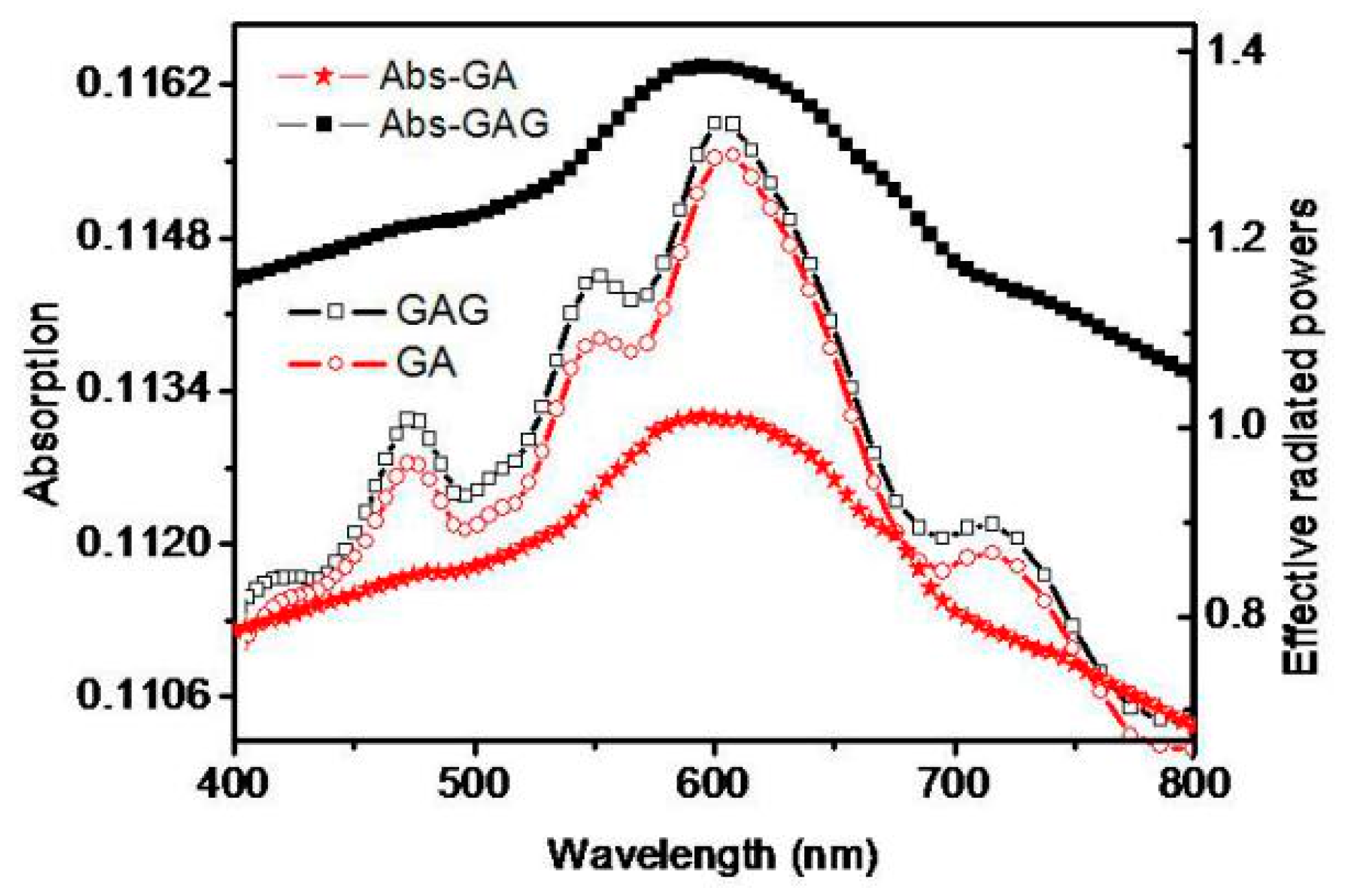

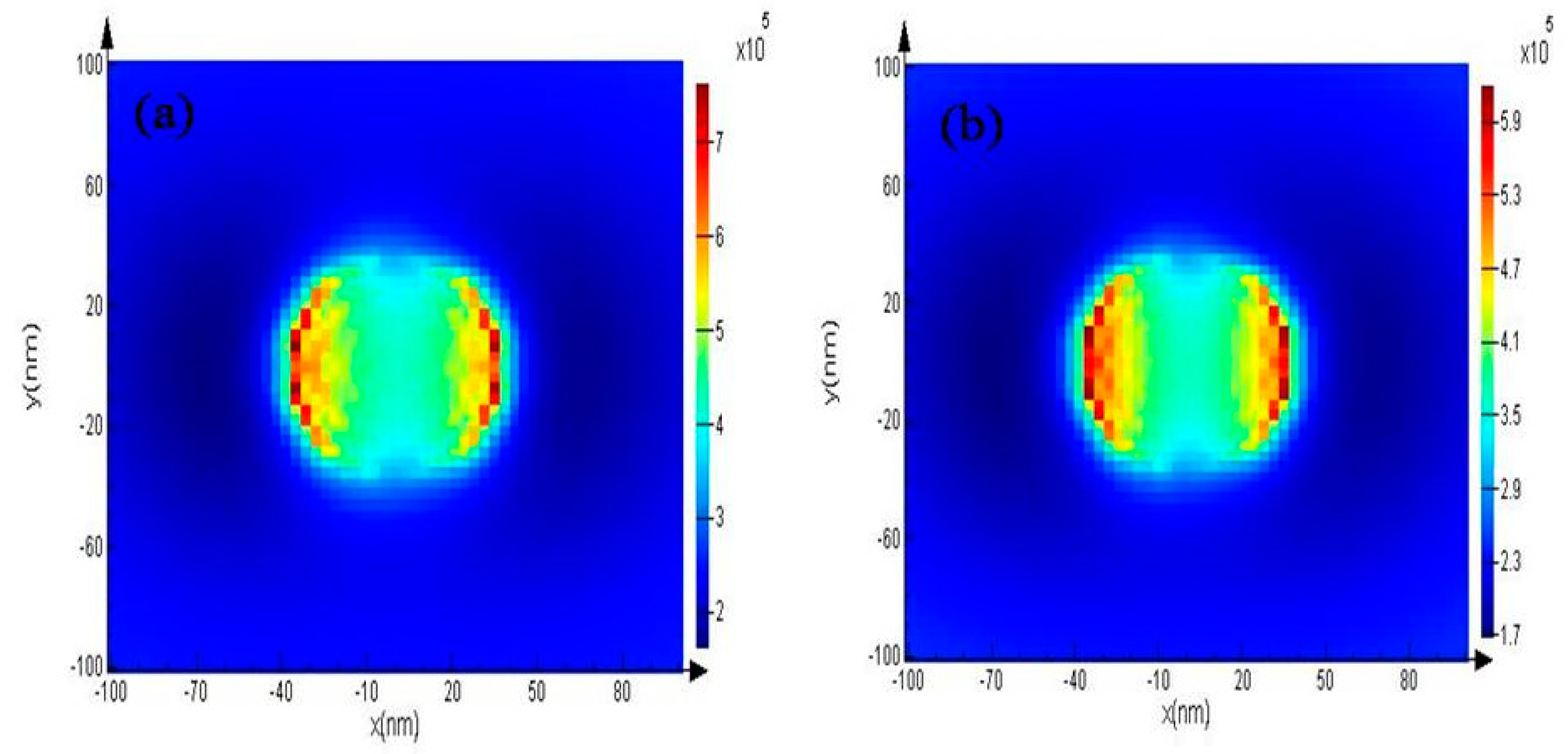

2.5. Theoretical Model

2.6. Simulation Method

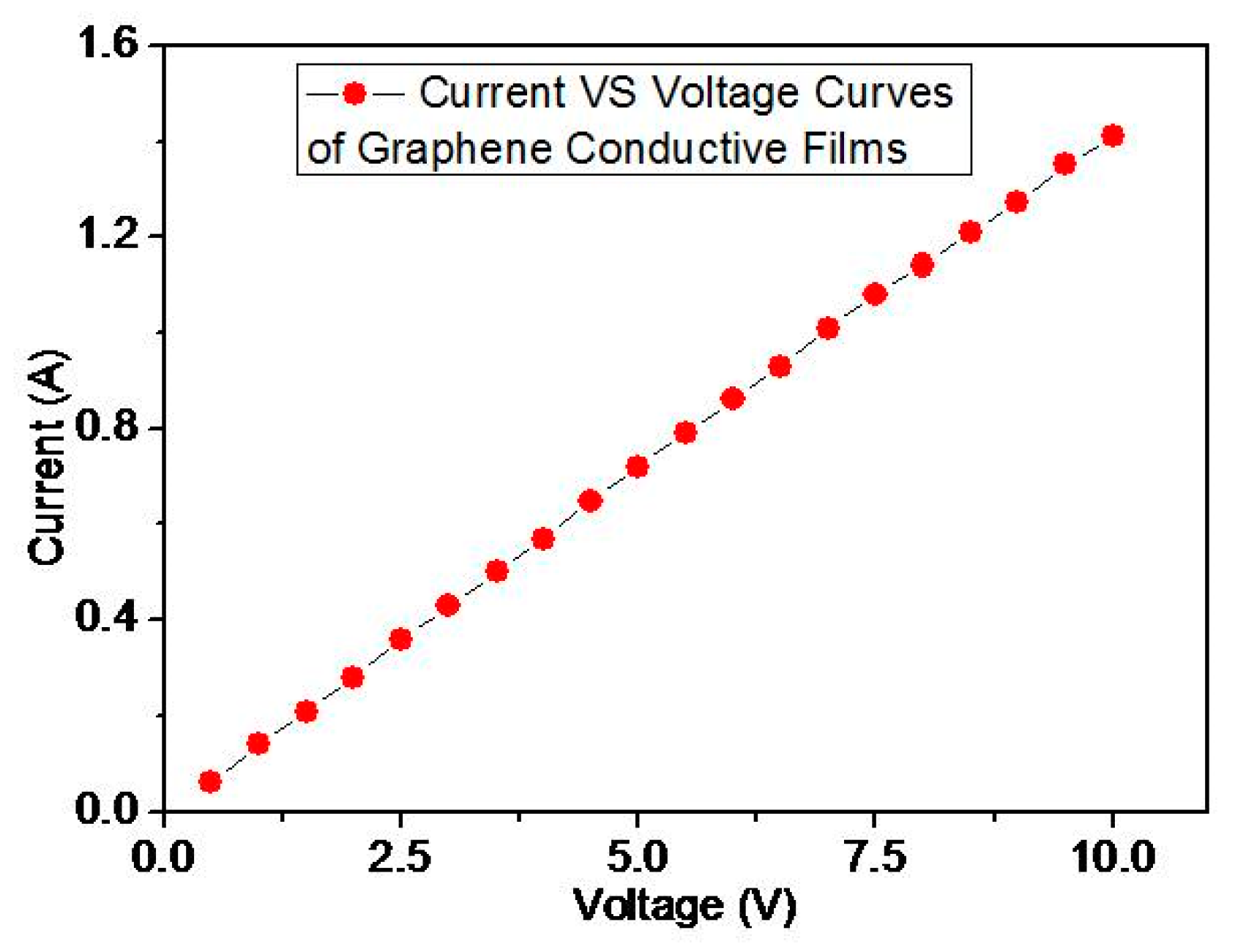

2.7. Characterization

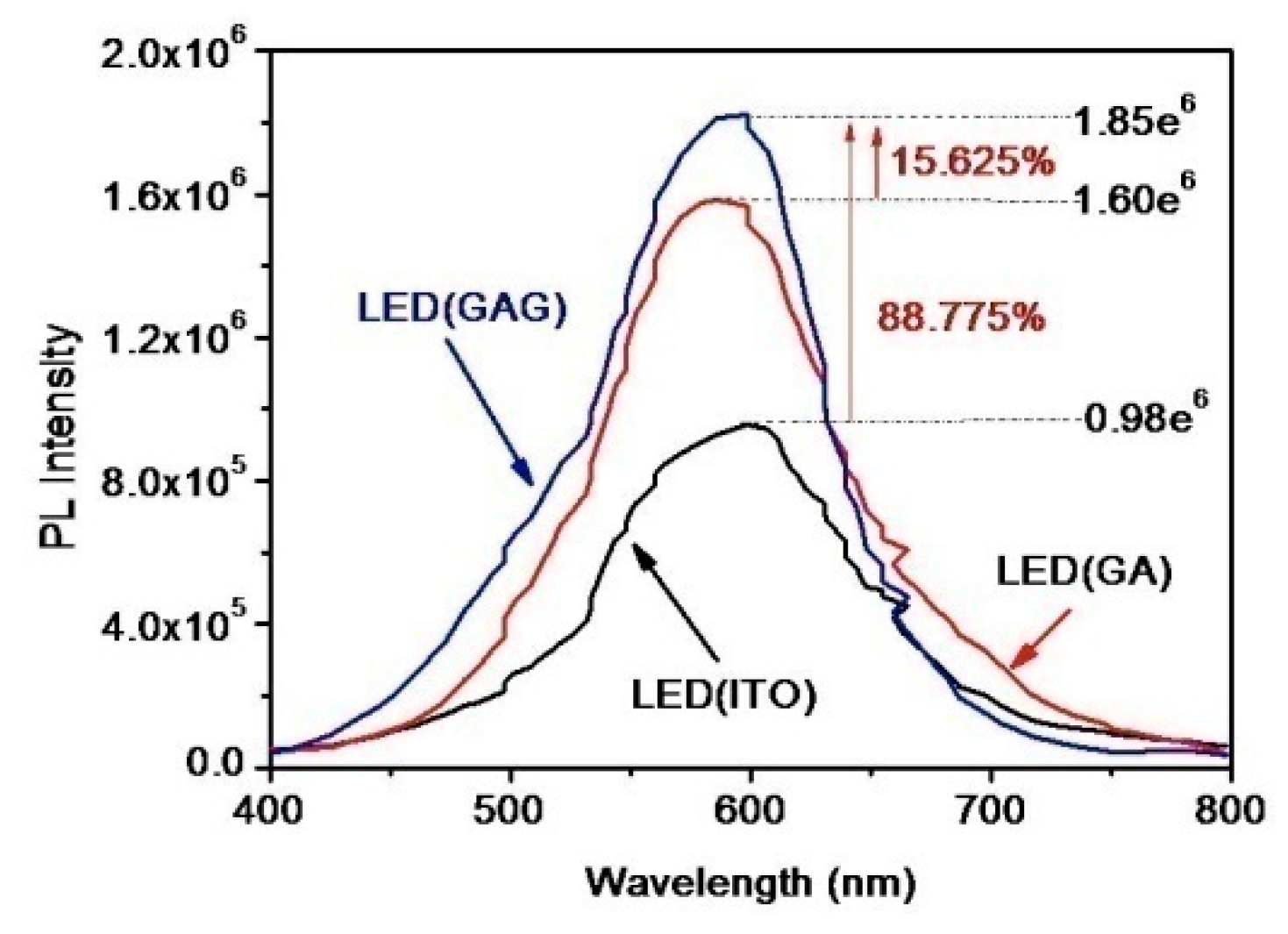

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Lee, J.; Govorov, A.O.; Dulka, J.; Kotov, N.A. Bioconjugates of CdTe Nanowires and Au Nanoparticles: Plasmon-Exciton Interactions, Luminescence Enhancement, and Collective Effects. Nano Lett. 2004, 4, 2323–2330. [Google Scholar] [CrossRef]

- Rojas-Hernandez, R.E.; Rubio-Marcos, F.; Serrano, A.; Del, C.A.; Fernandez, J.F. Precise Tuning of the Nanostructured Surface leading to the Luminescence Enhancement in SrAl2O4 Based Core/Shell Structure. Sci. Rep. 2017, 7, 462. [Google Scholar] [CrossRef] [PubMed]

- Fukuura, T. Plasmons excited in a large dense silver nanoparticle layer enhance the luminescence intensity of organic light emitting diodes. Appl. Surf. Sci. 2015, 346, 451–457. [Google Scholar] [CrossRef]

- Phillips, M.R. Stability of InGaN/GaN MQW Luminescence Under Prolonged High Current Injection. Microsc. Microanal. 2012, 18, 1876–1877. [Google Scholar] [CrossRef]

- Yoo, J.; Ma, X.; Tang, W.; Yi, G.C. Metal-Lined Semiconductor Nanotubes for Surface Plasmon-Mediated Luminescence Enhancement. Nano Lett. 2013, 5, 2134–2140. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.R.; Liao, K.C.; Wu, C.H.; Lin, S.Y. Luminescence Enhancement and Enlarged Dirac Point Shift of MoS2/Graphene Hetero-Structure Photodetectors with Post growth Annealing Treatment. IEEE J. Sel. Top. Quantum Electron. 2016, 23, 101–105. [Google Scholar] [CrossRef]

- Ellmer, K. Past achievements and future challenges in the development of optically transparent electrodes. Nat. Photonics 2012, 6, 809. [Google Scholar] [CrossRef]

- Wang, Y.B.; Wei, X.H.; Chang, L.; Xu, D.G.; Dai, B.; Pierson, J.F.; Wang, Y. Room temperature fabrication of transparent p-NiO/n-ZnO junctions with tunable electrical properties. Vacuum 2018, 149, 331–335. [Google Scholar] [CrossRef]

- Ievtushenko, A.I.; Karpyna, V.; Eriksson, J.; Tsiaoussis, I.; Shtepliuk, I.; Lashkarev, G.; Yakimova, R.; Khranovskyy, V. Effect of Ag doping on the structural, electrical and optical properties of ZnO grown by MOCVD at different substrate temperatures. Superlattices Microstruct. 2018, 117, 121–131. [Google Scholar] [CrossRef]

- Myroniuk, D.V.; Ievtushenko, A.I.; Lashkarev, G.V.; Maslyuk, V.T.; Timofeeva, I.I.; Baturin, V.A.; Karpenko, O.Y.; Kuznetsov, V.M.; Dranchuk, M.V. Effect of electron irradiation on transparent conductive films ZnO: Al deposited at different sputtering power. Semicond. Phys. Quantum Electron. Optoelectron. 2015, 18, 286–291. [Google Scholar] [CrossRef]

- Jeong, H.; Jeong, M.S. Confocal electroluminescence investigations of highly efficient green InGaN LED via ZnOnanorods. J. Alloys Compd. 2016, 660, 480–485. [Google Scholar] [CrossRef]

- Han, T.H.; Jeong, S.H.; Lee, Y.; Seo, H.K.; Kwon, S.J.; Park, M.H.; Lee, T.W. Flexible transparent electrodes for organic light-emitting diodes. J. Inf. Disp. 2015, 16, 71–84. [Google Scholar] [CrossRef]

- Liu, Y.F.; Feng, J.; Zhang, Y.F.; Cui, H.F.; Yin, D.; Bi, Y.G.; Song, J.F.; Chen, Q.D.; Sun, H.B. Improved efficiency of indium-tin-oxide-free organic light-emitting devices using PEDOT: PSS/graphene oxide composite anode. Org. Electron. 2015, 26, 81–85. [Google Scholar] [CrossRef]

- Seo, Y.K.; Joo, C.W.; Lee, J.; Han, J.W.; Cho, N.S.; Lim, K.T.; Yu, S.; Kang, M.H.; Yun, C.; Choi, B.H. Efficient ITO-free organic light-emitting diodes comprising PEDOT: PSS transparent electrodes optimized with 2-ethoxyethanol and post treatment. Org. Electron. 2016, 42, 348–354. [Google Scholar] [CrossRef]

- Li, H.; Ying, L.; Xin, Z.; Wang, X.; Liu, X. High-performance ITO-free electrochromic films based on bi-functional stacked WO3/Ag/WO3 structures. Sol. Energy Mater. Sol. Cells 2015, 136, 86–91. [Google Scholar] [CrossRef]

- Lin, B.; Lan, C.; Li, C.; Chen, Z. Effect of thermal annealing on the performance of WO3–Ag–WO3 transparent conductive film. Thin Solid Films 2014, 571, 134–138. [Google Scholar] [CrossRef]

- Koubli, E.; Tsakanikas, S.; Leftheriotis, G.; Syrrokostas, G.; Yianoulis, P. Optical properties and stability of near-optimum WO3/Ag/WO3 multilayers for electrochromic applications. Solid State Ion. 2015, 272, 30–38. [Google Scholar] [CrossRef]

- Kim, J.H.; Joo, C.W.; Lee, J.; Seo, Y.K.; Han, J.W.; Oh, J.Y.; Kim, J.S.; Yu, S.; Lee, J.H.; Lee, J.I. Highly Conductive PEDOT: PSS Films with 1,3-Dimethyl-2-Imidazolidinone as Transparent Electrodes for Organic Light-Emitting Diodes. Macromol. Rapid Commun. 2016, 37, 1427–1433. [Google Scholar] [CrossRef]

- Xu, K.; Chen, X.; Deng, J.; Zhu, Y.; Guo, W.; Mao, M.; Lei, Z.; Jie, S. Graphene transparent electrodes grown by rapid chemical vapor deposition with ultrathin indium tin oxide contact layers for GaN light emitting diodes. Appl. Phys. Lett. 2013, 102, 666. [Google Scholar]

- Son, K.J.; Kim, T.K.; Cha, Y.J.; Oh, S.K.; You, S.J.; Ryou, J.H.; Kwak, J.S. Impact of plasma electron flux on plasma damage-free sputtering of ultrathin tin-doped indium oxide contact layer onp-GaN for InGaN/GaN light-emitting diodes. Adv. Sci. 2018, 5, 1700637. [Google Scholar] [CrossRef]

- Lai, W.C.; Lin, C.N.; Lai, Y.C.; Yu, P.; Chi, G.C.; Chang, S.J. GaN-based light-emitting diodes with graphene/indium tin oxide transparent layer. Opt. Express 2014, 22, A396–A401. [Google Scholar] [CrossRef] [PubMed]

- Sun, G.; Khurgin, J.B.; Soref, R.A. Practicable enhancement of spontaneous emission using surface plasmons. Appl. Phys. Lett. 2007, 90, 11564. [Google Scholar] [CrossRef]

- Neogi, A.; Lee, C.-W.; Everitt, H.; Kuroda, T.; Tackeuchi, A.; Yablonovitch, E. Enhancement of spontaneous emission in a nitride based quantum well by resonant surface plasmon coupling. Phys. Rev. B Condens. Matter 2002, 66, 153305. [Google Scholar] [CrossRef]

- Chen, H.-S.; Chen, C.-F.; Kuo, Y.; Chou, W.-H.; Shen, C.-H.; Jung, Y.-L.; Kiang, Y.-W.; Yang, C.C. Surface plasmon coupled light-emitting diode with metal protrusions into p-GaN. Appl. Phys. Lett. 2013, 102, 041108. [Google Scholar] [CrossRef]

- Lin, C.H.; Su, C.Y.; Yang, K.; Chen, C.H.; Yao, Y.F.; Shih, P.Y.; Chen, H.S.; Hsieh, C.; Kiang, Y.W.; Yang, C.C. Further reduction of efficiency droop effect by adding a lower-index dielectric interlayer in a surface plasmon coupled blue light-emitting diode with surface metal nanoparticles. Appl. Phys. Lett. 2014, 105, 101106. [Google Scholar] [CrossRef]

- Lu, C.H.; Wu, S.E.; Lai, Y.L.; Li, Y.L.; Liu, C.P. Improved light emission of GaN-based light-emitting diodes by efficient localized surface plasmon coupling with silver nanoparticles. J. Alloys Compd. 2014, 585, 460–464. [Google Scholar] [CrossRef]

- Kuo, Y.; Chang, W.Y.; Chen, H.S.; Kiang, Y.W.; Yang, C.C. Surface plasmon coupling with a radiating dipole near a Ag nanoparticle embedded in GaN. Appl. Phys. Lett. 2013, 102, 161103. [Google Scholar] [CrossRef]

- Liu, X.; Gu, J.; Singh, R.; Ma, Y.; Zhu, J.; Zhen, T.; He, M.; Han, J.; Zhang, W. Electromagnetically induced transparency in terahertz plasmonicmetamaterials via dual excitation pathways of the dark mode. Appl. Phys. Lett. 2012, 100, 36. [Google Scholar]

- Singh, R.; Al-Naib, I.A.I.; Yang, Y.; Chowdhury, D.R.; Wei, C.; Rockstuhl, C.; Ozaki, T.; Morandotti, R.; Zhang, W. Observing metamaterial induced transparency in individual Fano resonators with broken symmetry. Appl. Phys. Lett. 2011, 99, 201107. [Google Scholar] [CrossRef]

- Xiao, S.; Wang, T.; Liu, T.; Yan, X.; Li, Z.; Xu, C. Active modulation of electromagnetically induced transparency analogue in terahertz hybrid metal-graphenemetamaterials. Carbon 2018, 126, 271–278. [Google Scholar] [CrossRef]

- Manjappa, M.; Turaga, S.P.; Srivastava, Y.K.; Bettiol, A.A.; Singh, R. Magnetic annihilation of the dark mode in a strongly coupled bright-dark terahertz metamaterial. Opt. Lett. 2017, 42, 2106–2109. [Google Scholar] [CrossRef] [PubMed]

- Xiao, S.; Wang, T.; Jiang, X.; Yan, X.; Cheng, L.; Wang, B.; Chen, X. Strong interaction between graphene layer and Fano resonance in terahertz metamaterials. J. Phys. D Appl. Phys. 2017, 50, 195101. [Google Scholar] [CrossRef]

- Zhao, X.; Yuan, C.; Zhu, L.; Yao, J. Graphene-based tunable terahertz pplasmon-induced transparency metamaterial. Nanoscale 2016, 8, 15273–15280. [Google Scholar] [CrossRef] [PubMed]

- Watanabe, E.; Tsukagoshi, K.; Yagi, I.; Aoyagi, Y. Fabrication of coulomb blockade device utilizing the 0.34 nm interlayer spacing in a multiwalled Carbon nanotube. Microelectron. Eng. 2004, 3–74, 666–669. [Google Scholar] [CrossRef]

- Low, F.W.; Lai, C.W.; Hamid, S.B.A. Surface modification of reduced graphene oxide film by Ti ion implantation technique for high dye-sensitized solar cells performance. Ceram. Int. 2017, 43, 625–633. [Google Scholar] [CrossRef]

- Dong, C. Evolution of Pt Clusters on Graphene Induced by Electron Irradiation. J. Appl. Mech. 2013, 80, 040904. [Google Scholar] [CrossRef]

- Kuo, Y.; Chang, W.Y.; Chen, H.S.; Wu, Y.R.; Yang, C.C.; Kiang, Y.W. Surface-plasmon-coupled emission enhancement of a quantum well with a metal nanoparticle embedded in a light-emitting diode. J. Opt. Soc. Am. B 2013, 30, 2599. [Google Scholar] [CrossRef]

- Fridén, J.; Razavi, A.; Stjernman, A.; Wu, Y.R.; Yang, C.C.; Kiang, Y.W. Angular sampling. Test Signal, and Near Field Aspects for Over-the-Air Total Radiated Power Assessment in Anechoic Chambers. IEEE Access 2018, 6, 57826–57839. [Google Scholar]

- Xie, R.; Li, Z.; Li, X.; Gu, E.; Niu, L.; Sha, X. Emission enhancement of light-emitting diode by localized surface plasmon induced by Ag/p-GaN double grating. Opt. Commun. 2018, 419, 108–113. [Google Scholar] [CrossRef]

- Li, Z.; Xie, R.; Li, X.; Gu, E.; Niu, L.; Sha, X. Luminous enhancement of nitride light-emitting diodes by localized surface plasmon and triangular structure. Superlattices Microstruct. 2018, 120, 127–135. [Google Scholar] [CrossRef]

- Yao, S.; Guo, Z.-Y.; Sun, H. Emission enhancement of surface plasmon coupled blue LED with a surface Al nanoparticle. IEEE Photonics Technol. Lett. 2017, 29, 1011–1014. [Google Scholar] [CrossRef]

- Zhao, M.Q.; Zhang, Q.; Huang, J.Q.; Tian, G.L.; Nie, J.Q.; Peng, H.J.; Wei, F. Unstacked double-layer templatedgraphene for high-rate lithium-sulphur batteries. Nat. Commun. 2014, 5, 3410. [Google Scholar] [CrossRef]

- Valmorra, F.; Scalari, G.; Maissen, C.; Fu, W.; SchoNenberger, C.; Choi, J.W.; Park, H.G.; Beck, M.; Faist, J. Low-bias active control of terahertz waves by coupling large-area CVD graphene to a terahertz metamaterial. Nano Lett. 2013, 13, 3193–3198. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Cui, M.; Wu, G.; Wang, T.; Mbengue, J.M.; Li, Y.; Li, M. Fast growth of large single-crystalline graphene assisted by sequential double oxygen passivation. Carbon 2017, 116, 133–138. [Google Scholar] [CrossRef]

- Sun, L.; Lin, L.; Zhang, J.; Wang, H.; Peng, H.; Liu, Z. Visualizing fast growth of large single-crystalline graphene by tunable isotopic carbon source. Nano Res. 2017, 10, 355–363. [Google Scholar] [CrossRef]

- Lin, L.; Li, J.; Ren, H.; Koh, A.L.; Kang, N.; Peng, H.; Xu, H.Q.; Liu, Z. Surface Engineering of Copper Foils for Growing Centimeter-Sized Single-Crystalline Graphene. ACS Nano 2016, 10, 2922–2929. [Google Scholar] [CrossRef]

- Buron, J.D.; Pizzocchero, F.; Jessen, B.S.; Booth, T.J.; Nielsen, P.F.; Hansen, O.; Hilke, M.; Whiteway, E.; Jepsen, P.U.; Bøggild, P.; et al. Electrically Continuous Graphene from Single Crystal Copper Verified by Terahertz Conductance Spectroscopy and Micro Four-Point Probe. Nano Lett. 2014, 14, 6348–6355. [Google Scholar] [CrossRef]

- Gan, L.; Luo, Z. Turning Off Hydrogen to Realize Seeded Growth of Sub-Centimeter Single Crystal Graphene Grains on Copper. ACS Nano 2013, 7, 9480–9488. [Google Scholar] [CrossRef]

- Chen, X.; Zhao, P.; Xiang, R.; Kim, S.; Cha, J.; Chiashi, S.; Maruyama, S. Chemical Vapor Deposition Growth of 5 mm Hexagonal Single-Crystal Graphene from Ethanol. Carbon 2015, 94, 810–815. [Google Scholar] [CrossRef]

- Sun, J.; Egbert, G.D. A thin-sheet model for global electromagnetic induction. Geophys. J. Int. 2018, 189, 343–356. [Google Scholar] [CrossRef]

- Sigman, J.B.; Barrowes, B.E.; O’Neill, K.; Wang, Y.; Simms, J.E.; Bennett, H.H.; Yule, D.E.; Shubitidze, F. High-Frequency Electromagnetic Induction Sensing of Nonmetallic Materials. IEEE Trans. Geosci. Remote Sens. 2017, 55, 5254–5263. [Google Scholar] [CrossRef]

- Gao, M.; Wang, Y.; Wang, Y.; Wang, P. Experimental investigation of non-linear multi-stable electromagnetic-induction energy harvesting mechanism by magnetic levitation oscillation. Appl. Energy 2018, 220, S030626191830518X. [Google Scholar] [CrossRef]

- Kholmanov, I.N.; Magnuson, C.W.; Aliev, A.E.; Li, H.; Zhang, B.; Suk, J.W.; Zhang, L.L.; Peng, E.; Mousavi, S.H.; Khanikaev, A.B. Improved electrical conductivity of graphene films integrated with metal nanowires. Nano Lett. 2012, 12, 5679. [Google Scholar] [CrossRef] [PubMed]

- Moradi, O.; Gupta, V.K.; Agarwal, S.; Tyagi, I.; Asif, M.; Makhlouf, A.S.H.; Sadegh, H.; Shahryari-ghoshekandi, R. Characteristics and electrical conductivity of graphene and graphene oxide for adsorption of cationic dyes from liquids: Kinetic and thermodynamic study. J. Ind. Eng. Chem. 2015, 28, 294–301. [Google Scholar] [CrossRef]

- Ijam, A.; Saidur, R.; Ganesan, P.; Golsheikh, A.M. Stability, thermo-physical properties, and electrical conductivity of graphene oxide-deionized water/ethylene glycol based nanofluid. Int. J. Heat Mass Transf. 2015, 87, 92–103. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, H.; Guo, Z.; Feng, S.; Sun, H.; Yao, S.; Wang, X.; Lu, D.; Zhang, Y.; Li, Y. Fabrication of Graphene-Metal Transparent Conductive Nanocomposite Layers for Photoluminescence Enhancement. Polymers 2019, 11, 1037. https://doi.org/10.3390/polym11061037

Huang H, Guo Z, Feng S, Sun H, Yao S, Wang X, Lu D, Zhang Y, Li Y. Fabrication of Graphene-Metal Transparent Conductive Nanocomposite Layers for Photoluminescence Enhancement. Polymers. 2019; 11(6):1037. https://doi.org/10.3390/polym11061037

Chicago/Turabian StyleHuang, Hongyong, Zhiyou Guo, Sitong Feng, Huiqing Sun, Shunyu Yao, Xidu Wang, Dong Lu, Yaohua Zhang, and Yuan Li. 2019. "Fabrication of Graphene-Metal Transparent Conductive Nanocomposite Layers for Photoluminescence Enhancement" Polymers 11, no. 6: 1037. https://doi.org/10.3390/polym11061037

APA StyleHuang, H., Guo, Z., Feng, S., Sun, H., Yao, S., Wang, X., Lu, D., Zhang, Y., & Li, Y. (2019). Fabrication of Graphene-Metal Transparent Conductive Nanocomposite Layers for Photoluminescence Enhancement. Polymers, 11(6), 1037. https://doi.org/10.3390/polym11061037