Expanded Vermiculite-Filled Polyurethane Foam-Core Bionic Composites: Preparation and Thermal, Compression, and Dynamic Cushion Properties

Abstract

1. Introduction

2. Materials and Methods

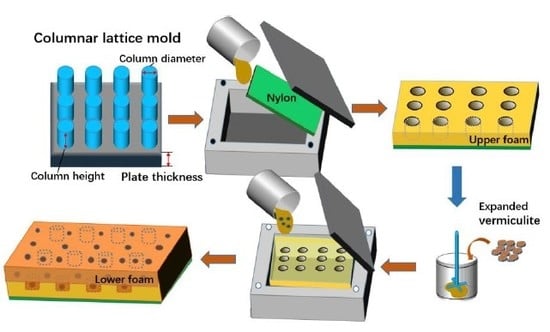

2.1. Materials and Preparation

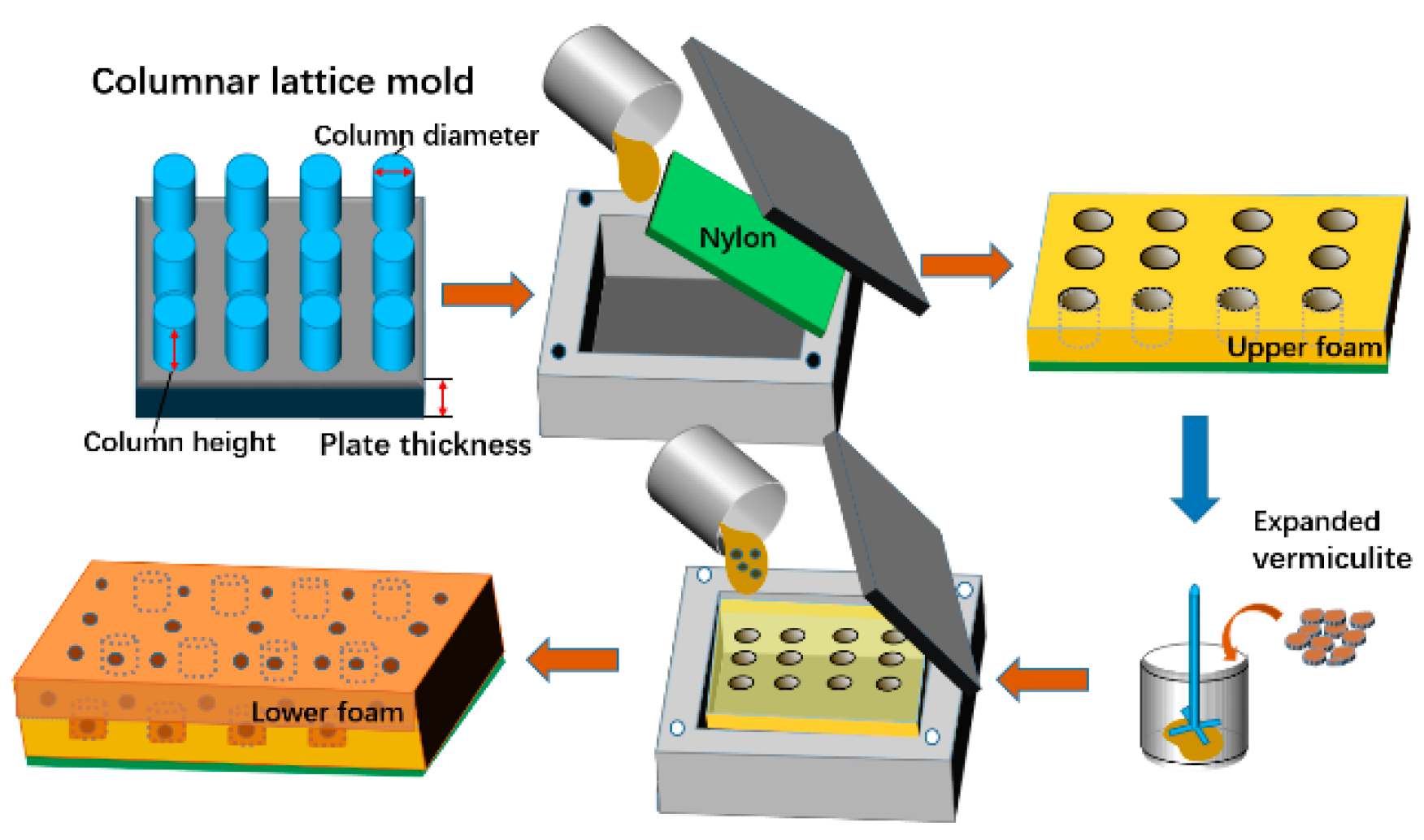

2.2. Testing

3. Results and Discussion

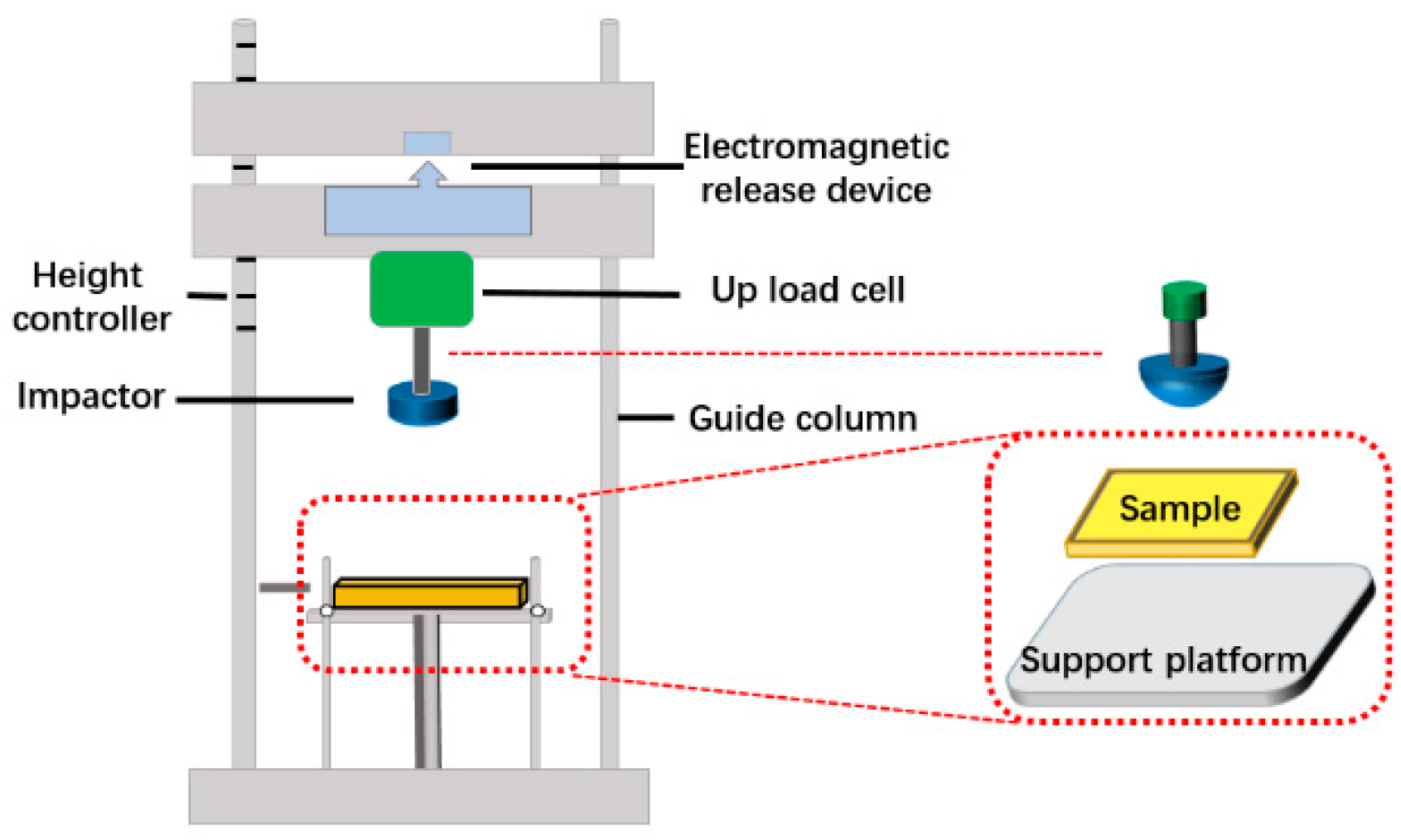

3.1. Structural Features of the Pomelo Peel and Bionic Composites

3.2. Quasi-Static Compression and Dynamic Cushioning Properties of the Pomelo Peel and Bionic Composites

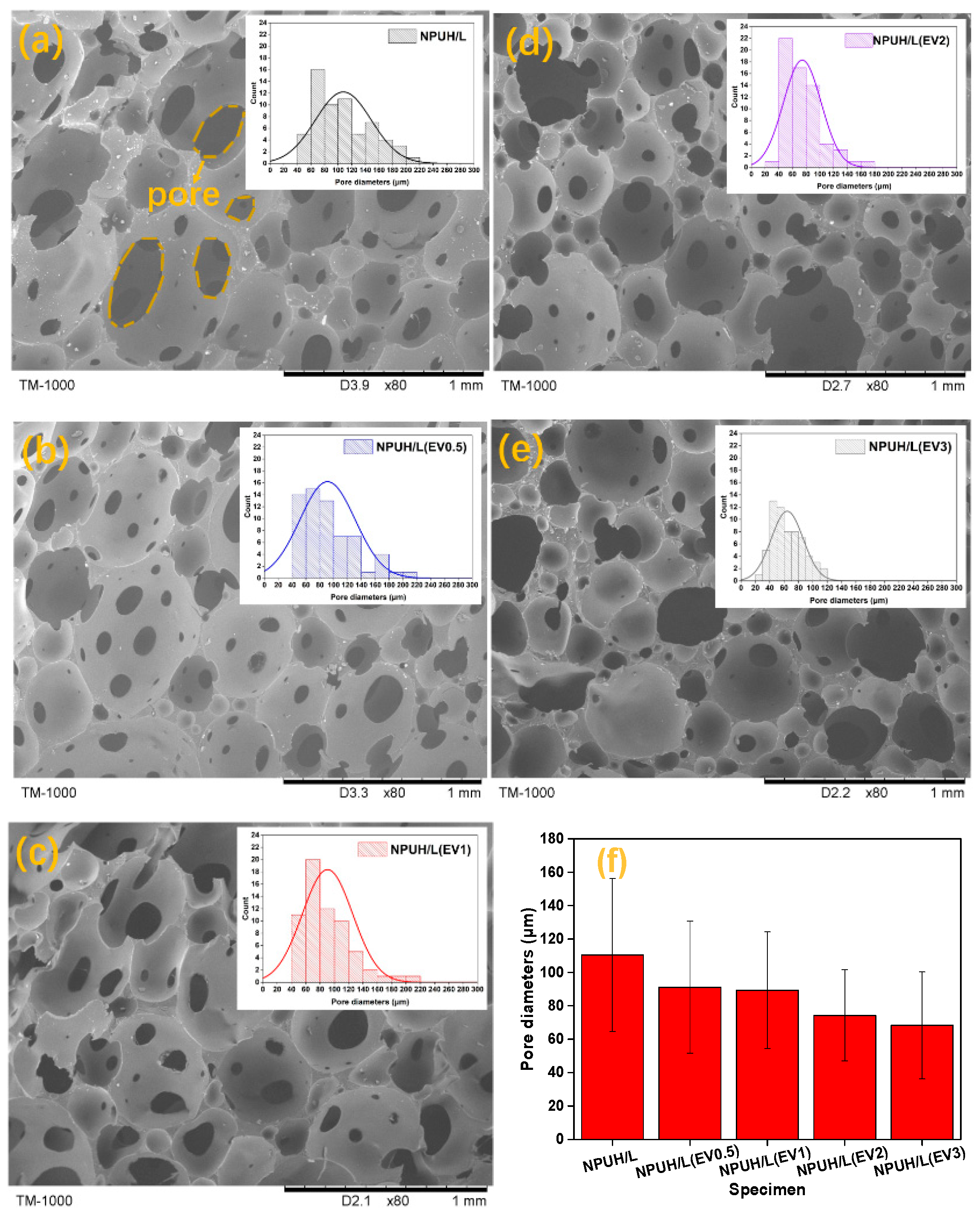

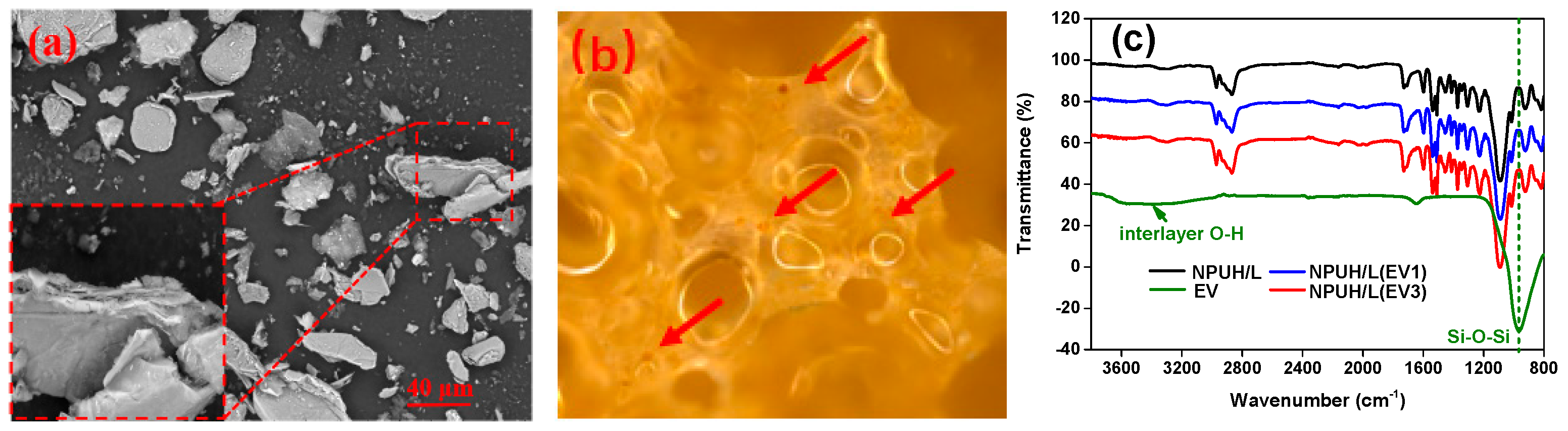

3.3. Effect of EV Content on Morphology of Lower Layer Foam

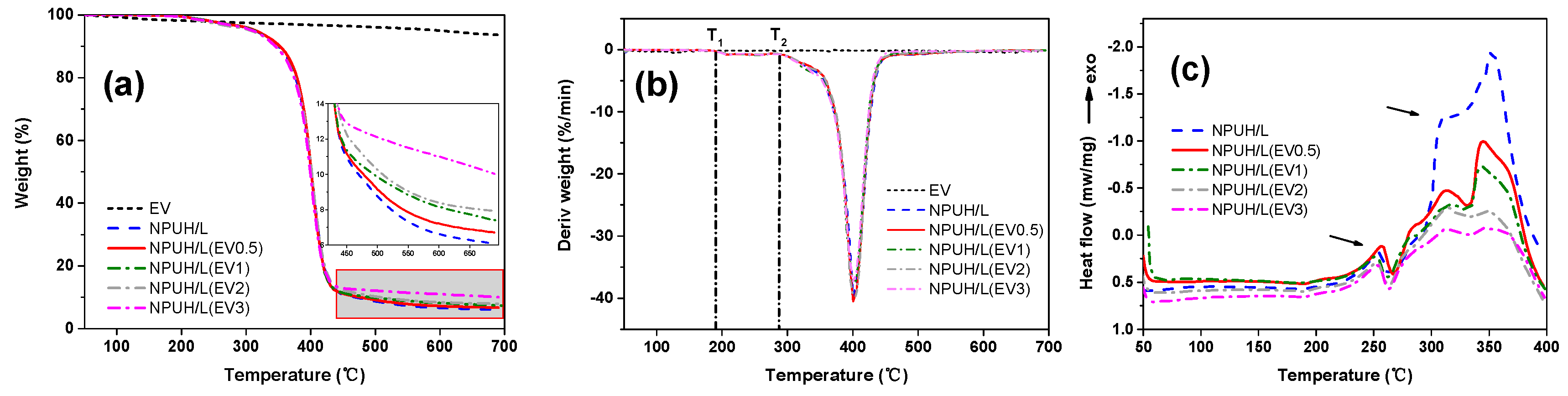

3.4. Effect of EV Content on Thermal Properties of Composites

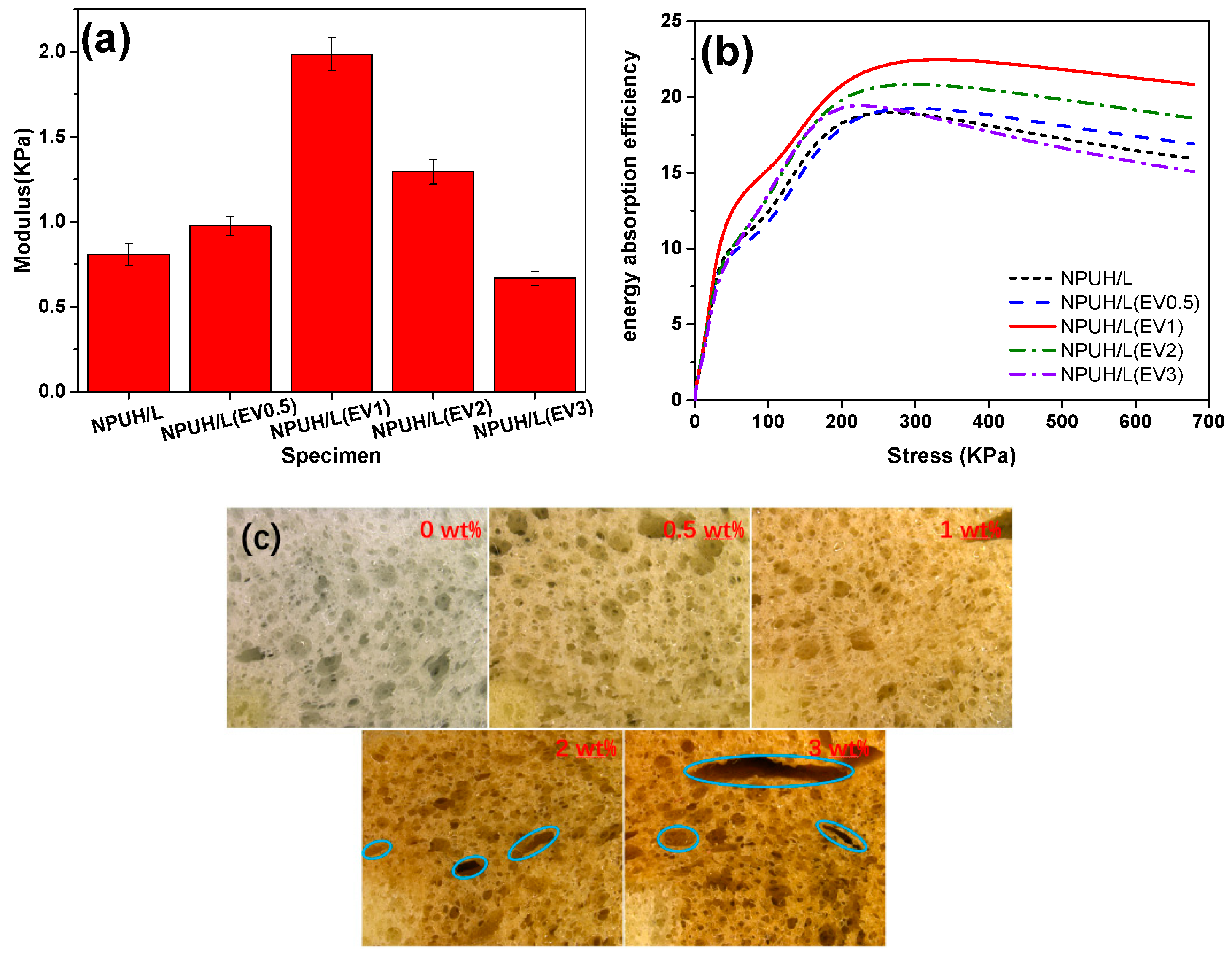

3.5. Effect of EV Contents on Compressive Properties of Bionic Composites

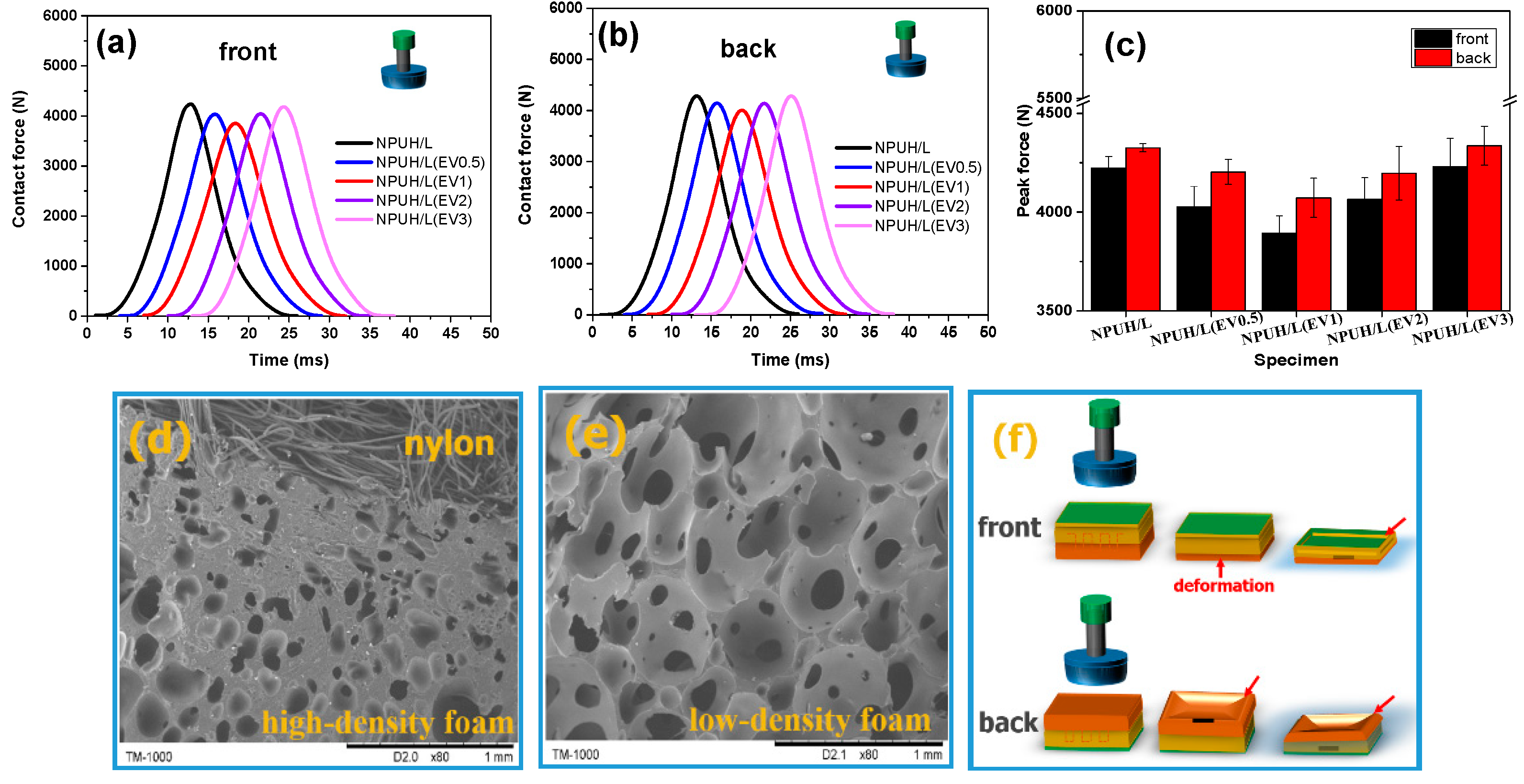

3.6. Effect of EV Content on the Cushioning Properties of Bionic Composites

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Loganathan, S.B.; Shivanand, H.K. Effect of Core Thickness and Core Density on Low Velocity Impact Behavior of Sandwich Panels with PU Foam Core. J. Miner. Mater. Charact. Eng. 2015, 3, 164–170. [Google Scholar] [CrossRef][Green Version]

- Birman, V.; Chandrashekhara, K.; Hopkins, M.S.; Volz, J.S. Effects of nanoparticle impregnation of polyurethane foam core on the performance of sandwich beams. Compos. Part B Eng. 2013, 46, 234–246. [Google Scholar] [CrossRef]

- Zhang, L.; Yilmaz, E.D.; Schjødt-Thomsen, J.; Rauhe, J.C.; Pyrz, R. MWNT reinforced polyurethane foam: Processing, characterization and modelling of mechanical properties. Compos. Sci. Technol. 2011, 71, 877–884. [Google Scholar] [CrossRef]

- Pham, T.M.; Chen, W.; Kingston, J.; Hao, H. Impact response and energy absorption of single phase syntactic foam. Compos. Part B Eng. 2018, 150, 226–233. [Google Scholar] [CrossRef]

- Sung, G.; Kim, J.H. Influence of filler surface characteristics on morphological, physical, acoustic properties of polyurethane composite foams filled with inorganic fillers. Compos. Sci. Technol. 2017, 146, 147–154. [Google Scholar] [CrossRef]

- Mareri, P.; Bastide, S.; Binda, N.; Crespy, A. Mechanical behaviour of polypropylene composites containing fine mineral filler: Effect of filler surface treatment. Compos. Sci. Technol. 1998, 58, 747–752. [Google Scholar] [CrossRef]

- Li, T.; Chuang, Y.; Huang, C.; Lou, C.; Lin, J. Applying vermiculite and perlite fillers to sound-absorbing/thermal-insulating resilient PU foam composites. Fibers Polym. 2015, 16, 691–698. [Google Scholar] [CrossRef]

- Xu, W.; Wang, G.; Zheng, X. Research on highly flame-retardant rigid PU foams by combination of nanostructured additives and phosphorus flame retardants. Polym. Degrad. Stab. 2015, 111, 142–150. [Google Scholar] [CrossRef]

- Khidas, Y.; Haffner, B.; Pitois, O. Critical size effect of particles reinforcing foamed composite materials. Compos. Sci. Technol. 2015, 119, 62–67. [Google Scholar] [CrossRef]

- Colton, J.S.; Suh, N. The Nucleation of Microcellular Thermoplastic Foam With Additives: Part I: Theoretical Considerations. Polym. Eng. Sci. 1987, 27, 485–492. [Google Scholar] [CrossRef]

- Qian, Y.; Lindsay, C.I.; Macosko, C.; Stein, A. Synthesis and Properties of Vermiculite-Reinforced Polyurethane Nanocomposites. ACS Appl. Mater. Interfaces 2011, 3, 3709–3717. [Google Scholar] [CrossRef] [PubMed]

- Zhi, C.; Long, H. Flexural Properties of Syntactic foam Reinforced by Warp Knitted Spacer Fabric. Autex Res. J. 2016, 16, 57–66. [Google Scholar] [CrossRef]

- Caliskan, U.; Apalak, M.K. Low velocity bending impact behavior of foam core sandwich beams: Experimental. Compos. Part B Eng. 2017, 112, 158–175. [Google Scholar] [CrossRef]

- Velosa, J.C.; Rana, S.; Fangueiro, R.; Van Hattum, F.W.J.; Soutinho, F.; Marques, S. Mechanical behavior of novel sandwich composite panels based on 3D-knitted spacer fabrics. J. Reinf. Plast. Compos. 2012, 31, 95–105. [Google Scholar] [CrossRef]

- Fischer, S.F.; Thielen, M.; Loprang, R.R.; Seidel, R.; Fleck, C.; Speck, T.; Bührig-Polaczek, A. Pummelos as Concept Generators for Biomimetically Inspired Low Weight Structures with Excellent Damping Properties. Adv. Eng. Mater. 2010, 12, B658–B663. [Google Scholar] [CrossRef]

- Gupta, N. A functionally graded syntactic foam material for high energy absorption under compression. Mater. Lett. 2007, 61, 979–982. [Google Scholar] [CrossRef]

- Cao, S.C.; Liu, J.; Zhu, L.; Li, L.; Dao, M.; Lu, J.; Ritchie, R.O. Nature-Inspired Hierarchical Steels. Sci. Rep. 2018, 8, 5088. [Google Scholar] [CrossRef]

- Seidel, R.; Thielen, M.; Schmitt, C.; Bührig-Polaczek, A.; Fleck, C.; Speck, T. Fruit walls and nut shells as an inspiration for the design of bio-inspired impact-resistant hierarchically structured materials. Int. J. Des. Nat. Ecodyn. 2013, 8, 172–179. [Google Scholar] [CrossRef]

- Wang, H.; Li, T.; Wu, L.; Lou, C.; Lin, J. Multifunctional, Polyurethane-Based Foam Composites Reinforced by a Fabric Structure: Preparation, Mechanical, Acoustic, and EMI Shielding Properties. Materials 2018, 11, 2085. [Google Scholar] [CrossRef]

- Yan, R.; Huang, S.; Huang, C.; Hsieh, C.; Lou, C.; Lin, J. Effects of needle-punched nonwoven structure on the properties of sandwich flexible composites under static loading and low-velocity impact. J. Compos. Mater. 2016, 51, 1045–1056. [Google Scholar] [CrossRef]

- Li, T.; Wang, H.; Huang, S.; Lou, C.; Lin, J. Bioinspired foam composites resembling pomelo peel: Structural design and compressive, bursting and cushioning properties. Compos. Part B Eng. 2019, 172, 290–298. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, H.; Long, H.; Zhao, L. Impact compressive behavior of warp-knitted spacer fabrics for protective applications. Text. Res. J. 2011, 82, 773–788. [Google Scholar] [CrossRef]

- Han, C.; Sun, C.T. Attenuation of stress wave propagation in periodically layered elastic media. J. Sound Vib. 2001, 243, 747–761. [Google Scholar] [CrossRef]

- Zhai, W.; Yu, J.; Wu, L.; Ma, W.; He, J. Heterogeneous nucleation uniformizing cell size distribution in microcellular nanocomposites foams. Polymer 2006, 47, 7580–7589. [Google Scholar] [CrossRef]

- Ito, Y.; Yamashita, M.; Okamoto, M. Foam Processing and Cellular Structure of Polycarbonate-Based Nanocomposites. Macromol. Mater. Eng. 2006, 291, 773–783. [Google Scholar] [CrossRef]

- Chen, L.; Rende, D.; Schadler, L.S.; Ozisik, R. Polymer nanocomposite foams. J. Mater. Chem. A 2013, 1, 3837–3850. [Google Scholar] [CrossRef]

- Sachse, S.; Poruri, M.; Silva, F.; Michalowski, S.; Pielichowski, K.; Njuguna, J. Effect of nanofillers on low energy impact performance of sandwich structures with nanoreinforced polyurethane foam cores. J. Sandw. Struct. Mater. 2014, 16, 173–194. [Google Scholar] [CrossRef]

- Zeng, C.; Hossieny, N.; Zhang, C.; Wang, B. Synthesis and processing of PMMA carbon nanotube nanocomposite foams. Polymer 2010, 51, 655–664. [Google Scholar] [CrossRef]

- Norimichi Yoshitake, M.F. Thermal degradation mechanism of α,γ-diphenyl alkyl allophanate as a model polyurethane by pyrolysis- high-resolution gas chromatography/FT-IR. J. Anal. Appl. Pyrolysis 1995, 33, 269–281. [Google Scholar] [CrossRef]

- Pagacz, J.; Hebda, E.; Micha Owski, S.A.; Ozimek, J.; Sternik, D.; Pielichowski, K. Polyurethane foams chemically reinforced with POSS—Thermal degradation studies. Thermochim. Acta. 2016, 642, 95–104. [Google Scholar] [CrossRef]

- Gomez-Fernandez, S.; Ugarte, L.; Pena-Rodriguez, C.; Zubitur, M.; Angeles Corcuera, M.; Eceiza, A. Flexible polyurethane foam nanocomposites with modified layered double hydroxides. Appl. Clay Sci. 2016, 123, 109–120. [Google Scholar] [CrossRef]

- Fu, Y.; Li, D.; Xu, W.; Qi, Y.; Shang, W.; Wu, W.; Wang, Y. Applying Vermiculite-Modified Polypropylene Film to Flexible Packaging Material. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Cheng, J.; Shi, B.; Zhou, F.; Chen, X. Effects of Inorganic Fillers on the Flame- Retardant and Mechanical Properties of Rigid Polyurethane Foams. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Metın, D.; Tihminlioğlu, F.; Balköse, D.; Ülkü, S. The effect of interfacial interactions on the mechanical properties of polypropylene/natural zeolite composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 23–32. [Google Scholar] [CrossRef]

- Liu, Y.; Au, W.M.; Hu, H. Protective properties of warp-knitted spacer fabrics under impact in hemispherical form. Part I: Impact behavior analysis of a typical spacer fabric. Text. Res. J. 2013, 84, 422–434. [Google Scholar] [CrossRef]

- Wang, X.K.; Zheng, Z.J.; Yu, J.L.; Wang, C.F. Impact Resistance and Energy Absorption of Functionally Graded Cellular Structures. Appl. Mech. Mater. 2011, 69, 73–78. [Google Scholar] [CrossRef]

- Wang, B.; Chen, Y.; Fan, H.; Jin, F. Investigation of low-velocity impact behaviors of foamed concrete material. Compos. Part B Eng. 2019, 162, 491–499. [Google Scholar] [CrossRef]

- Bührig-Polaczek, A.; Fleck, C.; Speck, T.; Schüler, P.; Fischer, S.F.; Caliaro, M.; Thielen, M. Biomimetic cellular metals-using hierarchical structuring for energy absorption. Bioinspir. Biomim. 2016, 11, 45002. [Google Scholar] [CrossRef]

- Mitrevski, T.; Marshall, I.H.; Thomson, R.; Jones, R.; Whittingham, B. The effect of impactor shape on the impact response of composite laminates. Compos. Struct. 2005, 67, 139–148. [Google Scholar] [CrossRef]

| Sample Code | Surface Layer | Upper Foam | Lower Foam | EV Content (wt%) |

|---|---|---|---|---|

| NPUH/L | Nylon | high-density | low-density | 0 |

| NPUH/L(EV0.5) | Nylon | high-density | low-density | 0.5 |

| NPUH/L(EV1) | Nylon | high-density | low-density | 1 |

| NPUH/L(EV2) | Nylon | high-density | low-density | 2 |

| NPUH/L(EV3) | Nylon | high-density | low-density | 3 |

| Specimen | EV Content (%) | T1 (°C) | T2 (°C) | Char Yield (%) |

|---|---|---|---|---|

| NPUH/L | 0 | 166.7 | 289.2 | 6.09 |

| NPUH/L(EV0.5) | 0.5 | 166.5 | 289.4 | 6.70 |

| NPUH/L(EV1) | 1 | 166.9 | 289.3 | 7.36 |

| NPUH/L(EV2) | 2 | 166.7 | 289.3 | 7.91 |

| NPUH/L(EV3) | 3 | 166.7 | 289.3 | 10.03 |

| EV | 100 | - | - | 93.62 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Li, T.-T.; Ren, H.; Peng, H.; Huang, S.-Y.; Lin, Q.; Lin, J.-H.; Lou, C.-W. Expanded Vermiculite-Filled Polyurethane Foam-Core Bionic Composites: Preparation and Thermal, Compression, and Dynamic Cushion Properties. Polymers 2019, 11, 1028. https://doi.org/10.3390/polym11061028

Wang H, Li T-T, Ren H, Peng H, Huang S-Y, Lin Q, Lin J-H, Lou C-W. Expanded Vermiculite-Filled Polyurethane Foam-Core Bionic Composites: Preparation and Thermal, Compression, and Dynamic Cushion Properties. Polymers. 2019; 11(6):1028. https://doi.org/10.3390/polym11061028

Chicago/Turabian StyleWang, Hongyang, Ting-Ting Li, Haitao Ren, Haokai Peng, Shih-Yu Huang, Qi Lin, Jia-Horng Lin, and Ching-Wen Lou. 2019. "Expanded Vermiculite-Filled Polyurethane Foam-Core Bionic Composites: Preparation and Thermal, Compression, and Dynamic Cushion Properties" Polymers 11, no. 6: 1028. https://doi.org/10.3390/polym11061028

APA StyleWang, H., Li, T.-T., Ren, H., Peng, H., Huang, S.-Y., Lin, Q., Lin, J.-H., & Lou, C.-W. (2019). Expanded Vermiculite-Filled Polyurethane Foam-Core Bionic Composites: Preparation and Thermal, Compression, and Dynamic Cushion Properties. Polymers, 11(6), 1028. https://doi.org/10.3390/polym11061028