Effect of Poly(styrene-ran-methyl acrylate) Inclusion on the Compatibility of Polylactide/Polystyrene-b-Polybutadiene-b-Polystyrene Blends Characterized by Morphological, Thermal, Rheological, and Mechanical Measurements

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of S-MA by Surfactant-Free Emulsion Copolymerization

2.3. Preparation of S-MA-Compatibilized PLA/SBS Blends

2.4. Field-Emission Scanning Electron Microscopy (FE-SEM)

2.5. Differential Scanning Calorimetry (DSC)

2.6. Thermogravimetric Analysis (TGA)

2.7. Rheological Measurements

2.8. Mechanical Properties Measurements

3. Results and Discussion

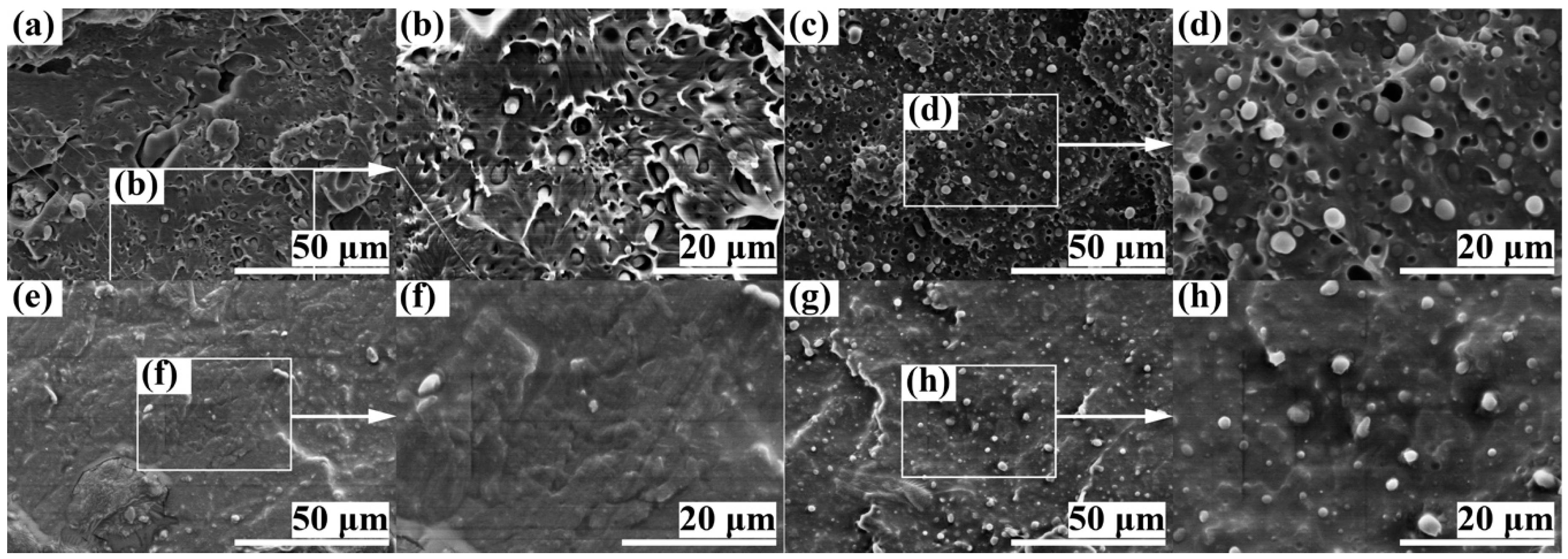

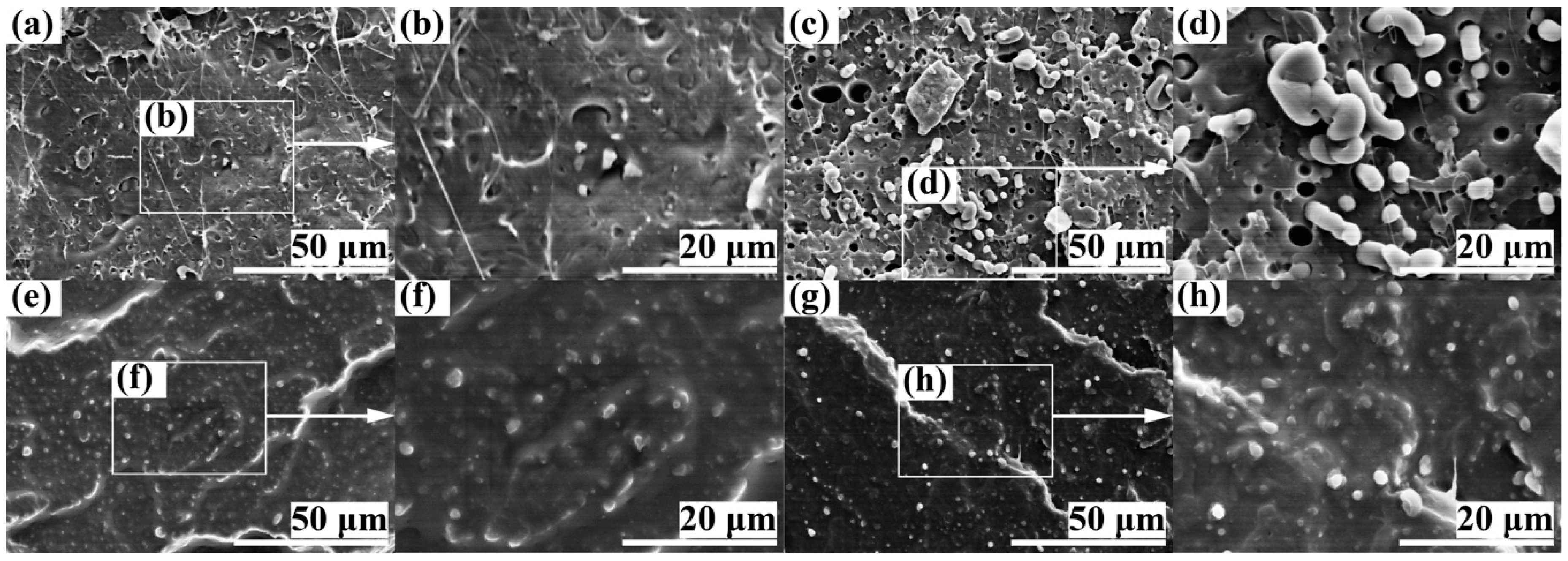

3.1. Effect of S-MA Compatibilization on the Morphology of PLA/SBS Blends

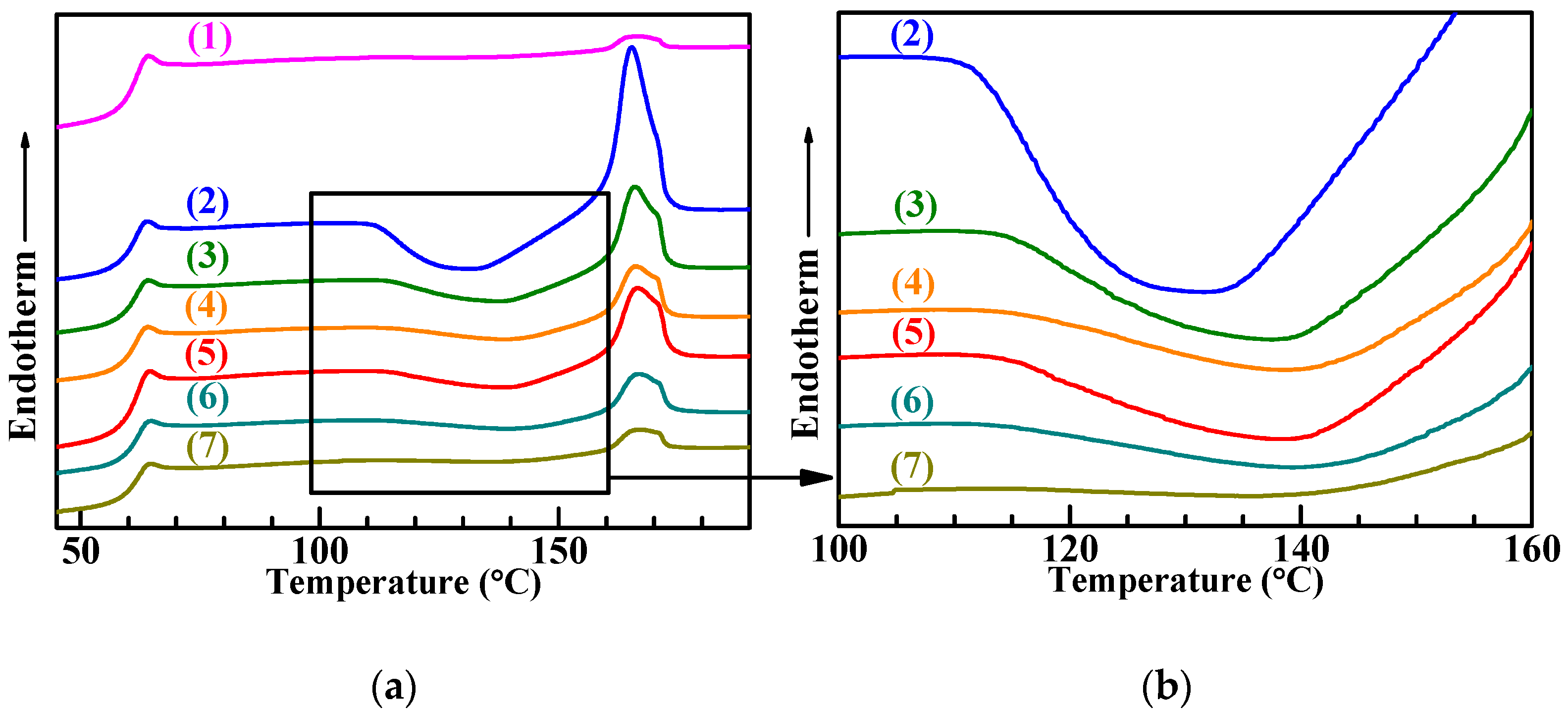

3.2. Effect of S-MA Compatibilization on the Thermal Transition Behavior of PLA/SBS Blends

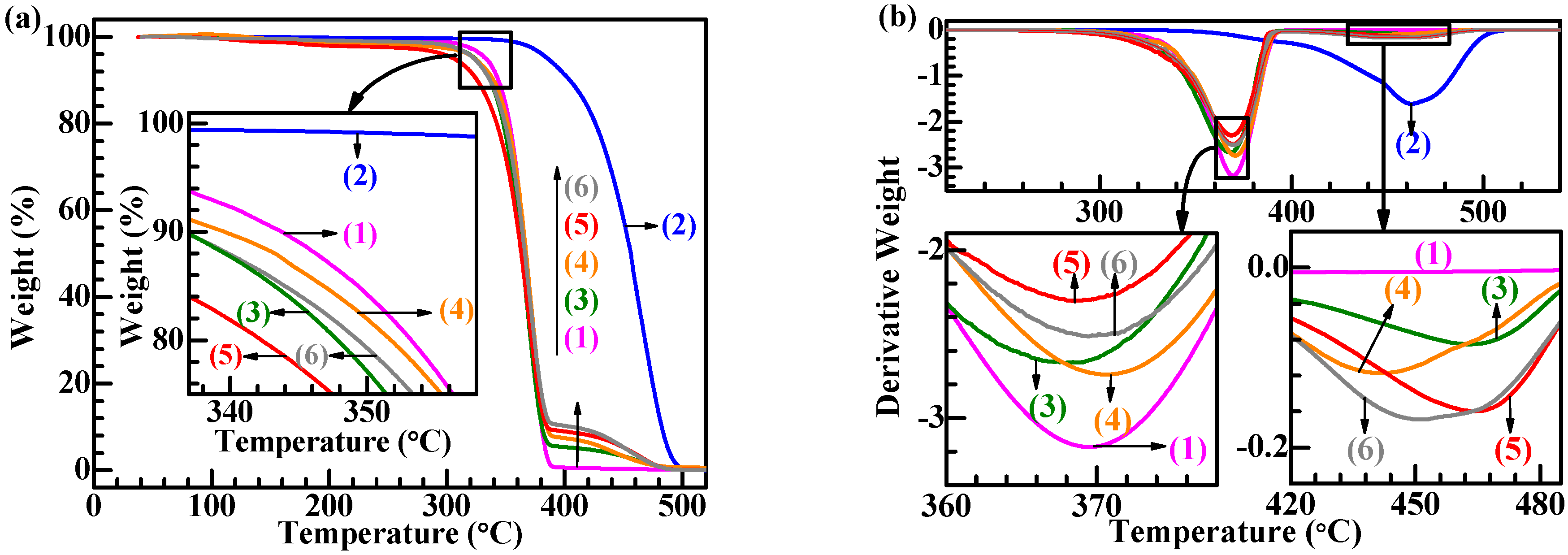

3.3. Effect of S-MA Compatibilization on the Thermal Decomposition Behavior of PLA/SBS Blends

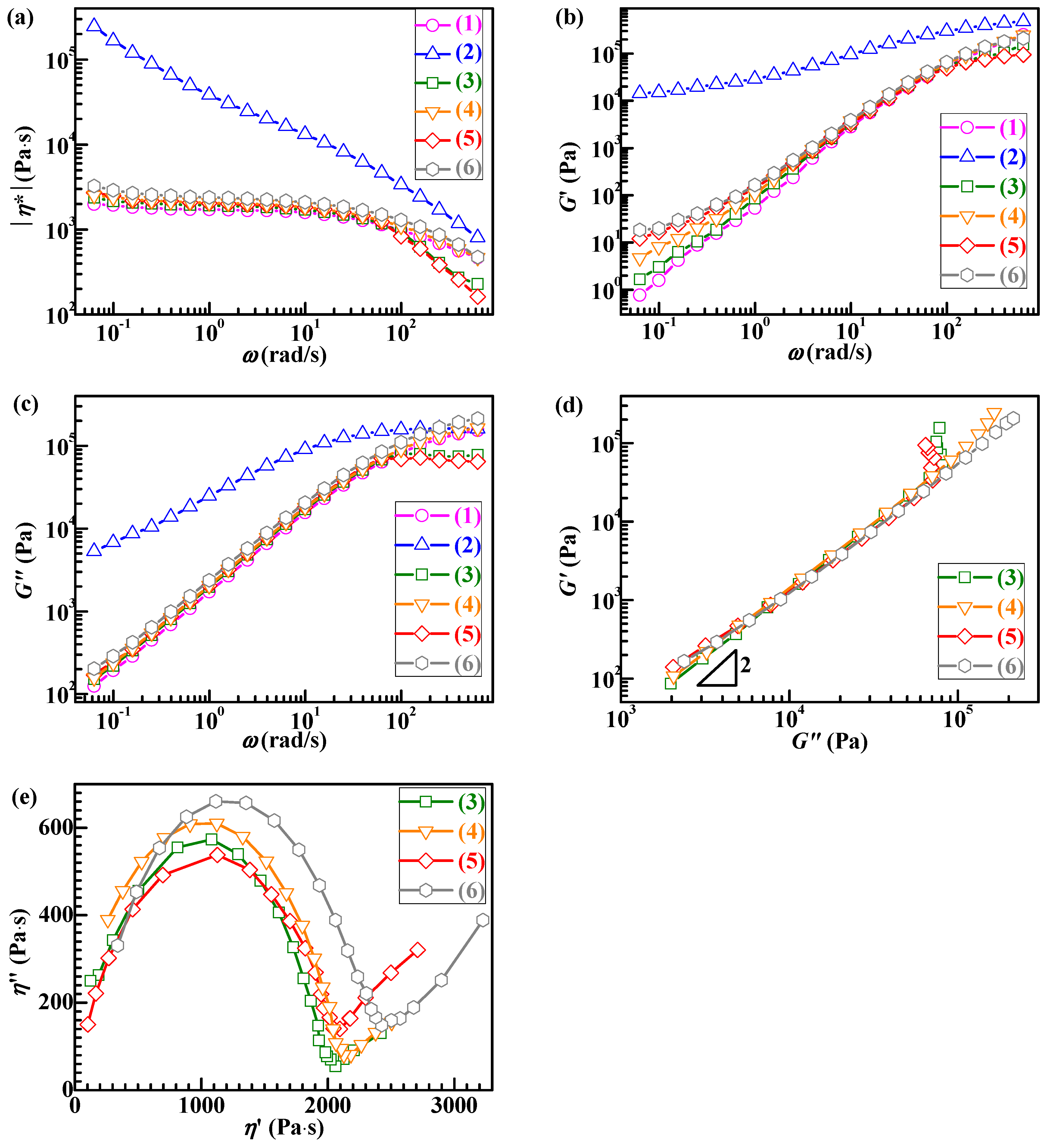

3.4. Effects of S-MA Compatibilization on the Rheological Properties of PLA/SBS Blends

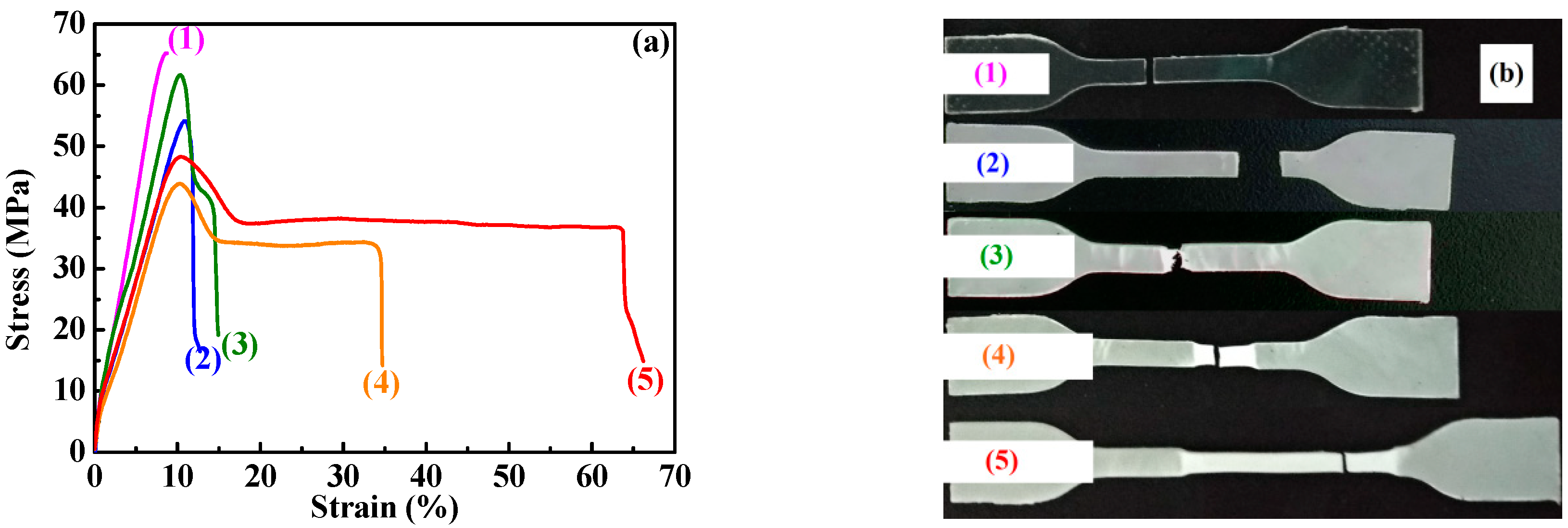

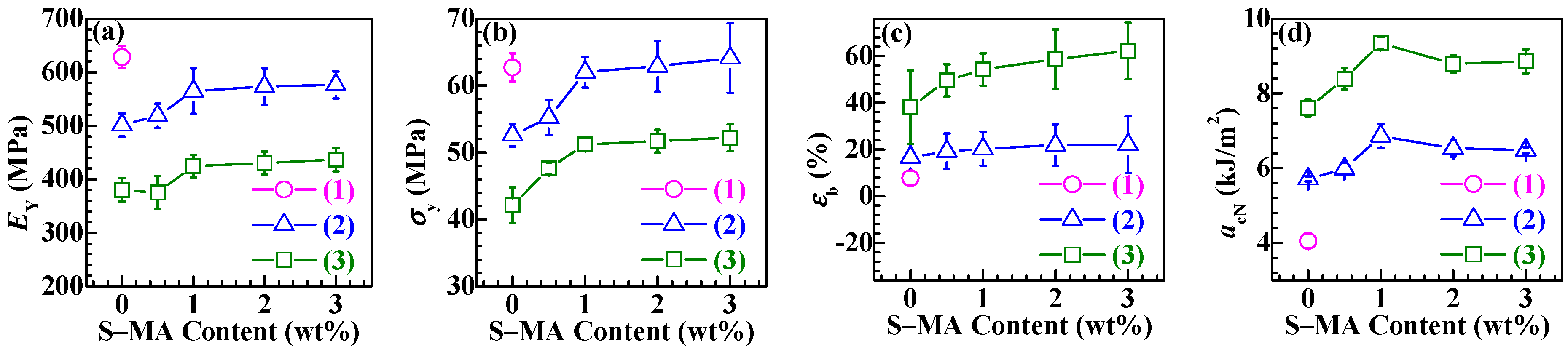

3.5. Effects of S-MA Compatibilization on the Mechanical Properties of PLA/SBS Blends

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nakajima, H.; Dijkstra, P.; Loos, K. The recent developments in biobased polymers toward general and engineering applications: Polymers that are upgraded from biodegradable polymers, analogous to petroleum-derived polymers, and newly developed. Polymers 2017, 9, 523. [Google Scholar] [CrossRef] [PubMed]

- Saini, P.; Arora, M.; Ravi Kumar, M.N.V. Poly(lactic acid) blends in biomedical applications. Adv. Drug Deliver. Rev. 2016, 107, 47–59. [Google Scholar] [CrossRef] [PubMed]

- Hamad, K.; Kaseem, M.; Ayyoob, M.; Joo, J.; Deri, F. Polylactic acid blends: The future of green, light and tough. Prog. Polym. Sci. 2018, 85, 83–127. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, Z.; Leng, X.; Shen, K.; Li, Y. Highly toughened polylactide with epoxidized polybutadiene by in-situ reactive compatibilization. Polymer 2016, 92, 74–83. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, Z.; Li, Y. Highly toughened polylactide/epoxidized poly(styrene-b-butadiene-b-styrene) blends with excellent tensile performance. Eur. Polym. J. 2016, 85, 92–104. [Google Scholar] [CrossRef]

- Wu, C.P.; Wang, C.C.; Chen, C.Y. Enhancing the PLA Crystallization Rate and Mechanical Properties by Melt Blending with Poly(styrene-butadiene-styrene) Copolymer. Polym.-Plast. Technol. Eng. 2015, 54, 1043–1050. [Google Scholar] [CrossRef]

- Su, Z.; Li, Q.; Liu, Y.; Hu, G.H.; Wu, C. Compatibility and phase structure of binary blends of poly(lactic acid) and glycidyl methacrylate grafted poly(ethylene octane). Eur. Polym. J. 2009, 45, 2428–2433. [Google Scholar] [CrossRef]

- Ding, Y.; Feng, W.; Lu, B.; Wang, P.; Wang, G.; Ji, J. PLA-PEG-PLA tri-block copolymers: Effective compatibilizers for promotion of the interfacial structure and mechanical properties of PLA/PBAT blends. Polymer 2018, 146, 179–187. [Google Scholar] [CrossRef]

- Rigoussen, A.; Verge, P.; Raquez, J.M.; Habibi, Y.; Dubois, P. In-depth investigation on the effect and role of cardanol in the compatibilization of PLA/ABS immiscible blends by reactive extrusion. Eur. Polym. J. 2017, 93, 272–283. [Google Scholar] [CrossRef]

- Lis-Bartos, A.; Smieszek, A.; Frańczyk, K.; Marycz, K. Fabrication, characterization, and cytotoxicity of thermoplastic polyurethane/poly(lactic acid) material using human adipose derived mesenchymal stromal stem cells (hASCs). Polymers 2018, 10, 1073. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wei, H.; Wang, Z.; Li, Q.; Tian, N. Simultaneous enhancement of strength and toughness of PLA induced by miscibility variation with PVA. Polymers 2018, 10, 1178. [Google Scholar] [CrossRef] [PubMed]

- Singla, R.K.; Zafar, M.T.; Maiti, S.N.; Ghosh, A.K. Physical blends of PLA with high vinyl acetate containing EVA and their rheological, thermos-mechanical and morphological responses. Polym. Test. 2017, 63, 398–406. [Google Scholar] [CrossRef]

- Supthanyakul, R.; Kaabbuathong, N.; Chirachanchai, S. Random poly(butylene succinate-co-lactic acid) as a multi-functional additive for miscibility, toughness, and clarity of PLA/PBS blends. Polymer 2016, 105, 1–9. [Google Scholar] [CrossRef]

- Zhang, B.; Bian, X.; Xiang, S.; Li, G.; Chen, X. Synthesis of PLLA-based block copolymers for improving melt strength and toughness of PLLA by in situ reactive blending. Polym. Degrad. Stab. 2017, 136, 58–70. [Google Scholar] [CrossRef]

- Gallego, R.; López-Quintana, S.; Basurto, F.; Núñez, K.; Villarreal, N.; Merino, J.C. Synthesis of New Compatibilizers to Poly(lactic acid) Blends. Polym. Eng. Sci. 2014, 54, 522–530. [Google Scholar] [CrossRef]

- Si, W.J.; Yuan, W.Q.; Li, Y.D.; Chen, Y.K.; Zeng, J.B. Tailoring toughness of biobased poly(lactic acid)/natural rubber blends through dynamic vulcanization. Polym. Test. 2018, 65, 249–255. [Google Scholar] [CrossRef]

- Zare, Y.; Garmabi, H.; Rhee, K.Y. Prediction of complex modulus in phase-separated poly(lactic acid)/poly(ethylene oxide)/carbon nanotubes nanocomposites. Polym. Test. 2018, 66, 189–194. [Google Scholar] [CrossRef]

- Gong, X.; Gao, X.; Tang, C.Y.; Law, W.C.; Chen, L.; Hu, T.; Wu, C.; Tsui, C.P.; Rao, N. Compatibilization of poly(lactic acid)/high impact polystyrene interface using copolymer poly(stylene-ran-methyl acrylate). J. Appl. Polym. Sci. 2018, 135, 45799. [Google Scholar] [CrossRef]

- Hashima, K.; Nishitsuji, S.; Inoue, T. Structure-properties of super-tough PLA alloy with excellent heat resistance. Polymer 2010, 51, 3934–3939. [Google Scholar] [CrossRef]

- Li, L.; Cao, Z.Q.; Bao, R.Y.; Xie, B.H.; Yang, M.B.; Yang, W. Poly(L-lactic acid)-polyethylene glycol-poly(L-lactic acid) triblock copolymer: A novel macromolecular plasticizer to enhance the crystallization of poly(L-lactic acid). Eur. Polym. J. 2017, 97, 272–281. [Google Scholar] [CrossRef]

- Sikka, M.; Pellegrini, N.N.; Schmitt, E.A.; Winey, K.I. Modifying a polystyrene/poly(methyl methacrylate) interface with poly(styrene-co-methyl methacrylate) random copolymers. Macromolecules 1997, 30, 445–455. [Google Scholar] [CrossRef]

- Gao, X.; Wang, M.; Chen, Y.; Hu, T.; Wang, X.; Wu, C.; Gong, X. Effect of poly(stylene co methyl acrylate) on mechanical and rheological properties of polystyrene/poly(lactic acid) blends. Polym. Mater. Sci. Eng. 2017, 33, 69–75. [Google Scholar]

- Jelcic, Z.; Holjevac-Grguric, T.; Rek, V. Mechanical properties and fractal morphology of high-impact polystyrene/poly(styrene-b-butadiene-b-styrene) blends. Polym. Degrad. Stab. 2005, 90, 295–302. [Google Scholar] [CrossRef]

- Ren, P.G.; Wang, J.; Fan, Q.; Yang, S.; Wu, Z.Q.; Yan, D.X.; Chen, Y.H. Synergetic toughening effect of carbon nanotubes and β-nucleating agents on the polypropylene random copolymer/styrene-ethylene-butylene-styrene block copolymer blends. Polymers 2019, 11, 29. [Google Scholar] [CrossRef] [PubMed]

- Canto, L.B.; Hage, E.; Pessan, L.A. Effects of the molecular structure of impact modifier and compatibilizer on the toughening of PBT/SBS/PS-GMA blends. J. Appl. Polym. Sci. 2006, 102, 5795–5807. [Google Scholar] [CrossRef]

- Banerjee, R.; Ray, S.S.; Ghosh, A.K. Microstructure development and its influence on the properties of styrene-ethylene-styrene/polystyrene blends. Polymers 2018, 10, 400. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Nie, S.; Zhu, J. A comparative study on different rubbery modifiers: Effect on morphologies, mechanical, and thermal properties of PLA blends. J. Appl. Polym. Sci. 2016, 133, 43340. [Google Scholar] [CrossRef]

- Eguiburu, J.L.; Iruin, J.J.; Fernandez-Berridi, M.J.; San Román, J. Blends of amorphous and crystalline polylactides with poly(methyl methacrylate) and poly(methyl acrylate): A miscibility study. Polymer 1998, 39, 6891–6897. [Google Scholar] [CrossRef]

- Anakabe, J.; Zaldua Huici, A.M.; Eceiza, A.; Arbelaiz, A.; Avérous, L. Combined effect of nucleating agent and plasticizer on the crystallization behavior of polylactide. Polym. Bull. 2017, 74, 4857–4886. [Google Scholar] [CrossRef]

- Pivsa-Art, S.; Kord-Sa-Ard, J.; Pivsa-Art, W.; Wongpajan, R.; O-Charoen, N.; Pavasupree, S.; Hamada, H. Effect of compatibilizer on PLA/PP blend for injection molding. Energy Procedia 2016, 89, 353–360. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, Z.; Zheng, Z.; Zhu, X.; Wang, H. Shape memory polymer hybrids of SBS/dl-PLA and their shape memory effects. Mater. Chem. Phys. 2013, 137, 750–755. [Google Scholar] [CrossRef]

- Saeidlou, S.; Huneault, M.A.; Li, H.; Park, C.B. Poly(lactic acid) crystallization. Prog. Polym. Sci. 2012, 37, 1657–1677. [Google Scholar] [CrossRef]

- Shieh, Y.T.; Liu, G.L. Temperature-modulated differential scanning calorimetry studies on the origin of double melting peaks in isothermally melt-crystallized poly(L-lactic acid). J. Polym. Sci. Part B Polym. Phys. 2007, 45, 466–474. [Google Scholar] [CrossRef]

- Gong, X.; Pan, L.; Tang, C.Y.; Chen, L.; Li, C.; Wu, C.; Law, W.C.; Wang, X.; Tsui, C.P.; Xie, X. Investigating the crystallization behavior of poly(lactic acid) using CdSe/ZnS quantum dots as heterogeneous nucleating agents. Compos. B Eng. 2016, 91, 103–110. [Google Scholar] [CrossRef]

- Lin, Z.; Guan, Z.; Xu, B.; Chen, C.; Guo, G.; Zhou, J.; Xian, J.; Cao, L.; Wang, Y.; Li, M.; et al. Crystallization and melting behavior of polypropylene in β-PP/polyamide 6 blends containing PP-g-MA. J. Ind. Eng. Chem. 2013, 19, 692–697. [Google Scholar] [CrossRef]

- Zhou, Y.X.; Huang, Z.G.; Diao, X.Q.; Weng, Y.X.; Wang, Y.Z. Characterization of the effect of REC on the compatibility of PHBH and PLA. Polym. Test. 2015, 42, 17–25. [Google Scholar] [CrossRef]

- Han, C.D.; Kim, J. Rheological Technique for determining the crder-disorder transition of block copolymers. J. Polym. Sci. Part B Polym. Phys. 1987, 25, 1741–1764. [Google Scholar] [CrossRef]

- Han, C.D. Influence of molecular weight distribution on the linear viscoelastic properties of polymer blends. J. Appl. Polym. Sci. 1988, 35, 167–213. [Google Scholar] [CrossRef]

- Wang, R.; Yang, Q.; Huang, Y.; Li, G.; Wang, J.; Lai, R. Melt compatibility of metallocene linear low-density polyethylene and high-density polyethylene blends. Atca Polym. Sin. 2010, 9, 1108–1115. [Google Scholar] [CrossRef]

- Li, R.; Yu, W.; Zhou, C. Phase behavior and its viscoelastic responses of poly(methyl methacrylate) and poly(styrene-co-maleic anhydride) blend systems. Polym. Bull. 2006, 56, 455–466. [Google Scholar] [CrossRef]

- Cole, K.S.; Cole, R.H. Dispersion and absorption in dielectrics I. Alternating current characteristics. J. Chem. Phys. 1941, 9, 341–351. [Google Scholar] [CrossRef]

- Bucknall, C.B. New criterion for craze initiation. Polymer 2007, 48, 1030–1041. [Google Scholar] [CrossRef]

| Composition | Tg (°C) | Tcc (°C) | ΔHcc (J/g) | Tm (°C) | ΔHm (J/g) | Xc (%) |

|---|---|---|---|---|---|---|

| PLA | 61.6 | 137.2 | 1.1 | 165.7 | 1.3 | 1.4 |

| PLA/SBS (95/5) | 61.4 | 132.1 | 16.1 | 165.4 | 17.2 | 19.5 |

| PLA/SBS/S-MA (95/5/1.0) | 61.7 | 137.9 | 9.0 | 165.8 | 9.9 | 11.3 |

| PLA/SBS/S-MA (95/5/3.0) | 61.7 | 139.2 | 5.3 | 165.8 | 6.1 | 7.1 |

| PLA/SBS (90/10) | 61.7 | 139.5 | 5.1 | 166.3 | 6.0 | 7.2 |

| PLA/SBS/S-MA (90/10/1.0) | 61.7 | 140.1 | 4.0 | 166.6 | 4.8 | 5.8 |

| PLA/SBS/S-MA (90/10/3.0) | 62.0 | 140.2 | 2.5 | 166.8 | 2.8 | 3.4 |

| Composition | Tmd1 (°C) | Tmd2 (°C) | (Tmd2 − Tmd1) (°C) |

|---|---|---|---|

| (1) PLA | 369.5 | ‒ 1 | ‒ 1 |

| (2) SBS | ‒ 1 | 459.5 | ‒ 1 |

| (3) PLA/SBS (95/5) | 367.6 | 463.8 | 96.2 |

| (4) PLA/SBS/S-MA (95/5/3.0) | 370.7 | 442.6 | 71.9 |

| (5) PLA/SBS (90/10) | 368.7 | 464.9 | 96.2 |

| (6) PLA/SBS/S-MA (90/10/3.0) | 370.3 | 449.3 | 79.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Tu, Z.; Wu, C.; Hu, T.; Wang, X.; Long, S.; Gong, X. Effect of Poly(styrene-ran-methyl acrylate) Inclusion on the Compatibility of Polylactide/Polystyrene-b-Polybutadiene-b-Polystyrene Blends Characterized by Morphological, Thermal, Rheological, and Mechanical Measurements. Polymers 2019, 11, 846. https://doi.org/10.3390/polym11050846

Wang B, Tu Z, Wu C, Hu T, Wang X, Long S, Gong X. Effect of Poly(styrene-ran-methyl acrylate) Inclusion on the Compatibility of Polylactide/Polystyrene-b-Polybutadiene-b-Polystyrene Blends Characterized by Morphological, Thermal, Rheological, and Mechanical Measurements. Polymers. 2019; 11(5):846. https://doi.org/10.3390/polym11050846

Chicago/Turabian StyleWang, Bocheng, Zheng Tu, Chonggang Wu, Tao Hu, Xiaotao Wang, Shijun Long, and Xinghou Gong. 2019. "Effect of Poly(styrene-ran-methyl acrylate) Inclusion on the Compatibility of Polylactide/Polystyrene-b-Polybutadiene-b-Polystyrene Blends Characterized by Morphological, Thermal, Rheological, and Mechanical Measurements" Polymers 11, no. 5: 846. https://doi.org/10.3390/polym11050846

APA StyleWang, B., Tu, Z., Wu, C., Hu, T., Wang, X., Long, S., & Gong, X. (2019). Effect of Poly(styrene-ran-methyl acrylate) Inclusion on the Compatibility of Polylactide/Polystyrene-b-Polybutadiene-b-Polystyrene Blends Characterized by Morphological, Thermal, Rheological, and Mechanical Measurements. Polymers, 11(5), 846. https://doi.org/10.3390/polym11050846