Hydrogel Small-Diameter Vascular Graft Reinforced with a Braided Fiber Strut with Improved Mechanical Properties

Abstract

1. Introduction

2. Materials and Methods

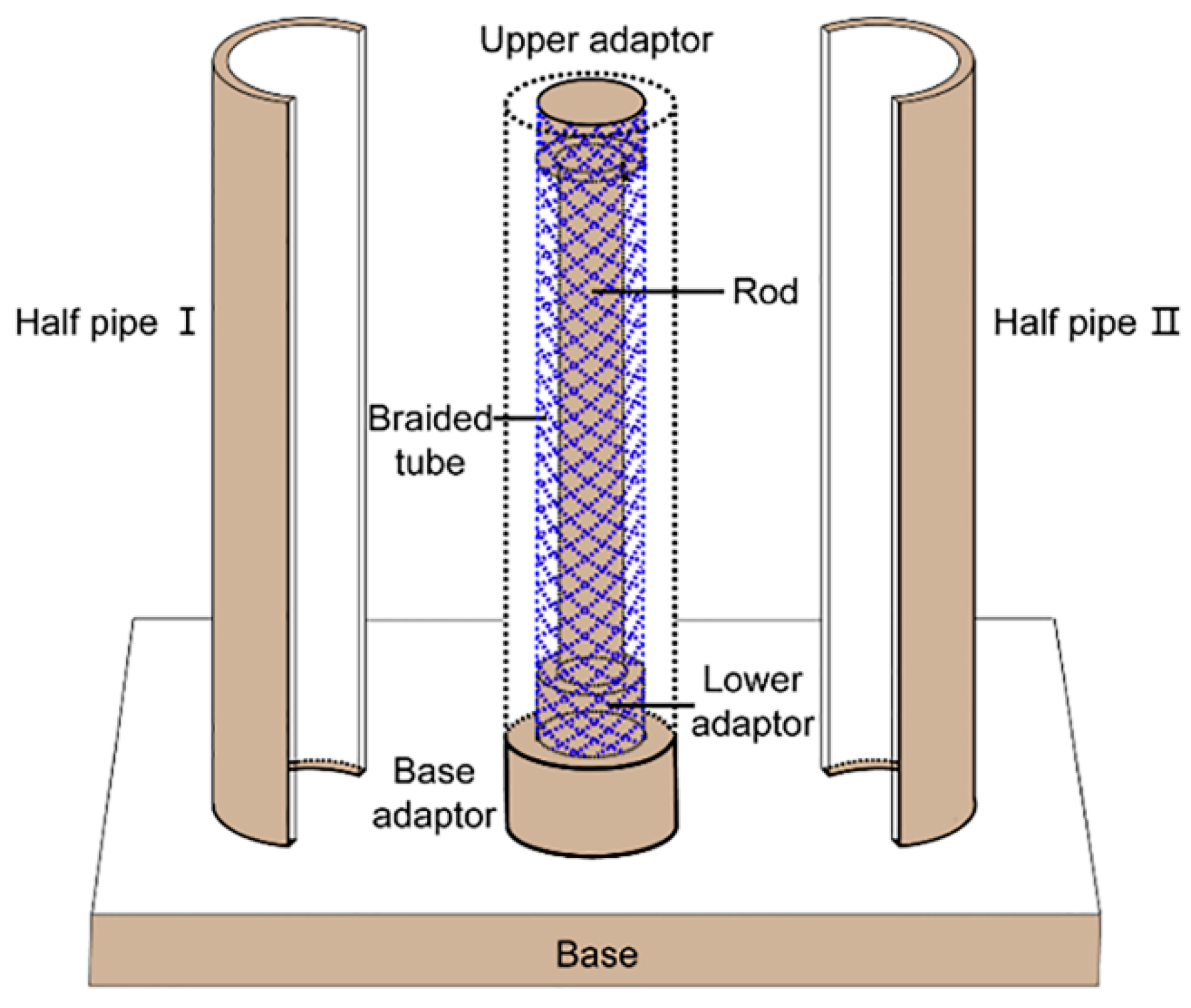

2.1. Design and Fabrication of a 3D Casting Mold

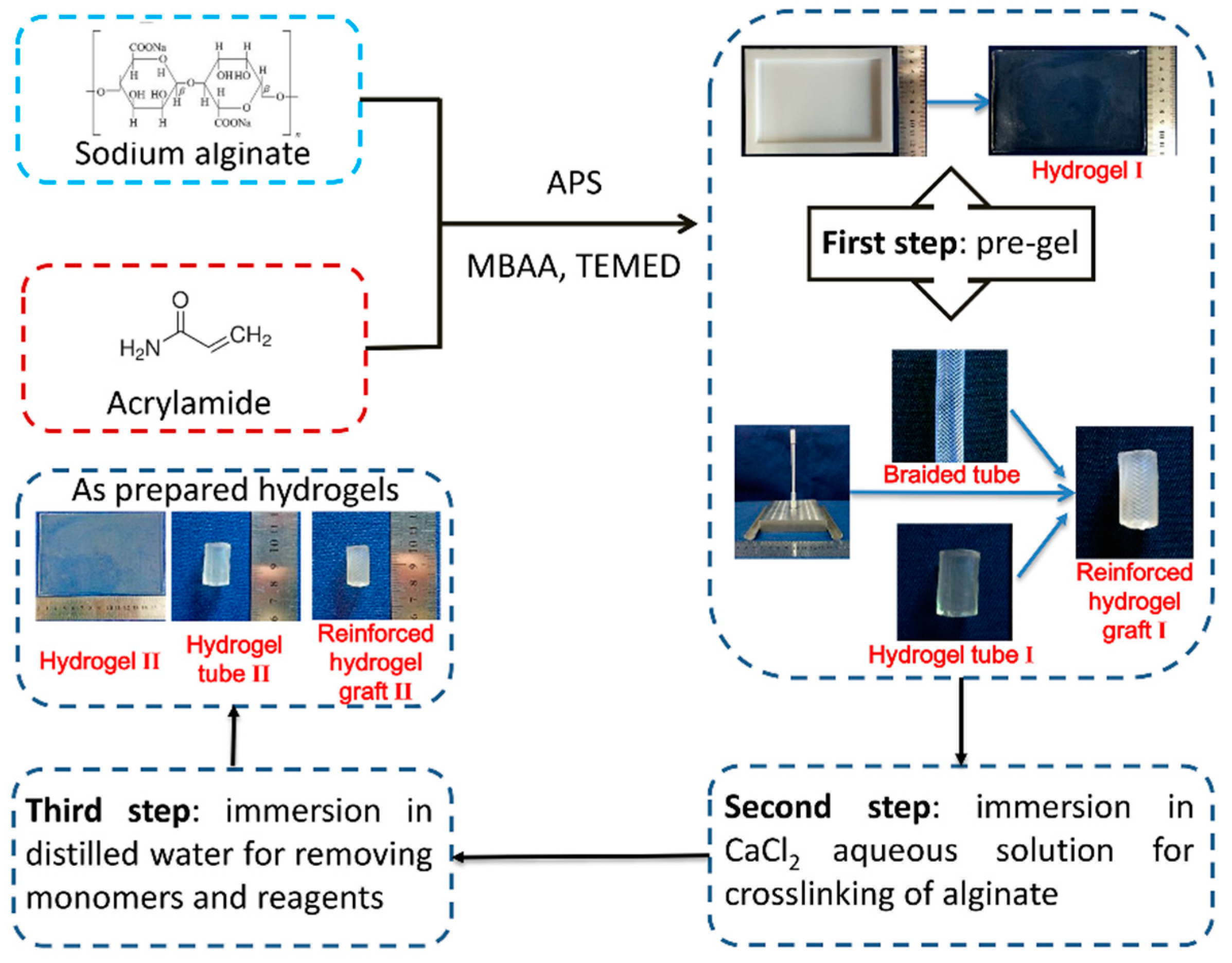

2.2. Preparation of the Ca Alginate/Polyacrylamide Hydrogel

2.3. Scanning Electron Microscopy (SEM) of the Hydrogels

2.4. Volume Swellability of the Hydrogels

2.5. Tensile Strength and Elongation of the Hydrogels

2.6. Design and Fabrication of a Braided Fiber Strut

2.7. Fabrication of Braided Fiber Strut-Reinforced Hydrogel Vascular Grafts

2.8. Mechanical Properties of the Reinforced Grafts

2.9. In Vitro Cytotoxicity Assay of the Reinforced Grafts

2.10. Hemolysis Test of the Graft

2.11. Statistical Analysis

3. Results and Discussion

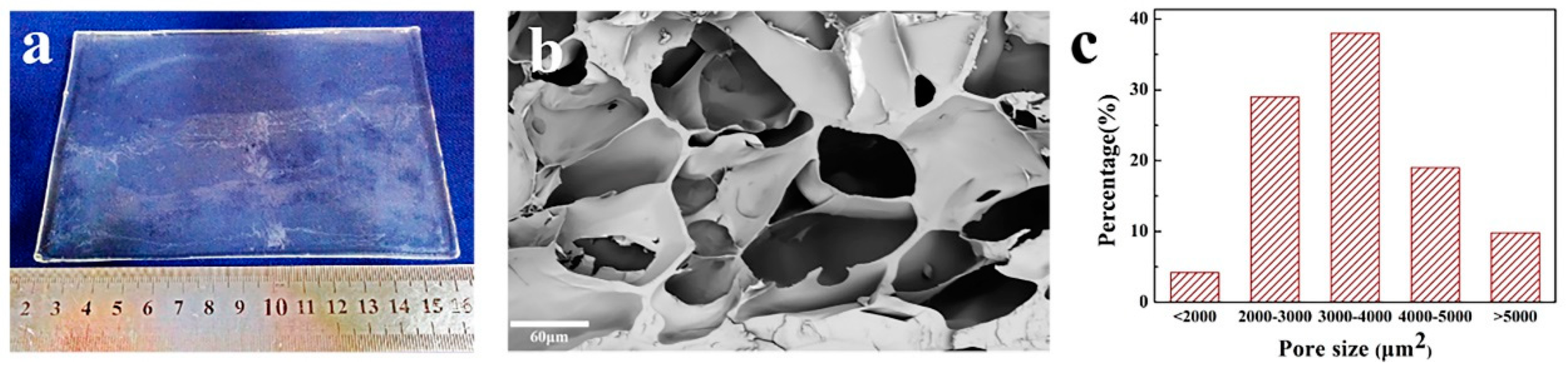

3.1. Morphology and Porous Structure of the Ca Alginate/Polyacrylamide Hydrogel

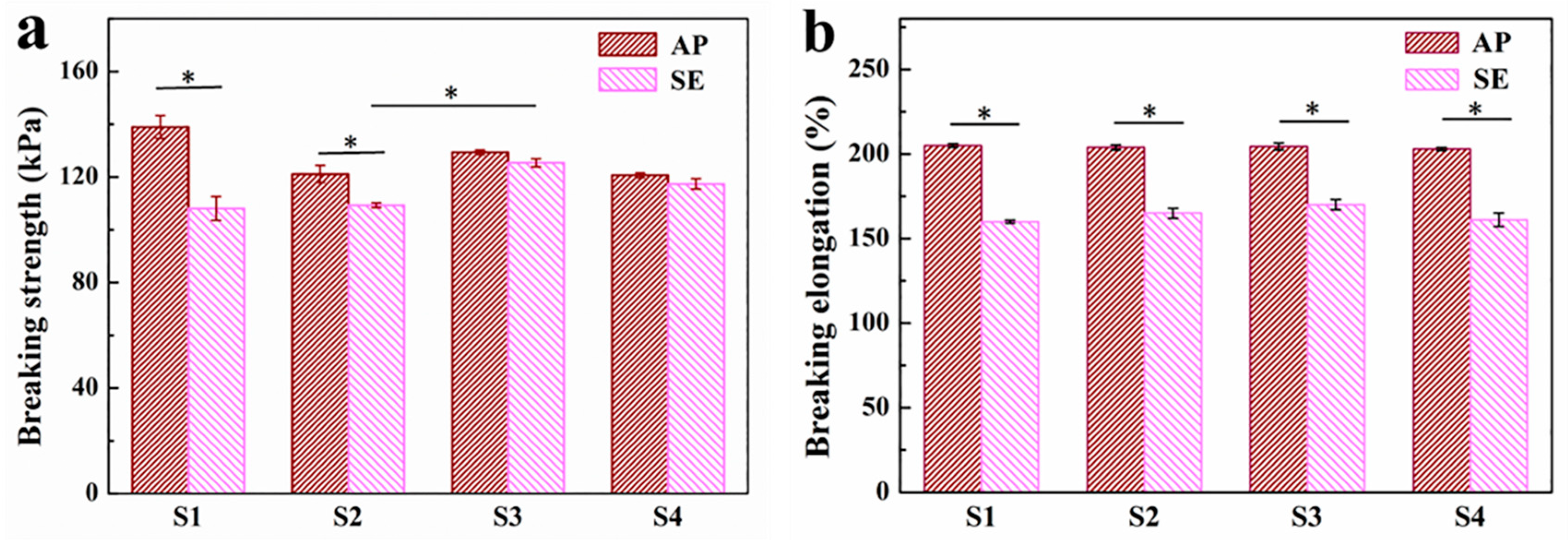

3.2. Tensile Strength of the Ca Alginate/Polyacrylamide Hydrogel

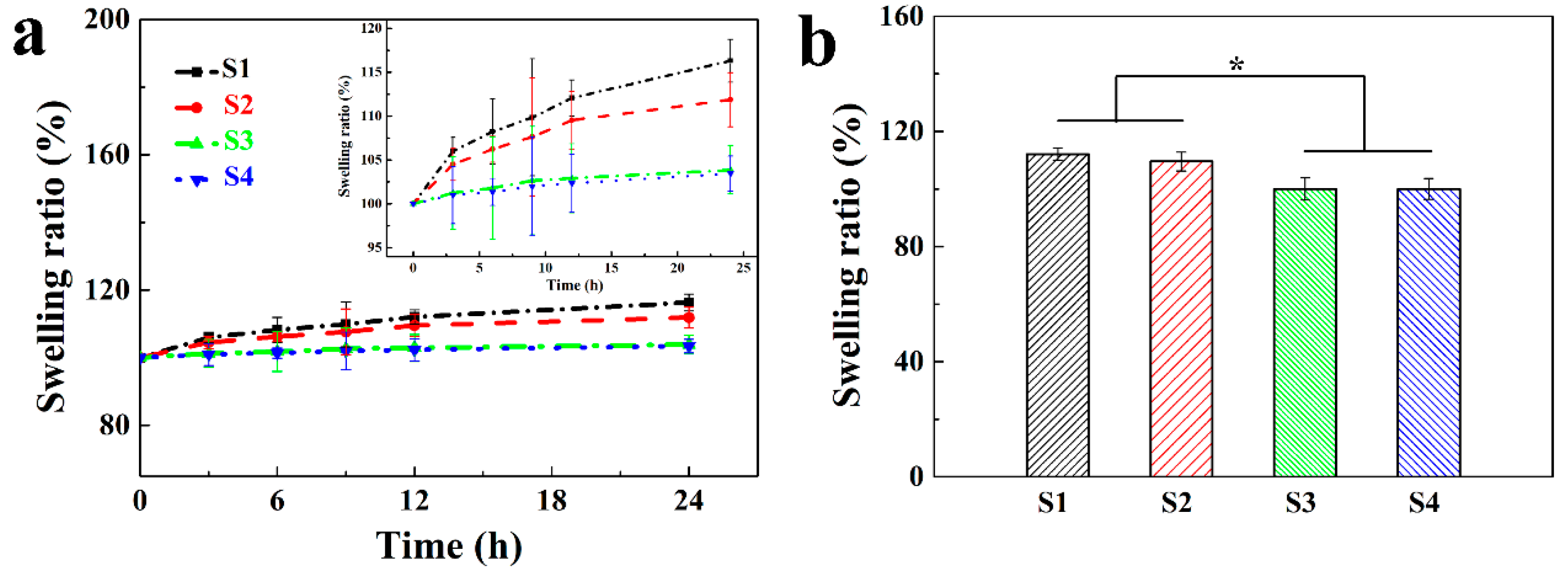

3.3. Volume Swellability of the Ca Alginate/Polyacrylamide Hydrogel

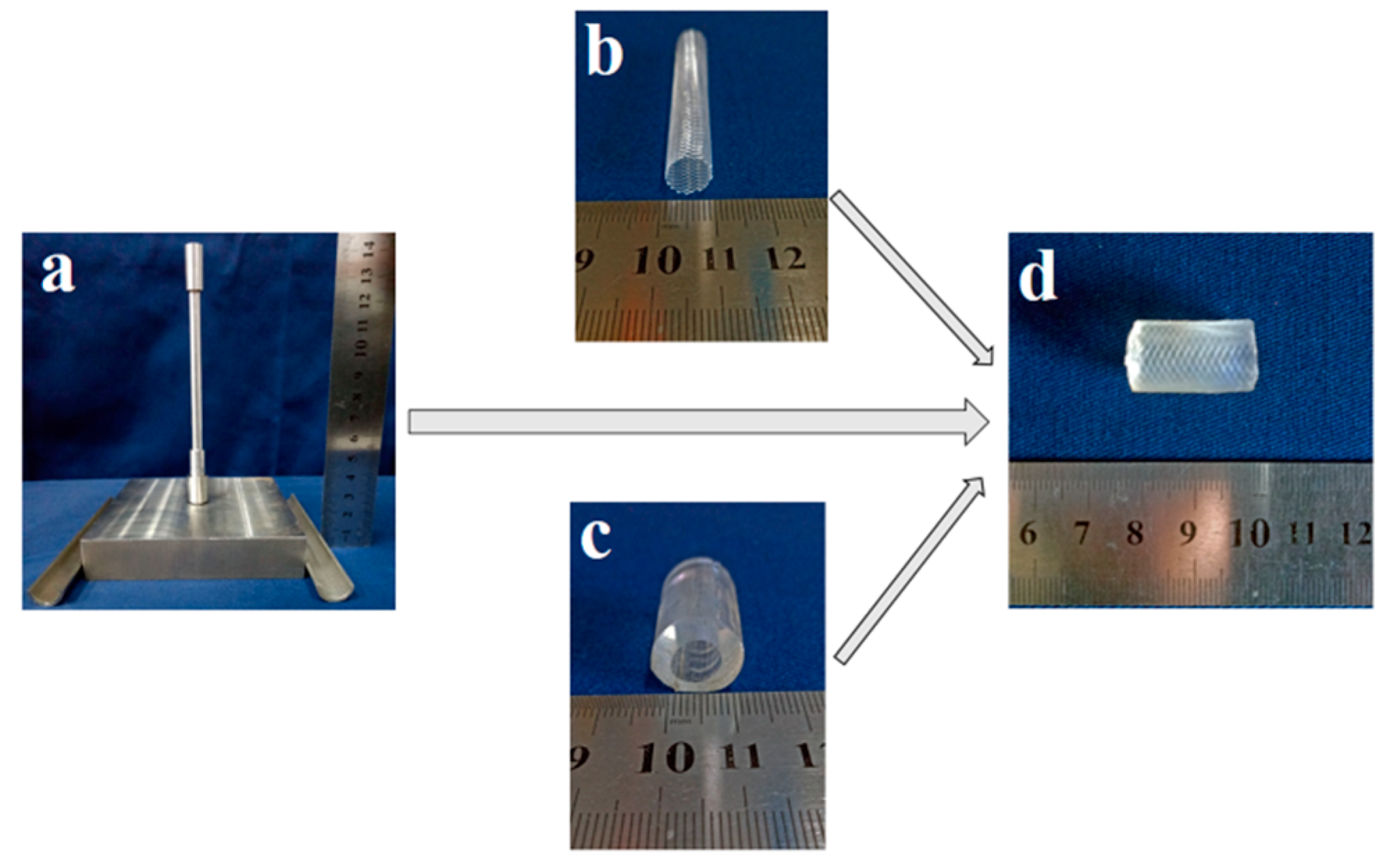

3.4. Fabrication of Strut-Reinforced Hydrogel Vascular Grafts

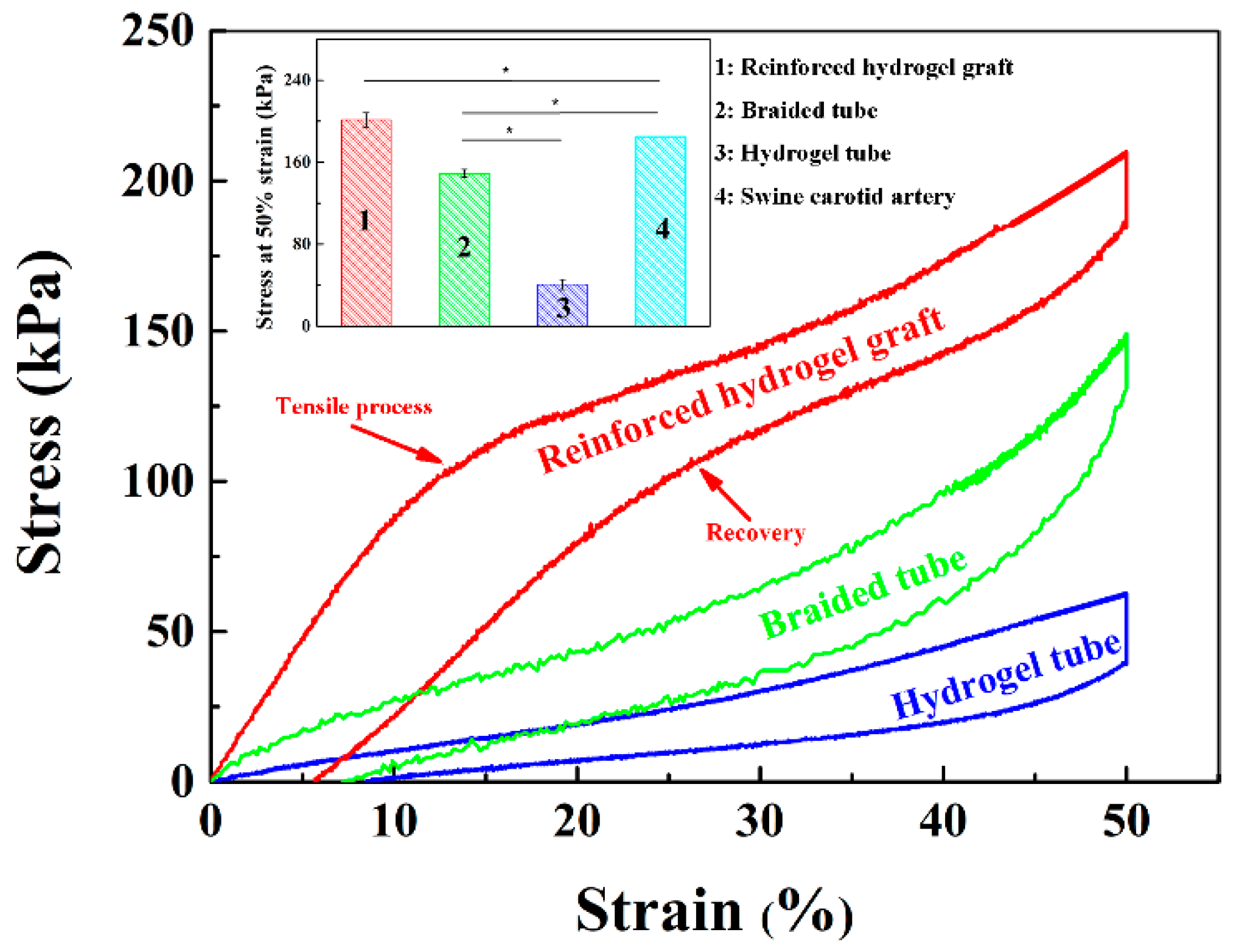

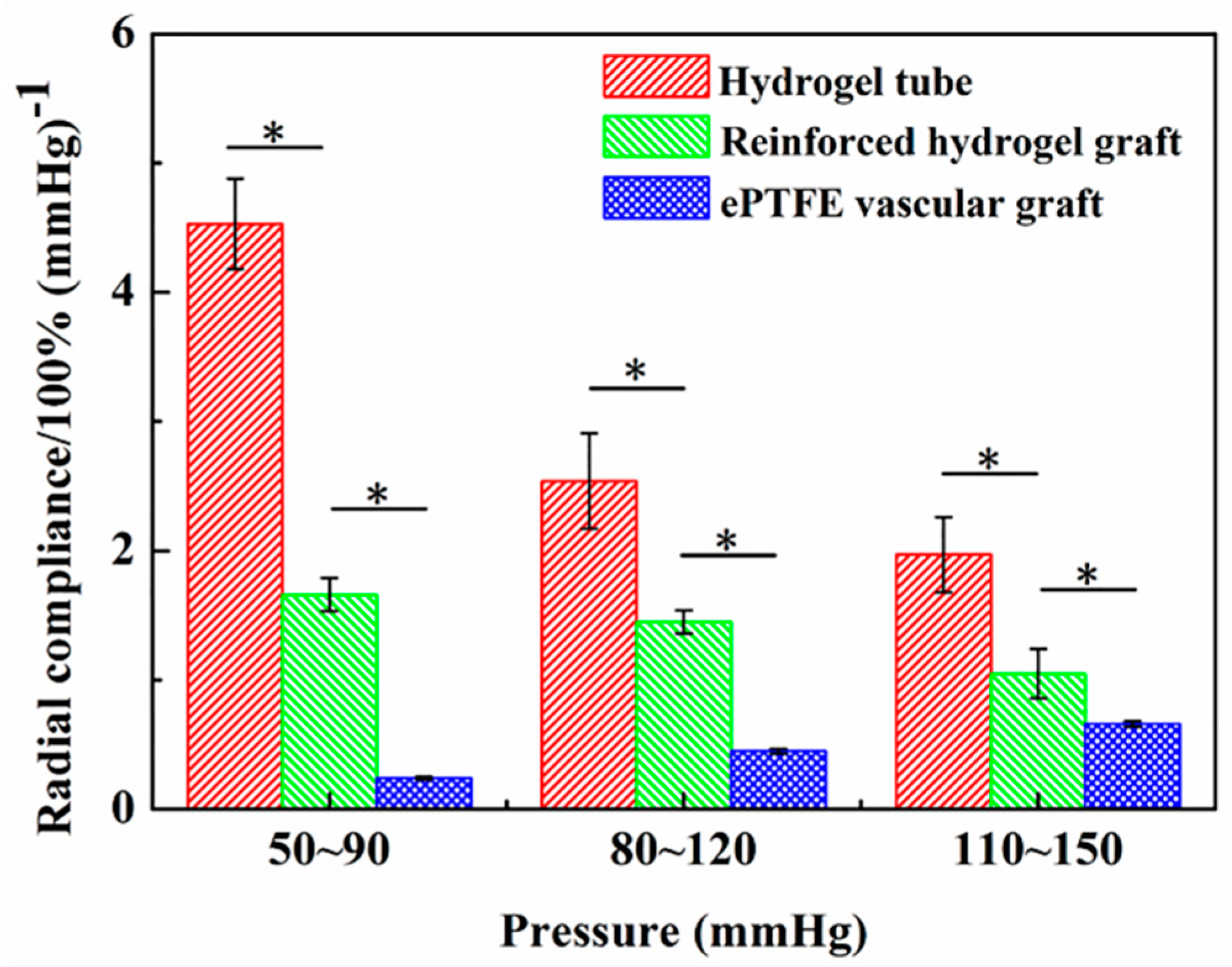

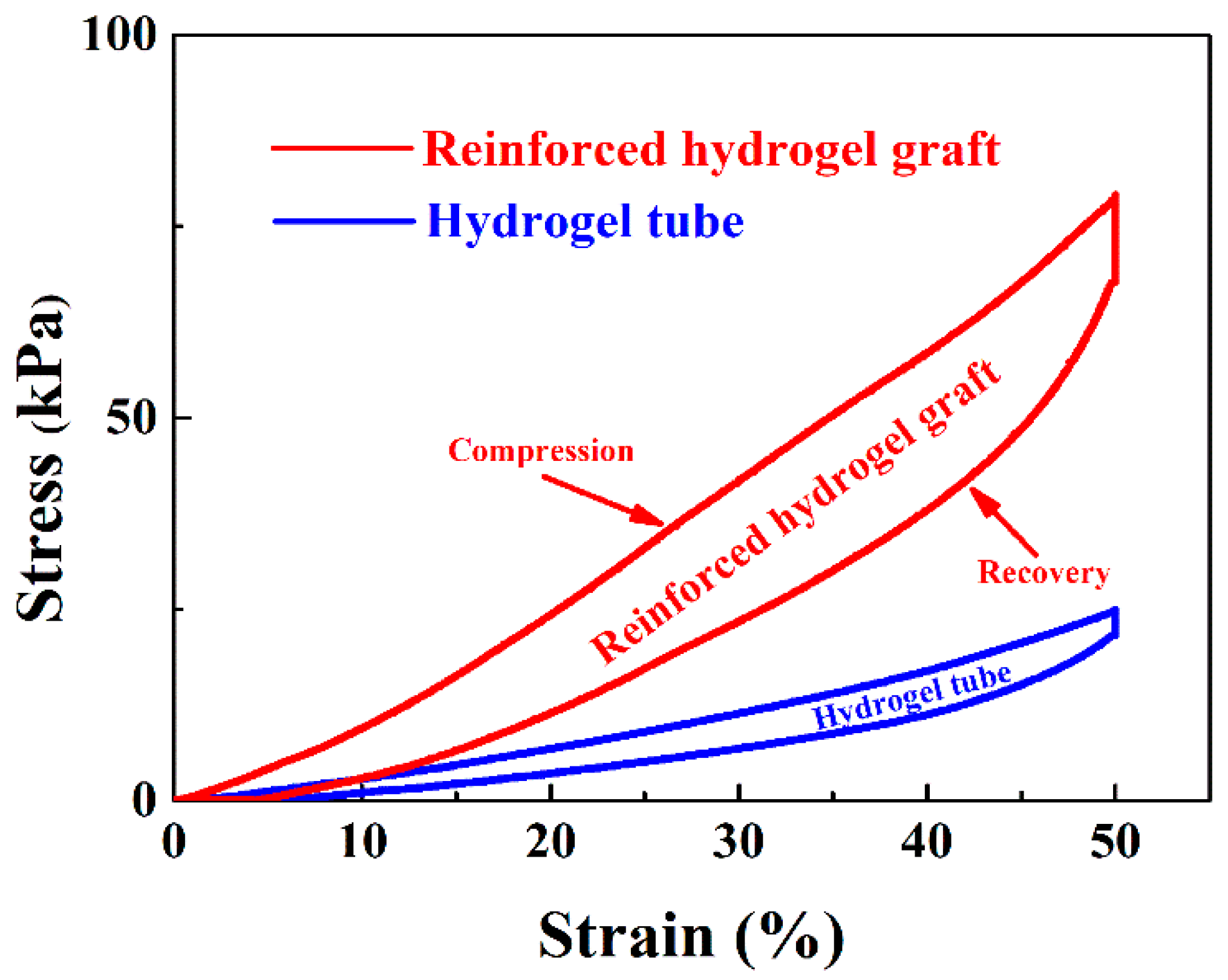

3.5. Mechanical Properties of the Strut-Reinforced Hydrogel Grafts

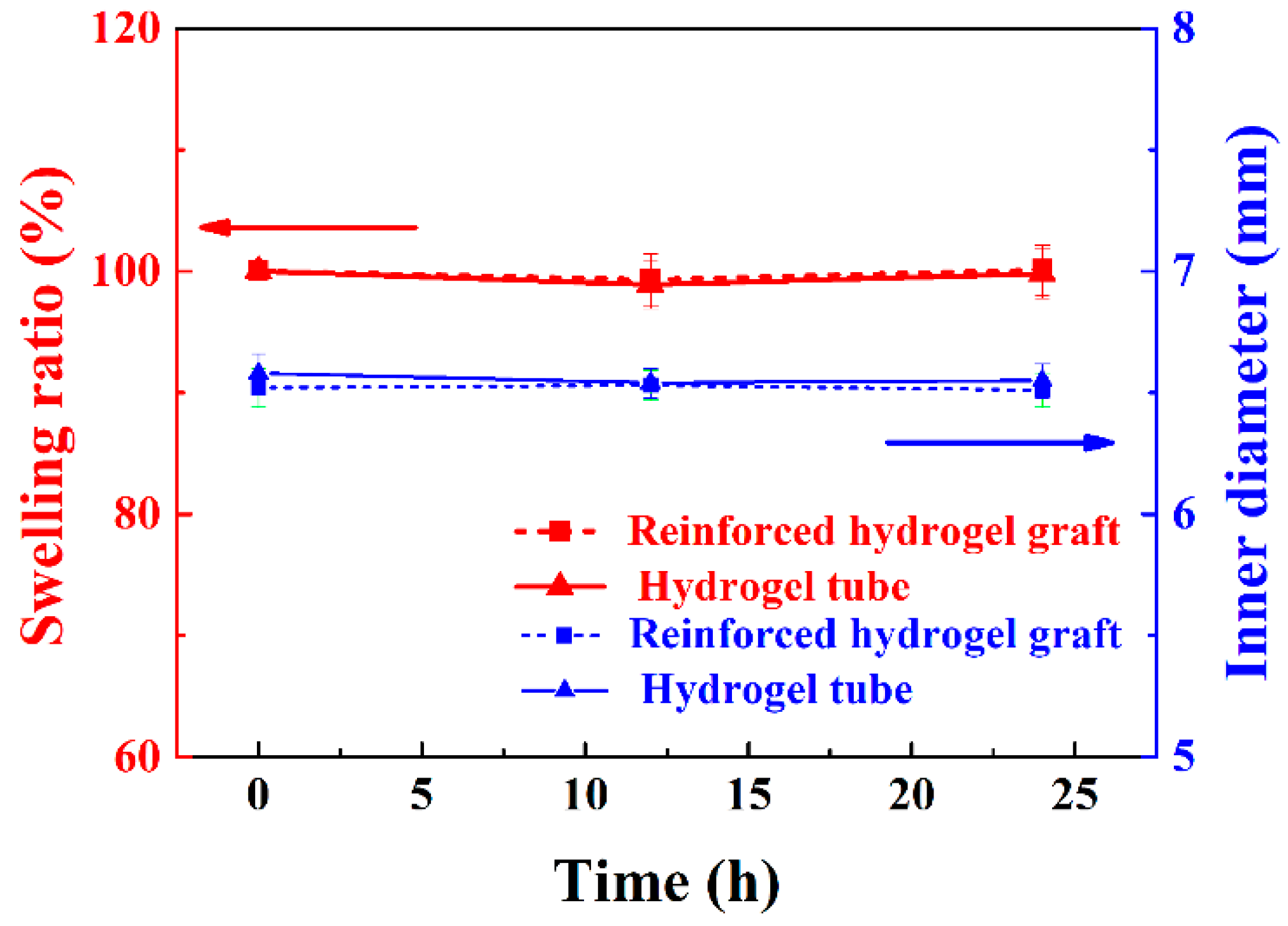

3.6. Swellability of the Strut-Reinforced Vascular Grafts

3.7. In Vitro Cellular Viability of the Strut-Reinforced Vascular Grafts

3.8. Hemolysis Percentage of the Reinforced Graft

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chou, R.; Dana, T.; Blazina, I.; Daeges, M.; Jeanne, T.L. Statins for Prevention of Cardiovascular Disease in Adults Evidence Report and Systematic Review for the US Preventive Services Task Force. J. Am. Med. Assoc. 2016, 316, 2008–2024. [Google Scholar] [CrossRef] [PubMed]

- Roger, V.L.; Go, A.S.; Lloyd-Jones, D.M.; Adams, R.J.; Berry, J.D.; Brown, T.M.; Carnethon, M.R.; Dai, S.F.; de Simone, G.; Ford, E.S.; et al. Executive Summary: Heart Disease and Stroke Statistics-2011 Update a Report from the American Heart Association. Circulation 2011, 123, 459–463. [Google Scholar] [CrossRef]

- Seifu, D.G.; Purnama, A.; Mequanint, K.; Mantovani, D. Small-diameter vascular tissue engineering. Nat. Rev. Cardiol. 2013, 10, 410–421. [Google Scholar] [CrossRef] [PubMed]

- Veith, F.J.; Gupta, S.K.; Ascer, E.; Whiteflores, S.; Samson, R.H.; Scher, L.A.; Towne, J.B.; Bernhard, V.M.; Bonier, P.; Flinn, W.R.; et al. Six-year prospective multicenter randomized comparison of autologous saphenous vein and expanded polytetrafluoroethylene grafts in infrainguinal arterial reconstructions. J. Vasc. Surg. 1986, 3, 104–114. [Google Scholar] [CrossRef]

- Zilla, P.; Bezuidenhout, D.; Human, P. Prosthetic vascular grafts: Wrong models, wrong questions and no healing. Biomaterials 2007, 28, 5009–5027. [Google Scholar] [CrossRef] [PubMed]

- Nomi, M.; Atala, A.; De Coppi, P.; Soker, S. Principals of neovascularization for tissue engineering. Mol. Asp. Med. 2002, 23, 463–483. [Google Scholar] [CrossRef]

- Alexandre, N.; Amorim, I.; Caseiro, A.R.; Pereira, T.; Alvites, R.; Rema, A.; Goncalves, A.; Valadares, G.; Costa, E.; Santos-Silva, A.; et al. Long term performance evaluation of small-diameter vascular grafts based on polyvinyl alcohol hydrogel and dextran and MSCs-based therapies using the ovine pre-clinical animal model. Int. J. Pharm. 2016, 513, 332–346. [Google Scholar] [CrossRef]

- Heath, D.E. Promoting Endothelialization of Polymeric Cardiovascular Biomaterials. Macromol. Chem. Phys. 2017, 218, 10. [Google Scholar] [CrossRef]

- Schmedlen, R.H.; Elbjeirami, W.M.; Gobin, A.S.; West, J.L. Tissue engineered small-diameter vascular grafts. Clin. Plast. Surg. 2003, 30, 507–517. [Google Scholar] [CrossRef]

- Langer, R.; Vacanti, J.P. Tissue engineering. Science 1993, 260, 920–926. [Google Scholar] [CrossRef]

- Cai, Q.; Yang, J.A.; Bei, J.Z.; Wang, S.G. A novel porous cells scaffold made of polylactide-dextran blend by combining phase-separation and particle-leaching techniques. Biomaterials 2002, 23, 4483–4492. [Google Scholar] [CrossRef]

- Lee, S.J.; Lee, D.; Yoon, T.R.; Kim, H.K.; Jo, H.H.; Park, J.S.; Lee, J.H.; Kim, W.D.; Kwon, I.K.; Park, S.A. Surface modification of 3D-printed porous scaffolds via mussel-inspired polydopamine and effective immobilization of rhBMP-2 to promote osteogenic differentiation for bone tissue engineering. Acta Biomater. 2016, 40, 182–191. [Google Scholar] [CrossRef]

- Moghadam, M.Z.; Hassanajili, S.; Esmaeilzadeh, F.; Ayatollahi, M.; Ahmadi, M. Formation of porous HPCL/LPCL/HA scaffolds with supercritical CO2 gas foaming method. J. Mech. Behav. Biomed. 2017, 69, 115–127. [Google Scholar] [CrossRef] [PubMed]

- Badylak, S.F. The extracellular matrix as a biologic scaffold material. Biomaterials 2007, 28, 3587–3593. [Google Scholar] [CrossRef]

- Shin, Y.M.; Lee, Y.B.; Kim, S.J.; Kang, J.K.; Park, J.C.; Jang, W.; Shin, H. Mussel-Inspired Immobilization of Vascular Endothelial Growth Factor (VEGF) for Enhanced Endothelialization of Vascular Grafts. Biomacromolecules 2012, 13, 2020–2028. [Google Scholar] [CrossRef] [PubMed]

- Antonova, L.V.; Sevostyanova, V.V.; Kutikhin, A.G.; Mironov, A.V.; Krivkina, E.O.; Shabaev, A.R.; Matveeva, V.G.; Velikanova, E.A.; Sergeeva, E.A.; Burago, A.Y.; et al. Vascular Endothelial Growth Factor Improves Physico-Mechanical Properties and Enhances Endothelialization of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/Poly(epsilon-caprolactone) Small-Diameter Vascular Grafts In vivo. Front. Pharmacol. 2016, 7, 8. [Google Scholar] [CrossRef] [PubMed]

- Calvert, P. Hydrogels for Soft Machines. Adv. Mater. 2009, 21, 743–756. [Google Scholar] [CrossRef]

- Kwon, H.J.; Yasuda, K.; Gong, J.P.; Ohmiya, Y. Polyelectrolyte hydrogels for replacement and regeneration of biological tissues. Macromol. Res. 2014, 22, 227–235. [Google Scholar] [CrossRef]

- Drury, J.L.; Mooney, D.J. Hydrogels for tissue engineering: Scaffold design variables and applications. Biomaterials 2003, 24, 4337–4351. [Google Scholar] [CrossRef]

- Lee, K.Y.; Mooney, D.J. Hydrogels for tissue engineering. Chem. Rev. 2001, 101, 1869–1879. [Google Scholar] [CrossRef]

- Ghobril, C.; Grinstaff, M.W. The chemistry and engineering of polymeric hydrogel adhesives for wound closure: A tutorial. Chem. Soc. Rev. 2015, 44, 1820–1835. [Google Scholar] [CrossRef]

- Billiet, T.; Vandenhaute, M.; Schelfhout, J.; Van Vlierberghe, S.; Dubruel, P. A review of trends and limitations in hydrogel-rapid prototyping for tissue engineering. Biomaterials 2012, 33, 6020–6041. [Google Scholar] [CrossRef]

- Bryant, S.J.; Vernerey, F.J. Programmable Hydrogels for Cell Encapsulation and Neo-Tissue Growth to Enable Personalized Tissue Engineering. Adv. Healthc. Mater. 2018, 7, 13. [Google Scholar] [CrossRef]

- Dou, X.Q.; Feng, C.L. Amino Acids and Peptide-Based Supramolecular Hydrogels for Three-Dimensional Cell Culture. Adv. Mater. 2017, 29, 21. [Google Scholar] [CrossRef]

- Seliktar, D. Designing Cell-Compatible Hydrogels for Biomedical Applications. Science 2012, 336, 1124–1128. [Google Scholar] [CrossRef]

- Browning, M.B.; Guiza, V.; Russell, B.; Rivera, J.; Cereceres, S.; Hook, M.; Hahn, M.S.; Cosgriff-Hernandez, E.M. Endothelial Cell Response to Chemical, Biological, and Physical Cues in Bioactive Hydrogels. Tissue Eng. Part A 2014, 20, 3130–3141. [Google Scholar] [CrossRef]

- Fan, M.; Ma, Y.; Tan, H.P.; Jia, Y.; Zou, S.Y.; Guo, S.X.; Zhao, M.; Huang, H.; Ling, Z.H.; Chen, Y.; et al. Covalent and injectable chitosan-chondroitin sulfate hydrogels embedded with chitosan microspheres for drug delivery and tissue engineering. Mat. Sci. Eng. C-Mater. 2017, 71, 67–74. [Google Scholar] [CrossRef]

- Alexandre, N.; Ribeiro, J.; Gartner, A.; Pereira, T.; Amorim, I.; Fragoso, J.; Lopes, A.; Fernandes, J.; Costa, E.; Santos-Silva, A.; et al. Biocompatibility and hemocompatibility of polyvinyl alcohol hydrogel used for vascular grafting—In vitro and in vivo studies. J. Biomed. Mater. Res. A 2014, 102, 4262–4275. [Google Scholar] [CrossRef]

- Sun, J.Y.; Zhao, X.H.; Illeperuma, W.R.K.; Chaudhuri, O.; Oh, K.H.; Mooney, D.J.; Vlassak, J.J.; Suo, Z.G. Highly stretchable and tough hydrogels. Nature 2012, 489, 133–136. [Google Scholar] [CrossRef]

- Kamata, H.; Akagi, Y.; Kayasuga-Kariya, Y.; Chung, U.; Sakai, T. “Nonswellable” Hydrogel without Mechanical Hysteresis. Science 2014, 343, 873–875. [Google Scholar] [CrossRef]

- Darnell, M.C.; Sun, J.Y.; Mehta, M.; Johnson, C.; Arany, P.R.; Suo, Z.G.; Mooney, D.J. Performance and biocompatibility of extremely tough alginate/polyacrylamide hydrogels. Biomaterials 2013, 34, 8042–8048. [Google Scholar] [CrossRef]

- Yang, C.H.; Wang, M.X.; Haider, H.; Yang, J.H.; Sun, J.Y.; Chen, Y.M.; Zhou, J.X.; Suo, Z.G. Strengthening Alginate/Polyacrylamide Hydrogels Using Various Multivalent Cations. ACS Appl. Mater. Interfaces 2013, 5, 10418–10422. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Zhang, G.P.; Sun, R.; Wong, C.P. Mechanical strengthened alginate/polyacrylamide hydrogel crosslinked by barium and ferric dual ions. J. Mater. Sci. 2017, 52, 8538–8545. [Google Scholar] [CrossRef]

- Li, Y.L.; Wang, C.X.; Zhang, W.; Yin, Y.J.; Rao, Q.Q. Preparation and Characterization of PAM/SA Tough Hydrogels Reinforced by IPN Technique Based on Covalent/Ionic Crosslinking. J. Appl. Polym. Sci. 2015, 132, 7. [Google Scholar] [CrossRef]

- Yang, X.Y.; Wang, L.; Guan, G.P.; Zhang, H.Q.; Shen, G.T.; Guan, Y.; Peng, L.; Li, Y.L.; King, M.W. Mechanical and biocompatibility performance of bicomponent polyester/silk fibroin small-diameter arterial prostheses. J. Appl. Biomater. Funct. 2015, 13, E201–E209. [Google Scholar] [CrossRef]

- Zou, T.; Wang, L.; Li, W.C.; Wang, W.Z.; Chen, F.; King, M.W. A resorbable bicomponent braided ureteral stent with improved mechanical performance. J. Mech. Behav. Biomed. 2014, 38, 17–25. [Google Scholar] [CrossRef] [PubMed]

- Ren, Z.C.; Chen, G.Y.; Wei, Z.Y.; Sang, L.; Qi, M. Hemocompatibility evaluation of polyurethane film with surface-grafted poly(ethylene glycol) and carboxymethyl-chitosan. J. Appl. Polym. Sci. 2013, 127, 308–315. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Wang, S.G.; Guo, Q.S.; Shen, M.W.; Shi, X.Y. Hemocompatibility of electrospun halloysite nanotube- and carbon nanotube-doped composite poly(lactic-co-glycolic acid) nanofibers. J. Appl. Polym. Sci. 2013, 127, 4825–4832. [Google Scholar] [CrossRef]

- He, Q.J.; Zhang, J.M.; Shi, J.L.; Zhu, Z.Y.; Zhang, L.X.; Bu, W.B.; Guo, L.M.; Chen, Y. The effect of PEGylation of mesoporous silica nanoparticles on nonspecific binding of serum proteins and cellular responses. Biomaterials 2010, 31, 1085–1092. [Google Scholar] [CrossRef]

- Lin, Y.S.; Haynes, C.L. Synthesis and Characterization of Biocompatible and Size-Tunable Multifunctional Porous Silica Nanoparticles. Chem. Mater. 2009, 21, 3979–3986. [Google Scholar] [CrossRef]

- Hiob, M.A.; She, S.; Muiznieks, L.D.; Weiss, A.S. Biomaterials and Modifications in the Development of Small-Diameter Vascular Grafts. ACS Biomater. Sci. Eng. 2017, 3, 712–723. [Google Scholar] [CrossRef]

- Shen, G.; Zhang, W.; Lin, J.; Wang, L. Effects of testing conditions on radial compliance of textile vascular prostheses. J. Med. Biomech. 2014, 29, 113–118. [Google Scholar]

- Zeugolis, D.I.; Khew, S.T.; Yew, E.S.Y.; Ekaputra, A.K.; Tong, Y.W.; Yung, L.Y.L.; Hutmacher, D.W.; Sheppard, C.; Raghunath, M. Electro-spinning of pure collagen nano-fibres—Just an expensive way to make gelatin? Biomaterials 2008, 29, 2293–2305. [Google Scholar] [CrossRef]

- Xie, Y.; Guan, Y.; Kim, S.H.; King, M.W. The mechanical performance of weft-knitted/electrospun bilayer small diameter vascular prostheses. J. Mech. Behav. Biomed. 2016, 61, 410–418. [Google Scholar] [CrossRef] [PubMed]

- Nottelet, B.; Pektok, E.; Mandracchia, D.; Tille, J.C.; Walpoth, B.; Gurny, R.; Moller, M. Factorial design optimization and in vivo feasibility of poly(epsilon-caprolactone)-micro- and narofiber-based small diameter vascular grafts. J. Biomed. Mater. Res. A 2009, 89A, 865–875. [Google Scholar] [CrossRef] [PubMed]

- Kong, X.Y.; Han, B.Q.; Wang, H.X.; Li, H.; Xu, W.H.; Liu, W.S. Mechanical properties of biodegradable small-diameter chitosan artificial vascular prosthesis. J. Biomed. Mater. Res. A 2012, 100A, 1938–1945. [Google Scholar] [CrossRef] [PubMed]

- Tang, J.Y.; Bao, L.H.; Li, X.; Chen, L.; Hong, F.F. Potential of PVA-doped bacterial nano-cellulose tubular composites for artificial blood vessels. J. Mater. Chem. B 2015, 3, 8537–8547. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, X.X.; Wang, H.Y.; Li, F.B.; Li, M.Q.; Yang, K.; Zhang, E.L. The antibacterial properties and biocompatibility of a Ti-Cu sintered alloy for biomedical application. Biomed. Mater. 2014, 9, 11. [Google Scholar] [CrossRef] [PubMed]

- Deng, J.; Cheng, C.; Teng, Y.Y.; Nie, C.X.; Zhao, C.S. Mussel-inspired post-heparinization of a stretchable hollow hydrogel tube and its potential application as an artificial blood vessel. Polym. Chem. 2017, 8, 2266–2275. [Google Scholar] [CrossRef]

- Li, L.H.; Tu, M.; Mou, S.S.; Zhou, C.G. Preparation and blood compatibility of polysiloxane/liquid-crystal composite membranes. Biomaterials 2001, 22, 2595–2599. [Google Scholar] [CrossRef]

- Mercado-Pagan, A.E.; Stahl, A.M.; Shanjani, Y.; Yang, Y.Z. Vascularization in Bone Tissue Engineering Constructs. Ann. Biomed. Eng. 2015, 43, 718–729. [Google Scholar] [CrossRef] [PubMed]

| Number | Braiding Angle (°) | Diameter Reduction Rate (%) |

|---|---|---|

| 1 | 50 ± 0.5 | 26.52 ± 0.64 |

| 2 | 55 ± 0.5 | 18.73 ± 0.68 |

| 3 | 60 ± 0.5 | 7.98 ± 0.22 |

| S3 | / | 18.14 ± 0.94 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, G.; Yu, C.; Xing, M.; Wu, Y.; Hu, X.; Wang, H.; Wang, L. Hydrogel Small-Diameter Vascular Graft Reinforced with a Braided Fiber Strut with Improved Mechanical Properties. Polymers 2019, 11, 810. https://doi.org/10.3390/polym11050810

Guan G, Yu C, Xing M, Wu Y, Hu X, Wang H, Wang L. Hydrogel Small-Diameter Vascular Graft Reinforced with a Braided Fiber Strut with Improved Mechanical Properties. Polymers. 2019; 11(5):810. https://doi.org/10.3390/polym11050810

Chicago/Turabian StyleGuan, Guoping, Chenglong Yu, Meiyi Xing, Yufen Wu, Xingyou Hu, Hongjun Wang, and Lu Wang. 2019. "Hydrogel Small-Diameter Vascular Graft Reinforced with a Braided Fiber Strut with Improved Mechanical Properties" Polymers 11, no. 5: 810. https://doi.org/10.3390/polym11050810

APA StyleGuan, G., Yu, C., Xing, M., Wu, Y., Hu, X., Wang, H., & Wang, L. (2019). Hydrogel Small-Diameter Vascular Graft Reinforced with a Braided Fiber Strut with Improved Mechanical Properties. Polymers, 11(5), 810. https://doi.org/10.3390/polym11050810