Comparison on the Aging of Woods Exposed to Natural Sunlight and Artificial Xenon Light

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Natural Sunlight Weathering

2.3. Artificial Xenon Light Weathering

2.4. Colorimetric Analysis

2.5. ATR-FTIR Analysis

3. Results and Discussion

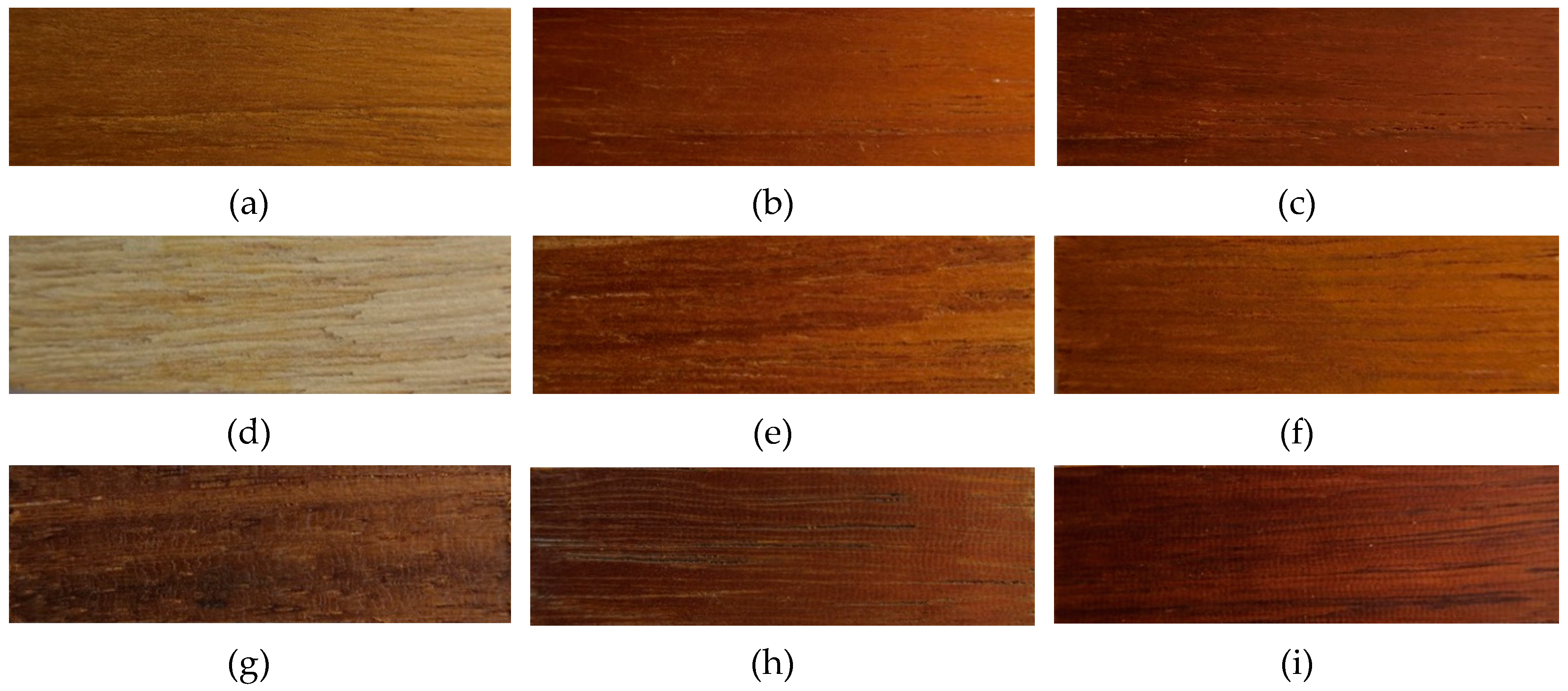

3.1. Visual Observation

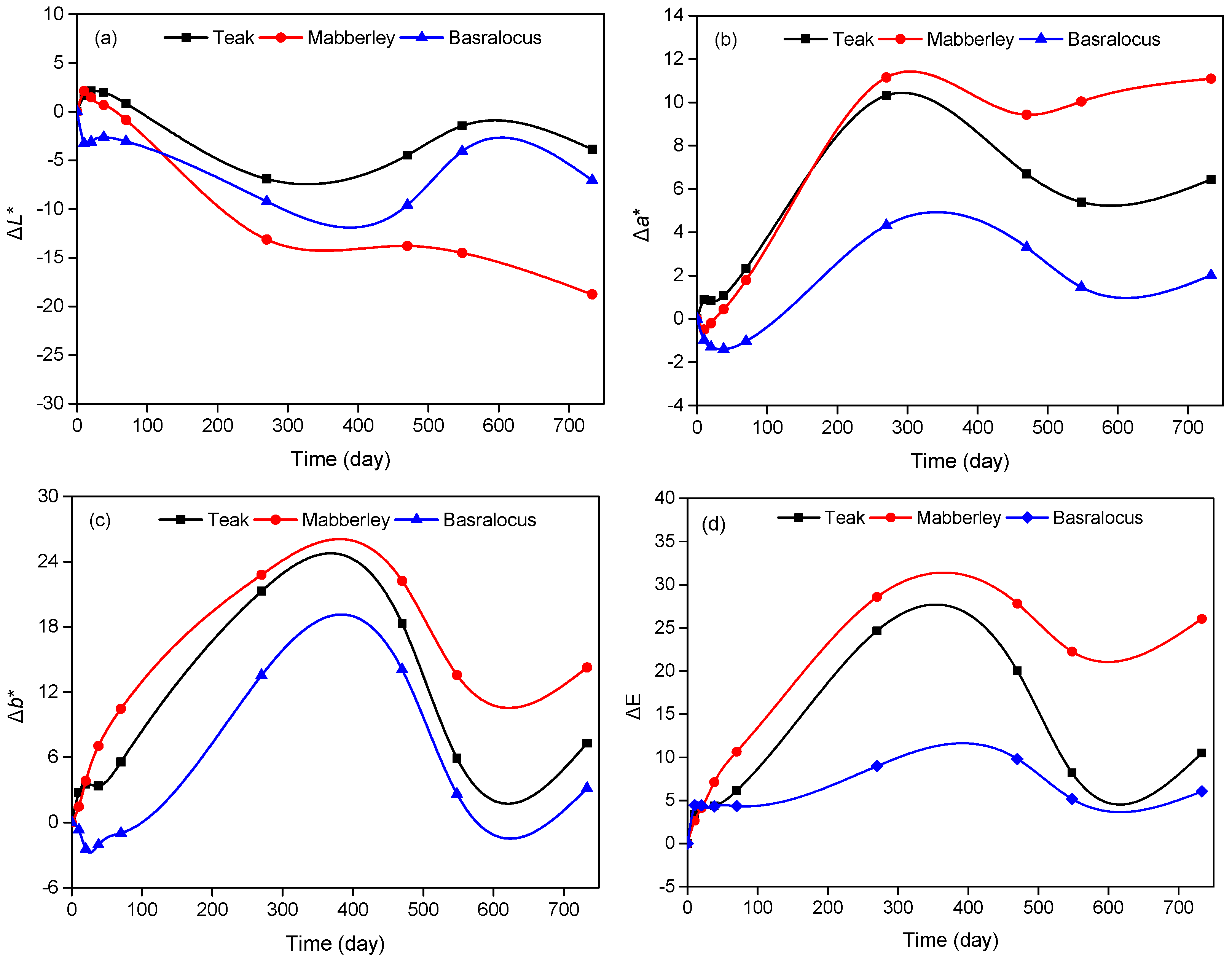

3.2. Natural Sunlight Weathering

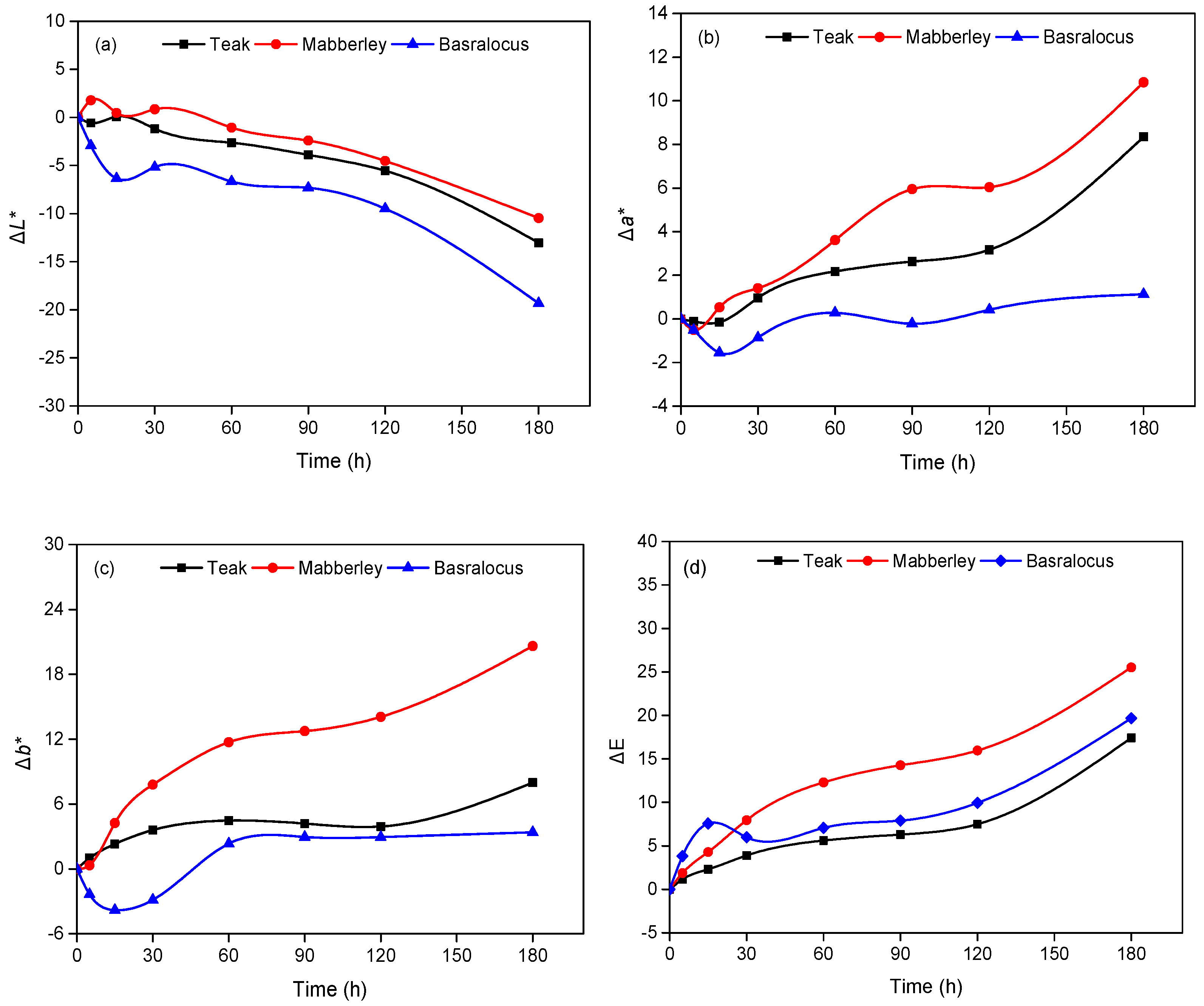

3.3. Artificial Xenon Light Weathering

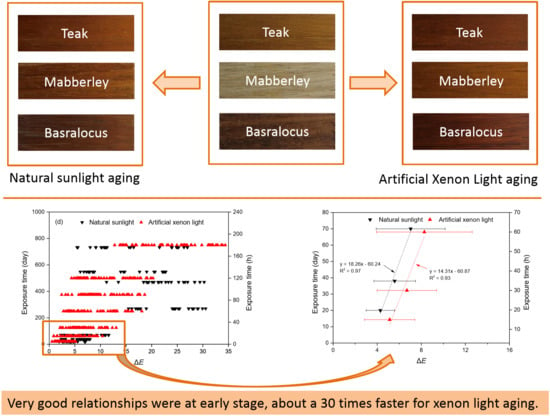

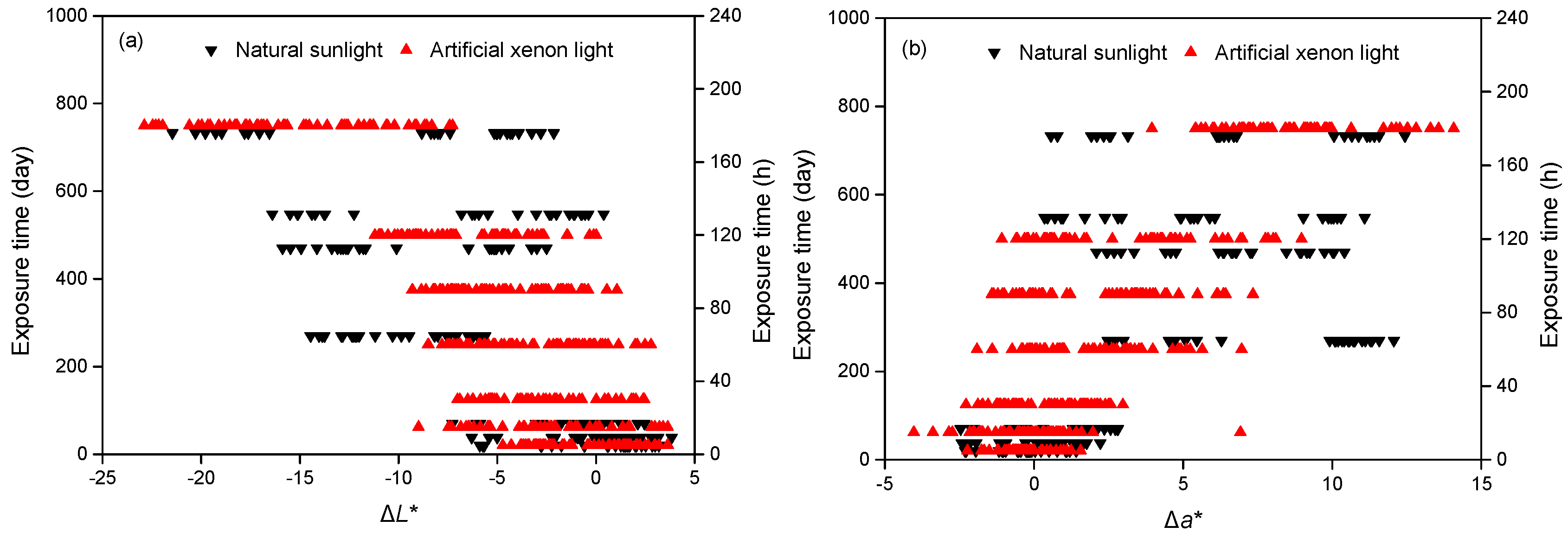

3.4. Correlation between Natural Sunlight and Artificial Xenon Light

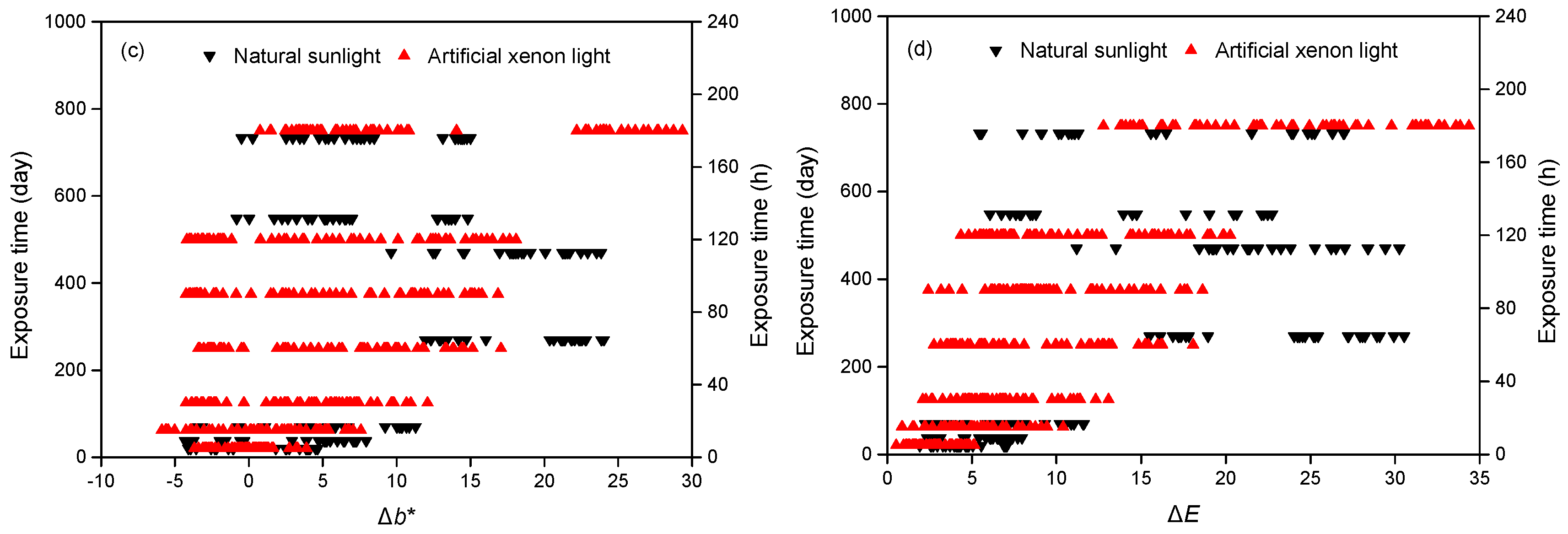

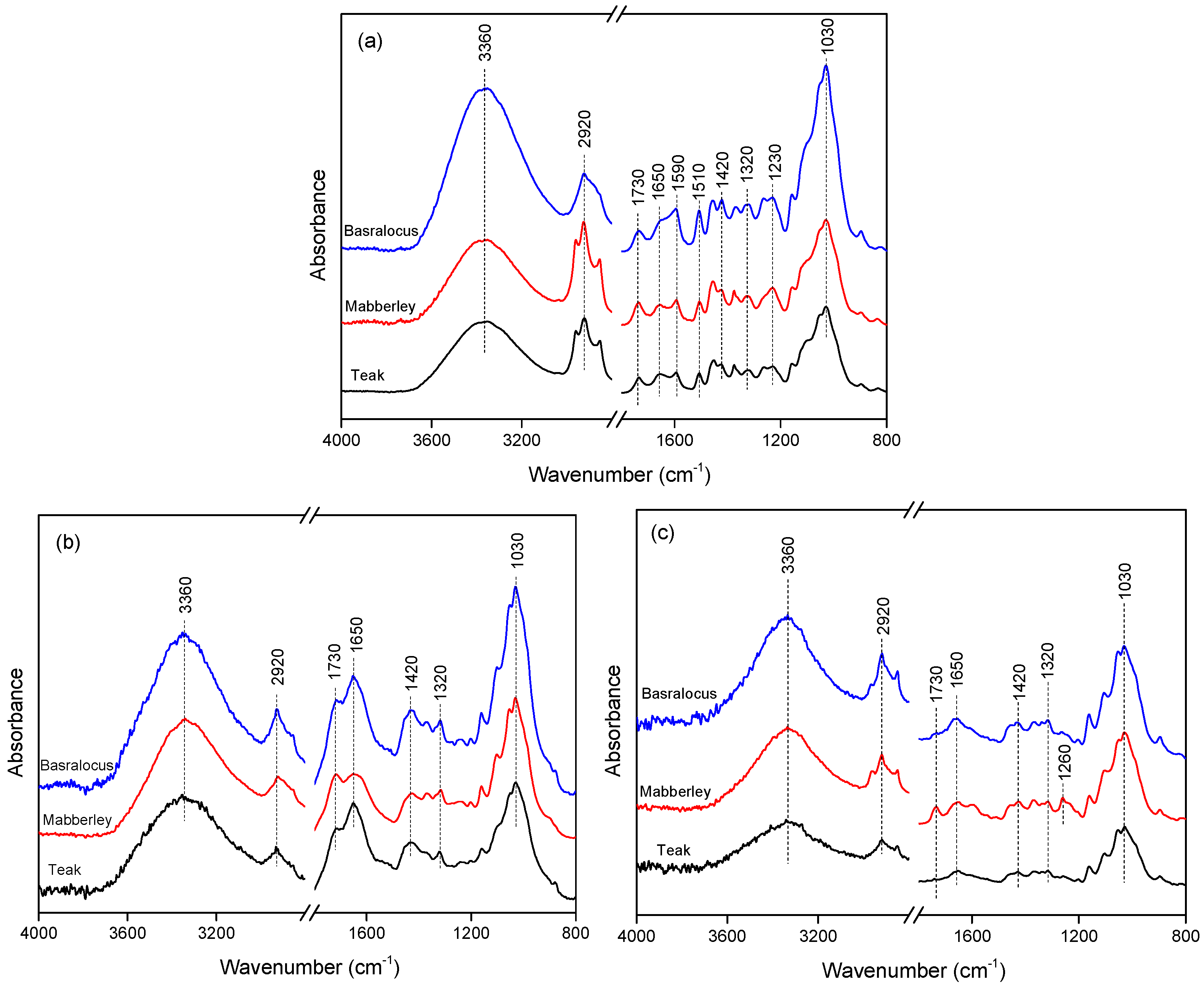

3.5. Surface Chemical Changes

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rosu, D.; Teaca, C.A.; Bodirlau, R.; Rosu, L. FTIR and color change of the modified wood as a result of artificial light irradiation. J. Photochem. Photobiol. B Biol. 2010, 99, 144–149. [Google Scholar] [CrossRef]

- Sun, Q.; Lu, Y.; Zhang, H.; Zhao, H.; Yu, H.; Xu, J.; Fu, Y.; Yang, D.; Liu, Y. Hydrothermal fabrication of rutile TiO2 submicrospheres on wood surface: An efficient method to prepare UV-protective wood. Mater. Chem. Phys. 2012, 133, 253–258. [Google Scholar] [CrossRef]

- Kalita, K.; Das, N.; Boruah, P.K.; Sarma, U. Development of a strain measurement system for the study of effect of relative humidity on wood. Measurement 2016, 94, 265–272. [Google Scholar] [CrossRef]

- Grüll, G.; Forsthuber, B.; Tscherne, F.; Spitaler, I. Weathering indicator for artificial and natural weathering of wood coatings. Eur. J. Wood Prod. 2014, 72, 681–684. [Google Scholar] [CrossRef]

- Deka, M.; Humar, M.; Rep, G.; Kričej, B.; Šentjurc, M.; Petrič, M. Effects of UV light irradiation on colour stability of thermally modified, copper ethanolamine treated and non-modified wood: EPR and DRIFT spectroscopic studies. Wood Sci. Technol. 2008, 42, 5–20. [Google Scholar] [CrossRef]

- Muller, U.; Ratzsch, M.; Schwanninger, M.; Steiner, M.; Zobi, H. Yellowing and IR changes of spruce wood as a result of UV-irradiation. J. Photochem. Photobiol. B Biol. 2003, 69, 97–105. [Google Scholar] [CrossRef]

- Evans, P.D.; Thay, P.D.; Schmalzl, K.J. Degradation of wood surfaces during natural weathering. Effects on lignin and cellulose and on the adhesion of acrylic latex primers. Wood Sci. Technol. 1996, 30, 411–422. [Google Scholar] [CrossRef]

- Persze, L.; Tolvaj, L. Photodegradation of wood at elevated temperature: Colour change. J. Photochem. Photobiol. B Biol. 2012, 108, 44–47. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Kocaefe, D.; Kocaefe, Y.; Boluk, Y.; Pichette, A. Study of the degradation behavior of heat-treated jack pine (Pinus banksiana) under artificial sunlight irradiation. Polym. Degrad. Stab. 2012, 97, 1197–1214. [Google Scholar] [CrossRef]

- Srinivas, K.; Pandey, K.K. Photodegradation of thermally modified wood. J. Photochem. Photobiol. B Biol. 2012, 117, 140–145. [Google Scholar] [CrossRef]

- George, B.; Suttie, E.; Merlin, A.; Deglise, X. Photodegradation and photostabilisation of wood-the state of the art. Polym. Degrad. Stab. 2005, 88, 268–274. [Google Scholar] [CrossRef]

- Salaita, G.N.; Ma, F.M.S.; Parker, T.C.; Hoflund, G.B. Weathering properties of treated southern yellow pine wood examined by X-ray photoelectron spectroscopy, scanning electron microscopy and physical characterization. Appl. Surf. Sci. 2008, 254, 3925–3934. [Google Scholar] [CrossRef]

- Bryne, L.E.; Wålinder, M.E.P. Ageing of modified wood. Part 1: Wetting properties of acetylated, furfurylated, and thermally modified wood. Holzforschung 2010, 64, 295–304. [Google Scholar] [CrossRef]

- Ayadi, N.; Lejeune, F.; Charrier, F.; Charrier, B.; Merlin, A. Colour stability of heat treated wood during artificial weathering. Holz. Roh-Werkst. 2003, 61, 221–226. [Google Scholar] [CrossRef]

- Pandey, K.K. A study of chemical structure of soft and hardwood and wood polymers by FTIR spectroscopy. J. Appl. Polym. Sci. 1999, 71, 1969–1975. [Google Scholar] [CrossRef]

- Pandey, K.K. Study of the effect of photo-irradiation on the surface chemistry of wood. Polym. Degrad. Stab. 2005, 90, 9–20. [Google Scholar] [CrossRef]

- Chang, T.C.; Chang, H.T.; Wu, C.L.; Chang, S.T. Influences of extractives on the photodegradation of wood. Polym. Degrad. Stab. 2010, 95, 516–521. [Google Scholar] [CrossRef]

- Baar, J.; Wimmer, R.; D’Amico, S. Dependence of colour and discolouration on total extractive content of African Padauk and Jatoba. Wood Sci. Technol. 2014, 48, 1155–1165. [Google Scholar] [CrossRef]

- Timar, M.C.; Varodi, A.M.; Gurău, L. Comparative study of photodegradation of six wood species after short-time UV exposure. Wood Sci. Technol. 2016, 50, 135–163. [Google Scholar] [CrossRef]

- Colom, X.; Carrillo, F.; Nogués, F.; Garriga, P. Structural analysis of photodegraded wood by means of FTIR spectroscopy. Polym. Degrad. Stab. 2003, 80, 543–549. [Google Scholar] [CrossRef]

- Wang, X.; Ren, H. Comparative study of the photo-discoloration of moso bamboo (Phyllostachys pubescens Mazel) and two wood species. Appl. Surf. Sci. 2008, 254, 7029–7034. [Google Scholar] [CrossRef]

- Tomak, E.D.; Ustaomer, D.; Yildiz, S.; Pesman, E. Changes in surface and mechanical properties of heat treated wood during natural weathering. Measurement 2014, 53, 30–39. [Google Scholar] [CrossRef]

- Liu, R.; Pang, X.; Yang, Z. Measurement of three wood materials against weathering during long natural sunlight exposure. Measurement 2017, 102, 179–185. [Google Scholar] [CrossRef]

- Tolvaj, L.; Mitsui, K. Light source dependence of the photodegradation of wood. J. Wood Sci. 2005, 51, 468–473. [Google Scholar] [CrossRef]

- Mitsui, K. Changes in color of spruce by repetitive treatment of light-irradiation and heat treatment. Holz. Roh-Werkst. 2006, 64, 243–244. [Google Scholar] [CrossRef]

- Teacă, C.A.; Roşu, D.; Bodîrlău, R.; Roşu, L. Structural changes in wood under artificial UV light irradiation determined by FTIR spectroscopy and color measurements—A brief review. Bioresources 2013, 8, 1478–1507. [Google Scholar] [CrossRef]

- International Standard, ISO 4892-2:2013(E). Plastic-Methods of Exposure to Laboratory Light Sources—Part 2: Xenon-Arc Lamps; International Organization for Standardization: Geneva, Switzerland, 2013. [Google Scholar]

- De Moura, L.F.; Hernández, R.E. Evaluation of varnish coating performance for two surfacing methods on sugar maple wood. Wood Fiber Sci. 2005, 37, 355–366. [Google Scholar]

- Peng, Y.; Liu, R.; Cao, J.; Chen, Y. Effects of UV weathering on surface properties of polypropylenecomposites reinforced with wood flour, lignin, and cellulose. Appl. Surf. Sci. 2014, 317, 385–392. [Google Scholar] [CrossRef]

- Tolvaj, L.; Varga, D. Photodegradation of timber of three hardwood species caused by different light sources. Acta Silv. Lign. Hung. 2012, 8, 145–155. [Google Scholar] [CrossRef]

- Mitsui, K.; Takada, H.; Sugiyama, M.; Hasegawa, R. Changes in the properties of light-irradiated wood with heat treatment Part 1. Effect of treatment conditions on the change in color. Holzforschung 2001, 55, 601–605. [Google Scholar] [CrossRef]

- Stark, N.M.; Matuana, L.M. Surface chemistry changes of weathered HDPE/wood-flour composites studied by XPS and FTIR spectroscopy. Polym. Degrad. Stab. 2004, 86, 1–9. [Google Scholar] [CrossRef]

- Chirkova, J.; Andersone, I.; Irbe, I.; Spince, B.; Andersons, B. Lignins as agents for bio-protection of wood. Holzforschung 2011, 65, 497–502. [Google Scholar] [CrossRef]

| Woods | Species | Density (g/cm3)* | Sources |

|---|---|---|---|

| Teak | Tectona grandis L.F. | 0.62~0.68 | Nature Flooring Industries, Inc, Foshan, China |

| Mabberley | Stereospermum colais | 0.71~0.76 | As above |

| Basralocus | Dicorynia guianensis | 0.82~0.85 | As above |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, R.; Zhu, H.; Li, K.; Yang, Z. Comparison on the Aging of Woods Exposed to Natural Sunlight and Artificial Xenon Light. Polymers 2019, 11, 709. https://doi.org/10.3390/polym11040709

Liu R, Zhu H, Li K, Yang Z. Comparison on the Aging of Woods Exposed to Natural Sunlight and Artificial Xenon Light. Polymers. 2019; 11(4):709. https://doi.org/10.3390/polym11040709

Chicago/Turabian StyleLiu, Ru, Hanwen Zhu, Kang Li, and Zhong Yang. 2019. "Comparison on the Aging of Woods Exposed to Natural Sunlight and Artificial Xenon Light" Polymers 11, no. 4: 709. https://doi.org/10.3390/polym11040709

APA StyleLiu, R., Zhu, H., Li, K., & Yang, Z. (2019). Comparison on the Aging of Woods Exposed to Natural Sunlight and Artificial Xenon Light. Polymers, 11(4), 709. https://doi.org/10.3390/polym11040709