Effects of Various Antifouling Coatings and Fouling on Marine Sonar Performance

Abstract

1. Introduction

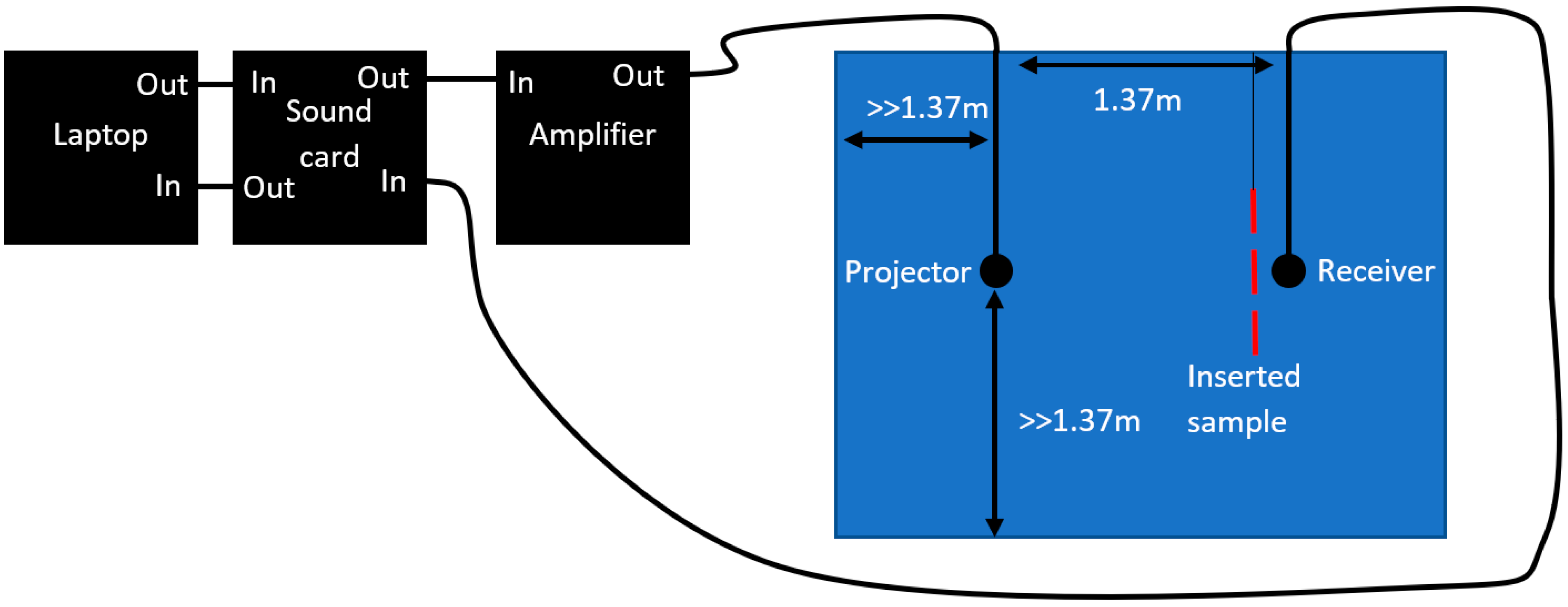

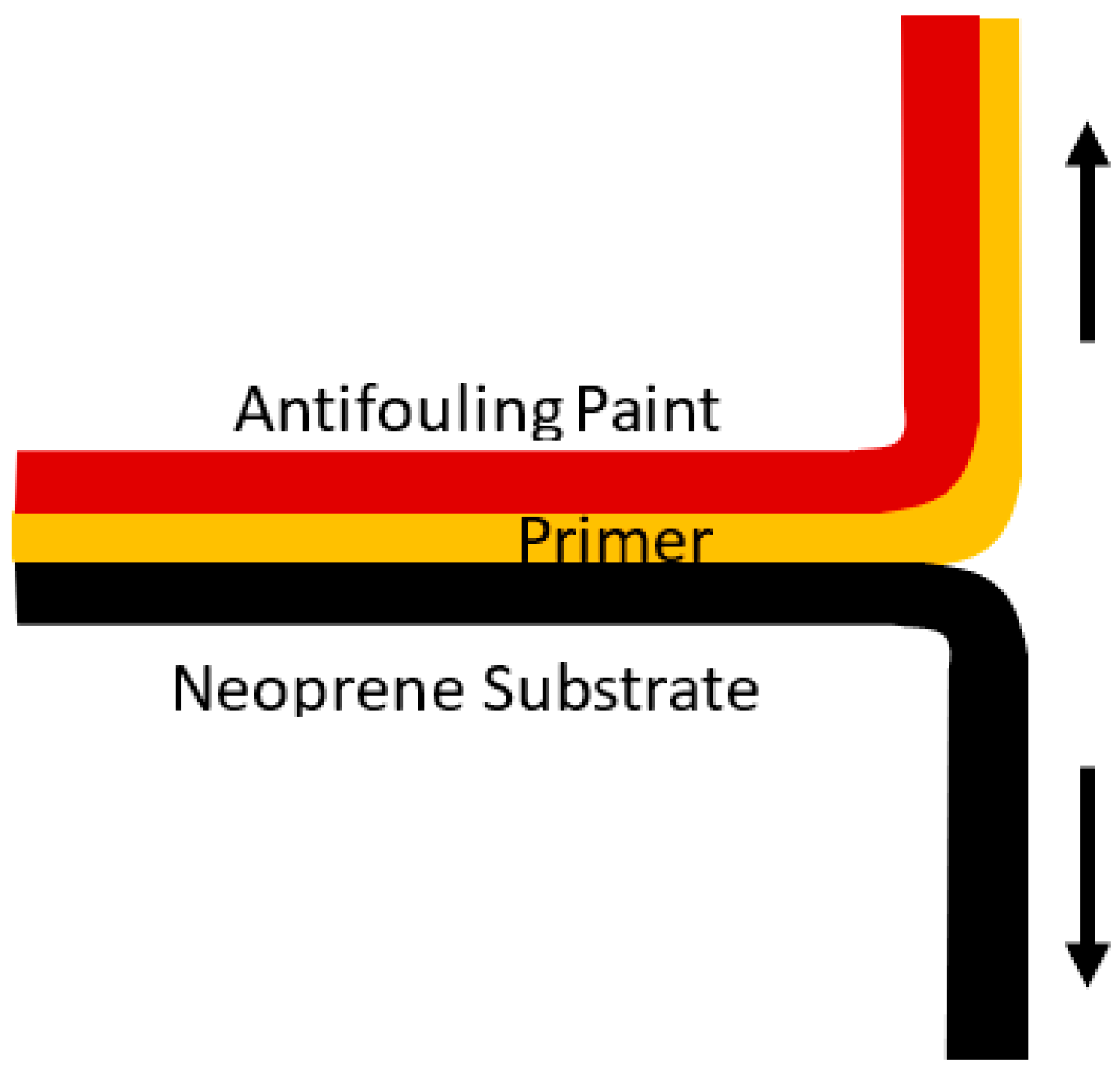

2. Materials Preparation and Characterizations

2.1. Materials

2.2. Sample Preparations

2.3. Material Surface and Mechanical Characterisation

3. Results and Discussion

3.1. Material Surface and Sample Characterizations

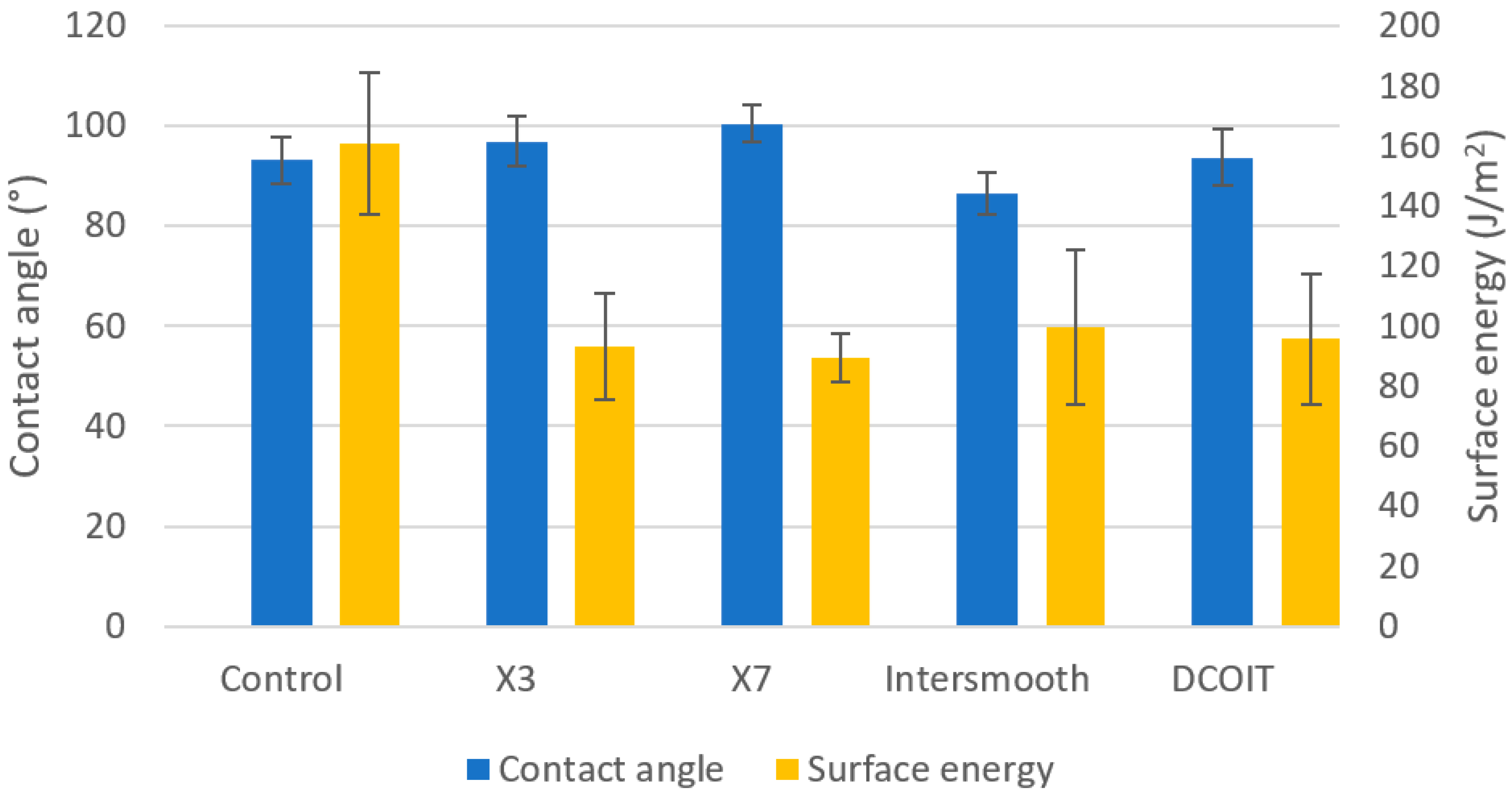

3.2. Contact Angle and Surface Tension

3.3. Immersion

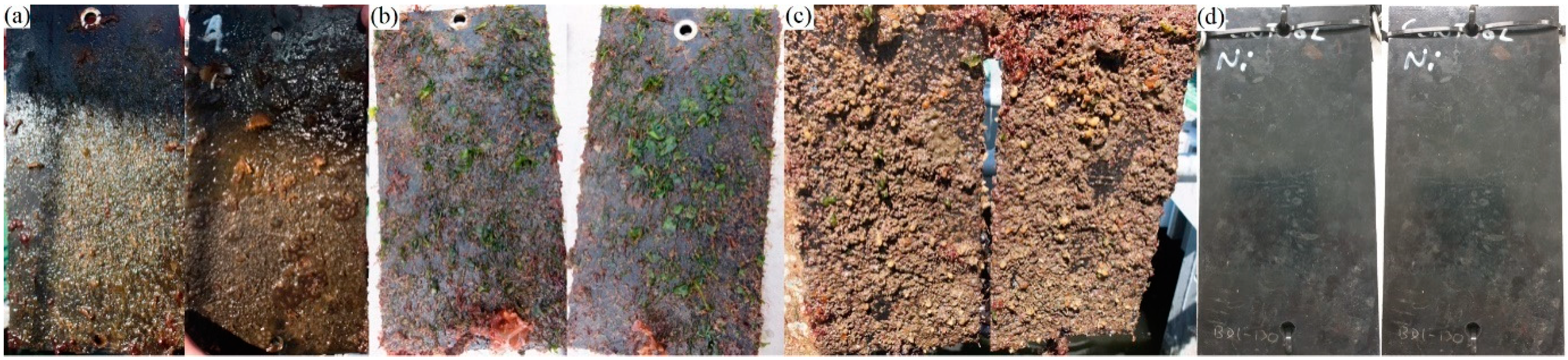

3.3.1. Fouling Characterization

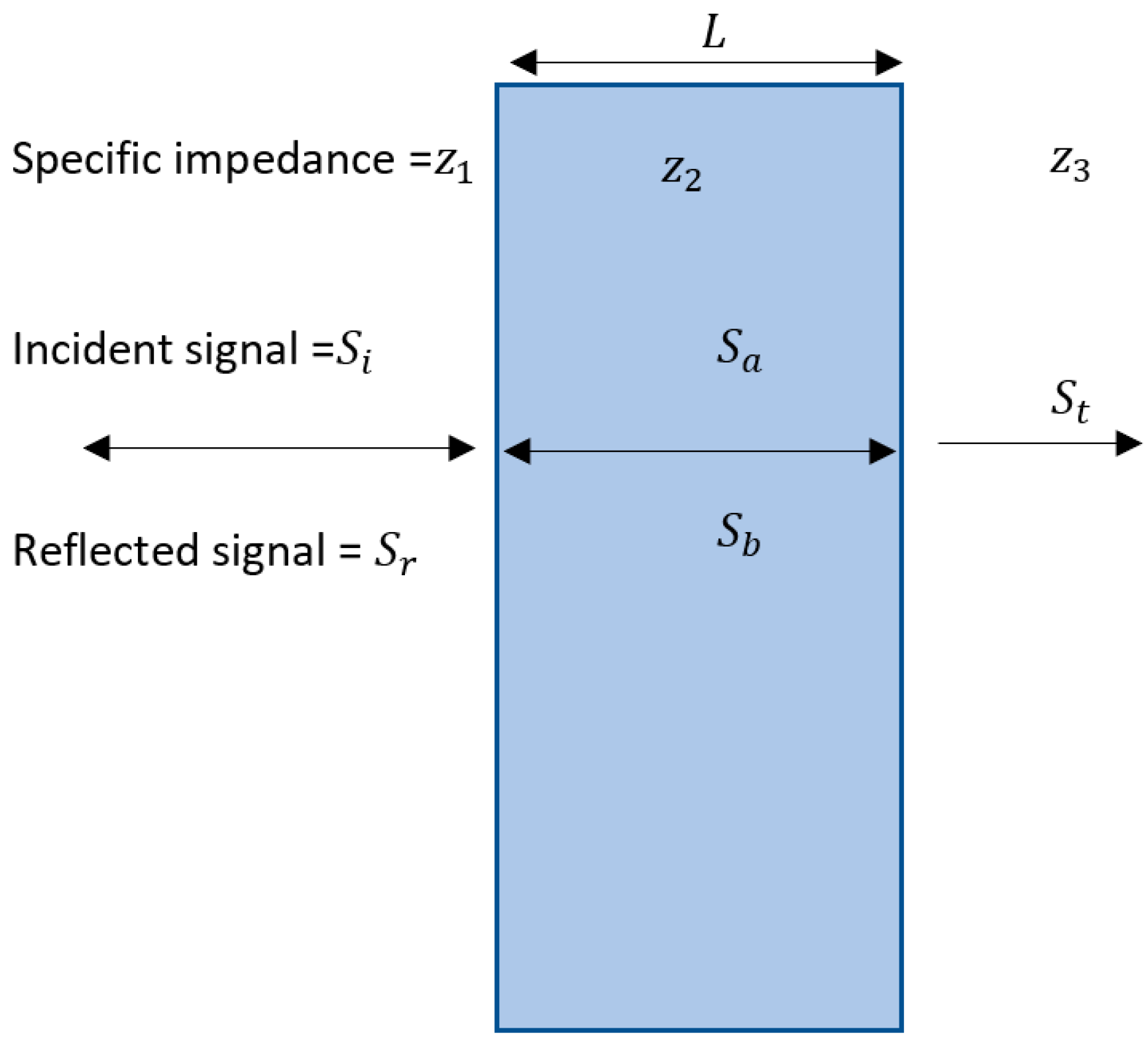

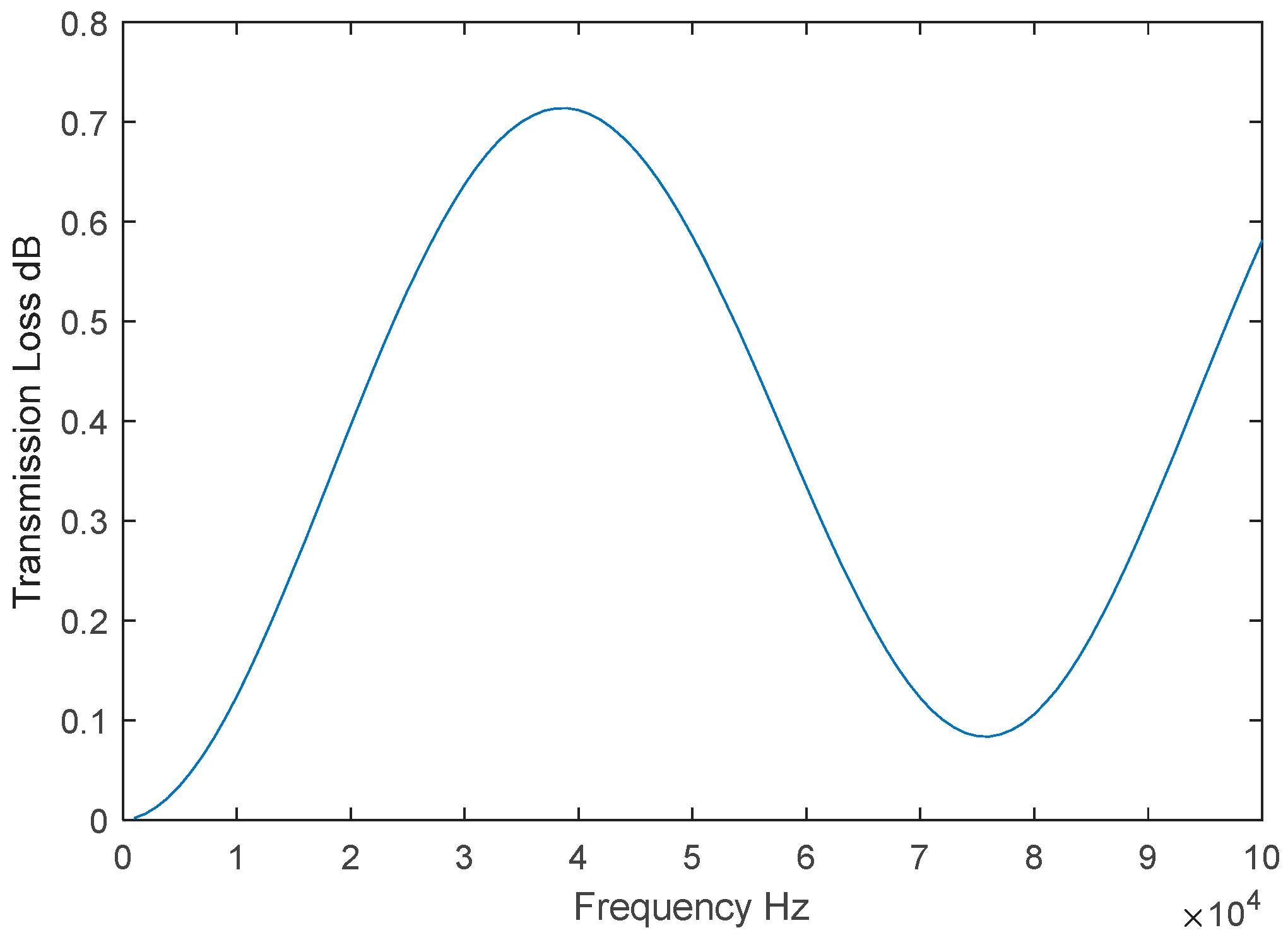

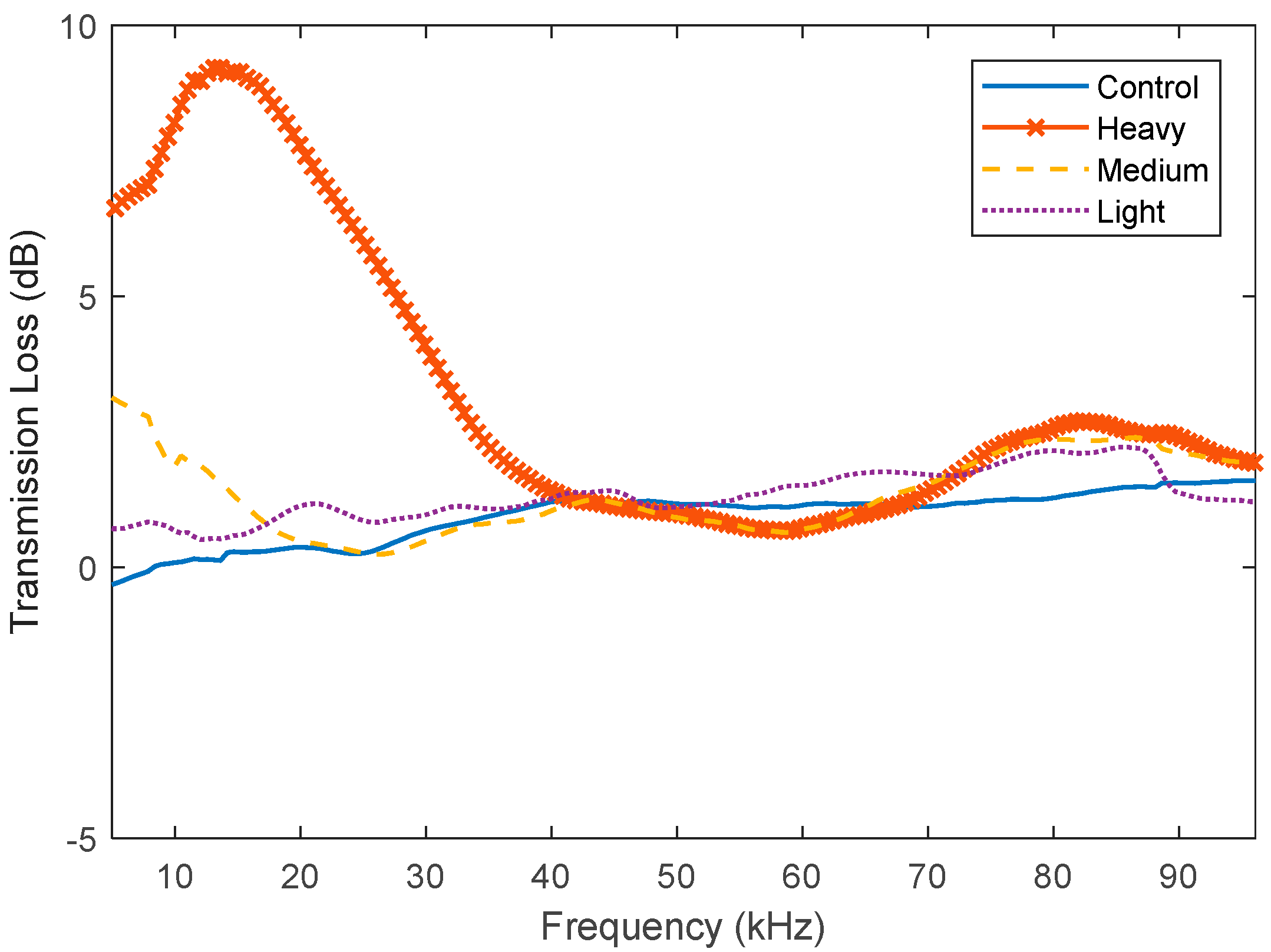

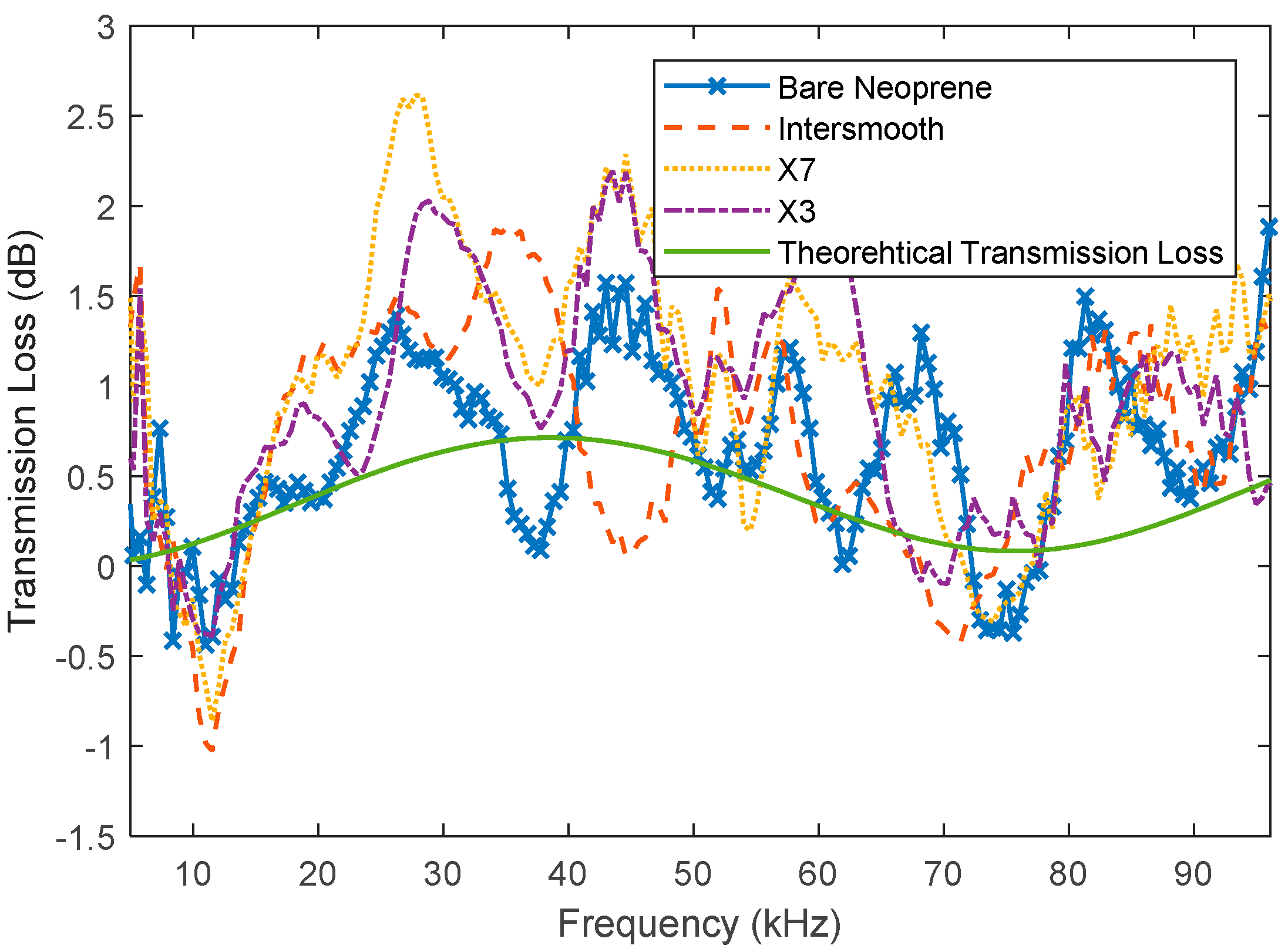

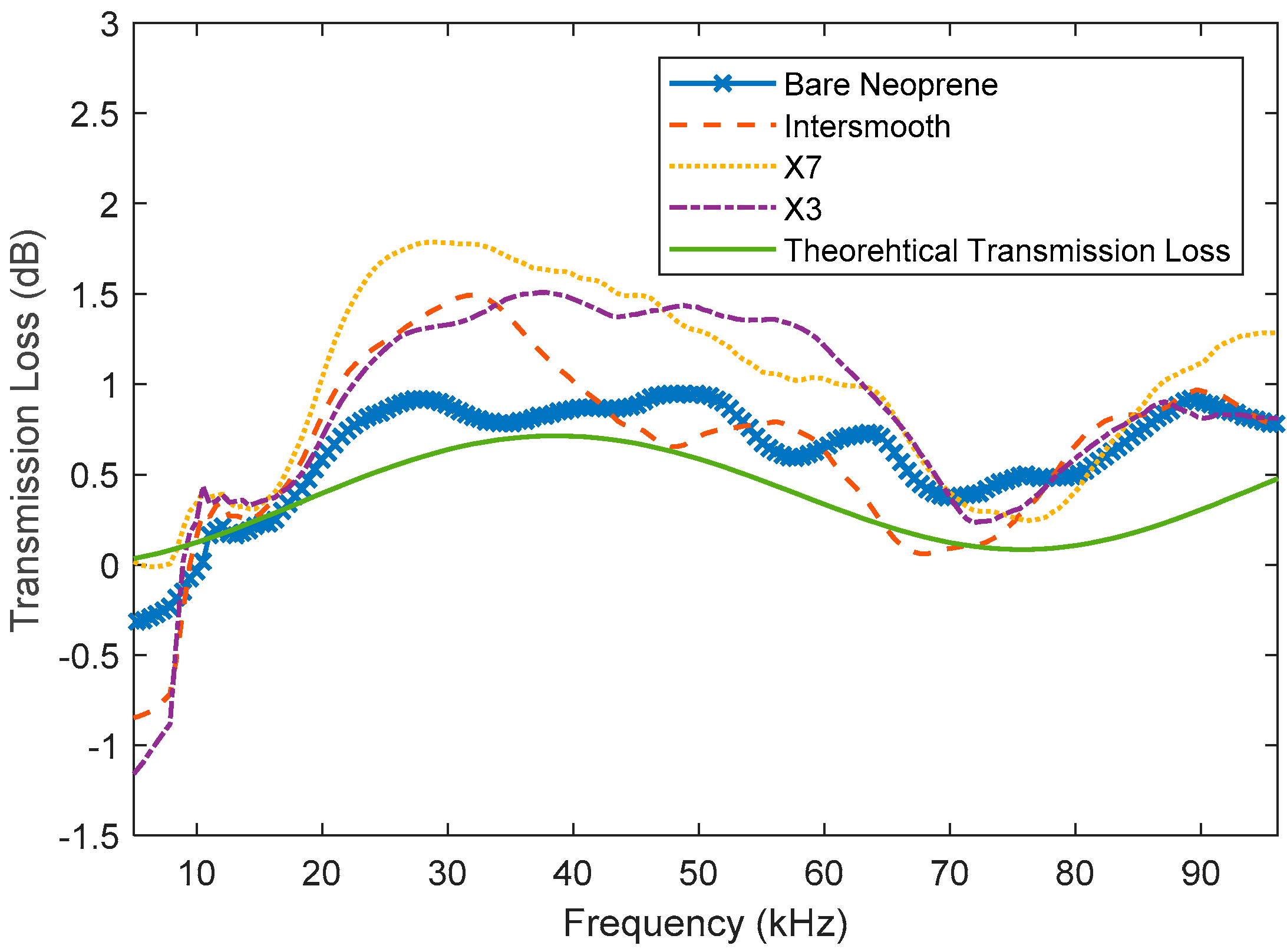

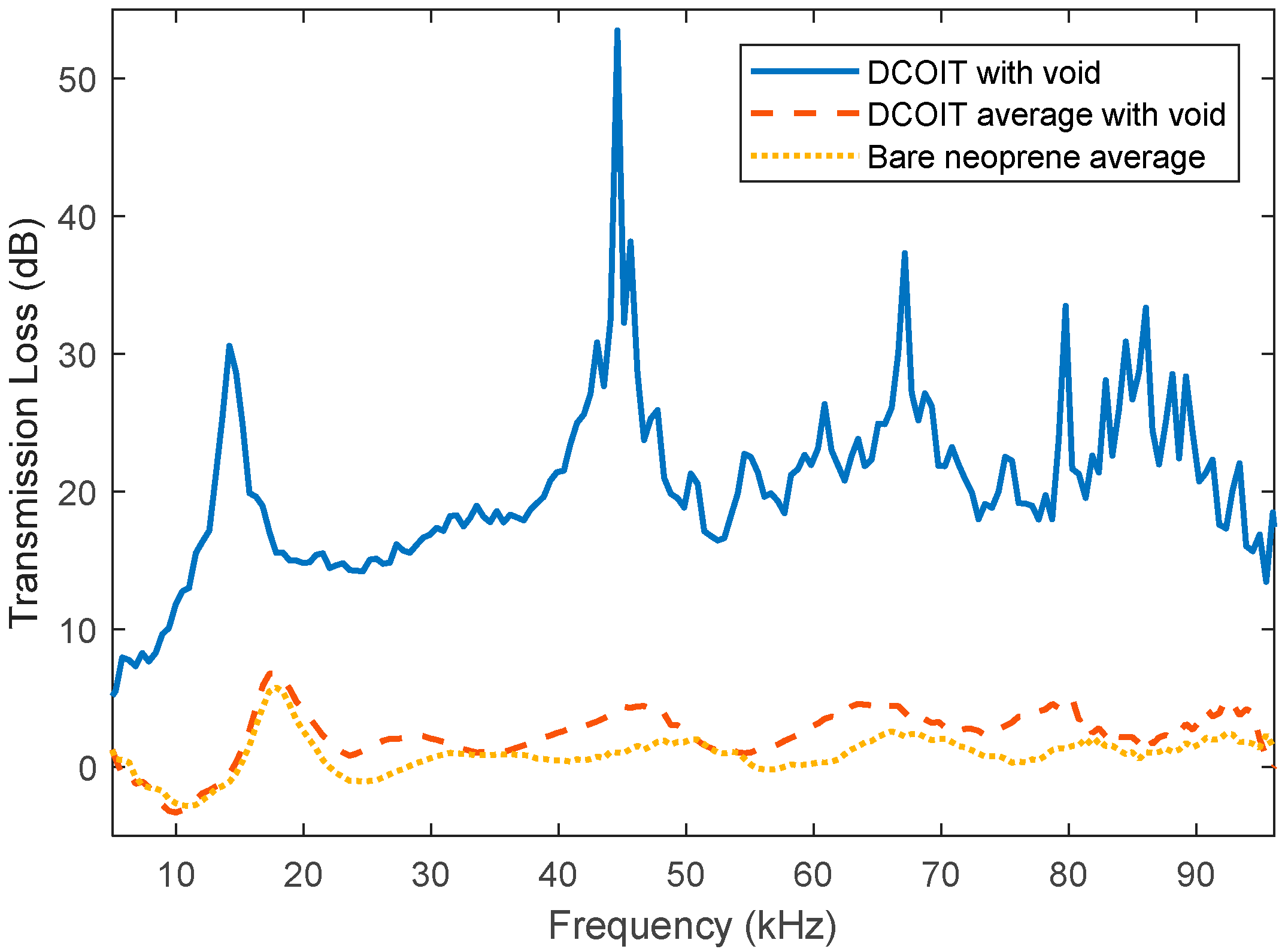

3.3.2. Acoustic Transparency Characterization

3.3.3. Comparison of the Effects of Coating and Fouling

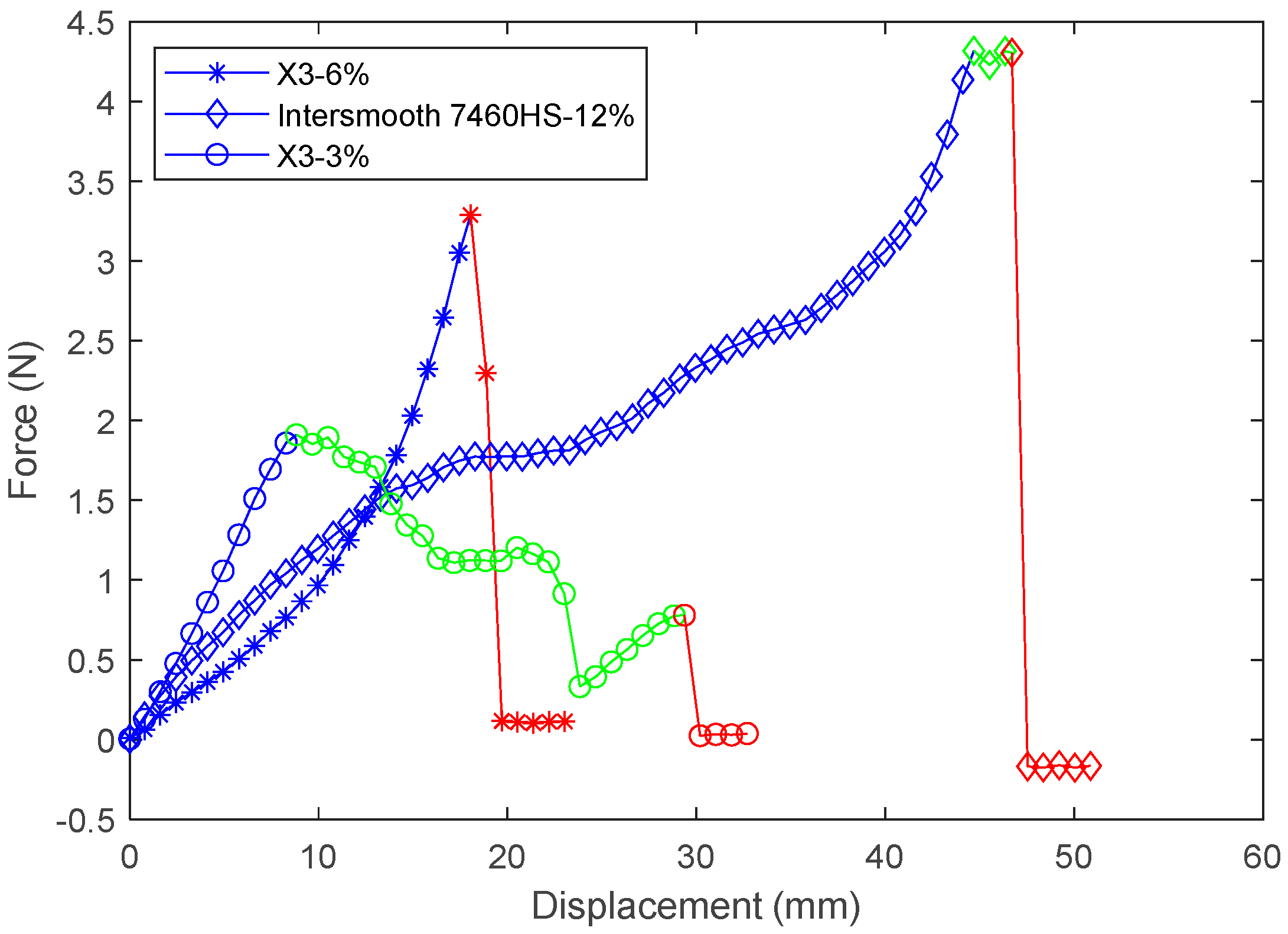

3.4. Adhesion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Müller, W.E.G.; Wang, X.; Proksch, P.; Perry, C.C.; Osinga, R.; Gardères, J.; Schröder, H.C. Principles of biofouling protection in marine sponges: A model for the design of novel biomimetic and bio-inspired coatings in the marine environment? Mar. Biotechnol. 2013, 15, 375–398. [Google Scholar] [CrossRef] [PubMed]

- Fusetani, N. Biofouling and antifouling. Nat. Prod. Rep. 2004, 21, 94. [Google Scholar] [CrossRef] [PubMed]

- Schultz, M.P.; Bendick, J.A.; Holm, E.R.; Hertel, W.M. Economic impact of biofouling on a naval surface ship. Biofouling 2011, 27, 87–98. [Google Scholar] [CrossRef] [PubMed]

- Hulme, P.E. Trade, transport and trouble: Managing invasive species pathways in an era of globalization. J. Appl. Ecol. 2009, 46, 10–18. [Google Scholar] [CrossRef]

- Murray, C.C.; Pakhomov, E.A.; Therriault, T.W. Recreational boating: A large unregulated vector transporting marine invasive species. Divers. Distrib. 2011, 17, 1161–1172. [Google Scholar] [CrossRef]

- Fitzgerald, J.W.; Davis, M.E.; Hurdle, B.G. Some acoustic properties of marine fouling. J. Acoust. Soc. Am. 1947, 19, 332–337. [Google Scholar] [CrossRef]

- Heupel, M.R.; Reiss, K.L.; Yeiser, B.G.; Simpfendorfer, C.A. Effects of biofouling on performance of moored data logging acoustic receivers. Limnol. Oceanogr. Methods 2008, 6, 327–335. [Google Scholar] [CrossRef]

- Williams, A.J. Sensor fouling prevention in an acoustic current meter, MAVS. In Proceedings of the 2012 Oceans-Yeosu, Yeosu, Korea, 21–24 May 2012. [Google Scholar]

- Legg, M.; Yücel, M.K.; de Carellan, I.G.; Kappatos, V.; Selcuk, C.; Gan, T.H. Acoustic Methods for Biofouling Control: A Review; Elsevier Ltd: Amsterdam, The Netherlands, 2015; Volume 103, pp. 237–247. [Google Scholar]

- Booth, C.; Wheeler, P.; Hancock, J.; Ximenes, R.; Patterson, D.E. Optical behavior of antibiofouling additives in environment-friendly coverglass materials for bio-sensors and solar panels. Polym. Adv. Technol. 2009, 20, 626–630. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1994, 40, 546. [Google Scholar] [CrossRef]

- Kirschner, C.M.; Brennan, A.B. Bio-inspired antifouling strategies. Annu. Rev. Mater. Res. 2012, 42, 211–229. [Google Scholar] [CrossRef]

- Baier, R.E. The role of surface energy in thrombogenesis. Bull. N. Y. Acad. Med. 1972, 48, 257–272. [Google Scholar] [PubMed]

- Callow, J.A.; Callow, M.E. Trends in the development of environmentally friendly fouling-resistant marine coatings. Nat. Commun. 2011, 2, 244. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Neumann, A.W. Equation of state for interfacial tensions of solid-liquid systems. Adv. Colloid Interface Sci. 1992, 39, 299–345. [Google Scholar] [CrossRef]

- Waterborne Underwater Hull Cleaning of Navy Ships. In Naval Ships’ Technical Manual; rev. 5; Naval Sea Systems Command: Washington, DC, USA, 2006; pp. 1–18.

- Bobber, R.J. Underwater Electroacoustic Measurements; Naval Research Laboratory Underwater Sound Reference Division: Orlando, FL, USA, 1970. [Google Scholar]

- ASTM Standard D3359. Standard Test Methods for Rating Adhesion by Tape Test; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar] [CrossRef]

- Kinsler, L.E. Fundamentals of Acoustics; Wiley: Hoboken, NJ, USA, 2000. [Google Scholar]

- Morse, P.M.; Ingard, K.U.; Shankland, R.S. Theoretical Acoustics. Phys. Today 1969, 22, 98–99. [Google Scholar] [CrossRef]

- Chen, C.-F.; Wharton, K. Characterization and failure mode analyses of air plasma oxidized PDMS–PDMS bonding by peel testing. RSC Adv. 2017, 7, 1286–1289. [Google Scholar] [CrossRef]

| Type | Fouling Rating | Description |

|---|---|---|

| Soft | 0 | A clean, foul free surface. |

| Soft | 10 | Light shades of red and green incipient slime. Bare metal visible beneath the fouling. |

| Soft | 20 | Slime as dark green patches with yellow or brown colored areas (advanced slime). Bare metal is obscured by the fouling. Fouling can be removed by hand. |

| Soft | 30 | Green weed as filaments up to 75 mm in length, projections up to 6 mm in height or a flat network of filaments that are green, yellow or brown in color. Soft non-calcareous fouling projecting up to 6 mm in height. The fouling cannot be easily removed by hand. |

| Hard | 40 | Calcareous fouling in the form of encrusting bryozoans less than 6 mm in height. |

| Hard | 50 | Calcareous fouling in the form of tubeworms or barnacles less than 6 mm in diameter or height. |

| Hard | 60 | Combination of encrusting bryozoans, tubeworms or barnacles, less than 6 mm in diameter or height. |

| Hard | 70 | Combination of encrusting bryozoans, tubeworms or barnacles, greater than 6 mm in diameter or height. |

| Hard | 80 | Tubeworms closely packed together and growing upright away from the surface. Barnacles, tubeworms and/or encrusting bryozoans growing one on top of another, 6 mm or less in height. Calcareous shells appear clean or white in color. |

| Hard | 90 | Dense growth of tubeworms, encrusting bryozoans or barnacles, 6 mm or greater in height. Calcareous shells brown in color or with slime or grassy overlay. |

| Composite | 100 | All forms of fouling present, particularly soft sedentary animals without calcareous covering growing over various forms of hard growth. |

| Coating | Peak Difference (dB) | Average Difference (dB) | 5–33 kHz Average Difference (dB) | 33–65 kHz Average Difference (dB) | 65–100 kHz Average Difference (dB) |

|---|---|---|---|---|---|

| Light (FR 20) | 1.92 | 0.43 ± 0.38 | 0.69 ± 0.39 | 0.17 ± 0.18 | 0.42 ± 0.38 |

| Medium (FR30) | 4.28 | 0.55 ± 1.03 | 1.28 ± 1.53 | −0.23 ± 0.14 | 0.55 ± 0.84 |

| Heavy (FR70) | 9.09 | 2.49 ± 3.17 | 6.40 ± 2.0 | −0.02 ± 0.49 | 2.06 ± 2.88 |

| Coating | Peak Difference (dB) | Average Difference (dB) | 5–33 kHz Average Difference (dB) | 33–65 kHz Average Difference (dB) | 65–100 kHz Average Difference (dB) |

|---|---|---|---|---|---|

| X7 | 0.97 | 0.38 ± 0.31 | 0.52 ± 0.29 | 0.51 ± 0.21 | 0.31 ± 0.32 |

| X3 | −1.34 | 0.20 ± 0.38 | −0.03 ± 0.55 | 0.54 ± 0.14 | 0.17 ± 0.29 |

| Intersmooth | 0.68 | 0.02 ± 0.30 | 0.09 ± 0.41 | −0.01 ± 0.27 | 0.01 ± 0.27 |

| Coating–Etchant Strength | Average Peak Force (N) | Did Peeling Occur? | Average Peel Force (N) | Average Peel Length (mm) |

|---|---|---|---|---|

| 7460HS-3% | 5.76 ± 0.33 | Yes | 5.50 ± 0.81 | 45.36 ± 0 |

| 7460HS-6% | 4.70 ± 0.08 | No | N/A | N/A |

| 7460HS-12% | 4.46 ± 0.31 | Yes | 3.50 ± 0.27 | 4.63 ± 2.61 |

| X7-3% | 3.48 ± 0.49 | Yes | 3.27 ± 0.11 | 0.69 ± 0.18 |

| X7-6% | 3.35 ± 0.80 | No | N/A | N/A |

| X7-12% | 3.67 ± 0.47 | No | N/A | N/A |

| X3-3% | 3.21 ± 0.55 | Yes | 1.14 ± 0.46 | 20.53 ± 0 |

| X3-6% | 3.74 ± 0.32 | No | N/A | N/A |

| X3-12% | 3.32 ± 1.01 | No | N/A | N/A |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Donnelly, B.; Bedwell, I.; Dimas, J.; Scardino, A.; Tang, Y.; Sammut, K. Effects of Various Antifouling Coatings and Fouling on Marine Sonar Performance. Polymers 2019, 11, 663. https://doi.org/10.3390/polym11040663

Donnelly B, Bedwell I, Dimas J, Scardino A, Tang Y, Sammut K. Effects of Various Antifouling Coatings and Fouling on Marine Sonar Performance. Polymers. 2019; 11(4):663. https://doi.org/10.3390/polym11040663

Chicago/Turabian StyleDonnelly, Bradley, Ian Bedwell, Jim Dimas, Andrew Scardino, Youhong Tang, and Karl Sammut. 2019. "Effects of Various Antifouling Coatings and Fouling on Marine Sonar Performance" Polymers 11, no. 4: 663. https://doi.org/10.3390/polym11040663

APA StyleDonnelly, B., Bedwell, I., Dimas, J., Scardino, A., Tang, Y., & Sammut, K. (2019). Effects of Various Antifouling Coatings and Fouling on Marine Sonar Performance. Polymers, 11(4), 663. https://doi.org/10.3390/polym11040663