A Review of Recent Advances in Nanoengineered Polymer Composites

Abstract

1. Introduction

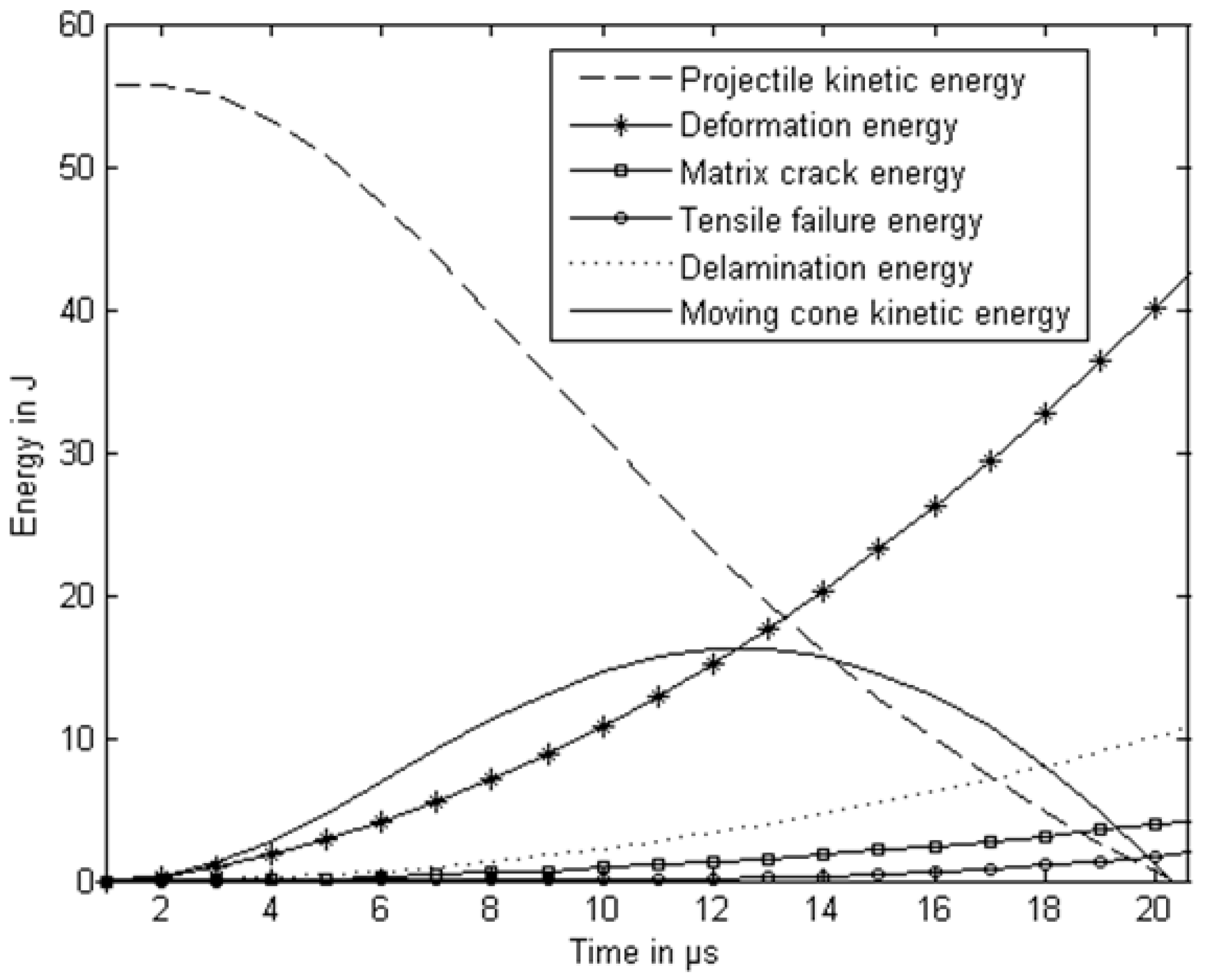

1.1. Impact on Composites

- Moving cone formed on the back face of the target.

- Shear plugging of the projectile into the target.

- Tensile failure of the primary fibers.

- Elastic deformation of the secondary fibers.

- Matrix cracking and delamination and frictional energy absorbed during penetration.

1.2. State-Of-The-Art in Composite Impact Research

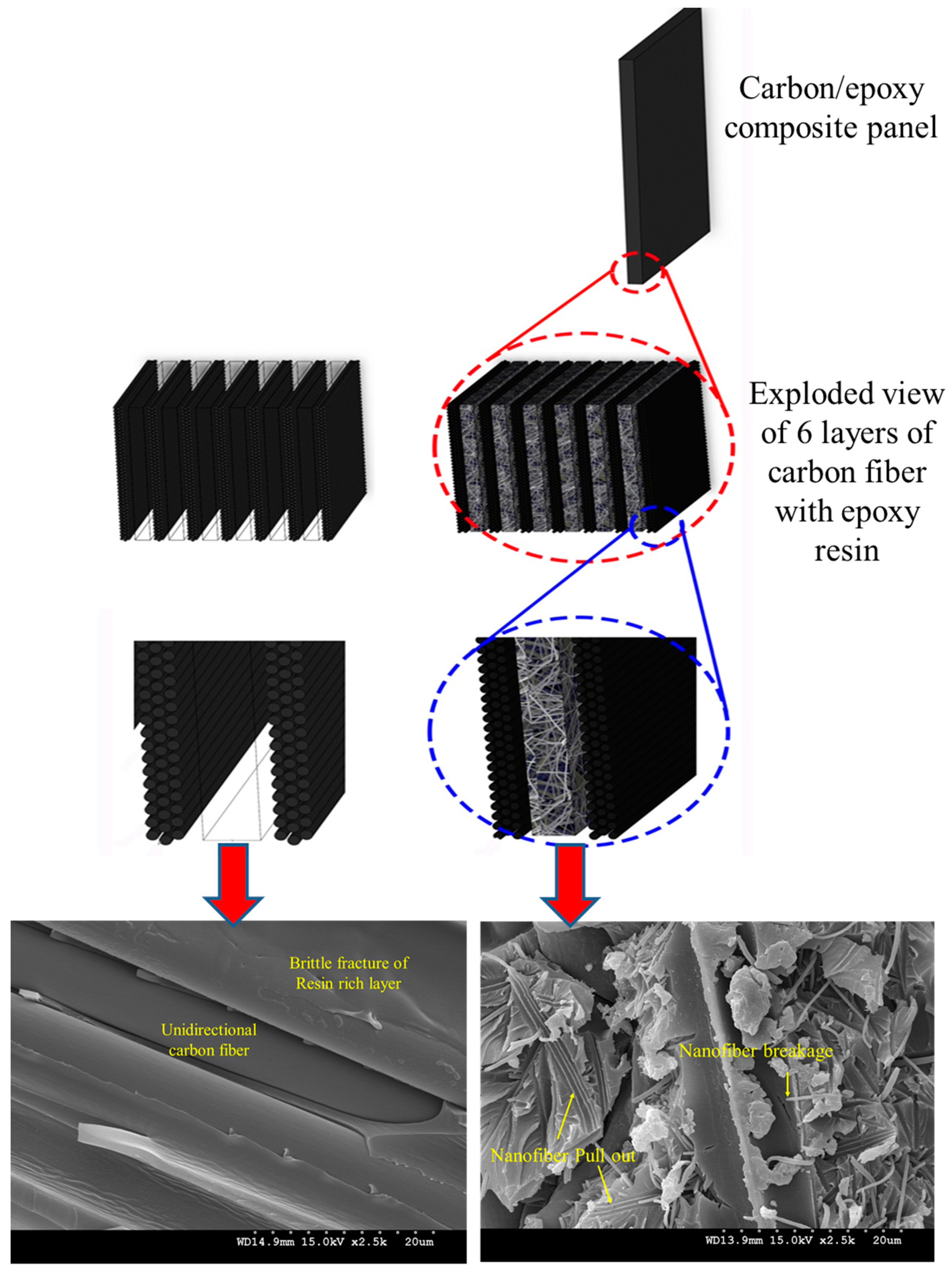

2. Electrospun Nanofiber Interleaved Polymer Matrix Composites

2.1. Electrospun Nanofiber Mats

- Thinness and lightness: They can range from few microns to even subnanometric ranges and are as light as a few grams per square meter, making the impact to weight and thickness of the final manufactured negligible.

- Porosity: They are highly porous, allowing the matrix to impregnate through them while still maintaining a solid bonding between the two layers of fibers encapsulating them.

- Tiny volume: The actual volume of these nanomats is negligible owing to the fact that they accumulate with the resin.

- Mechanical properties: They show highly improved properties compared to their bulk counterparts.

2.2. Impact on Nano-Interleaved Composites

3. Nanofiller Reinforced Polymer Matrix Composites

4. Self-Healing Polymer Matrix Composites

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Jian, S.; Zhu, J.; Jiang, S.; Chen, S.; Fang, H.; Song, Y.; Duan, G.; Zhang, Y.; Hou, H. Nanofibers with diameter below one nanometer from electrospinning. RSC Adv. 2018, 8, 4794–4802. [Google Scholar] [CrossRef]

- Vijay Kumar, V.; Ramakrishna, S.; Kong Yoong, J.L.; Esmaeely Neisiany, R.; Surendran, S.; Balaganesan, G. Electrospun nanofiber interleaving in fiber reinforced composites—Recent trends. Mater. Des. Process. Commun. 2019, 1, e24. [Google Scholar] [CrossRef]

- Soutis, C. Fibre reinforced composites in aircraft construction. Prog. Aerosp. Sci. 2005, 41, 143–151. [Google Scholar] [CrossRef]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Park, Y.; Kim, Y.; Lee, S.-H. Long-term flexural behaviors of GFRP reinforced concrete beams exposed to accelerated aging exposure conditions. Polymers 2014, 6, 1773–1793. [Google Scholar] [CrossRef]

- Ferreira, J.G.; Branco, F.A. Structural application of GRC in telecommunication towers. Constr. Build. Mater. 2007, 21, 19–28. [Google Scholar] [CrossRef]

- Hak, D.J.; Mauffrey, C.; Seligson, D.; Lindeque, B. Use of carbon-fiber-reinforced composite implants in orthopedic surgery. Orthopedics 2014, 37, 825–830. [Google Scholar]

- Scribante, A.; Vallittu, P.K.; Özcan, M. Fiber-Reinforced Composites for Dental Applications. BioMed Res. Int. 2018, 2018. [Google Scholar] [CrossRef]

- Hollaway, L.C. 10—High performance fibre-reinforced composites for sustainable energy applications. In High Performance Textiles and Their Applications; Lawrence, C.A., Ed.; Woodhead Publishing: Cambridge, UK, 2014; pp. 366–417. [Google Scholar]

- Mouritz, A.P.; Gellert, E.; Burchill, P.; Challis, K. Review of advanced composite structures for naval ships and submarines. Compos. Struct. 2001, 53, 21–42. [Google Scholar] [CrossRef]

- Wu, X.F.; Yarin, A.L. Recent progress in interfacial toughening and damage self-healing of polymer composites based on electrospun and solution-blown nanofibers: An overview. J. Appl. Polym. Sci. 2013, 130, 2225–2237. [Google Scholar] [CrossRef]

- Evci, C.; Gülgeç, M. An experimental investigation on the impact response of composite materials. Int. J. Impact Eng. 2012, 43, 40–51. [Google Scholar] [CrossRef]

- Prachasaree, W.; Sangkaew, A.; Limkatanyu, S.; GangaRao, H.V.S. Parametric Study on Dynamic Response of Fiber Reinforced Polymer Composite Bridges. Int. J. Polym. Sci. 2015, 2015. [Google Scholar] [CrossRef]

- Othman, A.R.; Hassan, M.H. Effect of different construction designs of aramid fabric on the ballistic performances. Mater. Des. 2013, 44, 407–413. [Google Scholar] [CrossRef]

- Sangamesh; Ravishankar, K.S.; Kulkarni, S.M. Ballistic Impact Study on Jute-Epoxy and Natural Rubber Sandwich Composites. Mater. Today Proc. 2018, 5, 6916–6923. [Google Scholar] [CrossRef]

- Wang, B.; Xiong, J.; Wang, X.; Ma, L.; Zhang, G.-Q.; Wu, L.-Z.; Feng, J.-C. Energy absorption efficiency of carbon fiber reinforced polymer laminates under high velocity impact. Mater. Des. 2013, 50, 140–148. [Google Scholar] [CrossRef]

- Heimbs, S.; Bergmann, T.; Schueler, D.; Toso-Pentecôte, N. High velocity impact on preloaded composite plates. Compos. Struct. 2014, 111, 158–168. [Google Scholar] [CrossRef]

- Sudhir Sastry, Y.B.; Budarapu, P.R.; Krishna, Y.; Devaraj, S. Studies on ballistic impact of the composite panels. Theor. Appl. Fract. Mech. 2014, 72, 2–12. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Milanezi, T.L.; Louro, L.H.L.; Lima, É.P.; Braga, F.O.; Gomes, A.V.; Drelich, J.W. Novel ballistic ramie fabric composite competing with Kevlar™ fabric in multilayered armor. Mater. Des. 2016, 96, 263–269. [Google Scholar] [CrossRef]

- Haro, E.E.; Odeshi, A.G.; Szpunar, J.A. The energy absorption behavior of hybrid composite laminates containing nano-fillers under ballistic impact. Int. J. Impact Eng. 2016, 96, 11–22. [Google Scholar] [CrossRef]

- Naik, N.K.; Shrirao, P.; Reddy, B.C.K. Ballistic impact behaviour of woven fabric composites: Formulation. Int. J. Impact Eng. 2006, 32, 1521–1552. [Google Scholar] [CrossRef]

- Reddy, P.R.S.; Reddy, T.S.; Mogulanna, K.; Srikanth, I.; Madhu, V.; Rao, K.V. Ballistic Impact Studies on Carbon and E-glass Fibre Based Hybrid Composite Laminates. Procedia Eng. 2017, 173, 293–298. [Google Scholar] [CrossRef]

- Razali, N.; Sultan, M.; Mustapha, F.; Yidris, N.; Ishak, M. Impact damage on composite structures—A review. Int. J. Eng. Sci. 2014, 3, 8–20. [Google Scholar]

- Sekine, H.; Hu, N.; Fukunaga, H.; Natsume, T. Low-velocity impact response of composite laminates with a delamination. Mech. Compos. Mater. Struct. 1998, 5, 257–278. [Google Scholar] [CrossRef]

- Antonucci, V.; Ricciardi, M.R.; Caputo, F.; Langella, A.; Lopresto, V.; Riccio, A.; Zarrelli, M. Low Velocity Impact Response of Carbon Fibre Laminates Made by Pulsed Infusion. Procedia Eng. 2014, 88, 230–234. [Google Scholar] [CrossRef][Green Version]

- Hutchings, I.M. The Behaviour of Metals Under Ballistic Impact at Sub-Ordnance Velocities. In Material Behavior Under High Stress and Ultrahigh Loading Rates; Mescall, J., Weiss, V., Eds.; Springer: Boston, MA, USA, 1983; pp. 161–196. [Google Scholar]

- Finnegan, S.A.; Schulz, J.C.; Heimdahl, O.E.R. Spatial fragment mass and velocity distributions for ordnance and ultra-ordnance speed impacts. Int. J. Impact Eng. 1990, 10, 159–170. [Google Scholar] [CrossRef]

- Gao, G.-W.; Tang, E.-L.; Feng, M.-H.; Han, Y.-F.; Li, Y.; Liu, M.; Xu, Y.-L.; Wang, L.; Lin, X.-C.; Wang, R.-Z.; et al. Research on dynamic response characteristics of CFRP/Al HC SPs subjected to high-velocity impact. Def. Technol. 2018, 14, 503–512. [Google Scholar] [CrossRef]

- Grytten, F. Low-Velocity Penetration of Aluminium Plates; Norwegian University of Science and Technology: Trondheim, Norway, April 2008; ISBN 978-82-471-6843-1. [Google Scholar]

- Rilo, N.F.; Ferreira, L.M.S. Experimental study of low-velocity impacts on glass-epoxy laminated composite plates. Int. J. Mech. Mater. Des. 2008, 4, 291–300. [Google Scholar] [CrossRef]

- Davies, G.; Olsson, R. Impact on composite structures. Aeronaut. J. 2004, 108, 541–563. [Google Scholar] [CrossRef]

- Sabet, A.; Fagih, N.; Beheshty, M.H. Effect of reinforcement type on high velocity impact response of GRP plates using a sharp tip projectile. Int. J. Impact Eng. 2011, 38, 715–722. [Google Scholar] [CrossRef]

- Abrate, S. Impact on Composite Structures; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Palazzetti, R.; Zucchelli, A. Electrospun nanofibers as reinforcement for composite laminates materials—A review. Compos. Struct. 2017, 182, 711–727. [Google Scholar] [CrossRef]

- Silva, M.A.; Cismaşiu, C.; Chiorean, C. Numerical simulation of ballistic impact on composite laminates. Int. J. Impact Eng. 2005, 31, 289–306. [Google Scholar] [CrossRef]

- Kim, H.; Welch, D.A.; Kedward, K.T. Experimental investigation of high velocity ice impacts on woven carbon/epoxy composite panels. Compos. Part A 2003, 34, 25–41. [Google Scholar] [CrossRef]

- Fujii, K.; Aoki, M.; Kiuchi, N.; Yasuda, E.; Tanabe, Y. Impact perforation behavior of CFRPs using high-velocity steel sphere. Int. J. Impact Eng. 2002, 27, 497–508. [Google Scholar] [CrossRef]

- Sevkat, E.; Liaw, B.; Delale, F.; Raju, B.B. A combined experimental and numerical approach to study ballistic impact response of S2-glass fiber/toughened epoxy composite beams. Compos. Sci. Technol. 2009, 69, 965–982. [Google Scholar] [CrossRef]

- López-Puente, J.; Varas, D.; Loya, J.A.; Zaera, R. Analytical modelling of high velocity impacts of cylindrical projectiles on carbon/epoxy laminates. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1223–1230. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Sundararaj, U. A review of vapor grown carbon nanofiber/polymer conductive composites. Carbon 2009, 47, 2–22. [Google Scholar] [CrossRef]

- Neisiany, R.E.; Khorasani, S.N.; Naeimirad, M.; Lee, J.K.Y.; Ramakrishna, S. Improving Mechanical Properties of Carbon/Epoxy Composite by Incorporating Functionalized Electrospun Polyacrylonitrile Nanofibers. Macromol. Mater. Eng. 2017, 302, 1600551. [Google Scholar] [CrossRef]

- Neisiany, R.E.; Khorasani, S.N.; Lee, J.K.Y.; Naeimirad, M.; Ramakrishna, S. Interfacial toughening of carbon/epoxy composite by incorporating styrene acrylonitrile nanofibers. Theor. Appl. Fract. Mech. 2018, 95, 242–247. [Google Scholar] [CrossRef]

- Ramadhan, A.A.; Abu Talib, A.R.; Mohd Rafie, A.S.; Zahari, R. High velocity impact response of Kevlar-29/epoxy and 6061-T6 aluminum laminated panels. Mater. Des. 2013, 43, 307–321. [Google Scholar] [CrossRef]

- De Schoenmaker, B.; Van der Heijden, S.; De Baere, I.; Van Paepegem, W.; De Clerck, K. Effect of electrospun polyamide 6 nanofibres on the mechanical properties of a glass fibre/epoxy composite. Polym. Test. 2013, 32, 1495–1501. [Google Scholar] [CrossRef]

- Li, D.; Xia, Y. Electrospinning of nanofibers: Reinventing the wheel? Adv. Mater. 2004, 16, 1151–1170. [Google Scholar] [CrossRef]

- Wang, G.; Yu, D.; Kelkar, A.D.; Zhang, L. Electrospun nanofiber: Emerging reinforcing filler in polymer matrix composite materials. Prog. Polym. Sci. 2017, 75, 73–107. [Google Scholar] [CrossRef]

- Razavi, S.M.J.; Neisiany, R.E.; Khorasani, S.N.; Ramakrishna, S.; Berto, F. Effect of neat and reinforced polyacrylonitrile nanofibers incorporation on interlaminar fracture toughness of carbon/epoxy composite. Theor. Appl. Mech. Lett. 2018, 8, 126–131. [Google Scholar] [CrossRef]

- Sharifi, A.; Khorasani, S.N.; Borhani, S.; Neisiany, R.E. Alumina reinforced nanofibers used for exceeding improvement in mechanical properties of the laminated carbon/epoxy composite. Theor. Appl. Fract. Mech. 2018, 96, 193–201. [Google Scholar] [CrossRef]

- Razavi, S.M.J.; Neisiany, R.E.; Ayatollahi, M.R.; Ramakrishna, S.; Khorasani, S.N.; Berto, F. Fracture assessment of polyacrylonitrile nanofiber-reinforced epoxy adhesive. Theor. Appl. Fract. Mech. 2018, 97, 448–453. [Google Scholar] [CrossRef]

- Lu, Y.; Shah, K.W.; Xu, J. Synthesis, Morphologies and Building Applications of Nanostructured Polymers. Polymers 2017, 9, 506. [Google Scholar] [CrossRef]

- Musiari, F.; Pirondi, A.; Zucchelli, A.; Menozzi, D.; Belcari, J.; Brugo, T.M.; Zomparelli, L. Experimental investigation on the enhancement of Mode I fracture toughness of adhesive bonded joints by electrospun nanofibers. J. Adhes. 2018, 94, 974–990. [Google Scholar] [CrossRef]

- Jiang, S.; Chen, Y.; Duan, G.; Mei, C.; Greiner, A.; Agarwal, S. Electrospun nanofiber reinforced composites: A review. Polym. Chem. 2018, 9, 2685–2720. [Google Scholar] [CrossRef]

- Davies, G.A.O.; Olsson, R. Impact on Composite Structures. Aeronaut. J. 2004, 108, 541–563. [Google Scholar] [CrossRef]

- Balaganesan, G.; Velmurugan, R.; Kanny, K. Dynamic response of nanocomposite laminates during low, medium and high velocity impact loading. Front. Aerosp. Eng. 2015, 4, 56–69. [Google Scholar] [CrossRef]

- Balaganesan, G.; Velmurugan, R.; Srinivasan, M.; Gupta, N.; Kanny, K. Energy absorption and ballistic limit of nanocomposite laminates subjected to impact loading. Int. J. Impact Eng. 2014, 74, 57–66. [Google Scholar] [CrossRef]

- Velmurugan, R.; Balaganesan, G. Energy absorption characteristics of glass/epoxy nano composite laminates by impact loading. Int. J. Crashworthiness 2013, 18, 82–92. [Google Scholar] [CrossRef]

- Velmurugan, R.; Balaganesan, G.; Gupta, N. Impact Loading on Glass/Epoxy Composite Laminates with Nano Clay. Key Eng. Mater. 2013, 535–536, 72–75. [Google Scholar] [CrossRef]

- Velmurugan, R.; Balaganesan, G. Modal analysis of pre and post impacted nano composite laminates. Lat. Am. J. Solids Struct. 2011, 8, 9–26. [Google Scholar] [CrossRef]

- Balaganesan, G.; Velmurugan, R. Vibration and Energy Dissipation of Nanocomposite Laminates for Below Ballistic Impact Loading. Lat. Am. J. Solids Struct. 2015, 12, 2259–2280. [Google Scholar] [CrossRef]

- Avila, A.; Duarte, H.V.; Soares, M.I. The nanoclay influence on impact response of laminated plates. Lat. Am. J. Solids Struct. 2006, 3, 3–20. [Google Scholar]

- Pandya, K.S.; Akella, K.; Joshi, M.; Naik, N.K. Ballistic impact behavior of carbon nanotube and nanosilica dispersed resin and composites. J. Appl. Phys. 2012, 112, 113522. [Google Scholar] [CrossRef]

- Pol, M.H.; Liaghat, G.H.; Hajiarazi, F. Effect of nanoclay on ballistic behavior of woven fabric composites: Experimental investigation. J. Compos. Mater. 2012, 47, 1563–1573. [Google Scholar] [CrossRef]

- Nasirzadeh, R.; Sabet, A.R. Influence of nanoclay reinforced polyurethane foam toward composite sandwich structure behavior under high velocity impact. J. Cell. Plast. 2014, 52, 253–275. [Google Scholar] [CrossRef]

- Naeimirad, M.; Zadhoush, A.; Kotek, R.; Esmaeely Neisiany, R.; Nouri Khorasani, S.; Ramakrishna, S. Recent advances in core/shell bicomponent fibers and nanofibers: A review. J. Appl. Polym. Sci. 2018, 135, 46265. [Google Scholar] [CrossRef]

- Sinha-Ray, S.; Pelot, D.; Zhou, Z.; Rahman, A.; Wu, X.-F.; Yarin, A.L. Encapsulation of self-healing materials by coelectrospinning, emulsion electrospinning, solution blowing and intercalation. J. Mater. Chem. 2012, 22, 9138–9146. [Google Scholar] [CrossRef]

- Wu, X.F.; Rahman, A.; Zhou, Z.; Pelot, D.D.; Sinha-Ray, S.; Chen, B.; Payne, S.; Yarin, A.L. Electrospinning core-shell nanofibers for interfacial toughening and self-healing of carbon-fiber/epoxy composites. J. Appl. Polym. Sci. 2013, 129, 1383–1393. [Google Scholar] [CrossRef]

- Neisiany, R.E.; Lee, J.K.Y.; Khorasani, S.N.; Ramakrishna, S. Self-healing and interfacially toughened carbon fibre-epoxy composites based on electrospun core–shell nanofibres. J. Appl. Polym. Sci. 2017, 134, 44956. [Google Scholar] [CrossRef]

- Neisiany, R.E.; Lee, J.K.Y.; Khorasani, S.N.; Ramakrishna, S. Towards the development of self-healing carbon/epoxy composites with improved potential provided by efficient encapsulation of healing agents in core-shell nanofibers. Polym. Test. 2017, 62, 79–87. [Google Scholar] [CrossRef]

- Esmaeely Neisiany, R.; Lee, J.K.Y.; Nouri Khorasani, S.; Bagheri, R.; Ramakrishna, S. Facile strategy toward fabrication of highly responsive self-healing carbon/epoxy composites via incorporation of healing agents encapsulated in poly(methylmethacrylate) nanofiber shell. J. Ind. Eng. Chem. 2018, 59, 456–466. [Google Scholar] [CrossRef]

- Seyyed Monfared Zanjani, J.; Saner Okan, B.; Yilmaz, C.; Menceloglu, Y.; Yildiz, M. Monitoring the interface and bulk self-healing capability of tri-axial electrospun fibers in glass fiber reinforced epoxy composites. Compos. Part A Appl. Sci. Manuf. 2017, 99, 221–232. [Google Scholar] [CrossRef]

- Neisiany, R.E.; Khorasani, S.N.; Kong Yoong Lee, J.; Ramakrishna, S. Encapsulation of epoxy and amine curing agent in PAN nanofibers by coaxial electrospinning for self-healing purposes. RSC Adv. 2016, 6, 70056–70063. [Google Scholar] [CrossRef]

- Monfared Zanjani, J.S.; Okan, B.S.; Letofsky-Papst, I.; Menceloglu, Y.; Yildiz, M. Repeated self-healing of nano and micro scale cracks in epoxy based composites by tri-axial electrospun fibers including different healing agents. RSC Adv. 2015, 5, 73133–73145. [Google Scholar] [CrossRef]

| Velocity | Impact Testing Equipment | Material Test Method | Applications |

|---|---|---|---|

| Low (0–50 m/s) |

|

|

|

| Sub-ordnance (50–500 m/s) |

|

|

|

| Ordnance (500–1300 m/s) |

|

|

|

| Ultra-ordnance (1300–3000 m/s) |

|

|

|

| Hypervelocity (>3000 m/s) |

|

|

|

| Nano-Fibers | Diameter (nm) | Matrix | Properties: Value of Matrix/Value of Composites; % Absolute Increased Properties |

|---|---|---|---|

| Nylon-4,6 | 30–200 | Epoxy | Transparent; Young’s modulus: 2.5/91 MPa; fracture stress: 1.82/2.4 MPa |

| Gr-nylon-6 (Gr 0.01 wt.%) | 300–500 | PMMA | Transparent; tensile strength: 56%; modulus: 113%; toughness: 250% |

| Nylon-6 | 200–400 | PMMA | Transparent; bending strength: 12%; bending modulus: 30%; tensile strength: 20%; tensile modulus: 32% |

| Nylon-6 | 200–400 | PMMA | Transparent; tensile strength and modulus: >20% |

| Nylon-6 | 134 | PVA | Tensile failure stress: 34/740 MPa; tensile failure strain: 340%/490% |

| Nylon-6 | 100–600 | BIS-GMA/TEGDMA | Flexural strength: 36%; elastic modulus: 26%; work of fracture: 42% |

| Nylon-6/silica nanocrystal | 250 | BIS-GMA/TEGDMA | Flexural strength: 23%; elastic modulus: 25%; work of fracture: 98% |

| Nylon-6,6 | 150 | Epoxy | Mechanical energy absorbing capability: 23.2%; maximum stress: 6.5% |

| Nylon-6,6 | 75–250 | Epoxy | Impact force: 900/2100 N; impact energy: 0.46/1.8 J; impact damage growth rate: 0.115/0.105 mm2 N−1 |

| Nylon-6,6 | 150–300 | Carbon/epoxy | Fracture toughness: 156% (mode I) and 69% (mode II) |

| Nylon-6 | (A) 150 | Glass fiber/epoxy | (A) Stress: 550/581 MPa, shear modulus: 4.0/4.7 GPa |

| (B) 230 | (B) Stress: 550/611 MPa, shear modulus: 4.0/4.7 GP; GIC: 1264/1447 J m−2 | ||

| Nylon-6,6 | 150 | Glass/epoxy | Energy release rate GI: 4.5%; GII: 68% |

| Nylon-6 | 800 | PCL | Young’s modulus: 352/530 MPa; stress at break: 15.9/18.1 MPa; strain at break: 467%/601% |

| Nylon-6 | 800 | PLA | Modulus: 2.4/6.6 GPa; stress at break: 48/46 MPa; strain at break: 3.6%/1.7% |

| Nylon-6 | 220 | Melamine-formaldehyde | (A) Stress: 47.5/74.5 MPa; strain: 76.2%/2.85%; modulus: 0.37/2.88 GPa; toughness: 21.8/1.0 J g−1 |

| (B) Stress: 47.5/77.9 MPa; strain: 76.2%/38.4%; modulus: 0.37/0.85 GPa; toughness: 21.8/17.6 J g−1 | |||

| Nylon-6 | 150–300 | TPU | Transparent; stress: 42.27/82.98 MPa; strain: 672.9%/876.0%; modulus: 27.1/ 51.9 MPa; toughness: 108.47/274.83 J g−1 |

| Nylon-6,6 | 200–350 | Polyethylene | Tensile strength: 27.74/32.56 MPa; elongation: 1184%/1341%; toughness: 249.36/315.07 MJ m−3 |

| Nylon-6,6 | 150 | Gr-epoxy | Mechanical energy absorbing capability: 23.2%; GIC: 5% |

| Nylon-6,6/GNPs | 90–150 | Aramid/epoxy | Elongation at break: 19.9%/34.48%; toughness: 68% |

| Nylon-6 | 200–400 | PMMA | Transparent; tensile strength: 27.5/54.4 MPa; modulus: 0.61/1.12 GPa; toughness: 0.7/2.1 MJ m−3 |

| Nylon-6,6 | 300 | Cyclic butylene terephthalate | Transparent; stress: 25/44 MPa |

| Nylon-6 | 100 | Protein | Tensile strength: 0.024/0.136 MPa; elastic modulus: 1.57/1.8 GPa |

| Composite | Method of Encapsulation | Healing Agent | Shell Material | Methods of Self-Healing Evaluation | Reference |

|---|---|---|---|---|---|

| Carbon/epoxy | Emulsion electrospinning | dicyclopentadiene and isophorone diisocyanate | Polyacrylonitrile | Fractographical analysis | [65] |

| Carbon/epoxy | Coaxial electrospinning | dicyclopentadiene | Polyacrylonitrile | Mechanical tests and Fractographical analysis | [66] |

| Carbon/epoxy | Coaxial electrospinning | Low viscosity epoxy resin and amine-based curing agent | Polyacrylonitrile | Mechanical tests and Fractographical analysis | [67] |

| Carbon/epoxy | Coaxial electrospinning | Low viscosity epoxy resin and amine-based curing agent | poly(styrene-co-acrylonitrile) | Mechanical tests, heat of healing reaction, and Fractographical analysis | [68] |

| Carbon/epoxy | Coaxial electrospinning | Low viscosity epoxy resin and amine-based curing agent | poly(methyl methacrylate) | Mechanical tests and Fractographical analysis | [69] |

| Glass fiber/epoxy | Tri-axial electrospinning | epoxy resin and its curing agent | poly(methyl methacrylate) as outer shell and polyacrylamide as middle wall | Mechanical tests and Fractographical analysis | [70] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vijay Kumar, V.; Balaganesan, G.; Lee, J.K.Y.; Neisiany, R.E.; Surendran, S.; Ramakrishna, S. A Review of Recent Advances in Nanoengineered Polymer Composites. Polymers 2019, 11, 644. https://doi.org/10.3390/polym11040644

Vijay Kumar V, Balaganesan G, Lee JKY, Neisiany RE, Surendran S, Ramakrishna S. A Review of Recent Advances in Nanoengineered Polymer Composites. Polymers. 2019; 11(4):644. https://doi.org/10.3390/polym11040644

Chicago/Turabian StyleVijay Kumar, Vishnu, G. Balaganesan, Jeremy Kong Yoong Lee, Rasoul Esmaeely Neisiany, S. Surendran, and Seeram Ramakrishna. 2019. "A Review of Recent Advances in Nanoengineered Polymer Composites" Polymers 11, no. 4: 644. https://doi.org/10.3390/polym11040644

APA StyleVijay Kumar, V., Balaganesan, G., Lee, J. K. Y., Neisiany, R. E., Surendran, S., & Ramakrishna, S. (2019). A Review of Recent Advances in Nanoengineered Polymer Composites. Polymers, 11(4), 644. https://doi.org/10.3390/polym11040644