Flexible Random Laser Using Silver Nanoflowers

Abstract

:1. Introduction

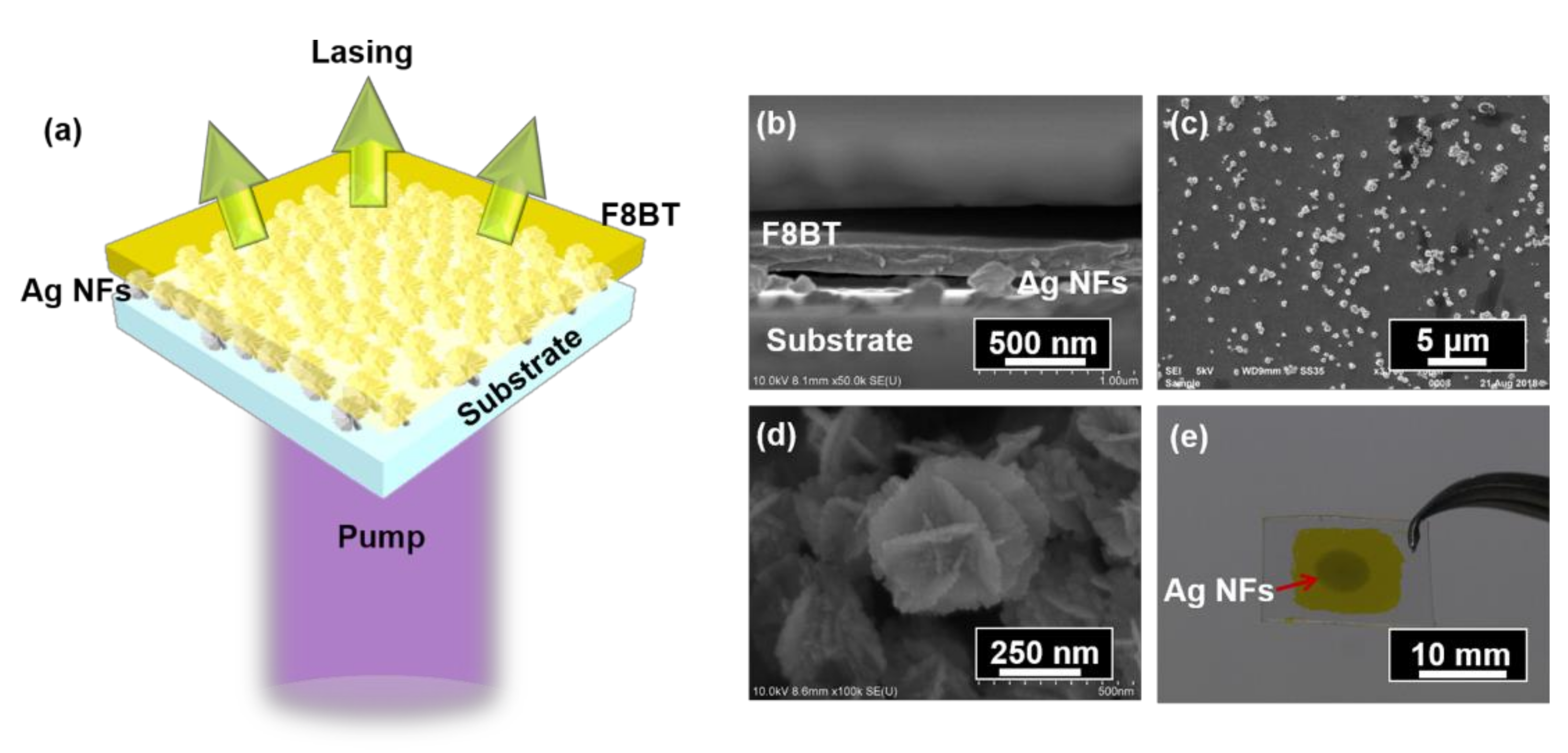

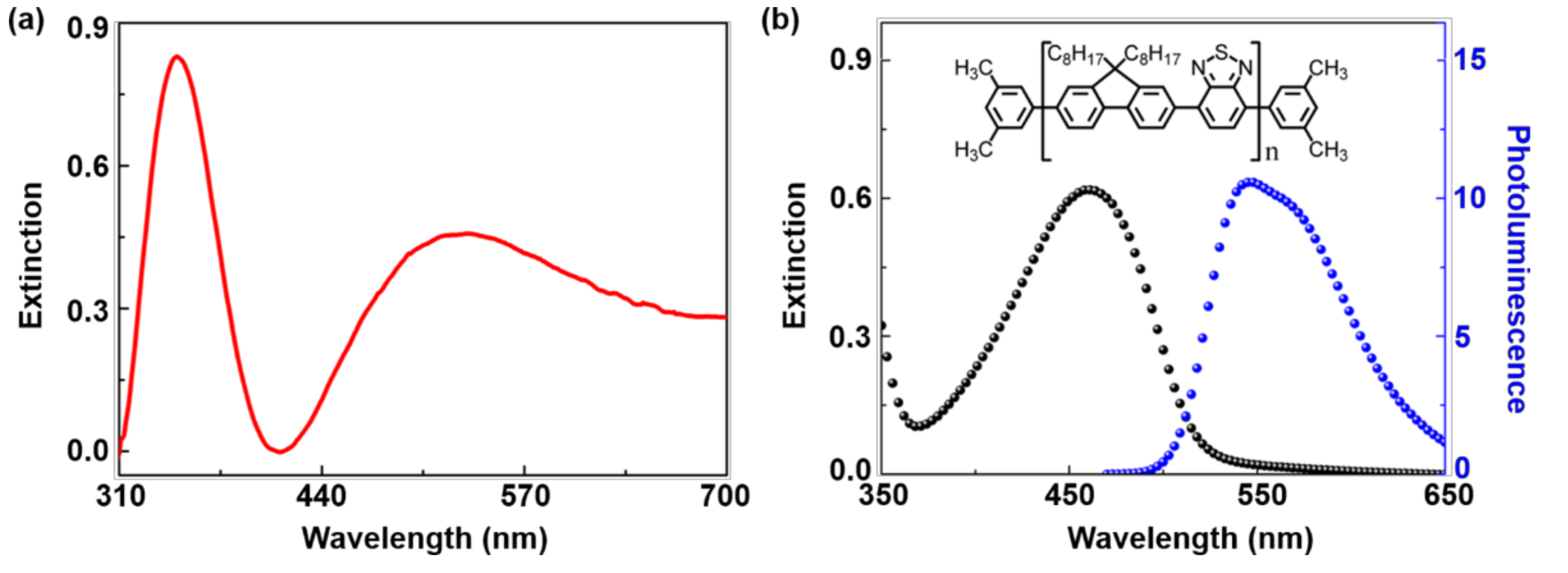

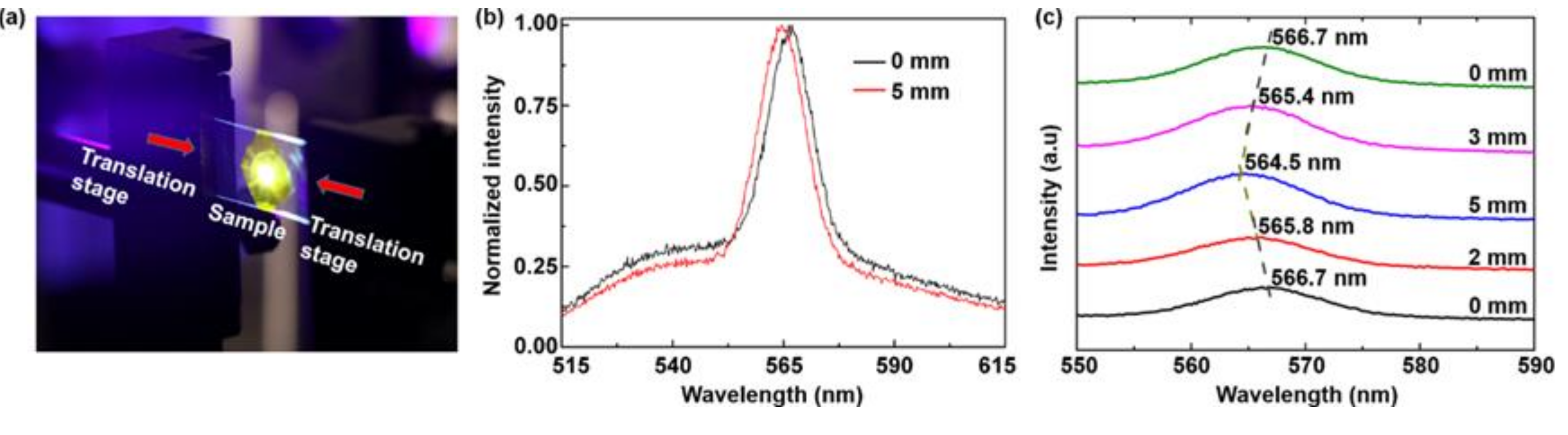

2. Fabrication Methods and Spectra Characterizations

3. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wiersma, D.S. The physics and applications of random lasers. Nat. Phys. 2008, 4, 359–367. [Google Scholar] [CrossRef]

- Cao, H.; Zhao, Y.G.; Wang, Q.H.; Chang, R.P.H. Random laser action in semiconductor powder. Phys. Rev. Lett. 1999, 82, 2278–2281. [Google Scholar] [CrossRef]

- Luan, F.; Gu, B.; Gomes, A.S.L.; Yong, K.; Wen, S.; Prasad, P.N. Lasing in nanocomposite random media. Nano Today 2015, 10, 168–192. [Google Scholar] [CrossRef]

- Redding, B.; Choma, M.A.; Cao, H. Speckle-free laser imaging using random laser illumination. Nat. Photon. 2012, 6, 355–359. [Google Scholar] [CrossRef] [PubMed]

- Polson, R.C.; Vardeny, Z.V. Random lasing in human tissues. Appl. Phys. Lett. 2004, 85, 1289–1291. [Google Scholar] [CrossRef]

- Chang, S.W.; Liao, W.C.; Liao, Y.M.; Lin, H.; Lin, H.Y.; Lin, W.J.; Lin, S.Y.; Perumal, P.; Haider, G.; Tai, C.T.; et al. A white random laser. Sci. Rep. 2018, 8, 2720. [Google Scholar] [CrossRef]

- Shi, X.; Wang, Y.; Wang, Z.; Wei, S.; Sun, Y.; Liu, D.; Zhou, J.; Zhang, Y.; Shi, J. Random lasing with a high quality factor over the whole visible range based on cascade energy transfer. Adv. Opt. Mater. 2014, 2, 88–93. [Google Scholar] [CrossRef]

- Shi, X.; Wang, Y.; Wang, Z.; Sun, Y.; Liu, D.; Zhang, Y.; Li, Q.; Shi, J. High performance plasmonic random laser based on nanogaps in bimetallic porous nanowires. Appl. Phys. Lett. 2013, 103, 023504. [Google Scholar] [CrossRef]

- Li, S.; Wang, L.; Zhai, T.; Tong, J.; Niu, L.; Tong, F.; Cao, F.; Liu, H.; Zhang, X. A dual-wavelength polymer random laser with the step-type cavity. Org. Electron. 2018, 57, 323–326. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.; Sun, H.; Zeng, H. Amino-mediated anchoring perovskite quantum dots for stable and low-threshold random lasing. Adv. Mater. 2017, 29, 1701185. [Google Scholar] [CrossRef]

- Lee, Y.J.; Chou, C.Y.; Yang, Z.P.; Nguyen, T.B.H.; Yao, Y.C.; Yeh, T.W.; Tsai, M.T.; Kuo, H.C. Flexible random lasers with tunable lasing emissions. Nanoscale 2018, 10, 10403. [Google Scholar] [CrossRef]

- Zhai, T.; Chen, J.; Chen, L.; Wang, J.; Wang, L.; Liu, D.; Li, S.; Liu, H.; Zhang, X. A plasmonic random laser tunable through stretching silver nanowires embedded in a flexible substrate. Nanoscale 2015, 7, 2235–2240. [Google Scholar] [CrossRef] [PubMed]

- Lau, S.P.; Yang, H.; Yu, S.F.; Yuen, C.; Leong, E.S.P.; Li, H.; Hng, H.H. Flexible ultraviolet random lasers based on nanoparticles. Small 2005, 1, 956–959. [Google Scholar] [CrossRef] [PubMed]

- Sun, T.M.; Wang, C.S.; Liao, C.S.; Lin, S.Y.; Perumal, P.; Chiang, C.W.; Chen, Y.F. Stretchable random lasers with tunable coherent loops. ACS Nano 2015, 9, 12436–12441. [Google Scholar] [CrossRef] [PubMed]

- Hu, H.W.; Haider, G.; Liao, Y.M.; Roy, P.K.; Ravindranath, R.; Chang, H.T.; Lu, C.H.; Tseng, C.Y.; Lin, T.Y.; Shih, W.H.; et al. Wrinkled 2D materials: A versatile platform for low-threshold stretchable random lasers. Adv. Mater. 2017, 29, 1703549. [Google Scholar] [CrossRef]

- Liao, W.C.; Liao, Y.M.; Su, C.T.; Perumal, P.; Lin, S.Y.; Lin, W.J.; Chang, C.H.; Lin, H.I.; Haider, G.; Chang, C.Y.; et al. Plasmonic carbon-dot-decorated nanostructured semiconductors for efficient and tunable random laser action. ACS Nano 2018, 1, 152–159. [Google Scholar] [CrossRef]

- Santos, M.; Dominguez, C.; Schiavon, J.; Barud, H.; Melo, L.; Ribeiro, S.; Gomes, A.; Araujo, C. Random laser action from flexible biocellulose-based device. J. Appl. Phys. 2014, 115, 083108. [Google Scholar] [CrossRef]

- Zhai, T.; Xu, Z.; Wu, X.; Wang, Y.; Liu, F.; Zhang, X. Ultra-thin plasmonic random lasers. Opt. Express 2016, 24, 437–442. [Google Scholar] [CrossRef]

- Dice, G.D.; Mujumdar, S.; Elezzabi, A.Y. Plasmonically enhanced diffusive and subdiffusive metal nanoparticle-dye random laser. Appl. Phys. Lett. 2005, 86, 131105. [Google Scholar] [CrossRef]

- Li, S.; Wang, L.; Zhai, T.; Xu, Z.; Wang, Y.; Wang, J.; Zhang, X. Plasmonic random laser on the fiber facet. Opt. Express 2015, 23, 23985–23991. [Google Scholar] [CrossRef]

- Zhai, T.; Zhang, X.; Pang, Z.; Su, X.; Liu, H.; Feng, S.; Wang, L. Random laser based on waveguided plasmonic gain channels. Nano Lett. 2011, 11, 4295–4298. [Google Scholar] [CrossRef]

- Liu, X.; Wu, D.; Chang, Q.; Zhou, J.; Zhang, Y.; Wang, Z. Grooved nanoplate assembly for rapid detection of surface enhanced Raman scattering. Nanoscale 2017, 9, 15390–15396. [Google Scholar] [CrossRef] [PubMed]

- Liang, H.; Li, Z.; Wang, W.; Wu, Y.; Xu, H. Highly surface-roughened ‘‘flower-like’’ silver nanoparticles for extremely sensitive substrates of surface-enhanced Raman scattering. Adv. Mater. 2009, 21, 4614–4618. [Google Scholar] [CrossRef]

- Liu, T.; Li, D.; Yang, D.; Jiang, M. Fabrication of flower-like silver structures through anisotropic growth. Langmuir 2011, 27, 6211–6217. [Google Scholar] [CrossRef] [PubMed]

- Chang, Q.; Shi, X.; Liu, X.; Tong, J.; Liu, D.; Wang, Z. Broadband plasmonic silver nanoflowers for high-performance random lasing covering visible region. Nanophotonics 2017, 6, 1151–1160. [Google Scholar] [CrossRef]

- Zhai, T.; Tong, F.; Cao, F.; Niu, L.; Li, S.; Wang, M.; Zhang, X. Distributed feedback lasing in a metallic cavity. Appl. Phys. Lett. 2017, 111, 111901. [Google Scholar] [CrossRef]

- Chen, C.; Tong, F.; Cao, F.; Tong, J.; Zhai, T.; Zhang, X. Tunable polymer lasers based on metal dielectric hybrid cavity. Opt. Express 2018, 26, 32048–32054. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Choy, W.C.H.; Lu, H.; Sha, W.E.I.; Ho, A.H.P. Efficiency enhancement of organic solar cells by using shape-dependent broadband plasmonic absorption in metallic nanoparticles. Adv. Funct. Mater. 2013, 23, 2728–2735. [Google Scholar] [CrossRef]

- Zhai, T.; Niu, L.; Cao, F.; Tong, F.; Li, S.; Wang, M.; Zhang, X. A RGB random laser on optical fiber facet. RSC Adv. 2017, 7, 45852. [Google Scholar] [CrossRef]

- Zhai, T.; Wu, X.; Li, S.; Liang, S.; Niu, L.; Wang, M.; Feng, S.; Liu, H.; Zhang, X. Polymer lasing in a periodic-random compound cavity. Polymers 2018, 10, 1194. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tong, J.; Li, S.; Chen, C.; Fu, Y.; Cao, F.; Niu, L.; Zhai, T.; Zhang, X. Flexible Random Laser Using Silver Nanoflowers. Polymers 2019, 11, 619. https://doi.org/10.3390/polym11040619

Tong J, Li S, Chen C, Fu Y, Cao F, Niu L, Zhai T, Zhang X. Flexible Random Laser Using Silver Nanoflowers. Polymers. 2019; 11(4):619. https://doi.org/10.3390/polym11040619

Chicago/Turabian StyleTong, Junhua, Songtao Li, Chao Chen, Yulan Fu, Fengzhao Cao, Lianze Niu, Tianrui Zhai, and Xinping Zhang. 2019. "Flexible Random Laser Using Silver Nanoflowers" Polymers 11, no. 4: 619. https://doi.org/10.3390/polym11040619

APA StyleTong, J., Li, S., Chen, C., Fu, Y., Cao, F., Niu, L., Zhai, T., & Zhang, X. (2019). Flexible Random Laser Using Silver Nanoflowers. Polymers, 11(4), 619. https://doi.org/10.3390/polym11040619