1. Introduction

A hybrid resin involves the combination of two constituents: an organic and an inorganic constituent. We have to mention that most attempts at obtaining such resins pertain to the lacquer industry (see [

1,

2,

3]).

Starting from the fact that natural resins cannot make thick resins (see, for instance, [

1] and [

2]), we may draw the conclusion that the bio-resins studied until now have actually been hybrid resins. Therefore, we will refer below to a selective bibliography concerning this type of research.

Bio-resins are resins derived from a biological source, and consequently, they can be biodegradable and compostable; thus, hypothetically, after they have been utilized, they can be decomposed. Sandarac, copal, and dammar are the most often employed vegetable resins. Natural resins are insoluble in water; however, they are slightly soluble in oil, alcohol, and, partly, in petrol. They form solutions with certain organic solvents, solutions that can be used as covering lacquers. Turpentine, colophony, and mastic are products resulting from the distillation of conifer resins. A study concerning the chemical composition of the properties of these resins was carried out in [

4], and the applications were shown in [

5].

In [

6], mechanical characteristics, characteristics of water vapor transmission, and characteristics of moisture absorption of dammar films were studied. These had been produced by the method of solvent casting/evaporation from solutions, which did not contain a softening agent and which contained a softening agent.

The work [

7] shows a new binder, modified from silicon and dammar, which can decrease the use of synthetic binders and features improved and more ecological properties. This binder was put to use to cover some aluminum panels that had been submitted to impact, hardness, tensile, and adherence stresses. The optimal composition ensuring the best properties was determined.

In [

8], the author focused on the creep behavior, the rigidity, the modulus of elasticity, and the hardness of the modified dammar-silicon, using nanoindentation testing, and we studied the way in which the dammar addition had contributed to improving the elastic behavior.

The work [

9] concentrated on extending the knowledge about the microbiological bio-deterioration of dammar-based lacquers in works of art submitted to unsuitable protection conditions, particularly when exposed for a long time to high levels of relative humidity, suggesting that some microorganisms foster natural deterioration phenomena in the case of dammar lacquer films.

The paper [

10] focused on composites that make use of starch-based green resins. Different types of fibers were used, and the stratification structure was modified in order to obtain the desired mechanical properties of the composite.

The reaction to the compression stress of palm tree oil treated with different amounts of dammar resin was analyzed in [

11].

The paper [

12] studied the effects of the waste, residues, or by products on natural fiber-polymer composites and evaluated the potential of these constituents.

The effect of polymethyl methacrylate (PMMA) on the physical properties of dammar for the application of covering lacquers was investigated in [

13]. We found out that dammar, when mixed with PMMA, could be used as a cold covering of laminated steel.

The work [

14] looked into the possibility of using tallow and dammar for beeswax as PCM (phase change materials) on concrete buildings. The research was conducted in several steps, beginning with testing the thermal properties of beeswax, tallow, and dammar, continuing with the preparation of the concrete cement containing these materials, and, then, the final testing of the concrete having PCM.

The work [

15] presented a new type of green composite, in which preforms of short, rigid, and robust natural fibers are used.

In [

16], dammar gum was analyzed as a supplementary material meant to improve thermal conductivity and thermal performance in preparing the material for changing the composite phase.

The work [

17] approached the manufacture of bio-composite sandwich structures, when both the resin and the reinforcements were natural. In the same line, the work [

18] described a new manufacture process for sandwich-type composites, and the test results were statistically analyzed in order to evaluate the effects and responsiveness of the processing parameters, along with the effects of the environment conditions.

Considerable interest has developed recently in using natural fibers instead of synthetic fibers to make composite materials (see [

19,

20]). These natural fibers include flax, hemp, jute, sisal, knead, coconut, kapok, bananas, henequen, and many others. Natural fibers proved to be suitable reinforcing materials for composites due to a combination of good mechanical properties and advantages as far as the environment protection was concerned, such as renewability and biodegradability (see [

21,

22]). The advantages of the natural fibers compared to the traditional fibers include: relatively lower cost, light weight, less damage to the operating equipment, improved surface finishing of the cast pieces (in comparison with steel fiber composites), and good relative mechanical properties.

The main disadvantages of natural fibers are: their processing is limited to low-temperature processing (limited thermal stability); their tendency to form piles; and their hydrophilic nature (see [

23,

24,

25]). The experimental data on their mechanical properties, particularly when they are tested under various processing conditions, have shown inconsistent values in many cases (see [

20,

21,

22]). The irregular characteristics of natural fibers are one of the reasons explaining this. In addition, in many cases, there are problems linked to the interfacial properties of this type of composite (see [

20,

21,

22]). Good results were also obtained through the development of the biopolymer nanocomposites (see, for example, [

26,

27]), as a successful strategy to obtain green composites with excellent performances.

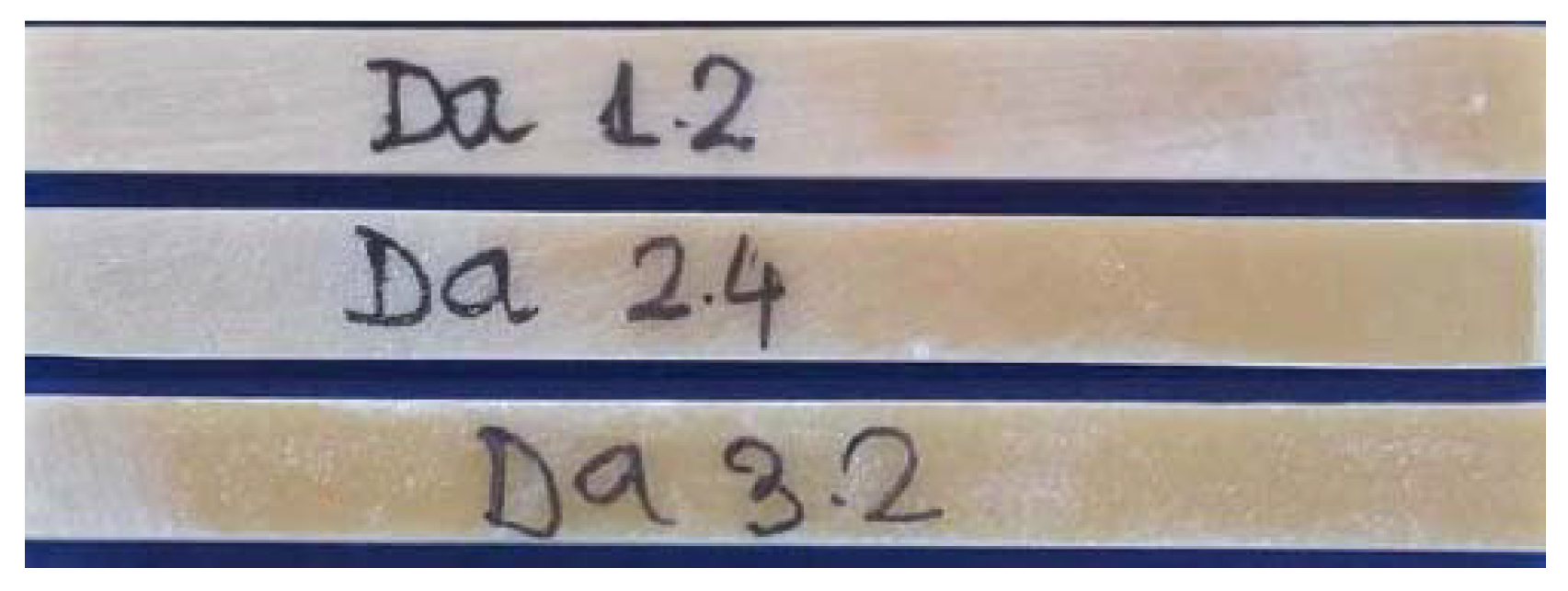

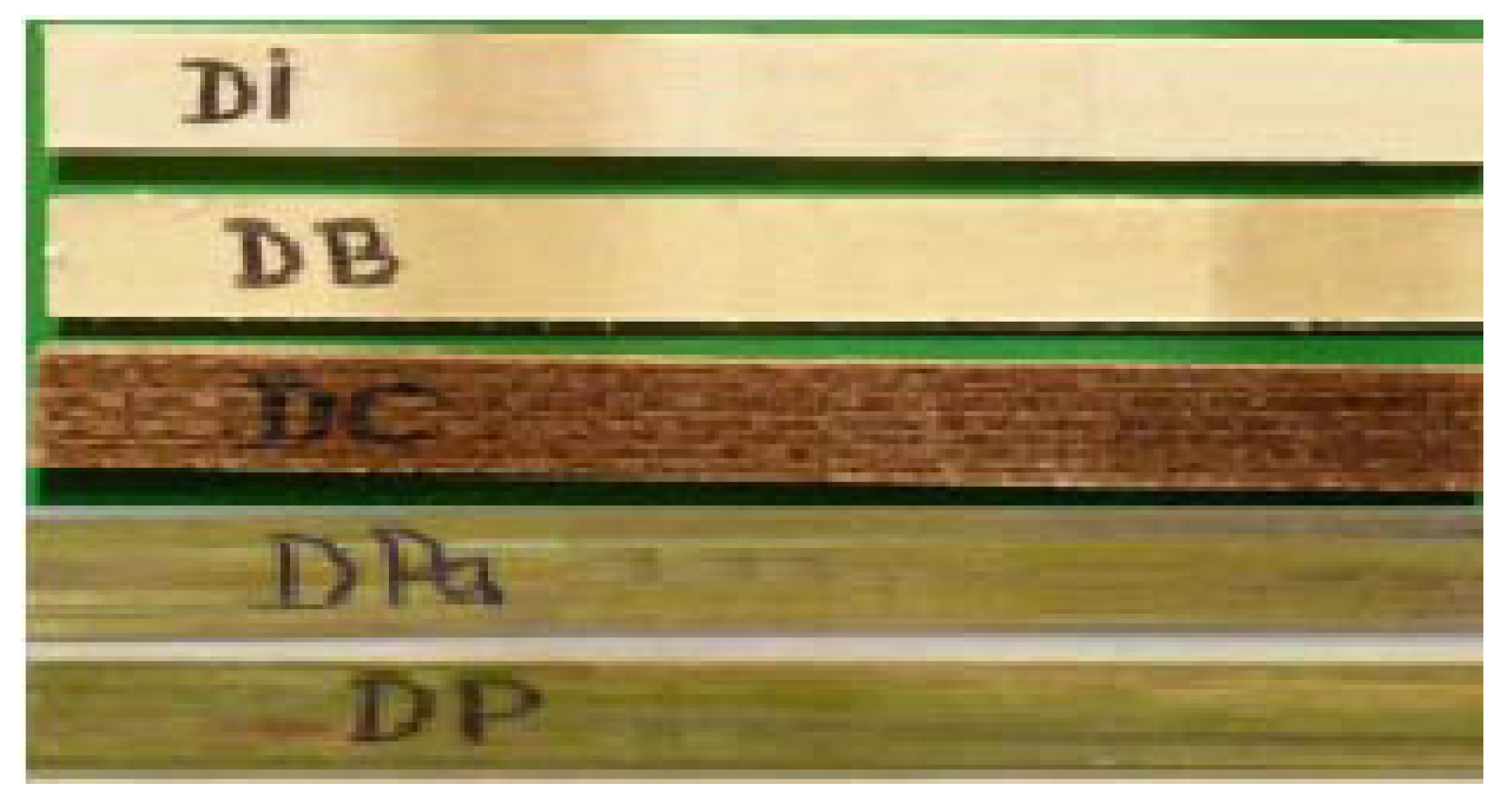

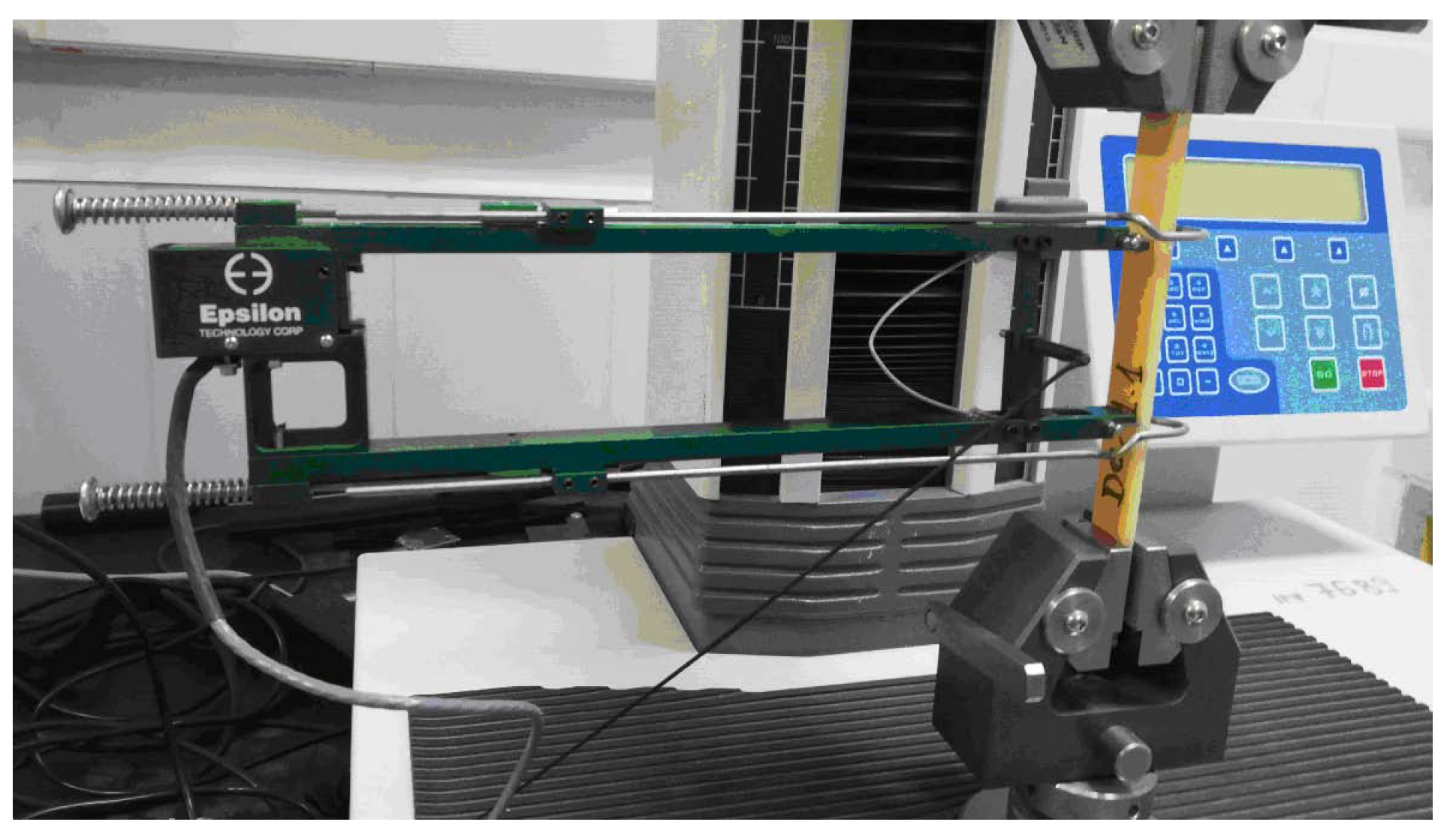

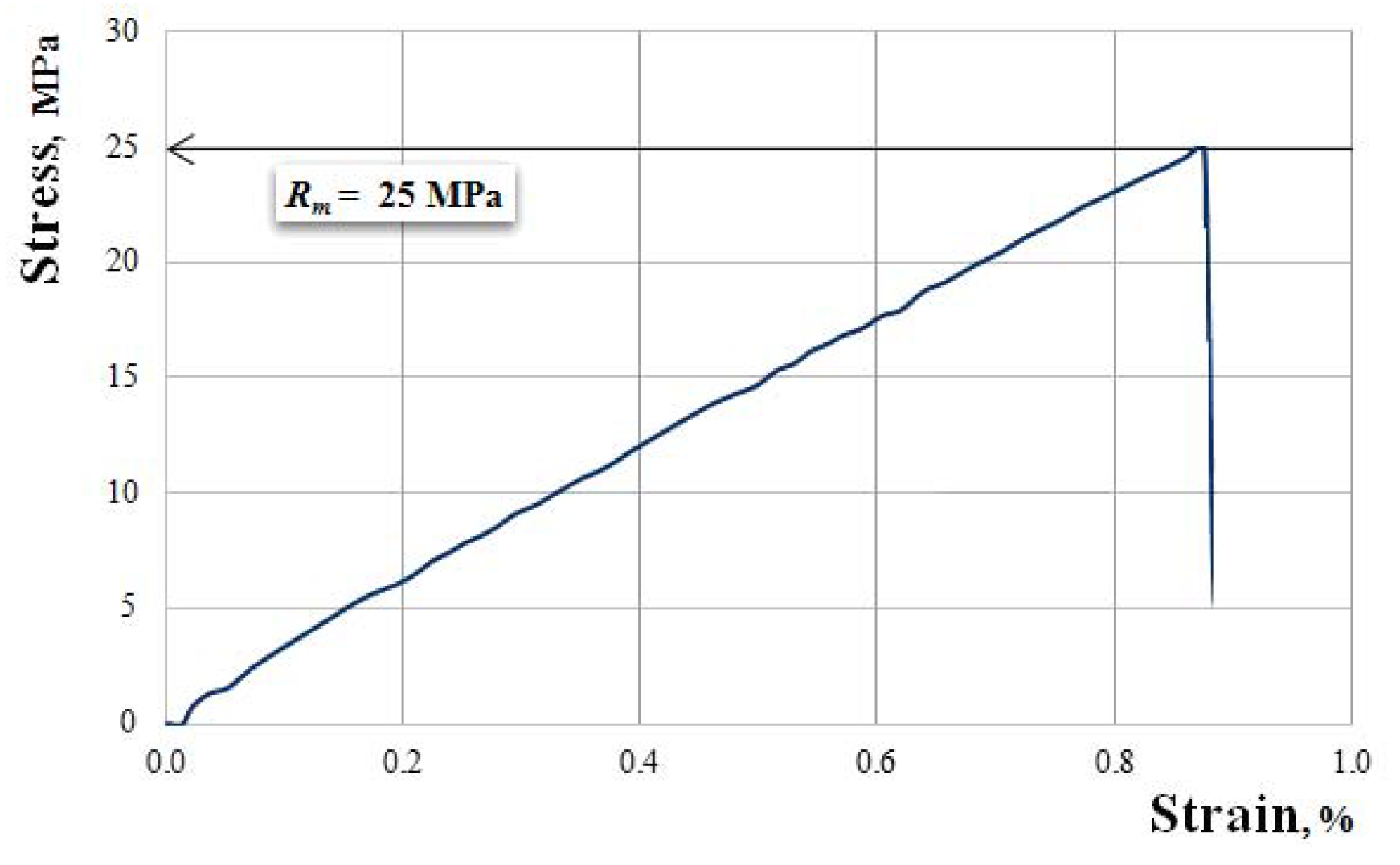

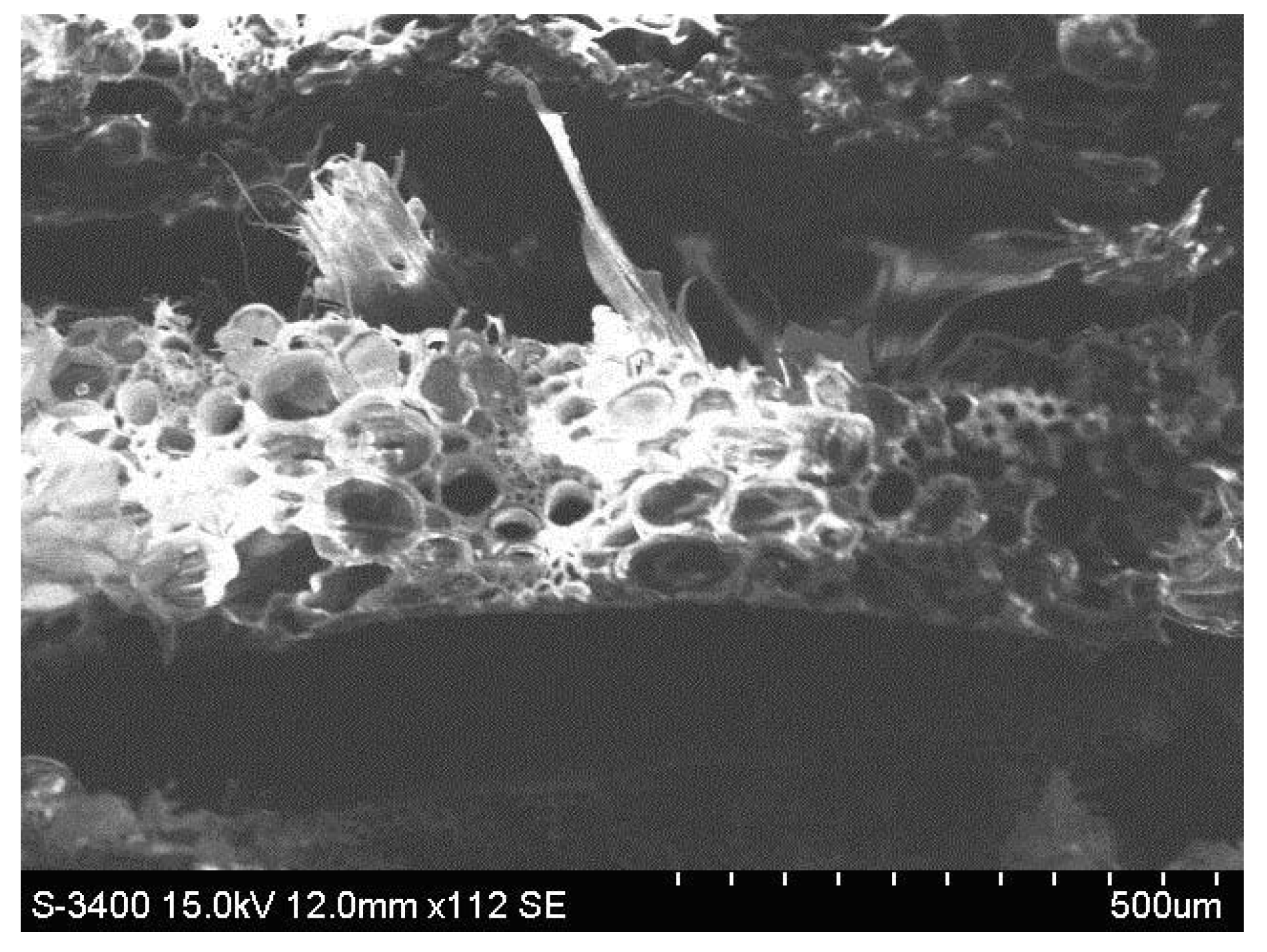

In this paper, we present some mechanical properties of three sets of samples made of a hybrid resin, in the composition of which we used a dammar volume proportion of 55%, 65%, and 75%, respectively. The difference, up to 100%, consisted of epoxy resin and its associated reinforcement. The properties were determined based on tensile tests. We picked a hybrid resin sample of each set of samples, and we determined its chemical composition by using EDS (energy-dispersive X-ray spectroscopy). We studied the influence of the epoxy resin volume proportion on the mechanical behavior of the hybrid resin. We also determined, based on tensile testing, the characteristic curves, tensile strength, elongation at break, modulus of elasticity, and the images of the break area for the samples made of composite materials with the hybrid resin matrix that we had obtained previously. As for reinforcement, we used fabrics of hemp, cotton, and flax, wheat straws and cattail leaves. In order to expand the applicability of these composite materials, we also looked into the vibration damping properties.

4. Discussion and Conclusions

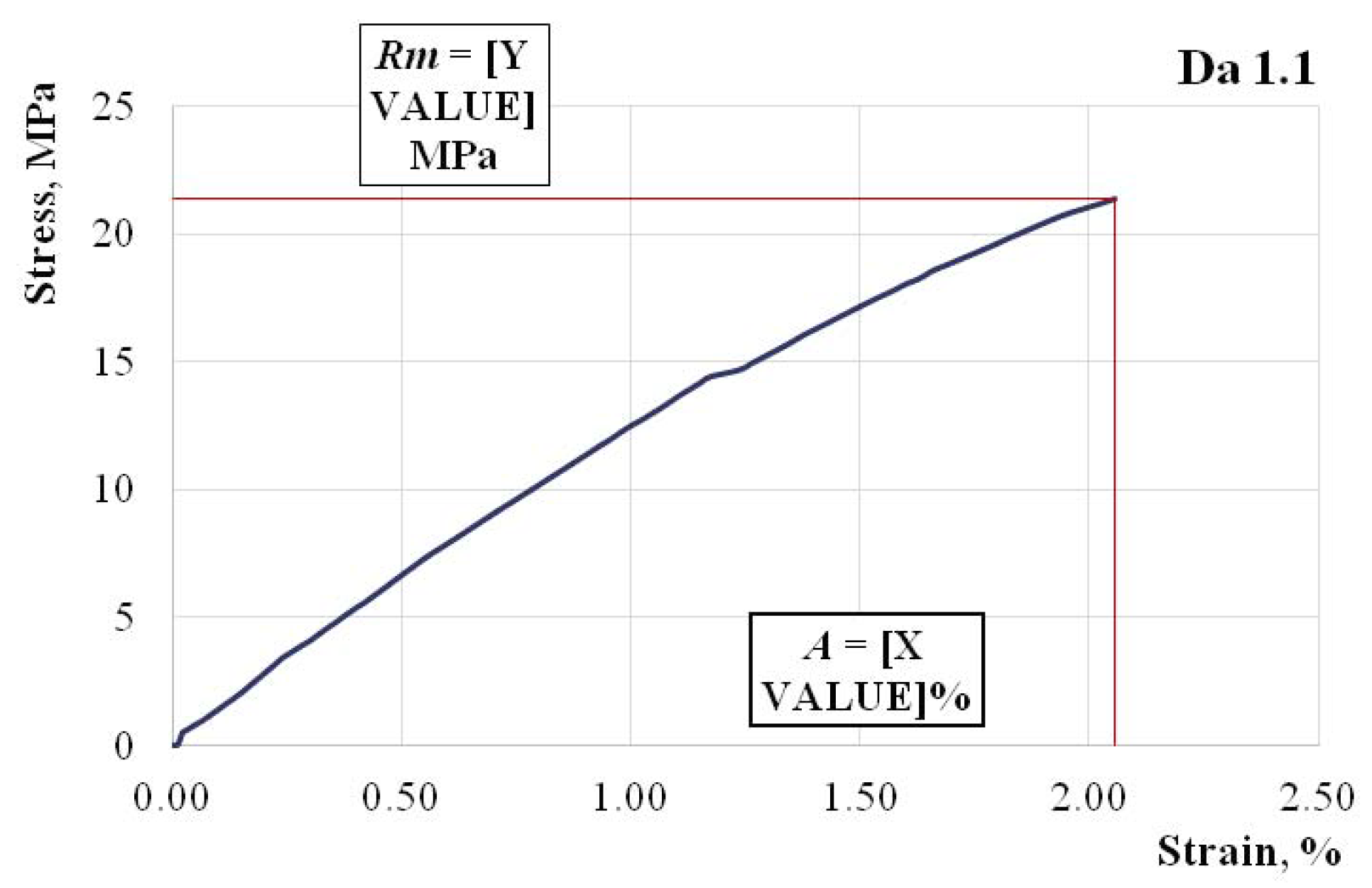

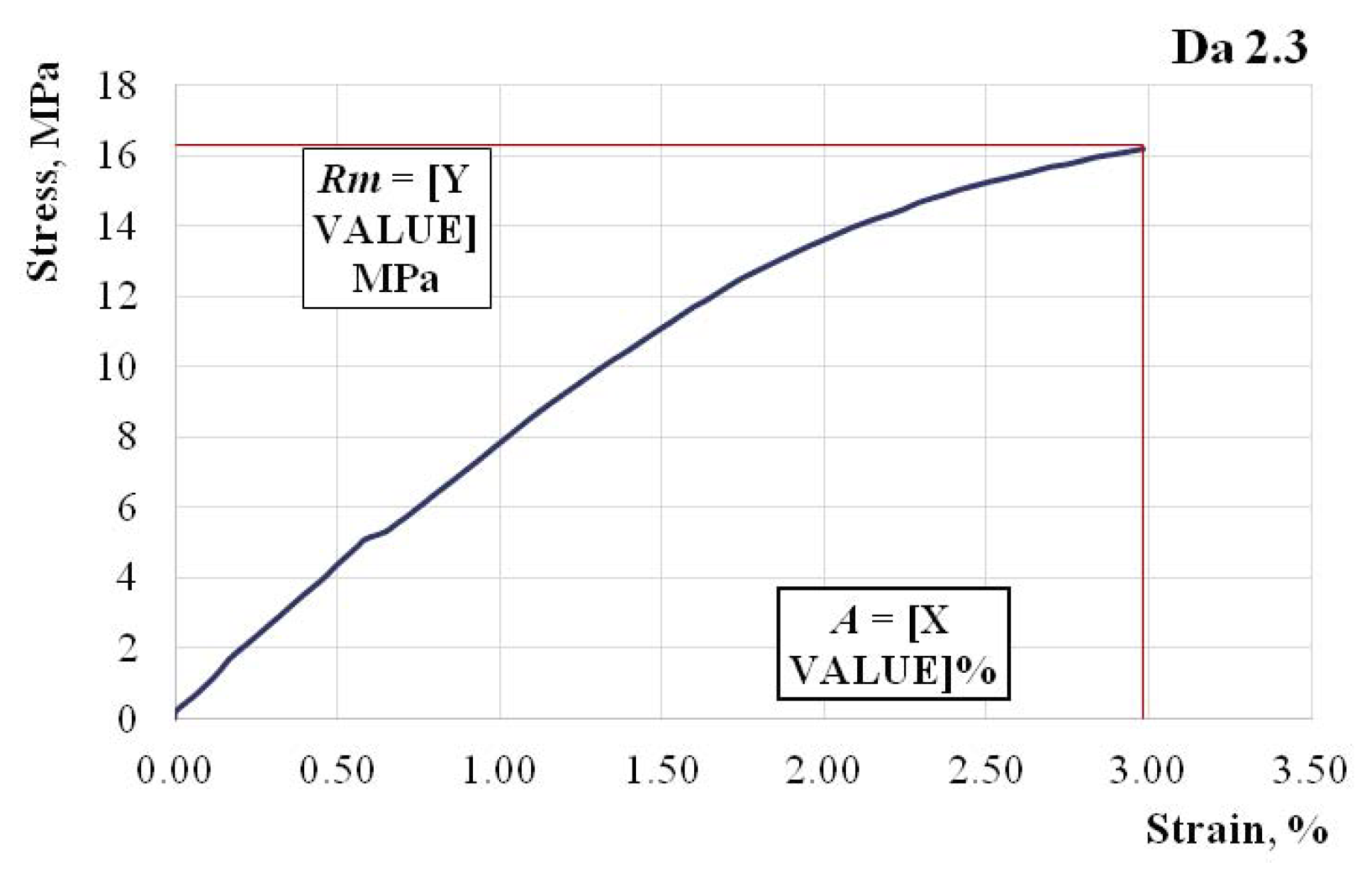

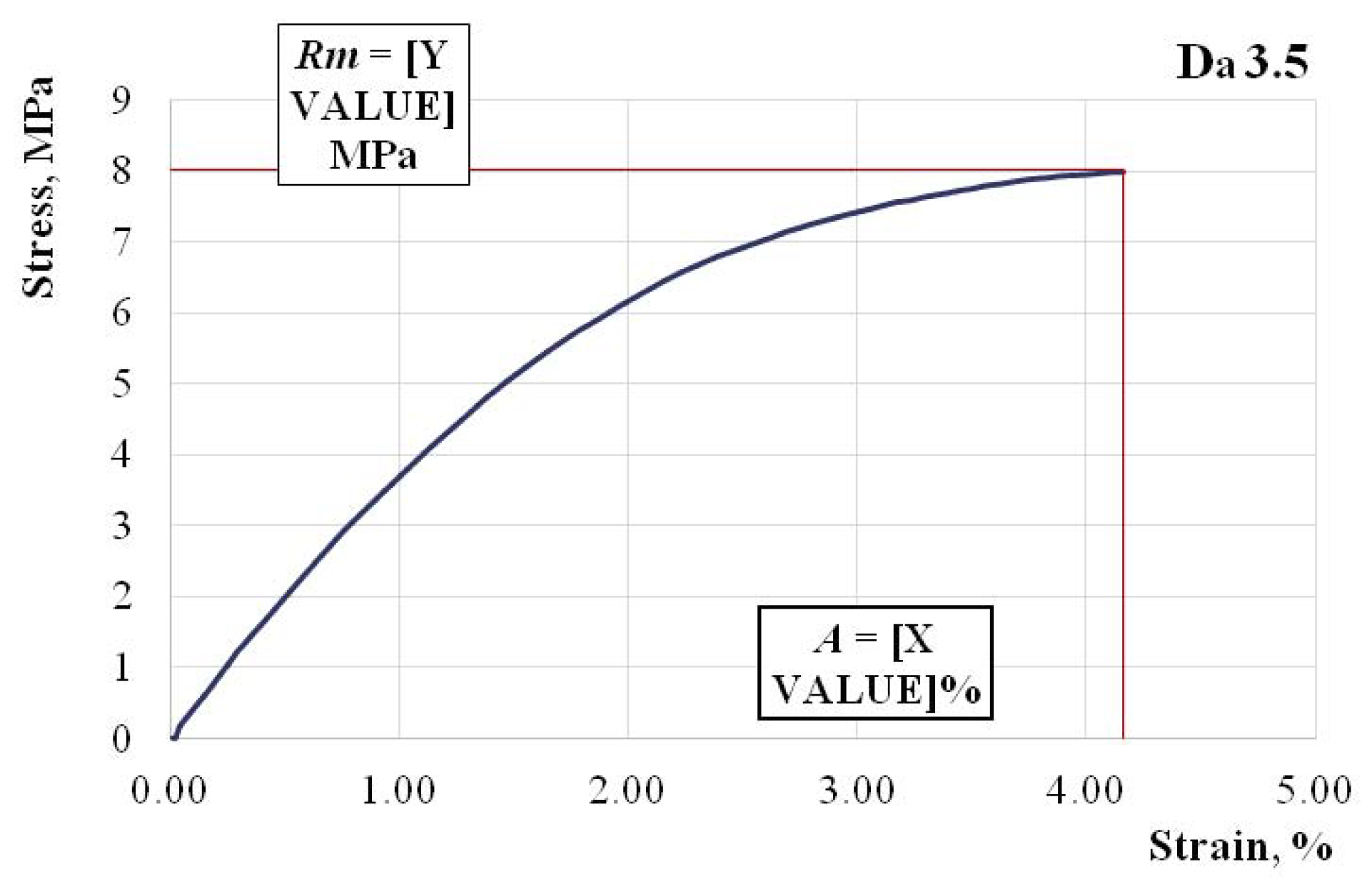

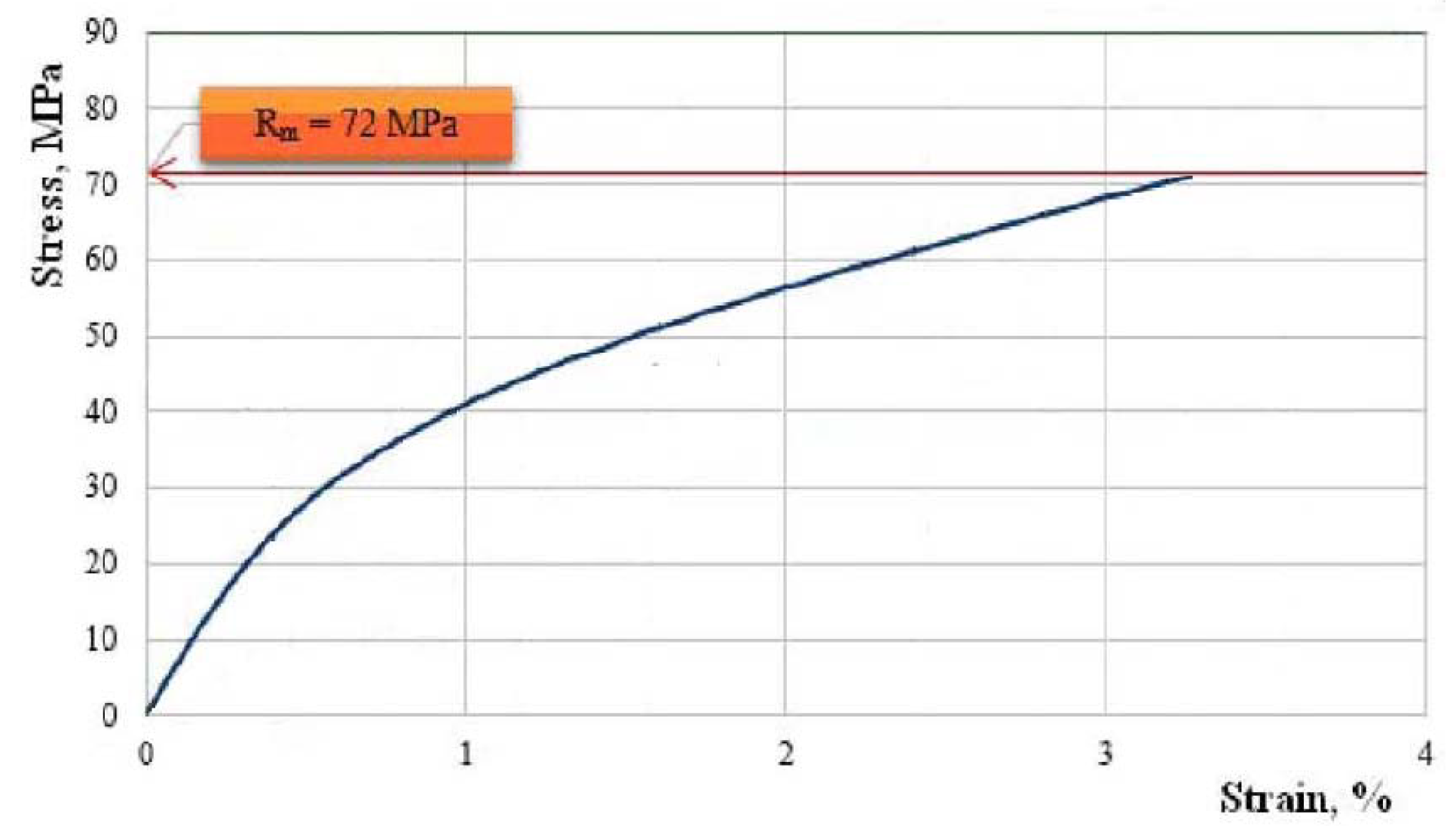

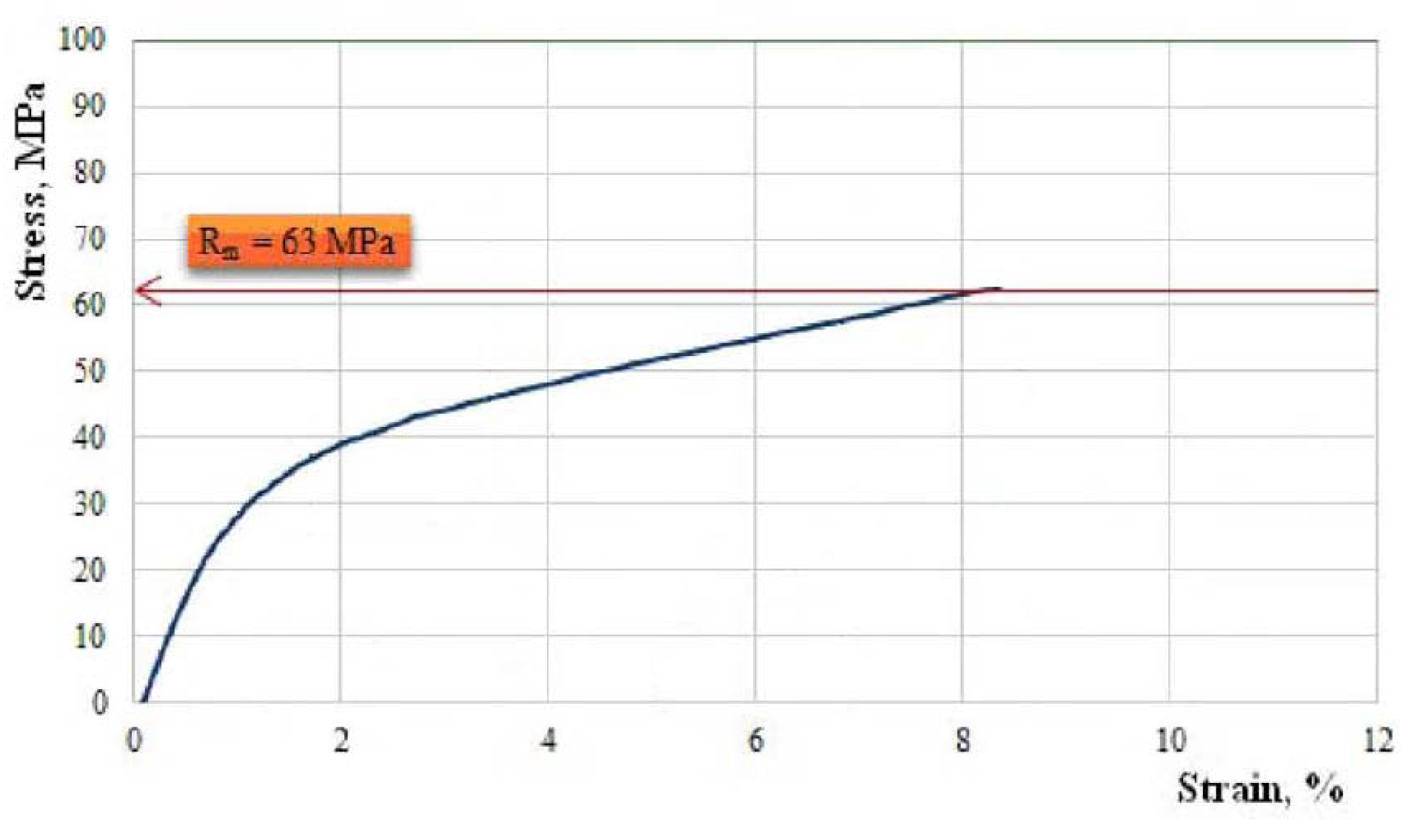

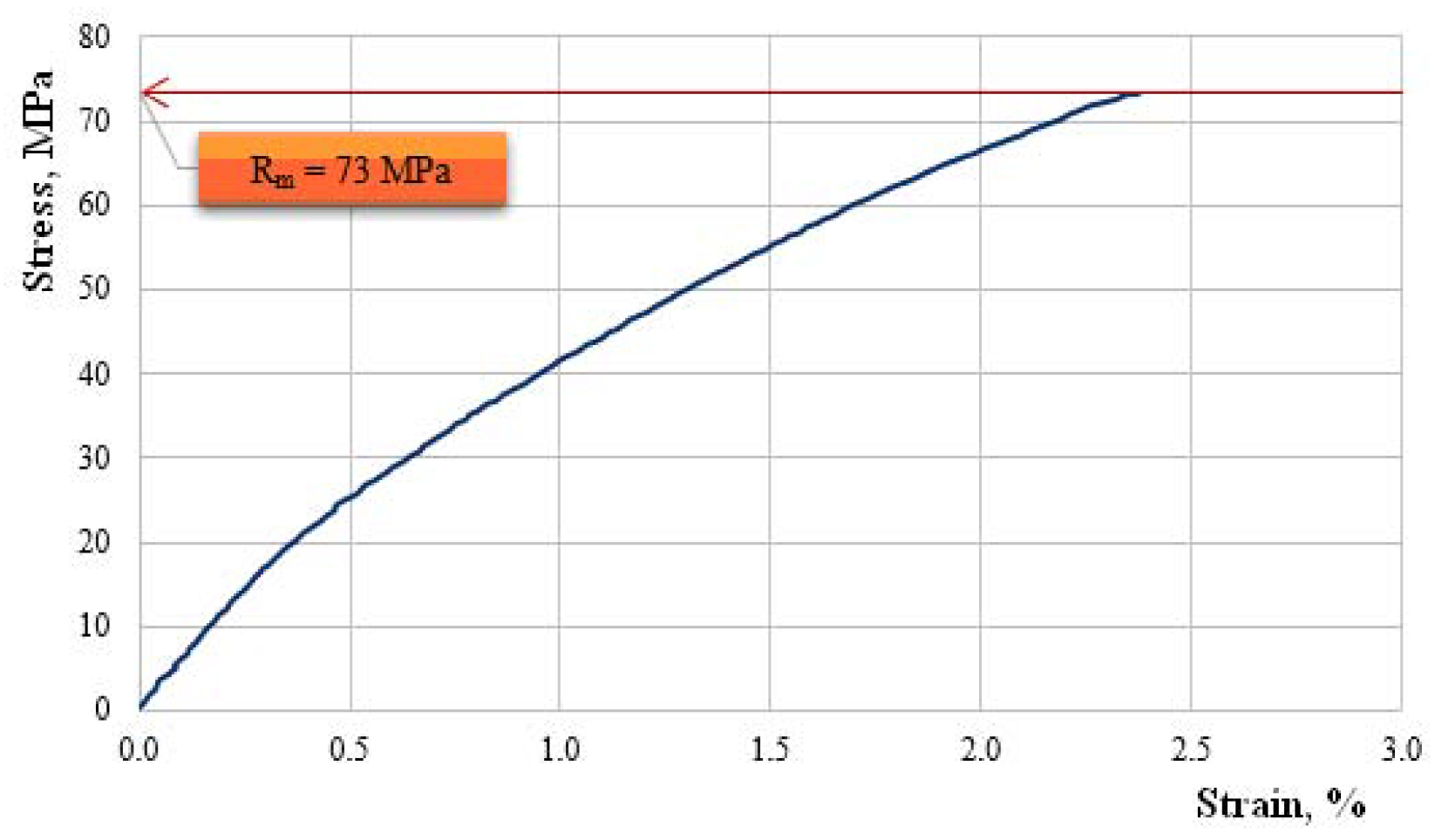

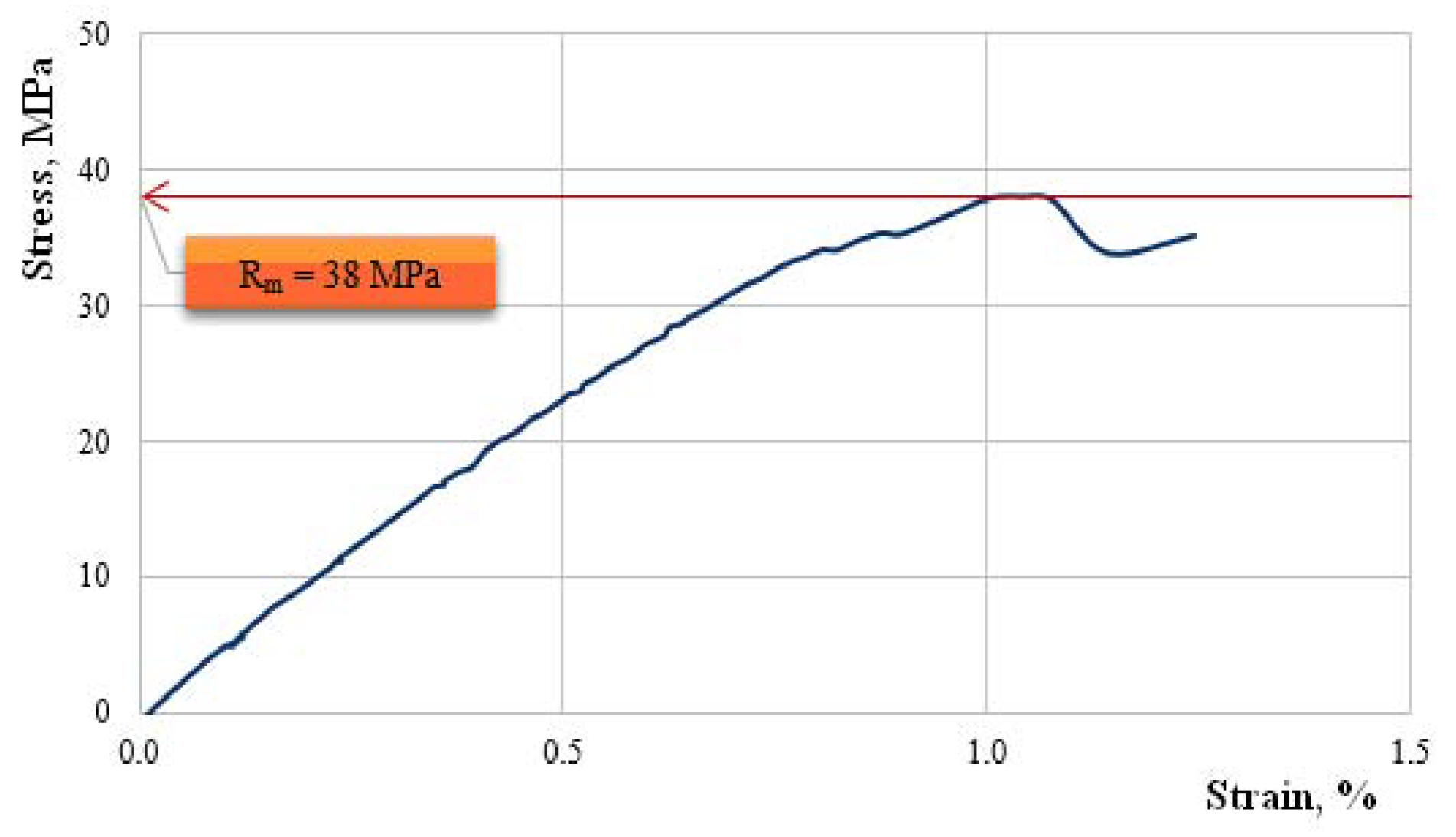

Comparing the experimental results shows an important change in the mechanical properties when the proportion between dammar and epoxy resin was changed. We noticed a decrease in the values of the tensile strength and the modulus of elasticity as the dammar volume proportion was increased in the mixture. Although the mixtures with a higher epoxy resin quantity had superior mechanical properties, we cannot state that there was a proportionality between the tensile strength or the modulus of elasticity and the epoxy resin volume proportion. Thus, for the 55% dammar mixture, we had the highest values of the mechanical properties. For the 65% dammar mixture, where the epoxy resin volume proportion dropped by 22%, the tensile strength decreased by 24% and the modulus of elasticity decreased by 40%. For the 75% dammar mixture, the epoxy resin volume proportion dropped by 44%, the tensile strength decreased by 63% and the modulus of elasticity by 56%.

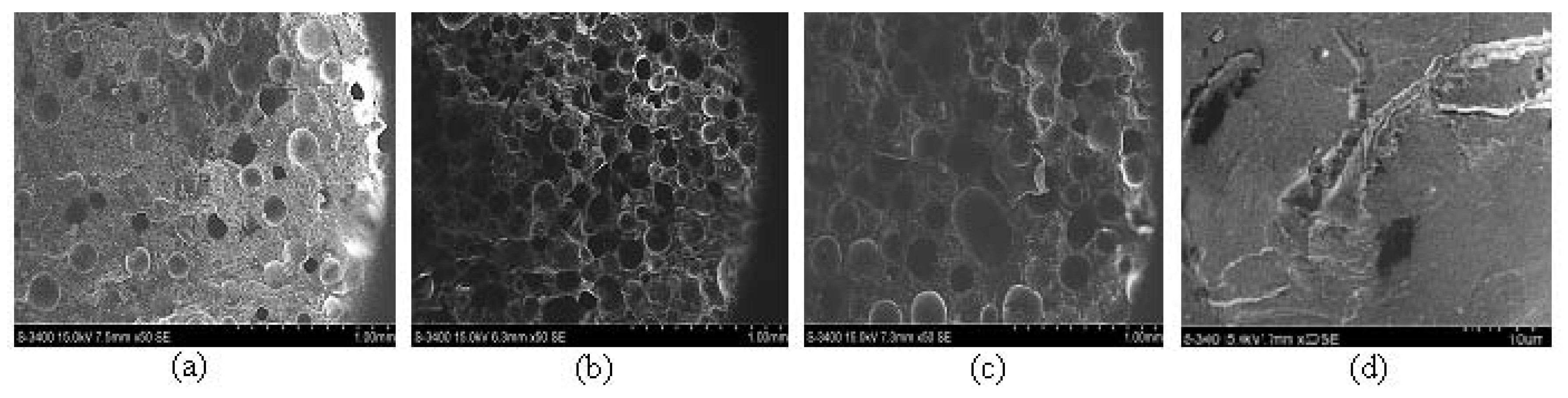

The increase of the air volume in the hybrid resin, together with an increase of the dammar volume proportion may explain this decrease. Another explanation might be that the higher proportion of dammar simply weakened the hardened matrix.

Changes also appeared in the forms of the characteristic curves. If in the 55% dammar mixture, the characteristic curve was almost linear, in the 75% dammar mixture, there was an obvious nonlinearity of the characteristic curve.

Changes appeared in the elongation at break as well, which was approximately 2% in the mixture with 55% dammar, 3% in the mixture with 65% dammar, and 4% in the mixture with 75% dammar. This also points to a weaker, more elastic system.

The analysis of the characteristic curves shows a difference in behavior depending on the reinforcing materials. The elongation at break of the composites was comparable with the elongation at break of the reinforcing materials.

The composites reinforced with fabric of flax or hemp fibers (which had elongations at break below 4%) had a low elongation at break, of almost 8.5%.

In the case of the composites with wheat straw or cattail, the elongation at break was very low, around 1%, and at their break, the breaking stress for the resin was reached as well, which yielded in turn. Actually, the characteristic curves of these materials were almost linear as well, linearity being obvious in the cattail leaves-reinforced materials.

If in the case of cattail leaves-reinforced composite materials, we obtained properties comparable to those of the matrix, and in the case of the wheat straw-reinforced composites, we noticed a significant increase in the modulus of elasticity, which was higher than in all the studied materials.

In the case of the composite materials reinforced with cotton fabric, three zones of the characteristic curve can be highlighted. In the first zone, there was a linear dependence between stress and strain, as validated by Hooke’s law. In this zone, the composite behaved as a unit, the fibers and the matrix taking over the stresses together. The second zone was characterized by a significant nonlinearity that was due to important deformations appearing in the matrix; the matrix began to yield, and the stress was transferred to the fibers. In the third zone, linearity reappeared, explained by the fact that the stresses were mostly taken over by the longitudinal fibers, the stress going up to the break of the fibers.

In the samples reinforced with hemp fabric, where the elongation at break of the reinforcing material was small, the nonlinearity of the characteristic curve was smaller, although it had been manifest since the beginning of the stress. This can be explained by the fact that the matrix and the reinforcing material, together, took over the external load during the whole stress time.

In the case of the samples of flax fabric-reinforced composite materials, the behavior of the composite material had an intermediary character; more precisely, the characteristic curve displayed three zones, like in the case of the cotton-reinforced samples; however, the nonlinearities were present in all the zones, as in the hemp-reinforced samples.

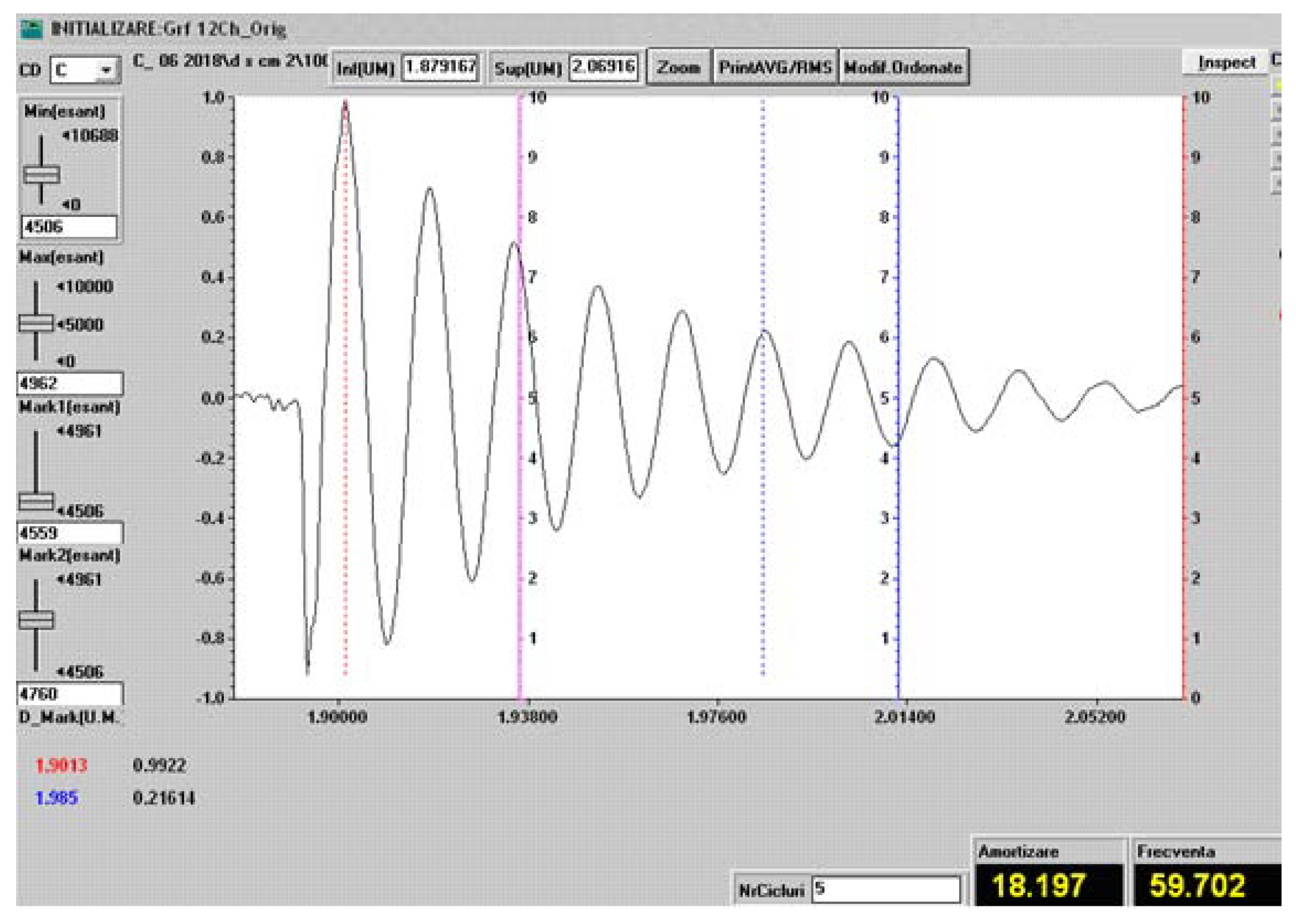

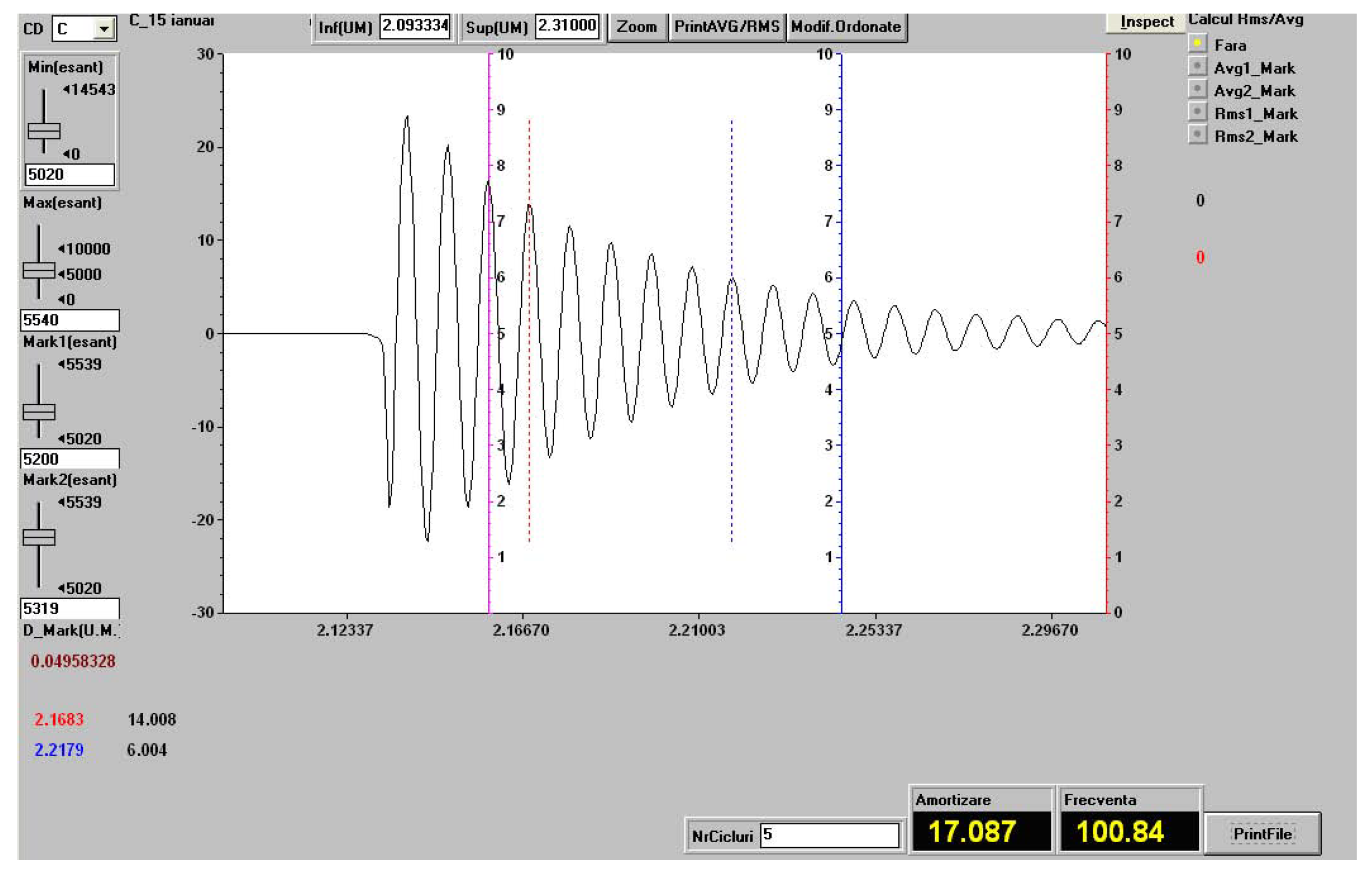

The damping capacity is given by the

loss factor. In the study of damped vibrations, the complex modulus of elasticity was used:

Under these conditions, the loss factor is a property of the material, in the same way as the modulus of elasticity, tensile strength, and others.

Since the damping factor depends on the sample length, we may calculate the loss factor (calculated with the ratio

given in [

35], where

and

v are the damping factor and the frequency, according to

Table 4 and

Table 7) for each of the materials. The following average results were obtained:

- -

for epoxy resin ;

- -

for 55% dammar hybrid resin ;

- -

for 65% dammar hybrid resin ;

- -

for 75% dammar hybrid resin ;

- -

for flax fabric-reinforced composites ;

- -

for cotton fabric-reinforced composites ;

- -

for hemp fabric-reinforced composites .

We may notice that the loss factor decreased as the bar rigidity increased, which is directly proportional to the modulus of elasticity of the material.

Concerning the behavior of sample on vibration, we noticed an increase in the damping capacity (given by ), when the dammar proportion increased in the composition.

If we compare the damping factor value for hybrid resin with 65% dammar resin and the values of the composite materials reinforced with fabric of flax, cotton, or hemp, we realize that there were no significant differences.

In the case of the loss factor, we saw a decrease of the obtained values for the composite materials, compared to hybrid resin with 65% dammar resin. More precisely, the lowest decrease was in the case of cotton fabric-reinforced composites, and the highest was in the case of hemp fabric-reinforced composites.

The mechanical properties, together with the vibration damping properties obtained for the studied composites, recommend them to be used for:

- -

making reusable devices to immobilize fractures, more precisely for making one-size-fits-all pieces that can be fixed afterwards by a self-adhesive bandage system;

- -

making wainscoting or “almost environment-friendly” parquet blocks (as an alternative to wood and PVC);

- -

making reusable formworks for some construction elements.