Mechanically and Thermally Induced Degradation and Modification of Cereal Biopolymers during Grinding

Abstract

:1. Introduction

2. Materials and Methods

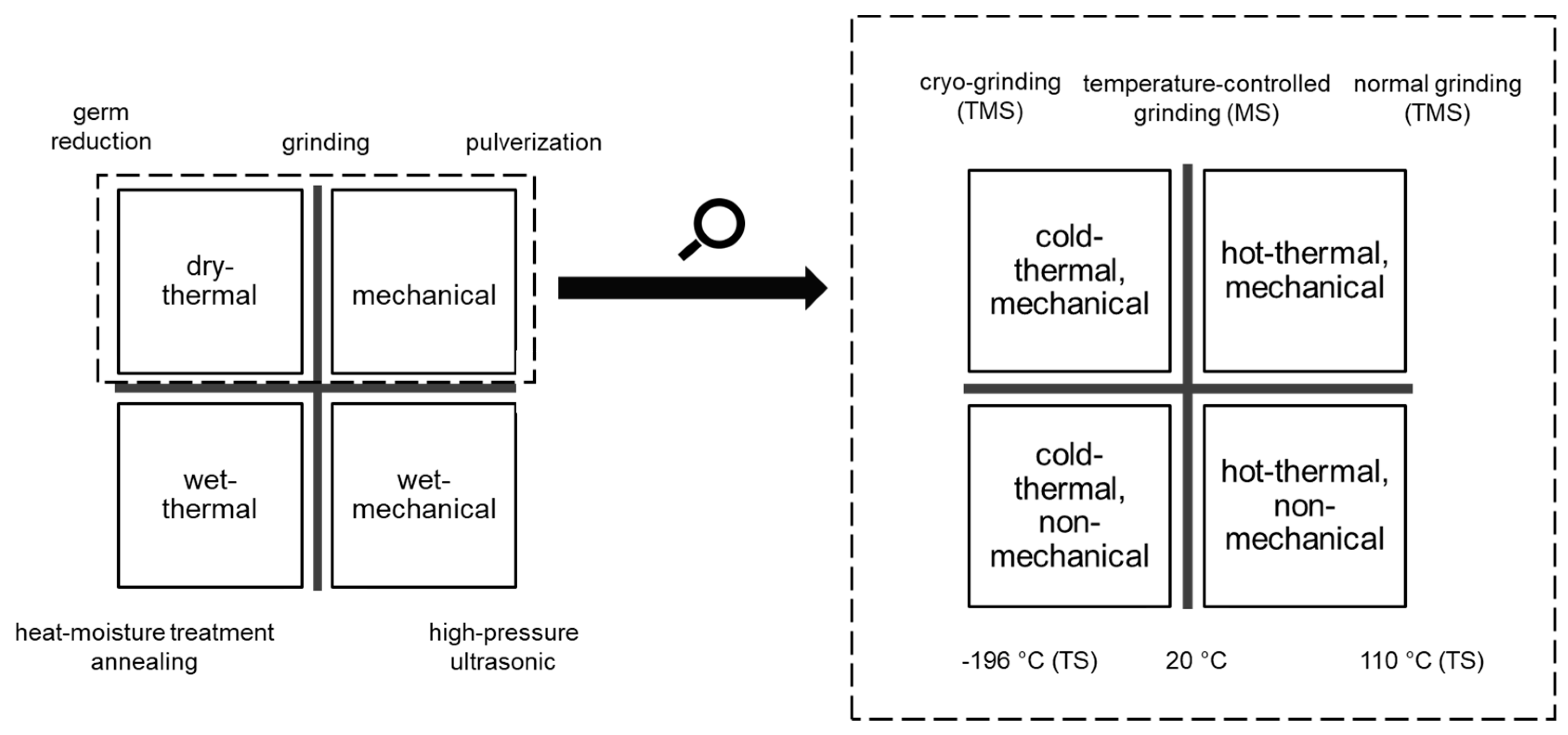

2.1. Physical Treatments of Raw Materials

2.2. Particle size Distribution

2.3. Starch Modification Degree

2.4. Starch Crystal Melting (Gelatinization Properties)

2.5. Water Retention Capacity (WRC)

2.6. Dough Properties (Z-Kneading System)

2.7. Statistical Analysis

3. Results and Discussion

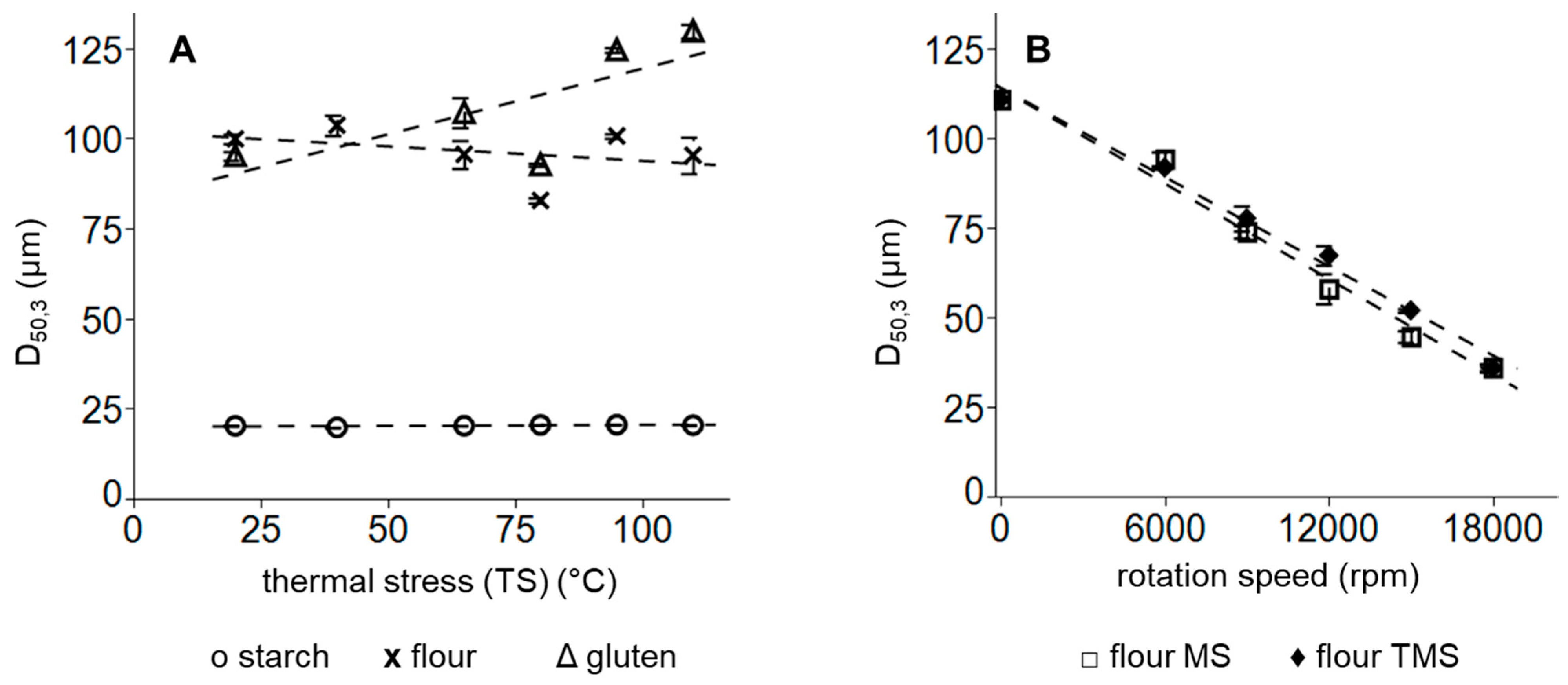

3.1. Particle Size Distribution

3.2. Starch Modification Degree

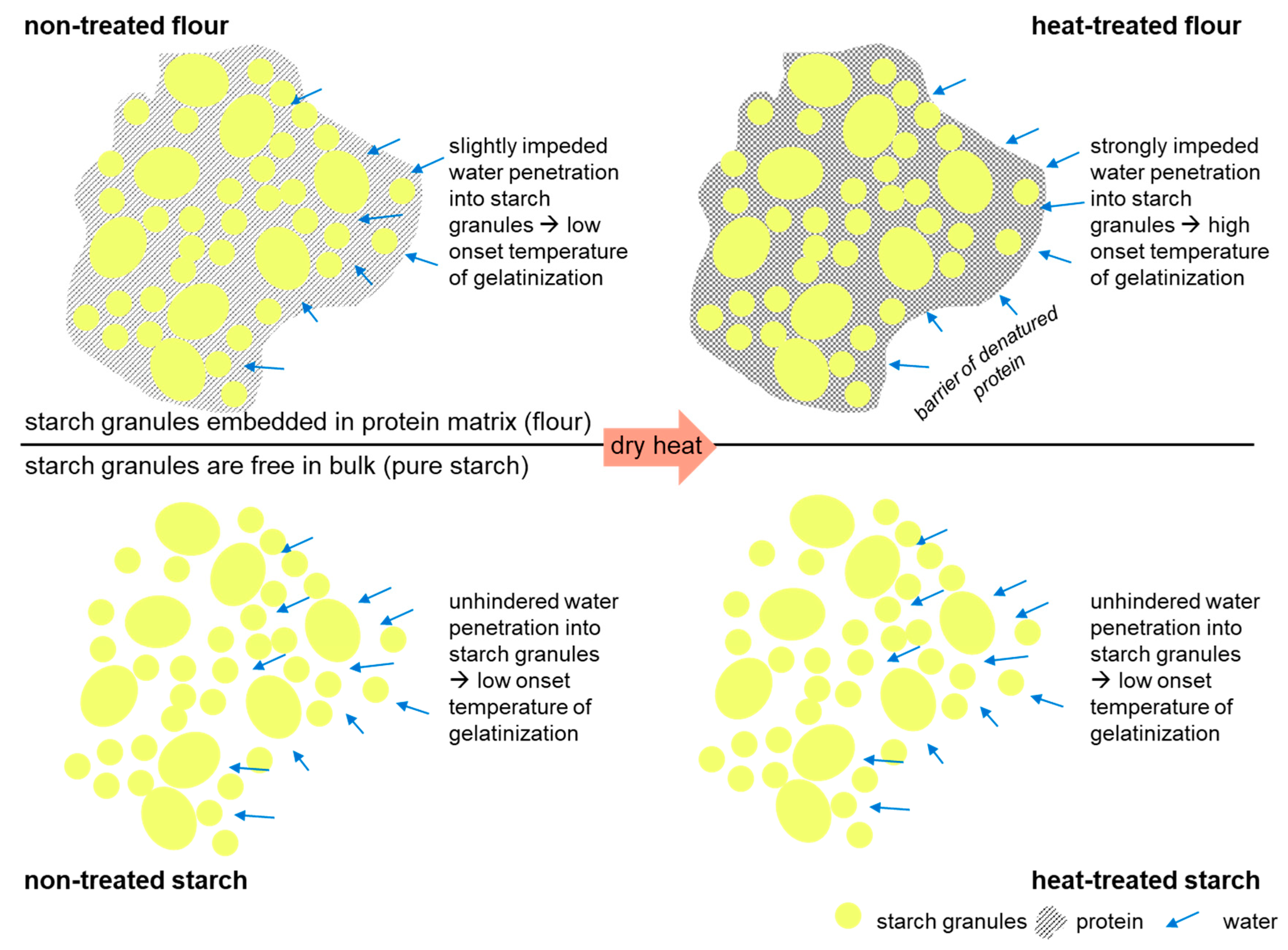

3.3. Gelatinization Properties

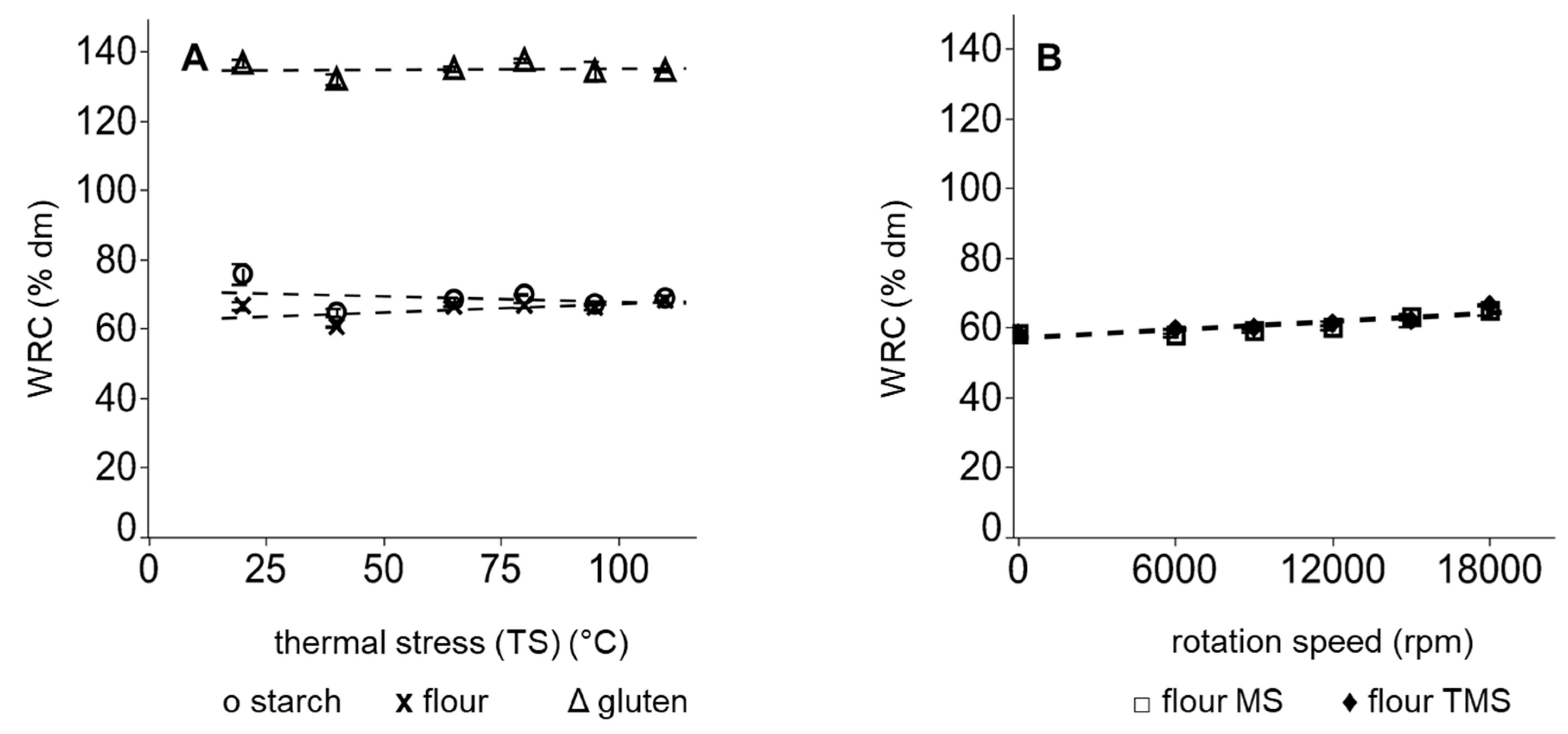

3.4. Functional Alterations of Cereal Polymers

3.5. Transferability to Other Cereal Flours

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lee, M.-R.; Swanson, B.G.; Baik, B.-K. Influence of amylose content on properties of wheat starch and breadmaking quality of starch and gluten blends. Cereal Chem. 2007, 78, 701–706. [Google Scholar] [CrossRef]

- Barak, S.; Mudgil, D.; Khatkar, B.S. Effect of flour particle size and damaged starch on the quality of cookies. J. Food Sci. Technol. 2014, 51, 1342–1348. [Google Scholar] [CrossRef] [PubMed]

- Ali, R.; Khan, M.S.; Sayeed, S.A.; Ahmed, R.; Saeed, G.; Mobin, L. Relationship of damaged starch with some physicochemical parameters in assessment of wheat flour quality. Pak. J. Bot. 2014, 46, 2217–2225. [Google Scholar]

- León, A.E.; Barrera, G.N.; Pérez, G.T.; Ribotta, P.D.; Rosell, C.M. Effect of damaged starch levels on flour-thermal behaviour and bread staling. Eur. Food Res. Technol. 2006, 224, 187–192. [Google Scholar] [CrossRef]

- Jakobi, S.; Jekle, M.; Becker, T. Direct link between specific structural levels of starch and hydration properties. Carbohydr. Polym. 2018, 181, 159–166. [Google Scholar] [CrossRef] [PubMed]

- Martínez, M.; Oliete, B.; Gómez, M. Effect of the addition of extruded wheat flours on dough rheology and bread quality. J. Cereal Sci. 2013, 57, 424–429. [Google Scholar] [CrossRef]

- Hackenberg, S.; Verheyen, C.; Jekle, M.; Becker, T. Effect of mechanically modified wheat flour on dough fermentation properties and bread quality. Eur. Food Res. Technol. 2017, 243, 287–296. [Google Scholar] [CrossRef]

- Schlesinger, J. Results of ball-milling buhler experimentally milled hard winter wheat flour. Cereal Chem. 1964, 41, 465–473. [Google Scholar]

- Mao, Y.; Flores, R.A. Mechanical starch damage effects on wheat flour tortilla texture. Cereal Chem. J. 2001, 78, 286–293. [Google Scholar] [CrossRef]

- Hormdok, R.; Noomhorm, A. Hydrothermal treatments of rice starch for improvement of rice noodle quality. LWT Food Sci. Technol. 2007, 40, 1723–1731. [Google Scholar] [CrossRef]

- Khunae, P.; Tran, T.; Sirivongpaisal, P. Effect of heat-moisture treatment on structural and thermal properties of rice starches differing in amylose content. Starch Stärke 2007, 59, 593–599. [Google Scholar] [CrossRef]

- Anderson, A.K.; Guraya, H.S. Effects of microwave heat-moisture treatment on properties of waxy and non-waxy rice starches. Food Chem. 2006, 97, 318–323. [Google Scholar] [CrossRef]

- Gunaratne, A.; Hoover, R. Effect of heat–moisture treatment on the structure and physicochemical properties of tuber and root starches. Carbohydr. Polym. 2002, 49, 425–437. [Google Scholar] [CrossRef]

- Herceg, I.L.; Režek Jambrak, A.; Šubarić, D.; Brnčić, M.; Rimac Brnčić, S.; Badanjak, M.; Tripalo, B.; Ježek, D.; Novotni, D.; Herceg, Z. Texture and pasting properties of ultrasonically treated corn starch. Czech J. Food Sci. 2010, 28, 83–93. [Google Scholar] [CrossRef]

- Luo, Z.; Fu, X.; He, X.; Luo, F.; Gao, Q.; Yu, S. Effect of ultrasonic treatment on the physicochemical properties of maize starches differing in amylose content. Starch Stärke 2008, 60, 646–653. [Google Scholar] [CrossRef]

- Jakobi, S.; Jekle, M.; Becker, T. High-pressure treatment of non-hydrated flour affects structural characteristics and hydration. Foods 2018, 7, 78. [Google Scholar] [CrossRef]

- Tran, T.T.B.; Shelat, K.J.; Tang, D.; Li, E.; Gilbert, R.G.; Hasjim, J. Milling of rice grains. The degradation on three structural levels of starch in rice flour can be independently controlled during grinding. J. Agric. Food Chem. 2011, 59, 3964–3973. [Google Scholar] [CrossRef]

- Giorni, P.; Dall’Asta, C.; Gregori, R.; Cirlini, M.; Galaverna, G.; Battilani, P. Starch and thermal treatment, important factors in changing detectable fumonisins in maize post-harvest. J. Cereal Sci. 2015, 61, 78–85. [Google Scholar] [CrossRef]

- Neill, G.; Al-Muhtaseb, A.H.; Magee, T.R.A. Optimisation of time/temperature treatment, for heat treated soft wheat flour. J. Food Eng. 2012, 113, 422–426. [Google Scholar] [CrossRef]

- Qin, Y.; Liu, C.; Jiang, S.; Cao, J.; Xiong, L.; Sun, Q. Functional properties of glutinous rice flour by dry-heat treatment. PLoS ONE 2016, 11, e0160371. [Google Scholar] [CrossRef]

- Sun, Q.; Gong, M.; Li, Y.; Xiong, L. Effect of dry heat treatment on the physicochemical properties and structure of proso millet flour and starch. Carbohydr. Polym. 2014, 110, 128–134. [Google Scholar] [CrossRef] [PubMed]

- Zia-ud-Din; Xiong, H.; Fei, P. Physical and chemical modification of starches: A review. Crit. Rev. Food Sci. Nutr. 2017, 57, 2691–2705. [Google Scholar] [CrossRef] [PubMed]

- Hareland, G.A. Evaluation of flour particle size distribution by laser diffraction, sieve analysis and near-infrared reflectance spectroscopy. J. Cereal Sci. 1994, 20, 183–190. [Google Scholar] [CrossRef]

- James, B.; Whistler, R. Starch Chemistry and Technology, 3rd ed.; James, B., Whistler, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2009; ISBN 9780080926551. [Google Scholar]

- Kumar, R.; Kumar, A.; Sharma, N.K.; Kaur, N.; Chunduri, V.; Chawla, M.; Sharma, S.; Singh, K.; Garg, M. Soft and hard textured wheat differ in starch properties as indicated by trimodal distribution, morphology, thermal and crystalline properties. PLoS ONE 2016, 11, e0147622. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, J.; Mulla, M.Z.; Arfat, Y.A. Particle size, rheological and structural properties of whole wheat flour doughs as treated by high pressure. Int. J. Food Prop. 2017, 20, 1829–1842. [Google Scholar] [CrossRef]

- Weegels, P.L.; de Groot, A.M.G.; Verhoek, J.A.; Hamer, R.J. Effects on gluten of heating at different moisture contents. II changes in physico-chemical properties and secondary structure. J. Cereal Sci. 1994, 19, 39–47. [Google Scholar] [CrossRef]

- Schofield, J.D.; Bottomley, R.C.; Timms, M.F.; Booth, M.R. The effect of heat on wheat gluten and the involvement of sulphydryl-disulphide interchange reactions. J. Cereal Sci. 1983, 1, 241–253. [Google Scholar] [CrossRef]

- Hossen, M.S.; Sotome, I.; Nanayama, K.; Sasaki, T.; Okadome, H. Functional properties of submicron-scale rice flour produced by wet media grinding. Cereal Chem. J. 2016, 93, 53–57. [Google Scholar] [CrossRef]

- Sharma, P.; Chakkaravarthi, A.; Singh, V.; Subramanian, R. Grinding characteristics and batter quality of rice in different wet grinding systems. J. Food Eng. 2008, 88, 499–506. [Google Scholar] [CrossRef]

- Sharif Hossen, M.; Sotome, I.; Takenaka, M.; Isobe, S.; Nakajima, M.; Okadome, H. Starch damage and pasting properties of rice flours produced by dry jet grinding. Cereal Chem. 2011, 88, 6–11. [Google Scholar] [CrossRef]

- Angelidis, G.; Protonotariou, S.; Mandala, I.; Rosell, C.M. Jet milling effect on wheat flour characteristics and starch hydrolysis. J. Food Sci. Technol. 2016, 53, 784–791. [Google Scholar] [CrossRef] [PubMed]

- Mu, T.-H.; Zhang, M.; Raad, L.; Sun, H.-N.; Wang, C. Effect of α-amylase degradation on physicochemical properties of pre-high hydrostatic pressure-treated potato starch. PLoS ONE 2015, 10, e0143620. [Google Scholar] [CrossRef]

- Blazek, J.; Gilbert, E.P. Effect of enzymatic hydrolysis on native starch granule structure. Biomacromolecules 2010, 11, 3275–3289. [Google Scholar] [CrossRef] [PubMed]

- Altay, F.; Gunasekaran, S. Influence of drying temperature, water content, and heating rate on gelatinization of corn starches. J. Agric. Food Chem. 2006, 54, 4235–4245. [Google Scholar] [CrossRef] [PubMed]

- Ayaslan, A.; Seib, P.; Chung, O. Properties of starch and vital gluten isolated from wheat flour by three different wet-milling methods. J. Appl. Biol. Sci. 2010, 4, 51–56. [Google Scholar]

- Zhang, Y.; Guo, Q.; Feng, N.; Wang, J.; Wang, S.; He, Z. Characterization of A- and B-type starch granules in Chinese wheat cultivars. J. Integr. Agric. 2016, 15, 2203–2214. [Google Scholar] [CrossRef]

- Arns, B.; Bartz, J.; Radunz, M.; do Evangelho, J.A.; Pinto, V.Z.; da Rosa Zavareze, E.; Dias, A.R.G. Impact of heat-moisture treatment on rice starch, applied directly in grain paddy rice or in isolated starch. LWT Food Sci. Technol. 2015, 60, 708–713. [Google Scholar] [CrossRef]

- Ratnayake, W.S.; Jackson, D.S. Gelatinization and solubility of corn starch during heating in excess water: New insights. J. Agric. Food Chem. 2006, 54, 3712–3716. [Google Scholar] [CrossRef]

- Muhrbeck, P.; Svensson, E. Annealing properties of potato starches with different degrees of phosphorylation. Carbohydr. Polym. 1996, 31, 263–267. [Google Scholar] [CrossRef]

- Maaurf, A.; Che Man, Y.; Asbi, B.; Junainah, A.; Kennedy, J. Gelatinisation of sago starch in the presence of sucrose and sodium chloride as assessed by differential scanning calorimetry. Carbohydr. Polym. 2001, 45, 335–345. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, Q.; Xu, X.; Qi, L.; Dong, Z.; Luo, Z.; Lu, X.; Peng, X. Structural changes of waxy and normal maize starches modified by heat moisture treatment and their relationship with starch digestibility. Carbohydr. Polym. 2017, 177, 232–240. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Hong, J.; Zheng, X. Effect of heat-moisture treatment on morphological, structural and functional characteristics of ball-milled wheat starches. Starch Stärke 2017, 69, 1500141. [Google Scholar] [CrossRef]

- Baldwin, P.M. Starch granule-associated proteins and polypeptides: A Review. Starch Stärke 2001, 53, 475. [Google Scholar] [CrossRef]

- Svihus, B.; Uhlen, A.K.; Harstad, O.M. Effect of starch granule structure, associated components and processing on nutritive value of cereal starch: A review. Anim. Feed Sci. Technol. 2005, 122, 303–320. [Google Scholar] [CrossRef]

- Rosell, C.M.; Collar, C. Effect of temperature and consistency on wheat dough performance. Int. J. Food Sci. Technol. 2009, 44, 493–502. [Google Scholar] [CrossRef]

- Saad, M.; Gaiani, C.; Scher, J.; Cuq, B.; Ehrhardt, J.J.; Desobry, S. Impact of re-grinding on hydration properties and surface composition of wheat flour. J. Cereal Sci. 2009, 49, 134–140. [Google Scholar] [CrossRef]

- Jacobs, P.J.; Hemdane, S.; Dornez, E.; Delcour, J.A.; Courtin, C.M. Study of hydration properties of wheat bran as a function of particle size. Food Chem. 2015, 179, 296–304. [Google Scholar] [CrossRef]

- Keppler, S.; Bakalis, S.; Leadley, C.E.; Sahi, S.S.; Fryer, P.J. Evaluation of dry heat treatment of soft wheat flour for the production of high ratio cakes. Food Res. Int. 2018, 107, 360–370. [Google Scholar] [CrossRef]

| Thermal Treatment (°C) | Tonset Flour (°C) | Tonset Starch (°C) |

|---|---|---|

| +20 | 46.62 ± 1.70 C | 52.73 ± 0.27 A |

| +40 | 46.92 ± 0.57 B,C | 52.52 ± 0.18 A |

| +65 | 50.67 ± 1.98 A,B,C | 52.24 ± 0.29 A |

| +80 | 51.97 ± 0.11 A,B | 52.35 ± 0.13 A |

| +95 | 52.81 ± 0.46 A | 52.31 ± 0.20 A |

| +110 | 52.01 ± 0.58 A | 52.44 ± 0.14 A |

| Thermal Treatment (°C) | Water Absorption (%) | Dough Development Time (min) |

|---|---|---|

| +20 | 61.0 ± 0.3 B | 3.4 ± 0.8 A |

| +40 | 61.6 ± 0.2 A,B | 3.4 ± 0.4 A |

| +65 | 61.2 ± 0.0 A,B | 3.4 ± 0.2 A |

| +80 | 61.3 ± 0.5 A,B | 3.7 ± 0.4 A |

| +95 | 61.4 ± 0.3 A,B | 3.8 ± 1.3 A |

| +110 | 62.0 ± 0.3 A | 4.0 ± 0.4 A |

| Sample | WRC (% dm) | SMD (% dm) |

|---|---|---|

| Ref rice | 95.97 ± 0.68 D | 8.71 ± 0.25 C |

| TS rice | 104.58 ± 0.70 C | 8.44 ± 0.12 C |

| TMS rice | 110.56 ± 1.18 B | 14.60 ± 0.12 B |

| MS rice | 114.57 ± 1.41 A | 15.96 ± 0.28 A |

| Ref rye | 124.74 ± 0.30 D | 4.67 ± 0.09 C |

| TS rye | 135.60 ± 0.97 B | 4.64 ± 0.15 C |

| TMS rye | 138.85 ± 0.97 A | 6.06 ± 0.13 A |

| MS rye | 132.95 ± 0.76 C | 5.73 ± 0.13 B |

| Ref wheat 2 | 49.02 ± 0.30 B | 6.91 ± 0.21 C |

| TS wheat 2 | 51.55 ± 3.41 A,B | 6.67 ± 0.28 C |

| TMS wheat 2 | 54.28 ± 1.55 A | 7.79 ± 0.39 B |

| MS wheat 2 | 55.26 ± 0.47 A | 8.81 ± 0.14 A |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paulik, S.; Jekle, M.; Becker, T. Mechanically and Thermally Induced Degradation and Modification of Cereal Biopolymers during Grinding. Polymers 2019, 11, 448. https://doi.org/10.3390/polym11030448

Paulik S, Jekle M, Becker T. Mechanically and Thermally Induced Degradation and Modification of Cereal Biopolymers during Grinding. Polymers. 2019; 11(3):448. https://doi.org/10.3390/polym11030448

Chicago/Turabian StylePaulik, Sabina, Mario Jekle, and Thomas Becker. 2019. "Mechanically and Thermally Induced Degradation and Modification of Cereal Biopolymers during Grinding" Polymers 11, no. 3: 448. https://doi.org/10.3390/polym11030448

APA StylePaulik, S., Jekle, M., & Becker, T. (2019). Mechanically and Thermally Induced Degradation and Modification of Cereal Biopolymers during Grinding. Polymers, 11(3), 448. https://doi.org/10.3390/polym11030448