Extruded Polystyrene Foams with Enhanced Insulation and Mechanical Properties by a Benzene-Trisamide-Based Additive

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Thermal Conductivity

2.3. Mechanical Properties

3. Results and Discussion

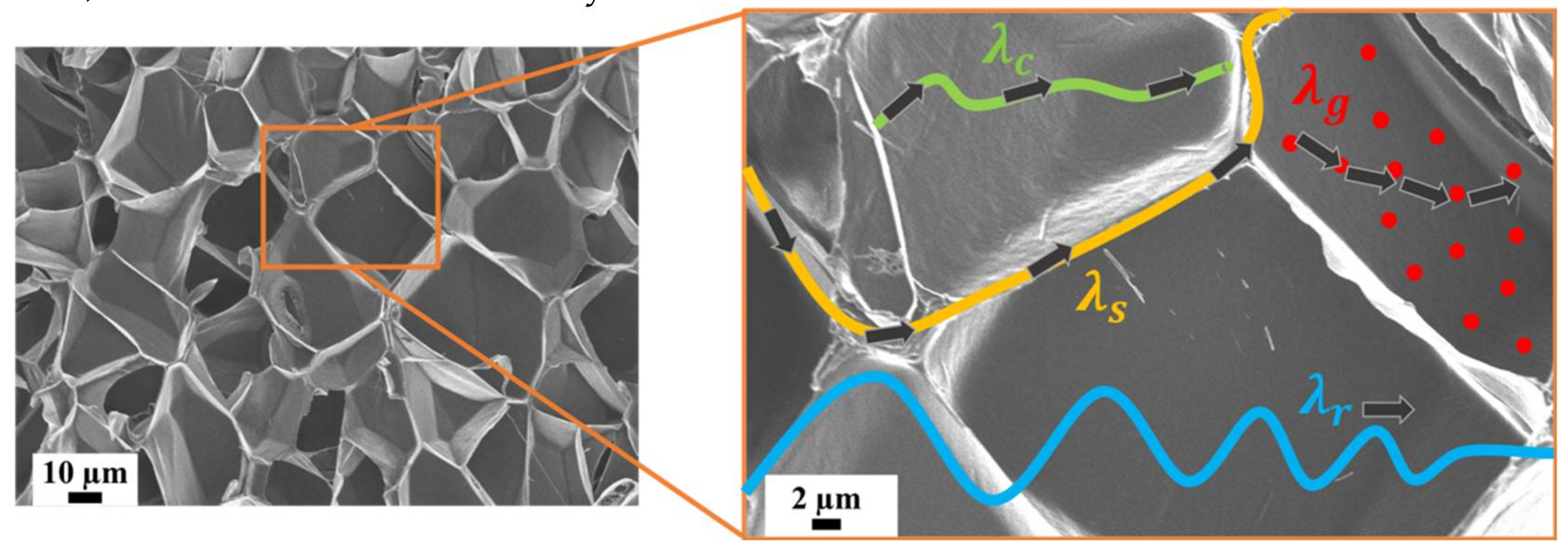

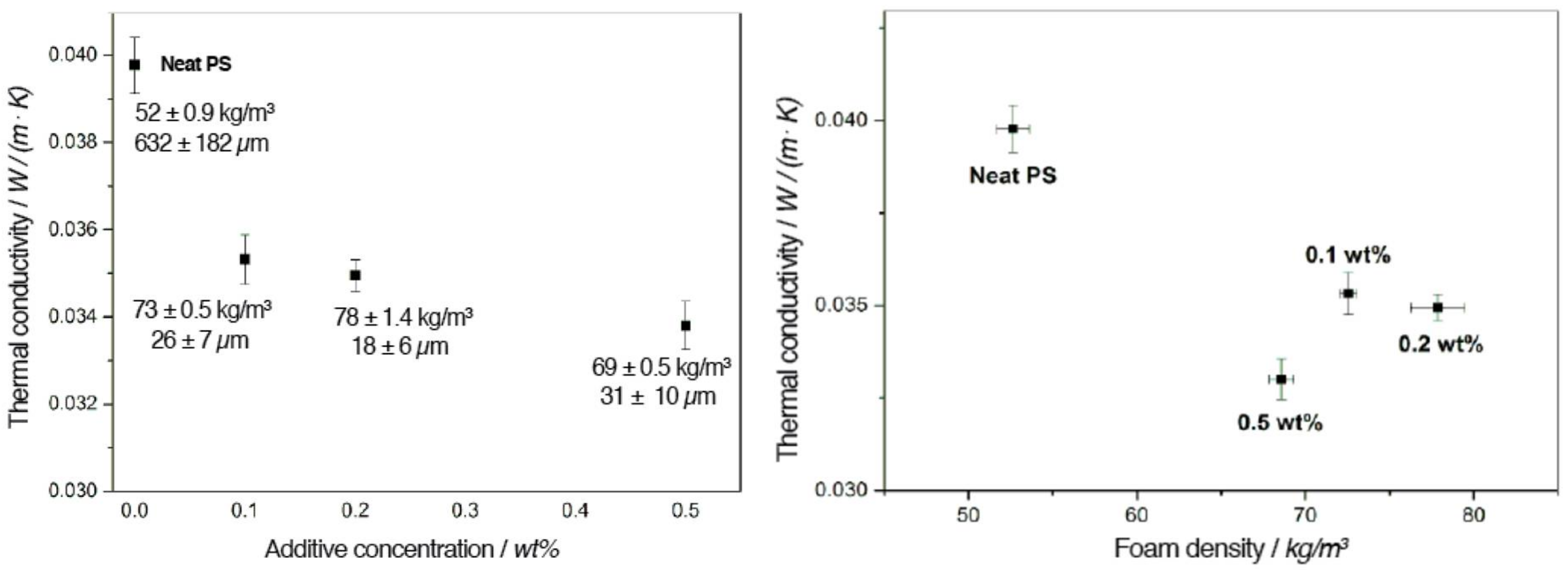

3.1. Effect of BTA on the Thermal Conductivity of XPS Foams

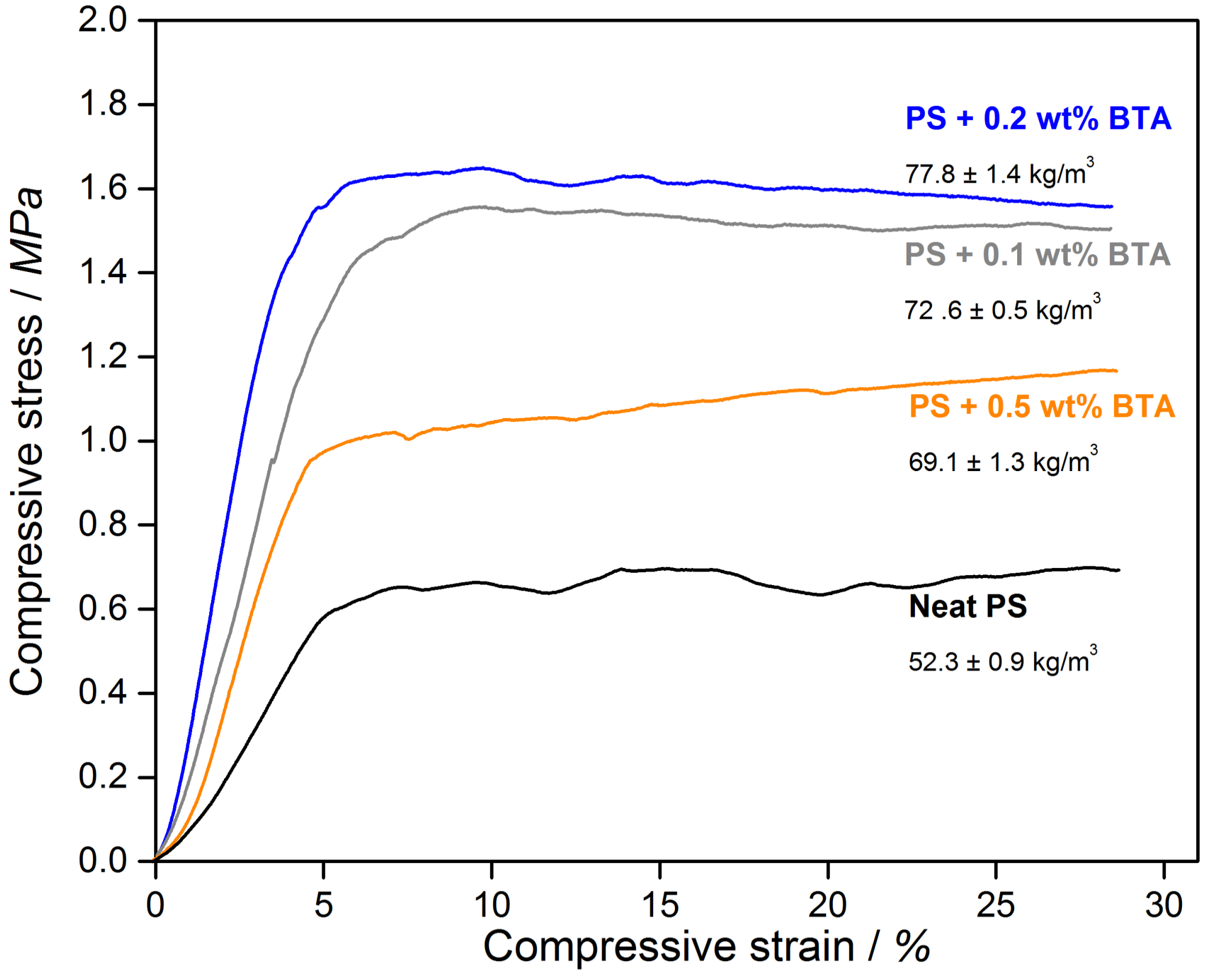

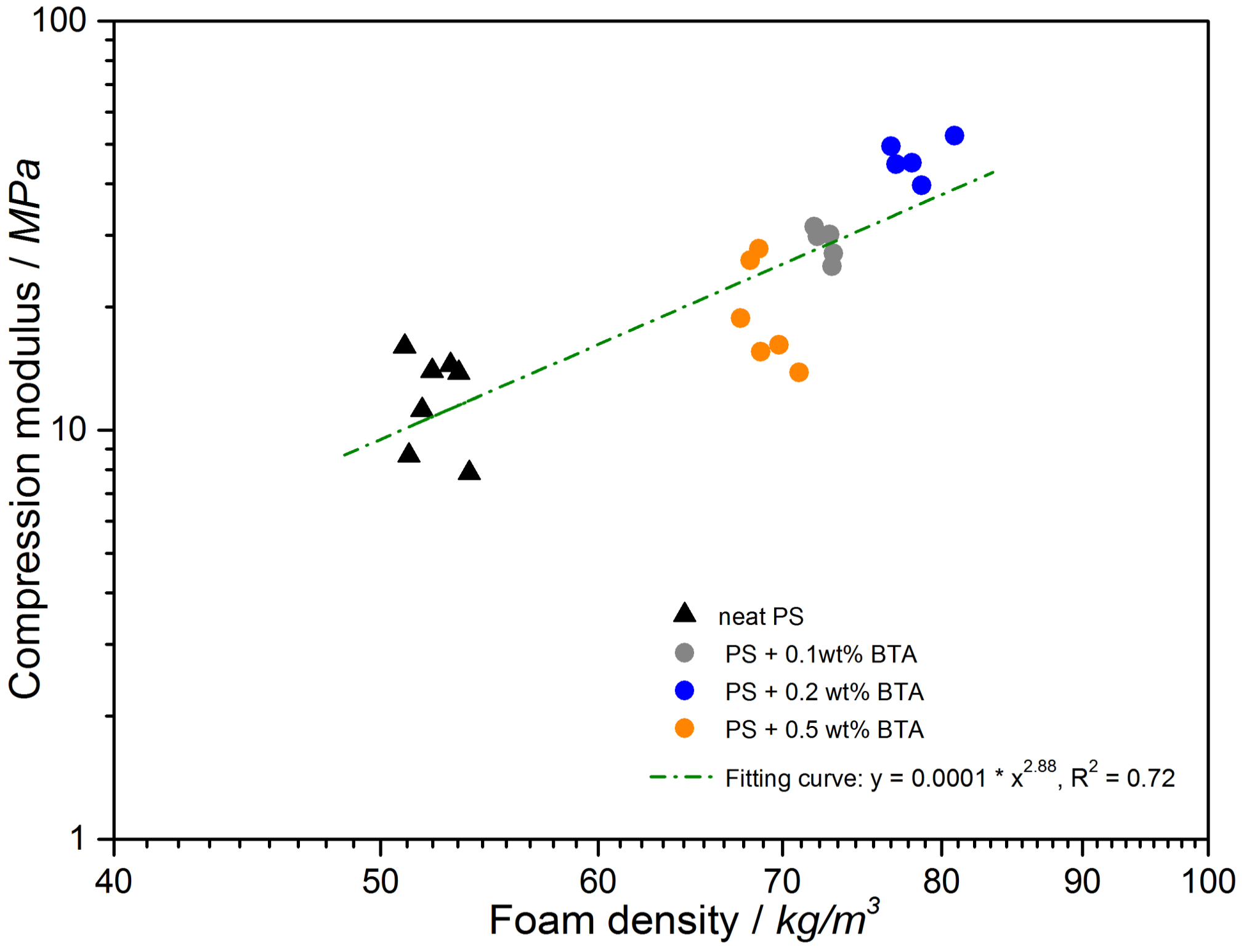

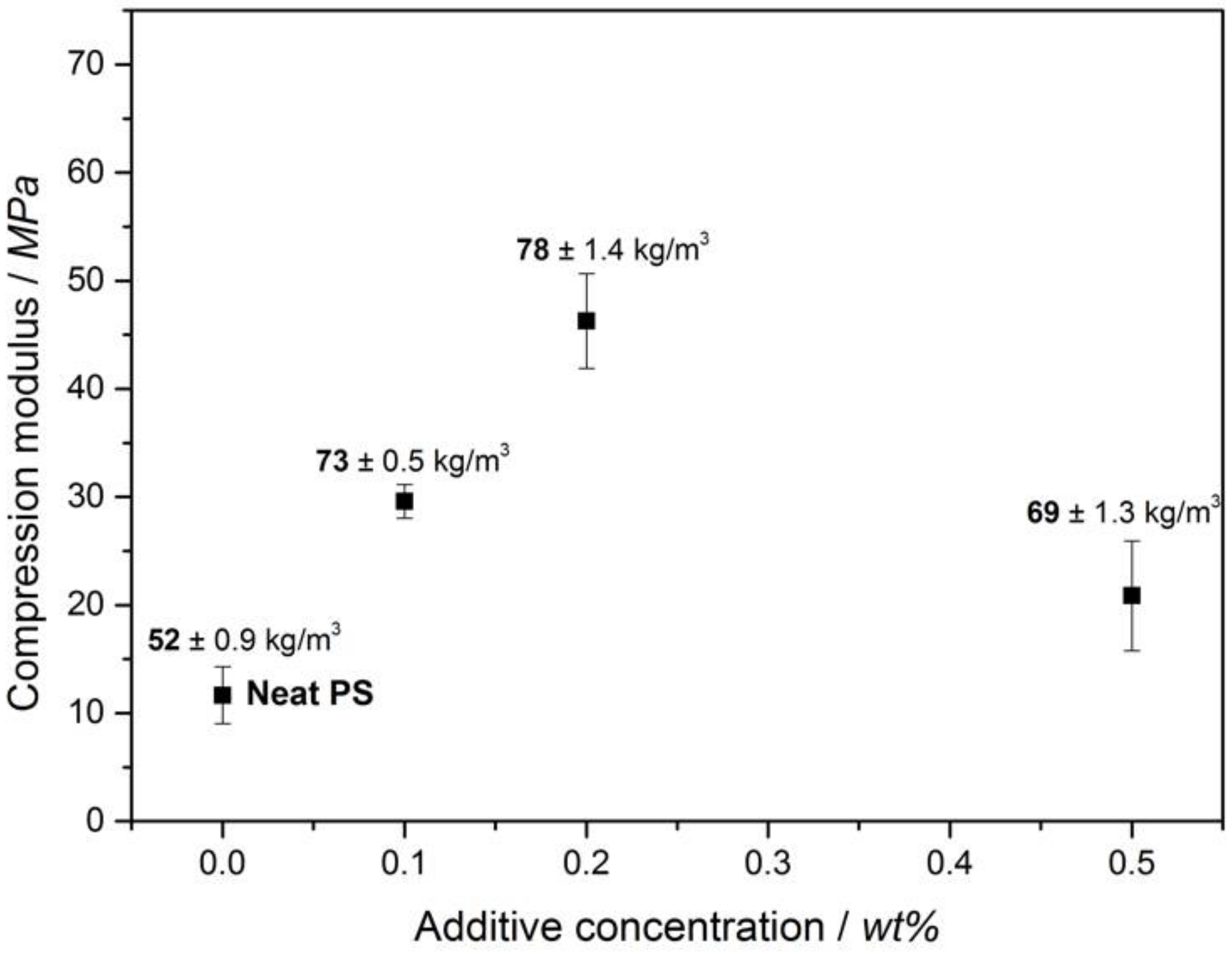

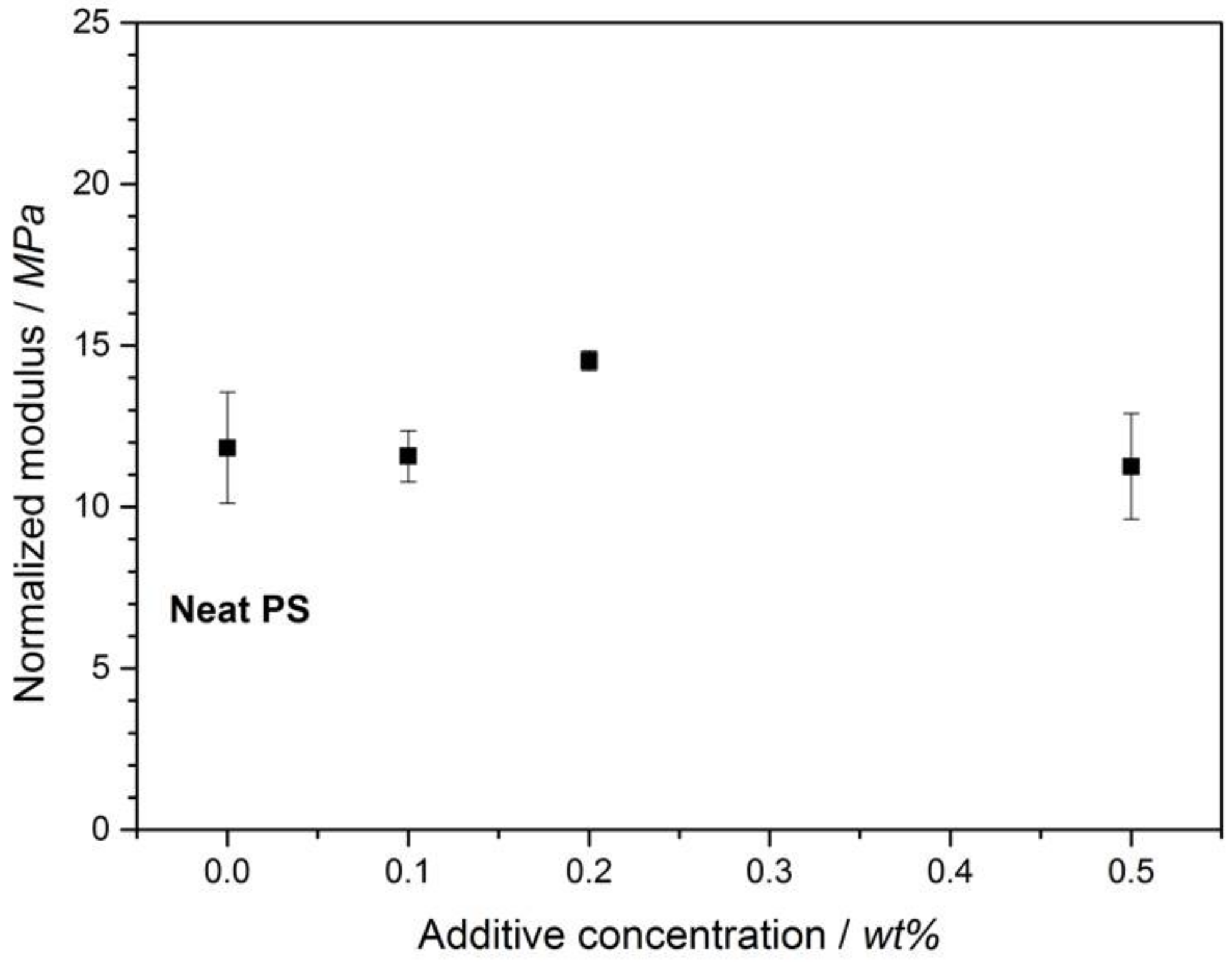

3.2. Effect of BTA on the Compression Modulus of XPS Foams

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Simona, P.L.; Spiru, P.; Ion, I.V. Increasing the energy efficiency of buildings by thermal insulation. Energy Procedia 2017, 128, 393–399. [Google Scholar] [CrossRef]

- Garay, R.; Arregi, B.; Elguezabal, P. Experimental Thermal Performance Assessment of a Prefabricated External Insulation System for Building Retrofitting. Procedia Environ. Sci. 2017, 38, 155–161. [Google Scholar] [CrossRef]

- Ürge-Vorsatz, D.; Harvey, L.D.D.; Mirasgedis, S.; Levine, M.D. Mitigating CO2 emissions from energy use in the world’s buildings. Build. Res. Inf. 2007, 35, 379–398. [Google Scholar] [CrossRef]

- Utrey, J.I.; Shorrock, L.D. BRE: Domestic Energy Fact File. 2008. Available online: https://www.bre.co.uk/page.jsp?id=879 (accessed on 20 March 2018).

- Meggers, F.; Leibundgut, H.; Kennedy, S.; Qin, M.; Schlaich, M.; Sobek, W.; Shukuya, M. Reduce CO2 from buildings with technology to zero emissions. Sustain. Cities Soc. 2012, 2, 29–36. [Google Scholar] [CrossRef]

- Pavel, C.C.; Blagoeva, D.T. Competitive Landscape of the EU’s Insulation Materials Industry for Energy-Efficient Buildings; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar]

- Gong, P.; Wang, G.; Tran, M.-P.; Buahom, P.; Zhai, S.; Li, G.; Park, C.B. Advanced bimodal polystyrene/multi-walled carbon nanotube nanocomposite foams for thermal insulation. Carbon N. Y. 2017, 120, 1–10. [Google Scholar] [CrossRef]

- Gong, P.; Buahom, P.; Tran, M.-P.; Saniei, M.; Park, C.B.; Pötschke, P. Heat transfer in microcellular polystyrene/multi-walled carbon nanotube nanocomposite foams. Carbon N. Y. 2015, 93, 819–829. [Google Scholar] [CrossRef]

- An, W.; Sun, J.; Liew, K.M.; Zhu, G. Flammability and safety design of thermal insulation materials comprising PS foams and fire barrier materials. Mater. Des. 2016, 99, 500–508. [Google Scholar] [CrossRef]

- Yeh, S.-K.; Yang, J.; Chiou, N.-R.; Daniel, T.; Lee, L.J. Introducing water as a coblowing agent in the carbon dioxide extrusion foaming process for polystyrene thermal insulation foams. Polym. Eng. Sci. 2010, 50, 1577–1584. [Google Scholar] [CrossRef]

- Vo, C.V.; Paquet, A.N. An evaluation of the thermal conductivity of extruded polystyrene foam blown with HFC-134a or HCFC-142b. J. Cell. Plast. 2004, 40, 205–228. [Google Scholar] [CrossRef]

- Berge, A.; Johansson, P.Ä.R. Literature Review of High Performance Thermal Insulation. Build. Phys. 2012, 40. [Google Scholar]

- Okolieocha, C.; Raps, D.; Subramaniam, K.; Altstädt, V. Microcellular to nanocellular polymer foams: Progress (2004–2015) and future directions—A review. Eur. Polym. J. 2015, 73, 500–519. [Google Scholar] [CrossRef]

- Okolieocha, C.; Köppl, T.; Kerling, S.; Tölle, F.J.; Fathi, A.; Mülhaupt, R.; Altstadt, V. Influence of graphene on the cell morphology and mechanical properties of extruded polystyrene foam. J. Cell. Plast. 2015, 51, 413–426. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, B.; Lee, L.J. Extrusion foaming of polystyrene/carbon particles using carbon dioxide and water as co-blowing agents. Polymer 2011, 52, 1847–1855. [Google Scholar] [CrossRef]

- Min, Z.; Yang, H.; Chen, F.; Kuang, T. Scale-up Production of Lightweight High-Strength Polystyrene/Carbonaceous Filler Composite Foams with High-performance Electromagnetic Interference Shielding. Mater. Lett. 2018, 230, 157–160. [Google Scholar] [CrossRef]

- Stumpf, M.; Spörrer, A.; Schmidt, H.-W.; Altstädt, V. Influence of supramolecular additives on foam morphology of injection-molded i-PP. J. Cell. Plast. 2011, 47, 519–534. [Google Scholar] [CrossRef]

- Mörl, M.; Steinlein, C.; Kreger, K.; Schmidt, H.W.; Altstädt, V. Improved compression properties of polypropylene extrusion foams by supramolecular additives. J. Cell. Plast. 2018, 54, 483–498. [Google Scholar] [CrossRef]

- Gutiérrez, C.; Garcia, M.T.; Mencía, R.; Garrido, I.; Rodríguez, J.F. Clean preparation of tailored microcellular foams of polystyrene using nucleating agents and supercritical CO2. J. Mater. Sci. 2016, 51, 4825–4838. [Google Scholar] [CrossRef]

- Blomenhofer, M.; Ganzleben, S.; Hanft, D. Altstädt, V. “Designer” Nucleating Agents for Polypropylene. Macromolecules 2005, 38, 3688–3695. [Google Scholar] [CrossRef]

- Scholz, P.; Jan-Erik, W. Polymeric Foam. US 2015/0166752, 18 June 2015. [Google Scholar]

- Aksit, M.; Klose, B.; Zhao, C.; Kreger, K.; Schmidt, H.-W.; Altstädt, V. Morphology control of extruded polystyrene foams with benzene-trisamide-based nucleating agents. J. Cell. Plast. (accepted).

- Holman, J. Heat transfer, 10th ed.; McGraw-Hill: New York, NY, USA, 1981. [Google Scholar]

- De Micco, C.; Aldao, C.M. On the prediction of the radiation term in the thermal conductivity of plastic foams. Lat. Am. Appl. Res. 2006, 36, 193–197. [Google Scholar]

- Hingmann, R.; Hahn, K.; Ruckdäschel, H. Trends in Research on Polymer Foams. Presented at Industrial Workshop on Polymer Foams, Bayreuth, Germany, 2011. [Google Scholar]

- Williams, R.J.J.; Aldao, C.M. Thermal conductivity of plastic foams. Polym. Eng. Sci. 1983, 23, 293–299. [Google Scholar] [CrossRef]

- Nait-Ali, B.; Haberko, K.; Vesteghem, H.; Absi, J.; Smith, D.S. Thermal conductivity of highly porous zirconia. J. Eur. Ceram. Soc. 2016, 26, 3567–3574. [Google Scholar] [CrossRef]

- High Density Extruded Polystyrene Insulation-CELLFORT® 300 & FOAMULAR® 400,600,1000 Insulation Boards, Product Description. Available online: http://www2.owenscorning.com/worldwide/admin/tempupload/pdf.3-74495-199_HighDensity_E.pdf (accessed on 21 August 2018).

- Gibson, I.; Ashby, M.F. The mechanics of three-dimensional cellular materials. Proc. R. Soc. Lond. A Math. Phys. Eng. Sci. 1982, 382, 43–59. [Google Scholar] [CrossRef]

- Menges, G.; Knipschild, F. Estimation of Mechanical Properties for Rigid Polyurethane Foams. Polym. Eng. Sci. 1975, 15, 623–627. [Google Scholar] [CrossRef]

- Lyon, C.K.; Garrett, V.H.; Goldblatt, L.E.O.A. Solvent-Blown Rigid Urethane Foams from Castor-Based Polyols. J. Am. Oil Chem. Soc. 1961, 38, 262–266. [Google Scholar] [CrossRef]

| Sample | Foam density (kg/m3) | Cell size (µm) | Cell density (cells/cm3) |

| Neat XPS | 52.3 0.9 | 632 182 | 2.7 × 103 |

| XPS + 0.1 wt % BTA | 72.6 0.5 | 26 7 | 5.6 × 107 |

| XPS + 0.2 wt % BTA | 77.8 1.4 | 18 6 | 1.5 × 108 |

| XPS + 0.5 wt % BTA | 69.1 1.3 | 31 10 | 3.1 × 107 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aksit, M.; Zhao, C.; Klose, B.; Kreger, K.; Schmidt, H.-W.; Altstädt, V. Extruded Polystyrene Foams with Enhanced Insulation and Mechanical Properties by a Benzene-Trisamide-Based Additive. Polymers 2019, 11, 268. https://doi.org/10.3390/polym11020268

Aksit M, Zhao C, Klose B, Kreger K, Schmidt H-W, Altstädt V. Extruded Polystyrene Foams with Enhanced Insulation and Mechanical Properties by a Benzene-Trisamide-Based Additive. Polymers. 2019; 11(2):268. https://doi.org/10.3390/polym11020268

Chicago/Turabian StyleAksit, Merve, Chunjing Zhao, Bastian Klose, Klaus Kreger, Hans-Werner Schmidt, and Volker Altstädt. 2019. "Extruded Polystyrene Foams with Enhanced Insulation and Mechanical Properties by a Benzene-Trisamide-Based Additive" Polymers 11, no. 2: 268. https://doi.org/10.3390/polym11020268

APA StyleAksit, M., Zhao, C., Klose, B., Kreger, K., Schmidt, H.-W., & Altstädt, V. (2019). Extruded Polystyrene Foams with Enhanced Insulation and Mechanical Properties by a Benzene-Trisamide-Based Additive. Polymers, 11(2), 268. https://doi.org/10.3390/polym11020268