Surface Treatment Effects on the Mechanical Properties of Silica Carbon Black Reinforced Natural Rubber/Butadiene Rubber Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PF-Treated SiCB

2.3. Optimization of PF-Treated SiCB Preparation

2.4. Preparation of Filler-Rubber Composites

2.5. Characterization

2.5.1. Microstructure

2.5.2. Mechanical Properties

2.5.3. Mullins Effect

2.5.4. Dynamic Mechanical Analysis (DMA)

3. Results and Discussion

3.1. Optimal Filler S/P-X Preparation Process

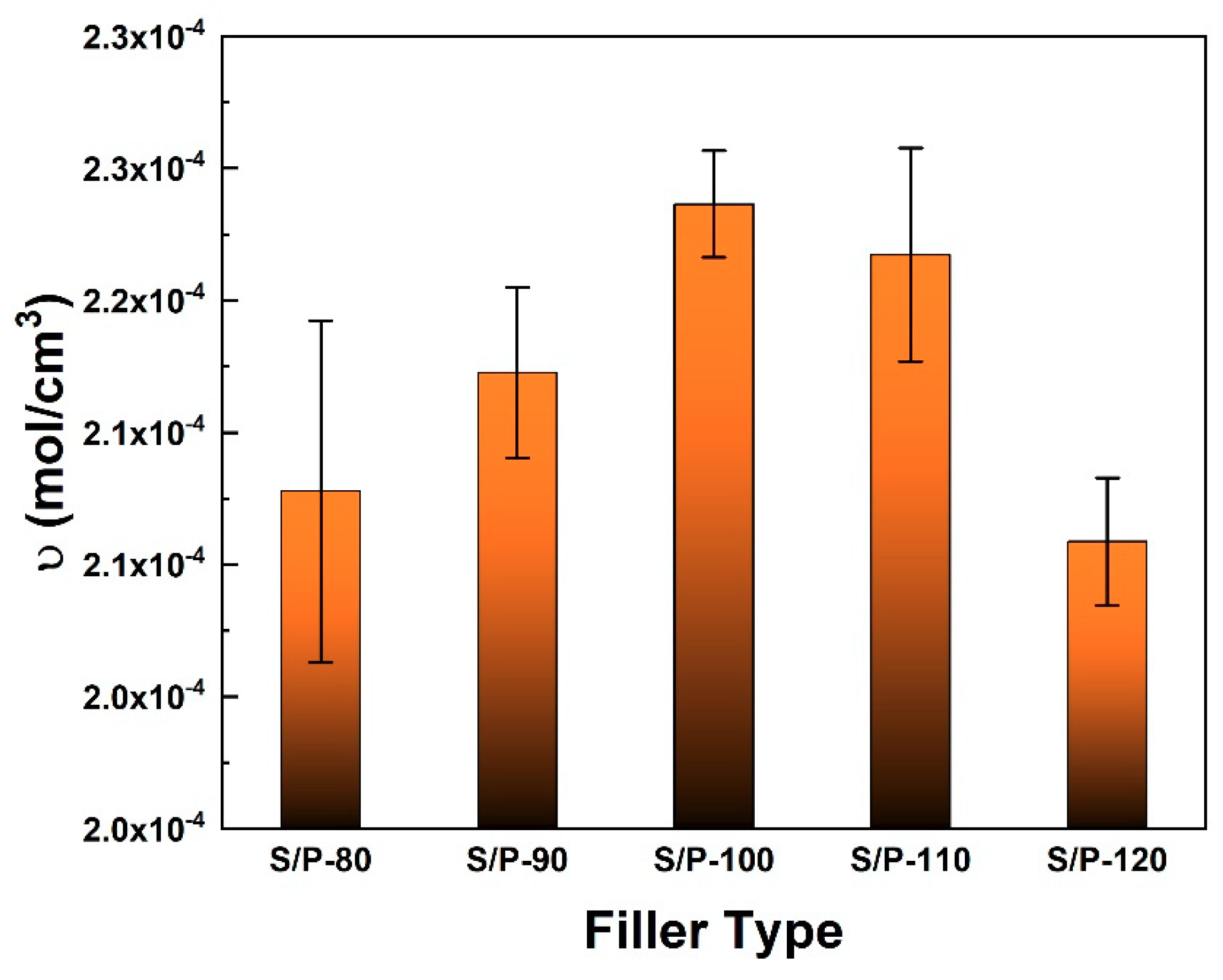

3.2. Cross-Link Density

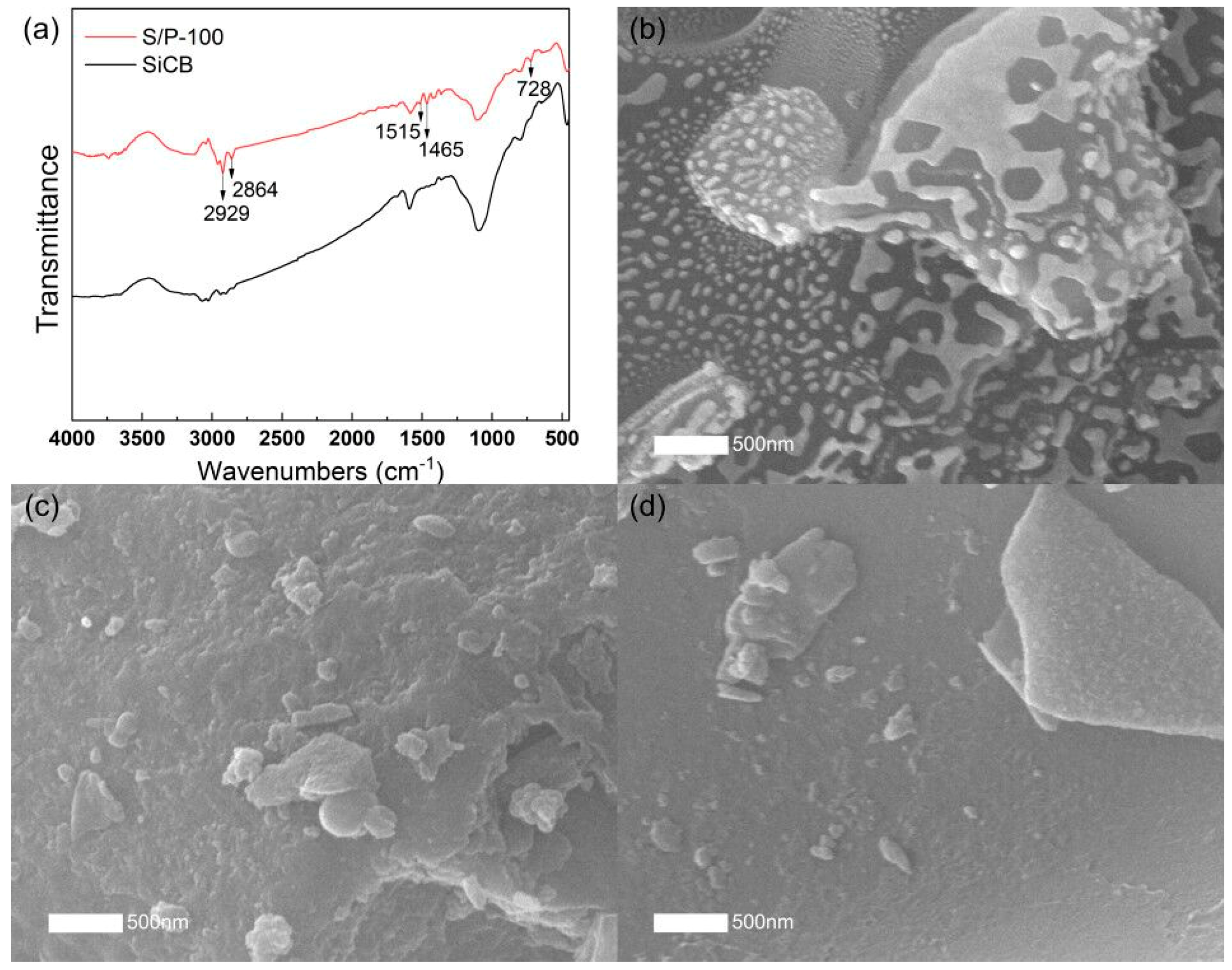

3.3. Characterization of the Fillers

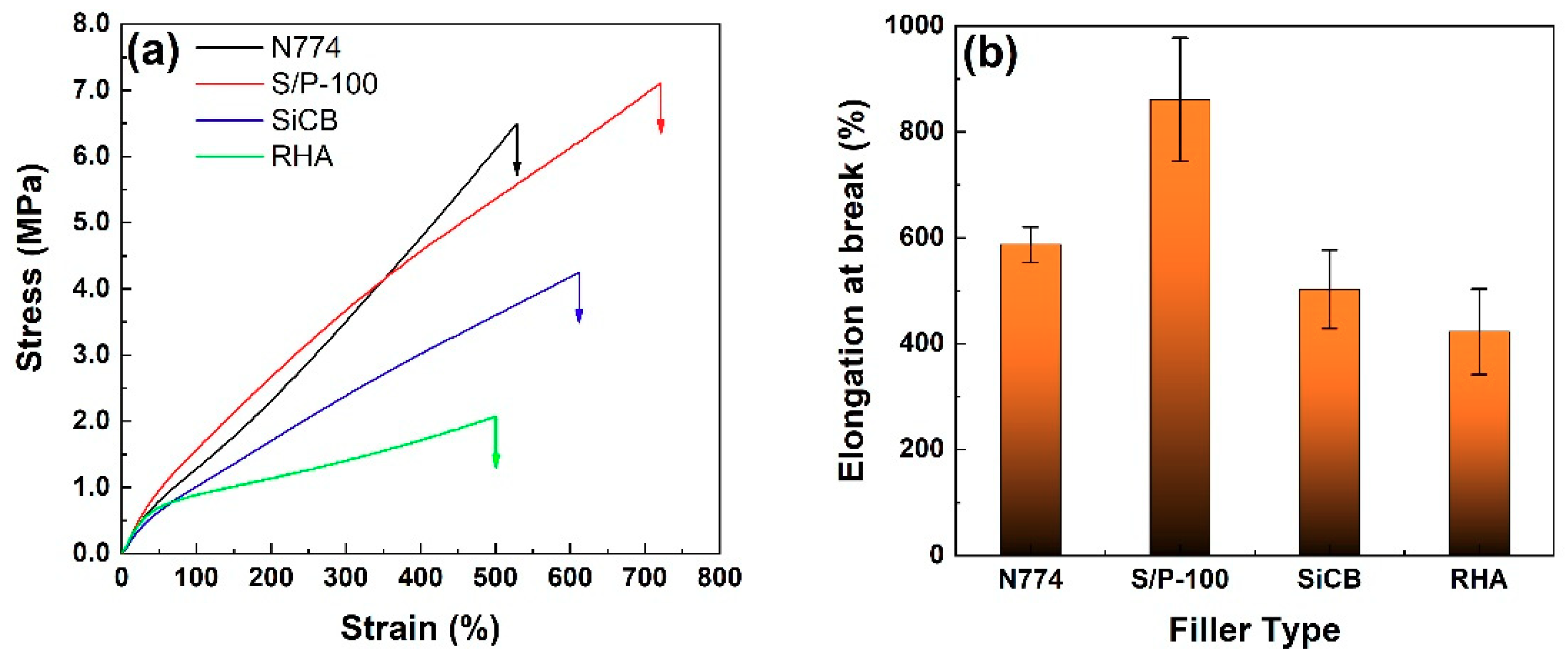

3.4. Mechanical Properties

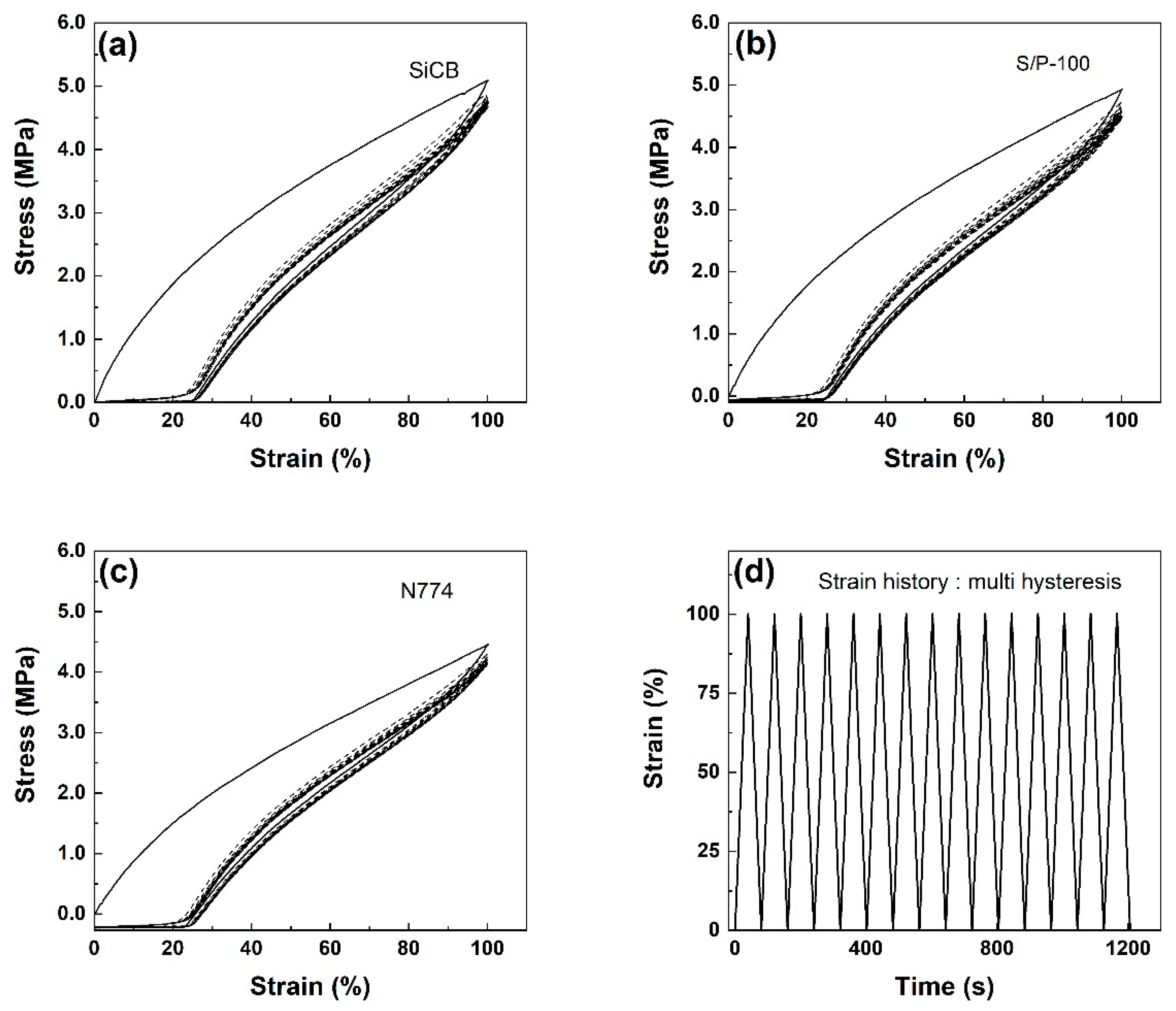

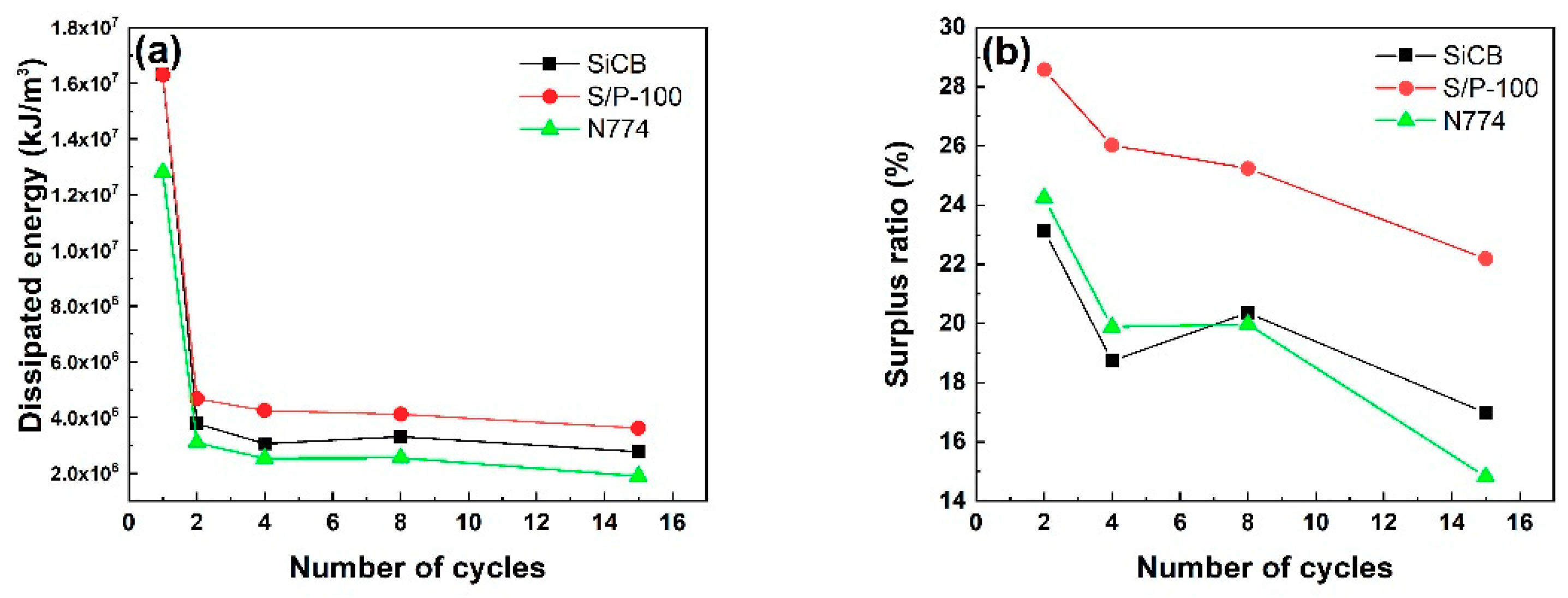

3.5. Mullins Effect

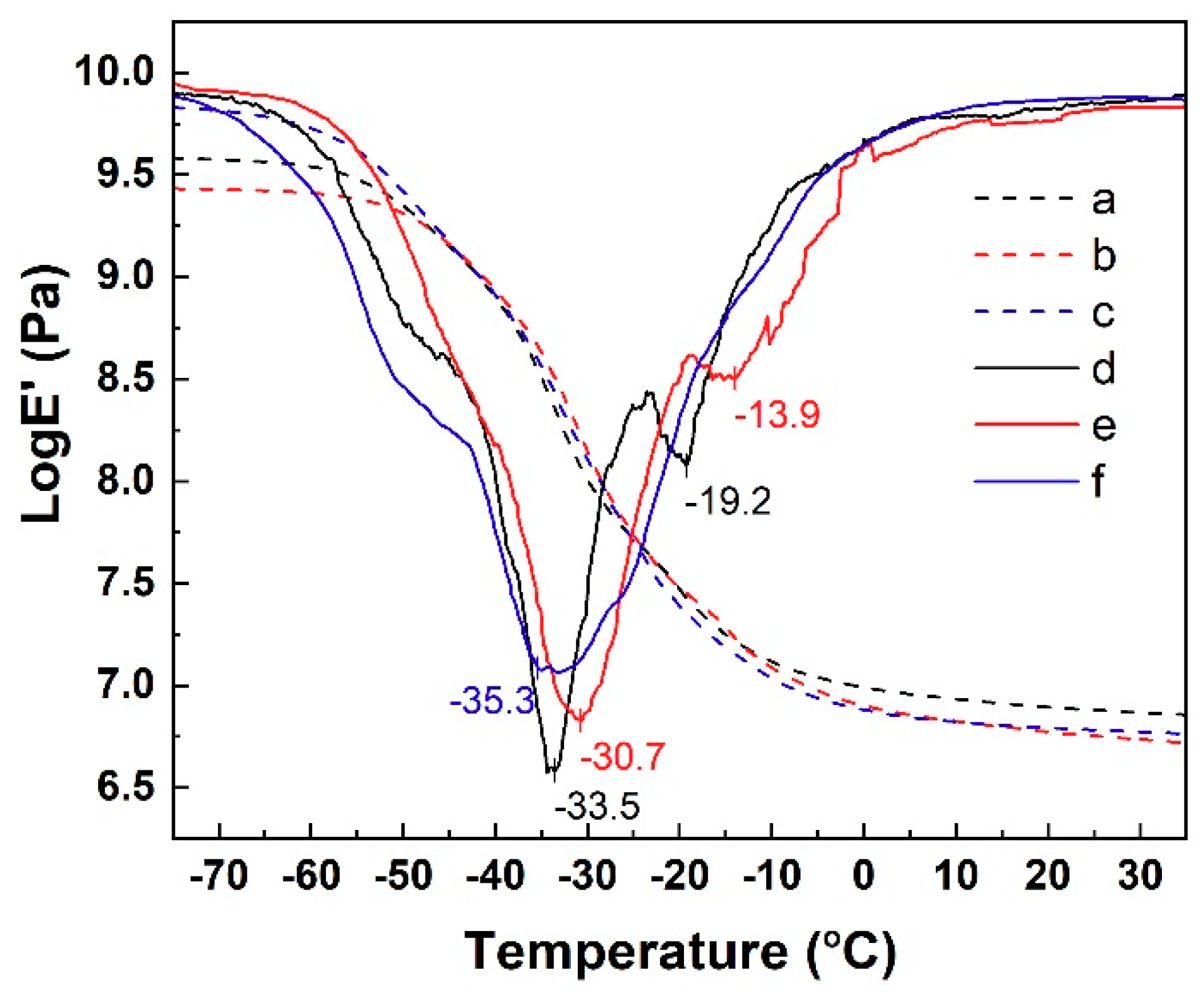

3.6. Dynamic Mechanical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Haxo, H.E.; Mehta, P.K. Ground Rice-Hull Ash as a Filler for Rubber. Rubber Chem. Technol. 1975, 48, 271–288. [Google Scholar] [CrossRef]

- Arayapranee, W.; Rempel, G.L.; Na-Ranong, N.; Na-Ranong, N. Application of rice husk ash as fillers in the natural rubber industry. J. Appl. Polym. Sci. 2005, 98, 34–41. [Google Scholar] [CrossRef]

- Da Costa, H.M.; Visconte, L.L.Y.; Nunes, R.C.R.; Furtado, C.R.G. Mechanical and dynamic mechanical properties of rice husk ash-filled natural rubber compounds. J. Appl. Polym. Sci. 2002, 83, 2331–2346. [Google Scholar] [CrossRef]

- Da Costa, H.M.; Visconte, L.L.Y.; Nunes, R.C.R.; Furtado, C.R.G. Rice husk ash filled natural rubber. I. Overall rate constant determination for the vulcanization process from rheometric data. J. Appl. Polym. Sci. 2003, 87, 1194–1203. [Google Scholar] [CrossRef]

- Da Costa, H.M.; Visconte, L.L.Y.; Nunes, R.C.R.; Furtado, C.R.G. Rice husk ash filled natural rubber. III. Role of metal oxides in kinetics of sulfur vulcanization. J. Appl. Polym. Sci. 2003, 90, 1519–1531. [Google Scholar] [CrossRef]

- Liu, X.Y.; Chen, X.D.; Yang, L.; Chen, H.Z.; Tian, Y.M.; Wang, Z.C. A review on recent advances in the comprehensive application of rice husk ash. Res. Chem. Intermed. 2016, 42, 893–913. [Google Scholar] [CrossRef]

- Sae-Oui, P.; Rakdee, C.; Thanmathorn, P.; Sae-Oui, P. Use of rice husk ash as filler in natural rubber vulcanizates: In comparison with other commercial fillers. J. Appl. Polym. Sci. 2002, 83, 2485–2493. [Google Scholar] [CrossRef]

- John, M.J.; Francis, B.; Varughese, K.; Thomas, S. Effect of chemical treatment on properties of hybrid fiber biocomposites. Compos Part A Appl. Sci. Manuf. 2008, 39, 352–363. [Google Scholar] [CrossRef]

- Kalia, S.; Kaith, B.; Kaur, I. Pretreatments of natural fibers and their application as reinforcing material in polymer composites—A review. Polym. Eng. Sci. 2009, 49, 1253–1272. [Google Scholar] [CrossRef]

- Cicala, G.; Cristaldi, G.; Recca, G.; Latteri, A. Composites Based on Natural Fibre Fabrics. Woven Fabr. Eng. 2010, 17, 317–342. [Google Scholar]

- Qiao, H.; Chao, M.; Hui, D.; Liu, J.; Zheng, J.; Lei, W.; Zhou, X.; Wang, R.; Zhang, L. Enhanced interfacial interaction and excellent performance of silica/epoxy group-functionalized styrene-butadiene rubber (SBR) nanocomposites without any coupling agent. Compos. Part B Eng. 2017, 114, 356–364. [Google Scholar] [CrossRef]

- Wang, X.F.; Zhou, Y.; Zhu, Y.C. Preparation Method of SiCB/Polyolefin Compounds. CN. Patent 201610600982.7, 28 July 2016. [Google Scholar]

- Qian, M.M.; Sui, J.Y.; Wang, X.F.; Zhu, Y.C. Mechanical properties of silicon carbon black filled natural rubber elastomer. Chem. Res. Chin. Univ. 2019, 35, 139–145. [Google Scholar] [CrossRef]

- Sadasivuni, K.K.; Ponnamma, D.; Kumar, B.; Strankowski, M.; Cardinaels, R.; Moldenaers, P.; Thomas, S.; Grohens, Y. Dielectric properties of modified graphene oxide filled polyurethane nanocomposites and its correlation with rheology. Compos. Sci. Technol. 2014, 104, 18–25. [Google Scholar] [CrossRef]

- Ponnamma, D.; Sadasivuni, K.K.; Grohens, Y.; Guo, Q.; Thomas, S. Carbon nanotube based elastomer composites—An approach towards multifunctional materials. J. Mater. Chem. C 2014, 2, 8446–8485. [Google Scholar] [CrossRef]

- Araby, S.; Meng, Q.; Zhang, L.; Kang, H.; Majewski, P.; Tang, Y.; Ma, J. Electrically and thermally conductive elastomer/graphene nanocomposites by solution mixing. Polymer 2014, 55, 201–210. [Google Scholar] [CrossRef]

- Sengloyluan, K.; Sahakaro, K.; Dierkes, W.K.; Noordermeer, J.W. Silica-reinforced tire tread compounds compatibilized by using epoxidized natural rubber. Eur. Polym. J. 2014, 51, 69–79. [Google Scholar] [CrossRef]

- Zhang, Y.; Mark, J.E.; Zhu, Y.; Ruoff, R.S.; Schaefer, D.W. Mechanical properties of polybutadiene reinforced with octadecylamine modified graphene oxide. Polymer 2014, 55, 5389–5395. [Google Scholar] [CrossRef]

- Chai, Y.; Liu, J.; Zhao, Y.; Yan, N. Characterization of Modified Phenol Formaldehyde Resole Resins Synthesized in Situ with Various Boron Compounds. Ind. Eng. Chem. Res. 2016, 55, 9840–9850. [Google Scholar] [CrossRef]

- Li, C.; Zhang, J.; Yi, Z.; Yang, H.; Zhao, B.; Zhang, W.; Li, J. Preparation and characterization of a novel environmentally friendly phenol–formaldehyde adhesive modified with tannin and urea. Int. J. Adhes. Adhes. 2016, 66, 26–32. [Google Scholar] [CrossRef]

- Ye, L.Z.; Zhang, Y.H. In-situ polymerized phenolic resin for reinforcement of chloroprene and ethylene–propylene rubber vulcanizates. J. Appl. Polym. Sci. 2009, 111, 1177–1184. [Google Scholar] [CrossRef]

- Ye, L.Z.; Zhang, Y.H.; Wang, Z.B. Mechanical properties and microstructure of acrylonitrile-butadiene rubber vulcanizates reinforced by in situ polymerized phenolic resin. J. Appl. Polym. Sci. 2007, 105, 3853–3857. [Google Scholar] [CrossRef]

- Wu, Y.P.; Qi, Q.; Liang, G.H.; Zhang, L.Q. A strategy to prepare high performance starch/rubber composites: In situ treatment during latex compounding process. Carbohyd. Polym. 2006, 65, 109–113. [Google Scholar] [CrossRef]

- Li, F.; Hua, Y.; Qu, C.B.; Ji, J.H.; Li, Y.Q.; Hu, N.; Fu, S.Y. Effectively enhanced mechanical properties of injection molded short carbon fiber reinforced polyethersulfone composites by phenol-formaldehyde resin sizing. Compos. Part B Eng. 2018, 139, 216–226. [Google Scholar] [CrossRef]

- Sekkar, V. Comparison between crosslink densities derived from stress-strain data and theoretically data evaluated through the alpha-model approach for a polyurethane network system based on hydroxyl terminated polybutadiene and isophorone-diisocyanate. J. Appl. Polym. Sci. 2010, 117, 920–925. [Google Scholar] [CrossRef]

- Saleesung, T.; Reichert, D.; Saalwächter, K.; Sirisinha, C. Correlation of crosslink densities using solid state NMR and conventional techniques in peroxide-crosslinked EPDM rubber. Polymer 2015, 56, 309–317. [Google Scholar] [CrossRef]

- El-Sabbaghm, S.H.; Yehia, A.A. Detection of Crosslink Density by Different Methods for Natural Rubber Blended with SBR and NBR. Egypt. J. Solids 2007, 30, 157–173. [Google Scholar]

- Sombatsompop, N. Practical concerns regarding the use of the Mooney-Rivlin equation to assess degree of crosslinking of swollen rubber vulcanisates. Polym. Polym. Compos. 1999, 7, 41–44. [Google Scholar]

- Mullins, L.; Tobin, N.R. Stress Softening in Rubber Vulcanizates. I. use of a Strain Amplification Factor to Describe Elastic Behavior of Filler-Reinforced Vulcanized Rubber. J. Appl. Polym. Sci. 1965, 9, 2993–3009. [Google Scholar] [CrossRef]

- Xu, S.H.; Gu, J.; Luo, Y.F.; Jia, D.M. Influence of nanocrystalline cellulose on structure and properties of natural rubber/silica composites. Polym. Compos. 2015, 36, 861–868. [Google Scholar] [CrossRef]

- Wagner, M.P. Reinforcing silicas and silicates rubber. Rubber. Chem. Technol. 1976, 49, 703–774. [Google Scholar] [CrossRef]

- Roslan, R.; Zakaria, S.; Chia, C.H.; Boehm, R.; Laborie, M.P. Physico mechanical properties of resol phenolic adhesives derived from liquefaction of oil palm empty fruit bunch fibers. Ind. Crops Prod. 2014, 62, 119–124. [Google Scholar] [CrossRef]

- Choi, M.H.; Byun, H.Y.; Chung, I.J. The effect of chain length of flexible diacid on morphology and mechanical property of modified phenolic resin. Polymer 2002, 43, 4437–4444. [Google Scholar] [CrossRef]

- Diani, J.; Fayolle, B.; Gilormini, P. A review on the Mullins effect. Eur. Polym. J. 2009, 45, 601–612. [Google Scholar] [CrossRef]

- Qi, H. Constitutive model for stretch-induced softening of the stress–stretch behavior of elastomeric materials. J. Mech. Phys. Solids 2004, 52, 2187–2205. [Google Scholar] [CrossRef]

- D’Ambrosio, P.; De Tommasi, D.; Ferri, D.; Puglisi, G. A phenomenological model for healing and hysteresis in rubber-like materials. Int. J. Eng. Sci. 2008, 46, 293–305. [Google Scholar] [CrossRef]

- Österlöf, R.; Wentzel, H.; Kari, L. An efficient method for obtaining the hyperelastic properties of filled elastomers in finite strain applications. Polym. Test. 2015, 41, 44–54. [Google Scholar] [CrossRef]

- Stockelhuber, K.W.; Svistkov, A.S.; Pelevin, A.G.; Heinrich, G. Impact of filler surface treatment on large scale mechanics of styrene butadiene/silica rubber composites. Macromolecules 2011, 44, 4366–4381. [Google Scholar] [CrossRef]

- Fröhlich, J.; Niedermeier, W.; Luginsland, H.D. The effect of filler–filler and filler–elastomer interaction on rubber reinforcement. Compos. Part A Appl. Sci. Manuf. 2005, 36, 449–460. [Google Scholar] [CrossRef]

- Bindu, P.; Thomas, S. Viscoelastic Behavior and Reinforcement Mechanism in Rubber Nanocomposites in the Vicinity of Spherical Nanoparticles. J. Phys. Chem. B 2013, 117, 12632–12648. [Google Scholar] [CrossRef]

- Hagen, L.; Michael, F. Constitutive generalization of a microstructure-based model for filled Elastomers. Macromol. Theory Simul. 2011, 20, 110–123. [Google Scholar]

- Ma, C.; Ji, T.; Robertson, C.G.; Rajeshbabu, R.; Zhu, J.; Dong, Y. Molecular insight into the Mullins effect: Irrecoverable disentanglement of polymer chains revealed by molecular dynamics simulations. Phys. Chem. Chem. Phys. 2017, 19, 19468–19477. [Google Scholar] [CrossRef] [PubMed]

- Webber, R.E.; Creton, C.; Brown, H.R.; Gong, J.P. Large Strain Hysteresis and Mullins Effect of Tough Double-Network Hydrogels. Macromolecules 2007, 40, 2919–2927. [Google Scholar] [CrossRef]

- Sui, J.Y.; Liu, X.Y.; Qian, M.M.; Zhu, Y.C.; Wang, X.F. Surface treatment of silica/carbon black derived from rice husks and its influence on natural rubber composites. Chem. J. Chin. Univ. 2019, 40, 1561–1570. [Google Scholar]

- Saleem, A.; Frormann, L.; Iqbal, A. High performance thermoplastic composites: Study on the mechanical, thermal, and electrical resistivity properties of carbon fiber-reinforced polyetheretherketone and polyethersulphone. Polym. Compos. 2007, 28, 785–796. [Google Scholar] [CrossRef]

- Karsli, N.G.; Ozkan, C.; Aytac, A.; Deniz, V. Characterization of poly (butylene terephthalate) composites prepared by using various types of sized carbon fibers. Mater. Des. 2015, 87, 318–323. [Google Scholar] [CrossRef]

| Factor | Packing Amount (g) | Temperature (°C) | Time (min) | PF Concentration (wt %) |

|---|---|---|---|---|

| Level 1 | 160 | 90 | 5 | 3 |

| Level 2 | 170 | 95 | 10 | 5 |

| Level 3 | 180 | 100 | 15 | 8 |

| Abbreviation | Composition and Treating Condition | ||

|---|---|---|---|

| Raw Material | Phenolic Resin or Not | Treatment Condition | |

| SiCB | Rice husk biochar | No phenolic resin | Untreated |

| SiCB/PF | Rice husk biochar + phenolic resin | Phenolic resin | Untreated |

| S/P-X a | Rice husk biochar + phenolic resin | Phenolic resin | 80–120 °C |

| RHA | Rice husk ash | No phenolic resin | Untreated |

| N774 | Commercial carbon black | No phenolic resin | Untreated |

| Ingredients | Amounts (phr) |

|---|---|

| NR/BR | 45/55 |

| Filler | 50 |

| ZnO | 3 |

| Stearic acid | 1.5 |

| Wax | 1.5 |

| DAE | 10 |

| Antioxidant RD | 1.5 |

| Antioxidant 4020 | 4 |

| Accelerator NS | 0.75 |

| Sulfur | 1.8 |

| Fillers | C1 (10−2 MPa) | C2 (10−2 MPa) | υ (10−5 mol/cm3) |

|---|---|---|---|

| S/P-80 | 26.3 ± 0.8 | 16.7 ± 0.7 | 21.3 ± 0.6 |

| S/P-90 | 26.9 ± 0.4 | 21.2 ± 0.4 | 21.7 ± 0.3 |

| S/P-100 | 27.7 ± 0.3 | 15.3 ± 0.2 | 22.4 ± 0.2 |

| S/P-110 | 27.4 ± 0.5 | 18.7 ± 0.6 | 22.2 ± 0.4 |

| S/P-120 | 26.1 ± 0.3 | 19.1 ± 0.4 | 21.1 ± 0.2 |

| Fillers | Tensile Strength (MPa) | Elongation at Break (%) | Stress at 300% Strain (MPa) | Tear Strength (kN/m) |

|---|---|---|---|---|

| RHA | 1.9 ± 0.04 | 422.7 ± 80.7 | 1.5 ± 0.1 | 15.0 ± 0.4 |

| SiCB | 4.1 ± 0.1 | 502.9 ± 74.3 | 2.9 ± 0.3 | 21.8 ± 0.4 |

| S/P-100 | 7.1 ± 0.1 | 861.5 ± 116.2 | 3.3 ± 0.4 | 26.4 ± 0.5 |

| N774 | 6.5 ± 0.1 | 587.1 ± 33.1 | 3.7 ± 0.4 | 27.4 ± 0.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, M.; Huang, W.; Wang, J.; Wang, X.; Liu, W.; Zhu, Y. Surface Treatment Effects on the Mechanical Properties of Silica Carbon Black Reinforced Natural Rubber/Butadiene Rubber Composites. Polymers 2019, 11, 1763. https://doi.org/10.3390/polym11111763

Qian M, Huang W, Wang J, Wang X, Liu W, Zhu Y. Surface Treatment Effects on the Mechanical Properties of Silica Carbon Black Reinforced Natural Rubber/Butadiene Rubber Composites. Polymers. 2019; 11(11):1763. https://doi.org/10.3390/polym11111763

Chicago/Turabian StyleQian, Miaomiao, Weimin Huang, Jinfeng Wang, Xiaofeng Wang, Weiping Liu, and Yanchao Zhu. 2019. "Surface Treatment Effects on the Mechanical Properties of Silica Carbon Black Reinforced Natural Rubber/Butadiene Rubber Composites" Polymers 11, no. 11: 1763. https://doi.org/10.3390/polym11111763

APA StyleQian, M., Huang, W., Wang, J., Wang, X., Liu, W., & Zhu, Y. (2019). Surface Treatment Effects on the Mechanical Properties of Silica Carbon Black Reinforced Natural Rubber/Butadiene Rubber Composites. Polymers, 11(11), 1763. https://doi.org/10.3390/polym11111763