Properties and Characterization of a PLA–Chitin–Starch Biodegradable Polymer Composite

Abstract

1. Introduction

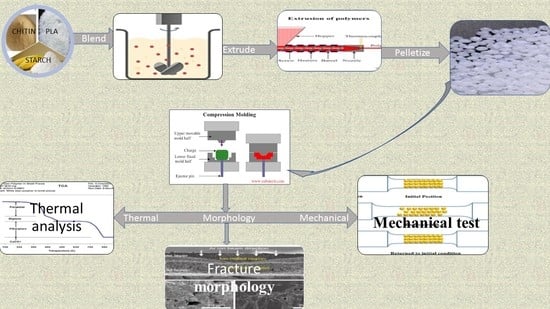

2. Materials and Methods

2.1. Materials

2.2. Composite Preparation

2.3. Characterization

2.3.1. Tensile Test

2.3.2. Impact Test

2.3.3. Dynamic Mechanical Analysis

2.3.4. Thermogravimetry Analysis Test

2.3.5. Microstructural Analysis

3. Results and Discussion

3.1. Tensile Properties of the Composite

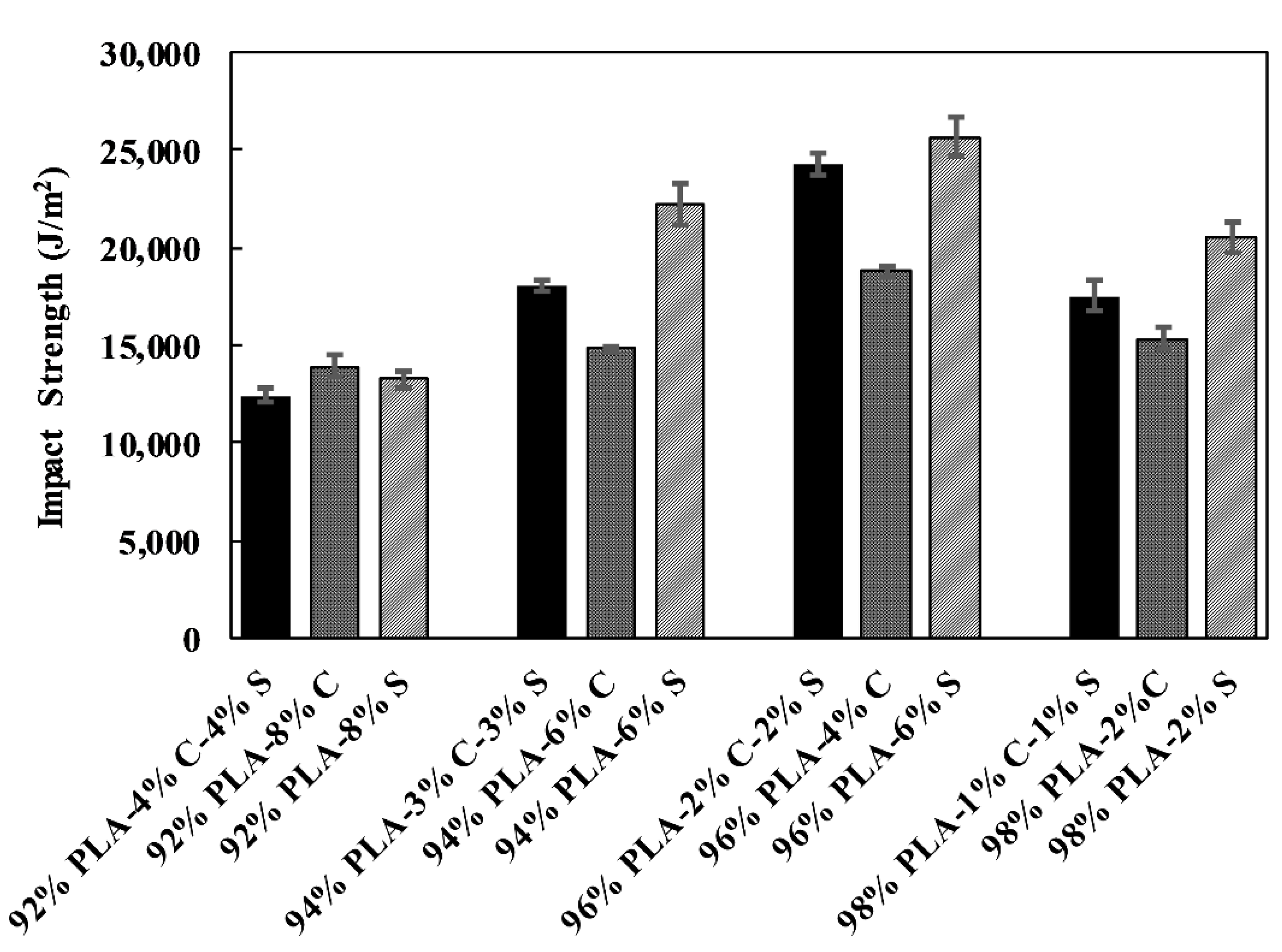

3.2. Impact Test

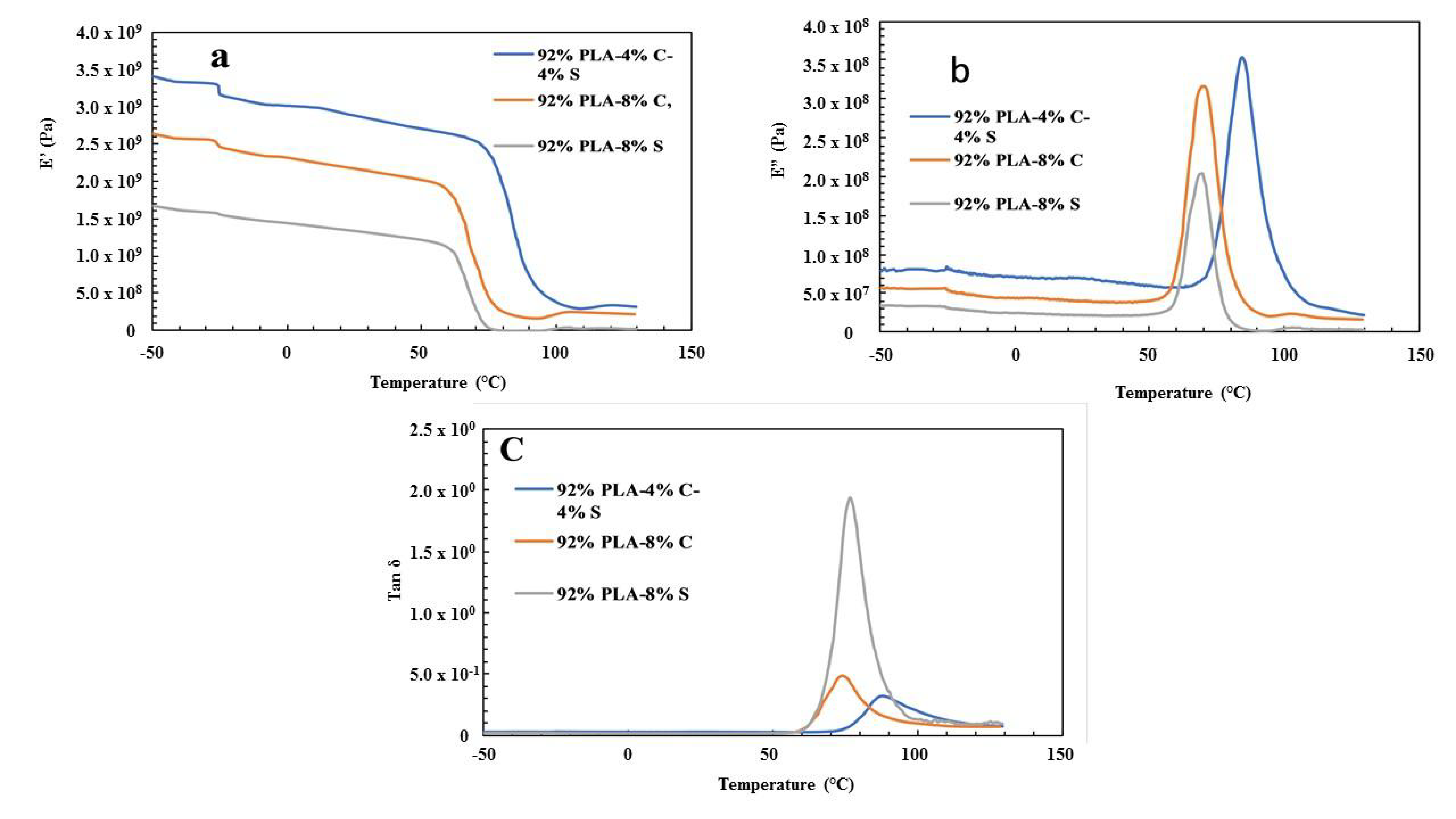

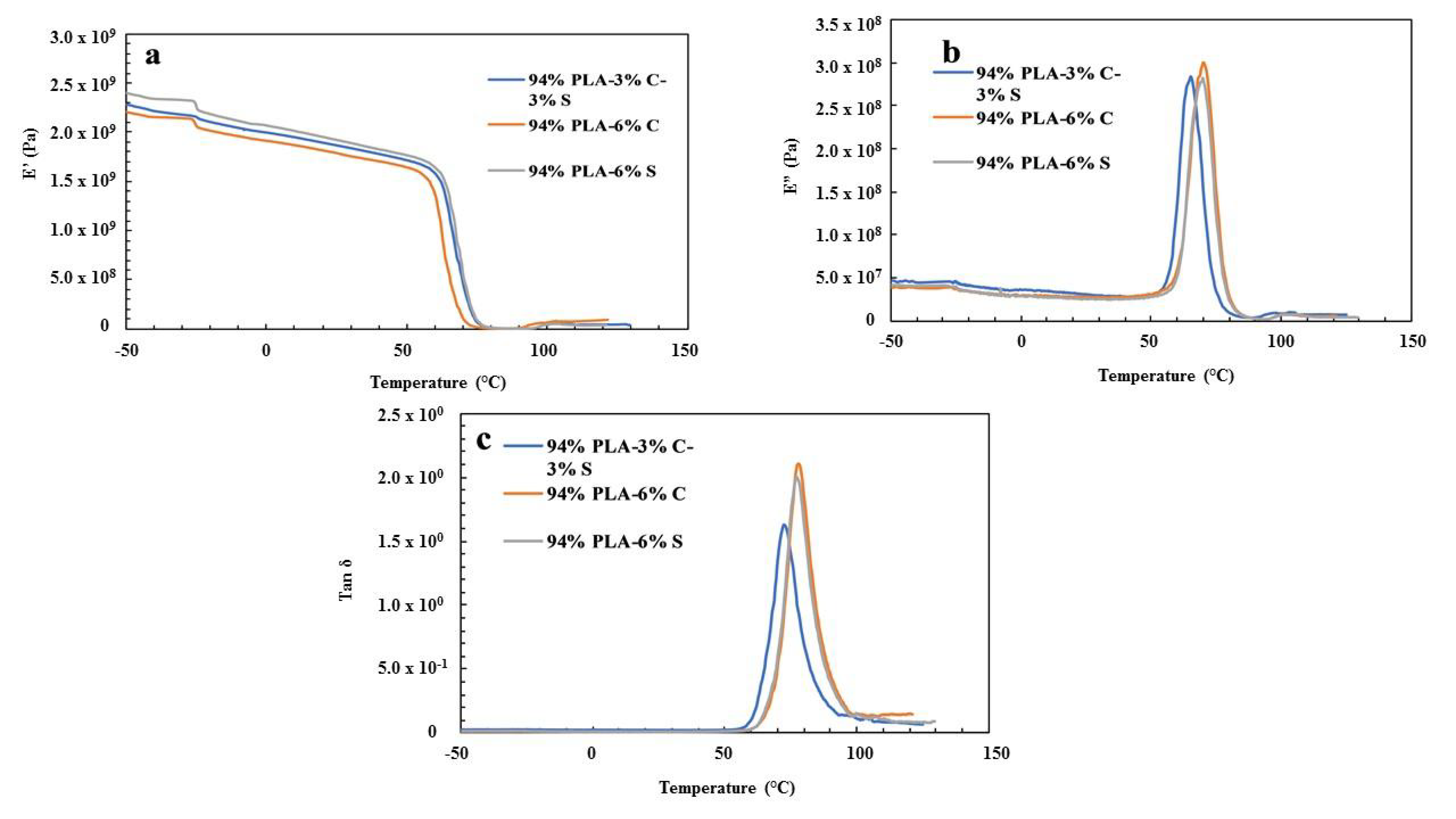

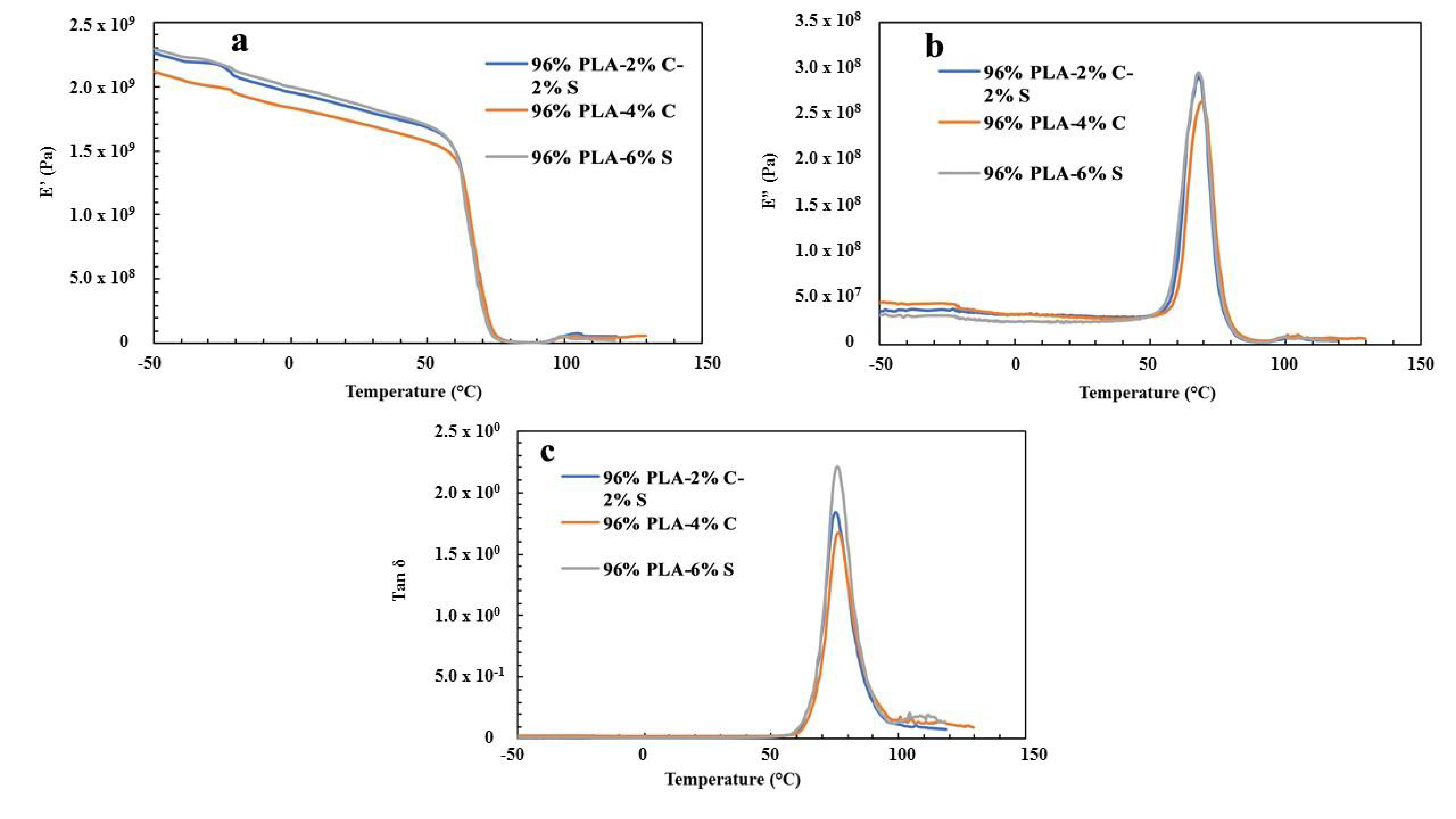

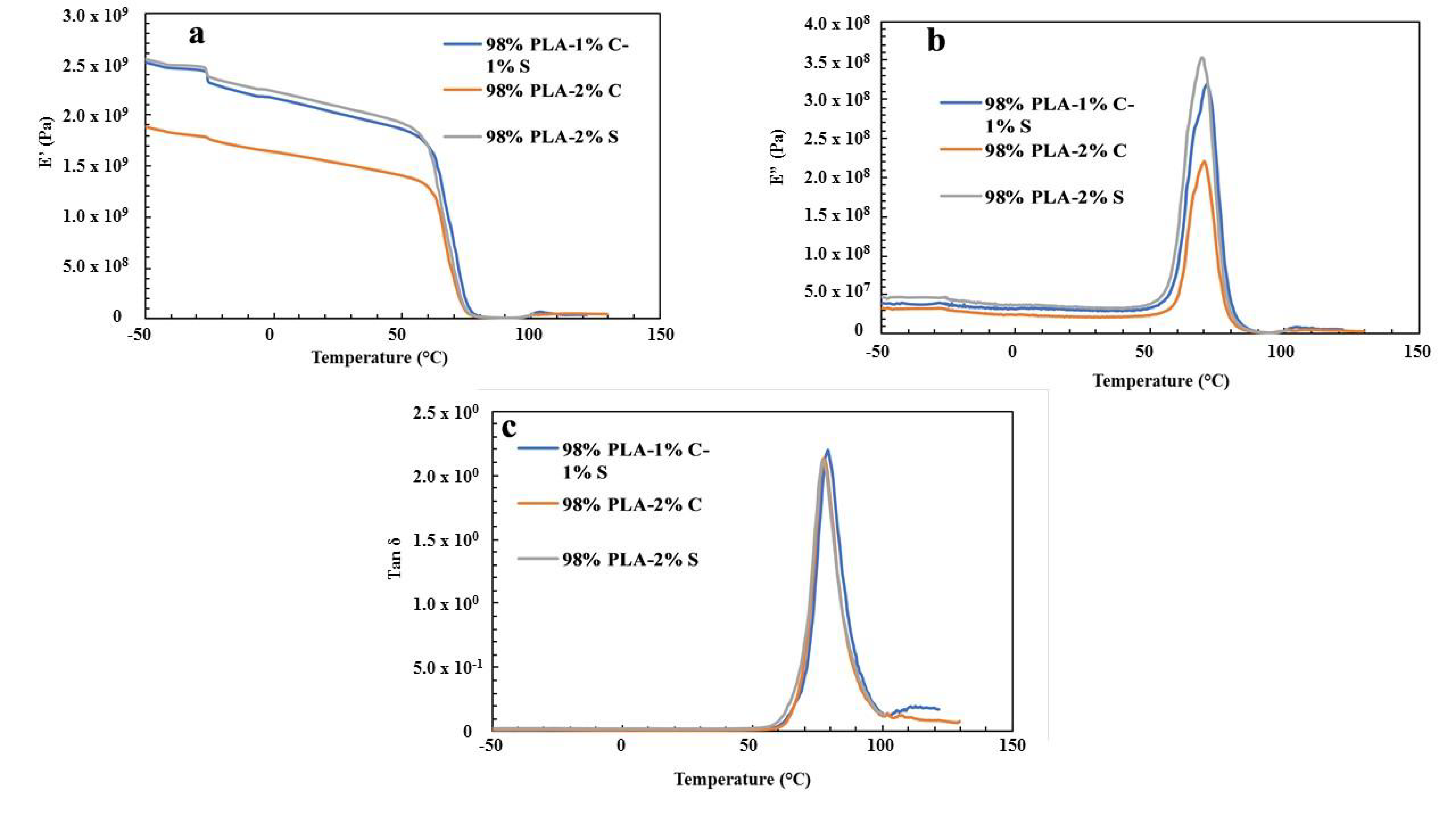

3.3. Dynamic Mechanical Analysis

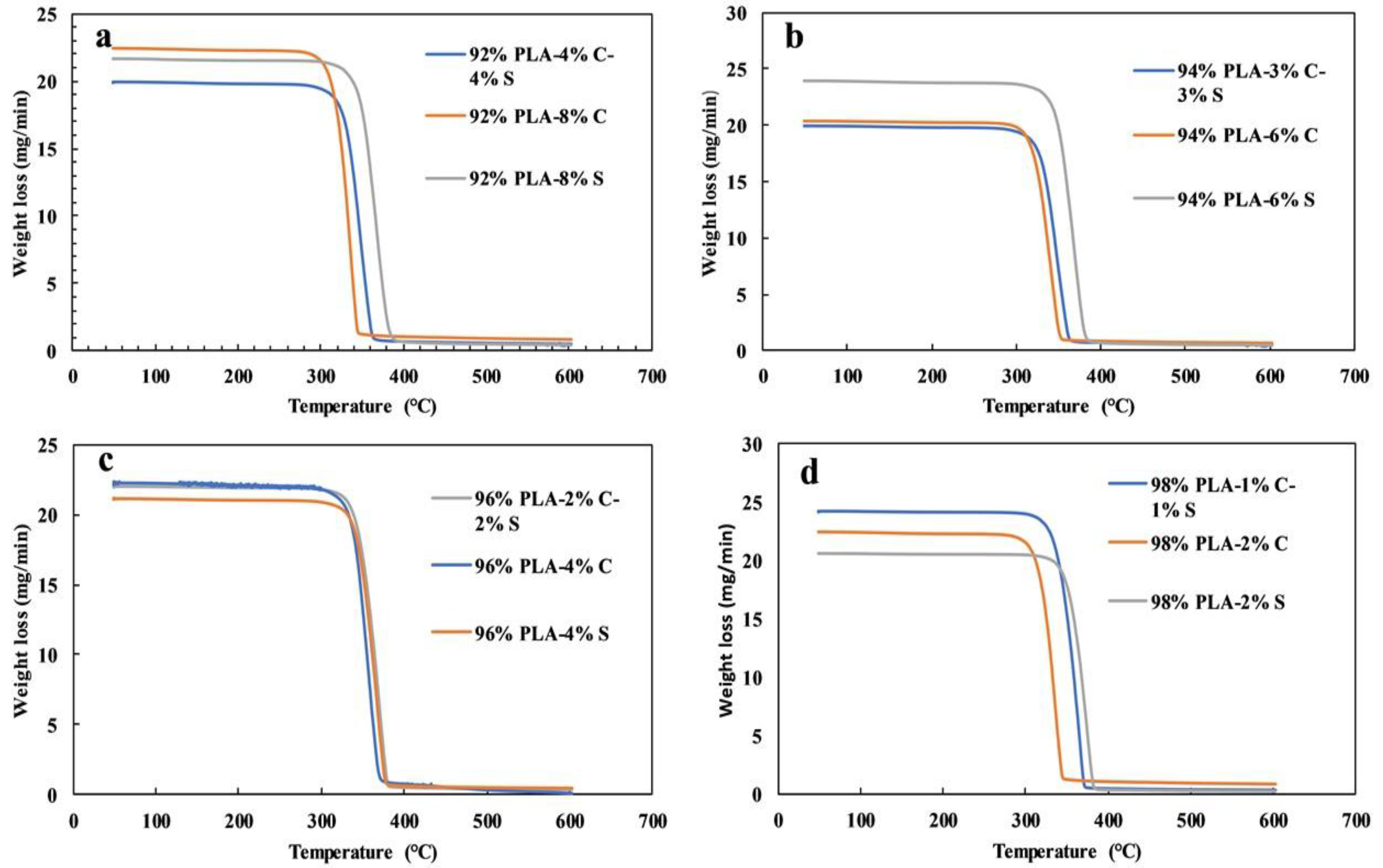

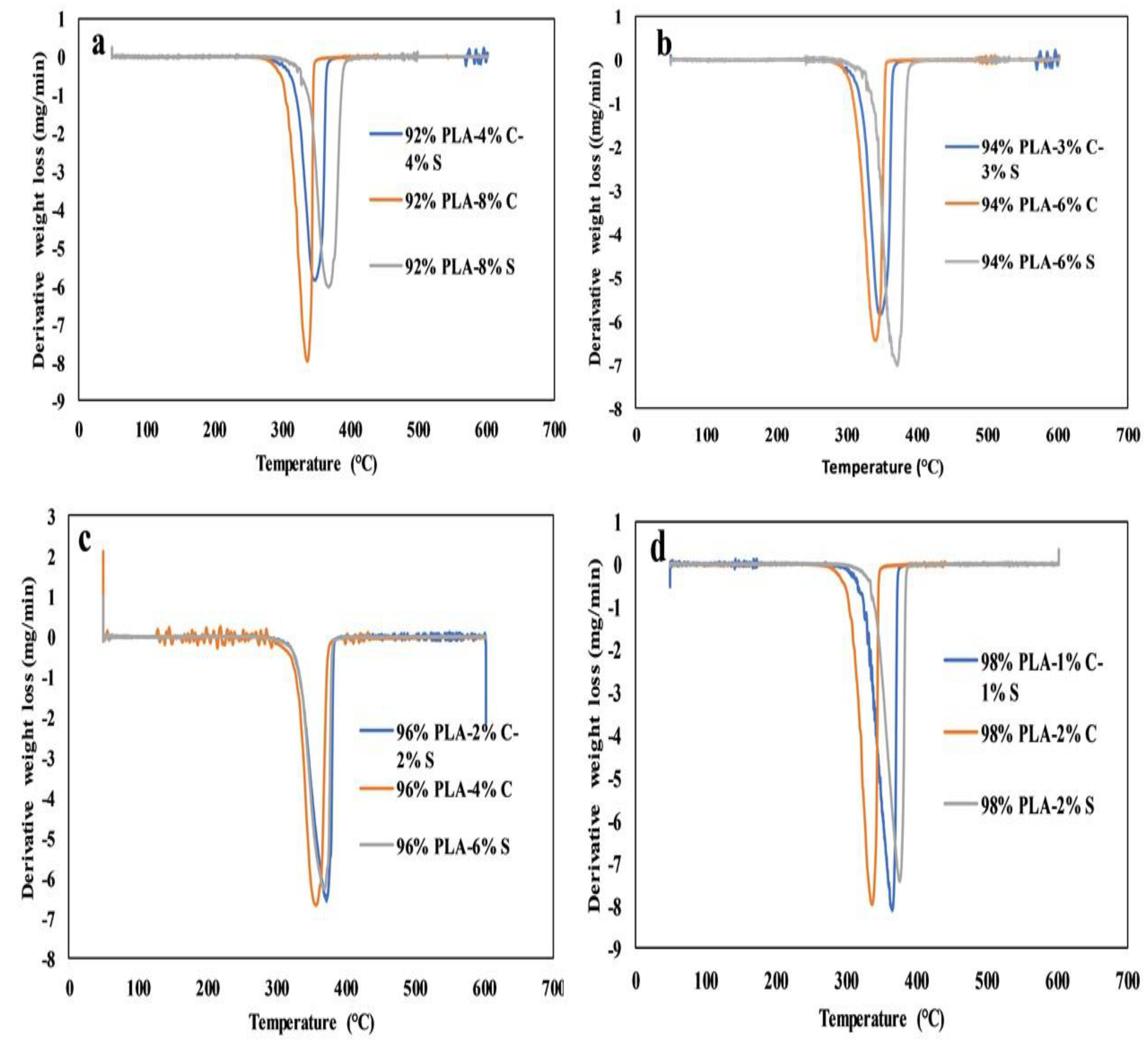

3.4. Thermogravimetry Analysis

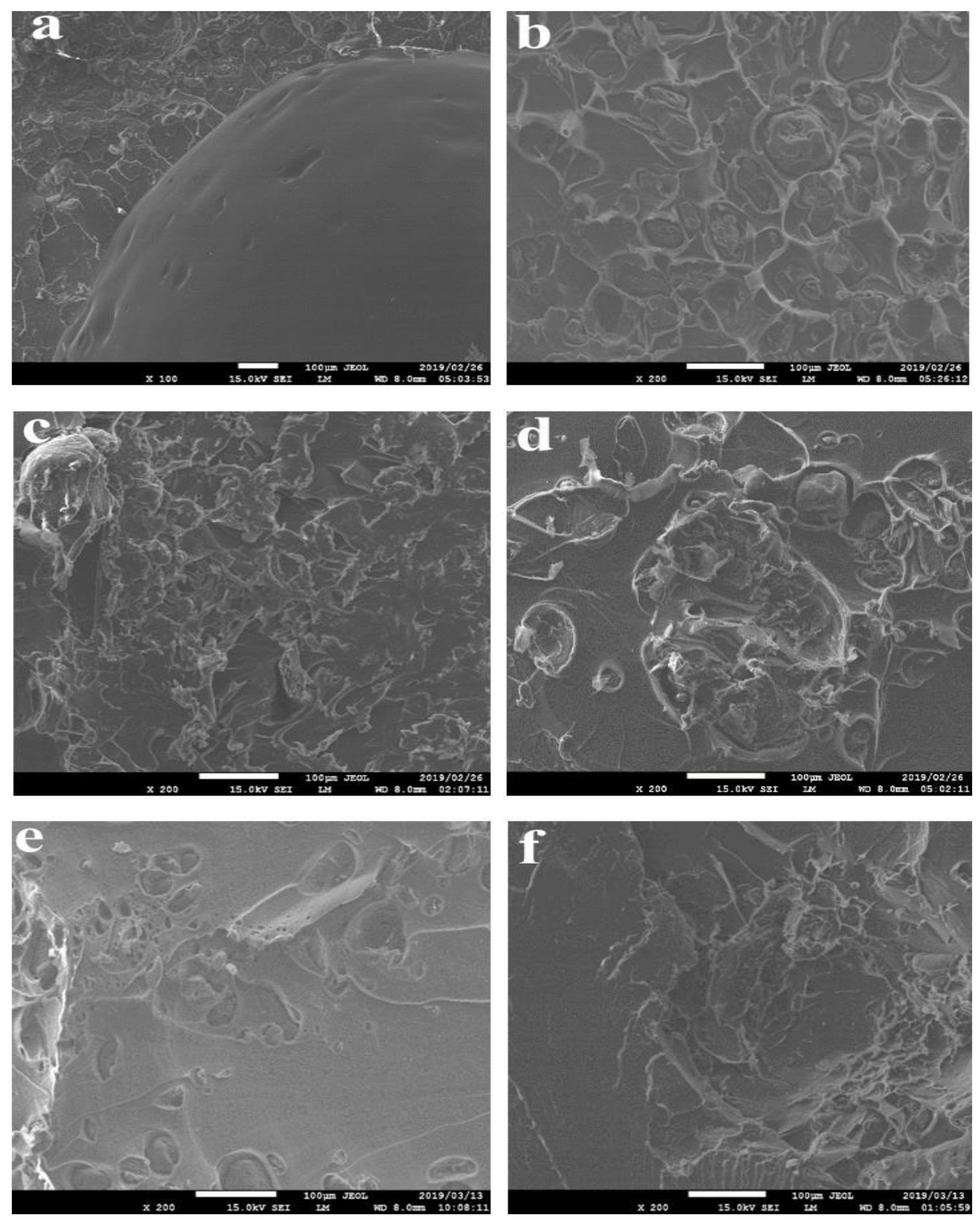

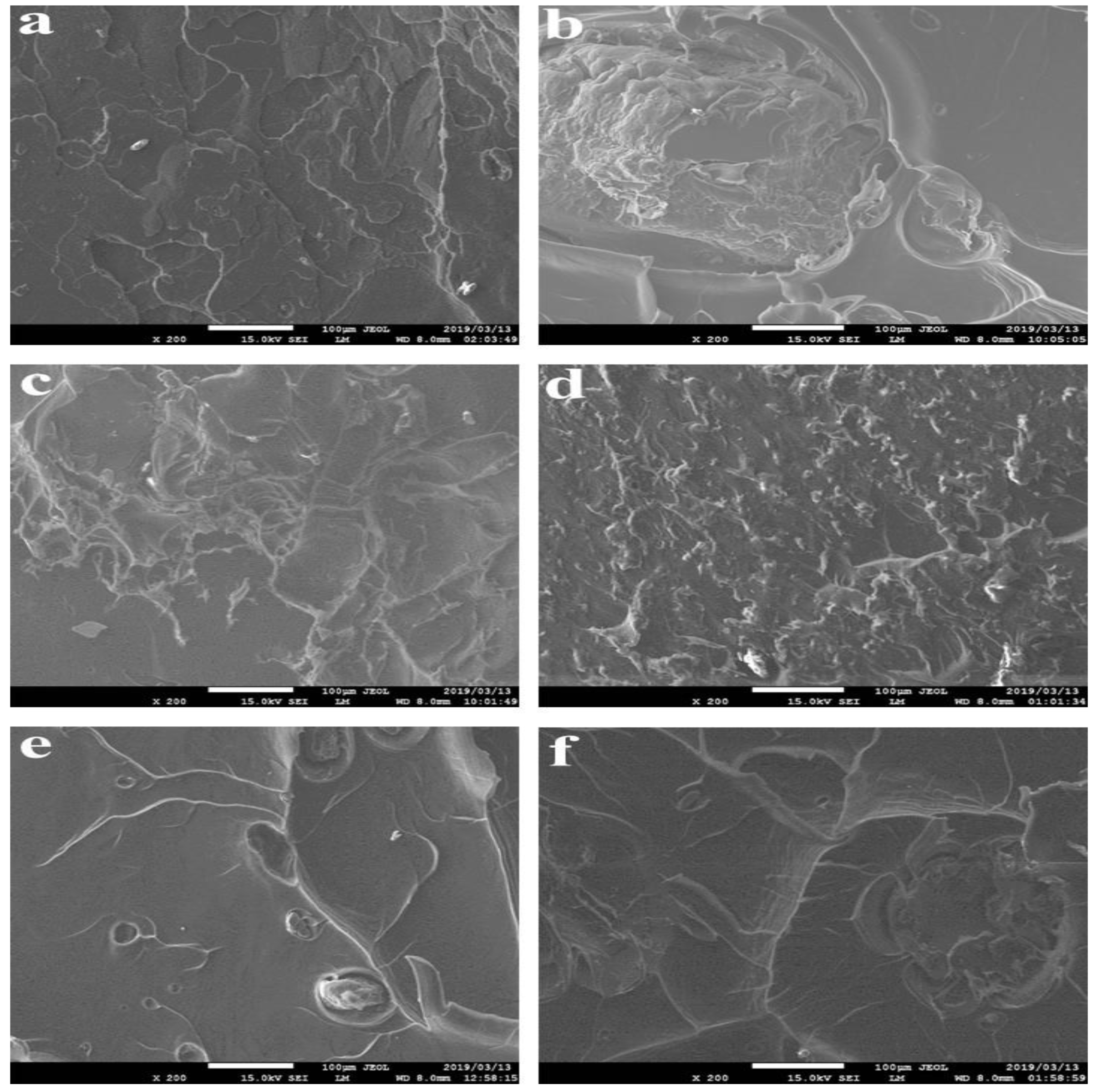

3.5. Scanning Electron Microscopy

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Author Aranda-García, F.J.; González-Núñez, R.; Jasso-Gastinel, C.F.; Mendizábal, E. Water Absorption and Thermomechanical Characterization of Extruded Starch/Poly (lactic acid)/Agave Bagasse Fiber Bioplastic Composites. Int. J. Polym. Sci. 2015, 2015, 343294. [Google Scholar] [CrossRef]

- Garlotta, D. A literature review of poly (lactic acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S. An overview of polylactides as packaging materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Hakkarainen, M. Recycling PLA to multifunctional oligomeric compatibilizers for PLA/starch composites. Eur. Polym. J. 2015, 64, 126–137. [Google Scholar] [CrossRef]

- Tokiwa, Y.; Jarerat, A. Biodegradation of poly(l-lactide). Biotechnol. Lett. 2004, 26, 771–777. [Google Scholar] [CrossRef] [PubMed]

- Jarerat, A.; Tokiwa, Y.; Tanaka, H. Production of poly(l-lactide)-degrading enzyme by Amycolatopsis orientalis for organic recycling of poly(l-lactide). Appl. Microbiol. Biotechnol. 2006, 72, 726–731. [Google Scholar] [CrossRef] [PubMed]

- Rizal, S.; Ikramullah; Gopakumar, D.A.; Thalib, S.; Huzni, S.; Abdul Khalil, H.P.S. Interfacial Compatibility Evaluation on the Fiber Treatment in the Typha Fiber Reinforced Epoxy Composites and Their Effect on the Chemical and Mechanical Properties. Polymers 2018, 10, 1316. [Google Scholar] [CrossRef] [PubMed]

- Hasan, M.; Chong, E.W.N.; Jafarzadeh, S.; Paridah, M.T.; Gopakumar, D.A.; Tajarudin, H.A.; Thomas, S.; Abdul Khalil, H.P.S. Enhancement in the Physico-Mechanical Functions of Seaweed Biopolymer Film via Embedding Fillers for Plasticulture Application—A Comparison with Conventional Biodegradable Mulch Film. Polymers 2019, 11, 210. [Google Scholar] [CrossRef]

- Rodriguez-Gonzalez, F.J.; Ramsay, B.A.; Favis, B.D. High-performance LDPE/thermoplastic starch blends: A sustainable alternative to pure polyethylene. Polymer 2003, 44, 1517–1526. [Google Scholar] [CrossRef]

- Zhang, J.F.; Sun, X. Mechanical properties of poly (lactic acid)/starch composites compatibilized by maleic anhydride. Biomacromolecules 2004, 5, 1446–1451. [Google Scholar] [CrossRef]

- Park, J.W.; Im, S.S.; Kim, S.H.; Kim, Y.H. Biodegradable polymer blends of poly (L-lactic acid) and gelatinized starch. Polym. Eng. Sci. 2000, 40, 2539–2550. [Google Scholar] [CrossRef]

- Yu, L.; Dean, K.; Li, L. Polymer blends and composites from renewable resources. Prog. Polym. Sci. 2006, 31, 576–602. [Google Scholar] [CrossRef]

- Gao, X.; Chen, X.; Zhang, J.; Guo, W.; Jin, F.; Yan, N. Transformation of Chitin and Waste Shrimp Shells into Acetic Acid and Pyrrole. ACS Sustain. Chem. Eng. 2016, 4, 3912–3920. [Google Scholar] [CrossRef]

- Gadgey, K.K.; Bahekar, A. Studies on extraction methods of chitin from crab shell and investigation of its mechanical properties. Int. J. Mech. Eng. Technol. 2017, 8, 220–231. [Google Scholar]

- Younes, I.; Rinaudo, M. Chitin and Chitosan Preparation from Marine Sources. Structure, Properties and Applications. Mar. Drugs 2015, 13, 1133–1174. [Google Scholar] [CrossRef] [PubMed]

- Coltelli, M.; Cinelli, P.; Aliotta, G.L.; Morganti, P.; Panariello, L.; Lazzeri, A. Chitin Nanofibrils in Poly (Lactic Acid) (PLA) Nan Composites: Dispersion and Thermo—Mechanical Properties. Int. J. Mol. Sci. 2019, 20, 504. [Google Scholar] [CrossRef]

- Zuo, Y.; Gu, J.; Cao, J.; Wei, S.; Tan, H.; Zhang, Y. Effect of Starch/Polylactic Acid Ratio on the Interdependence of Two-Phase and the Properties of Composites. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2015, 30, 1108–1114. [Google Scholar] [CrossRef]

- Wilfred, O.; Tai, H.; Marriott, R.; Liu, Q.; Tverezovskiy, V.; Curling, S.; Tai, H.; Fan, Z.; Wang, W. Biodegradation of Polylactic Acid and Starch Composites in Compost and Soil. Int. J. Nano Rech. 2018, 1, 1–11. [Google Scholar]

- Ogunrinola, T.M.; Akpan, U.G. Production of Cassava Starch Bioplastic Film Reinforced with Poly-Lactic Acid (PLA). Int. J. Eng. Res. Adv. Technol. 2018, 4, 56–61. [Google Scholar] [CrossRef]

- Móczó, J.; Kun, D.; Fekete, E. Desiccant effect of starch in polylactic acid composites. Express Polym. Lett. 2018, 12, 1014–1024. [Google Scholar] [CrossRef]

- Nurshahida, B.R.; Zainoha, Z. Biodegradability properties of chitin/polylactic acid composite films. eProc. Chem. 2016, 1, 48–52. [Google Scholar]

- Cinelli, P.; Coltelli, M.B.; Mallegni, N.; Morganti, P.; Lazzeri, A. Degradability and sustainability of nano Composites based on polylactic acid and chitin nanofibrils. Chem. Eng. Trans. 2017, 60, 115–120. [Google Scholar] [CrossRef]

- Jang, W.Y.; Shin, B.Y.; Lee, T.J.; Narayan, R. Thermal properties and morphology of biodegradable PLA/starch compatibilized blends. J. Ind. Eng. Chem. 2007, 13, 457–464. [Google Scholar]

- Jiang, L.; Liu, B.; Zhang, J. Novel high-strength thermoplastic starch reinforced by in situ poly (lactic acid) fibrillation. Macromol. Mater. Eng. 2009, 294, 301–305. [Google Scholar] [CrossRef]

- Nasrin, R.; Biswas, S.; Rashid, T.U.; Afrin, S.; Jahan, R.A.; Haque, P.; Rahman, M.M. Preparation of Chitin-PLA laminated composite for implantable application. Bioact. Mater. 2017, 2, 199–207. [Google Scholar] [CrossRef]

- Zainoha, Z.; Md Saiful, I.; Azman, H.; Haafiz, M.K.M.; Reza, A.; Inuwa, I.M.; Hasan, M. Mechanical Properties and Morphological Characterization of PLA/Chitosan/Epoxidized Natural Rubber Composites. Adv. Mater. Sci. Eng. 2013, 2013, 629092. [Google Scholar] [CrossRef]

- Maubane, L.; Suprakas, S.R.; Jalama, K. The effect of starch amylose content on the morphology and properties of melt-processed butyl-etherified starch/poly [(butylene succinate)-co-adipate] blends. Carbohydr. Polym. Elsevier 2017, 155, 89–100. [Google Scholar] [CrossRef]

- Zaaba, N.F.; Ismail, H. A review on tensile and morphological properties of poly (lactic acid) (PLA)/ thermoplastic starch (TPS) blends. Polym. Plast. Technol. Mater. 2019, 58, 1–20. [Google Scholar] [CrossRef]

- Cheng, S.; Lau, K.; Liu, T.; Zhao, Y.; Lam, P.; Yin, Y. Mechanical and thermal properties of chicken feather fibre/PLA green composites. Compos. Part B 2009, 40, 650–654. [Google Scholar] [CrossRef]

- Muller, J.; González-Martínez, C.; Chiralt, A. Combination of Poly (lactic) Acid and Starch for Biodegradable Food Packaging. Materials 2017, 10, 952. [Google Scholar] [CrossRef]

- Koh, J.J.; Zhang, X.; He, C. Review: Fully biodegradable Poly (lactic acid)/Starch blends: A review of toughening strategies. Int. J. Biol. Macromol. 2018, 109, 99–113. [Google Scholar] [CrossRef] [PubMed]

- Torres-Hernández, Y.; Ortega-Díaz, G.; Téllez-Jurado, L.; Castrejón-Jiménez, N.; Altamirano-Torres, A.; García-Pérez, B.; Balmori-Ramírez, H. Biological Compatibility of a Polylactic Acid Composite Reinforced with Natural Chitosan Obtained from Shrimp Waste. Materials 2018, 11, 1465. [Google Scholar] [CrossRef] [PubMed]

- Mendes, J.F.; Paschoalin, R.; Carmona, V.B.; Sena Neto, A.R.; Marques, A.C.P.; Marconcini, J.M.; Mattosob, L.H.C.; Medeirosd, E.S.; Oliveira, J.E. Biodegradable polymer blends based on corn starch and thermoplastic chitosan processed by extrusion. Carbohydr. Polym. 2016, 137, 452–458. [Google Scholar] [CrossRef] [PubMed]

- Pereira, F.S.; da Silva Agostini, D.L.; Job, A.E.; González, E.R.P. Thermal studies of chitin–chitosan derivatives. J. Therm. Anal. Calorim. 2012, 114, 321–327. [Google Scholar] [CrossRef]

| Particle Size | <1 µm | 1–45 µm | 46–75 µm | 76–150 µm | 151–500 µm | 501–700 µm | >700 µm |

|---|---|---|---|---|---|---|---|

| PLA % | 0.02 | 0.03 | 11.24 | 18.50 | 3.45 | 6.81 | 59.95 |

| Chitin % | 71.2 | 0.28 | 25.6 | 0.9 | 1.56 | 0.46 | 0 |

| Starch% | 11.01 | 34.8 | 49.64 | 0.31 | 4.24 | 0 | 0 |

| Composite | Proportion (wt.%) | |||

|---|---|---|---|---|

| PLA–chitin | 92:8 | 94:6 | 96:4 | 98:2 |

| PLA–starch | 92:8 | 94:6 | 96:4 | 98:2 |

| PLA–chitin–starch | 92:4:4 | 94:3:3 | 96:2:2 | 98:1:1 |

| Samples | Tensile Modulus | Yield Strength | Elongation (%) | Tensile Strength |

|---|---|---|---|---|

| (MPa) | (MPa) | (MPa) | ||

| 92% PLA–4%C–4% S | 2138.1 ± 107.3 | 75.3 ± 2.9 | 4.3 ± 0.3 | 75.3 ± 2.92 |

| 92% PLA–8% C | 2898.6 ± 104.9 | 82.8 ± 2.6 | 5.5 ± 0.7 | 82.9 ± 2.26 |

| 92% PLA–8% S | 2412.2 ± 117.9 | 82.8 ± 2.1 | 4.1 ± 0.3 | 82.8 ± 2.12 |

| 94% PLA–3% C–3% S | 2458.1 ± 108 | 84.4 ± 1.7 | 5.0 ± 0.9 | 84.4 ± 1.7 |

| 94% PLA–6% C | 2310.7 ± 101.6 | 83.0 ± 1.6 | 7.1 ± 1.4 | 83.0 ± 1.6 |

| 94% PLA–6% S | 2417.3 ± 101.6 | 70.6 ± 1.9 | 3.9 ± 0.3 | 70.6 ± 1.9 |

| 96% PLA–2% C–2% S | 2613.3 ± 103.3 | 83.0 ± 1.3 | 5.3 ± 1.8 | 83.0 ± 1.3 |

| 96% PLA–4% C | 2448.9 ± 102.1 | 80.8 ± 1.9 | 6.3 ± 2.2 | 80.8 ± 1.9 |

| 96% PLA–4% S | 2586.4 ± 106 | 79.7 ± 1.4 | 4.2 ± 0.4 | 79.7 ± 1.4 |

| 98% PLA–1% C–1% S | 2536.3 ± 108.3 | 82.6 ± 2.9 | 4.8 ± 0.4 | 82.6 ± 2.9 |

| 98% PLA–2% C | 2524.0 ± 105.8 | 77.4 ± 2.1 | 5.5 ± 1.2 | 77.4 ± 2.0 |

| 98% PLA–2% S | 2058.4 ± 104.3 | 72.1 ± 1.5 | 4.2 ± 0.3 | 72.1 ± 1.5 |

| 100% PLA | 3500.0 ± 100.1 | 53.5 ± 1.1 | 6.0 ± 0.2 | 60.0 ± 1.12 |

| Serial Number | Samples | Glass Transition Temperature |

|---|---|---|

| (°C) | ||

| 1 | 92% PLA–4% C–4% S | 73.0 |

| 2 | 92% PLA–8% C | 74.0 |

| 3 | 92% PLA–8% S | 91.6 |

| 4 | 94% PLA–3% C–3% S | 75.5 |

| 5 | 94% PLA–6% C | 76.4 |

| 6 | 94% PLA–6% S | 76.7 |

| 7 | 96% PLA–2% C–2% S | 67.0 |

| 8 | 96% PLA–4% C | 69.8 |

| 9 | 96% PLA–4% S | 76.7 |

| 10 | 98% PLA–1% C–1% S | 77.2 |

| 11 | 98% PLA–2% C | 76.9 |

| 12 | 98% PLA–2% S | 76.6 |

| 13 | 100% PLA | 60.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olaiya, N.G.; Surya, I.; Oke, P.K.; Rizal, S.; Sadiku, E.R.; Ray, S.S.; Farayibi, P.K.; Hossain, M.S.; Abdul Khalil, H.P.S. Properties and Characterization of a PLA–Chitin–Starch Biodegradable Polymer Composite. Polymers 2019, 11, 1656. https://doi.org/10.3390/polym11101656

Olaiya NG, Surya I, Oke PK, Rizal S, Sadiku ER, Ray SS, Farayibi PK, Hossain MS, Abdul Khalil HPS. Properties and Characterization of a PLA–Chitin–Starch Biodegradable Polymer Composite. Polymers. 2019; 11(10):1656. https://doi.org/10.3390/polym11101656

Chicago/Turabian StyleOlaiya, N.G., Indra Surya, P.K. Oke, Samsul Rizal, E.R. Sadiku, S.S. Ray, P.K. Farayibi, Md Sohrab Hossain, and H.P.S. Abdul Khalil. 2019. "Properties and Characterization of a PLA–Chitin–Starch Biodegradable Polymer Composite" Polymers 11, no. 10: 1656. https://doi.org/10.3390/polym11101656

APA StyleOlaiya, N. G., Surya, I., Oke, P. K., Rizal, S., Sadiku, E. R., Ray, S. S., Farayibi, P. K., Hossain, M. S., & Abdul Khalil, H. P. S. (2019). Properties and Characterization of a PLA–Chitin–Starch Biodegradable Polymer Composite. Polymers, 11(10), 1656. https://doi.org/10.3390/polym11101656