Efficient and Precise Micro-Injection Molding of Micro-Structured Polymer Parts Using Micro-Machined Mold Core by WEDM

Abstract

1. Introduction

2. Materials and Methods

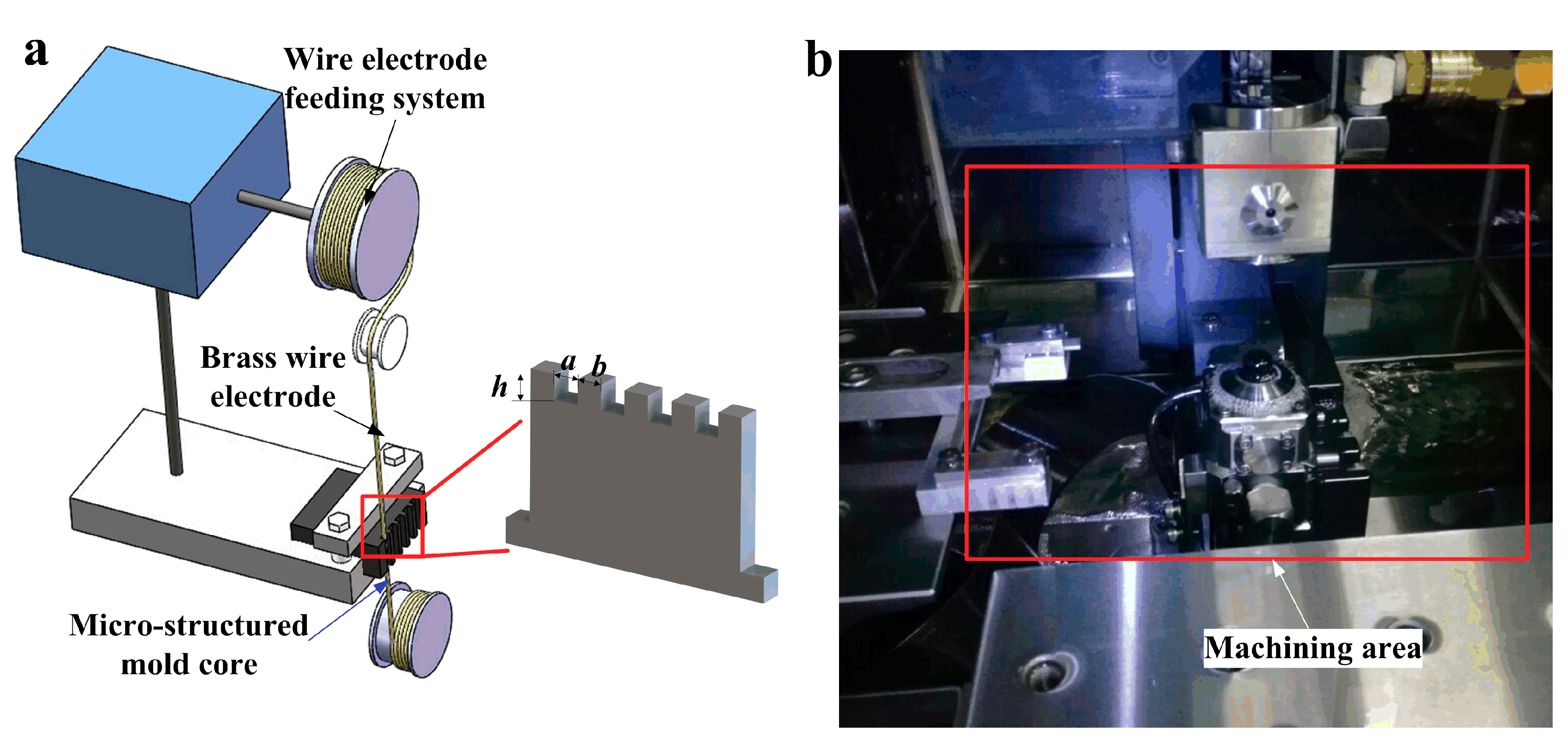

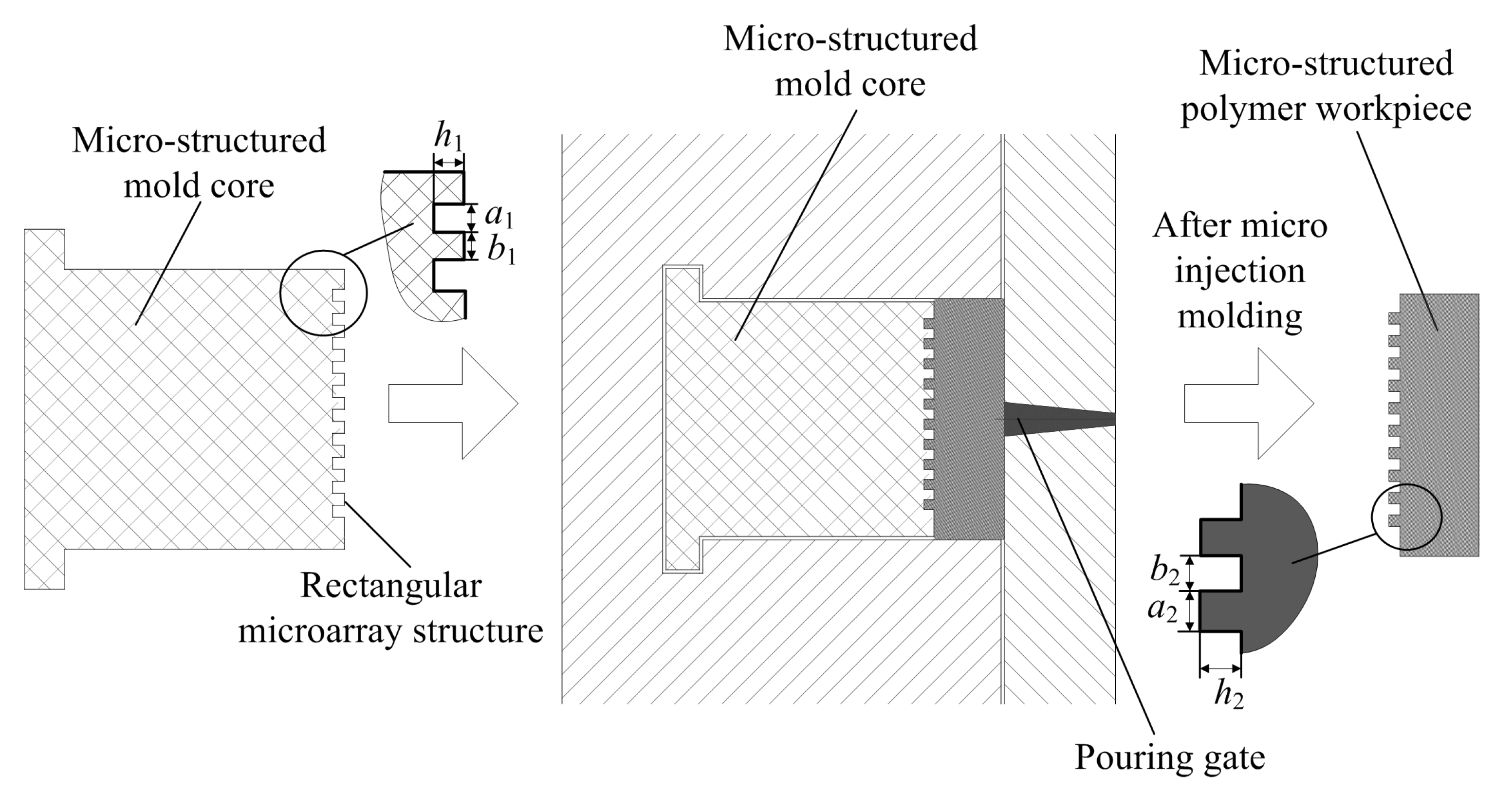

2.1. Wire Electrical Discharge Machining (WEDM) of Mold Core with Micro-Structures

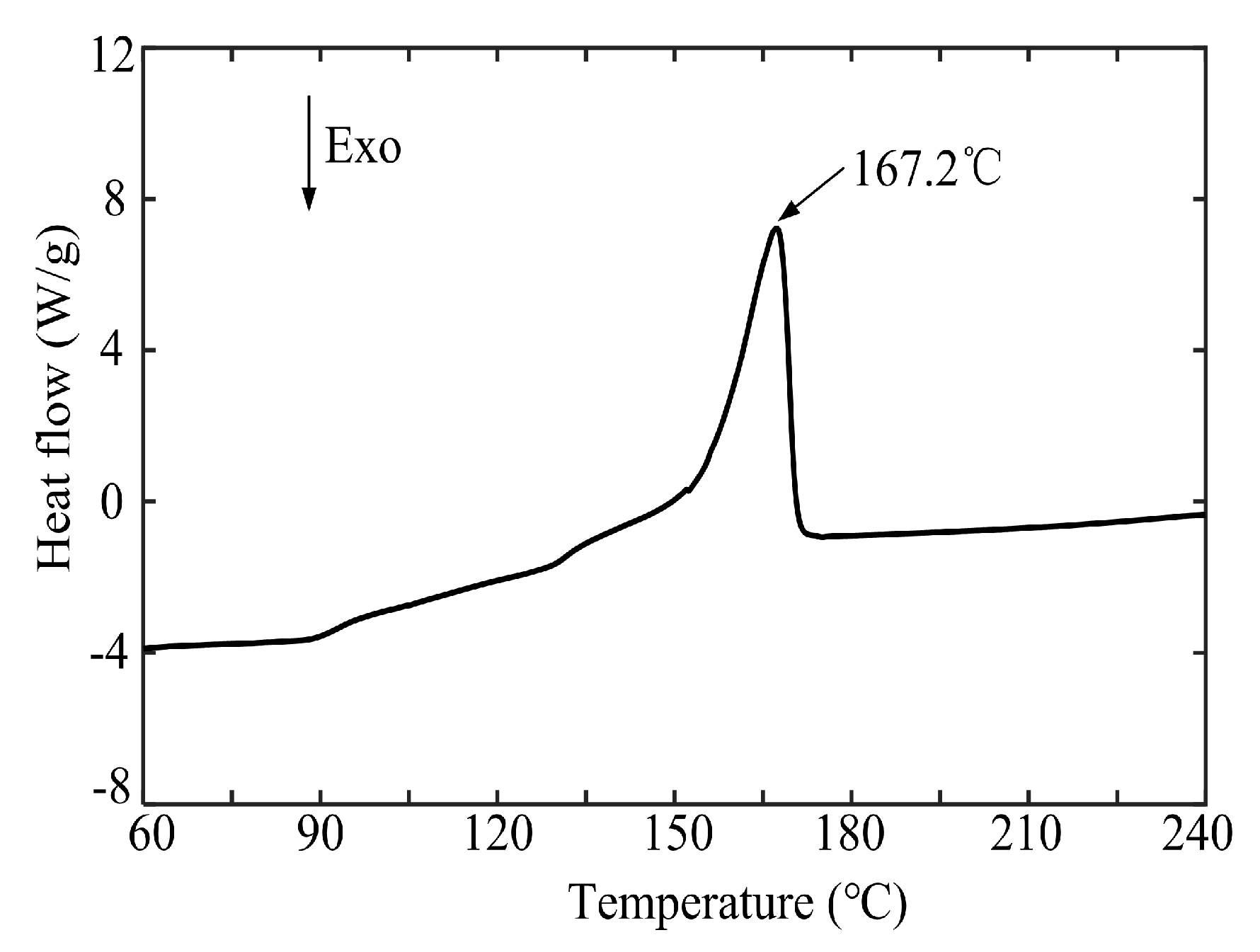

2.2. Micro-Injection Molding of Polymer Workpieces with Micro-Structures

2.3. Measurement of Micro-Structured Mold Core and Polymer Workpieces

3. Results and Discussions

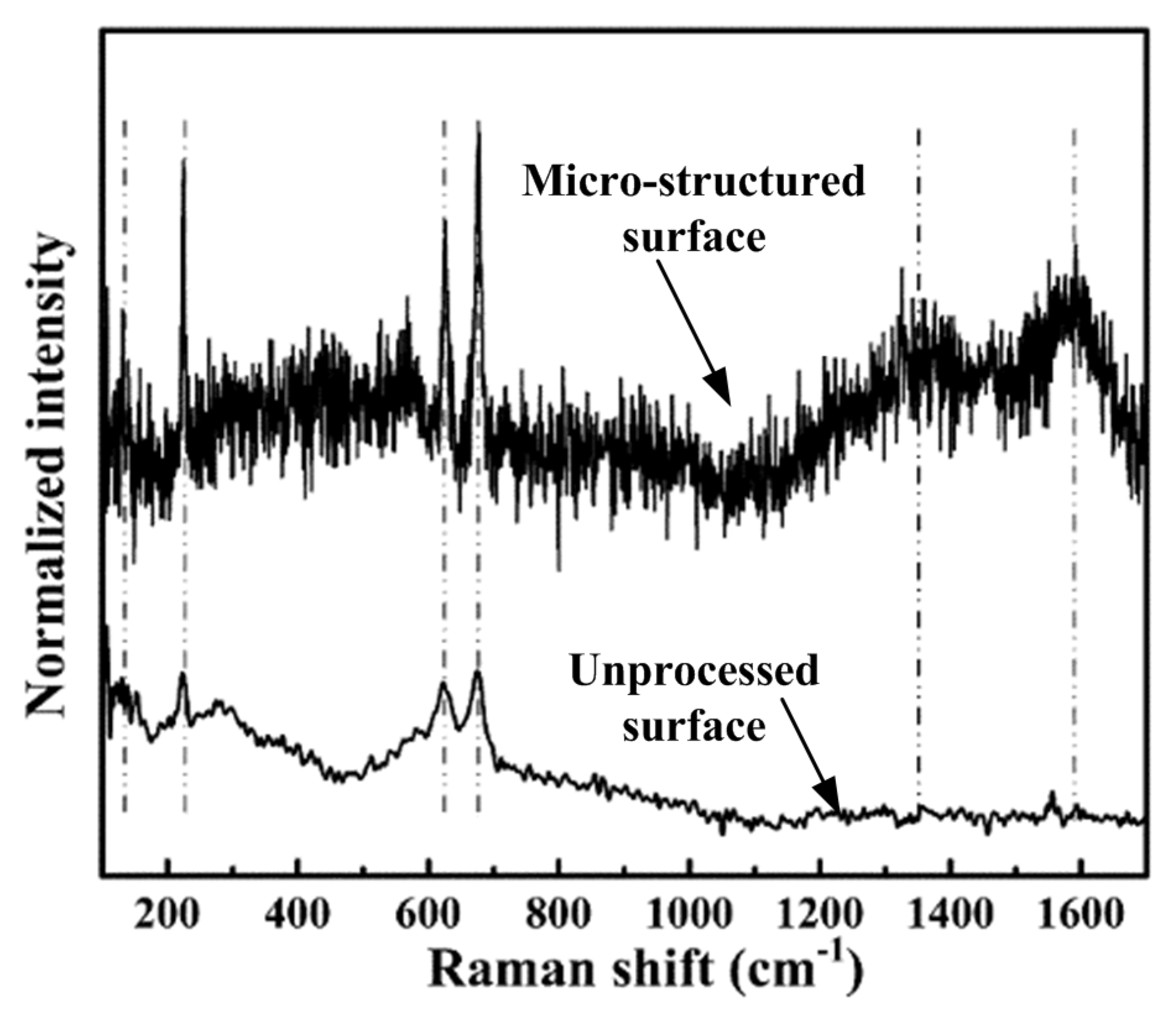

3.1. Phase Constitutions of the Micro-Structured Mold Core Surfaces

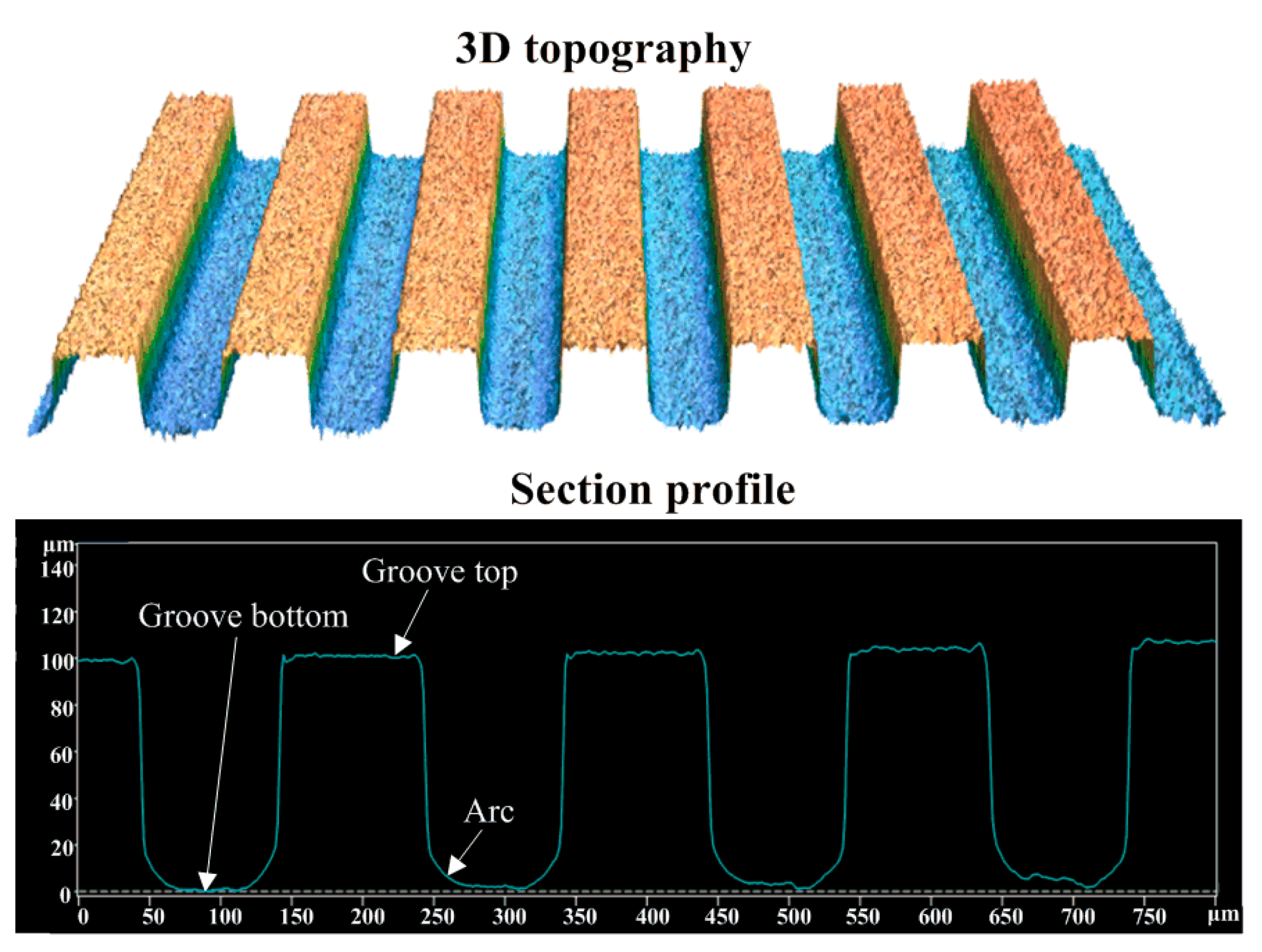

3.2. Topographies and Section Profile Curves of Micro-Structured Mold Core Surfaces

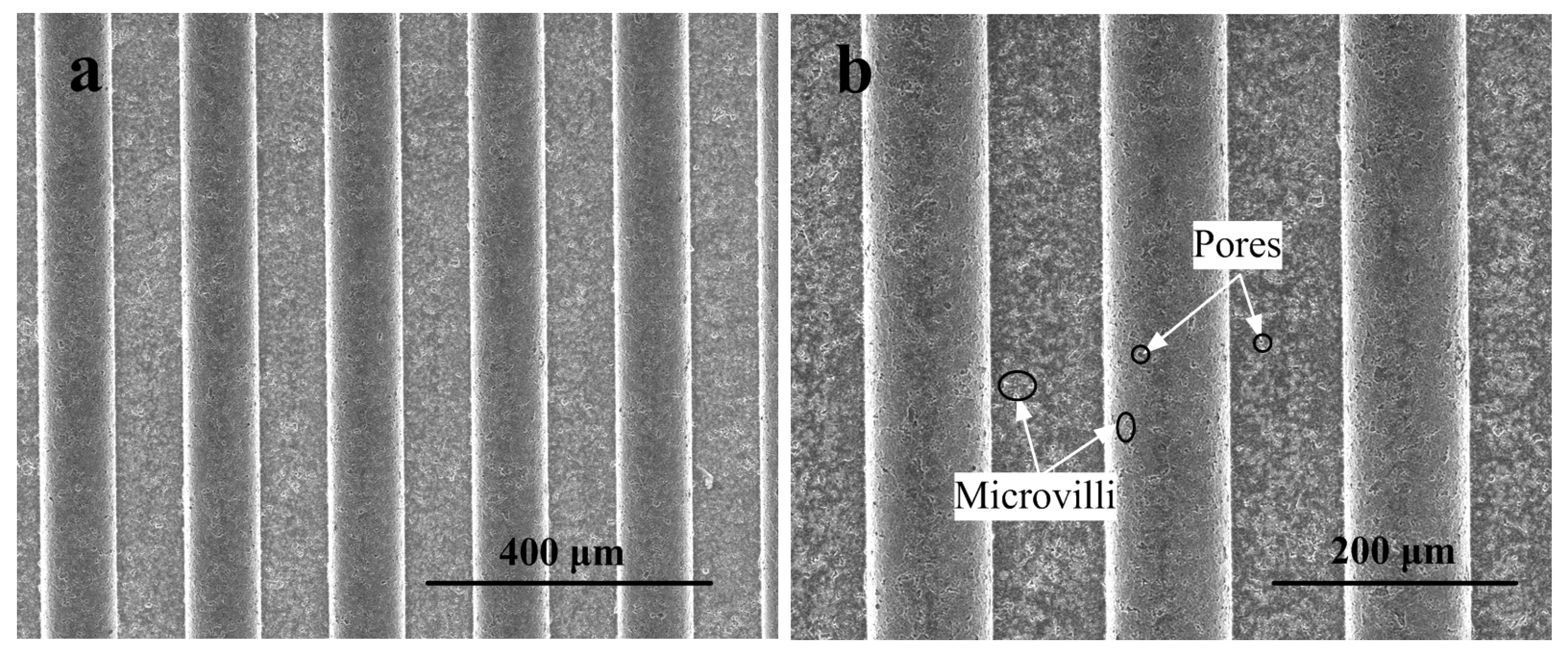

3.3. Topographies and Section Profile Curves of Micro-Structured Polymer Surfaces

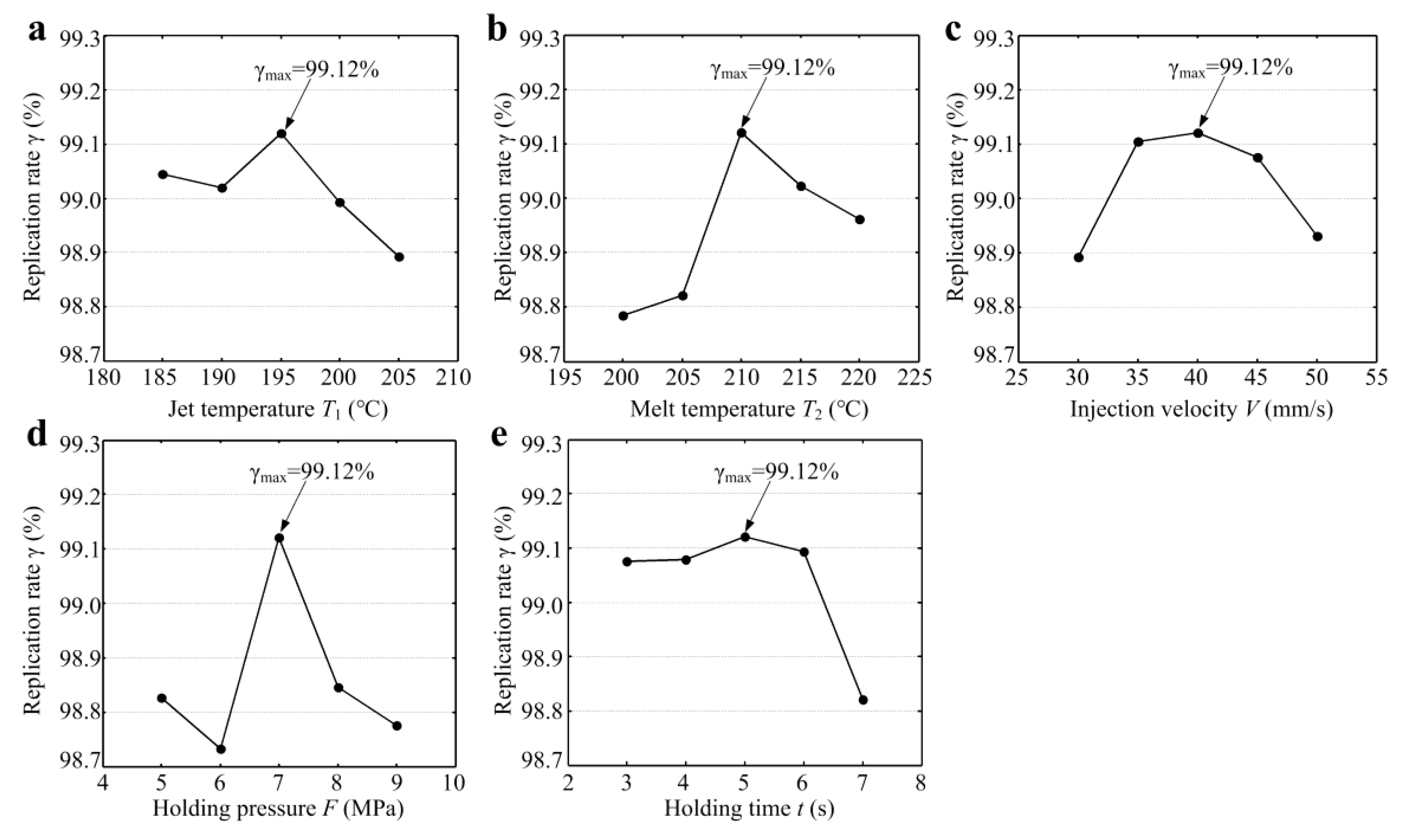

3.4. Effects of Micro-Injection Molding Parameters on Replication Rate of Micro-Structured Polymer

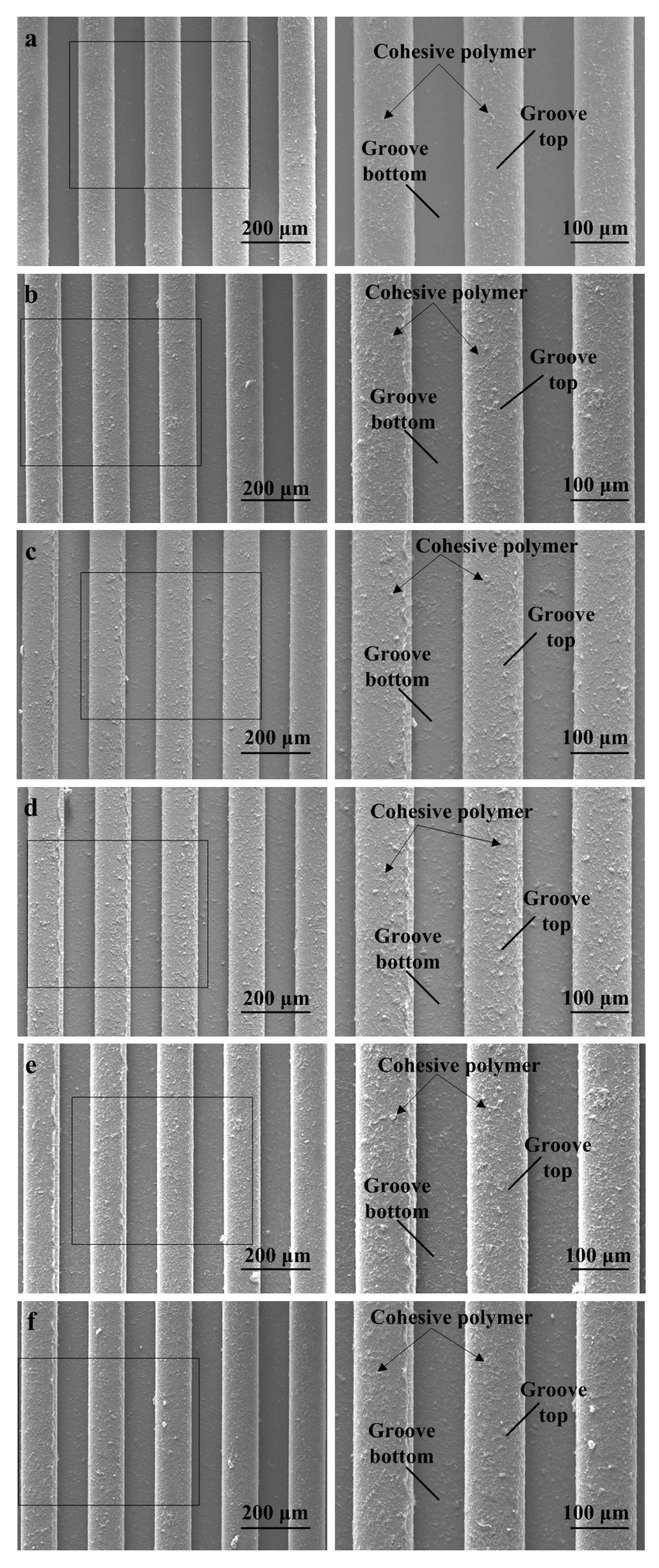

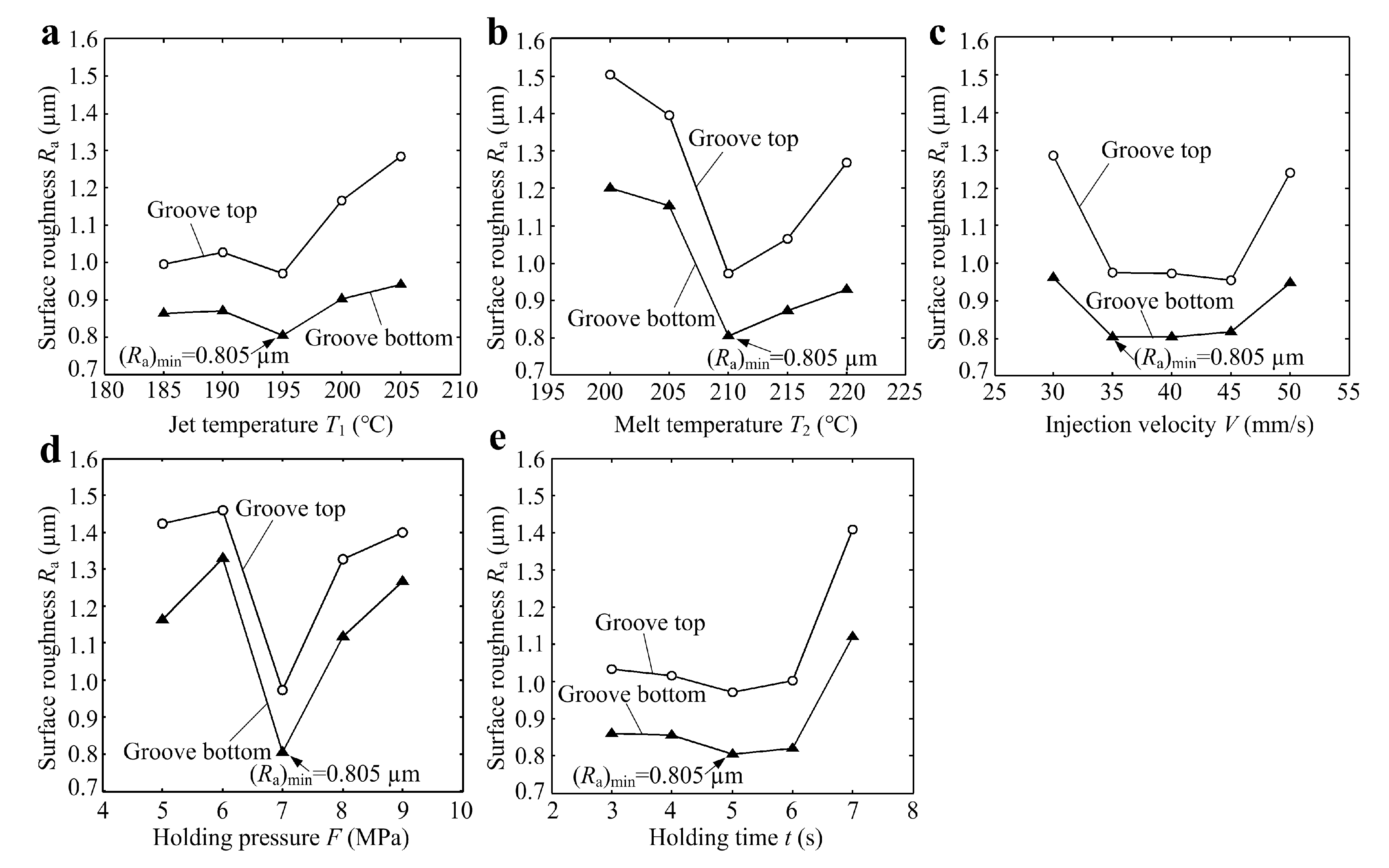

3.5. Effects of Micro-Injection Molding Parameters on Surface Quality of Micro-Structured Polymer

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xu, P.; Huang, Y.; Su, Z.; Zhang, X.; Luo, T.; Peng, W. Research of micro-prism distribution on the bottom surface of the small-size integrated light guide plate. Opt. Express 2015, 23, 4887–4896. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wang, S.; Wang, Y. Patterned fibers embedded microfluidic chips based on PLA and PDMS for Ag nanoparticle safety testing. Polymers 2016, 8, 402. [Google Scholar] [CrossRef] [PubMed]

- Danilevičius, P.; Rekštytė, S.; Balčiūnas, E.; Kraniauskas, A.; Širmenis, R.; Baltriukienė, D.; Bukelskienė, V.; Gadonas, R.; Sirvydis, V.; Piskarskas, A.; et al. Laser 3D micro/nanofabrication of polymers for tissue engineering applications. Opt. Laser Technol. 2013, 45, 518–524. [Google Scholar] [CrossRef]

- Vázquez, R.M.; Trotta, G.; Volpe, A.; Paturzo, M.; Modica, F.; Bianco, V.; Coppola, S.; Ancona, A.; Ferraro, P.; Fassi, I.; et al. Plastic Lab-on-Chip for the Optical Manipulation of Single Cells. In Factories of the Future; Springer: Cham, Switzerland, 2019; pp. 339–363. [Google Scholar]

- Maghsoudi, K.; Jafari, R.; Momen, G.; Farzaneh, M. Micro-nanostructured polymer surfaces using injection molding: A review. Mater. Toady Commun. 2017, 13, 126–143. [Google Scholar] [CrossRef]

- Lu, Y.J.; Chen, F.M.; Wu, X.Y.; Zhou, C.L.; Lou, Y.; Li, L.J. Fabrication of Micro-Structured Polymer by Micro Injection Molding Based on Precise Micro-Ground Mold Core. Micromachines 2019, 10, 253. [Google Scholar] [CrossRef] [PubMed]

- Jiang, B.Y.; Zhu, L.Y.; Min, L.P.; Li, X.L.; Zhai, Z.Y.; Drummer, D. Characterization of Microchannel Replicability of Injection Molded Electrophoresis Microfluidic Chips. Polymers 2019, 11, 608. [Google Scholar] [CrossRef]

- Trotta, G.; Martínez Vázquez, R.; Volpe, A.; Modica, F.; Ancona, A.; Fassi, I.; Osellame, R. Disposable optical stretcher fabricated by microinjection moulding. Micromachines 2018, 9, 388. [Google Scholar] [CrossRef]

- Trotta, G.; Volpe, A.; Ancona, A.; Fassi, I. Flexible micro manufacturing platform for the fabrication of PMMA microfluidic devices. J. Manuf. Process. 2018, 35, 107–117. [Google Scholar] [CrossRef]

- Suzuki, H.; Takayama, T.; Ito, H. Replication Behavior for Micro Surface Features with High Aspect Ratio and Structure Development in Injection Compression Molding. Int. J. Modern Phys. Conf. Ser. 2012, 6, 563–569. [Google Scholar] [CrossRef]

- Matschuk, M.; Larsen, N.B. Injection Molding of High Aspect Ratio sub-100 nm Nanostructures. J. Micromech. Microeng. 2013, 23, 025003. [Google Scholar] [CrossRef]

- Lucchetta, G.; Sorgato, M.; Carmignato, S.; Savio, E. Investigating the technological limits of micro-injection molding in replicating high aspect ratio micro-structured surfaces. CIRP Ann. Manuf. Technol. 2014, 63, 521–524. [Google Scholar] [CrossRef]

- Kim, J.H.; Mirzaei, A.; Kim, H.W. Facile fabrication of superhydrophobic surfaces from austenitic stainless steel (AISI 304) by chemical etching. Appl. Surf. Sci. 2018, 439, 598–604. [Google Scholar] [CrossRef]

- Zhou, C.L.; Ngai, T.W.L.; Li, L.J. Wetting behaviour of laser textured Ti3SiC2 surface with micro-grooved structures. Mater. Sci. Tech. 2016, 32, 805–812. [Google Scholar]

- Chen, Y.L.; Cai, Y.D.; Shimizu, Y.K.; Ito, S.; Gao, W.; Ju, B.F. Ductile Cutting of Silicon Microstructures with Surface Inclination Measurement and Compensation by Using a Force Sensor Integrated Single Point Diamond Tool. J. Micromech. Microeng. 2016, 26, 025002. [Google Scholar] [CrossRef]

- Bisaria, H.; Shandilya, P. Experimental Investigation on Wire Electric Discharge Machining (WEDM) of Nimonic C-263 Superalloy. Mater. Manuf. Process. 2019, 34, 83–92. [Google Scholar] [CrossRef]

- Zhou, C.L.; Wu, X.Y.; Lu, Y.J.; Wu, W.; Zhao, H.; Li, L.J. Fabrication of Hydrophobic Ti3SiC2 Surface with Micro-grooved Structures by Wire Electrical Discharge Machining. Ceram. Int. 2018, 44, 18227–18234. [Google Scholar] [CrossRef]

- Wang, Y.K.; Chen, X.; Gan, W.M.; Wang, Z.L.; Guo, C. Complex rotary structures machined by micro-WEDM. Procedia CIRP 2016, 42, 743–747. [Google Scholar]

- Weng, C.; Wang, F.; Zhou, M.Y. Fabrication of hierarchical polymer surfaces with superhydrophobicity by injection molding from nature and function-oriented design. Appl. Surf. Sci. 2018, 436, 224–233. [Google Scholar] [CrossRef]

- Iwko, J.; Steller, R.; Wróblewski, R. Experimentally Verified Mathematical Model of Polymer Plasticization Process in Injection Molding. Polymers 2018, 10, 968. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.L.; Ngai, T.W.L.; Lu, L. Fabrication and characterization of pure porous Ti3SiC2 with controlled porosity and pore features. Mater. Lett. 2014, 131, 280–283. [Google Scholar] [CrossRef]

- Zhou, C.L.; Wu, X.Y.; Ngai, T.W.L.; Li, L.J.; Ngai, S.L.; Chen, Z.M. Al Alloy/Ti3SiC2 Composites Fabricated by Pressureless Infiltration with Melt-spun Al Alloy Ribbons. Ceram. Int. 2018, 44, 6026–6032. [Google Scholar] [CrossRef]

- Wdowik, U.D.; Twardowska, A.; Mȩdala-Wa̧sik, M. Lattice dynamics of binary and ternary phases in Ti-Si-C system: A combined Raman spectroscopy and density functional theory study. Mater. Chem. Phys. 2015, 168, 58–65. [Google Scholar] [CrossRef]

- Vasanthakumar, K.; Bakshi, S.R. Effect of C/Ti ratio on densification, microstructure and mechanical properties of TiCx prepared by reactive spark plasma sintering. Ceram. Int. 2018, 44, 484–494. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Ibrahim, A.; Ali, H. Effect of graphene film on laser textured alumina surface characteristics. Ceram. Int. 2017, 43, 2012–2021. [Google Scholar] [CrossRef]

| No. | Jet Temperature T1 (°C) | Melt Temperature T2 (°C) | Injection Velocity V (mm/s) | Holding Pressure F (Mpa) | Holding Time t (s) |

|---|---|---|---|---|---|

| 1 | 185 | 210 | 40 | 7 | 5 |

| 2 | 190 | 210 | 40 | 7 | 5 |

| 3 | 195 | 210 | 40 | 7 | 5 |

| 4 | 200 | 210 | 40 | 7 | 5 |

| 5 | 205 | 210 | 40 | 7 | 5 |

| 6 | 195 | 200 | 40 | 7 | 5 |

| 7 | 195 | 205 | 40 | 7 | 5 |

| 8 | 195 | 215 | 40 | 7 | 5 |

| 9 | 195 | 220 | 40 | 7 | 5 |

| 10 | 195 | 210 | 30 | 7 | 5 |

| 11 | 195 | 210 | 35 | 7 | 5 |

| 12 | 195 | 210 | 45 | 7 | 5 |

| 13 | 195 | 210 | 50 | 7 | 5 |

| 14 | 195 | 210 | 40 | 5 | 5 |

| 15 | 195 | 210 | 40 | 6 | 5 |

| 16 | 195 | 210 | 40 | 8 | 5 |

| 17 | 195 | 210 | 40 | 9 | 5 |

| 18 | 195 | 210 | 40 | 7 | 3 |

| 19 | 195 | 210 | 40 | 7 | 4 |

| 20 | 195 | 210 | 40 | 7 | 6 |

| 21 | 195 | 210 | 40 | 7 | 7 |

| Sample | Width a1 (µm) | Depth h1 (µm) | Spacing b1 (µm) | Ra of Groove Top (µm) | Ra of Groove Bottom (µm) |

|---|---|---|---|---|---|

| Machined mold core | 99.683 | 99.601 | 100.465 | 1.354 | 1.476 |

| No. | Width a2 (µm) | Depth h2 (µm) | Spacing b2 (µm) | Ra of Groove Bottom (µm) | Ra of Groove Top (µm) |

|---|---|---|---|---|---|

| 1 | 100.44 | 100.967 | 98.164 | 0.864 | 0.996 |

| 2 | 99.069 | 101.469 | 98.278 | 0.871 | 1.028 |

| 3 | 100.339 | 101.183 | 98.503 | 0.805 | 0.972 |

| 4 | 98.090 | 100.667 | 100.981 | 0.903 | 1.166 |

| 5 | 97.087 | 100.932 | 100.016 | 0.943 | 1.286 |

| 6 | 97.805 | 100.534 | 101.451 | 1.202 | 1.503 |

| 7 | 98.086 | 99.998 | 101.229 | 1.153 | 1.396 |

| 8 | 99.414 | 101.665 | 98.140 | 0.874 | 1.065 |

| 9 | 98.253 | 100.006 | 100.986 | 0.929 | 1.269 |

| 10 | 100.009 | 101.48 | 101.581 | 0.962 | 1.287 |

| 11 | 100.05 | 101.965 | 98.943 | 0.804 | 0.976 |

| 12 | 99.925 | 101.764 | 100.834 | 0.817 | 0.955 |

| 13 | 98.515 | 102.109 | 100.161 | 0.948 | 1.241 |

| 14 | 98.198 | 100.111 | 101.439 | 1.163 | 1.422 |

| 15 | 97.441 | 99.720 | 100.570 | 1.329 | 1.459 |

| 16 | 98.231 | 101.845 | 98.972 | 1.118 | 1.326 |

| 17 | 99.185 | 101.487 | 101.915 | 1.267 | 1.398 |

| 18 | 98.299 | 101.786 | 99.534 | 0.860 | 1.035 |

| 19 | 98.870 | 102.251 | 99.934 | 0.856 | 1.016 |

| 20 | 100.909 | 101.483 | 100.076 | 0.822 | 1.003 |

| 21 | 98.472 | 99.670 | 101.289 | 1.120 | 1.411 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, Q.; Zhou, C.; Lu, Y.; Wu, X.; Chen, F.; Lou, Y. Efficient and Precise Micro-Injection Molding of Micro-Structured Polymer Parts Using Micro-Machined Mold Core by WEDM. Polymers 2019, 11, 1591. https://doi.org/10.3390/polym11101591

Liao Q, Zhou C, Lu Y, Wu X, Chen F, Lou Y. Efficient and Precise Micro-Injection Molding of Micro-Structured Polymer Parts Using Micro-Machined Mold Core by WEDM. Polymers. 2019; 11(10):1591. https://doi.org/10.3390/polym11101591

Chicago/Turabian StyleLiao, Qianghua, Chaolan Zhou, Yanjun Lu, Xiaoyu Wu, Fumin Chen, and Yan Lou. 2019. "Efficient and Precise Micro-Injection Molding of Micro-Structured Polymer Parts Using Micro-Machined Mold Core by WEDM" Polymers 11, no. 10: 1591. https://doi.org/10.3390/polym11101591

APA StyleLiao, Q., Zhou, C., Lu, Y., Wu, X., Chen, F., & Lou, Y. (2019). Efficient and Precise Micro-Injection Molding of Micro-Structured Polymer Parts Using Micro-Machined Mold Core by WEDM. Polymers, 11(10), 1591. https://doi.org/10.3390/polym11101591