Investigation on Rheological Properties and Storage Stability of Modified Asphalt Based on the Grafting Activation of Crumb Rubber

Abstract

:1. Introduction

2. Experimental

2.1. Materials

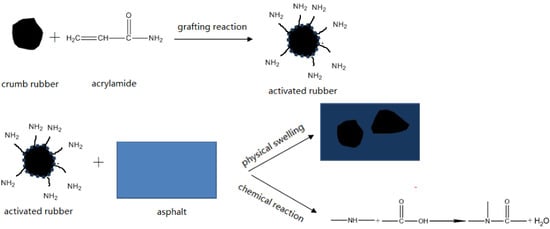

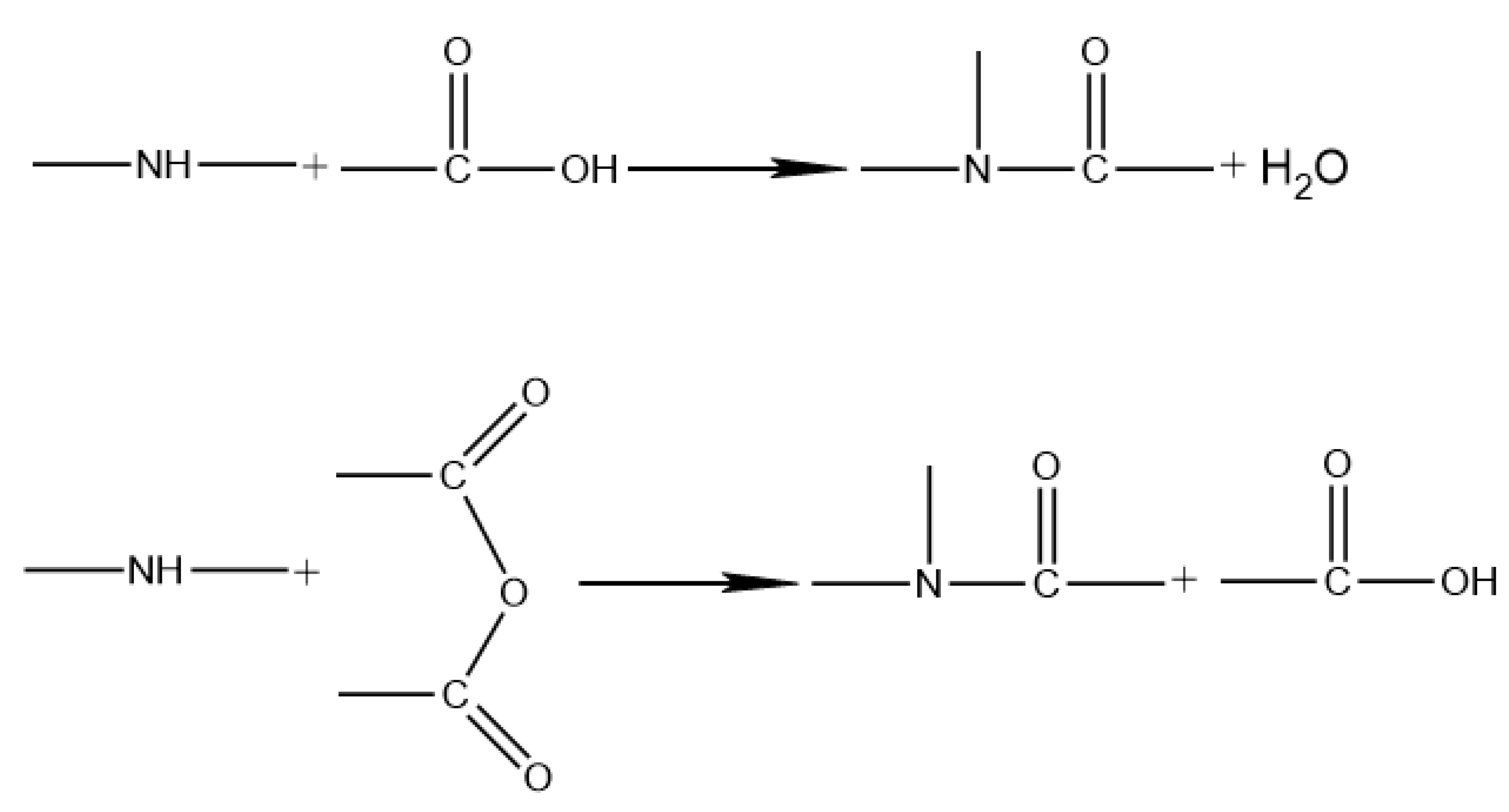

2.2. The Activation of Crumb Rubber

2.3. Preparation of Modified Asphalt

2.4. Test Methods

3. Results and Discussion

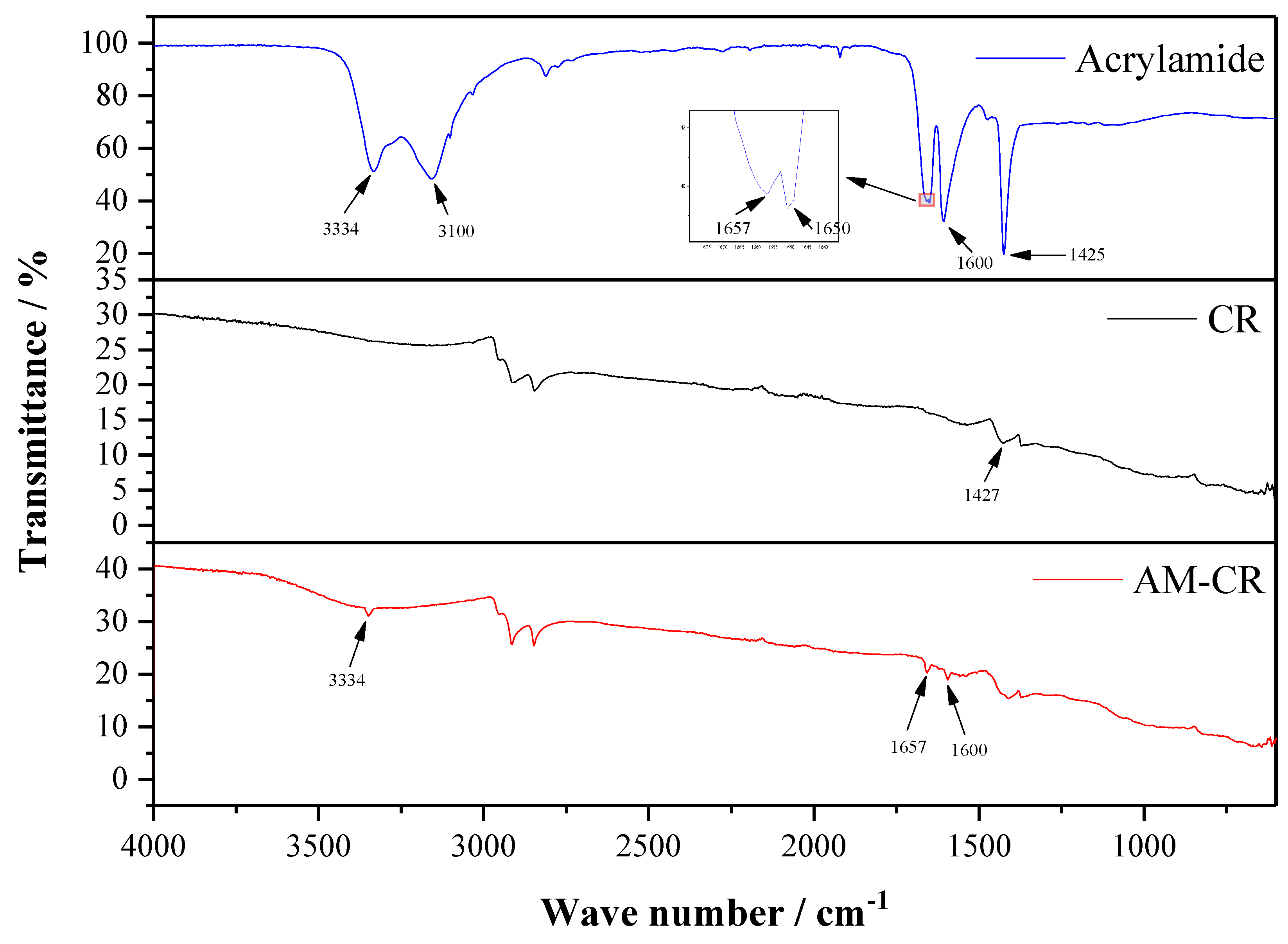

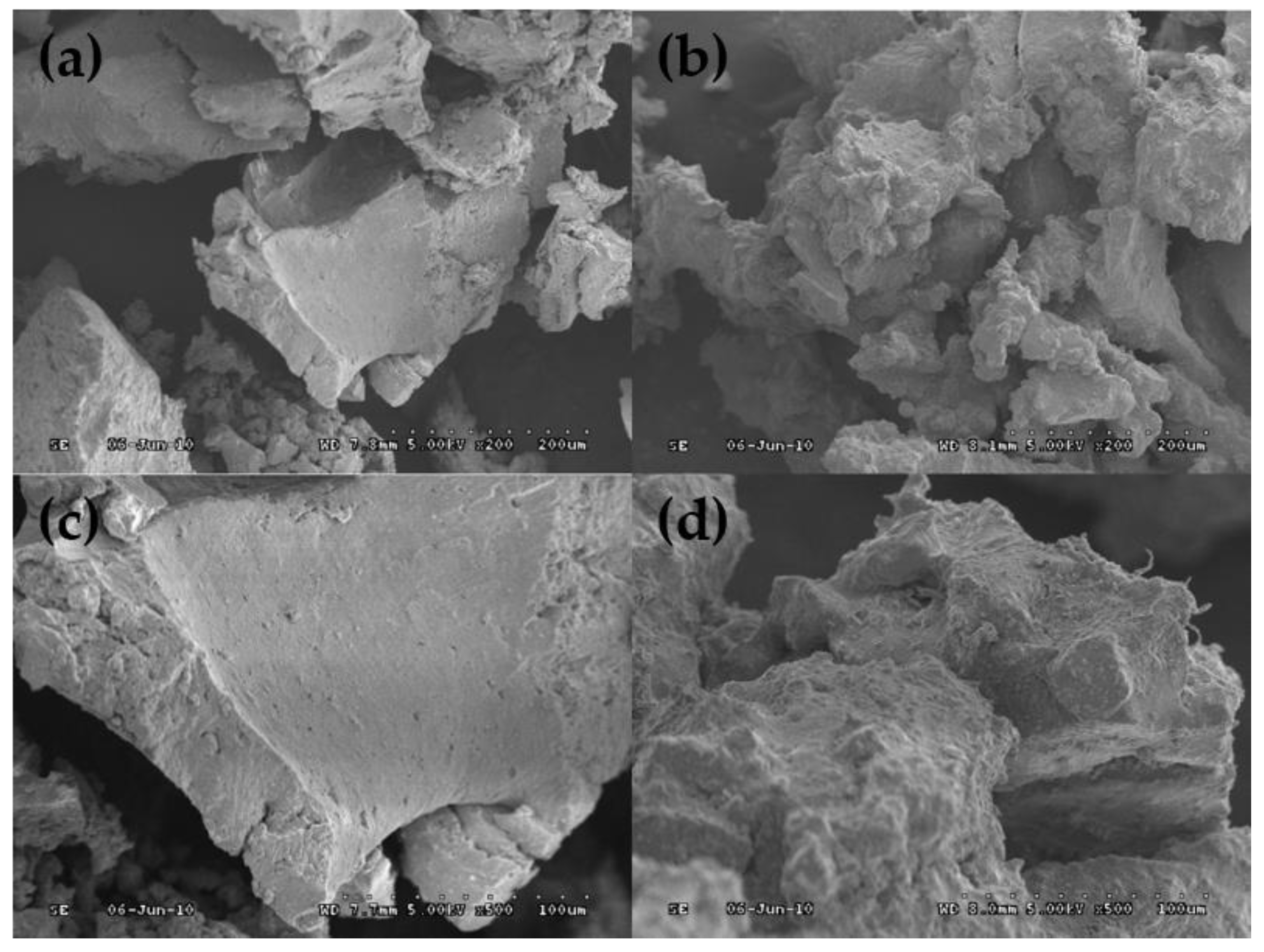

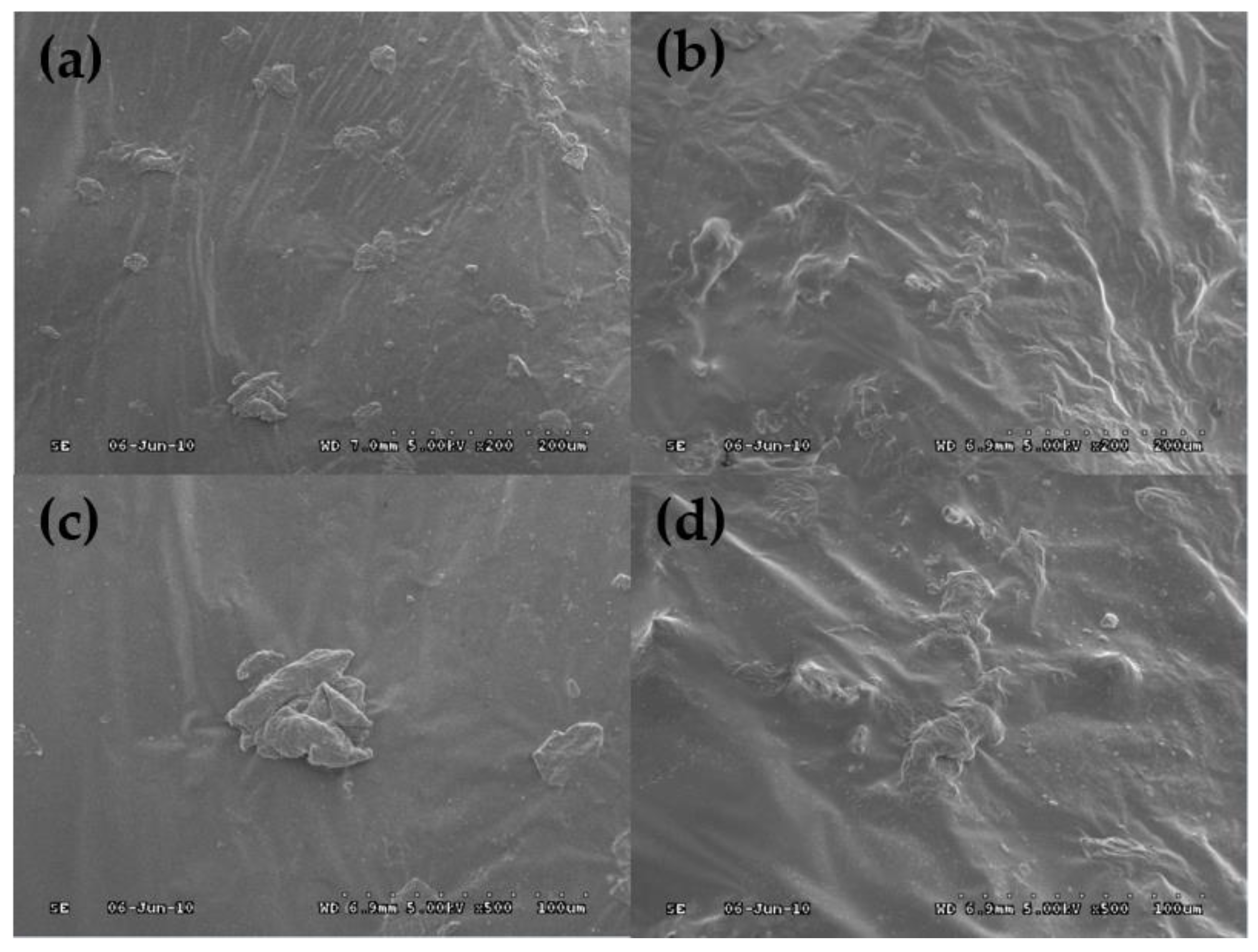

3.1. Microscopic Characterization of Crumb Rubber

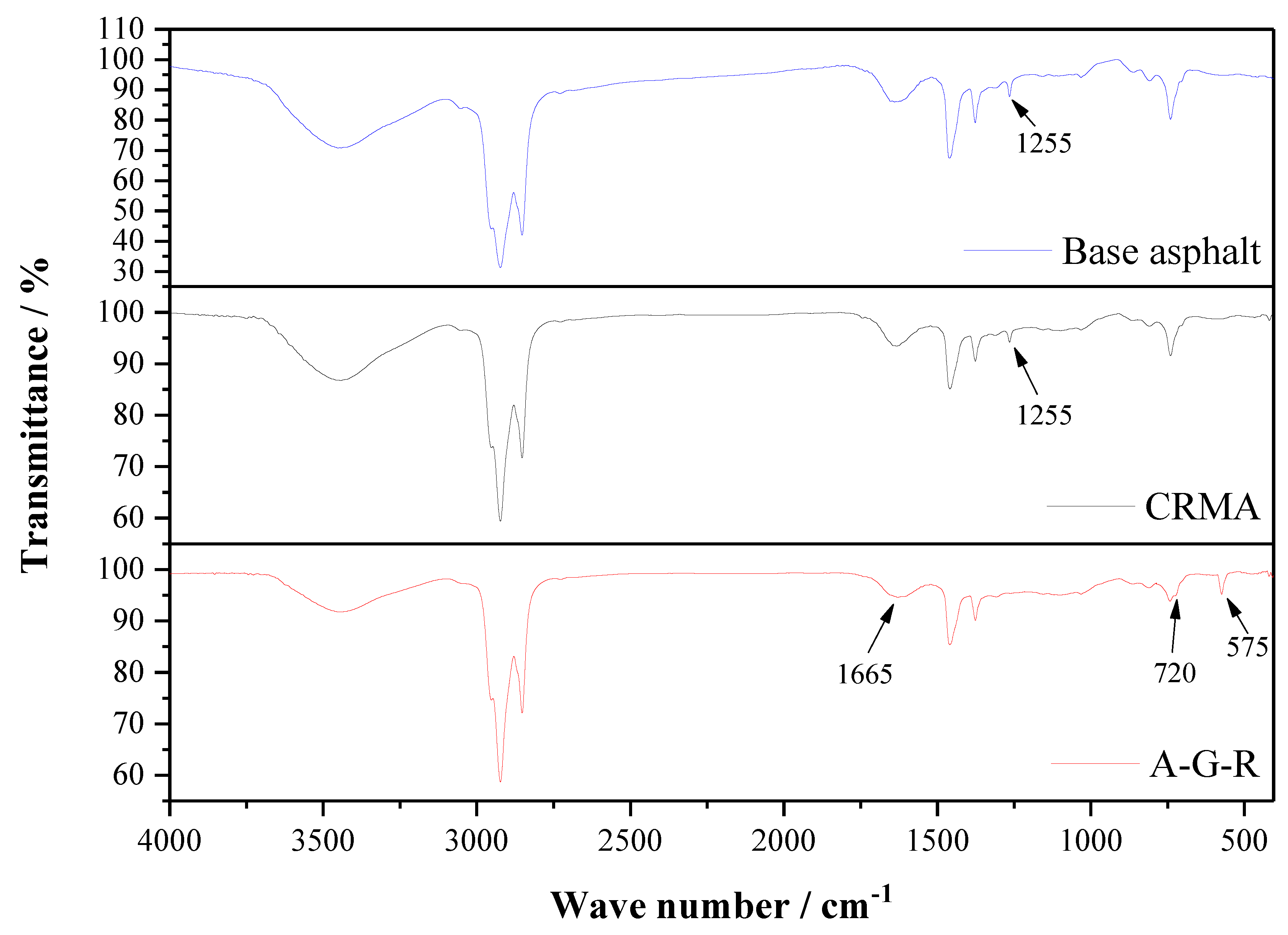

3.2. Characterization of Chemical Structure

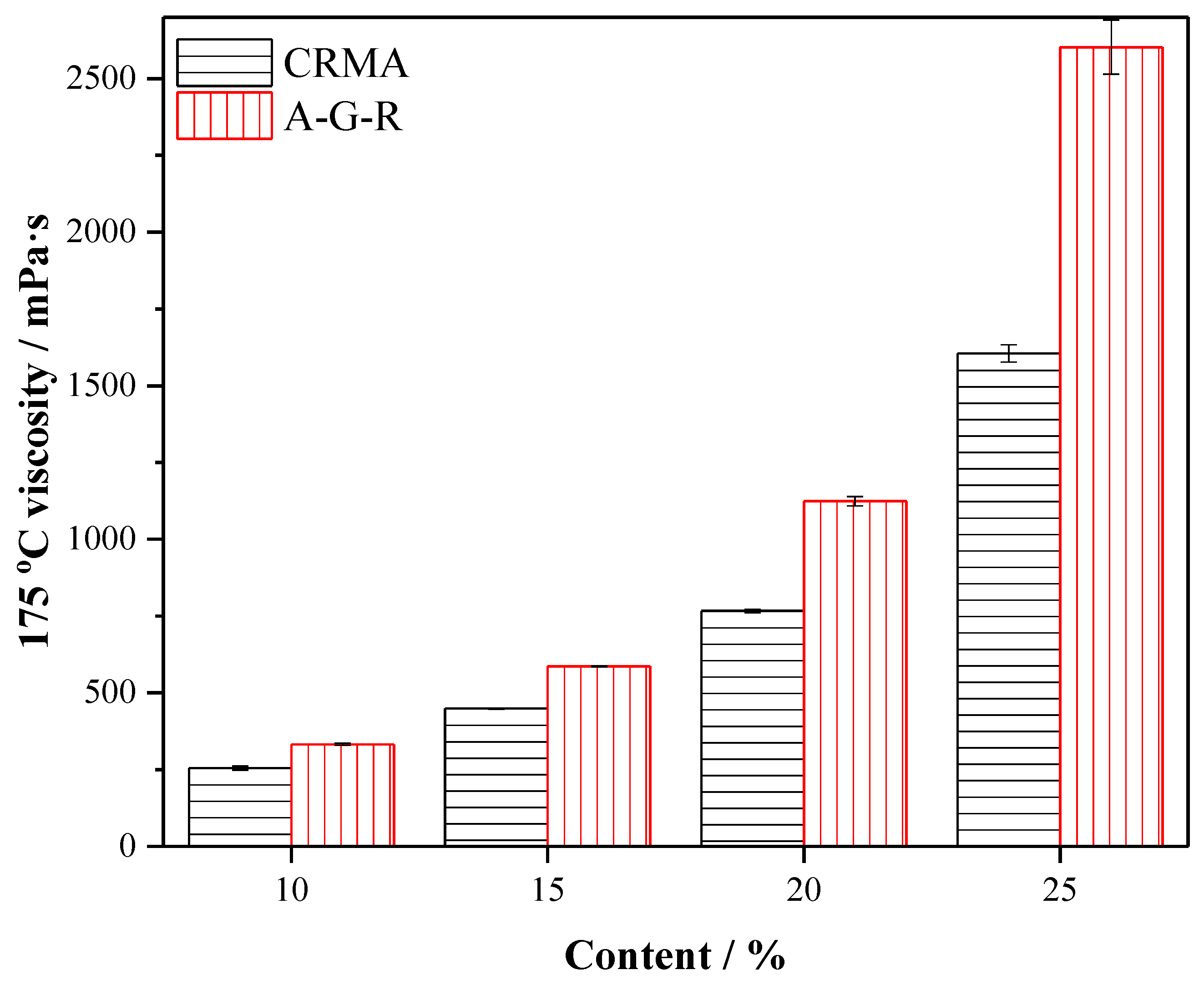

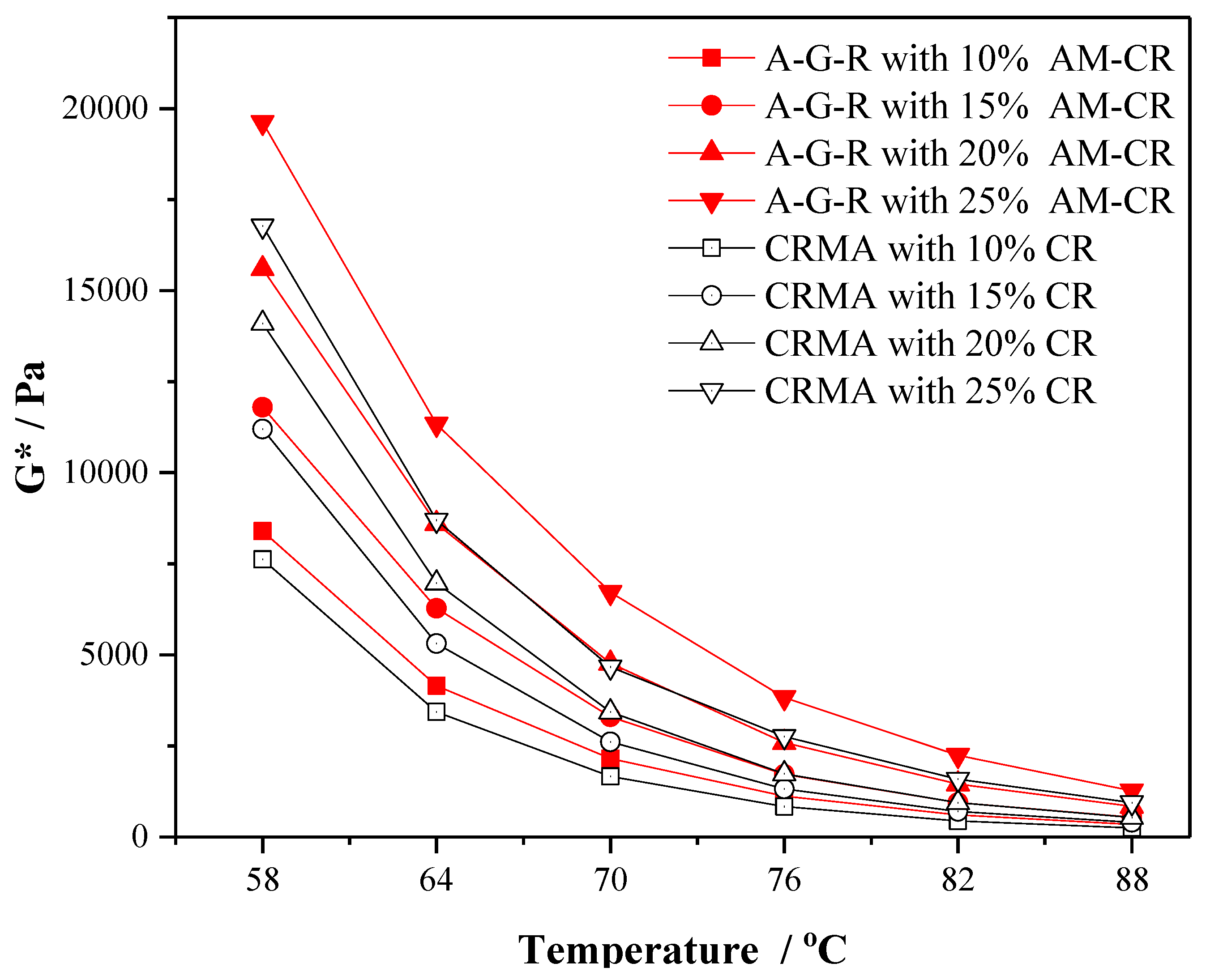

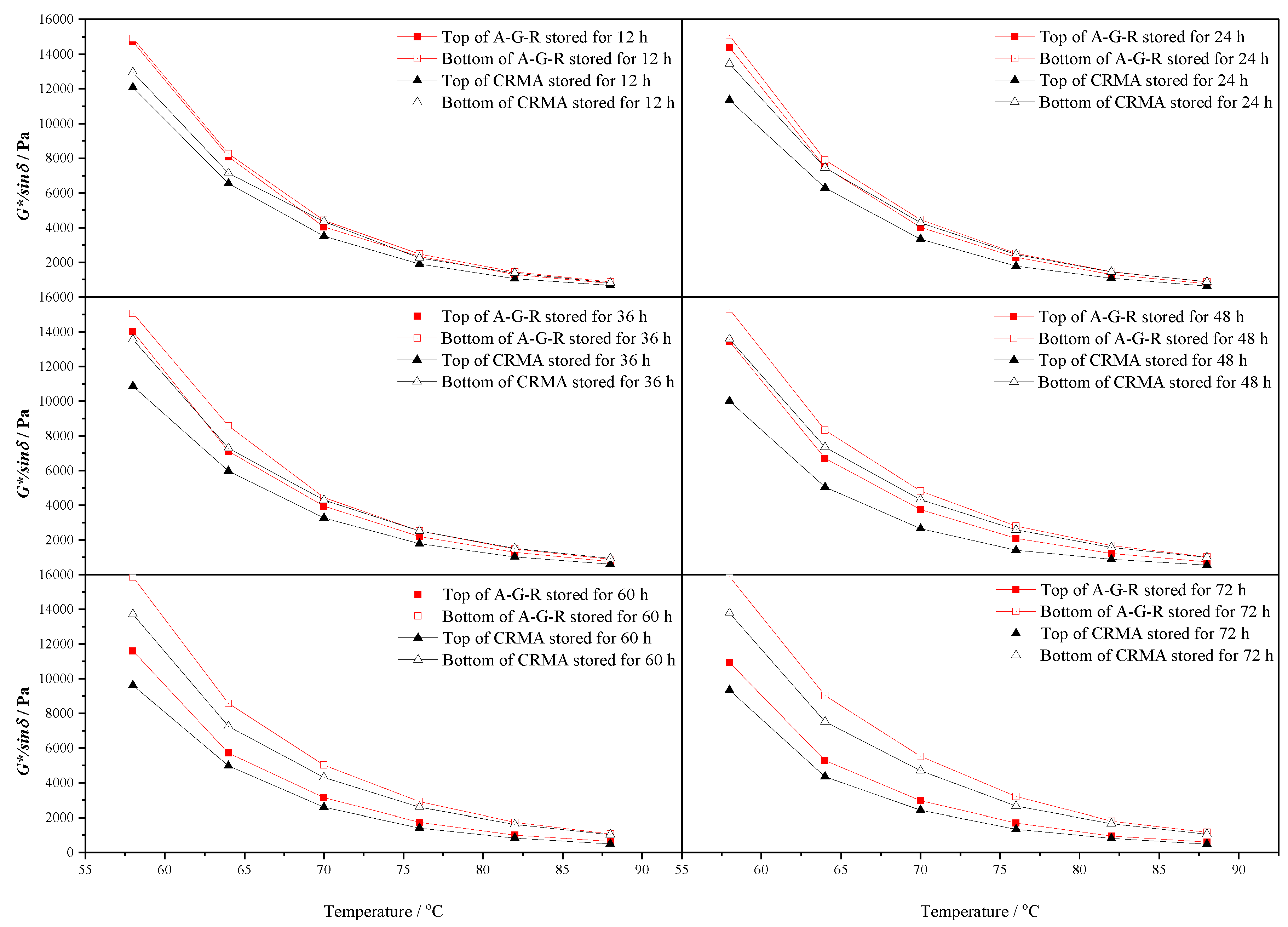

3.3. High Temperature Rheological Properties

3.4. Low Temperature Creep Properties

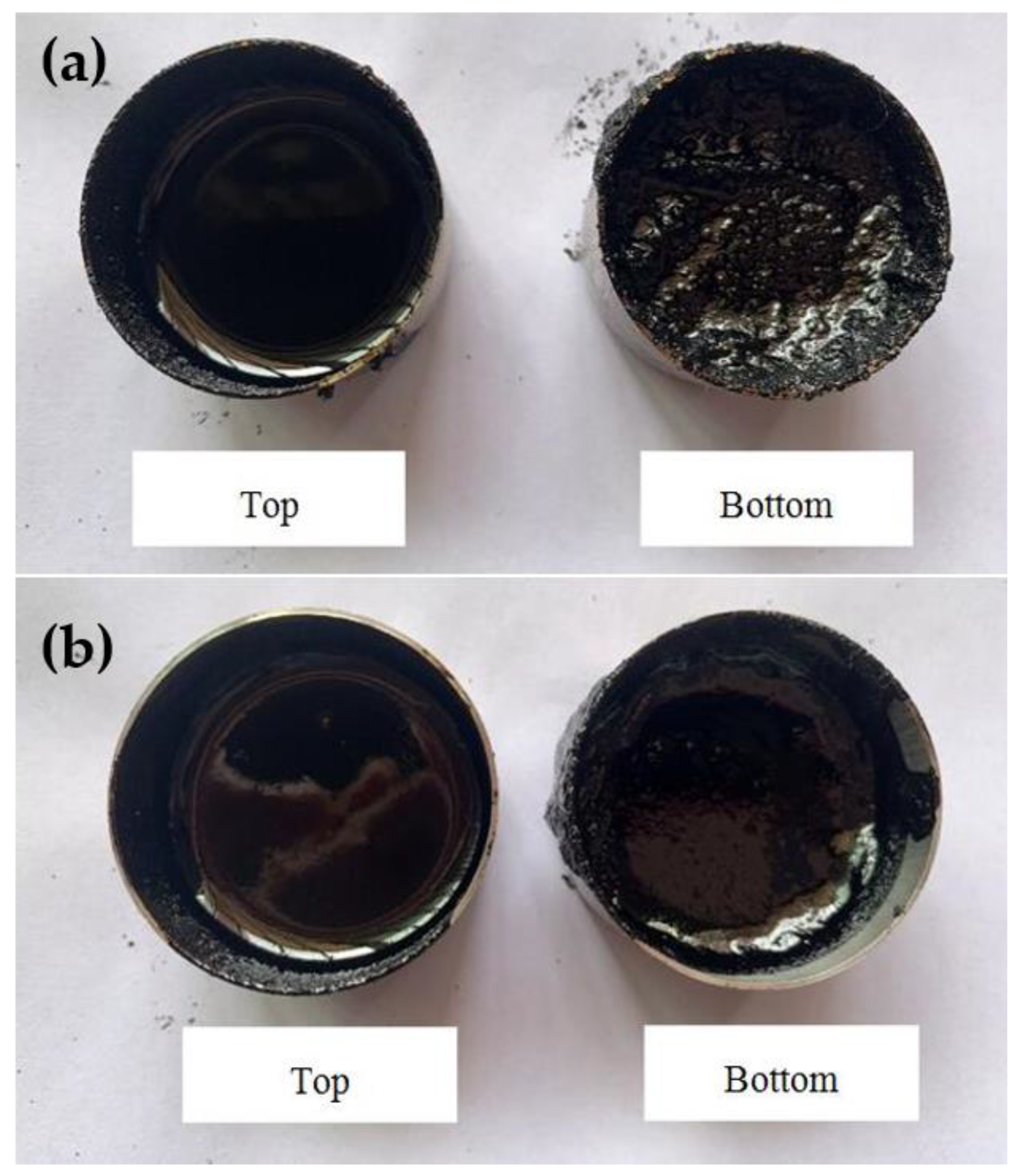

3.5. Morphology

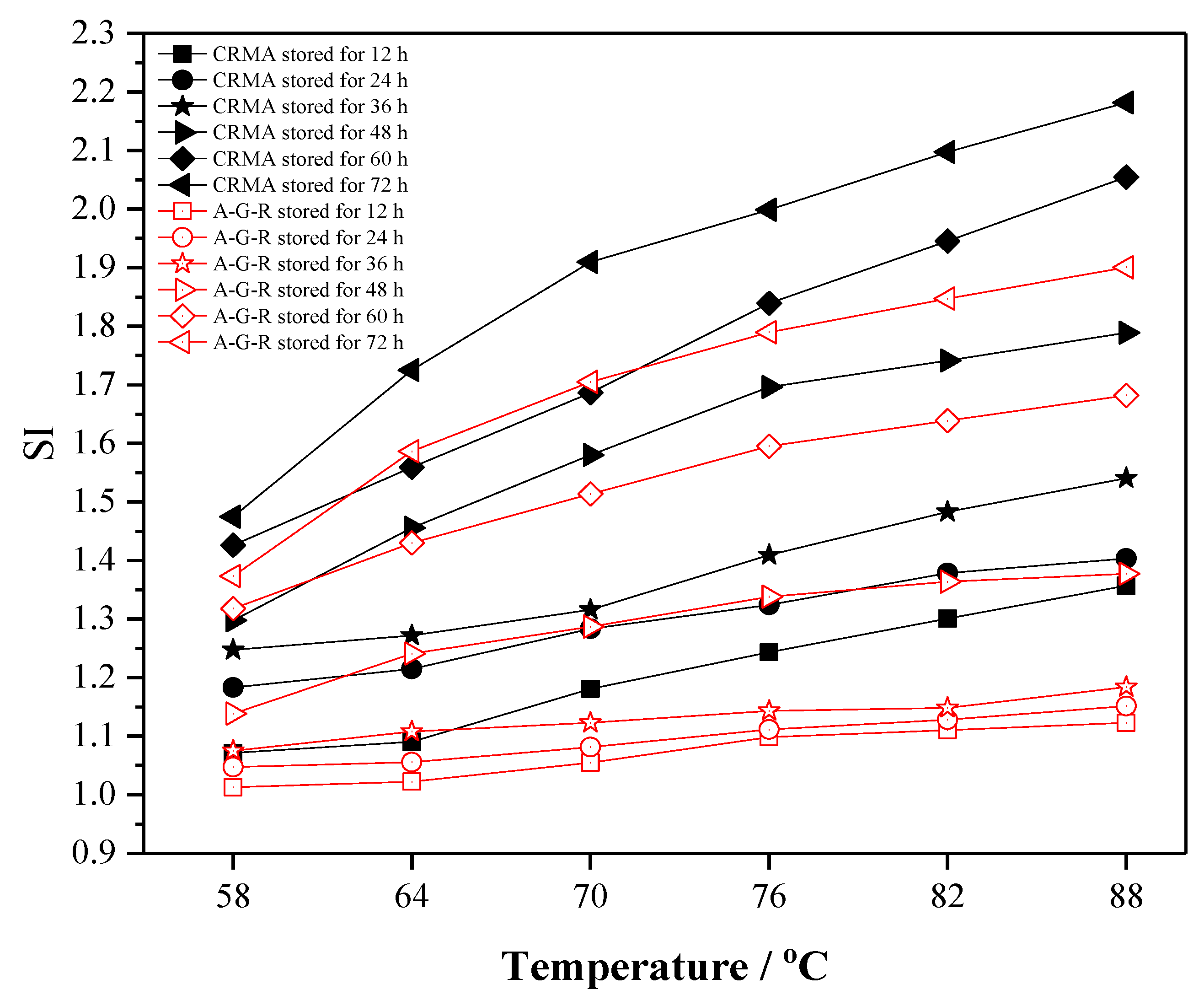

3.6. Storage Stability

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xiao, F.; Wang, T.; Wang, J.; Su, N.; Hou, X. Mechanism and research development of noise reduction technology of rubberized asphalt pavement. Chin. J. Highway Transport 2019, 32, 73–91. [Google Scholar] [CrossRef]

- Sienkiewicz, M.; Borzędowska-Labuda, K.; Zalewski, S.; Janik, H. The effect of tyre rubber grinding method on the rubber-asphalt binder properties. Constr. Build. Mater. 2017, 154, 144–154. [Google Scholar] [CrossRef]

- Han, M.; Zeng, X.; Muhammad, Y.; Li, J.; Yang, J.; Yang, S.; Wei, Y.; Meng, F. Preparation of octadecyl amine grafted over waste rubber powder (ODA-WRP) and properties of its incorporation in SBS-modified asphalt. Polymers 2019, 11, 665. [Google Scholar] [CrossRef] [PubMed]

- Hosseinnezhad, S.; Kabir, S.F.; Oldham, D.; Mousavi, M.; Fini, E.H. Surface functionalization of rubber particles to reduce phase separation in rubberized asphalt for sustainable construction. J. Cleaner Prod. 2019, 225, 82–89. [Google Scholar] [CrossRef]

- Asgharzadeh, S.M.; Sadeghi, J.; Peivast, P.; Pedram, M. Fatigue properties of crumb rubber asphalt mixtures used in railways. Constr. Build. Mater. 2018, 184, 248–257. [Google Scholar] [CrossRef]

- Lv, S.; Xia, C.; Liu, C.; Zheng, J.; Zhang, F. Fatigue equation for asphalt mixture under low temperature and low loading frequency conditions. Constr. Build. Mater. 2019, 211, 1085–1093. [Google Scholar] [CrossRef]

- Lv, S.; Liu, C.; Chen, D.; Zheng, J.; You, Z.; You, L. Normalization of fatigue characteristics for asphalt mixtures under different stress states. Constr. Build. Mater. 2018, 177, 33–42. [Google Scholar] [CrossRef]

- Lv, S.; Xia, C.; Liu, H.; You, L.; Qu, F.; Zhong, W.; Yang, Y.; Washko, S. Strength and fatigue performance for cement-treated aggregate base materials. Int. J. Pavement Eng. 2019, 1–10. [Google Scholar] [CrossRef]

- Jin, J.; Tan, Y.; Liu, R.; Zheng, J.; Zhang, J. Synergy effect of attapulgite, rubber, and diatomite on organic montmorillonite-modified asphalt. J. Mater. Civ. Eng. 2018, 31, 04018388. [Google Scholar] [CrossRef]

- Lo Presti, D.; Izquierdo, M.A.; Jiménez del Barco Carrión, A. Towards storage-stable high-content recycled tyre rubber modified bitumen. Constr. Build. Mater. 2018, 172, 106–111. [Google Scholar] [CrossRef]

- Navarro, F.J.; Partal, P.; Martínez-Boza, F.; Gallegos, C. Thermo-rheological behaviour and storage stability of ground tire rubber-modified bitumens. Fuel 2004, 83, 2041–2049. [Google Scholar] [CrossRef]

- Liang, M.; Xin, X.; Fan, W.; Sun, H.; Yao, Y.; Xing, B. Viscous properties, storage stability and their relationships with microstructure of tire scrap rubber modified asphalt. Constr. Build. Mater. 2015, 74, 124–131. [Google Scholar] [CrossRef]

- Yu, J.; Ren, Z.; Gao, Z.; Wu, Q.; Zhu, Z.; Yu, H. Recycled heavy bio oil as performance enhancer for rubberized bituminous binders. Polymers 2019, 11, 800. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Xi, M.; Zhang, D.; Zhang, H.; Zhang, B. The effect of styrene-butadiene-rubber/montmorillonite modification on the characteristics and properties of asphalt. Constr. Build. Mater. 2009, 23, 3112–3117. [Google Scholar] [CrossRef]

- Cheng, G.; Shen, B.; Zhang, J. A study on the performance and storage stability of crumb rubber-modified asphalts. Pet. Sci. Technol. 2011, 29, 192–200. [Google Scholar] [CrossRef]

- Gautam, P.K.; Kalla, P.; Jethoo, A.S.; Agrawal, R.; Singh, H. Sustainable use of waste in flexible pavement: A review. Constr. Build. Mater. 2018, 180, 239–253. [Google Scholar] [CrossRef]

- Qian, C.; Fan, W.; Liang, M.; He, Y.; Ren, S.; Lv, X.; Nan, G.; Luo, H. Rheological properties, storage stability and morphology of CR/SBS composite modified asphalt by high-cured method. Constr. Build. Mater. 2018, 193, 312–322. [Google Scholar] [CrossRef]

- Yu, J.; Ren, Z.; Yu, H.; Wang, D.; Svetlana, S.; Korolev, E.; Gao, Z.; Guo, F. Modification of asphalt rubber with nanoclay towards enhanced storage stability. Materials 2018, 11, 2093. [Google Scholar] [CrossRef] [PubMed]

- Xue, Y.; Zhao, H.; Wei, X.; Niu, Y. Performance analysis of compound rubber and steel slag filler modified asphalt composite. Materials 2019, 12, 2588. [Google Scholar] [CrossRef]

- Sienkiewicz, M.; Borzędowska-Labuda, K.; Wojtkiewicz, A.; Janik, H. Development of methods improving storage stability of bitumen modified with ground tire rubber: A review. Fuel Process. Technol. 2017, 159, 272–279. [Google Scholar] [CrossRef]

- Yu, G.-X.; Li, Z.-M.; Zhou, X.-L.; Li, C.-L. Crumb rubber-modified asphalt: Microwave treatment effects. Pet. Sci. Technol. 2011, 29, 411–417. [Google Scholar] [CrossRef]

- Cao, X.-W.; Luo, J.; Cao, Y.; Yin, X.-C.; He, G.-J.; Peng, X.-F.; Xu, B.-P. Structure and properties of deeply oxidized waster rubber crumb through long time ozonization. Polym. Degrad. Stab. 2014, 109, 1–6. [Google Scholar] [CrossRef]

- Xue, Z.; Qiao, Y.; Song, L.; Chen, H. Benzoyl peroxide oxidization of crumb tire rubber and its application in rubber asphalt. Chem. Res. Appl. 2017, 29, 1089–1093. [Google Scholar]

- Li, B.; Li, H.; Wei, Y.; Zhang, X.; Wei, D.; Li, J. Microscopic properties of hydrogen peroxide activated crumb rubber and its influence on the rheological properties of crumb rubber modified asphalt. Materials 2019, 12, 1434. [Google Scholar] [CrossRef] [PubMed]

- Shatanawi, K.M.; Biro, S.; Geiger, A.; Amirkhanian, S.N. Effects of furfural activated crumb rubber on the properties of rubberized asphalt. Constr. Build. Mater. 2012, 28, 96–103. [Google Scholar] [CrossRef]

- Adhikari, B.; De, D.; Maiti, S. Reclamation and recycling of waste rubber. Prog. Polym. Sci. 2000, 25, 909–948. [Google Scholar] [CrossRef]

- Medina, N.F.; Garcia, R.; Hajirasouliha, I.; Pilakoutas, K.; Guadagnini, M.; Raffoul, S. Composites with recycled rubber aggregates: Properties and opportunities in construction. Constr. Build. Mater. 2018, 188, 884–897. [Google Scholar] [CrossRef]

- Jin, L.; Xie, J.; Li, R. Grafting modification on surface of rubber powder and its characterization. Chin. Synth. Rubber Ind. 2007, 30, 290–293. [Google Scholar] [CrossRef]

- Baqersad, M.; Ali, H. Rheological and chemical characteristics of asphalt binders recycled using different recycling agents. Constr. Build. Mater. 2019, 228, 116738. [Google Scholar] [CrossRef]

- Girma, K.B.; Lorenz, V.; Blaurock, S.; Edelmann, F.T. Coordination chemistry of acrylamide. Coord. Chem. Rev. 2005, 249, 1283–1293. [Google Scholar] [CrossRef]

- Formela, K.; Cysewska, M.; Haponiuk, J.T. Thermomechanical reclaiming of ground tire rubber via extrusion at low temperature: Efficiency and limits. J. Vinyl Add. Tech. 2016, 22, 213–221. [Google Scholar] [CrossRef]

- Tang, J.; Zhu, C.; Zhang, H.; Xu, G.; Xiao, F.; Amirkhanian, S. Effect of liquid ASAs on the rheological properties of crumb rubber modified asphalt. Constr. Build. Mater. 2019, 194, 238–246. [Google Scholar] [CrossRef]

- Zhang, Y.; Mark, J.E.; Zhu, Y.; Ruoff, R.S.; Schaefer, D.W. Mechanical properties of polybutadiene reinforced with octadecylamine modified graphene oxide. Polymer 2014, 55, 5389–5395. [Google Scholar] [CrossRef]

- Huang, B.; Shu, X.; Cao, J. A two-staged surface treatment to improve properties of rubber modified cement composites. Constr. Build. Mater. 2013, 40, 270–274. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S. The influence of crumb rubber modifier (CRM) microstructures on the high temperature properties of CRM binders. Int. J. Pavement Eng. 2005, 6, 265–271. [Google Scholar] [CrossRef]

- Wang, S.; Cheng, D.; Xiao, F. Recent developments in the application of chemical approaches to rubberized asphalt. Constr. Build. Mater. 2017, 131, 101–113. [Google Scholar] [CrossRef]

- Yao, H.; Dai, Q.; You, Z. Fourier transform infrared spectroscopy characterization of aging-related properties of original and nano-modified asphalt binders. Constr. Build. Mater. 2015, 101, 1078–1087. [Google Scholar] [CrossRef]

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Interface Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef]

- Li, P.; Ding, Z.; Zou, P.; Sun, A. Analysis of physico-chemical properties for crumb rubber in process of asphalt modification. Constr. Build. Mater. 2017, 138, 418–426. [Google Scholar] [CrossRef]

- Li, P.; Jiang, X.; Ding, Z.; Zhao, J.; Shen, M. Analysis of viscosity and composition properties for crumb rubber modified asphalt. Constr. Build. Mater. 2018, 169, 638–647. [Google Scholar] [CrossRef]

- Cong, P.; Xun, P.; Xing, M.; Chen, S. Investigation of asphalt binder containing various crumb rubbers and asphalts. Constr. Build. Mater. 2013, 40, 632–641. [Google Scholar] [CrossRef]

- Kim, H.-S.; Lee, S.-J.; Amirkhanian, S. Rheology investigation of crumb rubber modified asphalt binders. KSCE J. Civ. Eng. 2010, 14, 839–843. [Google Scholar] [CrossRef]

- Zanzotto, L.; Kennepohl, G.J. Development of rubber and asphalt binders by depolymerization and devulcanization of scrap tires in asphalt. Transp. Res. Rec. 1996, 1530, 51–58. [Google Scholar] [CrossRef]

- Airey, G.; Singleton, T.; Collop, A. Properties of polymer modified bitumen after rubber-bitumen interaction. J. Mater. Civ. Eng. 2002, 14, 344–354. [Google Scholar] [CrossRef]

- Han, L.; Zheng, M.; Li, J.; Li, Y.; Zhu, Y.; Ma, Q. Effect of nano silica and pretreated rubber on the properties of terminal blend crumb rubber modified asphalt. Constr. Build. Mater. 2017, 157, 277–291. [Google Scholar] [CrossRef]

- Dong, F.; Xin, Y.; Chen, J.; Liu, S.; Qiao, C. Investigation on compatibility and microstructure of PCBs-modified asphalt. J. Appl. Polym. Sci. 2017, 134, 44798. [Google Scholar] [CrossRef]

- Wang, T.; Xiao, F.; Zhu, X.; Huang, B.; Wang, J.; Amirkhanian, S. Energy consumption and environmental impact of rubberized asphalt pavement. J. Clean. Prod. 2018, 180, 139–158. [Google Scholar] [CrossRef]

- Lo Presti, D. Recycled tyre rubber modified bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

| Item | Units | Test Results | Standard |

|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s) | 0.1 mm | 64.0 | JTG-T0604-2011 |

| Softening temperature | °C | 48.1 | JTG-T0606-2011 |

| Ductility (15 °C, 5 cm/min) | cm | >100 | JTG-T0605-2011 |

| Kinematic viscosity (135 °C) | mPa s | 158.5 | JTG-T0625-2011 |

| Density | g/cm3 | 1.034 | JTG-T0603-2011 |

| RTFO treated at 163 °C for 85 min | |||

| Quality change | % | −0.061 | JTG-T0610-1-2011 |

| Residual penetration ratio (25 °C) | % | 80.0 | JTG-T0610-2-2011 |

| Residual ductility (5 °C) | cm | 7.0 | JTG-T0605-2011 |

| Item | Result | Standard |

|---|---|---|

| Water content (%) | 0.96 | HG/TXXX-2001 7.2.2 |

| Ash content (%) | 9.3 | GB4498 |

| Acetone extract content (%) | 13.6 | GB/T3516 |

| Density (g/cm3) | 1.05 | GB/T533 |

| Tensile strength (MPa) | 6.4 | GB/T528 |

| Elongation at break (%) | 855 | GB/T52 |

| Simple | −12 °C | −18 °C | −24 °C | |||

|---|---|---|---|---|---|---|

| S | m | S | m | S | m | |

| CRMA with 10% CR | 115.0 | 0.368 | 231.3 | 0.324 | 457.7 | 0.275 |

| CRMA with 15% CR | 82.3 | 0.389 | 182.3 | 0.333 | 386.0 | 0.282 |

| CRMA with 20% CR | 75.6 | 0.396 | 159.7 | 0.350 | 297.3 | 0.296 |

| CRMA with 25% CR | 45.2 | 0.398 | 70.4 | 0.357 | 196.0 | 0.308 |

| A–G–R with 10% AM–CR | 104.0 | 0.371 | 219.7 | 0.329 | 411.0 | 0.282 |

| A–G–R with 15% AM–CR | 72.5 | 0.383 | 178.3 | 0.341 | 344.3 | 0.295 |

| A–G–R with 20% AM–CR | 67.3 | 0.413 | 147.7 | 0.359 | 240.0 | 0.307 |

| A–G–R with 25% AM–CR | 33.5 | 0.422 | 63.4 | 0.368 | 143.3 | 0.309 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, J.; Yang, Y.; Lv, S.; Zhang, Y.; Zhu, X.; Zheng, C. Investigation on Rheological Properties and Storage Stability of Modified Asphalt Based on the Grafting Activation of Crumb Rubber. Polymers 2019, 11, 1563. https://doi.org/10.3390/polym11101563

Xie J, Yang Y, Lv S, Zhang Y, Zhu X, Zheng C. Investigation on Rheological Properties and Storage Stability of Modified Asphalt Based on the Grafting Activation of Crumb Rubber. Polymers. 2019; 11(10):1563. https://doi.org/10.3390/polym11101563

Chicago/Turabian StyleXie, Juan, Yueming Yang, Songtao Lv, Yongning Zhang, Xuan Zhu, and Cece Zheng. 2019. "Investigation on Rheological Properties and Storage Stability of Modified Asphalt Based on the Grafting Activation of Crumb Rubber" Polymers 11, no. 10: 1563. https://doi.org/10.3390/polym11101563

APA StyleXie, J., Yang, Y., Lv, S., Zhang, Y., Zhu, X., & Zheng, C. (2019). Investigation on Rheological Properties and Storage Stability of Modified Asphalt Based on the Grafting Activation of Crumb Rubber. Polymers, 11(10), 1563. https://doi.org/10.3390/polym11101563