Fabrication of Active Polymer Optical Fibers by Solution Doping and Their Characterization

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

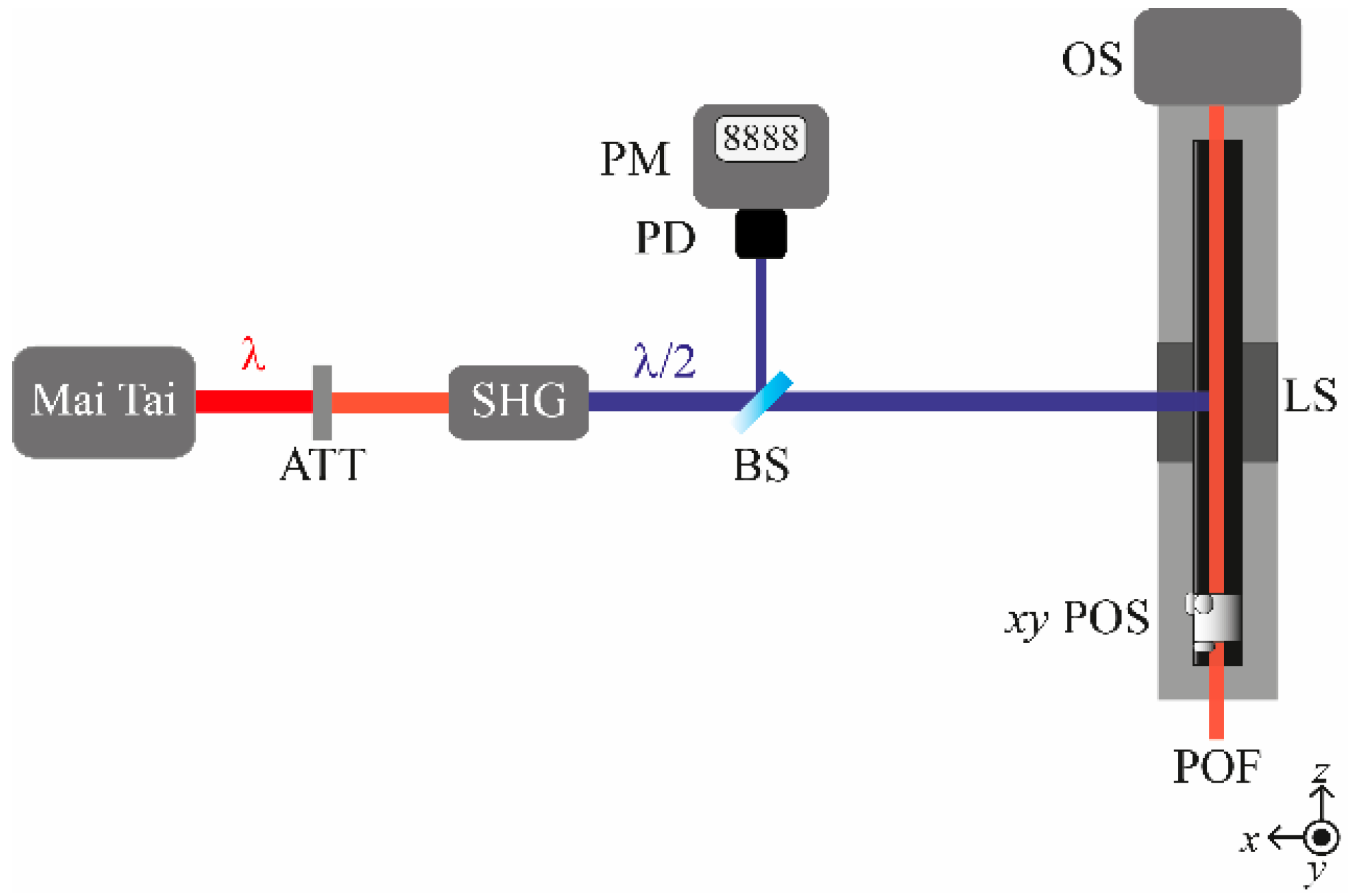

2.2. Experimental Setup

3. Results and Discussion

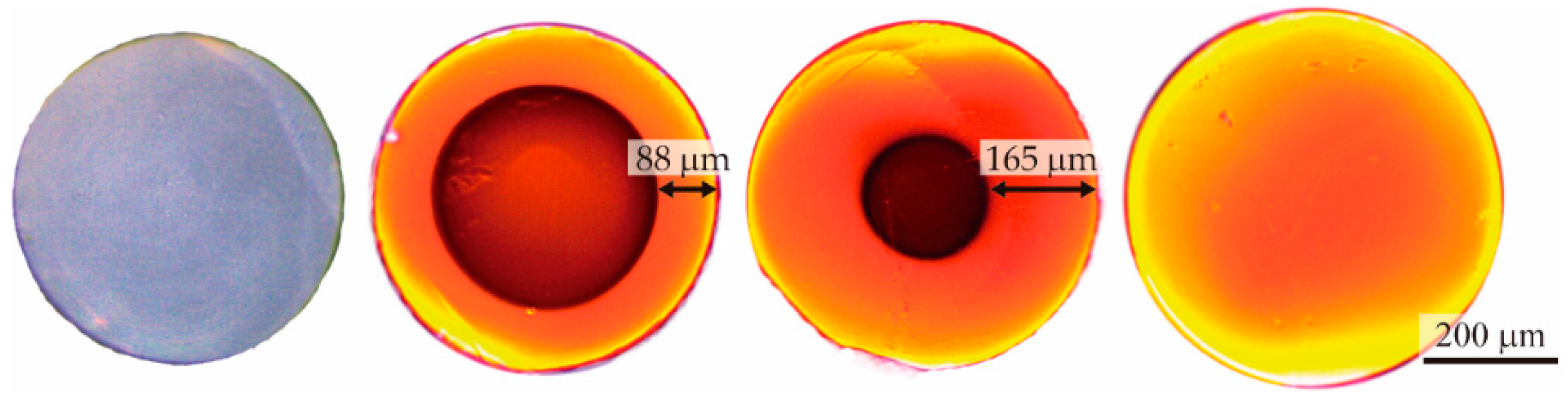

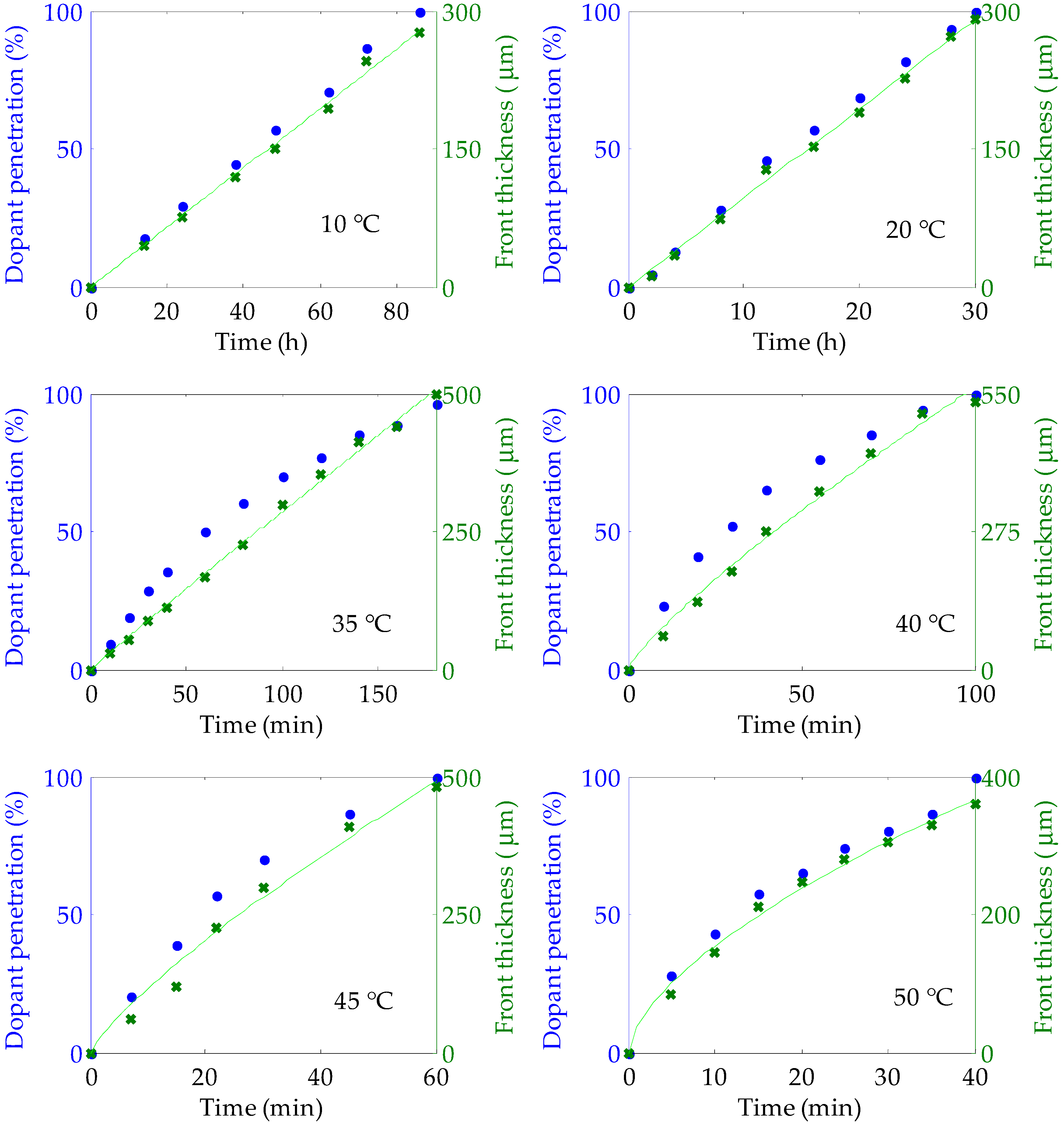

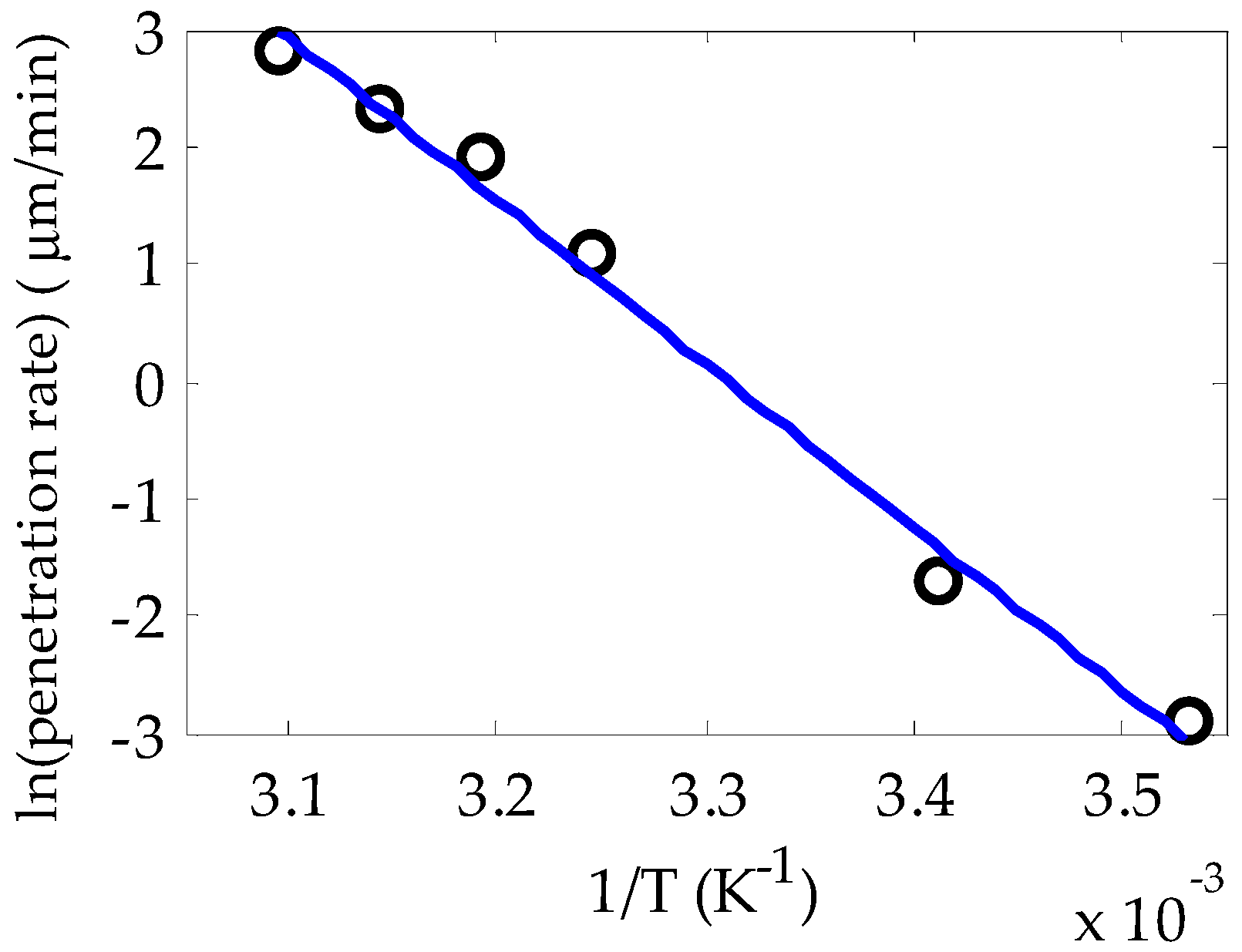

3.1. Penetration of the Solution

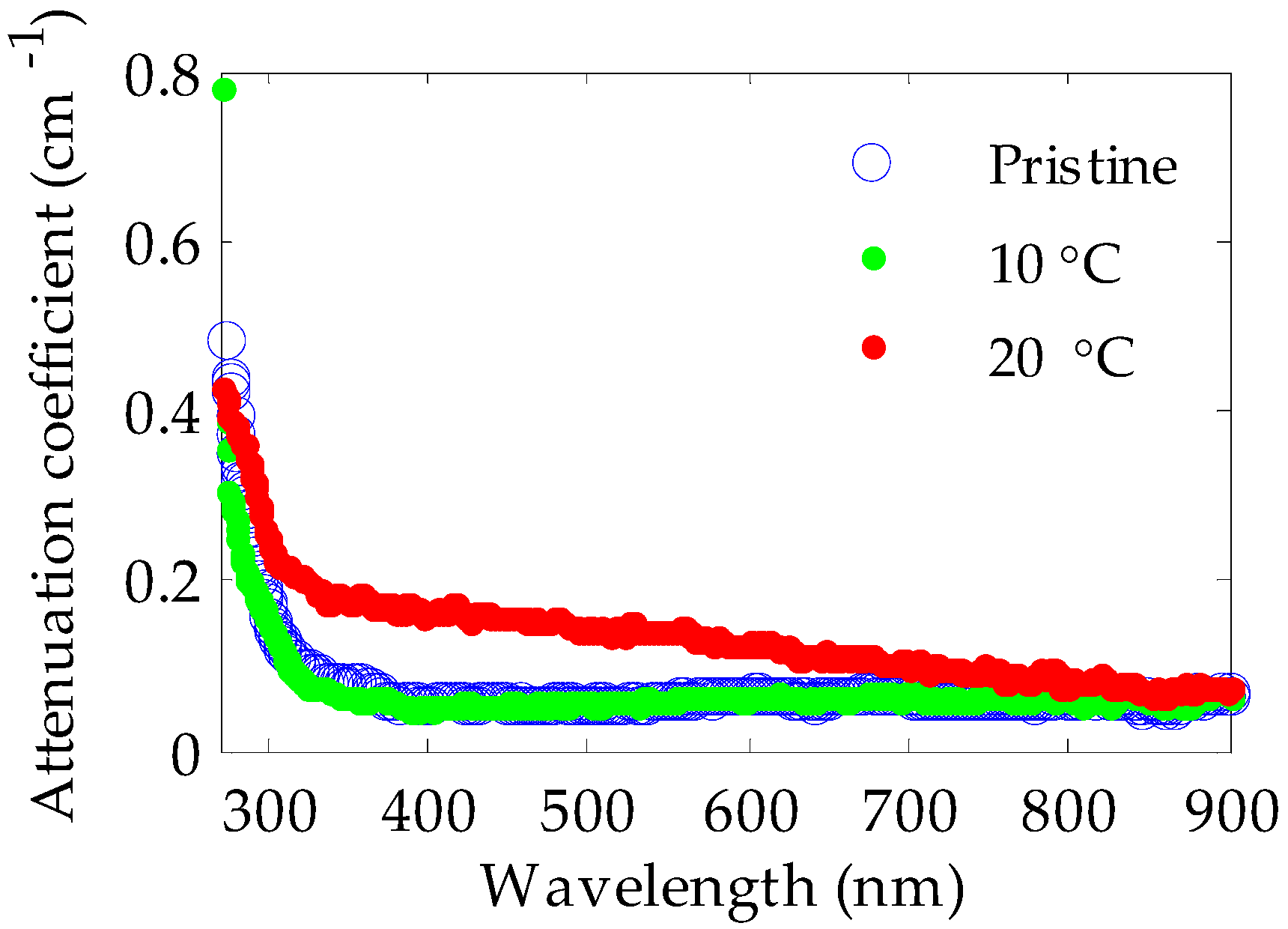

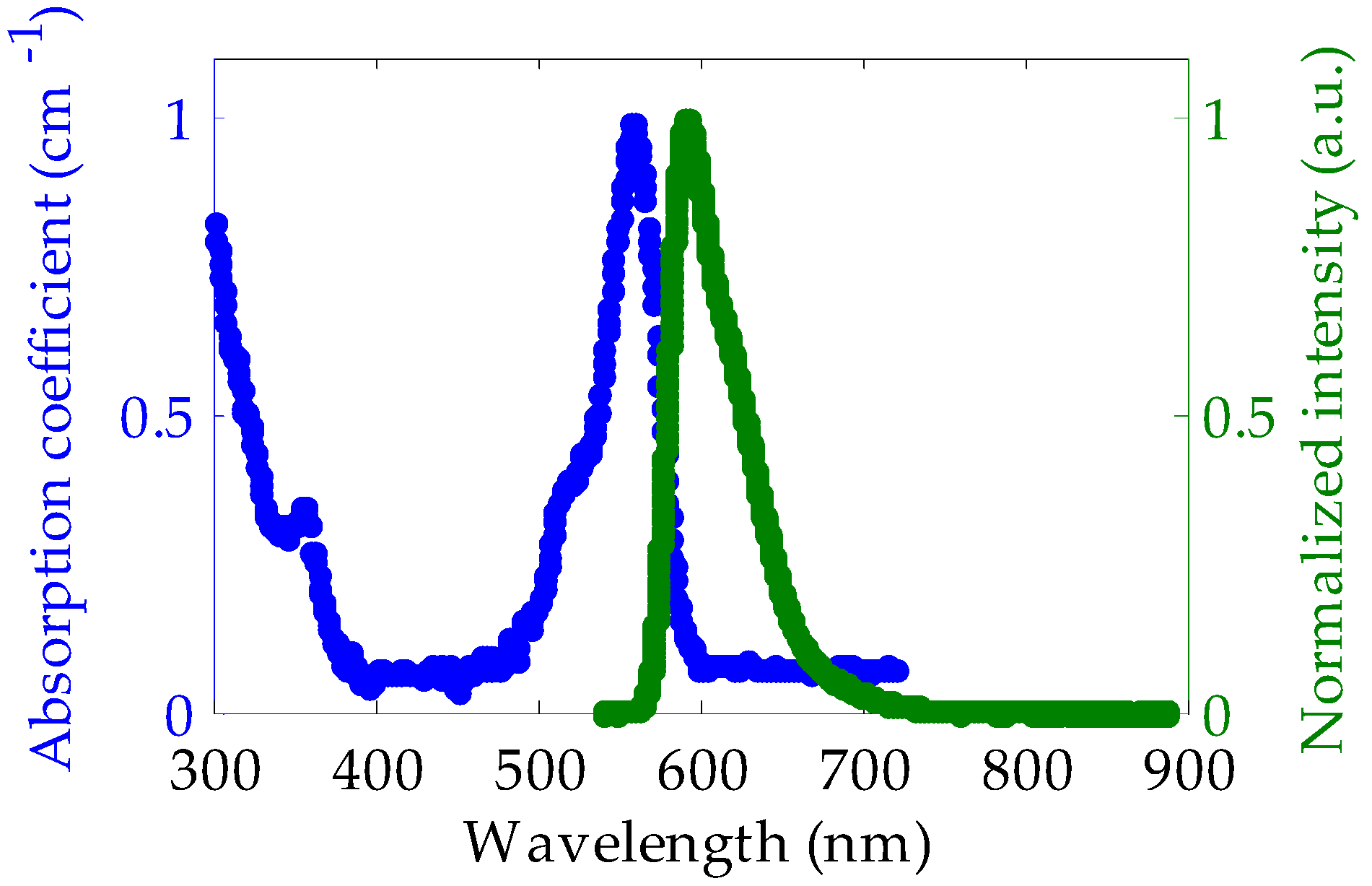

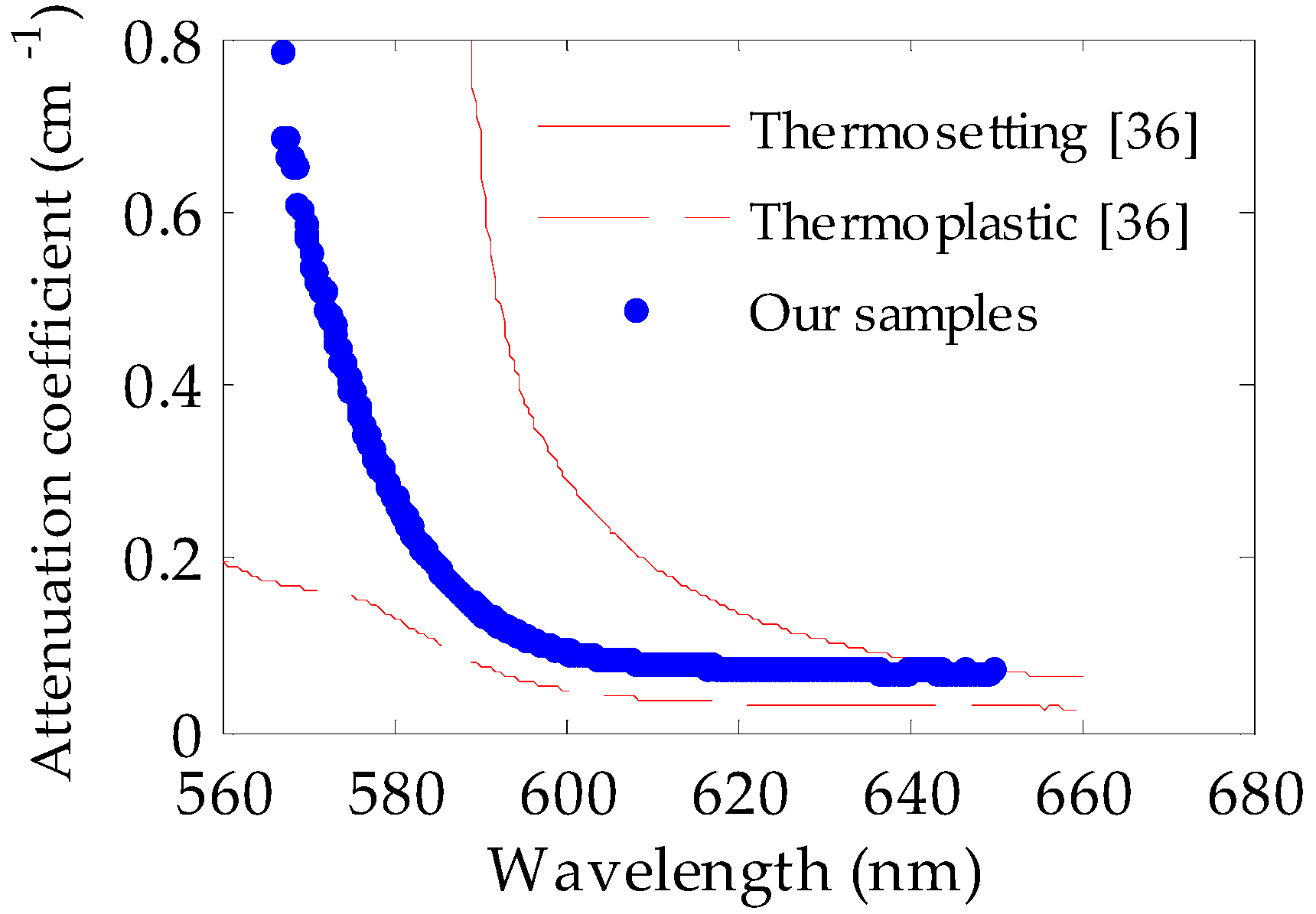

3.2. Optical Characterization

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Clark, J.; Lanzani, G. Organic photonics for communications. Nat. Photonics 2010, 7, 438–446. [Google Scholar] [CrossRef]

- Arrue, J.; Jiménez, F.; Ayesta, I.; Illarramendi, M.A.; Zubia, J. Polymer-optical-fiber lasers and amplifiers doped with organic dyes. Polymers 2011, 3, 1162–1180. [Google Scholar] [CrossRef]

- Koike, Y. Fundamentals of Plastic Optical Fibers; Wiley-VCH: Weinheim, Germany, 2015; ISBN 978-3-527-41006-4. [Google Scholar]

- Ziemann, O.; Krauser, J.; Zamzow, P.E.; Daum, W. POF-Polymer Optical Fibers for Data Communication; Springer: Berlin/Heidelberg, Germany, 2002; ISBN 978-3-662-04863-4. [Google Scholar]

- Ayesta, I.; Arrue, J.; Jiménez, F.; Illarramendi, M.A.; Zubia, J. Analysis of the emission features in graded-index polymer optical fiber amplifiers. J. Lightwave Technol. 2011, 29, 2629–2635. [Google Scholar] [CrossRef]

- Parola, I.; Illarramendi, M.A.; Arrue, J.; Ayesta, I.; Jiménez, F.; Zubia, J.; Tagaya, A.; Koike, Y. Characterization of the optical gain in doped polymer optical fibres. J. Lumin. 2016, 8, 1–8. [Google Scholar] [CrossRef]

- Peters, K. Polymer optical fiber sensors-A review. Smart Mater. Struct. 2011, 20, 1–17. [Google Scholar] [CrossRef]

- Kamimura, S.; Furukawa, R. Strain sensing based on radiative emission-absorption mechanism using dye-doped polymer optical fiber. Appl. Phys. Lett. 2017, 111, 1–5. [Google Scholar] [CrossRef]

- Parola, I.; Zaremba, D.; Evert, R.; Kielhorn, J.; Jakobs, F.; Illarramendi, M.A.; Zubia, J.; Kowalsky, W.; Johanes, H.-H. High performance fluorescent fiber solar concentrators employing double-doped polymer optical fibers. Sol. Energy Mater. Sol. Cells. 2018, 178, 20–28. [Google Scholar] [CrossRef]

- He, J.; Chan, W.-K.E.; Cheng, X.; Tse, M.-L.V.; Lu, C.; Wai, P.-K.A.; Savovic, S.; Tam, H.-Y. Experimental and theoretical investigation of the polymer optical fiber random laser with resonant feedback. Adv. Opt. Mater. 2018, 6, 1701187. [Google Scholar] [CrossRef]

- Liang, H.; Zheng, Z.; Li, Z.; Xu, J.; Chen, B.; Zhao, H.; Zhang, Q.; Ming, H. Fabrication and amplification of Rhodamine B-doped step-index polymer optical fiber. J. Appl. Polym. Sci. 2004, 93, 681–685. [Google Scholar] [CrossRef]

- Sheeba, M.; Rajesh, M.; Nampoori, V.P.N.; Radhakrishnan, P. Fabrication and characterization of dye mixture doped polymer optical fiber as a broad wavelength optical amplifier. Appl. Optics 2008, 47, 884–889. [Google Scholar] [CrossRef]

- Parola, I.; Arrospide, E.; Recart, F.; Illarramendi, M.A.; Durana, G.; Guarrotxena, N.; García, O.; Zubia, J. Fabrication and characterization of polymer optical fibers doped with perylene-derivatives for fluorescent lighting applications. Fibers 2017, 5, 28. [Google Scholar] [CrossRef]

- Large, M.C.J.; Ponrathnam, S.; Argyros, A.; Pujari, N.S.; Cox, F. Solution doping of microstructured polymer optical fibres. Opt. Express 2004, 12, 1966–1971. [Google Scholar] [CrossRef] [PubMed]

- Stajanca, P.; Topolniak, L.; Pötschke, S.; Krebber, K. Solution-mediated cladding doping of commercial polymer optical fibers. Opt. Fiber Technol. 2018, 41, 227–234. [Google Scholar] [CrossRef]

- Arrospide, E.; Durana, G.; Azkune, M.; Aldabaldetreku, G.; Bikandi, I.; Ruiz-Rubio, L.; Zubia, J. Polymers beyond standard optical fibres—Fabrication of microstructured polymer optical fibres. Polym. Int. 2018, 67, 1155–1163. [Google Scholar] [CrossRef]

- Argyros, A.; Van Eijkelenborg, M.A.; Jackson, S.D.; Mildren, R.P. Microstructured polymer fiber laser. Opt. Express 2004, 1882–1884. [Google Scholar] [CrossRef]

- Zubia, J.; Arrue, J. Plastic optical fibers: An introduction to their technological processes and applications. Opt. Fiber Technol. 2001, 7, 101–140. [Google Scholar] [CrossRef]

- Ayesta, I.; Illarramendi, M.A.; Arrue, J.; Jiménez, F.; Zubia, J.; Bikandi, I.; Ugartemendia, J.M.; Sarasua, J.R. Luminescence study of polymer optical fibers doped with conjugated polymers. J. Lightwave Technol. 2012, 30, 3367–3375. [Google Scholar] [CrossRef]

- Kruhlak, R.; Kuzyk, M. Side-illumination fluorescence spectroscopy. I. principles. J. Opt. Soc. Am. B-Opt. Phys. 1999, 16, 1749–1755. [Google Scholar] [CrossRef]

- Kruhlak, R.; Kuzyk, M. Side-illumination fluorescence spectroscopy. II. Applications to squaraine-dye-doped polymer optical fibers. J. Opt. Soc. Am. B-Opt. Phys. 1999, 16, 1756–1767. [Google Scholar] [CrossRef]

- Alfrey, T.; Gurnee, E.F.; Lloyd, W.G. Diffusion in glassy polymers. J. Polym. Sci. 1966, 12, 249–261. [Google Scholar] [CrossRef]

- Thomas, N.; Windle, A.H. Transport of methanol in poly(methyl methacrylate). Polymer 1978, 19, 255–265. [Google Scholar] [CrossRef]

- Thomas, N.; Windle, A.H. A deformation model for case II diffusion. Polymer 1980, 21, 613–619. [Google Scholar] [CrossRef]

- Fasano, A.; Woyessa, G.; Janting, J.; Rasmussen, H.K.; Bang, O. Solution-mediated annealing of polymer optical fiber bragg gratings at room temperature. IEEE Photonics Technol. Lett. 2017, 29, 687–690. [Google Scholar] [CrossRef]

- Williams, D.R.G.; Allen, P.E.M.; Truong, V.T. Glass transition temperature and stress relaxation of methanol equilibrated poly (methyl methacrylate). Eur. Polym. J. 1986, 22, 911–919. [Google Scholar] [CrossRef]

- Lin, C.B.; Liu, K.S.; Lee, S. Methanol-induced opacity in poly(methyl methacrylate). J. Polym. Sci. Pt. B-Polym. Phys. 1991, 29, 1457–1466. [Google Scholar] [CrossRef]

- Jiang, C.; Kuzyk, M.G.; Ding, J.-L.; Johns, W.E.; Welker, D.J. Fabrication and mechanical behavior of dye-doped polymer optical fiber. J. Appl. Phys. 2002, 92, 4–12. [Google Scholar] [CrossRef]

- Stajanca, P.; Cetinkaya, O.; Schukar, M.; Krebber, K. Molecular alignment relaxation in polymer optical fibers for sensing applications. Opt. Fiber Technol. 2016, 28, 11–17. [Google Scholar] [CrossRef]

- Arrue, J.; Jiménez, F.; Illarramendi, M.A.; Zubia, J.; Ayesta, I.; Bikandi, I.; Berganza, A. Computational analysis of the power spectral shifts and widths along dye-doped polymer optical fibers. IEEE Photonics J. 2010, 2, 521–531. [Google Scholar] [CrossRef]

- Tagaya, A.; Teramoto, S.; Nihei, E.; Sasaki, K.; Koike, Y. High-power and high-gain organic dye-doped polymer optical fiber amplifiers: Novel techniques for preparation and spectral investigation. Appl. Optics 1997, 36, 572–578. [Google Scholar] [CrossRef]

- Li, Z.-C.; Liang, H.; Zheng, Z.-Q.; Zhang, Q.-J.; Ming, H. Amplified spontaneous emission of rhodamine B-doped step-index polymer optical fibre. Chin. Phys. Lett. 2005, 22, 618–620. [Google Scholar]

- Kurian, A.; George, M.A.; Paul, B.; Nampoori, V.P.N.; Vallabhan, C.P.G. Studies on fluorescence efficiency and photodegradation of rhodamine 6g doped pmma using a dual beam thermal lens technique. Laser Chem. 2002, 20, 99–110. [Google Scholar] [CrossRef]

- Aiestaran, P.; Dominguez, V.; Arrue, J.; Zubia, J. A fluorescent linear optical fiber position sensor. Opt. Mat. 2009, 31, 1101–1104. [Google Scholar] [CrossRef]

- Illarramendi, M.A.; Zubia, J.; Bazzana, L.; Durana, G.; Aldabaldetreku, G.; Sarasua, J.R. Spectroscopic characterization of plastic optical fibers doped with fluorene oligomers. J. Lightwave Technol. 2009, 27, 3220–3226. [Google Scholar] [CrossRef]

- Ayesta, I.; Illarramendi, M.A.; Arrue, J.; Parola, I.; Jiménez, F.; Zubia, J.; Tagaya, A.; Koike, Y. Optical characterization of doped thermoplastic and thermosetting polymer-Optical-Fibers. Polymers 2017, 9, 90. [Google Scholar] [CrossRef]

- Peng, G.D.; Xiong, Z.; Chu, P.L. Fluorescence decay and recovery in organic dye-doped polymer optical fibers. J. Lightwave Technol. 1998, 16, 2365–2369. [Google Scholar] [CrossRef]

- De la Rosa-Cruz, E.; Dirk, C.W.; Rodríguez, A.; Castaño, V.M. Characterization of fluorescence induced by side illumination of rhodamine B doped plastic optical fibers. Fiber Integr. Opt. 2001, 20, 457–464. [Google Scholar] [CrossRef]

- Faloss, M.; Canva, M.; Georges, P.; Brun, A.; Chaput, F.; Boilot, J.P. Toward millions of laser pulses with pyrromethene-and perylene-doped xerogels. Appl. Opt. 1997, 36, 6760–6763. [Google Scholar] [CrossRef]

- Muto, J.; Kobayashi, K. Photobleaching behaviours of rhodamine 6G diffused in polymethyl methacrylate and in the copolymer of methyl methacrylate with methacrylic acid. Phys. Status. Solidi (a) 1984, 84, K29–K33. [Google Scholar] [CrossRef]

| Temperature (°C) | k | n | R2 |

|---|---|---|---|

| 10 | 3.2 ± 0.1 | 1 ± 0.05 | 0.9961 |

| 20 | 9.6 ± 0.2 | 1 ± 0.05 | 0.9972 |

| 35 | 3.3 ± 0.9 | 0.97 ± 0.06 | 0.9972 |

| 40 | 12 ± 5 | 0.83 ± 0.09 | 0.9922 |

| 45 | 18 ± 12 | 0.81 ± 0.09 | 0.9835 |

| 50 | 37 ± 9 | 0.62 ± 0.07 | 0.9935 |

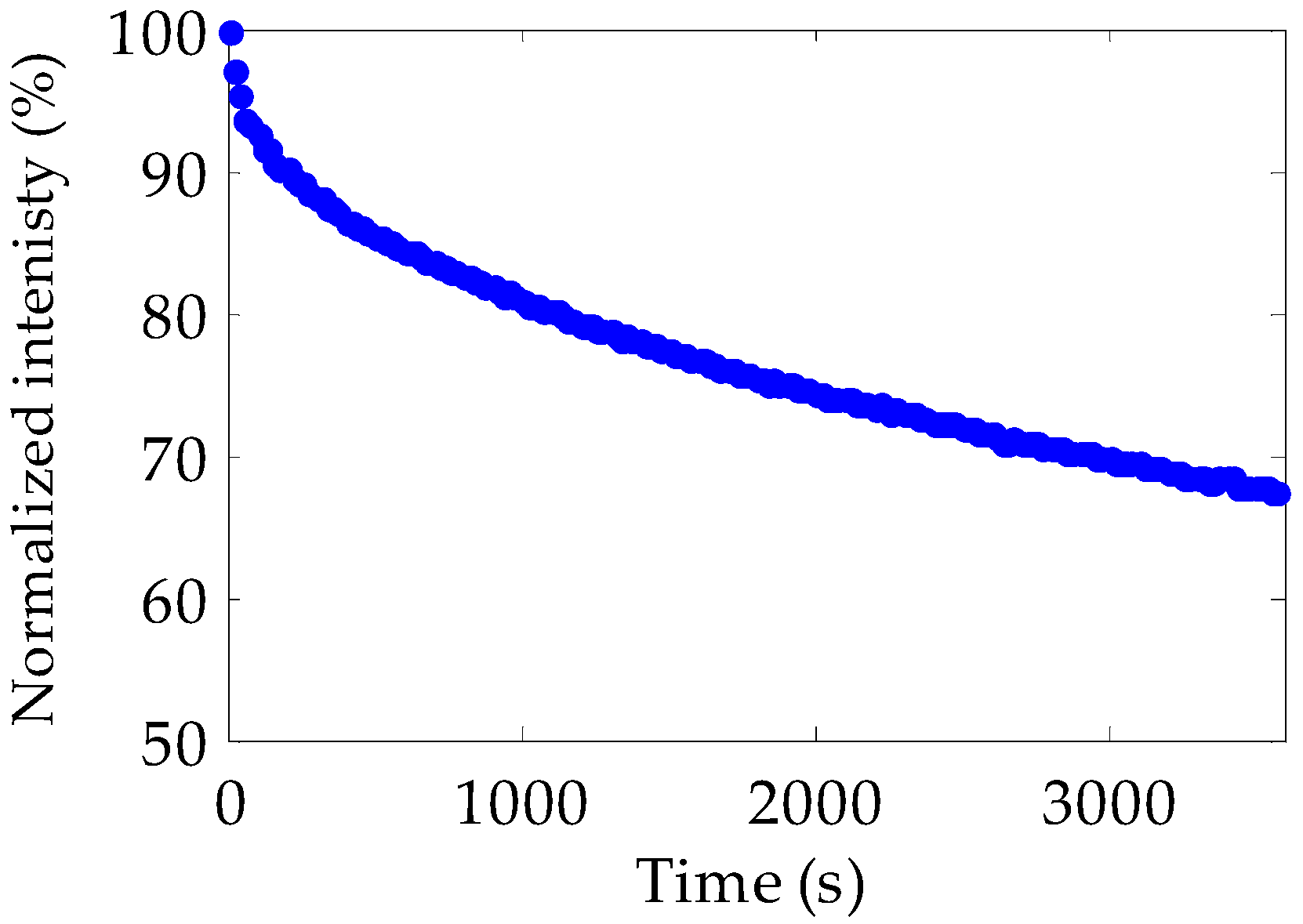

| Fiber Sample | Degradation (%) | Reference |

|---|---|---|

| Our samples | 32 | - |

| Thermoplastic fiber doped with rhodamine 6G | 39 | [36] |

| Thermosetting fiber doped with rhodamine 6G | 50 | [36] |

| PMMA POF doped with PFO | 81 | [19] |

| PMMA POF doped with F8T2 | 81 | [19] |

| PMMA POF doped with PF3T | 45 | [19] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ayesta, I.; Azkune, M.; Arrospide, E.; Arrue, J.; Illarramendi, M.A.; Durana, G.; Zubia, J. Fabrication of Active Polymer Optical Fibers by Solution Doping and Their Characterization. Polymers 2019, 11, 52. https://doi.org/10.3390/polym11010052

Ayesta I, Azkune M, Arrospide E, Arrue J, Illarramendi MA, Durana G, Zubia J. Fabrication of Active Polymer Optical Fibers by Solution Doping and Their Characterization. Polymers. 2019; 11(1):52. https://doi.org/10.3390/polym11010052

Chicago/Turabian StyleAyesta, Igor, Mikel Azkune, Eneko Arrospide, Jon Arrue, María Asunción Illarramendi, Gaizka Durana, and Joseba Zubia. 2019. "Fabrication of Active Polymer Optical Fibers by Solution Doping and Their Characterization" Polymers 11, no. 1: 52. https://doi.org/10.3390/polym11010052

APA StyleAyesta, I., Azkune, M., Arrospide, E., Arrue, J., Illarramendi, M. A., Durana, G., & Zubia, J. (2019). Fabrication of Active Polymer Optical Fibers by Solution Doping and Their Characterization. Polymers, 11(1), 52. https://doi.org/10.3390/polym11010052