Resistance to Cleavage of Core–Shell Rubber/Epoxy Composite Foam Adhesive under Impact Wedge–Peel Condition for Automobile Structural Adhesive

Abstract

1. Introduction

2. Materials and Methods

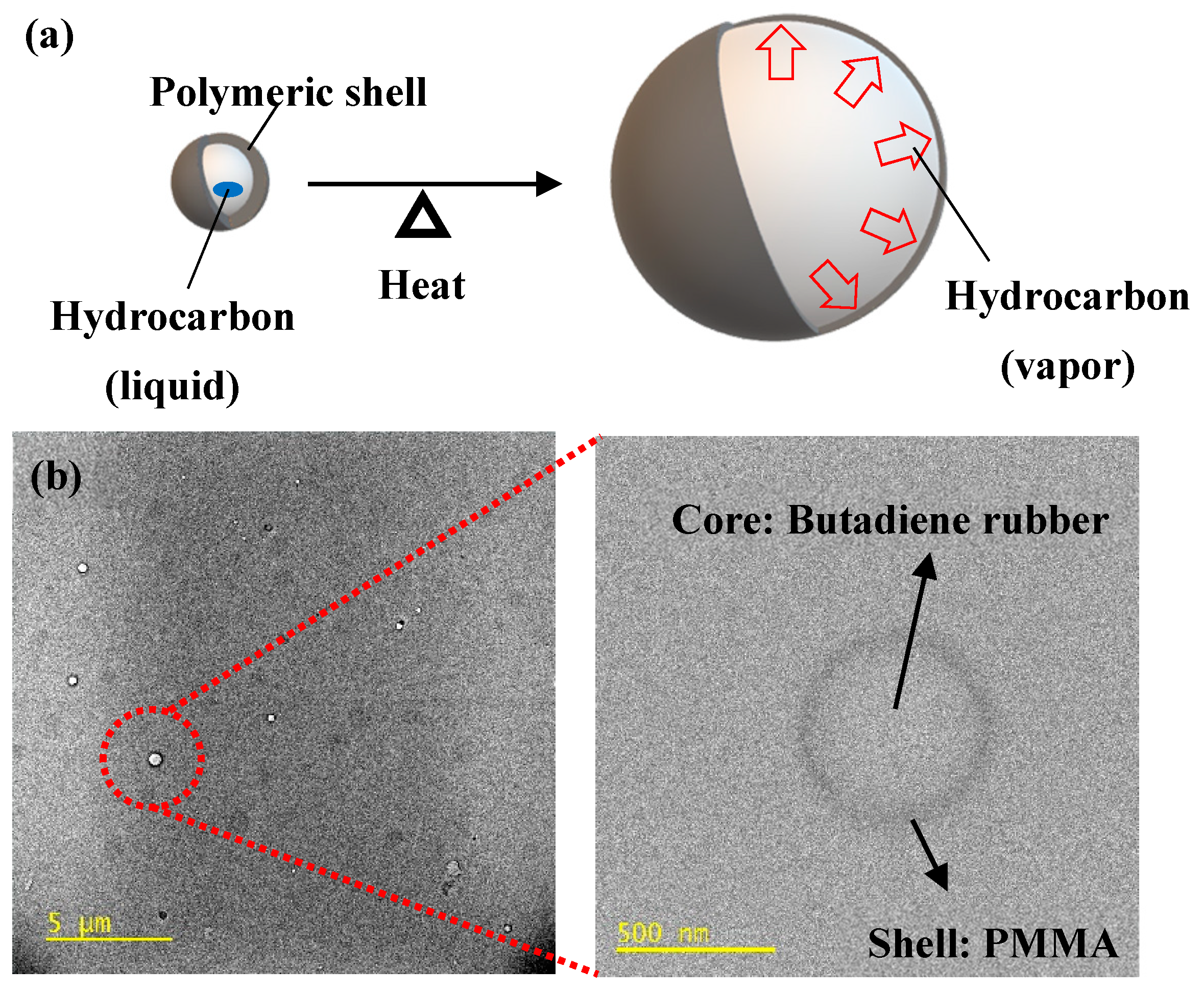

2.1. Materials

2.2. Curing and Foaming of CSR/Epoxy Composite Foam Adhesive

2.3. Differential Scanning Calorimetry (DSC)

2.4. X-ray Computed Tomography

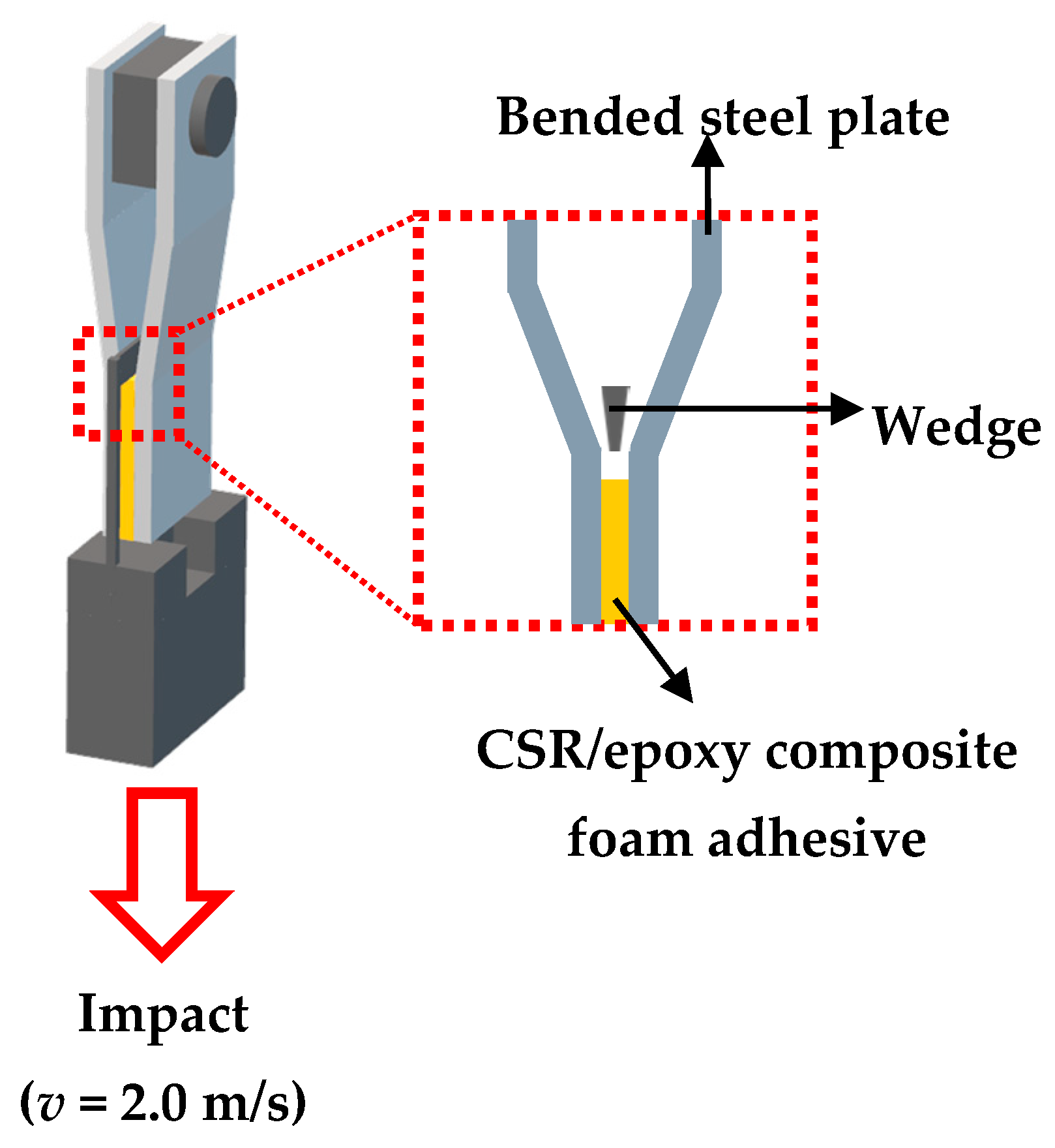

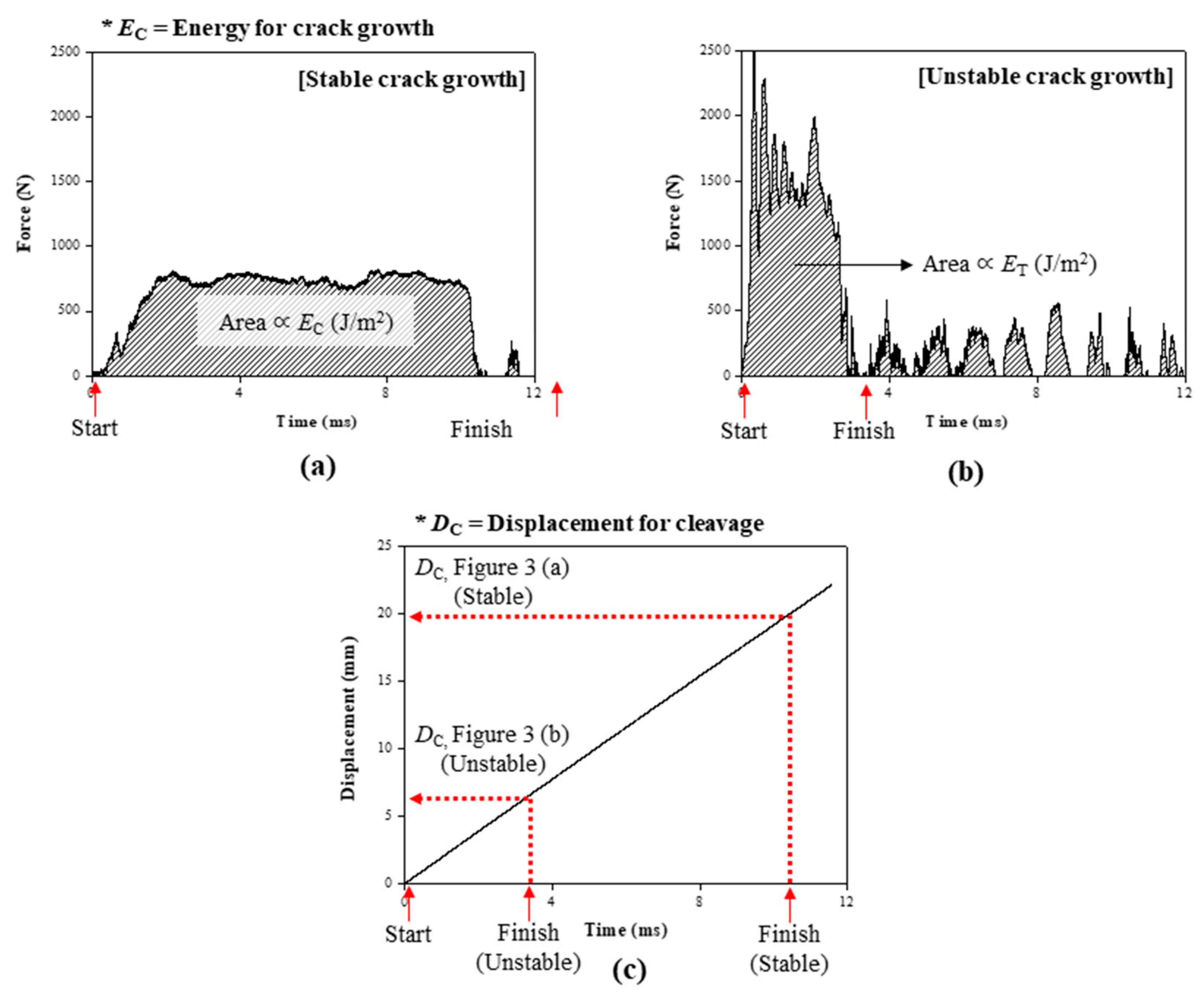

2.5. Impact Wedge–Peel Test

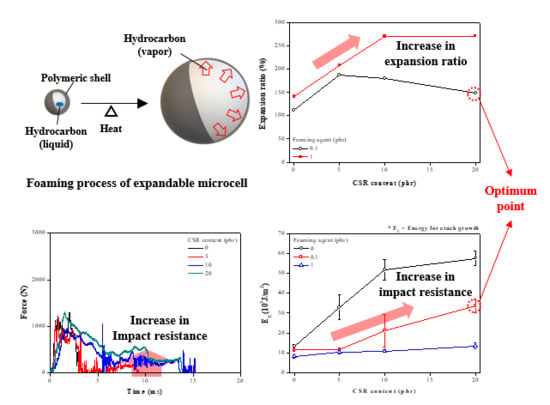

3. Results and Discussion

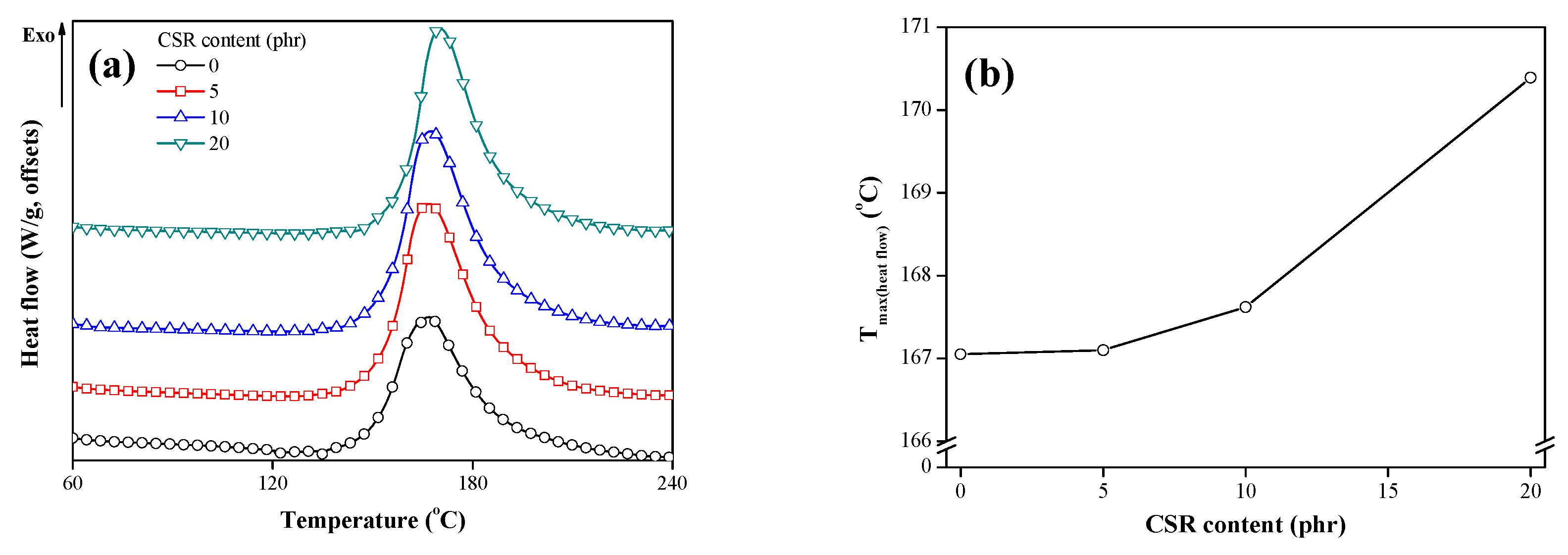

3.1. Curing Behavior of CSR/Epoxy Composite

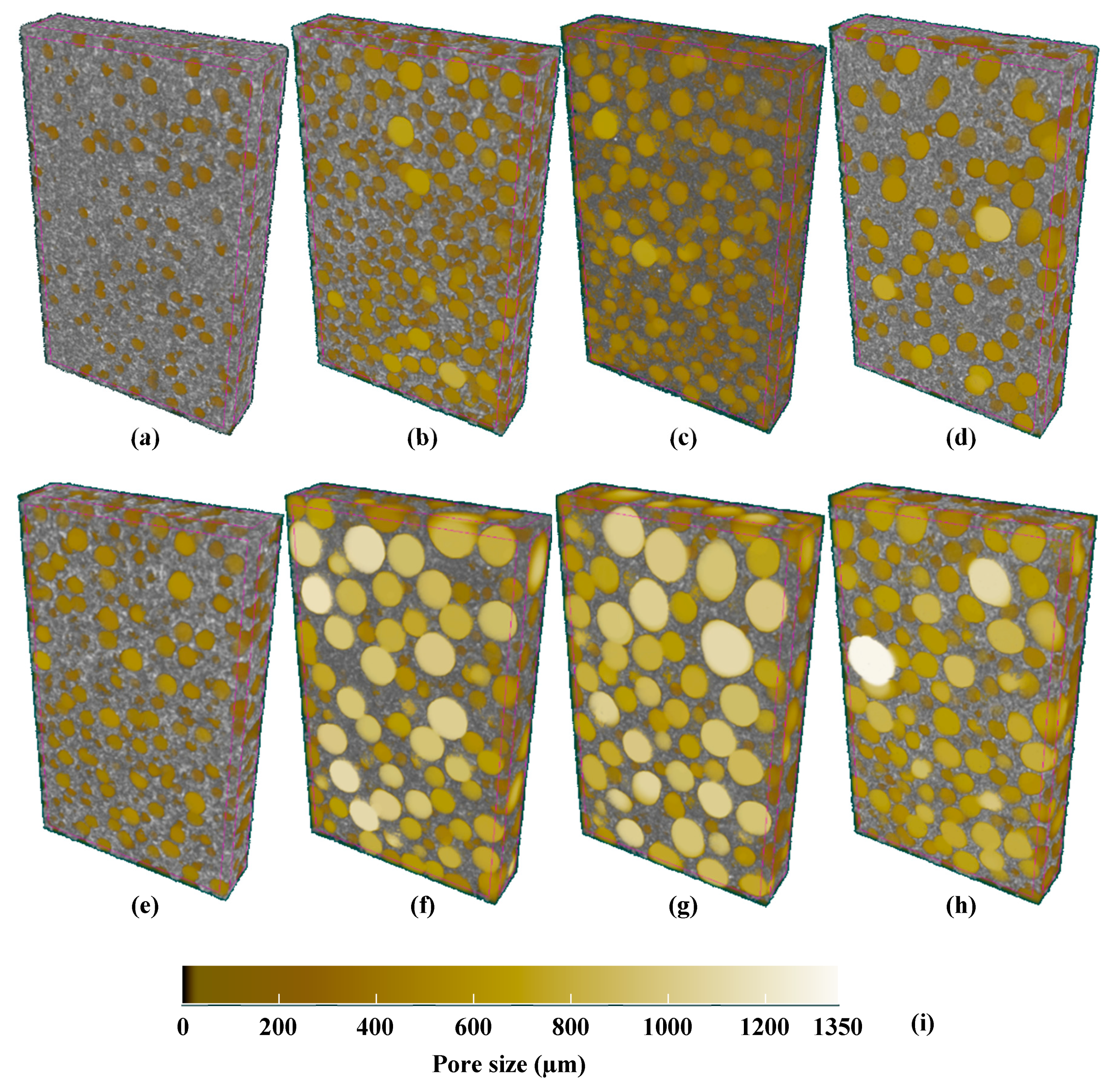

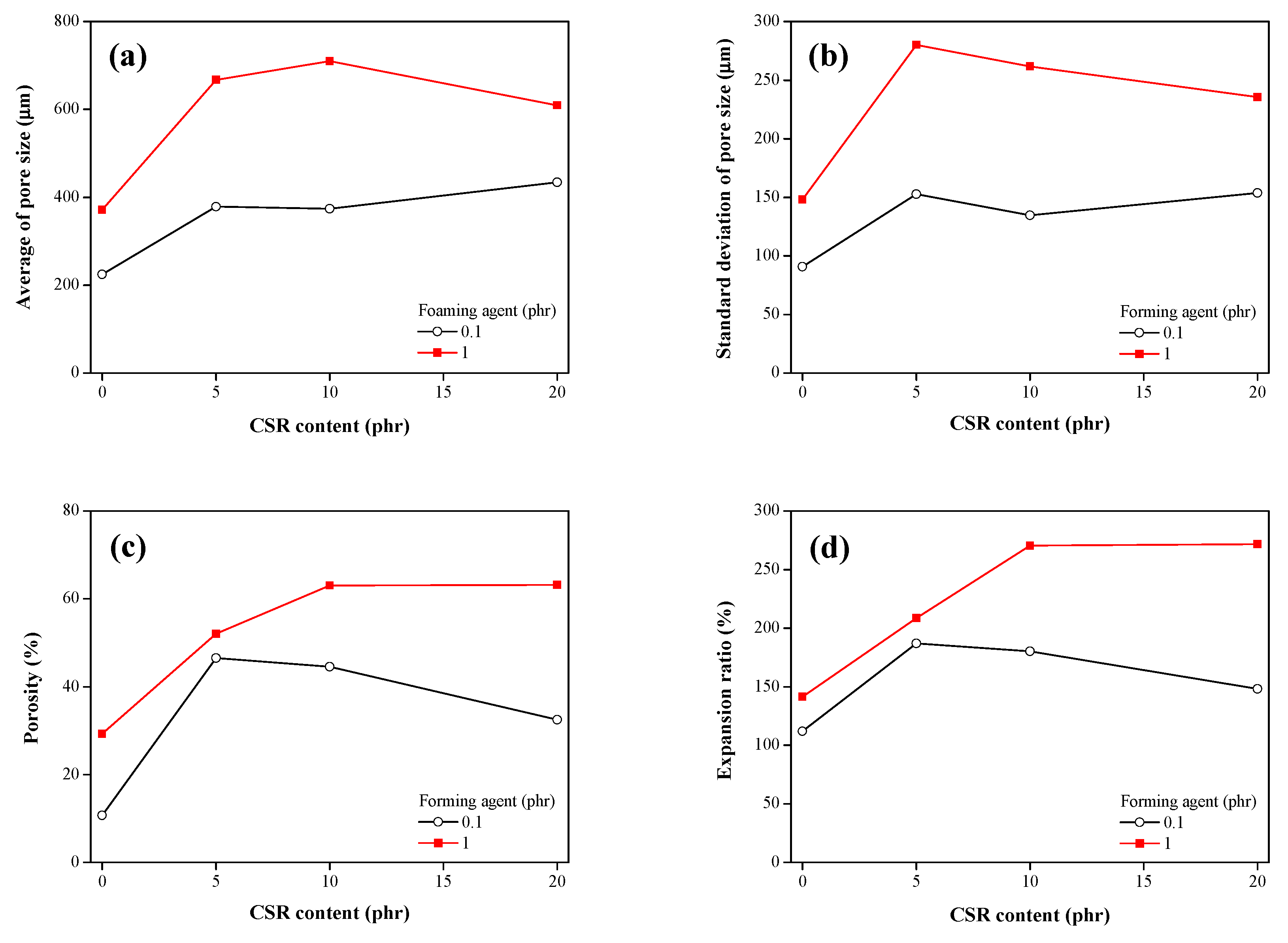

3.2. Pore Structure of CSR/Epoxy Composite Foam Adhesive

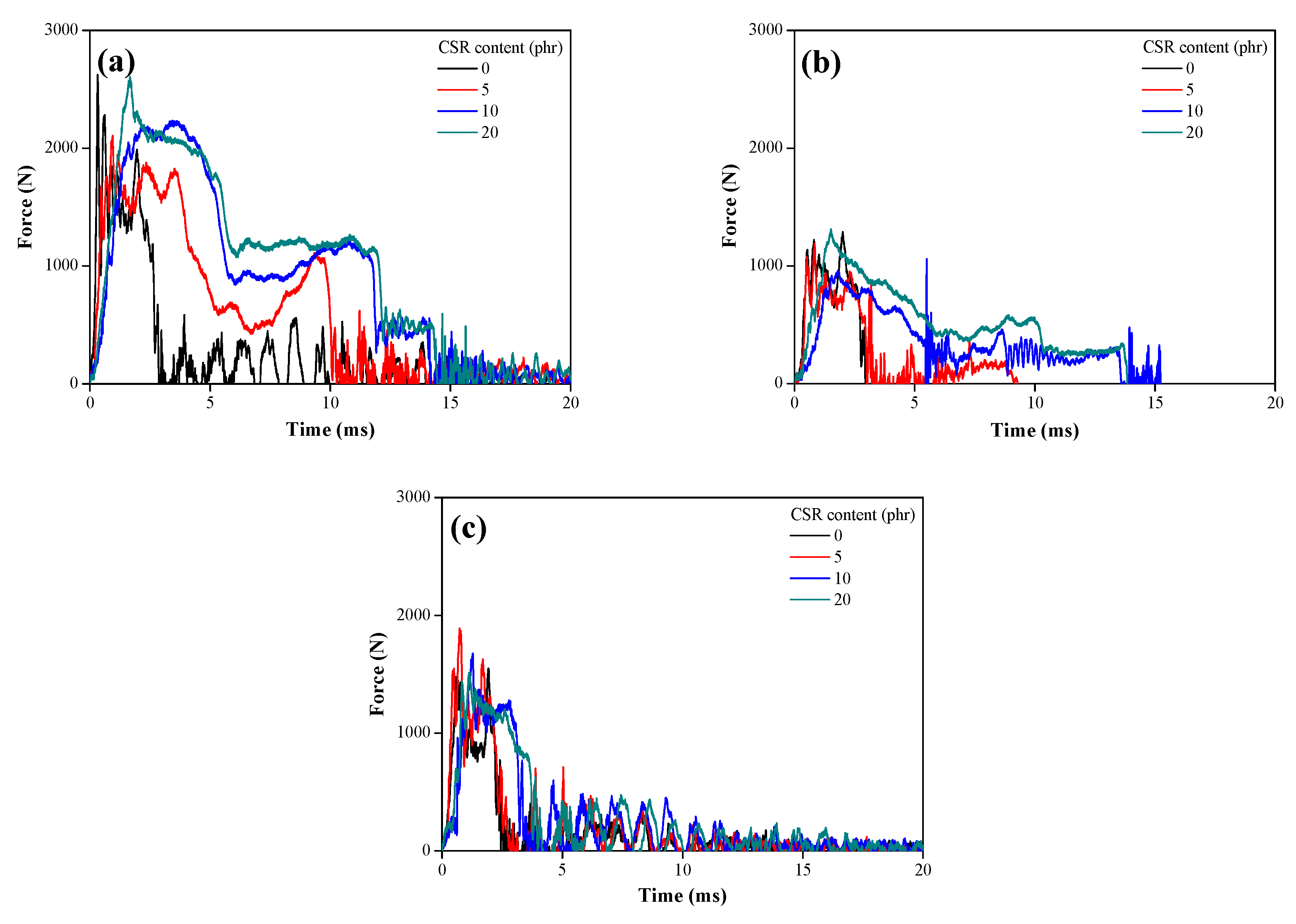

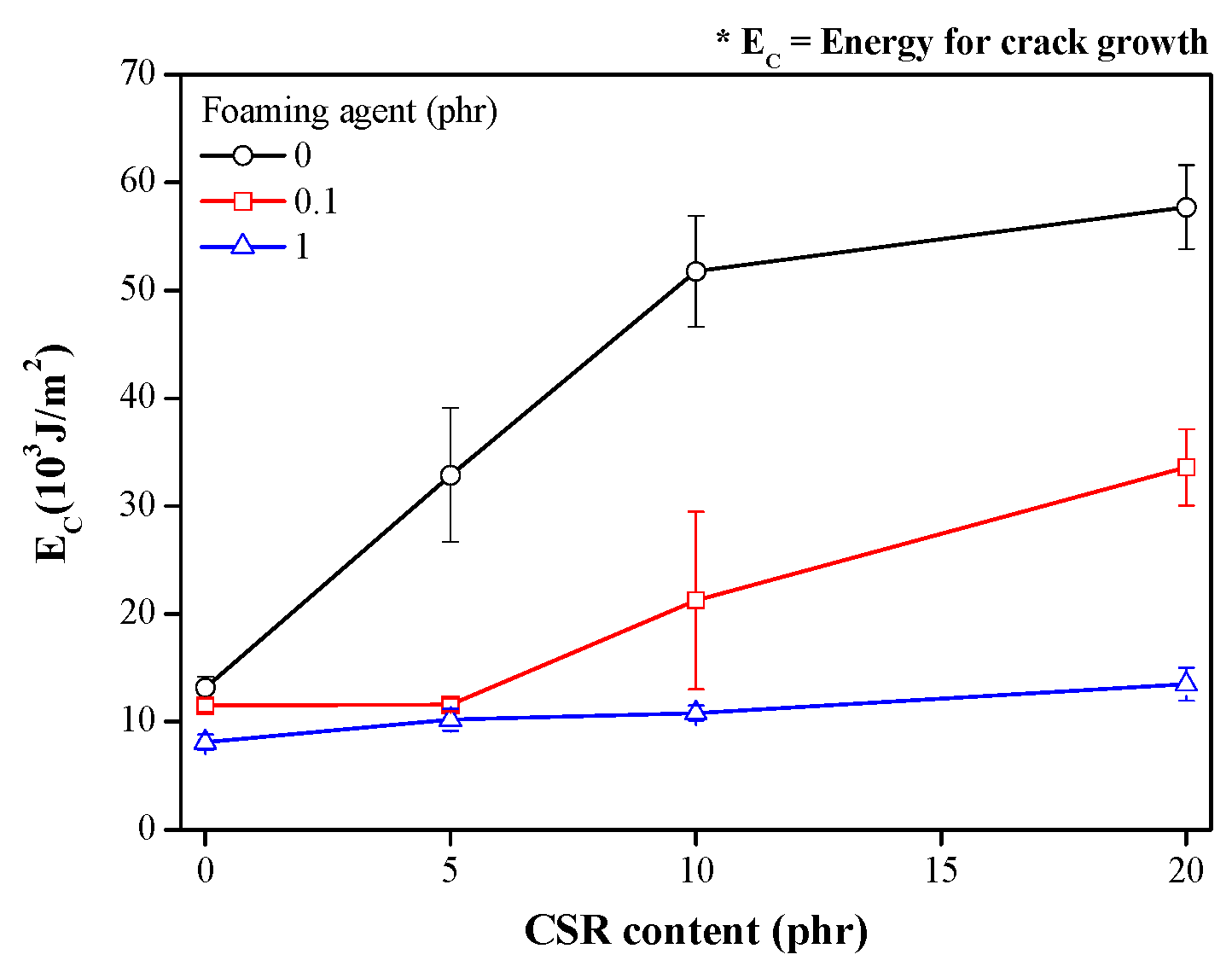

3.3. Resistance to Cleavage of Adhesive under Impact Wedge–Peel Condition

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Back, J.-H.; Hwang, J.-U.; Lee, Y.-H.; Baek, D.; Park, J.-W.; Kim, H.-J.; Kim, J.-H.; Song, H.-K.; Yoo, M.-J. Morphological study and mechanical property of epoxy-foam adhesives based on epoxy composites for automotive applications. Int. J. Adhes. Adhes. 2018, 87, 124–129. [Google Scholar] [CrossRef]

- Stroganov, V. Epoxy-foam adhesives. Polym. Sci. Ser. D 2013, 6, 275–279. [Google Scholar] [CrossRef]

- Wang, L.; Yang, X.; Zhang, J.; Zhang, C.; He, L. The compressive properties of expandable microspheres/epoxy foams. Compos. Part B Eng. 2014, 56, 724–732. [Google Scholar] [CrossRef]

- Kadioglu, F.; Adams, R.D. Flexible adhesives for automotive application under impact loading. Int. J. Adhes. Adhes. 2015, 56, 73–78. [Google Scholar] [CrossRef]

- Kim, J.-K.; Mackay, D.; Mai, Y.-W. Drop-weight impact damage tolerance of CFRP with rubber-modified epoxy matrix. Composites 1993, 24, 485–494. [Google Scholar] [CrossRef]

- Ratna, D.; Banthia, A.; Deb, P. Acrylate-based liquid rubber as impact modifier for epoxy resin. J. Appl. Polym. Sci. 2001, 80, 1792–1801. [Google Scholar] [CrossRef]

- Zhou, H.; Xu, S. A new method to prepare rubber toughened epoxy with high modulus and high impact strength. Mater. Lett. 2014, 121, 238–240. [Google Scholar] [CrossRef]

- Singh, K.; Nanda, T.; Mehta, R. Addition of nanoclay and compatibilized EPDM rubber for improved impact strength of epoxy glass fiber composites. Compos. Part A Appl. Sci. Manuf. 2017, 103, 263–271. [Google Scholar] [CrossRef]

- Memon, N.A. Rheological properties and the interface in polycarbonate/impact modifier blends: Effect of modifier shell molecular weight. J. Polym. Sci. Part B Polym. Phys. 1998, 36, 1095–1105. [Google Scholar] [CrossRef]

- Bain, E.D.; Knorr, D.B.; Richardson, A.D.; Masser, K.A.; Yu, J.; Lenhart, J.L. Failure processes governing high-rate impact resistance of epoxy resins filled with core–shell rubber nanoparticles. J. Mater. Sci. 2016, 51, 2347–2370. [Google Scholar] [CrossRef]

- Gao, G.; Zhou, C.; Yang, H.; Zhang, H. Influence of core–shell rubber particles synthesized with different initiation systems on the impact toughness of modified polystyrene. J. Appl. Polym. Sci. 2007, 103, 738–744. [Google Scholar] [CrossRef]

- Ren, Q.; Xu, H.; Yu, Q.; Zhu, S. Development of epoxy foaming with CO2 as latent blowing agent and principle in selection of amine curing agent. Ind. Eng. Chem. Res. 2015, 54, 11056–11064. [Google Scholar] [CrossRef]

- Stefani, P.; Cyras, V.; Tejeira Barchi, A.; Vazquez, A. Mechanical properties and thermal stability of rice husk ash filled epoxy foams. J. Appl. Polym. Sci. 2006, 99, 2957–2965. [Google Scholar] [CrossRef]

- Takiguchi, O.; Ishikawa, D.; Sugimoto, M.; Taniguchi, T.; Koyama, K. Effect of rheological behavior of epoxy during precuring on foaming. J. Appl. Polym. Sci. 2008, 110, 657–662. [Google Scholar] [CrossRef]

- Chen, K.; Tian, C.; Lu, A.; Zhou, Q.; Jia, X.; Wang, J. Effect of SiO2 on rheology, morphology, thermal, and mechanical properties of high thermal stable epoxy foam. J. Appl. Polym. Sci. 2014, 131, 40068. [Google Scholar]

- Patterson, B.M.; Henderson, K.; Smith, Z. Measure of morphological and performance properties in polymeric silicone foams by X-ray tomography. J. Mater. Sci. 2013, 48, 1986–1996. [Google Scholar] [CrossRef]

- Awaja, F.; Arhatari, B.; Wiesauer, K.; Leiss, E.; Stifter, D. An investigation of the accelerated thermal degradation of different epoxy resin composites using X-ray microcomputed tomography and optical coherence tomography. Polym. Degrad. Stab. 2009, 94, 1814–1824. [Google Scholar] [CrossRef]

- Khalili, S.; Shokuhfar, A.; Hoseini, S.; Bidkhori, M.; Khalili, S.; Mittal, R. Experimental study of the influence of adhesive reinforcement in lap joints for composite structures subjected to mechanical loads. Int. J. Adhes. Adhes. 2008, 28, 436–444. [Google Scholar] [CrossRef]

- Blackman, B.; Kinloch, A.; Taylor, A.; Wang, Y. The impact wedge-peel performance of structural adhesives. J. Mater. Sci. 2000, 35, 1867–1884. [Google Scholar] [CrossRef]

- Taylor, A.; Williams, J. Determining the fracture energy of structural adhesives from wedge-peel tests. J. Adhes. 2011, 87, 482–503. [Google Scholar] [CrossRef]

- Blackman, B.; Kinloch, A.; Sanchez, F.R.; Teo, W.; Williams, J. The fracture behaviour of structural adhesives under high rates of testing. Eng. Fract. Mech. 2009, 76, 2868–2889. [Google Scholar] [CrossRef]

| Materials | Composition | Abbreviation | Equivalent Weight (g/eq) |

|---|---|---|---|

| Epoxy | Bisphenol-A diglycidyl epoxy | BPA-E | 187 |

| Urethane-modified epoxy | UME | 475 | |

| Curing agent | Dicyandiamide | CA-1 | 21 |

| Substituted urea | CA-2 | 3 | |

| CSR + Epoxy | CSR in epoxy resin (35 wt %) | CSR mixture | 287.7 |

| Sample | BPA-E (g) | CSR Mixture (g) | CaCO3 (g) | Foaming Agent (g) |

|---|---|---|---|---|

| CSR 0/FA 0 | 14.96 | 0 | 6.03 | 0 |

| CSR 5/FA 0 | 12.16 | 4.31 | 4.52 | 0 |

| CSR 10/FA 0 | 9.36 | 8.62 | 3.02 | 0 |

| CSR 20/FA 0 | 3.76 | 17.23 | 0 | 0 |

| CSR 0/FA 0.1 | 14.96 | 0 | 6.03 | 0.032 |

| CSR 5/FA 0.1 | 12.16 | 4.31 | 4.52 | 0.032 |

| CSR 10/FA 0.1 | 9.36 | 8.62 | 3.02 | 0.032 |

| CSR 20/FA 0.1 | 3.76 | 17.23 | 0 | 0.032 |

| CSR 0/FA 1 | 14.96 | 0 | 6.03 | 0.32 |

| CSR 5/FA 1 | 12.16 | 4.31 | 4.52 | 0.32 |

| CSR 10/FA 1 | 9.36 | 8.62 | 3.02 | 0.32 |

| CSR 20/FA 1 | 3.76 | 17.23 | 0 | 0.32 |

| Foaming Agent Content (phr) | CSR Content (phr) | Type of Crack Growth | *DC (mm) |

|---|---|---|---|

| 0 | 0 | Unstable | 9.94 (±7.16) |

| 5 | Unstable/Stable | 22.11 (±5.17) | |

| 10 | Stable | 26.30 (±1.15) | |

| 20 | Stable | 26.57 (±0.93) | |

| 0.1 | 0 | Unstable | 9.23 (±5.53) |

| 5 | Unstable | 10.88 (±6.34) | |

| 10 | Unstable/Stable | 22.40 (±7.81) | |

| 20 | Stable | 28.87 (±0.55) | |

| 1 | 0 | Unstable | 5.85 (±1.22) |

| 5 | Unstable | 7.29 (±2.23) | |

| 10 | Unstable | 8.45 (±1.63) | |

| 20 | Unstable | 13.27 (±4.46) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Back, J.-H.; Baek, D.; Shin, J.-H.; Jang, S.-W.; Kim, H.-J.; Kim, J.-H.; Song, H.-K.; Hwang, J.-W.; Yoo, M.-J. Resistance to Cleavage of Core–Shell Rubber/Epoxy Composite Foam Adhesive under Impact Wedge–Peel Condition for Automobile Structural Adhesive. Polymers 2019, 11, 152. https://doi.org/10.3390/polym11010152

Back J-H, Baek D, Shin J-H, Jang S-W, Kim H-J, Kim J-H, Song H-K, Hwang J-W, Yoo M-J. Resistance to Cleavage of Core–Shell Rubber/Epoxy Composite Foam Adhesive under Impact Wedge–Peel Condition for Automobile Structural Adhesive. Polymers. 2019; 11(1):152. https://doi.org/10.3390/polym11010152

Chicago/Turabian StyleBack, Jong-Ho, Dooyoung Baek, Jae-Ho Shin, Seong-Wook Jang, Hyun-Joong Kim, Jong-Hak Kim, Hong-Kyu Song, Jong-Won Hwang, and Min-Jae Yoo. 2019. "Resistance to Cleavage of Core–Shell Rubber/Epoxy Composite Foam Adhesive under Impact Wedge–Peel Condition for Automobile Structural Adhesive" Polymers 11, no. 1: 152. https://doi.org/10.3390/polym11010152

APA StyleBack, J.-H., Baek, D., Shin, J.-H., Jang, S.-W., Kim, H.-J., Kim, J.-H., Song, H.-K., Hwang, J.-W., & Yoo, M.-J. (2019). Resistance to Cleavage of Core–Shell Rubber/Epoxy Composite Foam Adhesive under Impact Wedge–Peel Condition for Automobile Structural Adhesive. Polymers, 11(1), 152. https://doi.org/10.3390/polym11010152