Preparation and Properties of sc-PLA/PMMA Transparent Nanofiber Air Filter

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

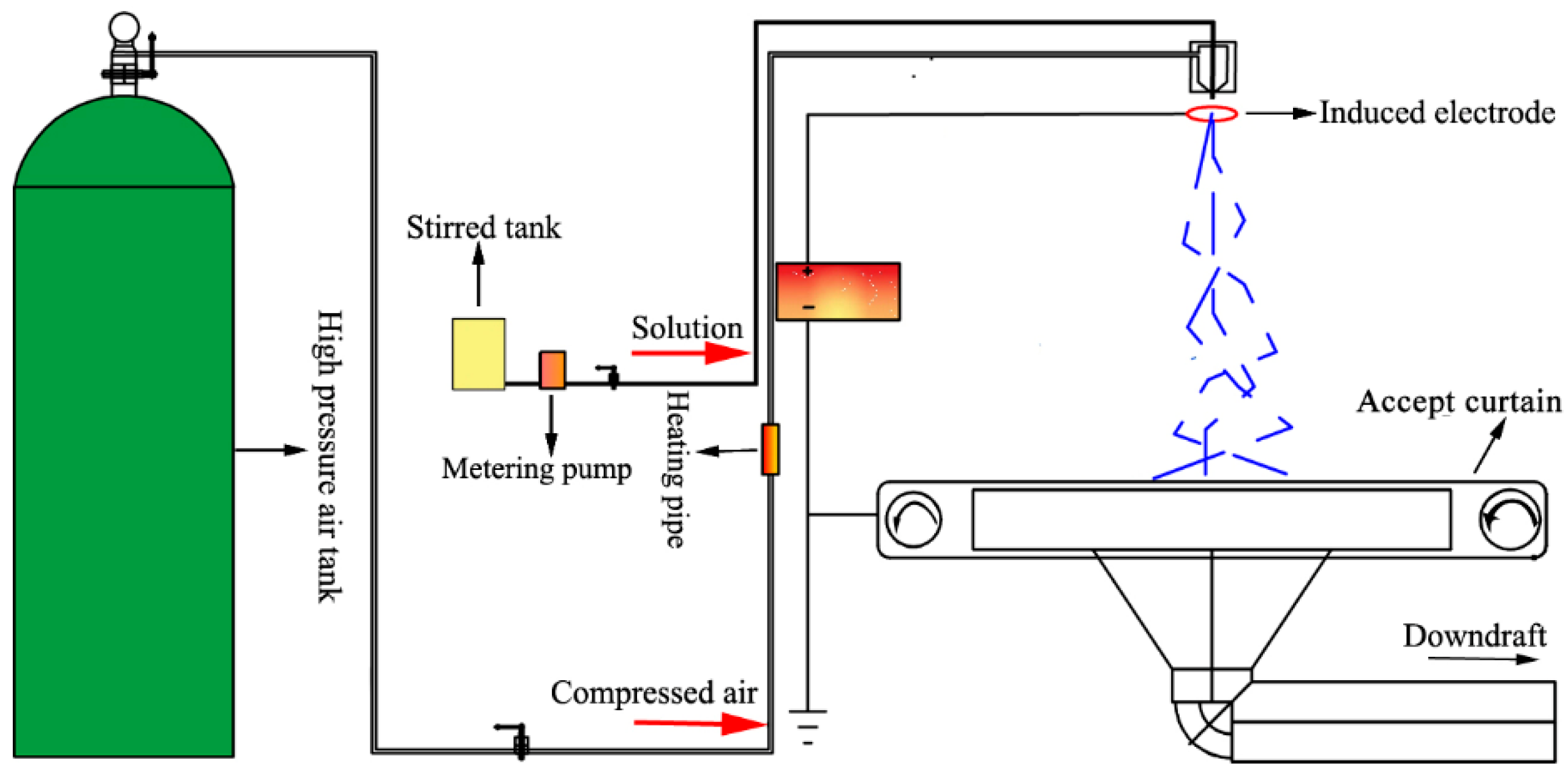

2.2. ESB of sc-PLA/PMMA Nanofibers

2.3. Characterization

2.3.1. Scanning Electron Microscopy (SEM)

2.3.2. Transmission Election Microscopy (TEM)

2.3.3. Differential Scanning Calorimetry (DSC)

2.3.4. Rheological Measurements

2.3.5. Mechanical Performance Measurement

2.3.6. Optical Properties of Nanofiber Filter

2.3.7. Measurement of Removal Efficiency

3. Results and Discussion

3.1. Formation of sc-PLA in PMMA Nanofibers

3.2. Performance of sc-PLA/PMMA Nanofiber Filters

3.2.1. Mechanical Properties

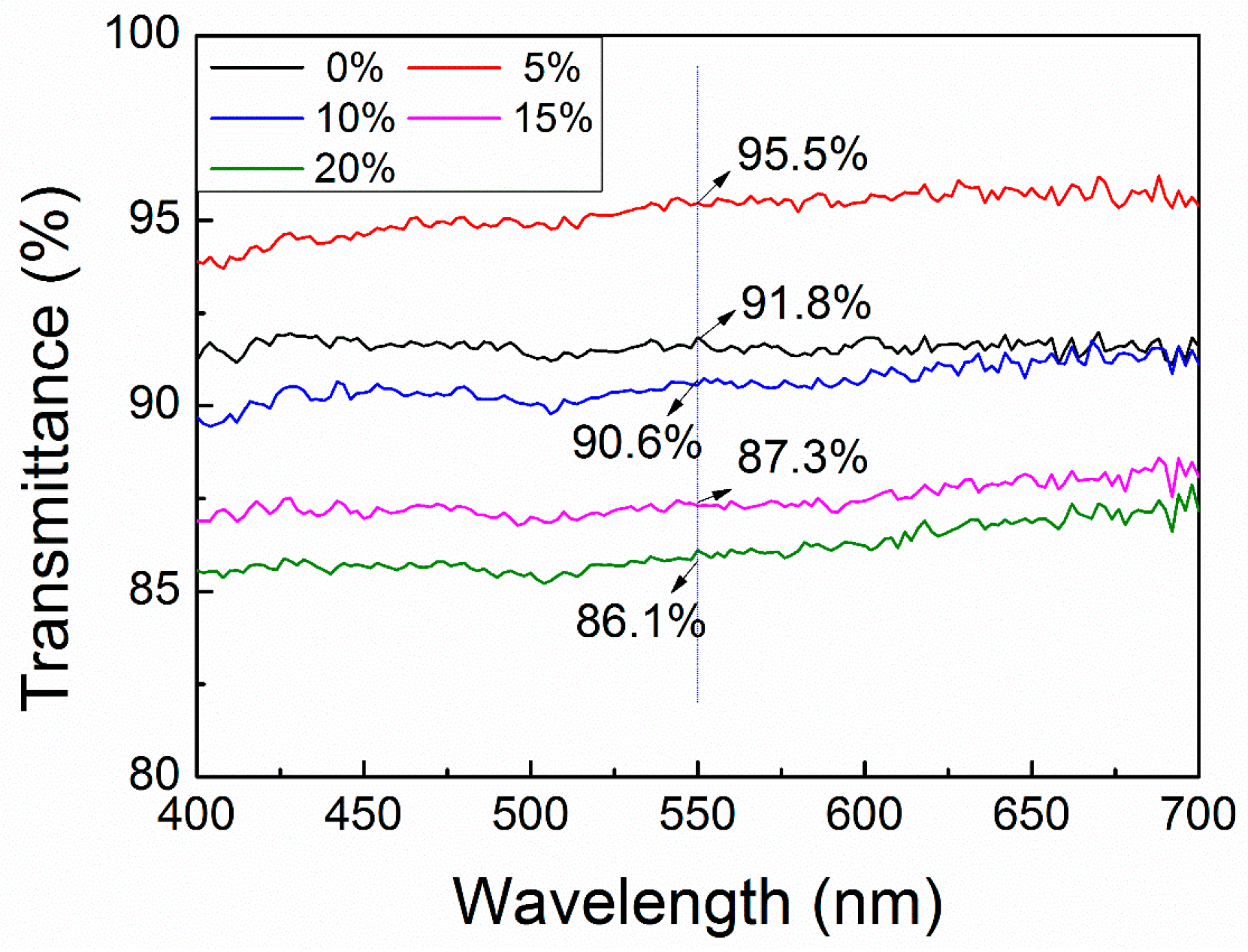

3.2.2. Optical Transmittance

3.2.3. PM Removal Efficiency

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Adam, M.; Schikowski, T.; Carsin, A.E.; Cai, Y.; Jacquemin, B.; Sanchez, M.; Vierkotter, A.; Marcon, A.; Keidel, D.; Sugiri, D.; et al. Adult lung function and long-term air pollution exposure. ESCAPE: a multicentre cohort study and meta-analysis. Eur. Respir. J. 2014, 45, 38–50. [Google Scholar] [CrossRef] [PubMed]

- Andreae, M.O.; Rosenfeld, D. Aerosol–cloud–precipitation interactions. Part 1. The nature and sources of cloud-active aerosols. Earth-Sci. Rev. 2008, 89, 13–41. [Google Scholar] [CrossRef]

- Fanizza, C.; De Berardis, B.; Ietto, F.; Soggiu, M.E.; Schirò, R.; Inglessis, M.; Ferdinandi, M.; Incoronato, F. Analysis of major pollutants and physico-chemical characteristics of PM2.5 at an urban site in Rome. Sci. Total Environ. 2018, 616–617, 1457–1468. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Jing, J.; Tao, J.; Hsu, S.-C.; Wang, G.; Cao, J.; Lee, C.S.L.; Zhu, L.; Chen, Z.; Zhao, Y.; et al. Chemical characterization and source apportionment of PM2.5 in Beijing: seasonal perspective. Atmos. Chem. Phys. 2013, 13, 7053–7074. [Google Scholar] [CrossRef]

- Horton, D.E.; Skinner, C.B.; Singh, D.; Diffenbaugh, N.S. Occurrence and persistence of future atmospheric stagnation events. Nat. Clim. Chang. 2014, 4, 698–703. [Google Scholar] [CrossRef] [PubMed]

- Streets, D.G.; Wu, Y.; Chin, M. Two-decadal aerosol trends as a likely explanation of the global dimming/brightening transition. Geophys. Res. Lett. 2006, 33. [Google Scholar] [CrossRef]

- Liu, C.; Hsu, P.-C.; Lee, H.-W.; Ye, M.; Zheng, G.; Liu, N.; Li, W.; Cui, Y. Transparent air filter for high-efficiency PM2.5 capture. Nat. Commun. 2015, 6, 6205. [Google Scholar] [CrossRef] [PubMed]

- Shi, S.; Bian, Y.; Zhang, L.; Chen, C. A method for assessing the performance of nanofiber films coated on window screens in reducing residential exposures to PM2.5 of outdoor origin in Beijing. Indoor Air 2017, 27, 1190–1200. [Google Scholar] [CrossRef] [PubMed]

- Höflinger, W.; Stöcklmayer, C.; Hackl, A. Model calculation of the compression behaviour of dust filter cakes. Filtr. Sep. 1994, 31, 807–811, 806. [Google Scholar] [CrossRef]

- Brown, R.C. Theory of airflow through filters modelled as arrays of parallel fibres. Chem. Eng. Sci. 1993, 48, 3535–3543. [Google Scholar] [CrossRef]

- Davies, C.N. The Separation of Airborne Dust and Particles. Proc. Inst. Mech. Eng. Part B 1953, 1, 185–213. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, S.; Wang, X.; Yu, J.; Ding, B. Efficient and reusable polyamide-56 nanofiber/nets membrane with bimodal structures for air filtration. J. Colloid Interface Sci. 2015, 457, 203–211. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Wu, S.; Jian, M.; Xie, J.; Xu, L.; Yang, S.; Zheng, Q.; Zhang, Y. Silk nanofibers as high efficient and lightweight air filter. Nano Res. 2016, 9, 2590–2597. [Google Scholar] [CrossRef]

- Wang, Z.; Pan, Z.; Wang, J.; Zhao, R. A Novel Hierarchical Structured Poly(lactic acid)/Titania Fibrous Membrane with Excellent Antibacterial Activity and Air Filtration Performance. J. Nanomater. 2016, 2016, 1–17. [Google Scholar] [CrossRef]

- Wang, Z.; Pan, Z. Preparation of hierarchical structured nano-sized/porous poly (lactic acid) composite fibrous membranes for air filtration. Appl. Surf. Sci. 2015, 356, 1168–1179. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, C.; Hsu, P.-C.; Zhang, C.; Liu, N.; Zhang, J.; Lee, H.R.; Lu, Y.; Qiu, Y.; Chu, S.; et al. Nanofiber Air Filters with High-Temperature Stability for Efficient PM2.5 Removal from the Pollution Sources. Nano Lett. 2016, 16, 3642–3649. [Google Scholar] [CrossRef] [PubMed]

- Chattopadhyay, S.; Huang, Y.F.; Jen, Y.J.; Ganguly, A.; Chen, K.H.; Chen, L.C. Anti-reflecting and photonic nanostructures. Mater. Sci. Eng. R Rep. 2010, 69, 1–35. [Google Scholar] [CrossRef]

- Wang, N.; Xiong, D. Comparison of micro-/nano-hierarchical and nano-scale roughness of silica membranes in terms of wetting behavior and transparency. Colloids Surf. A 2014, 446, 8–14. [Google Scholar] [CrossRef]

- Liu, T.; Xiang, F.; Qi, X.; Yang, W.; Huang, R.; Fu, Q. Optically transparent poly(methyl methacrylate) with largely enhanced mechanical and shape memory properties via in-situ formation of polylactide. Polymer 2017, 126, 231–239. [Google Scholar] [CrossRef]

- Putz, K.W.; Compton, O.C.; Palmeri, M.J.; Nguyen, S.T.; Brinson, L.C. High-Nanofiller-Content Graphene Oxide-Polymer Nanocomposites via Vacuum-Assisted Self-Assembly. Adv. Funct. Mater. 2010, 20, 3322–3329. [Google Scholar] [CrossRef]

- Anju, V.P.; Narayanankutty, S.K. Impact of Bis-(3-triethoxysilylpropyl) tetrasulphide on the properties of PMMA/Cellulose composite. Polymer 2017, 119, 224–237. [Google Scholar] [CrossRef]

- Fraser, R.A.; Stoeffler, K.; Ashrafi, B.; Zhang, Y.; Simard, B. Large-Scale Production of PMMA/SWCNT Composites Based on SWCNT Modified with PMMA. Acs Appl. Mater. Interfaces 2012, 4, 1990–1997. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.; Zhang, G.; Zhuo, S.; Jiang, H.; Shi, J.; Li, F.; Li, H. Dual responsive shape memory polymer/clay nanocomposites. Compos. Sci. Technol. 2016, 129, 53–60. [Google Scholar] [CrossRef]

- Zhang, X.; Nakagawa, R.; Chan, K.H.K.; Kotaki, M. Mechanical Property Enhancement of Polylactide Nanofibers through Optimization of Molecular Weight, Electrospinning Conditions, and Stereocomplexation. Macromolecules 2012, 45, 5494–5500. [Google Scholar] [CrossRef]

- Samuel, C.; Raquez, J.; Dubois, P. PLLA/PMMA blends: A shear-induced miscibility with tunable morphologies and properties? Polymer 2013, 54, 3931–3939. [Google Scholar] [CrossRef]

- López-Rodríguez, N.; Martínez De Arenaza, I.; Meaurio, E.; Sarasua, J.R. Improvement of toughness by stereocomplex crystal formation in optically pure polylactides of high molecular weight. J. Mech. Behav. Biomed. Mater. 2014, 37, 219–225. [Google Scholar] [CrossRef] [PubMed]

- Hao, X.; Kaschta, J.; Liu, X.; Pan, Y.; Schubert, D.W. Entanglement network formed in miscible PLA/PMMA blends and its role in rheological and thermo-mechanical properties of the blends. Polymer 2015, 80, 38–45. [Google Scholar] [CrossRef]

- Rana, D.; Mandal, B.M.; Bhattacharyya, S.N. Analogue Calorimetric Studies of Blends of Poly (vinyl ester)s and Polyacrylates. Macromolecules 1996, 29, 1579–1583. [Google Scholar] [CrossRef]

- Rana, D.; Mandal, B.M.; Bhattacharyya, S.N. Analogue calorimetry of polymer blends: Poly(styrene-co-acrylonitrile) and poly (phenyl acrylate) or poly(vinyl benzoate). Polymer 1996, 37, 2439–2443. [Google Scholar] [CrossRef]

- Rana, D.; Mandal, B.M.; Bhattacharyya, S.N. Miscibility and phase diagrams of poly (phenyl acrylate) and poly(styrene-co-acrylonitrile) blends. Polymer 1993, 34, 1454–1459. [Google Scholar] [CrossRef]

- Li, S.-H.; Woo, E.M. Immiscibility-miscibility phase transitions in blends of poly(L-lactide) with poly(methyl methacrylate). Polym. Int. 2008, 57, 1242–1251. [Google Scholar] [CrossRef]

- Hao, X.; Kaschta, J.; Pan, Y.; Liu, X.; Schubert, D.W. Intermolecular cooperativity and entanglement network in a miscible PLA/PMMA blend in the presence of nanosilica. Polymer 2016, 82, 57–65. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, J.; Wang, S.; Shen, D. Miscibility and phase structure of binary blends of polylactide and poly(methyl methacrylate). J. Polym. Sci. Part B Polym. Phys. 2003, 41, 23–30. [Google Scholar] [CrossRef]

- Tang, D.; Zhuang, X.; Zhang, C.; Cheng, B.; Li, X. Generation of nanofibers via electrostatic-Induction-assisted solution blow spinning. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Walczak, Z.K. VIII—PROCESS VARIABLES. In Processes of Fiber Formation; Walczak, Z.K., Ed.; Elsevier Science Ltd.: Kidlington, UK, 2002; pp. 296–311. ISBN 978-0-08-044040-8. [Google Scholar]

- Zhang, S.; Tang, N.; Cao, L.; Yin, X.; Yu, J.; Ding, B. Highly Integrated Polysulfone/Polyacrylonitrile/Polyamide-6 Air Filter for Multilevel Physical Sieving Airborne Particles. ACS Appl. Mater. Interfaces 2016, 8, 29062–29072. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Tian, R.; Na, B.; Lv, R.; Liu, Q. Intermolecular ordering as the precursor for stereocomplex formation in the electrospun polylactide fibers. Polymer 2015, 60, 221–227. [Google Scholar] [CrossRef]

- Longo, J.M.; DiCiccio, A.M.; Coates, G.W. Poly(propylene succinate): A New Polymer Stereocomplex. J. Am. Chem. Soc. 2014, 136, 15897–15900. [Google Scholar] [CrossRef] [PubMed]

- Lv, T.; Zhou, C.; Li, J.; Huang, S.; Wen, H.; Meng, Y.; Jiang, S. New insight into the mechanism of enhanced crystallization of PLA in PLLA/PDLA mixture. J. Appl. Polym. Sci. 2018, 135, 45663. [Google Scholar] [CrossRef]

- Li, S.-H.; Woo, E.M. Kinetic Analysis on Effect of Poly(4-vinyl phenol) on Complex-Forming Blends of Poly(L-lactide) and Poly(D-lactide). Polym. J. 2009, 41, 374–382. [Google Scholar] [CrossRef]

- Xie, Y.; Lan, X.-R.; Bao, R.-Y.; Lei, Y.; Cao, Z.-Q.; Yang, M.-B.; Yang, W.; Wang, Y.-B. High-performance porous polylactide stereocomplex crystallite scaffolds prepared by solution blending and salt leaching. Mater. Sci. Eng. C 2018, 90, 602–609. [Google Scholar] [CrossRef] [PubMed]

- Rana, D.; Cho, K.; Woo, T.; Lee, B.H.; Choe, S. Blends of ethylene 1-octene copolymer synthesized by Ziegler-Natta and metallocene catalysts. I. Thermal and mechanical properties. J. Appl. Polym. Sci. 1999, 74, 1169–1177. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, R.; Wang, X.; Sun, P.; Chen, W.; Shen, J.; Xue, G. Hydrogenation induced deviation of temperature and concentration dependences of polymer-solvent interactions in poly (vinyl chloride) and a new eco-friendly plasticizer. Eur. Phys. J. Plus 2015, 130, 116. [Google Scholar] [CrossRef]

- Gurtovenko, A.A.; Blumen, A. Relaxation of disordered polymer networks: Regular lattice made up of small-world Rouse networks. J. Chem. Phys. 2001, 115. [Google Scholar] [CrossRef]

- Arranz-Andrés, J.; Benavente, R.; Pérez, E.; Cerrada, M.L. Structure and Mechanical Behavior of the Mesomorphic Form in a Propylene-b-Poly(ethylene-co-propylene) Copolymer and Its Comparison with Other Thermal Treatments. Ploym. J. 2003, 35, 766–777. [Google Scholar] [CrossRef]

- Cui, L.; Wang, Y.; Guo, Y.; Liu, Y.; Zhao, J.; Zhang, C.; Zhu, P. Effects of Temperature and External Force on the Stereocomplex Crystallization in Poly (lactic acid) Blends. Adv. Polym. Tech. 2018, 37, 962–967. [Google Scholar] [CrossRef]

- Lin, X.; Li, K.; Gough, T.; Coates, P.; Wang, D.; Zhang, L. Influence of the morphological structure of carbon nanotubes on the viscoelasticity of PMMA-based nanocomposites. J. Appl. Polym. Sci. 2018, 135, 46444. [Google Scholar] [CrossRef]

- Rana, D.; Lim Kim, H.; Kwag, H.; Rhee, J.; Cho, K.; Woo, T.; Lee, B.H.; Choe, S. Blends of ethylene 1-octene copolymer synthesized by Ziegler–Natta and metallocene catalysts. II. Rheology and morphological behaviors. J. Appl. Polym. Sci. 2000, 76, 1950–1964. [Google Scholar] [CrossRef]

- Rana, D.; Sauvant, V.; Halary, J.L. Molecular analysis of yielding in pure and antiplasticized epoxy-amine thermosets. J. Mater. Sci. 2002, 37, 5267–5274. [Google Scholar] [CrossRef]

- Rana, D.; Lee, C.H.; Cho, K.; Lee, B.H.; Choe, S. Thermal and mechanical properties for binary blends of metallocene polyethylene with conventional polyolefins. J. Appl. Polym. Sci. 1998, 69, 2441–2450. [Google Scholar] [CrossRef]

- Shou, D.; Fan, J.; Zhang, H.; Qian, X.; Ye, L. Filtration Efficiency of Non-Uniform Fibrous Filters. Aerosol Sci. Technol. 2015, 49, 912–919. [Google Scholar] [CrossRef]

- Shou, D.; Fan, J.; Ye, L.; Zhang, H.; Qian, X.; Zhang, Z. Inverse Problem of Air Filtration of Nanoparticles: Optimal Quality Factors of Fibrous Filters. J. Nanomater. 2015, 2015, 1–11. [Google Scholar] [CrossRef]

| Sample | P (%) | E (%) | ΔP (Pa) | QF (Pa−1) |

|---|---|---|---|---|

| 0 wt % | 80 | 95.40 | 32 | 0.0962 |

| 5 wt % | 81 | 99.52 | 46 | 0.1161 |

| 10 wt % | 75 | 99.95 | 65 | 0.1169 |

| 15 wt % | 72 | 99.99 | 67 | 0.1374 |

| 20 wt % | 73 | 96.35 | 35 | 0.0966 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, S.; Zhao, X.; Shi, L.; Zhang, G.; Wang, S.; Kang, W.; Zhuang, X. Preparation and Properties of sc-PLA/PMMA Transparent Nanofiber Air Filter. Polymers 2018, 10, 996. https://doi.org/10.3390/polym10090996

Lv S, Zhao X, Shi L, Zhang G, Wang S, Kang W, Zhuang X. Preparation and Properties of sc-PLA/PMMA Transparent Nanofiber Air Filter. Polymers. 2018; 10(9):996. https://doi.org/10.3390/polym10090996

Chicago/Turabian StyleLv, Shengnan, Xin Zhao, Lei Shi, Gaokai Zhang, Shubo Wang, Weimin Kang, and Xupin Zhuang. 2018. "Preparation and Properties of sc-PLA/PMMA Transparent Nanofiber Air Filter" Polymers 10, no. 9: 996. https://doi.org/10.3390/polym10090996

APA StyleLv, S., Zhao, X., Shi, L., Zhang, G., Wang, S., Kang, W., & Zhuang, X. (2018). Preparation and Properties of sc-PLA/PMMA Transparent Nanofiber Air Filter. Polymers, 10(9), 996. https://doi.org/10.3390/polym10090996