Electrically Conductive Polyetheretherketone Nanocomposite Filaments: From Production to Fused Deposition Modeling

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

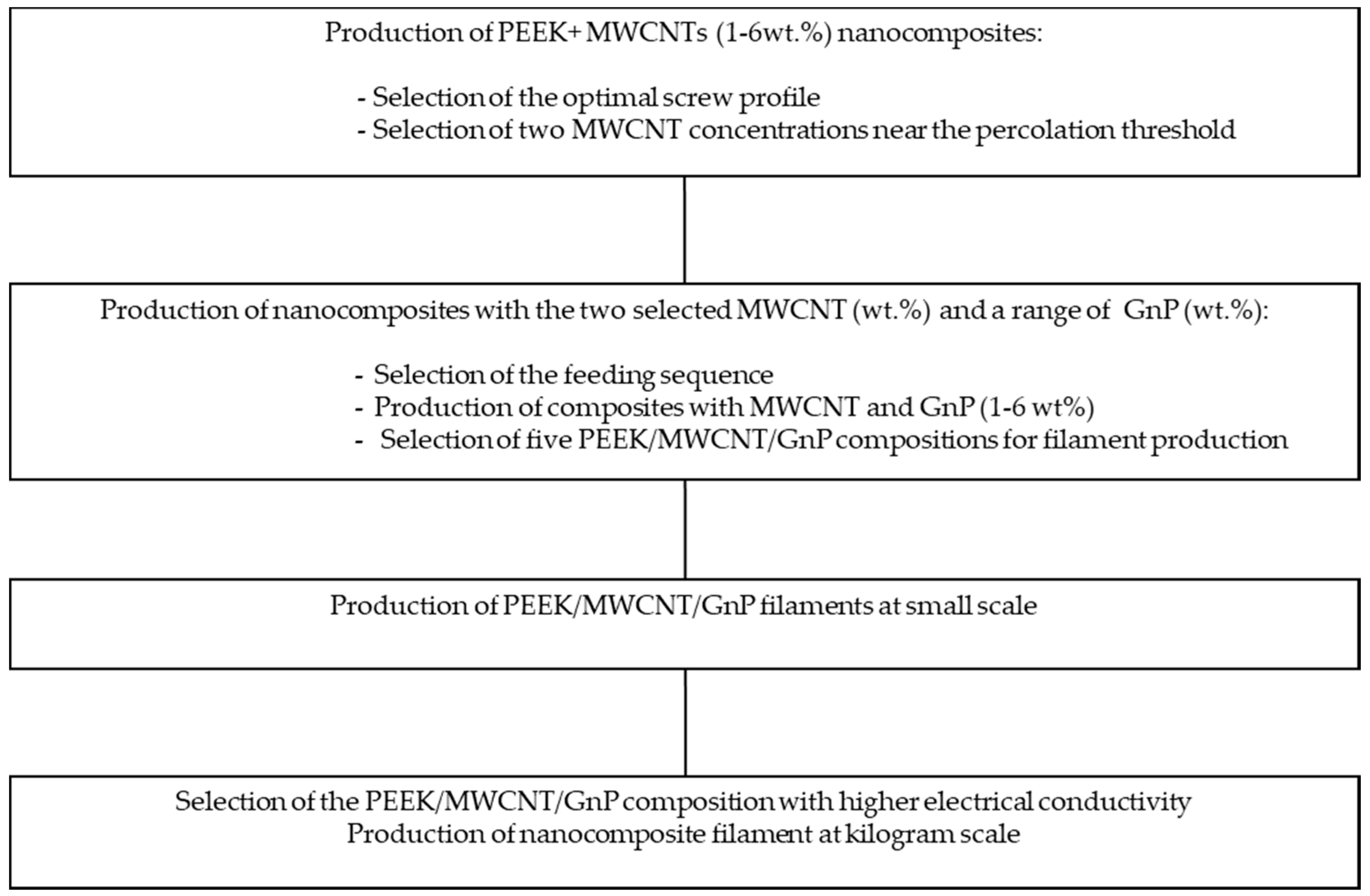

2.2. Experimental Design

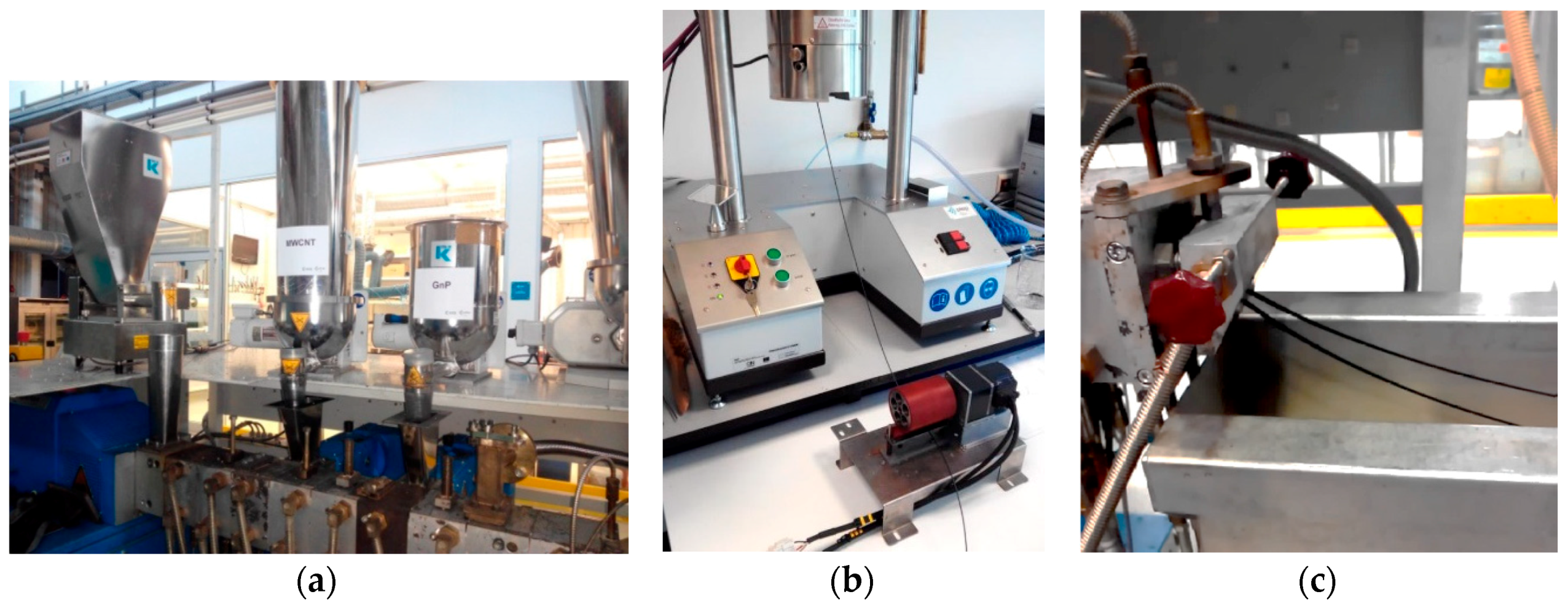

2.3. Processing

2.4. Characterization

2.4.1. Nanocomposites

2.4.2. Nanocomposite Filaments

2.4.3. 3D-Printed Specimens

3. Results and Discussion

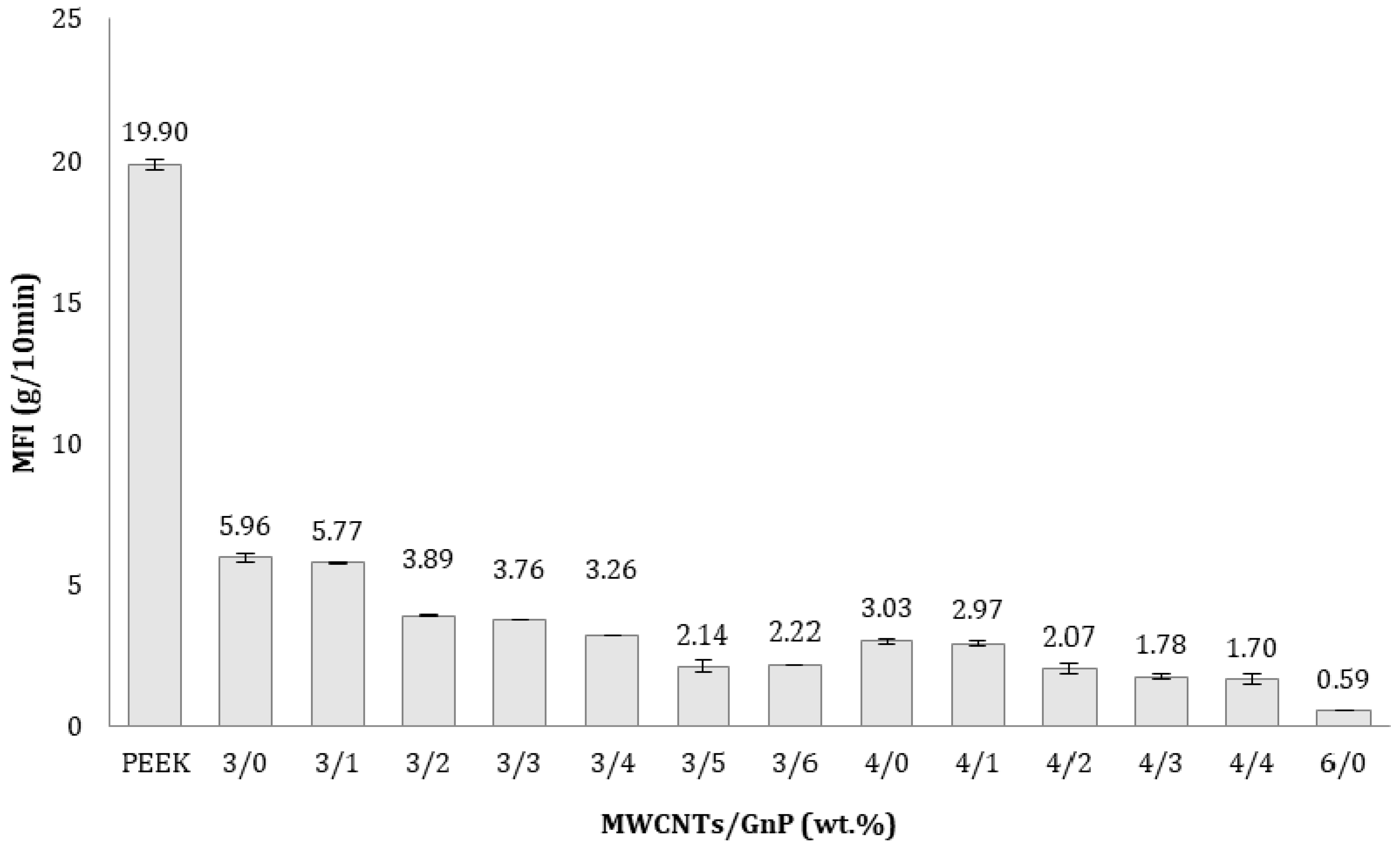

3.1. Nanocomposites

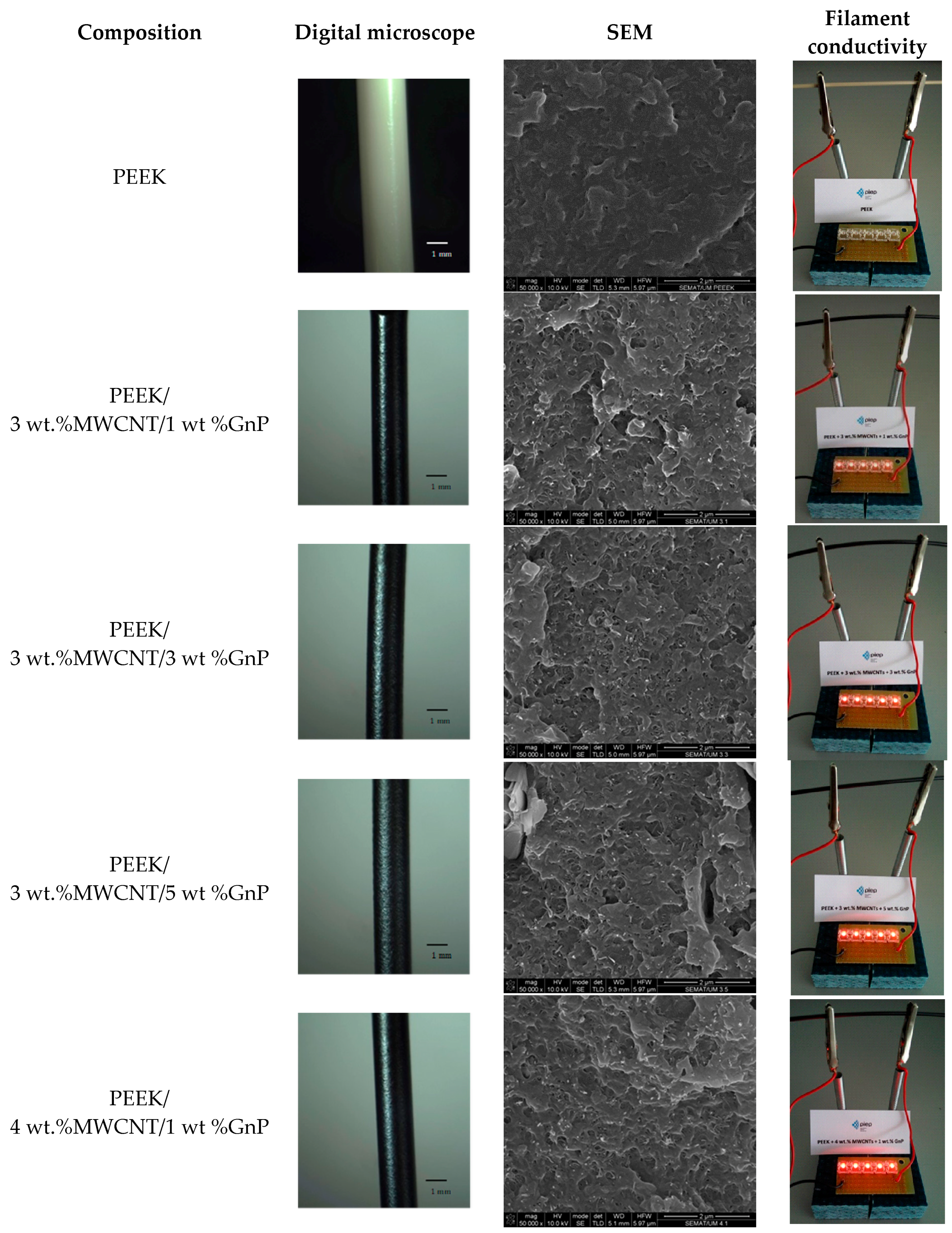

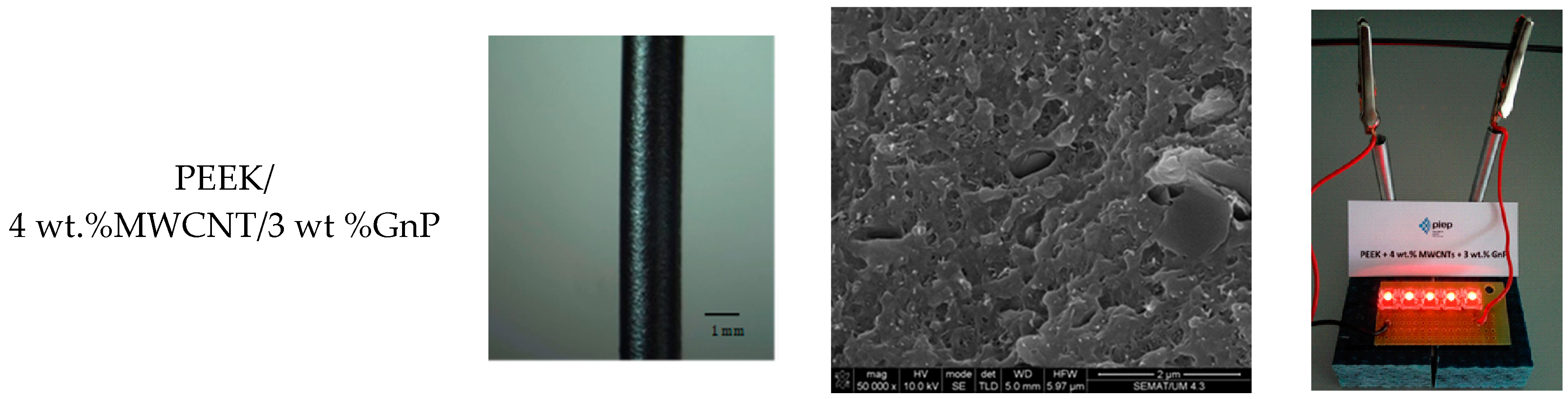

3.2. Filaments

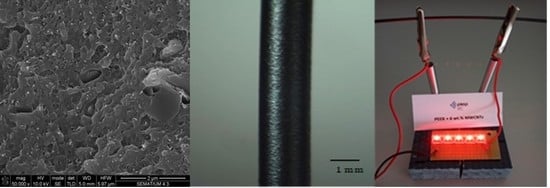

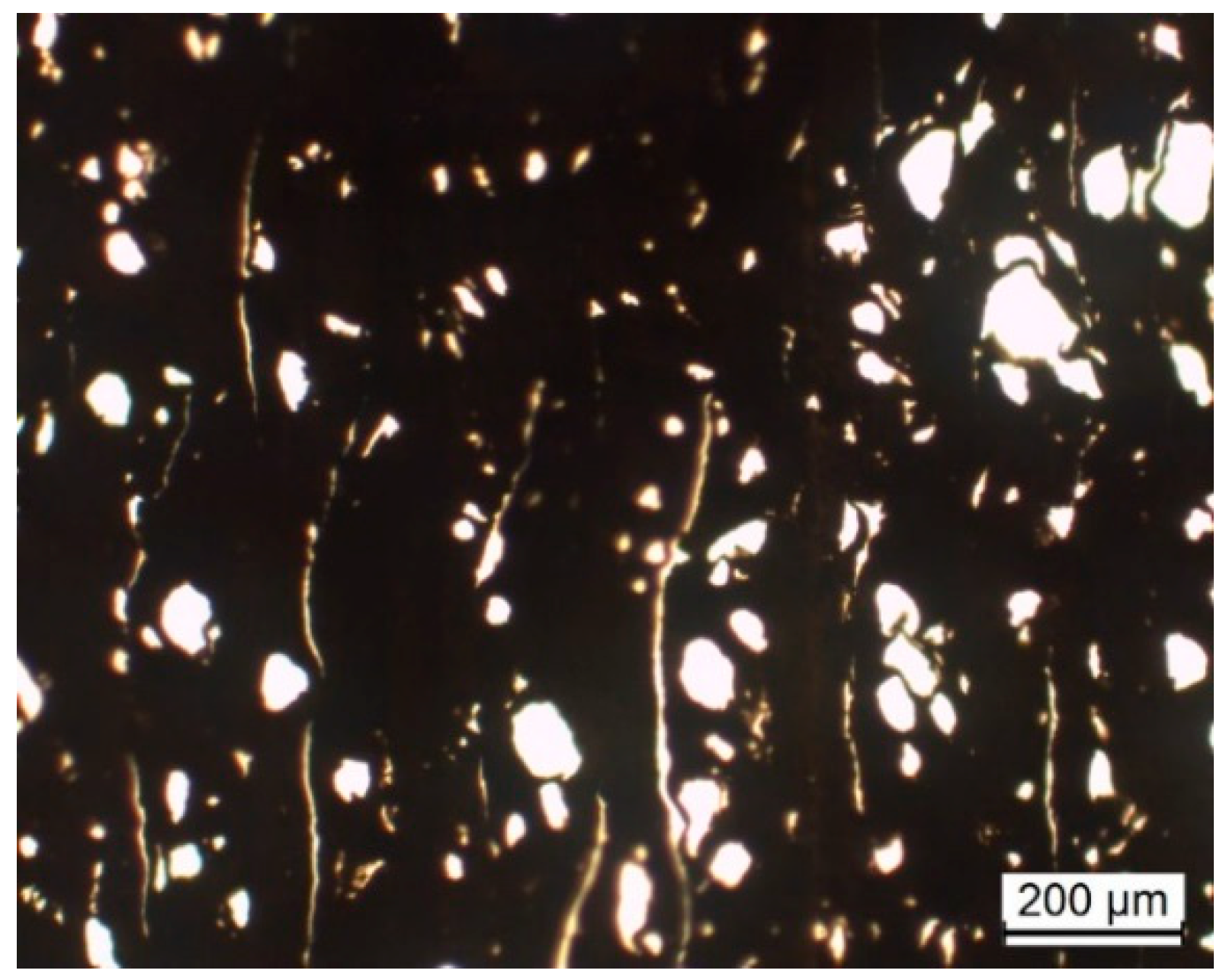

3.2.1. Filament Morphology

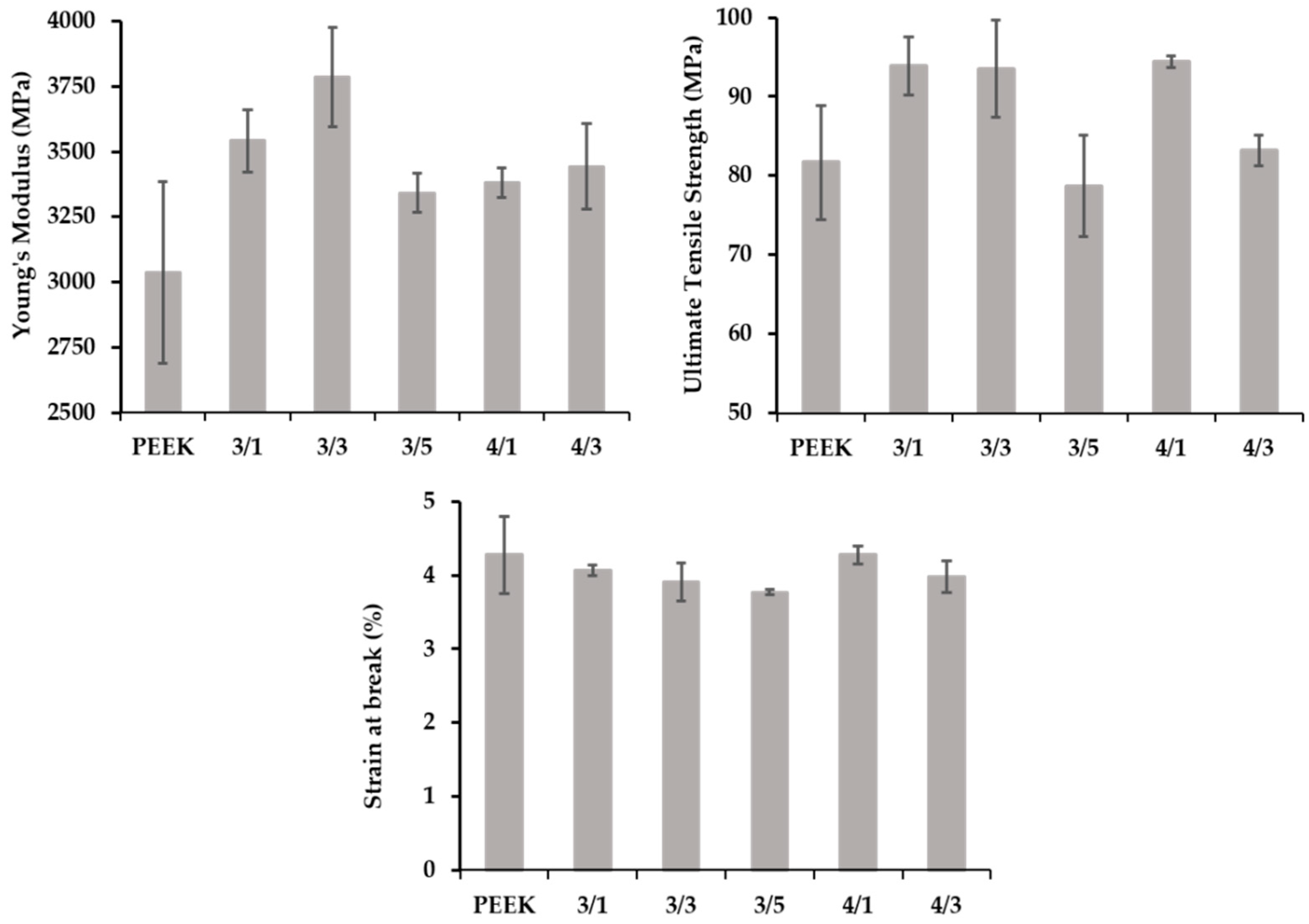

3.2.2. Tensile Properties

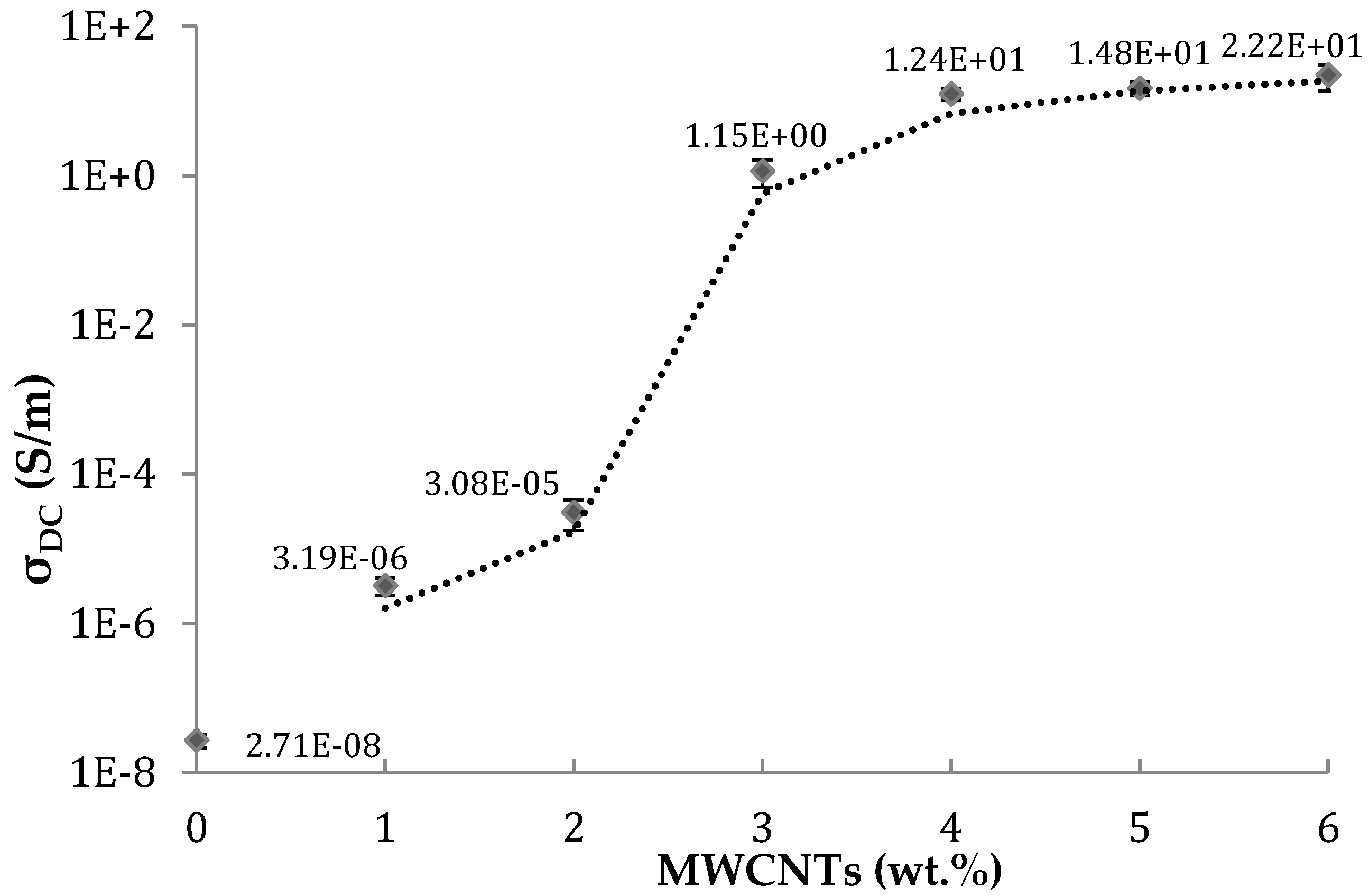

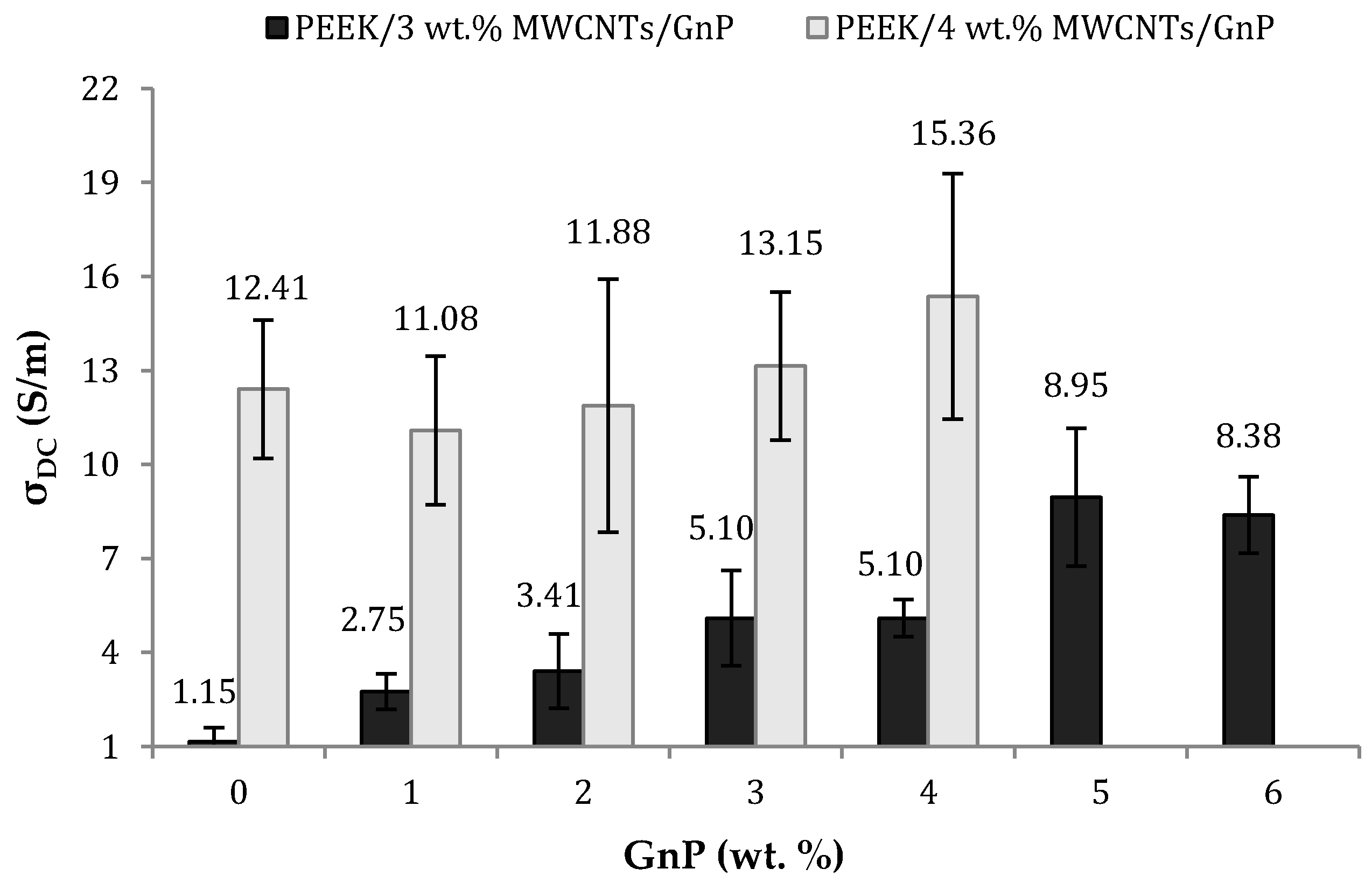

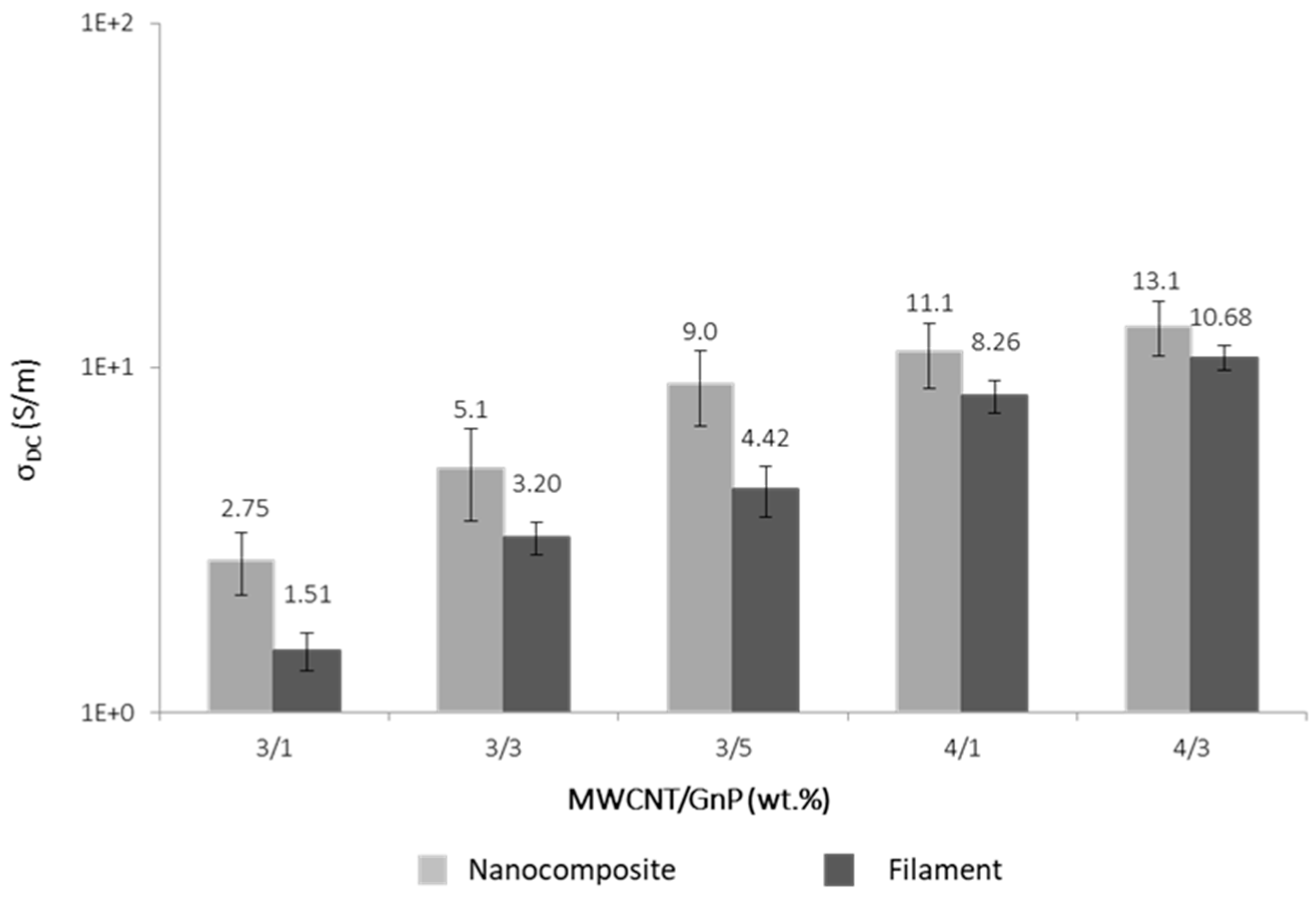

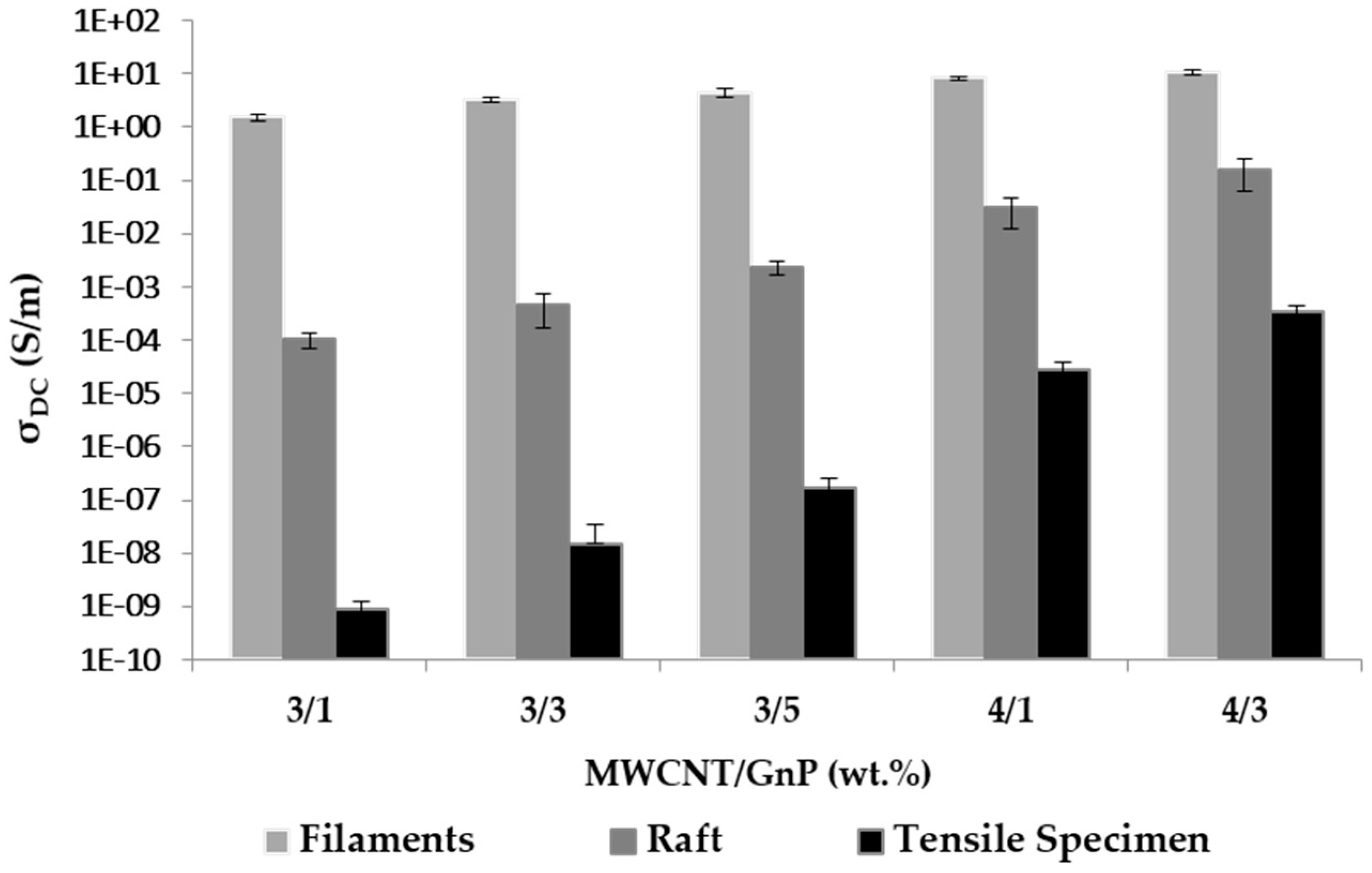

3.2.3. Electrical Conductivity

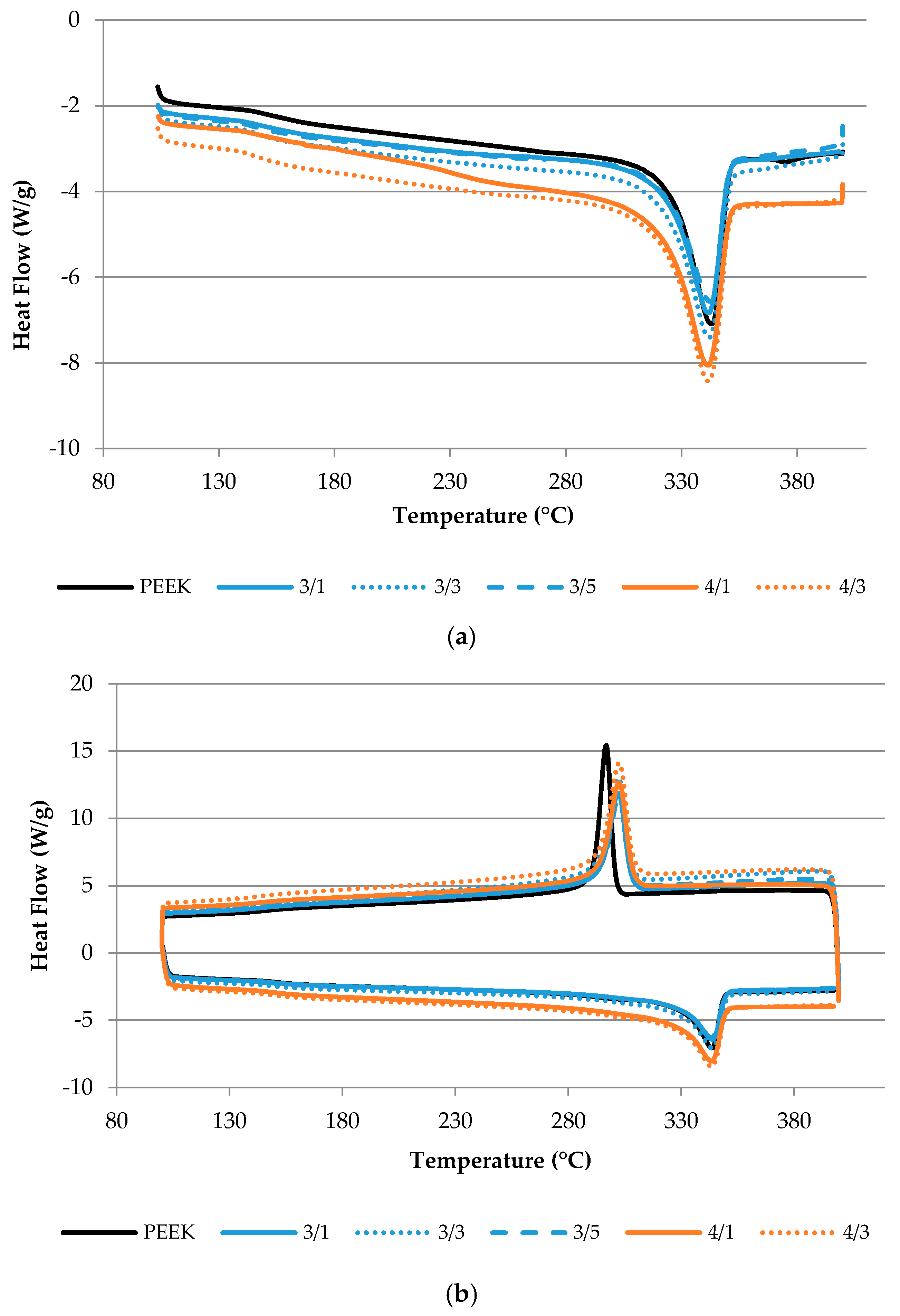

3.2.4. Differential Scanning Calorimetry

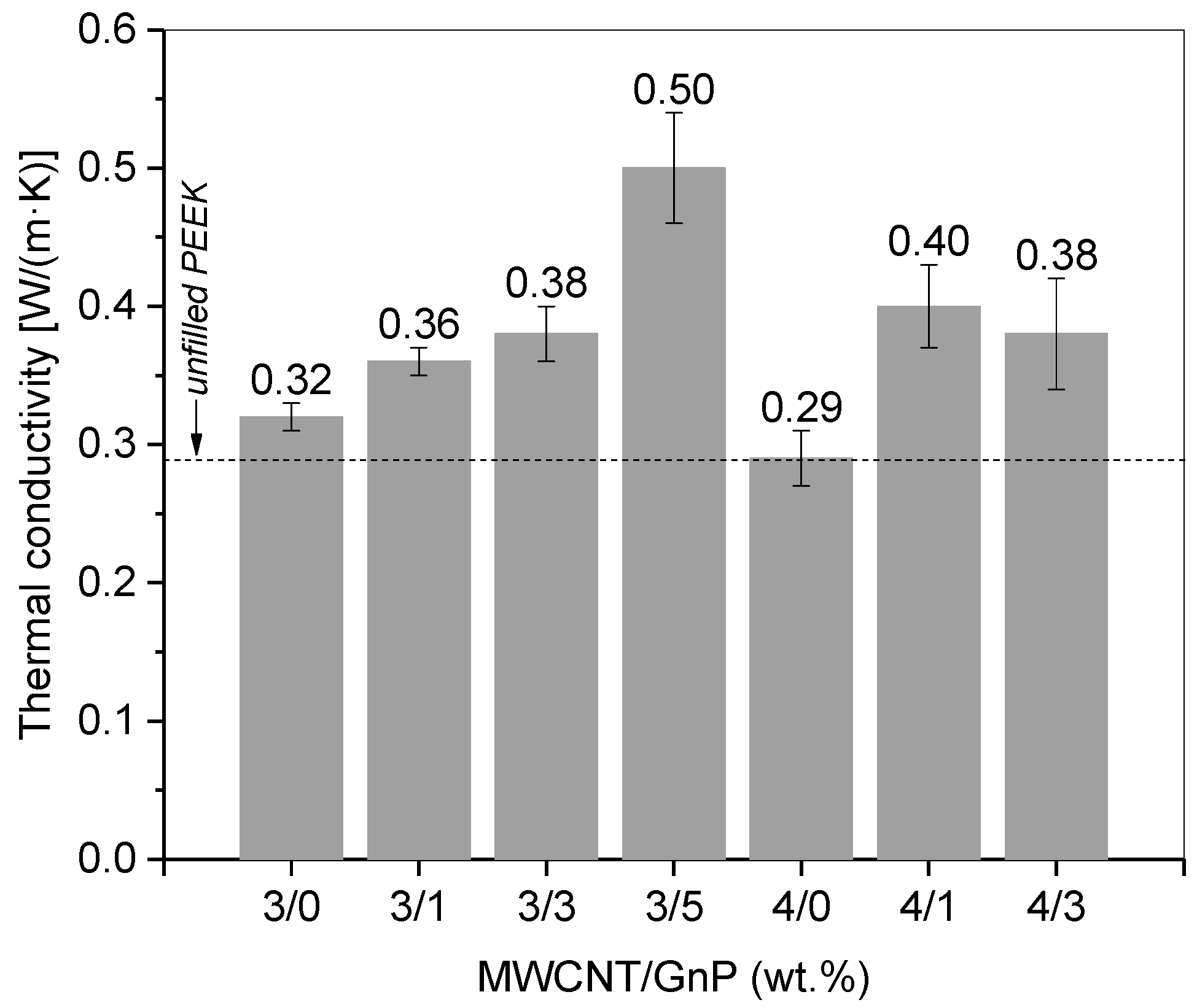

3.2.5. Thermal Conductivity

3.2.6. Thermoelectric Effects

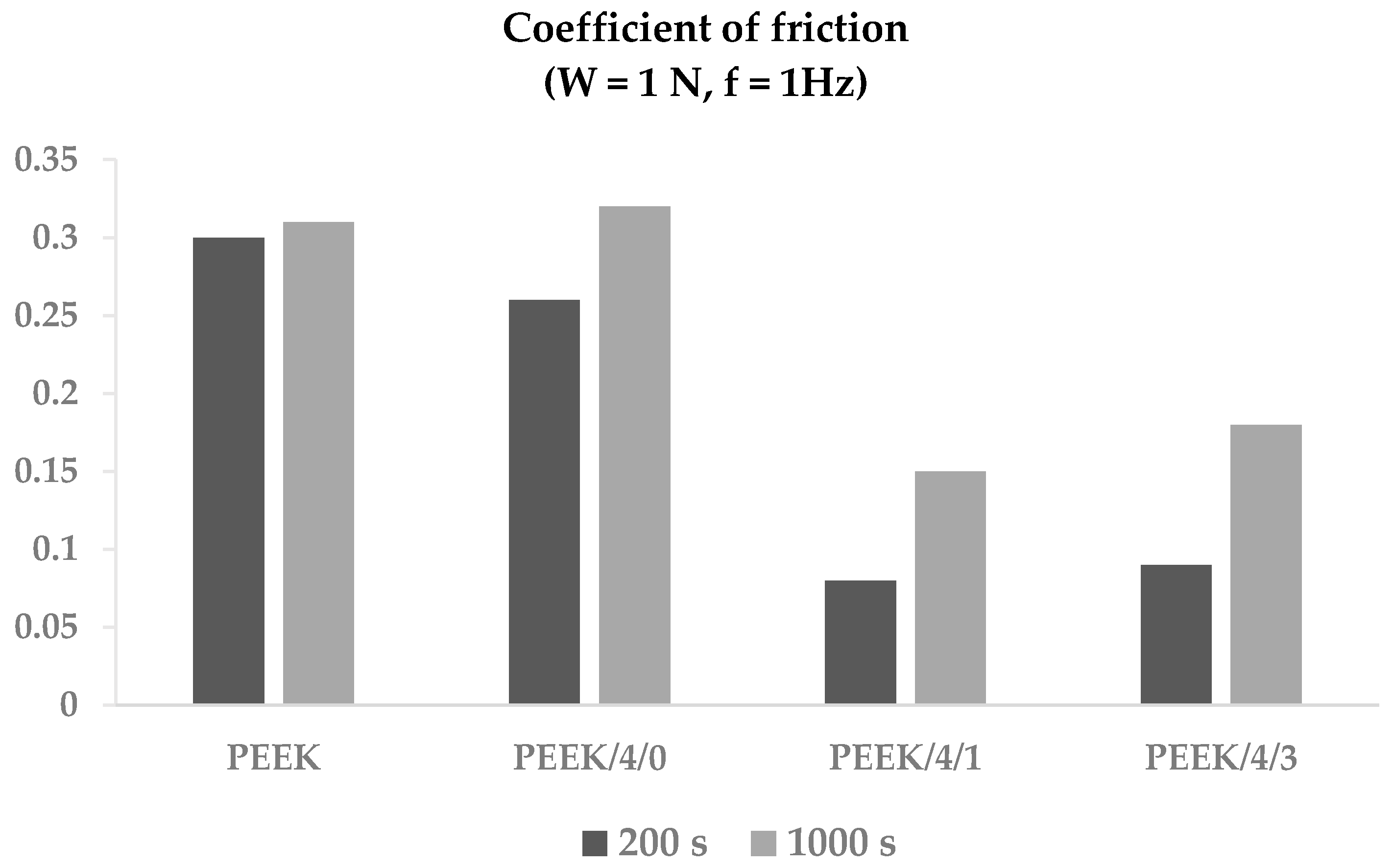

3.2.7. Tribological Properties

3.3. 3D-Printed Parts

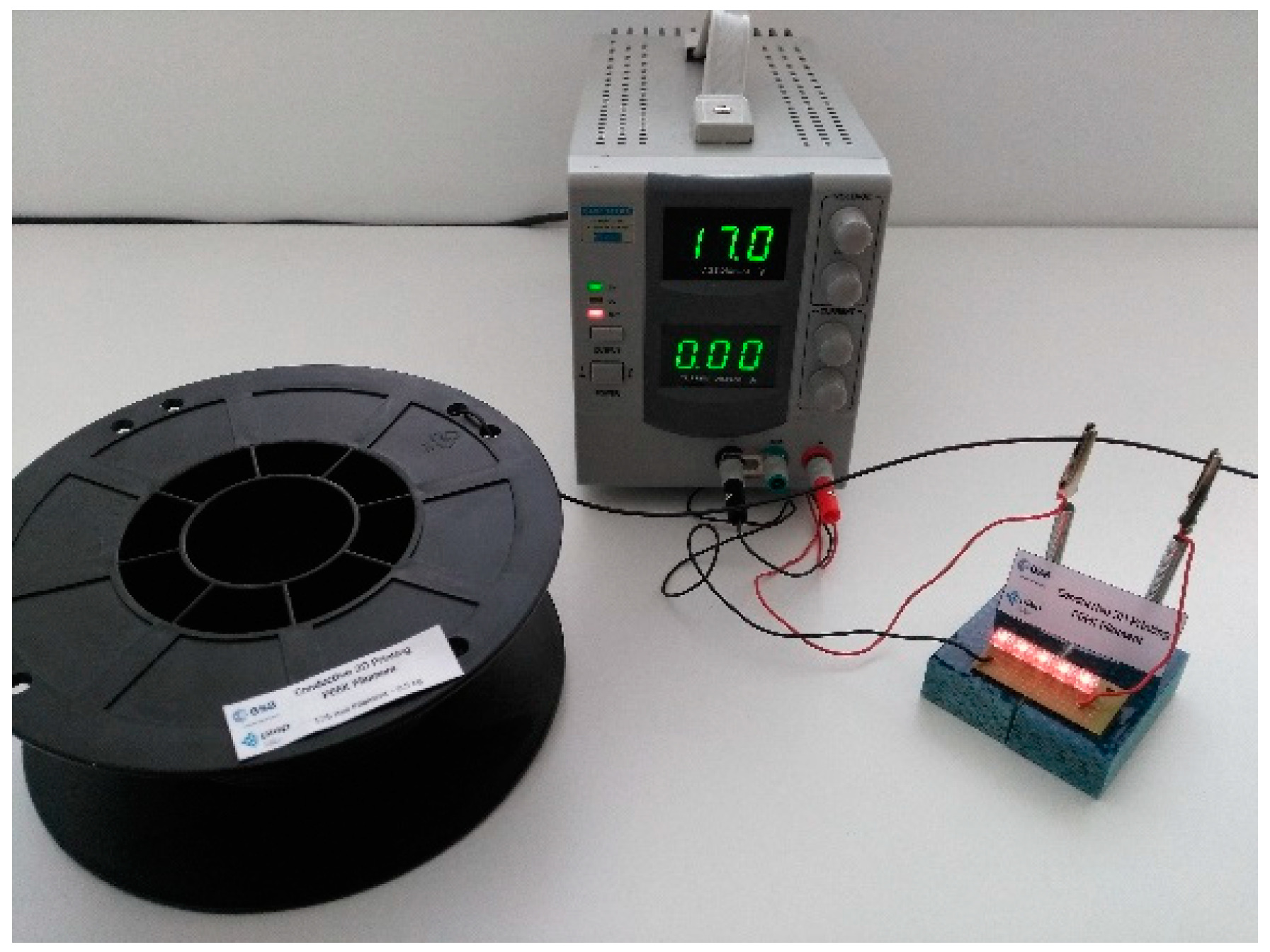

3.4. Scale up of the Filament Production

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing, 2nd ed.; Springer: New York, NY, USA, 2010. [Google Scholar]

- Standard Terminology for Additive Manufacturing—General Principles—Terminology; ISO/ASTM 52900:2015(E); International Organization for Standardization: Geneva, Switzerland, 2015.

- Dizona, J.R.C.; Espera, A.H., Jr.; Chena, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Wong, K.V.; Hernandez, A. A review of additive manufacturing. ISRN Mech. Eng. 2012, 2012, 208760. [Google Scholar] [CrossRef]

- Kim, H.; Park, E.; Kim, S.; Park, B.; Kim, N.; Lee, S. Experimental Study on Mechanical Properties of Single- and Dual-Material 3D Printed Products. Procedia Manuf. 2017, 10, 887–897. [Google Scholar] [CrossRef]

- Hertle, S.; Drexler, M.; Drummer, D. Additive Manufacturing of Poly(propylene) by Means of Melt Extrusion. Macromol. Mater. Eng. 2016, 301, 1482–1493. [Google Scholar] [CrossRef]

- Crump, S. Fast, Precise, Safe Prototype with FDM. ASME PED 1991, 50, 53–60. [Google Scholar]

- FDM 3D Printing Materials Compared. Available online: https://www.3dhubs.com/knowledge-base/fdm-3d-printing-materials-compared (accessed on 28 June 2018).

- Mohan, N.; Senthil, P.; Vinodh, S.; Jayanth, N. A review on composite materials and process parameters optimisation for the fused deposition modelling process. Virtual Phys. Prototyp. 2017, 12, 47–59. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, Y.; Wei, Y.; Li, Y. 3D printing of shape memory polymer for functional part fabrication. Int. J. Adv. Manuf. Technol. 2016, 84, 2079–2095. [Google Scholar] [CrossRef]

- Francis, V.; Jain, P.K. Experimental investigations on fused deposition modelling of polymer-layered silicate nanocomposite. Virtual Phys. Prototyp. 2016, 11, 109–121. [Google Scholar] [CrossRef]

- Dorigato, A.; Moretti, V.; Dula, S.; Unterberger, S.H.; Pegoretti, A. Electrically conductive nanocomposites for fused deposition modelling. Synth. Met. 2017, 226, 7–14. [Google Scholar] [CrossRef]

- Wei, X.; Li, D.; Jiang, W.; Gu, Z.; Wang, X.; Zhang, Z.; Sun, Z. 3D Printable Graphene Composite. Sci. Rep. 2015, 5, 11181. [Google Scholar] [CrossRef] [PubMed]

- Dul, S.; Fambri, L.; Pegoretti, A. Fused deposition modelling with ABS–graphene nanocomposites. Compos. Part A Appl. Sci. Manuf. 2016, 85, 181–191. [Google Scholar] [CrossRef]

- Patanwala, H.S.; Hong, D.; Vora, S.R.; Bognet, B.; Ma, A.W.K. The Microstructure and Mechanical Properties of 3D Printed Carbon Nanotube-Polylactic Acid Composites. Polym. Compos. 2018. [Google Scholar] [CrossRef]

- Prashantha, K.; Roger, F. Multifunctional properties of 3D printed poly(lactic acid)/graphene nanocomposites by fused deposition modeling. J. Macromol. Sci. A 2017, 54, 24–29. [Google Scholar] [CrossRef]

- Gnanasekaran, K.; Heijmans, T.; van Bennekom, S.; Woldhuis, H.; Wijnia, S.; de With, G.; Friedrich, H. 3D printing of CNT- and graphene-based conductive polymer nanocomposites by fused deposition modeling. Appl. Mater. Today 2017, 9, 21–28. [Google Scholar] [CrossRef]

- Zhu, D.; Ren, Y.; Liao, G.; Jiang, S.; Liu, F.; Guo, J.; Xu, G. Thermal and mechanical properties of polyamide 12/graphene nanoplatelets nanocomposites and parts fabricated by fused deposition modeling. J. Appl. Polym. Sci. 2017, 134, 45332. [Google Scholar] [CrossRef]

- Xiaoyong, S.; liangcheng, C.; Honglin, M.; Peng, G.; Zhanwei, B.; Cheng, L. Experimental Analysis of High Temperature PEEK Materials on 3D Printing Test. In Proceedings of the 2017 9th International Conference on Measuring Technology and Mechatronics Automation, Changsha, China, 14–15 January 2017. [Google Scholar]

- Deng, X.; Zeng, Z.; Peng, B.; Yan, S.; Ke, W. Mechanical Properties Optimization of Poly-Ether-Ether-Ketone via Fused Deposition Modeling. Materials 2018, 11, 216. [Google Scholar] [CrossRef] [PubMed]

- Berretta, S.; Davies, R.; Shyng, Y.T.; Wang, Y.; Ghita, O. Fused Deposition Modelling of high temperature polymers: Exploring CNT PEEK composites. Polym. Test. 2017, 63, 251–262. [Google Scholar] [CrossRef]

- Cicala, G.; Latteri, A.; Del Curto, B.; Lo Russo, A.; Recca, G.; Farè, S. Engineering thermoplastics for additive manufacturing: A critical perspective with experimental evidence to support functional applications. J. Appl. Biomater. Funct. Mater. 2017, 15, e10–e18. [Google Scholar] [CrossRef]

- Wenzheng, Wu.; Geng, P.; Li, G.; Zhao, D.; Zhang, H.; Zhao, J. Influence of Layer Thickness and Raster Angle on the Mechanical Properties of 3D-Printed PEEK and a Comparative Mechanical Study between PEEK and ABS. Materials 2015, 8, 5834–5846. [Google Scholar] [CrossRef]

- Kang, J.; Wang, L.; Yang, C.; Wang, L.; Yi, C.; He, J.; Li, D. Custom design and biomechanical analysis of 3D-printed PEEK rib prostheses. Biomech. Model. Mechanobiol. 2018. [Google Scholar] [CrossRef] [PubMed]

- Qingxi, H.; Lia, W.; Zhanga, H.; Liu, D.; Peng, F.; Duan, Y. Research into topology optimization and the FDM method for a space cracked membrane. Acta Astronaut. 2017, 136, 443–449. [Google Scholar]

- Li, J.; Wong, P.-S.; Kim, J.-K. Hybrid nanocomposites containing carbon nanotubes and graphite nanoplatelets. Mater. Sci. Eng. A 2008, 483, 660–663. [Google Scholar] [CrossRef]

- Kumar, S.; Sun, L.L.; Caceres, S.; Li, B.; Wood, W.; Perugini, A.; Maguire, R.G.; Zhonget, W.H. Dynamic synergy of graphitic nanoplatelets and multi-walled carbon nanotubes in polyetherimide nanocomposites. Nanotechnology 2010, 21, 105702. [Google Scholar] [CrossRef] [PubMed]

- Zhuo, D.; Wang, R.; Wu, L.; Guo, Y.; Ma, L.; Weng, Z.; Qi, J. Flame Retardancy Effects of Graphene Nanoplatelet/Carbon Nanotube Hybrid Membranes on Carbon Fiber Reinforced Epoxy Composites. J. Nanomater. 2013, 2013, 83. [Google Scholar] [CrossRef]

- Krause, B.; Pötschke, P. Electrical and Thermal Conductivity of Polypropylene Filled with Combinations of Carbon Fillers. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 1779; pp. 040003-1–040003-5. [Google Scholar]

- Sagalianov, I.; Vovchenko, L.; Matzui, L.; Lazarenko, O. Synergistic Enhancement of the Percolation Threshold in Hybrid Polymeric Nanocomposites Based on Carbon Nanotubes and Graphite Nanoplatelets. Nanoscale Res. Lett. 2017, 12, 140. [Google Scholar] [CrossRef] [PubMed]

- Perets, Y.; Aleksandrovych, L.; Melnychenko, M.; Lazarenko, O.; Vovchenko, L.; Matzui, L. The Electrical Properties of Hybrid Composites Based on Multiwall Carbon Nanotubes with Graphite Nanoplatelets. Nanoscale Res. Lett. 2017, 12, 406. [Google Scholar] [CrossRef] [PubMed]

- Prolongo, S.G.; Moriche, R.; Urena, A.; Florez, S.; Gaztelumendi, I.; Arribas, C.; Prolongo, M.G. Carbon nanotubes and graphene into thermosetting composites: Synergy and combined effect. J. Appl. Polym. Sci. 2018, 135, 46475. [Google Scholar] [CrossRef]

- European Space Agency Begins Testing 3D Printed PEEK CubeSats. Available online: http://www.3ders.org/articles/20170523-european-space-agency-begins-testing-3d-printed-peek-cubesats.html (accessed on 28 June 2018).

- Gnanaseelan, M.; Chen, Y.; Luo, J.; Krause, B.; Pionteck, J.; Pötschke, P.; Qi, H. Cellulose-carbon nanotube composite aerogels as novel thermoelectric materials. Comp. Sci. Technol. 2018, 163, 133–140. [Google Scholar] [CrossRef]

- Rowe, D.M. General Principles and Basic Considerations. In Thermoelectrics Handbook: Macro to Nano; Rowe, D.M., Ed.; CRC Press, Taylor & Francis: Boca Raton, FL, USA, 2005; pp. 1–14. ISBN 9780849322648. [Google Scholar]

- Socher, R.; Krause, B.; Müller, M.T.; Boldt, R.; Pötschke, P. The influence of matrix viscosity on MWCNT dispersion and electrical properties in different thermoplastic nanocomposites. Polymer 2012, 53, 495–504. [Google Scholar] [CrossRef]

- Pötschke, P.; Abdel-Goad, M.; Alig, I.; Dudkin, S.; Lellinger, D. Rheological and dielectrical characterization of melt mixed polycarbonate-multiwalled carbon nanotube composites. Polymer 2004, 45, 8863–8870. [Google Scholar] [CrossRef]

- Tambe, P.B.; Bhattacharyya, A.R.; Kulkarni, A.R. The Influence of Melt-Mixing Process Conditions on Electrical Conductivity of Polypropylene/Multiwall Carbon Nanotubes Composites. J. Appl. Polym. Sci. 2013, 127, 1017–1026. [Google Scholar] [CrossRef]

- Liebscher, M.; Gärtner, T.; Tzounis, L.; Mičušík, M.; Pötschke, P.; Stamm, M.; Heinrich, G.; Voit, B. Influence of the MWCNT surface functionalization on the thermoelectric properties of melt-mixed polycarbonate composites. Compos. Sci. Technol. 2014, 101, 133–138. [Google Scholar] [CrossRef]

- Pegel, S.; Pötschke, P.; Petzold, G.; Alig, I.; Dudkin, S.M.; Lellinger, D. Dispersion, Agglomeration, and Network Formation of Multiwalled Carbon Nanotubes in Polycarbonate Melts. Polymer 2008, 49, 974–984. [Google Scholar] [CrossRef]

- Jamali, S.; Paiva, M.C.; Covas, J.A. Dispersion and Re-Agglomeration Phenomena during Melt Mixing of Polypropylene with Multi-Wall Carbon Nanotubes. Polym. Test. 2013, 32, 701–707. [Google Scholar] [CrossRef]

- Vilaverde, C.; Santos, R.M.; Paiva, M.C.; Covas, J.A. Dispersion and Re-Agglomeration of Graphite Nanoplates in Polypropylene Melts under Controlled Flow Conditions. Compos. Part A Appl. Sci. Manuf. 2015, 78, 143–151. [Google Scholar] [CrossRef]

- Santos, R.M.; Vilaverde, C.; Cunha, E.; Paiva, M.C.; Covas, J.A. Probing Dispersion and Re-Agglomeration Phenomena upon Melt-Mixing of Polymer Functionalized Graphite Nanoplates. Soft Matter 2016, 12, 77–86. [Google Scholar] [CrossRef] [PubMed]

- VICTREX High Performance Polymers. Available online: https://www.victrex.com/~/media/datasheets/victrex_tds_450g.pdf (accessed on 28 June 2018).

- Sun, Y.-C.; Terakita, D.; Tseng, A.C.; Naguib, H.E. Study on the thermoelectric properties of PVDF/MWCNT and PVDF/GNP composite foam. Smart Mater. Struct. 2015, 24, 085034. [Google Scholar] [CrossRef]

- Antar, Z.; Feller, J.F.; Noël, H.; Glouannec, P.; Elleuch, K. Thermoelectric behaviour of melt processed carbon nanotube/graphite/poly(lactic acid) conductive biopolymer nanocomposites (CPC). Mater. Lett. 2012, 67, 210–214. [Google Scholar] [CrossRef]

| Nanoparticle/Manufacturer | Length/Width (μm) | Diameter/Thickness (nm) | Surface Area (m2/g) | Carbon Purity (%) | Bulk Density (g/cm3) |

|---|---|---|---|---|---|

| MWCNT NC 7000/Nanocyl, Belgium | 1.5 | 9.5 | 250–300 | >90 | 0.066 |

| xGnP-M/XG Science Inc, USA | 15 | 6–8 | 120–150 | >99.5 | 0.03–0.10 |

| Compositiong | Torque (%) | Pressure (Bar) | Melt Temperature (°C) | |

|---|---|---|---|---|

| Polyetheretherketone (PEEK) | 30–32 | 21–24 | 368 | |

| MWCNT (wt %)/GnP (wt %) | 1/0 | 35 | 25 | 369 |

| 2/0 | 35 | 28 | 372 | |

| 3/0 | 38 | 28 | 376 | |

| 4/0 | 40 | 32 | 379 | |

| 6/0 | 42 | 37 | 386 | |

| 3/1 | 37–39 | 25–28 | 376 | |

| 3/2 | 36–40 | 23–28 | 378 | |

| 3/3 | 36–40 | 23–30 | 379 | |

| 3/4 | 36–39 | 26–32 | 379 | |

| 3/5 | 37–38 | 28–30 | 380 | |

| 3/6 | 37–39 | 29–32 | 381 | |

| Composition | E (GPa) | σy (MPa) | UTS (MPa) | εbreak (%) |

|---|---|---|---|---|

| PEEK | 1.48 ± 0.1 | 85± 2 | - | >400 |

| PEEK/3/1 | 1.9 ± 0.1 | 84 ± 1 | 78.6 ± 0.7 | 42 ± 3 |

| PEEK/3/3 | 1.7 ± 0.1 | 88 ± 3 | 82 ± 4 | 39 ± 5 |

| PEEK/3/5 | 1.8 ± 0.1 | 92 ± 1 | 89 ± 1 | 27 ± 7 |

| PEEK/4/1 | 1.6 ± 0.1 | 90 ± 3 | 86 ± 3 | 53 ± 4 |

| PEEK/4/3 | 1.60 ± 0.1 | 92 ± 1 | 88 ± 1 | 53 ± 8 |

| Material | First Heating | Second Heating | Cooling | ||||

|---|---|---|---|---|---|---|---|

| Tm (°C) | ∆H (J/g) | Tm (°C) | ∆H (J/g) | Tm (°C) | ∆H (J/g) | ||

| PEEK | 342.9 ± 0.2 | 36.0 ± 2 | 343.4 ± 0.2 | 35.0 ± 1.0 | 296.9 ± 0.2 | 40.0 ± 2.0 | |

| MWCNT/GnP Ratio | 3/1 | 341.9 ± 0.03 | 37.0 ± 0.5 | 343.8 ± 0.1 | 37.8 ± 0.1 | 302.1 ± 0.1 | 36.3 ± 0.1 |

| 3/3 | 342.2 ± 0.1 | 37.3 ± 0.1 | 343.6 ± 0.1 | 39.0 ± 1.0 | 302.1 ± 0.2 | 36.0 ± 1.0 | |

| 3/5 | 343.0 ± 1.0 | 38.0 ± 1.0 | 343.5 ± 0.2 | 38.5 ± 0.7 | 302.4 ± 0.1 | 36.4 ± 0.4 | |

| 4/1 | 341.6 ± 0.1 | 40.0 ± 1.0 | 343.4 ± 0.04 | 41.1 ± 0.3 | 302.4 ± 0.1 | 39.2 ± 0.5 | |

| 4/3 | 341.9 ± 0.1 | 39.0 ± 1.0 | 343.2 ± 0.3 | 40.9 ± 0.9 | 302.5 ± 0.2 | 39.0 ± 1.0 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gonçalves, J.; Lima, P.; Krause, B.; Pötschke, P.; Lafont, U.; Gomes, J.R.; Abreu, C.S.; Paiva, M.C.; Covas, J.A. Electrically Conductive Polyetheretherketone Nanocomposite Filaments: From Production to Fused Deposition Modeling. Polymers 2018, 10, 925. https://doi.org/10.3390/polym10080925

Gonçalves J, Lima P, Krause B, Pötschke P, Lafont U, Gomes JR, Abreu CS, Paiva MC, Covas JA. Electrically Conductive Polyetheretherketone Nanocomposite Filaments: From Production to Fused Deposition Modeling. Polymers. 2018; 10(8):925. https://doi.org/10.3390/polym10080925

Chicago/Turabian StyleGonçalves, Jordana, Patrícia Lima, Beate Krause, Petra Pötschke, Ugo Lafont, José R. Gomes, Cristiano S. Abreu, Maria C. Paiva, and José A. Covas. 2018. "Electrically Conductive Polyetheretherketone Nanocomposite Filaments: From Production to Fused Deposition Modeling" Polymers 10, no. 8: 925. https://doi.org/10.3390/polym10080925

APA StyleGonçalves, J., Lima, P., Krause, B., Pötschke, P., Lafont, U., Gomes, J. R., Abreu, C. S., Paiva, M. C., & Covas, J. A. (2018). Electrically Conductive Polyetheretherketone Nanocomposite Filaments: From Production to Fused Deposition Modeling. Polymers, 10(8), 925. https://doi.org/10.3390/polym10080925