Fast Switchable Dual-Model Grating by Using Polymer-Stabilized Sphere Phase Liquid Crystal

Abstract

:1. Introduction

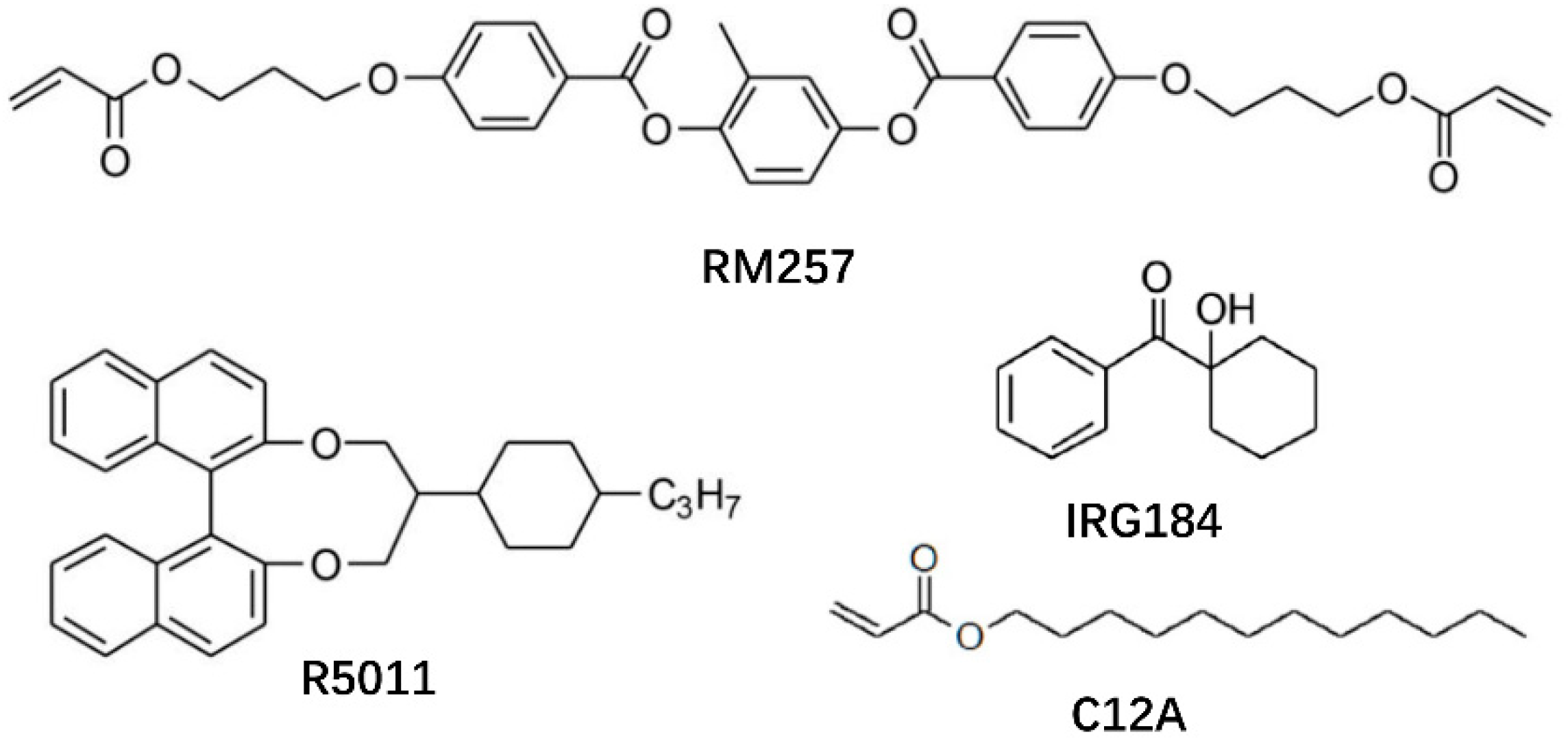

2. Materials and Methods

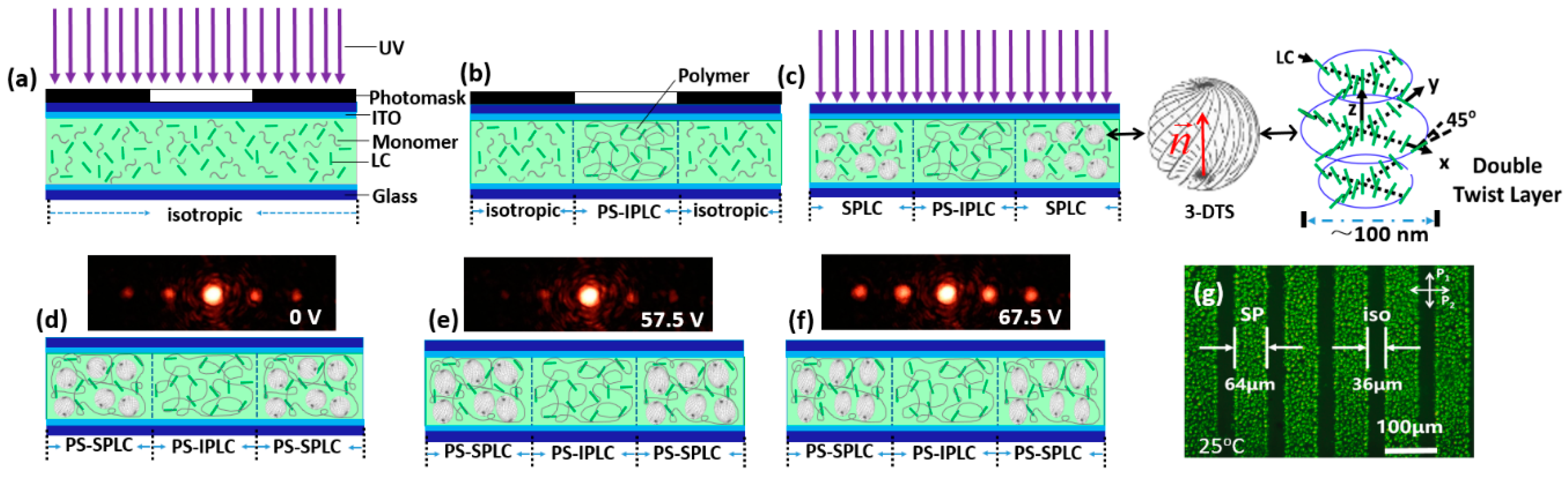

2.1. Method of Fabricating Liquid Crystal Gratings

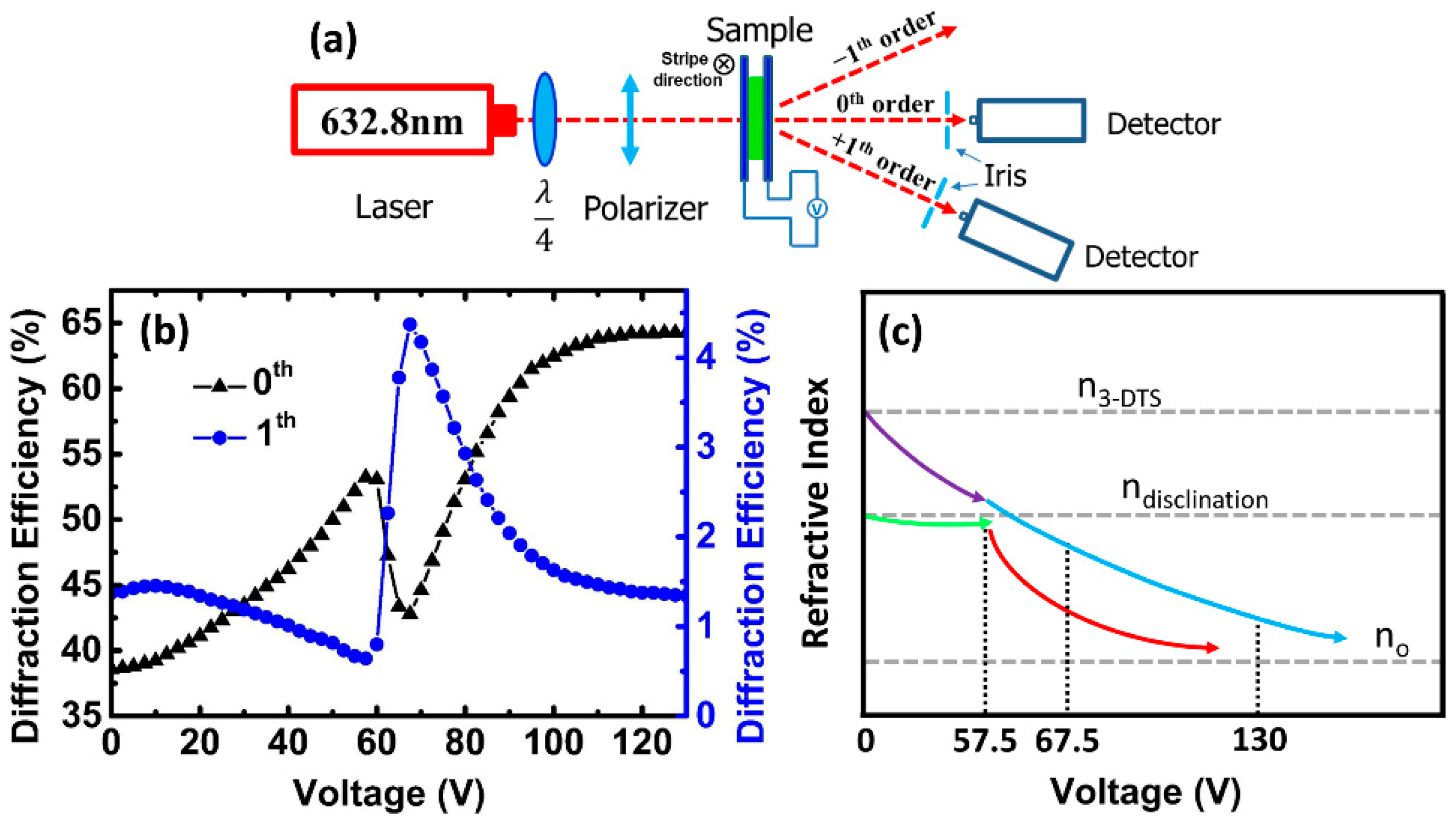

2.2. Characterization

2.3. Fundamentals of LC Gratings

3. Results

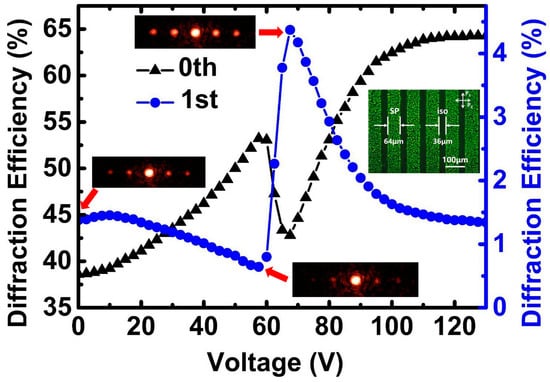

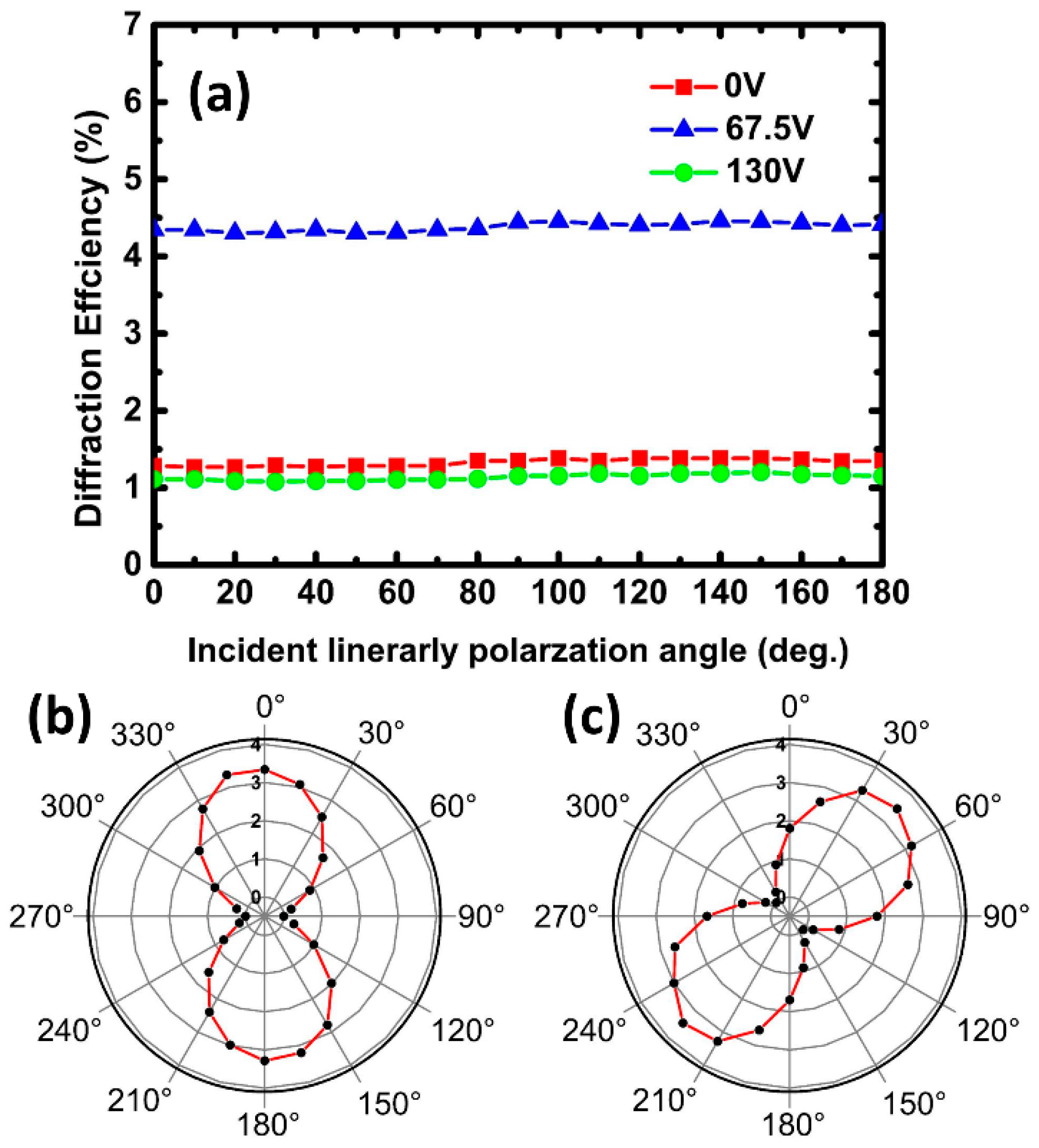

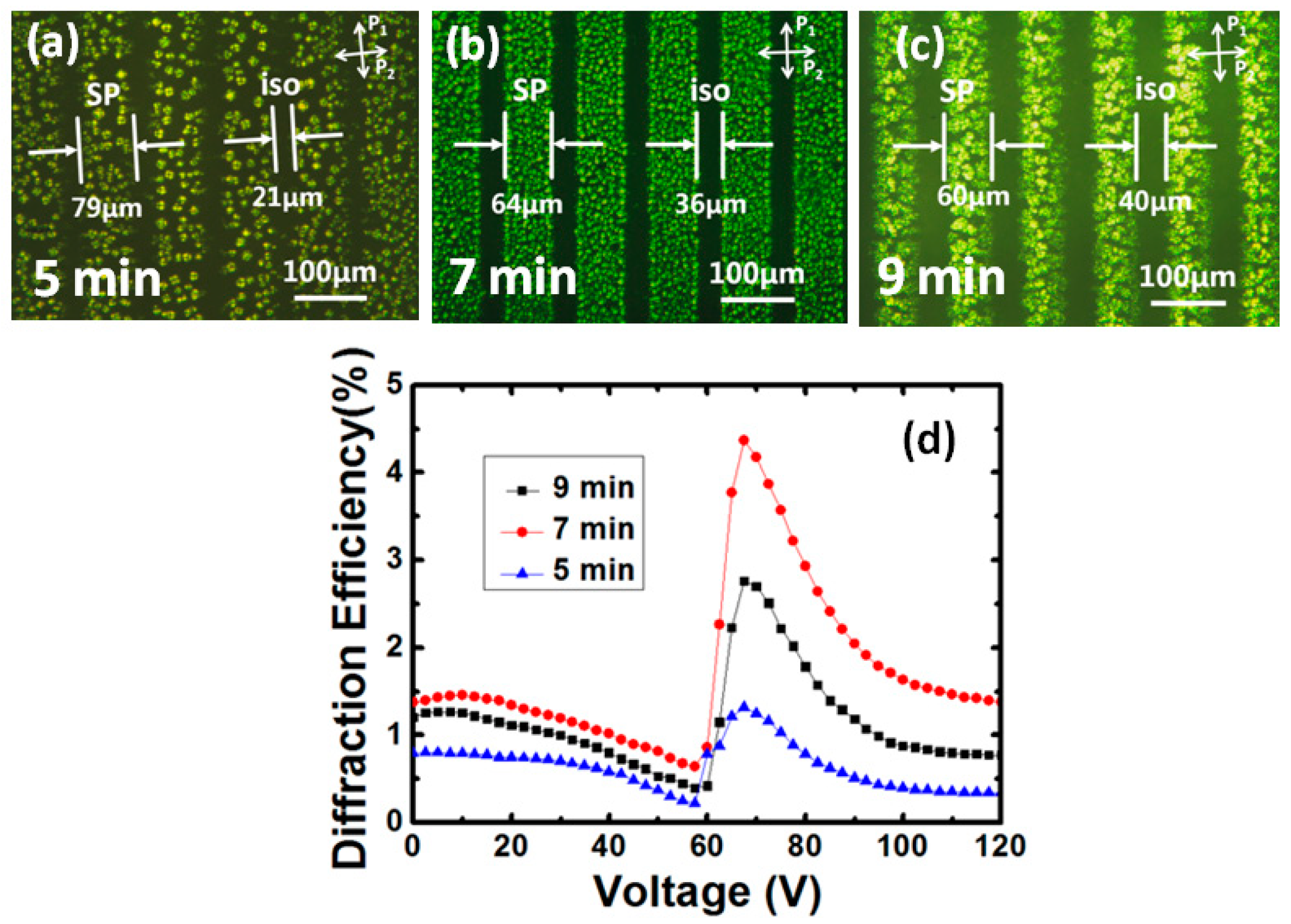

3.1. Diffraction Efficiency of LC Gratings

3.2. Diffraction Efficiency of LC Gratings

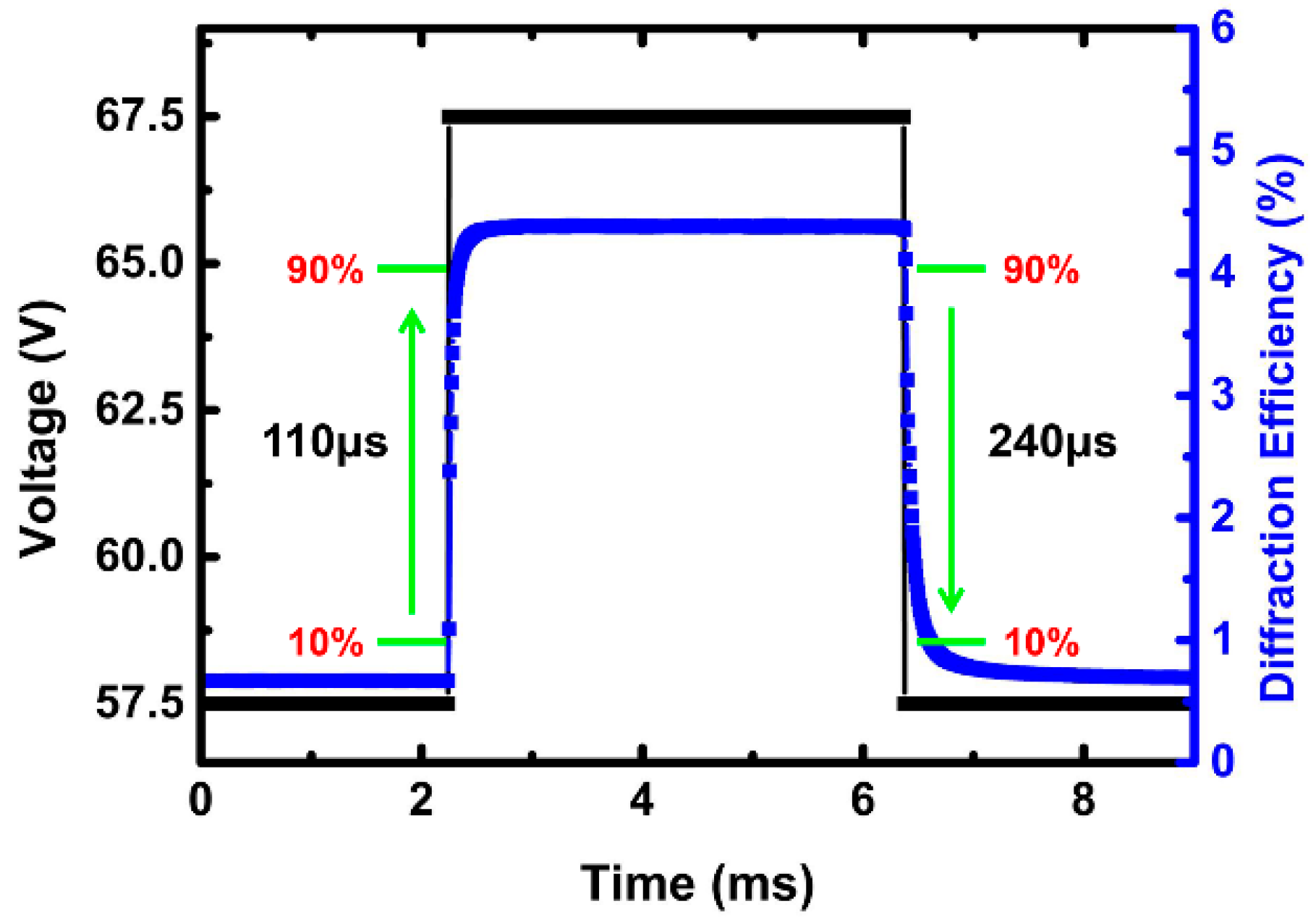

3.3. Response Time of LC Gratings

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.A.; Jin, T.; He, L.C.; Chu, Z.H.; Guo, T.L.; Zhou, X.T.; Lin, Z.X. Controllable liquid crystal gratings for an adaptive 2d/3d auto-stereoscopic display. Opt. Commun. 2017, 384, 16–24. [Google Scholar] [CrossRef]

- Hirabayashi, K.; Kurokawa, T. Liquid crystal devices for optical communication and information processing systems. Liq. Cryst. 1993, 14, 307–317. [Google Scholar] [CrossRef]

- Chen, H.W.; Weng, Y.S.; Xu, D.; Tabiryan, N.V.; Wu, S.T. Beam steering for virtual/augmented reality displays with a cycloidal diffractive waveplate. Opt. Express. 2016, 24, 7287–7298. [Google Scholar] [CrossRef] [PubMed]

- Apter, B.; Efron, U.; Bahat-Treidel, E. On the fringing-field effect in liquid-crystal beam-steering devices. Appl. Opt. 2004, 43, 11–19. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Li, Y.; Wu, S.T. High-efficiency and fast-response tunable phase grating using a blue phase liquid crystal. Opt. Lett. 2011, 36, 1404–1406. [Google Scholar] [CrossRef] [PubMed]

- Brown, C.V.; Kriezis, E.E.; Elston, S.J. Optical diffraction from a liquid crystal phase grating. J. Appl. Phys. 2002, 91, 3495–3500. [Google Scholar] [CrossRef]

- Zhu, J.L.; Lu, J.G.; Qiang, J.; Zhong, E.W.; Ye, Z.C. 1D/2D switchable grating based on field-induced polymer stabilized blue phase liquid crystal. J. Appl. Phys. 2012, 111, 033101. [Google Scholar] [CrossRef]

- Chen, J.; Bos, P.J.; Vithana, H.; Johnson, D.L. An electro-optically controlled liquid crystal diffraction grating. Appl. Phys. Lett. 1995, 67, 2588–2590. [Google Scholar] [CrossRef]

- Lin, Y.T.; Jau, H.C.; Lin, T.H. Polarization-independent rapidly responding phase grating based on hybrid blue phase liquid crystal. J. Appl. Phys. 2013, 113, 063103. [Google Scholar] [CrossRef]

- Avci, N.; Hwang, S.J. Electrically tunable polarisation-independent blue-phase liquid crystal binary phase grating via phase-separated composite films. Liq. Cryst. 2017, 44, 1559–1565. [Google Scholar] [CrossRef]

- Yuan, Y.C.; Li, Y.; Chen, C.P.; Liu, S.X.; Rong, N.; Li, W.H.; Li, X.; Zhou, P.C.; Lu, J.G.; Liu, R.I.; et al. Polymer-stabilized blue-phase liquid crystal grating cured with interfered visible light. Opt. Express 2015, 23, 20007–20013. [Google Scholar] [CrossRef] [PubMed]

- Gu, L.L.; Chen, X.N.; Jiang, W.; Howley, B.; Chen, R.T. Fringing-field minimization in liquid-crystal-based high-resolution switchable gratings. Appl. Phys. Lett. 2005, 87, 201106. [Google Scholar] [CrossRef]

- Wang, X.Q.; Wu, S.B.; Yang, W.Q.; Yuan, C.L.; Li, X.; Liu, Z.; Tseng, M.C.; Chigrinov, V.G.; Kwok, H.S.; Shen, D.; et al. Light-Driven Liquid Crystal Circular Dammann Grating Fabricated by a Micro-Patterned Liquid Crystal Polymer Phase Mask. Polymers 2017, 9, 380. [Google Scholar] [CrossRef]

- Subacius, D.; Shiyanovskii, S.V.; Bos, P.; Lavrentovich, O.D. Cholesteric gratings with field-controlled period. Appl. Phys. Lett. 1997, 71, 3323–3325. [Google Scholar] [CrossRef]

- Zhang, L.L.; Wang, L.; Hiremath, U.S.; Bisoyi, H.K.; Nair, G.G.; Yelamaggad, C.V.; Urbas, A.M.; Bunning, T.J.; Li, Q. Dynamic Orthogonal Switching of a Thermoresponsive Self-Organized Helical Superstructure. Adv. Mater. 2017, 29, 1700676. [Google Scholar] [CrossRef] [PubMed]

- Stracke, A.; Wendorff, J.H.; Goldmann, D.; Janietz, D.; Stiller, B. Gain effects in optical storage: Thermal induction of a surface relief grating in a smectic liquid crystal. Adv. Mater. 2000, 12, 282–285. [Google Scholar] [CrossRef]

- Li, Y.; Huang, S.J.; Zhou, P.C.; Liu, S.X.; Lu, J.G.; Li, X.; Su, Y.K. Polymer-Stabilized Blue Phase Liquid Crystals for Photonic Applications. Adv. Mater. Technol. 2016, 1, 1600102. [Google Scholar] [CrossRef]

- Yan, J.; Xing, Y.F.; Li, Q. Dual-period tunable phase grating using polymer stabilized blue phase liquid crystal. Opt. Lett. 2015, 40, 4520–4523. [Google Scholar] [CrossRef] [PubMed]

- Hu, W.; Srivastava, A.; Xu, F.; Sun, J.T.; Lin, X.W.; Cui, H.Q.; Chigrinov, V.; Lu, Y.Q. Liquid crystal gratings based on alternate TN and PA photoalignment. Opt. Express. 2012, 20, 5384–5391. [Google Scholar] [CrossRef] [PubMed]

- Sun, P.Z.; Liu, Z.; Wang, W.; Ma, L.L.; Shen, D.; Hu, W.; Lu, Y.Q.; Chen, L.J.; Zheng, Z.G. Light-reconfigured waveband-selective diffraction device enabled by micro-patterning of a photoresponsive self-organized helical superstructure. J. Mater. Chem. C 2016, 4, 9325. [Google Scholar] [CrossRef]

- Wang, L.; Chen, D.; Gutierrez-Cuevas, K.G.; Bisoyi, H.K.; Fan, J.; Zola, R.S.; Li, G.Q.; Urbas, A.M.; Bunning, T.J.; Weitz, D.A.; et al. Optically Reconfigurable Chiral Microspheres of Self-Organized Helical Superstructures with Handedness Inversion. Mater. Horiz. 2017, 4, 1190–1195. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Li, Q. Stimuli-Directing Self-Organized 3D Liquid-Crystalline Nanostructures: From Materials Design to Photonic Applications. Adv. Funct. Mater. 2016, 26, 10–28. [Google Scholar] [CrossRef]

- Wang, L.; Dong, H.; Li, Y.N.; Xue, C.M.; Sun, L.D.; Yan, C.H.; Li, Q. Reversible Near-Infrared Light Directed Reflection in a Self-Organized Helical Superstructure Loaded with Upconversion Nanoparticles. J. Am. Chem. Soc. 2014, 136, 4480–4483. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Bisoyi, H.K.; Zheng, Z.G.; Gutierrez-Cuevas, K.G.; Singh, G.; Kumar, S.; Bunning, T.J.; Li, Q. Stimuli-directed self-organized chiral superstructures for adaptive window senabled by mesogen-functionalized graphene. Mater. Today 2017, 20, 230–237. [Google Scholar] [CrossRef]

- Wang, L.; Li, Q. Photochromism into nanosystems: Towardslighting up the future nanoworld. Chem. Soc. Rev. 2018, 47, 1044–1097. [Google Scholar] [CrossRef] [PubMed]

- Wang, L. Self-activating liquid crystal devices for smart laser protection. Liq. Cryst. 2016, 43, 2062–2078. [Google Scholar] [CrossRef]

- Zhu, J.L.; Ni, S.B.; Chen, C.P.; Wu, D.Q.; Song, X.L.; Chen, C.Y.; Lu, J.G.; Su, Y.K.; Shieh, H.P. Chiral-induced self-assembly sphere phase liquid crystal with fast switching time. Appl. Phys. Lett. 2014, 104, 091116. [Google Scholar] [CrossRef]

- Chen, Z.P.; Hu, D.C.; Chen, X.W.; Zheng, D.R.; Lee, Y.J.; Chen, X.X.; Lu, J.G. Templated Sphere Phase Liquid Crystals for Tunable Random Lasing. Nanomaterials 2017, 7, 392. [Google Scholar] [CrossRef] [PubMed]

- Gao, L.; Gao, Y.P.; Du, X.W.; Ye, W.J.; Xu, Q.; Zhu, J.L.; Han, W.M.; Chen, C.Y.; Sun, Y.B. Electro-optical performance of polymer-stabilized sphere phase liquid crystal displays. Opt. Express 2017, 25, 18009–18016. [Google Scholar] [CrossRef] [PubMed]

- Magnusson, R.; Gaylord, T.K. Diffraction efficiencies of thin phase gratings with arbitrary grating space. J. Opt. Soc. Am. 1978, 68, 806–809. [Google Scholar] [CrossRef]

- Yan, J.; Li, Q.; Hu, K. Polarization independent blue phase liquid crystal gratings based on periodic polymer slices structure. J. Appl. Phys. 2013, 114, 153104. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Du, X.; Guo, P.; Zhu, J.; Ye, W.; Xu, Q.; Sun, Y. Fast Switchable Dual-Model Grating by Using Polymer-Stabilized Sphere Phase Liquid Crystal. Polymers 2018, 10, 884. https://doi.org/10.3390/polym10080884

Li X, Du X, Guo P, Zhu J, Ye W, Xu Q, Sun Y. Fast Switchable Dual-Model Grating by Using Polymer-Stabilized Sphere Phase Liquid Crystal. Polymers. 2018; 10(8):884. https://doi.org/10.3390/polym10080884

Chicago/Turabian StyleLi, Xuan, Xiaowei Du, Peiyun Guo, Jiliang Zhu, Wenjiang Ye, Qin Xu, and Yubao Sun. 2018. "Fast Switchable Dual-Model Grating by Using Polymer-Stabilized Sphere Phase Liquid Crystal" Polymers 10, no. 8: 884. https://doi.org/10.3390/polym10080884

APA StyleLi, X., Du, X., Guo, P., Zhu, J., Ye, W., Xu, Q., & Sun, Y. (2018). Fast Switchable Dual-Model Grating by Using Polymer-Stabilized Sphere Phase Liquid Crystal. Polymers, 10(8), 884. https://doi.org/10.3390/polym10080884