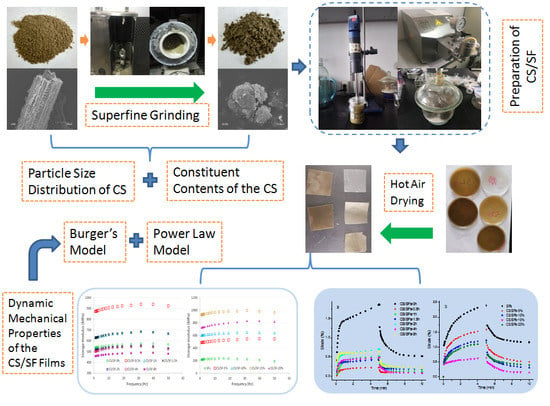

Processing of Superfine Grinding Corn Straw Fiber-Reinforced Starch Film and the Enhancement on Its Mechanical Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Preparation of Corn Straw Samples with Different Particle Sizes

2.3. Determination of Structural Carbohydrate Contents

2.4. Particle Size Distribution

2.5. Scanning Electron Microscopy (SEM)

2.6. Preparation of CS/SF Obtained with Different Superfine Grinding Periods or with Variations in Loading

2.7. Measurement of the Basic Properties of CS/SF

2.8. Frequency Sweep Test

2.9. Creep and Creep-Recovery Measurements

2.10. Burger’s Model

2.11. Statistical Analysis

3. Results and Discussion

3.1. The Basic Properties of the Corn Straws with Different Particle Sizes

3.1.1. The Constituent Contents of the Corn Straws with Different Particle Sizes

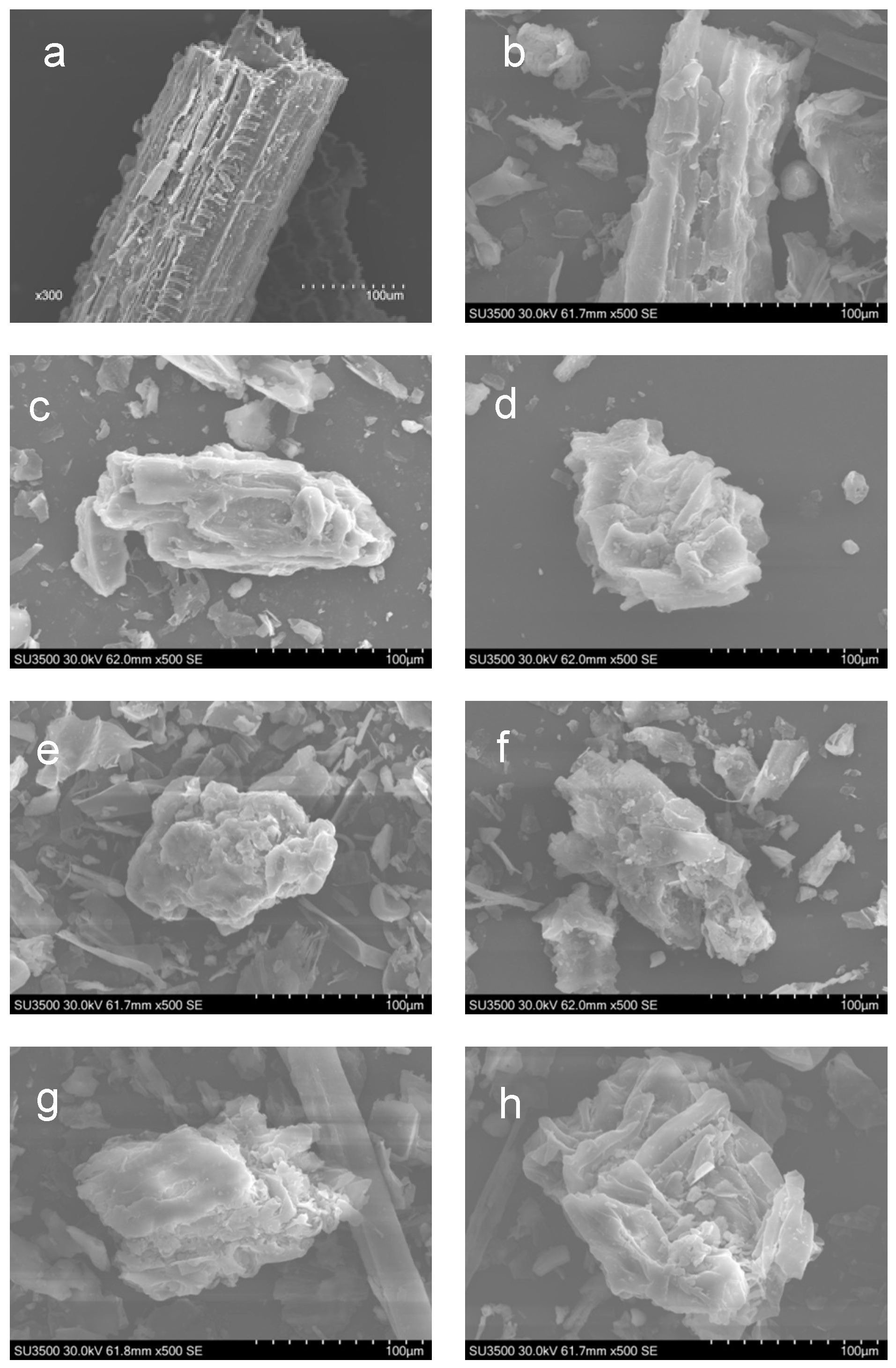

3.1.2. Morphological Properties of CS of Various Particle Sizes

3.1.3. Particle Size Distribution of CS

3.2. Properties of the Starch-Based Films Blended with CS

3.3. Frequency Sweep Properties of the CS/SF Films with Different Particle Sizes or Addition Amounts

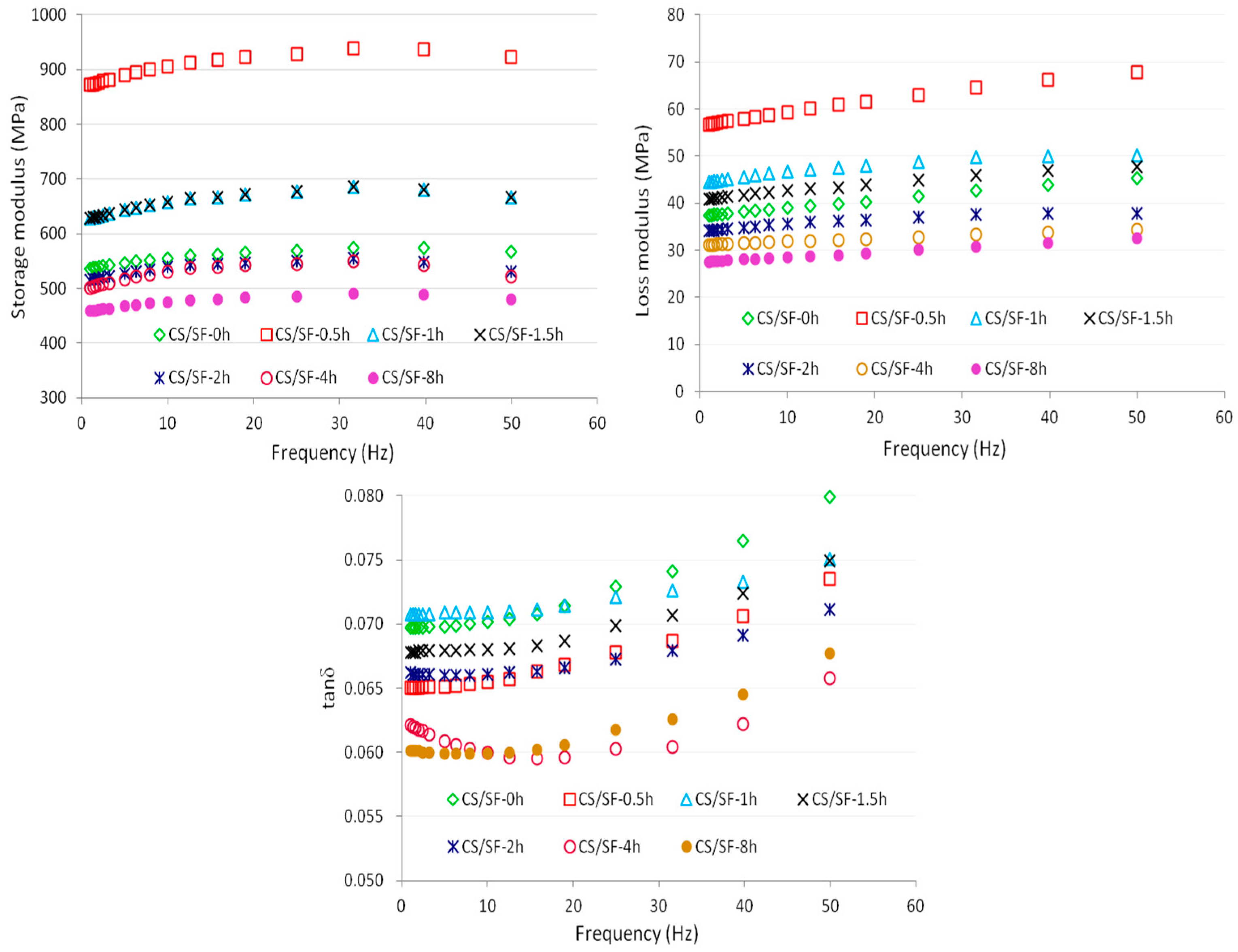

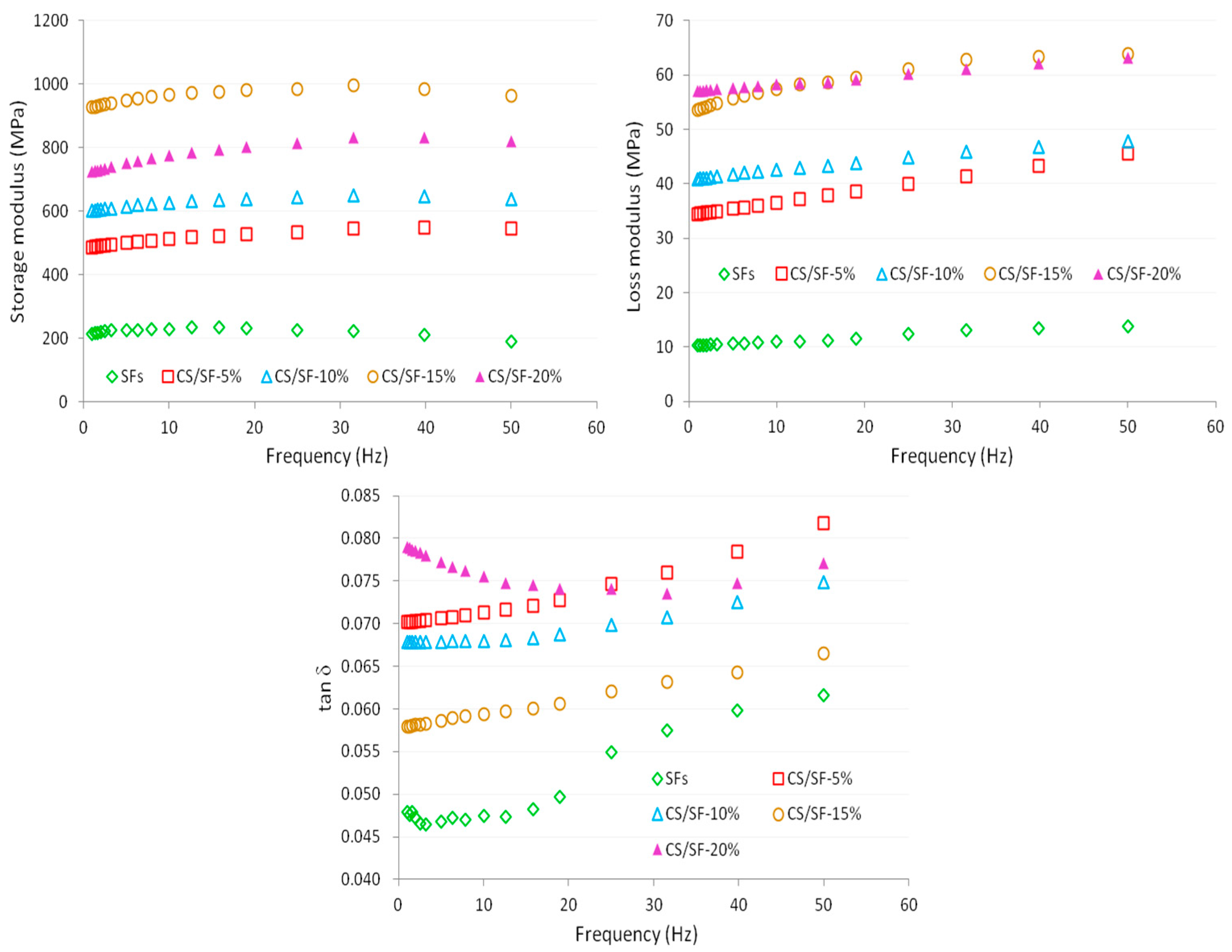

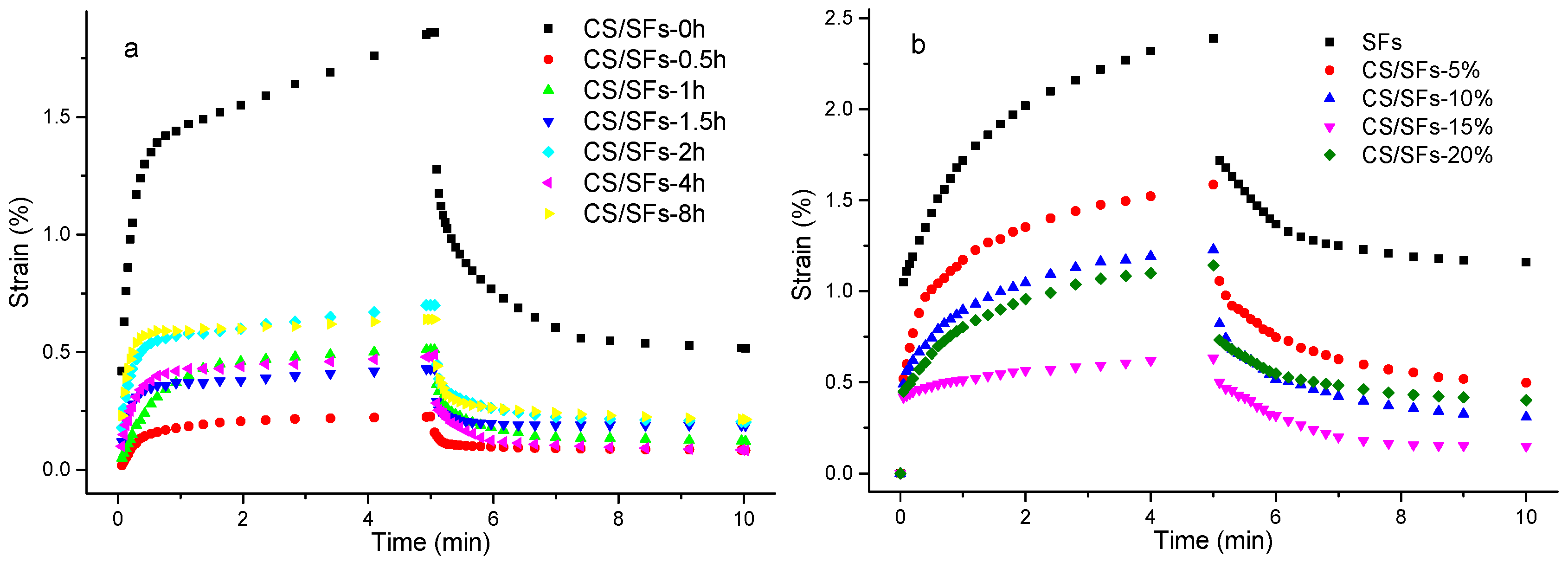

3.4. Dynamic Mechanical Properties of the CS/SF Films with Different Particle Sizes or Addition Amounts

3.5. Burger’s Model Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xu, W.; Fu, S.; Yang, Z.; Lu, J.; Guo, R. Improved methane production from corn straw by microaerobic pretreatment with a pure bacteria system. Bioresour. Technol. 2018, 259, 18. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Cheng, L.; Yin, C.; Lebailly, P.; Azadi, H. Urban residents’ willingness to pay for corn straw burning ban in Henan, China: Application of payment card. J. Clean. Prod. 2018, 193, 471–478. [Google Scholar] [CrossRef]

- Qi, Y.Z.; Zhen, W.C.; Li, H.Y. Allelopathy of decomposed maize straw products on three soil-born diseases of wheat and the analysis by GC-MS. J. Integr. Agric. 2015, 14, 88–97. [Google Scholar] [CrossRef]

- Hou, X.-Y.; Wang, F.-X.; Han, J.-J.; Kang, S.-Z.; Feng, S.-Y. Duration of plastic mulch for potato growth under drip irrigation in an arid region of Northwest China. Agric. For. Meteorol. 2010, 150, 115–121. [Google Scholar] [CrossRef]

- Barragán, D.; Pelacho, A.; Martin-Closas, L. Degradation of agricultural biodegradable plastics in the soil under laboratory conditions. Soil Res. 2016, 54, 216–224. [Google Scholar] [CrossRef]

- Hayes, D.G.; Wadsworth, L.C.; Sintim, H.Y.; Flury, M.; English, M.; Schaeffer, S.; Saxton, A.M. Effect of diverse weathering conditions on the physicochemical properties of biodegradable plastic mulches. Polym. Test. 2017, 62, 454–467. [Google Scholar] [CrossRef]

- Zhang, S.; Li, P.; Yang, X.; Wang, Z.; Chen, X. Effects of tillage and plastic mulch on soil water, growth and yield of spring-sown maize. Soil Tillage Res. 2011, 112, 92–97. [Google Scholar] [CrossRef]

- Russo, M.A.; O’Sullivan, C.; Rounsefell, B.; Halley, P.J.; Truss, R.; Clarke, W.P. The anaerobic degradability of thermoplastic starch: Polyvinyl alcohol blends: Potential biodegradable food packaging materials. Bioresour. Technol. 2009, 100, 1705–1710. [Google Scholar] [CrossRef] [PubMed]

- Gao, F.; Li, D.; Bi, C.-H.; Mao, Z.-H.; Adhikari, B. Preparation and characterization of starch crosslinked with sodium trimetaphosphate and hydrolyzed by enzymes. Carbohydr. Polym. 2014, 103, 310–318. [Google Scholar] [CrossRef] [PubMed]

- Kaith, B.; Jindal, R.; Jana, A.; Maiti, M. Development of corn starch based green composites reinforced with Saccharum spontaneum L fiber and graft copolymers—Evaluation of thermal, physico-chemical and mechanical properties. Bioresour. Technol. 2010, 101, 6843–6851. [Google Scholar] [CrossRef] [PubMed]

- Niazi, M.B.K.; Zijlstra, M.; Broekhuis, A.A. Influence of plasticizer with different functional groups on thermoplastic starch. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Wu, M.; Wang, L.-J.; Li, D.; Mao, Z.-H.; Adhikari, B. Effect of flaxseed meal on the dynamic mechanical properties of starch-based films. J. Food Eng. 2013, 118, 365–370. [Google Scholar] [CrossRef]

- Yang, J.; Tang, K.; Qin, G.; Chen, Y.; Peng, L.; Wan, X.; Xiao, H.; Xia, Q. Hydrogen bonding energy determined by molecular dynamics simulation and correlation to properties of thermoplastic starch films. Carbohydr. Polym. 2017, 166, 256–263. [Google Scholar] [CrossRef] [PubMed]

- Basiak, E.; Lenart, A.; Debeaufort, F. How glycerol and water contents affect the structural and functional properties of starch-based edible films. Polymers 2018, 10, 412. [Google Scholar] [CrossRef]

- Li, M.; Li, D.; Wang, L.-J.; Adhikari, B. Creep behavior of starch-based nanocomposite films with cellulose nanofibrils. Carbohydr. Polym. 2015, 117, 957–963. [Google Scholar] [CrossRef] [PubMed]

- Cao, C.; Yang, Z.; Han, L.; Jiang, X.; Ji, G. Study on in situ analysis of cellulose, hemicelluloses and lignin distribution linked to tissue structure of crop stalk internodal transverse section based on FTIR microspectroscopic imaging. Cellulose 2015, 22, 139–149. [Google Scholar] [CrossRef]

- Kanmani, P.; Aravind, J.; Kamaraj, M.; Sureshbabu, P.; Karthikeyan, S. Environmental applications of chitosan and cellulosic biopolymers: A comprehensive outlook. Bioresour. Technol. 2017, 242, 295–303. [Google Scholar] [CrossRef] [PubMed]

- Ji, G.; Han, L.; Gao, C.; Xiao, W.; Zhang, Y.; Cao, Y. Quantitative approaches for illustrating correlations among the mechanical fragmentation scales, crystallinity and enzymatic hydrolysis glucose yield of rice straw. Bioresour. Technol. 2017, 241, 262–268. [Google Scholar] [CrossRef] [PubMed]

- Avolio, R.; Bonadies, I.; Capitani, D.; Errico, M.E.; Gentile, G.; Avella, M. A multitechnique approach to assess the effect of ball milling on cellulose. Carbohydr. Polym. 2012, 87, 265–273. [Google Scholar] [CrossRef]

- Chen, R.; Yi, C.; Wu, H.; Guo, S. Degradation kinetics and molecular structure development of hydroxyethyl cellulose under the solid state mechanochemical treatment. Carbohydr. Polym. 2010, 81, 188–195. [Google Scholar] [CrossRef]

- Sanyang, M.L.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Recent developments in sugar palm (Arenga pinnata) based biocomposites and their potential industrial applications: A review. Renew. Sustain. Energy Rev. 2016, 54, 533–549. [Google Scholar] [CrossRef]

- Chaudhary, A.L.; Torley, P.J.; Halley, P.J.; Mccaffery, N.; Chaudhary, D.S. Amylose content and chemical modification effects on thermoplastic starch from maize—Processing and characterisation using conventional polymer equipment. Carbohydr. Polym. 2009, 78, 917–925. [Google Scholar] [CrossRef]

- Cheng, L.; Zhang, D.; Gu, Z.; Li, Z.; Hong, Y.; Li, C. Preparation of acetylated nanofibrillated cellulose from corn stalk microcrystalline cellulose and its reinforcing effect on starch films. Int. J. Biol. Macromol. 2018, 111, 959–966. [Google Scholar] [CrossRef] [PubMed]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of structural carbohydrates and lignin in biomass. Lab. Anal. Proced. 2008, 1617, 1–16. [Google Scholar]

- Standard Test Method for Determination of Acid-Insoluble Residue in Biomass; ASTM E1721-01; ASTM International: West Conshohocken, PA, USA, 2015.

- Standard Test Method for Ash in Biomass; ASTM E1755-01; ASTM International: West Conshohocken, PA, USA, 2015.

- Silva, G.G.D.; Couturier, M.; Berrin, J.-G.; Buléon, A.; Rouau, X. Effects of grinding processes on enzymatic degradation of wheat straw. Bioresour. Technol. 2012, 103, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Fu, Z.-Q.; Wang, L.-J.; Li, D.; Wei, Q.; Adhikari, B. Effects of high-pressure homogenization on the properties of starch-plasticizer dispersions and their films. Carbohydr. Polym. 2011, 86, 202–207. [Google Scholar] [CrossRef]

- Dias, A.B.; Müller, C.M.O.; Larotonda, F.D.S.; Laurindo, J.B. Biodegradable films based on rice starch and rice flour. J. Cereal Sci. 2010, 51, 213–219. [Google Scholar] [CrossRef]

- Shankar, S.; Reddy, J.P.; Rhim, J.-W.; Kim, H.-Y. Preparation, characterization, and antimicrobial activity of chitin nanofibrils reinforced carrageenan nanocomposite films. Carbohydr. Polym. 2015, 117 (Suppl. C), 468–475. [Google Scholar] [CrossRef] [PubMed]

- Arfat, Y.A.; Benjakul, S.; Prodpran, T.; Osako, K. Development and characterisation of blend films based on fish protein isolate and fish skin gelatin. Food Hydrocoll. 2014, 39 (Suppl. C), 58–67. [Google Scholar] [CrossRef]

- Pandini, S.; Passera, S.; Messori, M.; Paderni, K.; Toselli, M.; Gianoncelli, A.; Bontempi, E.; Riccò, T. Two-way reversible shape memory behaviour of crosslinked poly(ε-caprolactone). Polymer 2012, 53, 1915–1924. [Google Scholar] [CrossRef]

- Joshi, M.; Aldred, P.; Panozzo, J.F.; Kasapis, S.; Adhikari, B. Rheological and microstructural characteristics of lentil starch–lentil protein composite pastes and gels. Food Hydrocoll. 2014, 35, 226–237. [Google Scholar] [CrossRef]

- Findley, W.; Lai, J.; Onaran, K.; Christensen, R. Creep and relaxation of nonlinear viscoelastic materials with an introduction to linear viscoelasticity. J. Appl. Mech. 1977, 44, 364. [Google Scholar] [CrossRef]

- Jin, S.; Chen, H. Superfine grinding of steam-exploded rice straw and its enzymatic hydrolysis. Biochem. Eng. J. 2006, 30, 225–230. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, J.; Chen, F.; Wang, X.; Zhu, Q.; Ao, Q. Surface characterization of corn stalk superfine powder studied by FTIR and XRD. Colloid Surf. B 2013, 104, 207–212. [Google Scholar] [CrossRef] [PubMed]

- Agustin, M.B.; Ahmmad, B.; De Leon, E.R.P.; Buenaobra, J.L.; Salazar, J.R.; Hirose, F. Starch-based biocomposite films reinforced with cellulose nanocrystals from garlic stalks. Polym. Compos. 2013, 34, 1325–1332. [Google Scholar] [CrossRef]

- Dufresne, A. Polysaccharide nano crystal reinforced nanocomposites. Can. J. Chem. 2008, 86, 484–494. [Google Scholar] [CrossRef]

- Pereda, M.; Ponce, A.G.; Marcovich, N.E.; Ruseckaite, R.A.; Martucci, J.F. Chitosan-gelatin composites and bi-layer films with potential antimicrobial activity. Food Hydrocoll. 2011, 25, 1372–1381. [Google Scholar] [CrossRef]

- Kumar, T.S.M.; Rajini, N.; Reddy, K.O.; Rajulu, A.V.; Siengchin, S.; Ayrilmis, N. All-cellulose composite films with cellulose matrix and Napier grass cellulose fibril fillers. Int. J. Biol. Macromol. 2018, 11, 1310–1315. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Weng, L.; Cao, X. Biocomposites of plasticized starch reinforced with cellulose crystallites from cottonseed linter. Macromol. Biosci. 2005, 5, 1101–1107. [Google Scholar] [CrossRef] [PubMed]

- Slavutsky, A.M.; Bertuzzi, M.A. Water barrier properties of starch films reinforced with cellulose nanocrystals obtained from sugarcane bagasse. Carbohydr. Polym. 2014, 110, 53–61. [Google Scholar] [CrossRef] [PubMed]

- Tselev, A.; Brooks, C.M.; Anlage, S.M.; Zheng, H.; Salamanca-Riba, L.; Ramesh, R.; Subramanian, M.A. Evidence for power-law frequency dependence of intrinsic dielectric response in the CaCu3Ti4O12. Phys. Rev. B 2004, 70, 144101. [Google Scholar] [CrossRef]

- Tian, Z.; Duan, L.; Wu, L.; Shen, L.; Li, G. Rheological properties of glutaraldehyde-crosslinked collagen solutions analyzed quantitatively using mechanical models. Mater. Sci. Eng. C 2016, 63, 10–17. [Google Scholar] [CrossRef] [PubMed]

- Bi, C.-H.; Li, D.; Wang, L.-J.; Gao, F.; Adhikari, B. Effect of high shear homogenization on rheology, microstructure and fractal dimension of acid-induced SPI gels. J. Food Eng. 2014, 126, 48–55. [Google Scholar] [CrossRef]

- Kurt, A.; Cengiz, A.; Kahyaoglu, T. The effect of gum tragacanth on the rheological properties of salep based ice cream mix. Carbohydr. Polym. 2016, 143, 116–123. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.D.; Zhao, X.X. Modeling and characterization of viscoelasticity of PI/SiO2 nanocomposite films under constant and fatigue loading. Mater. Sci. Eng. A 2008, 486, 517–527. [Google Scholar] [CrossRef]

| Samples | Cellulose (%) | Hemicellulose (%) | Lignin (%) | Ash (%) |

|---|---|---|---|---|

| CS-0h | 19.94 ± 0.89 ab | 13.50 ± 0.73 a | 47.36 ± 2.07 abc | 5.23 ± 0.55 a |

| CS-0.5h | 19.87 ± 0.46 a | 14.11 ± 0.33 b | 49.91 ± 4.36 c | 6.29 ± 0.16 bc |

| CS-1h | 20.83 ± 0.58 c | 16.04 ± 0.98 d | 46.11 ± 1.04 abc | 5.39 ± 0.41 ab |

| CS-1.5h | 20.65 ± 0.44 ab | 15.87 ± 0.33 d | 44.07 ± 1.80 a | 5.97 ± 0.58 ab |

| CS-2h | 20.16 ± 0.21 ab | 14.95 ± 0.22 c | 44.83 ± 0.97 ab | 7.01 ± 0.37 c |

| CS-4h | 20.12 ± 0.53 ab | 15.22 ± 0.03 c | 49.04 ± 2.57 bc | 6.21 ± 0.42 bc |

| CS-8h | 20.73 ± 0.52 ab | 15.97 ± 0.09 d | 46.28 ± 0.45 abc | 5.71 ± 0.67 ab |

| Samples | D10 (μm) | D50 (μm) | D90 (μm) | SSPS |

|---|---|---|---|---|

| CS-0h | 19.17 ± 0.12 f | 85.33 ± 0.85 e | 198.00 ± 4.36 d | 2.10 ± 0.03 a |

| CS-0.5h | 1.98 ± 0.02 c | 11.50 ± 0.26 b | 48.10 ± 3.80 b | 4.01 ± 0.32 c |

| CS-1h | 1.55 ± 0.03 a | 9.46 ± 0.08 a | 43.07 ± 0.50 a | 4.39 ± 0.08 c |

| CS-1.5h | 1.88 ± 0.03 b | 11.23 ± 0.06 b | 51.67 ± 4.20 bc | 4.43 ± 0.35 c |

| CS-2h | 2.25 ± 0.02 d | 12.83 ± 0.21 c | 52.70 ± 2.23 bc | 3.93 ± 0.35 bc |

| CS-4h | 3.31 ± 0.08 e | 15.83 ± 0.32 d | 57.87 ± 1.15 c | 3.45 ± 0.03 b |

| CS-8h | 3.38 ± 0.02 e | 15.80 ± 0.10 d | 58.67 ± 0.81 c | 3.50 ± 0.04 b |

| Sample | Thickness (mm) | Density (g·cm−3) | Moisture Content (%) | Solubility (%) | Transparency | WVP (gm−2·h−1·Pa−1) |

|---|---|---|---|---|---|---|

| CS/SF-0h | 0.20 ± 0.01 a | 105.40 ± 0.21 a | 16.50 ± 0.11 c | 26.56 ± 0.01 c | 5.08 ± 0.04 e | 0.53 ± 0.03 d |

| CS/SF-0.5h | 0.20 ± 0.01 a | 124.25 ± 0.83 d | 11.31 ± 0.13 a | 22.60 ± 0.13 b | 2.63 ± 0.01 d | 0.40 ± 0.07 cd |

| CS/SF-1h | 0.20 ± 0.01 a | 118.07 ± 0.86 c | 11.38 ± 0.01 a | 19.78 ± 0.21 a | 1.15 ± 0.08 c | 0.33 ± 0.01 b |

| CS/SF-1.5h | 0.20 ± 0.01 a | 110.34 ± 0.88 b | 12.06 ± 0.09 b | 19.71 ± 0.22 a | 1.01 ± 0.01 b | 0.29 ± 0.01 a |

| CS/SF-2h | 0.26 ± 0.03 b | 122.44 ± 1.01 cd | 17.42 ± 0.21 d | 22.36 ± 0.08 b | 0.84 ± 0.01 a | 0.29 ± 0.01 a |

| CS/SF-4h | 0.20 ± 0.01 a | 130.06 ± 2.63 e | 29.85 ± 0.33 e | 26.18 ± 0.13 c | 0.86 ± 0.01 a | 0.37 ± 0.01 c |

| CS/SF-8h | 0.20 ± 0.01 a | 133.09 ± 5.05 e | 31.67 ± 0.26 f | 25.67 ± 0.15 c | 0.97 ± 0.13 ab | 0.34 ± 0.01 b |

| SFs | 0.18 ± 0.01 a | 93.40 ± 1.21 a | 17.50 ± 0.11 e | 26.96 ± 0.01 c | 0.18 ± 0.24 a | 1.02 ± 0.06 d |

| CS/SF-5% | 0.20 ± 0.01 a | 114.25 ± 0.83 b | 14.71 ± 0.13 d | 22.60 ± 0.13 bc | 0.36 ± 0.01 b | 0.57 ± 0.02 c |

| CS/SF-10% | 0.20 ± 0.01 a | 113.07 ± 0.86 b | 12.38 ± 0.01 c | 20.33 ± 0.11 b | 0.72 ± 0.08 c | 0.42 ± 0.01 b |

| CS/SF-15% | 0.20 ± 0.01 a | 118.07 ± 0.86 c | 11.38 ± 0.01 b | 19.78 ± 0.21 b | 1.15 ± 0.08 d | 0.33 ± 0.01 a |

| CS/SF-20% | 0.20 ± 0.03 a | 123.44 ± 1.01 d | 10.42 ± 0.21 a | 12.36 ± 0.08 a | 1.45 ± 0.01 d | 0.42 ± 0.01 b |

| Sample | K′ × 103 (Pa·sn) | n′ | R2 | K″ × 103 (Pa·sn) | n″ | R2 |

|---|---|---|---|---|---|---|

| CS/SF-0h | 36.085 ± 0.475 d | 0.045 ± 0.005 c | 0.922 | 0.532 ± 0.002 d | 0.019 ± 0.001 a | 0.952 |

| CS/SF-0.5h | 54.916 ± 0.586 e | 0.044 ± 0.004 c | 0.968 | 0.866 ± 0.003 g | 0.020 ± 0.001 a | 0.943 |

| CS/SF-1h | 55.986 ± 0.404 f | 0.023 ± 0.003 a | 0.996 | 0.712 ± 0.003 f | 0.039 ± 0.002 c | 0.962 |

| CS/SF-1.5h | 39.780 ± 0.368 c | 0.038 ± 0.004 bc | 0.970 | 0.598 ± 0.002 e | 0.021 ± 0.001 a | 0.944 |

| CS/SF-2h | 33.532 ± 0.147 c | 0.029 ± 0.002 b | 0.945 | 0.479 ± 0.002 b | 0.033 ± 0.002 b | 0.956 |

| CS/SF-4h | 30.660 ± 0.186 b | 0.022 ± 0.003 a | 0.929 | 0.501 ± 0.004 c | 0.022 ± 0.003 a | 0.978 |

| CS/SF-8h | 26.745 ± 0.306 a | 0.037 ± 0.005 bc | 0.905 | 0.456 ± 0.002 a | 0.018 ± 0.001 a | 0.924 |

| SFs | 9.621 ± 0.233 a | 0.078 ± 0.010 e | 0.911 | 0.219 ± 0.002 a | 0.015 ± 0.004 a | 0.905 |

| CS/SF-5% | 32.646 ± 0.640 b | 0.066 ± 0.008 d | 0.922 | 0.479 ± 0.002 b | 0.033 ± 0.002 b | 0.956 |

| CS/SF-10% | 39.780 ± 0.368 c | 0.038 ± 0.004 b | 0.970 | 0.514 ± 0.003 c | 0.018 ± 0.002 a | 0.994 |

| CS/SF-15% | 55.986 ± 0.404 e | 0.023 ± 0.003 a | 0.996 | 0.712 ± 0.003 d | 0.039 ± 0.002 c | 0.962 |

| CS/SF-20% | 52.243 ± 0.386 d | 0.048 ± 0.003 c | 0.943 | 0.925 ± 0.004 e | 0.017 ± 0.002 a | 0.950 |

| Sample | EM (×108 MPa) | EK (MPa) | τ (s) | ηM (MPa·s) | R2 | ε′(∞) (×10−3 s−1) |

|---|---|---|---|---|---|---|

| CS/SF-0h | 0.298 ± 0.526 a | 0.739 ± 0.047 a | 0.163 ± 0.019 b c | 9.952 ± 1.164 a | 0.982 | 101.411 ± 11.943 e |

| CS/SF-0.5h | 2.058 ± 0.031 c | 2.192 ± 0.129 bc | 0.398 ± 0.072 d | 103.538 ± 13.847 d | 0.956 | 33.240 ± 0.447 d |

| CS/SF-1h | 16.120 ± 0.079 g | 4.873 ± 0.313 e | 0.584 ± 0.069 e | 1607.628 ± 9.522 f | 0.988 | 0.961 ± 0.107 a |

| CS/SF-1.5h | 3.606 ± 0.011 f | 2.829 ± 0.110 d | 0.151 ± 0.008 b | 1041.054 ± 4.021 e | 0.982 | 11.000 ± 0.669 b |

| CS/SF-2h | 2.286 ± 0.440 e | 2.431 ± 0.128 c | 0.153 ± 0.009 b | 87.911 ± 2.236 c | 0.983 | 11.380 ± 0.291 b |

| CS/SF-4h | 2.172 ± 0.100 d | 1.855 ± 0.059 b | 0.220 ± 0.039 c | 68.579 ± 0.283 b | 0.950 | 14.582 ± 0.062 c |

| CS/SF-8h | 0.608 ± 0.018 b | 1.720 ± 0.120 b | 0.121 ± 0.017 a | 65.236 ± 8.600 b | 0.978 | 15.510 ± 2.062 c |

| SFs | 1.127 ± 0.031 a | 1.007 ± 0.093 a | 12.940 ± 0.920 a | 29.065 ± 3.222 a | 0.982 | 2.713 ± 0.038 e |

| CS/SF-5% | 1.265 ± 0.021 b | 1.512 ± 0.070 b | 24.273 ± 0.544 c | 52.541 ± 3.545 b | 0.989 | 1.532 ± 0.032 d |

| CS/SF-10% | 1.374 ± 0.003 c | 2.017 ± 0.102 c | 20.372 ± 0.852 b | 117.328 ± 16.490 d | 0.991 | 0.742 ± 0.097 b |

| CS/SF-15% | 1.752 ± 0.037 e | 3.742 ± 0.111 d | 20.879 ± 1.307 b | 428.140 ± 31.108 e | 0.983 | 0.199 ± 0.017 a |

| CS/SF-20% | 1.659 ± 0.043 d | 2.077 ± 0.252 c | 23.611 ± 0.367 c | 93.358 ± 7.062 c | 0.992 | 0.865 ± 0.033 c |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, M.; Gao, F.; Yin, D.-M.; Luo, Q.; Fu, Z.-Q.; Zhou, Y.-G. Processing of Superfine Grinding Corn Straw Fiber-Reinforced Starch Film and the Enhancement on Its Mechanical Properties. Polymers 2018, 10, 855. https://doi.org/10.3390/polym10080855

Wu M, Gao F, Yin D-M, Luo Q, Fu Z-Q, Zhou Y-G. Processing of Superfine Grinding Corn Straw Fiber-Reinforced Starch Film and the Enhancement on Its Mechanical Properties. Polymers. 2018; 10(8):855. https://doi.org/10.3390/polym10080855

Chicago/Turabian StyleWu, Min, Fei Gao, Dong-Min Yin, Qi Luo, Zong-Qiang Fu, and Yu-Guang Zhou. 2018. "Processing of Superfine Grinding Corn Straw Fiber-Reinforced Starch Film and the Enhancement on Its Mechanical Properties" Polymers 10, no. 8: 855. https://doi.org/10.3390/polym10080855

APA StyleWu, M., Gao, F., Yin, D.-M., Luo, Q., Fu, Z.-Q., & Zhou, Y.-G. (2018). Processing of Superfine Grinding Corn Straw Fiber-Reinforced Starch Film and the Enhancement on Its Mechanical Properties. Polymers, 10(8), 855. https://doi.org/10.3390/polym10080855