Coupled Hygro-Mechanical Finite Element Method on Determination of the Interlaminar Shear Modulus of Glass Fiber-Reinforced Polymer Laminates in Bridge Decks under Hygrothermal Aging Effects

Abstract

1. Introduction

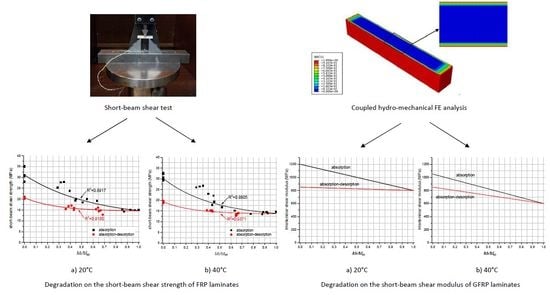

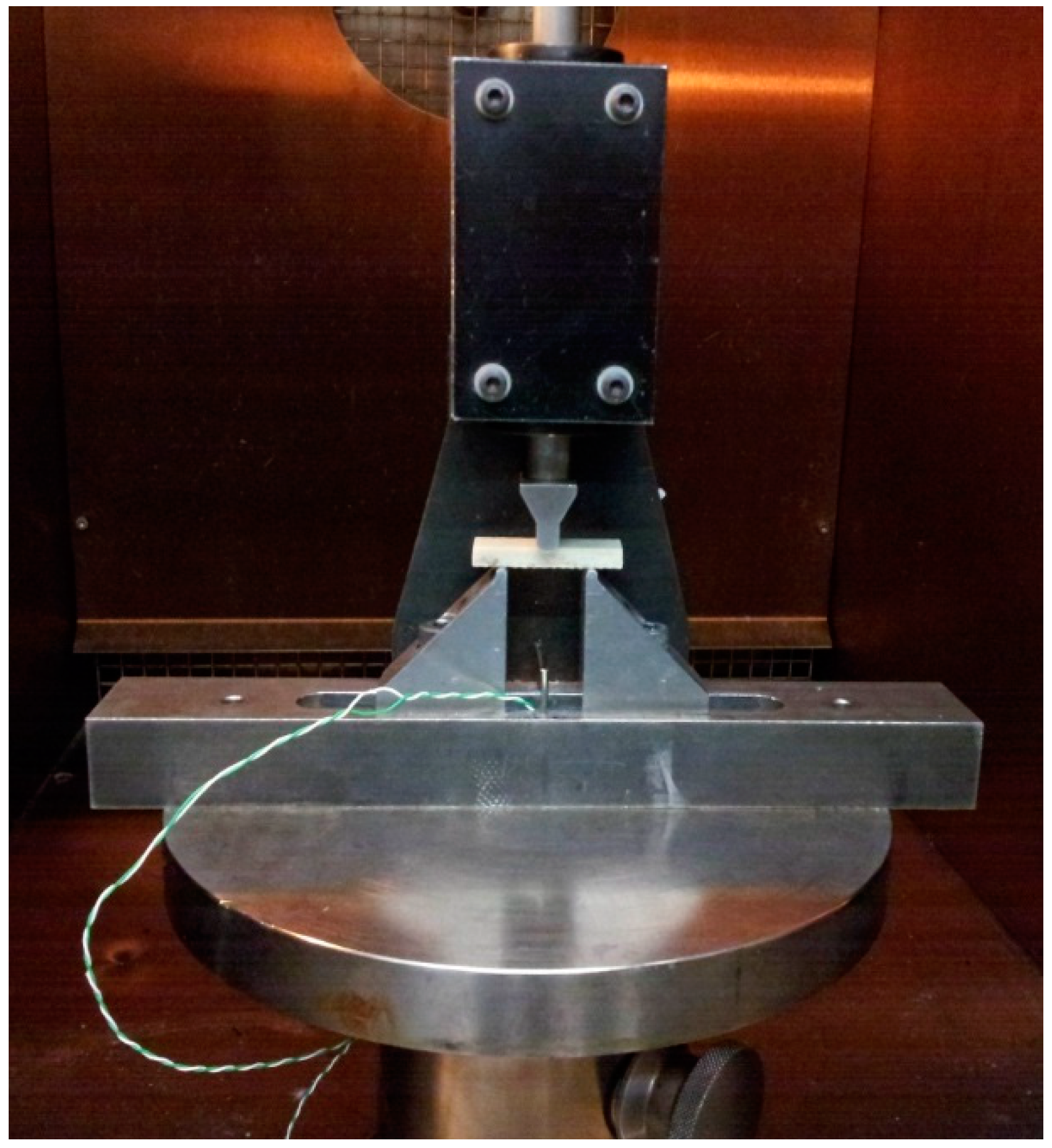

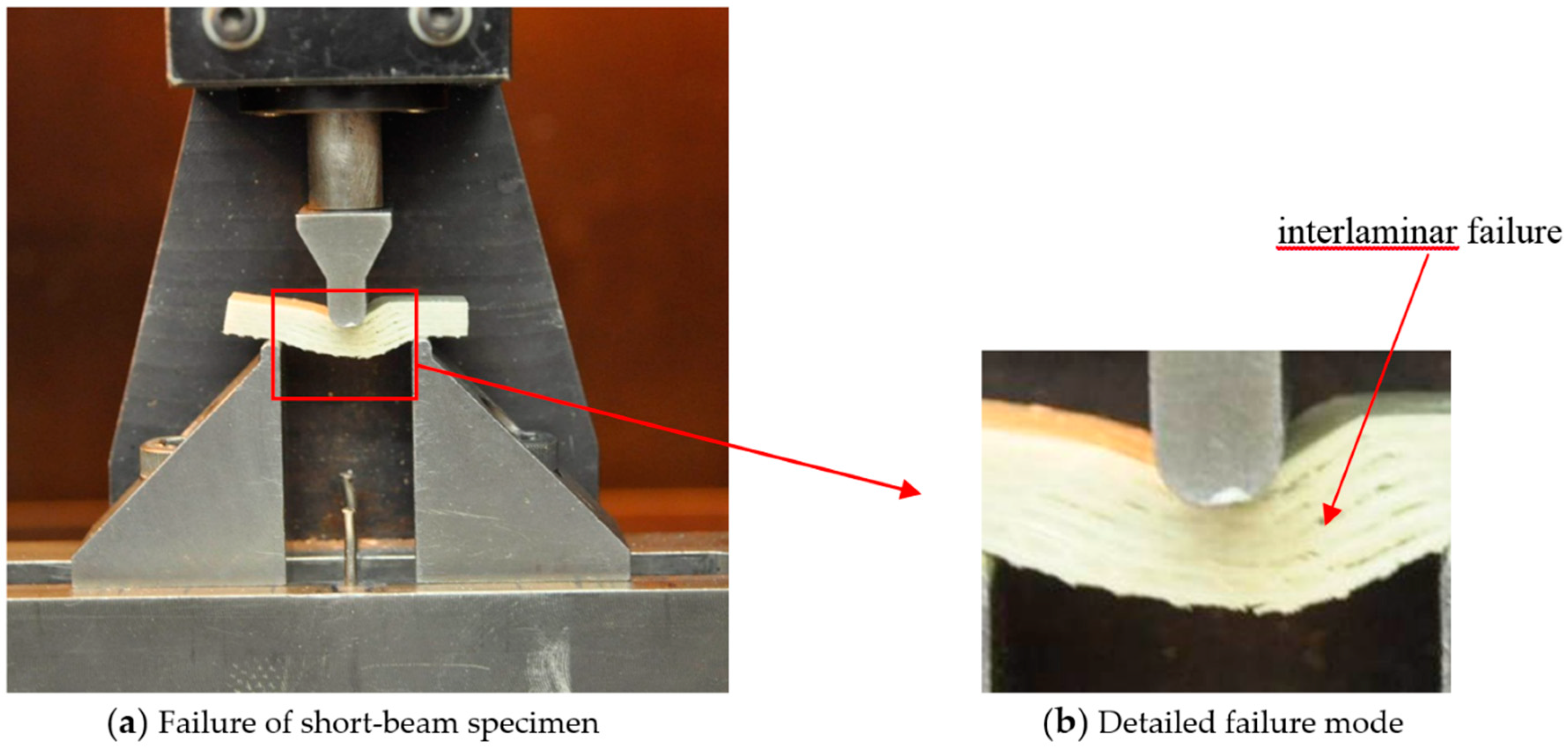

2. Experiment

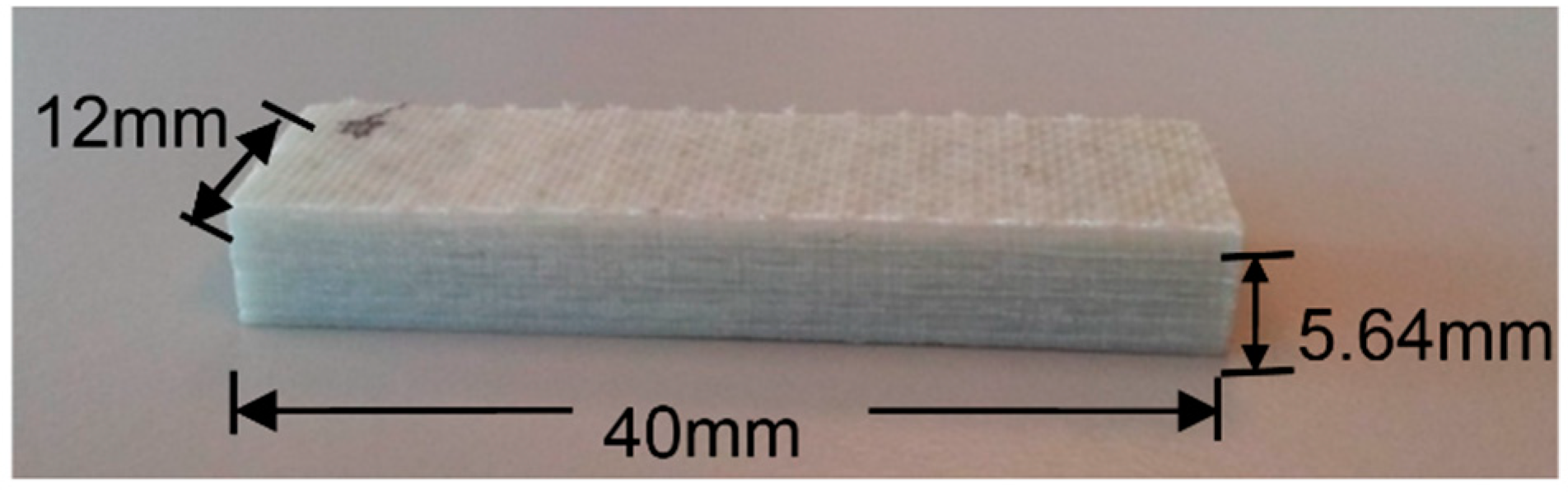

2.1. Material

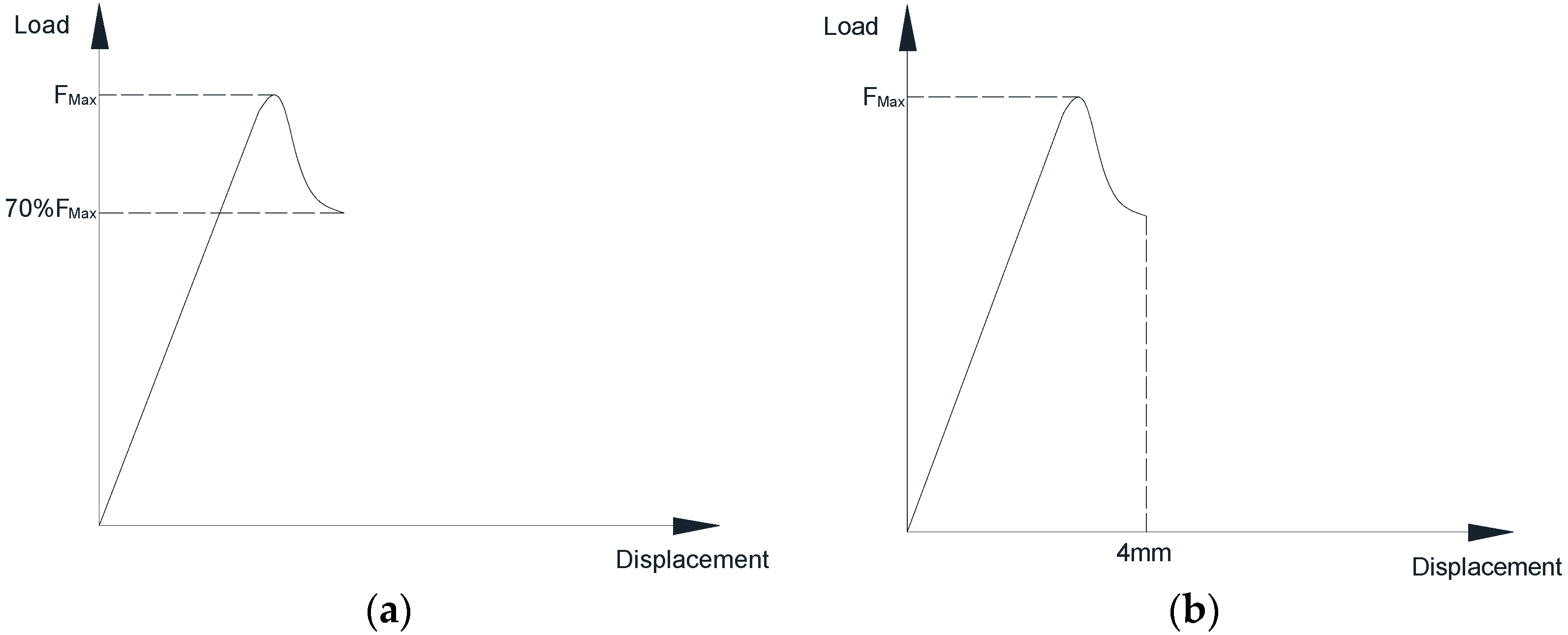

2.2. Methodology

- Fsbs = short-beam strength, MPa,

- Pm = maximum load observed during the test, N,

- b = measured specimen width, mm,

- h = measured specimen thickness, mm.

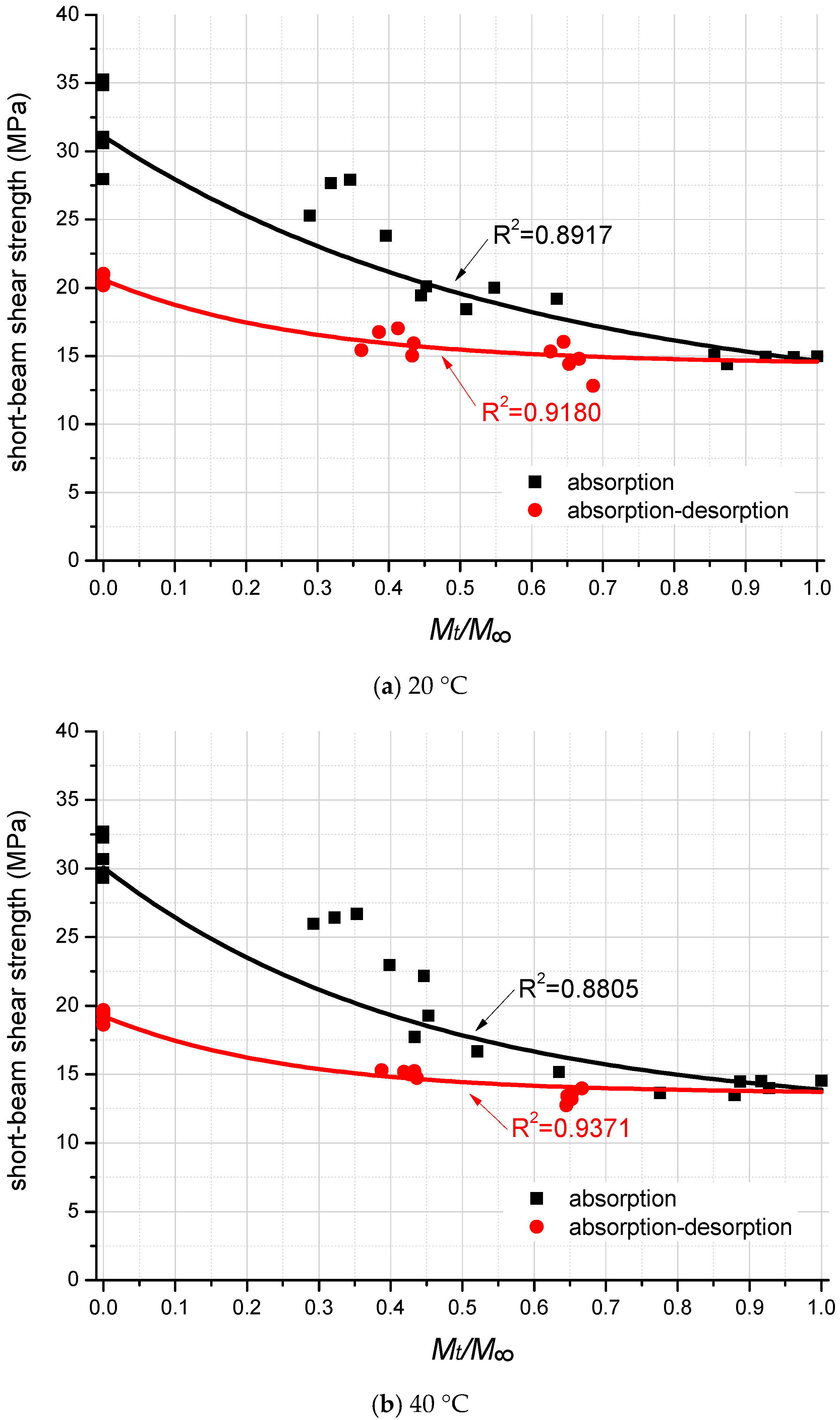

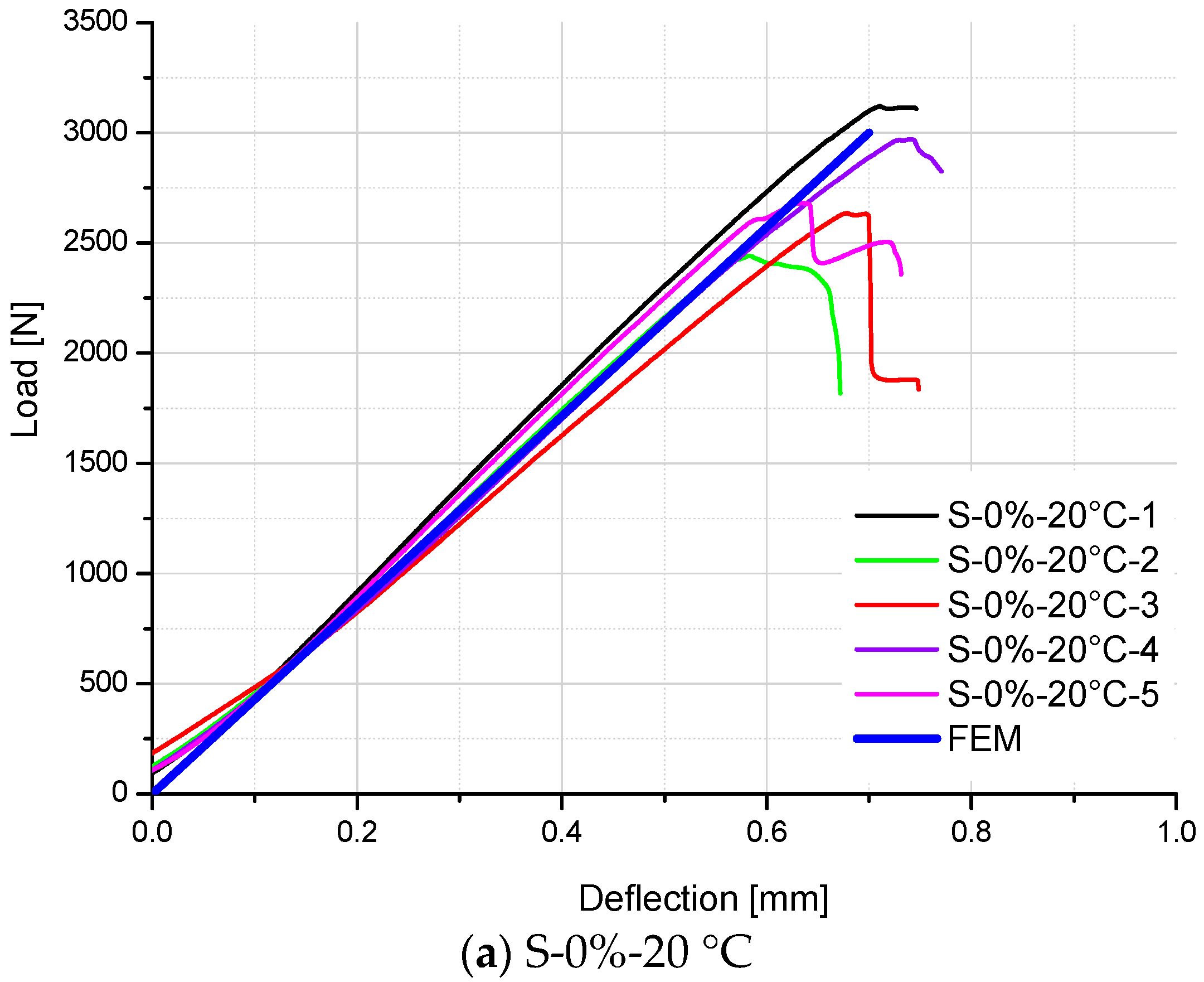

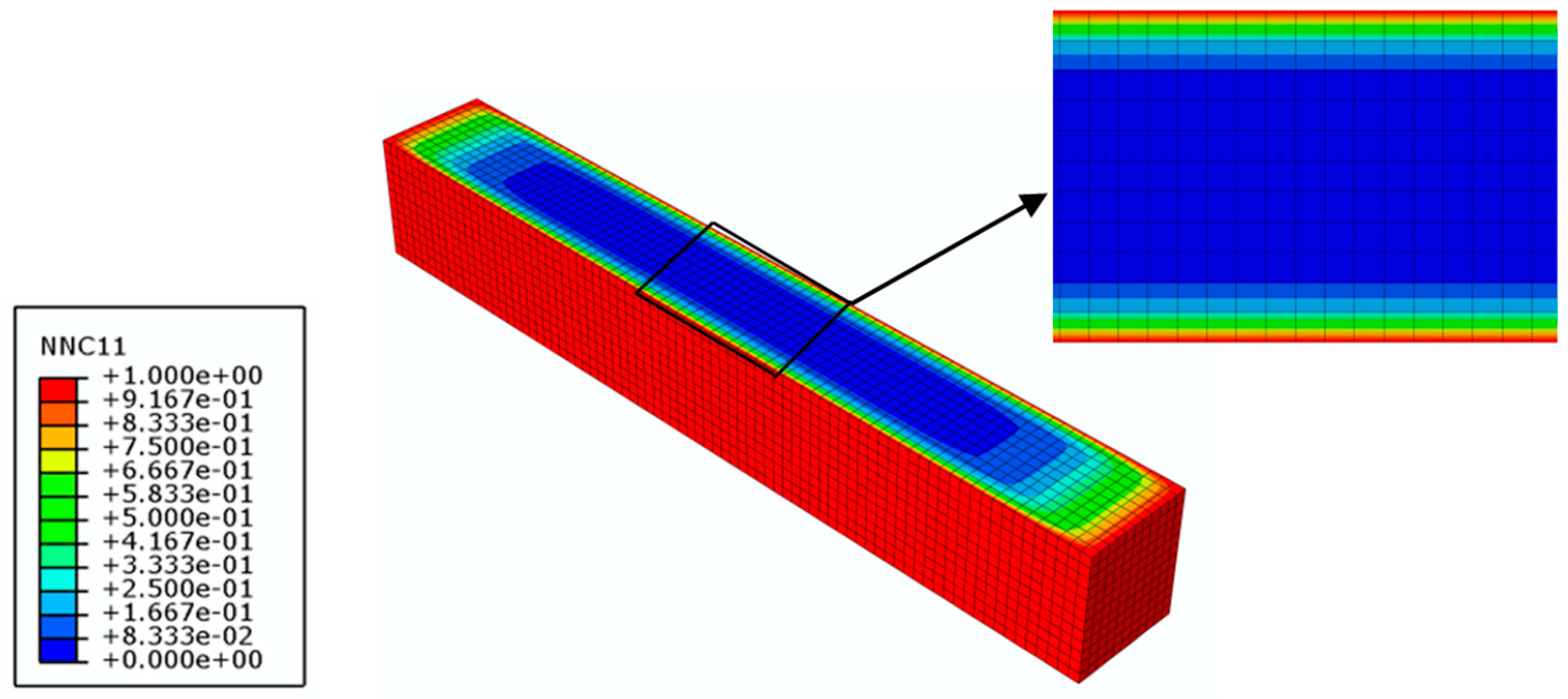

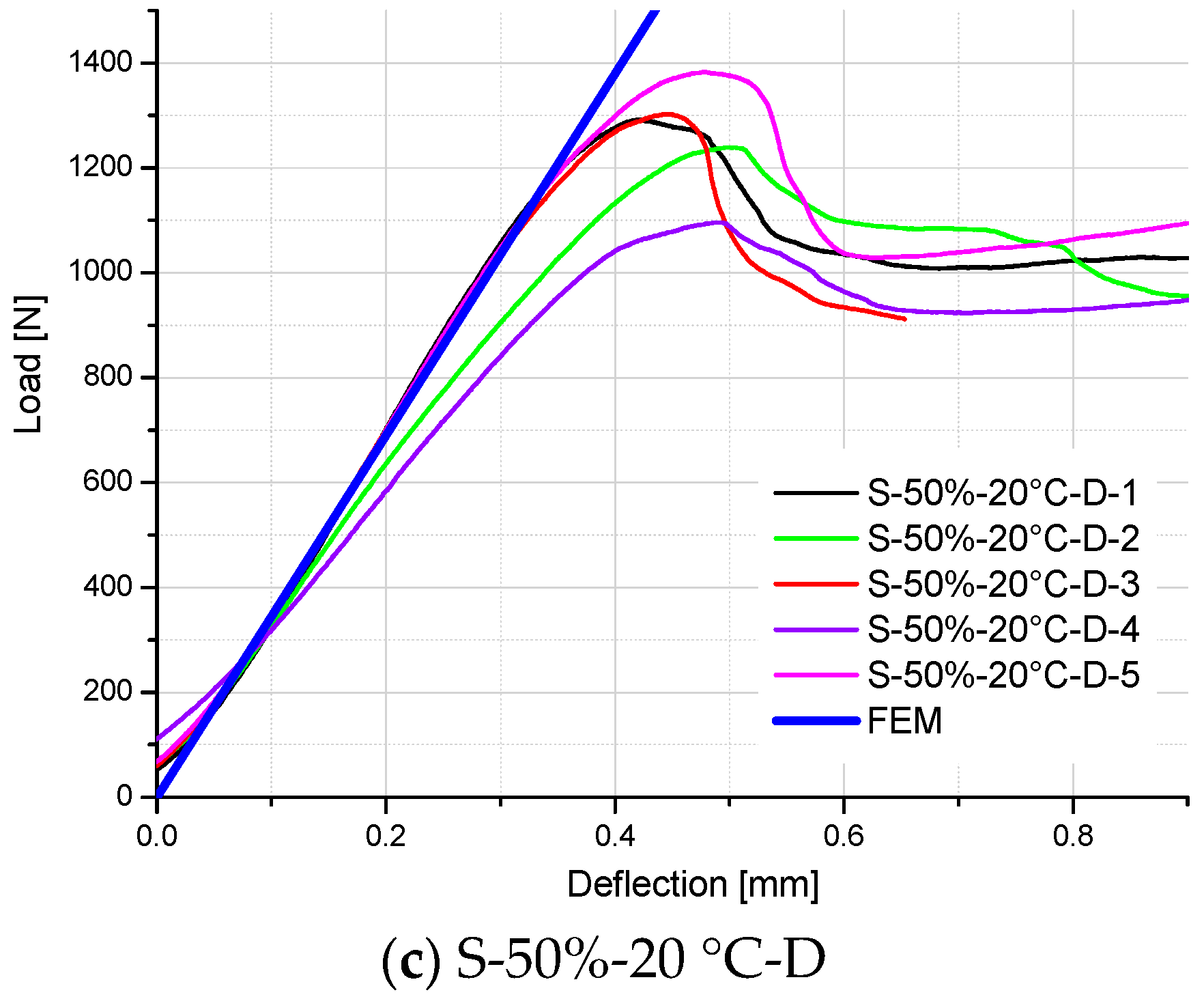

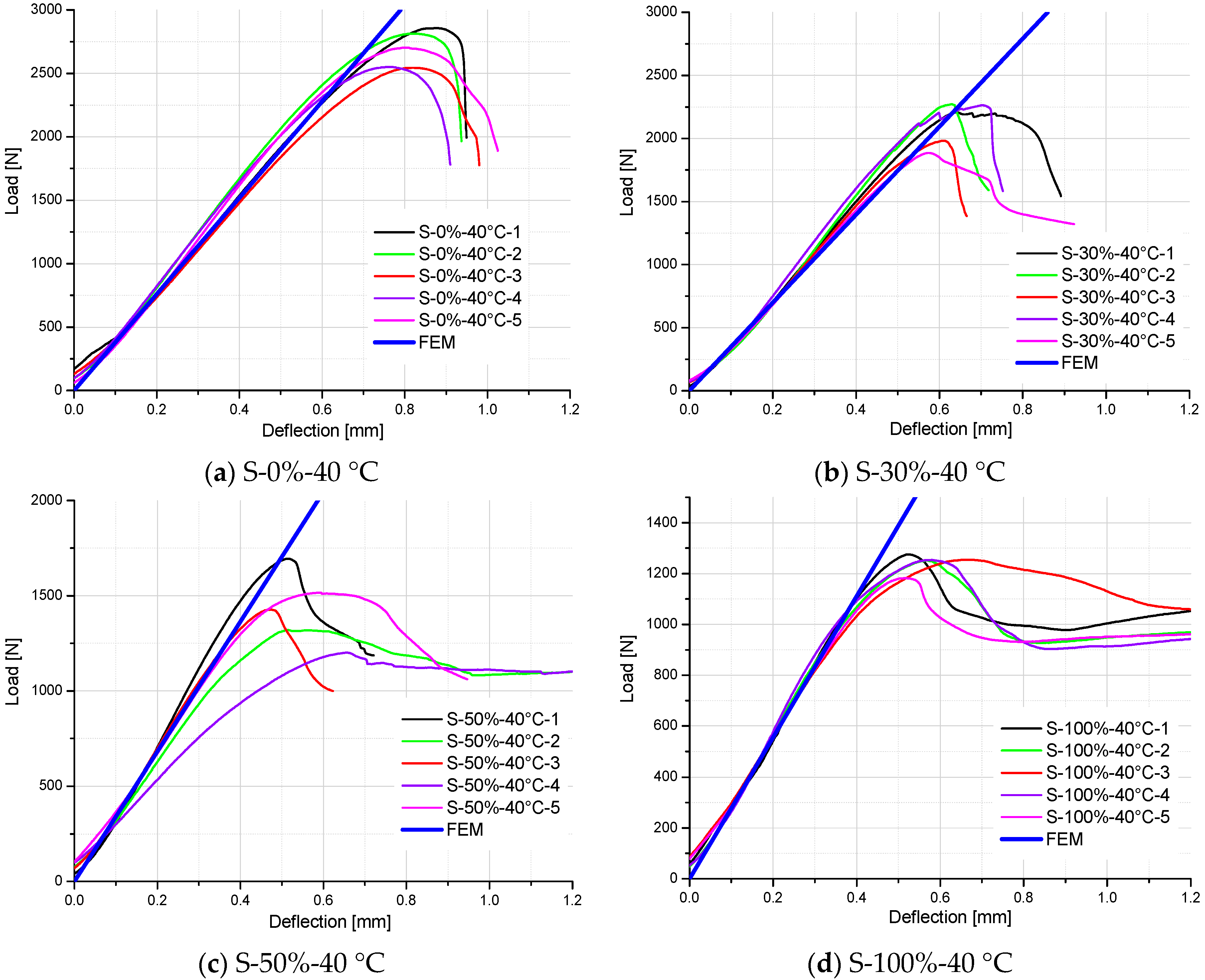

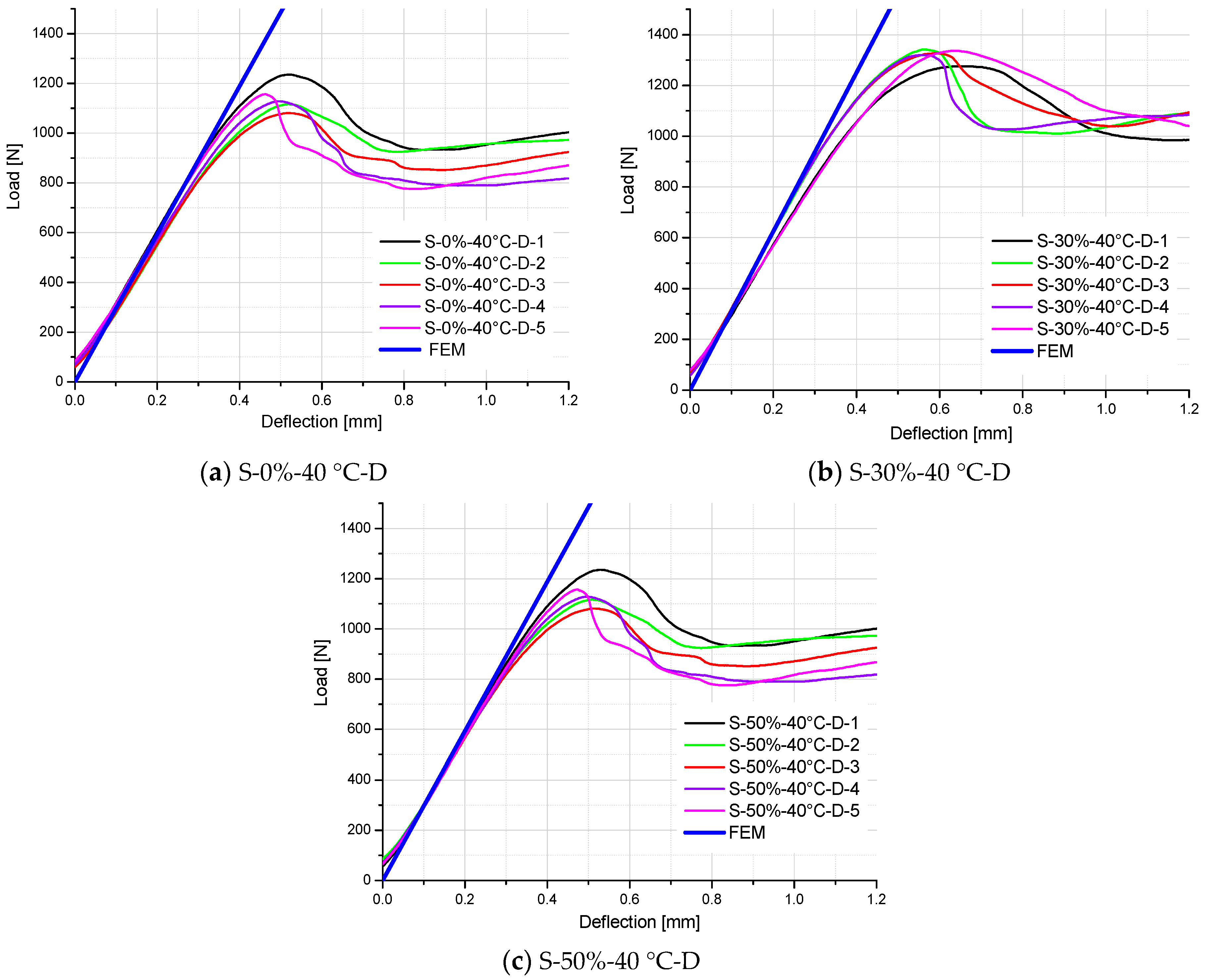

3. Experimental Results and Discussion

- 20 °C, absorption process:

- 20 °C, absorption–desorption process:

- 40 °C, absorption process:

- 40 °C, absorption–desorption process:

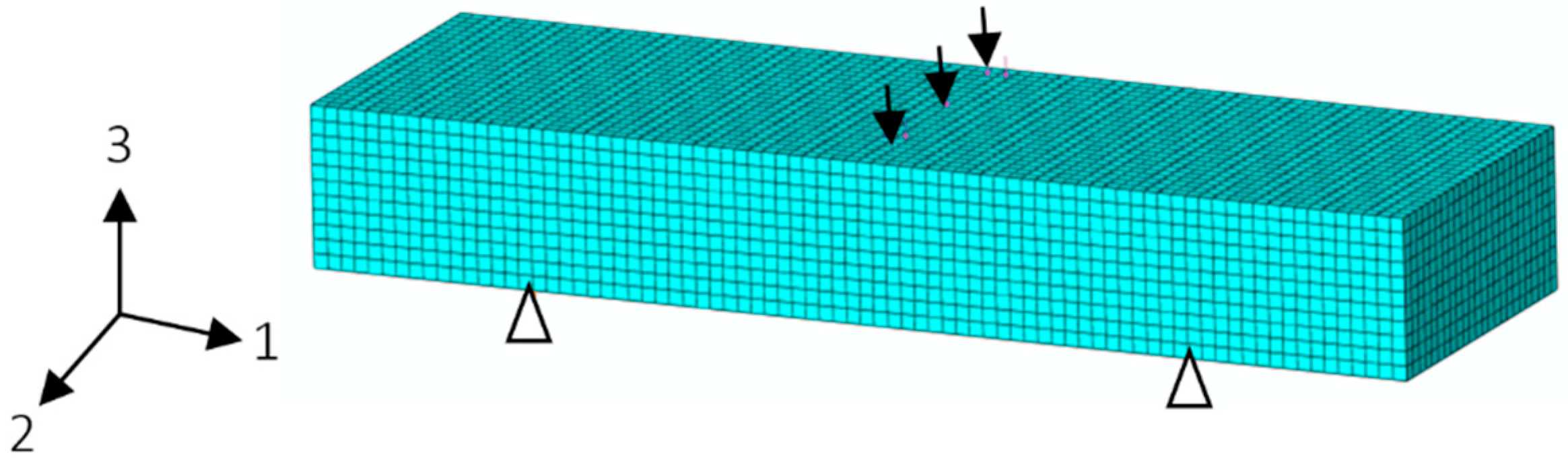

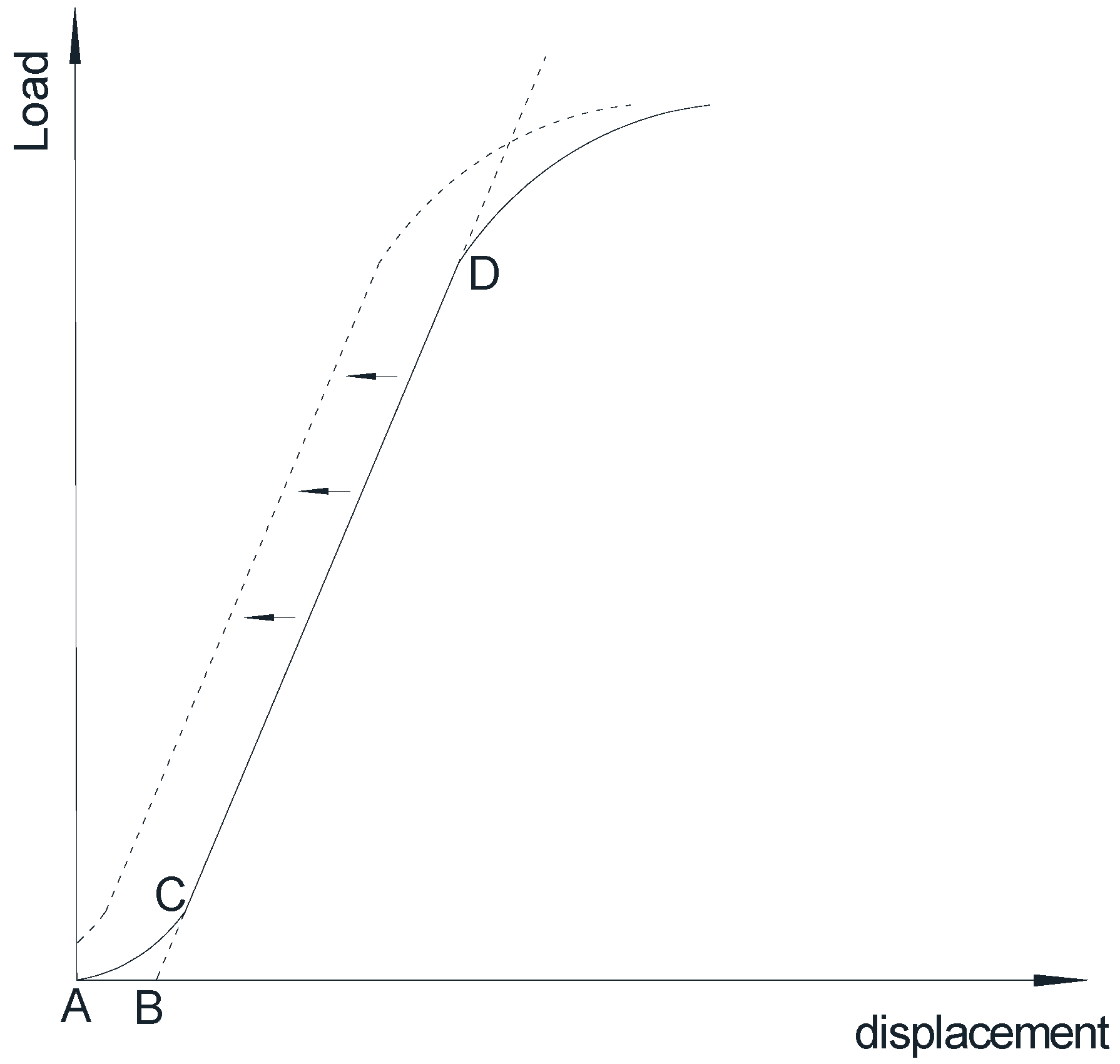

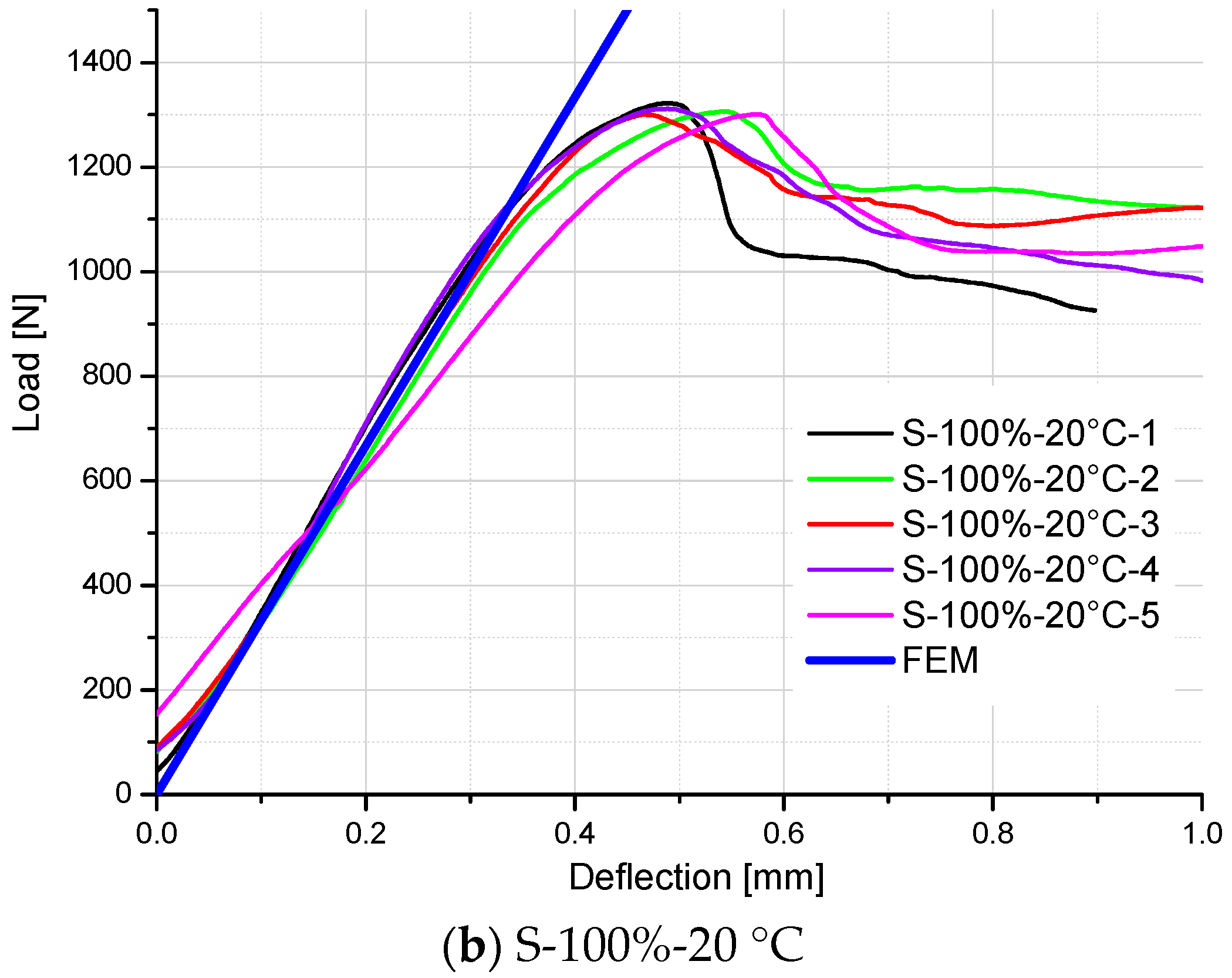

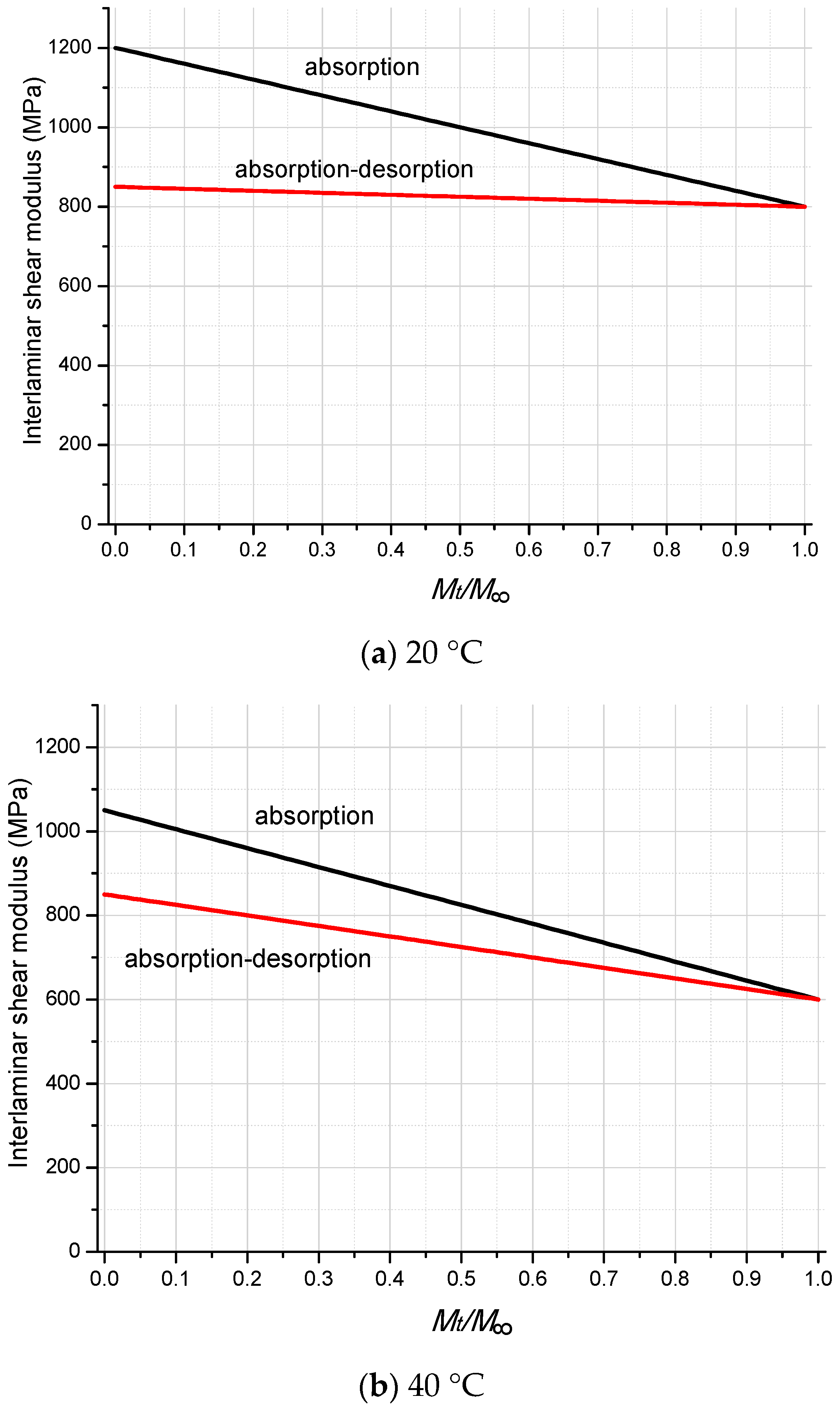

4. Coupled Hygro-Mechanical FE Method on Determination of the Interlaminar Shear Modulus of FRP Laminates

5. Conclusions

- The short-beam shear strength of the moisture-saturated specimens tested at 20 °C is 15 MPa, which is 53.1% lower than that of the unconditioned dry specimens (32 MPa). One cycle of the moisture absorption–desorption process degraded the shear strength of GFRP laminates by 34.4%. The elevated test temperature (40 °C) did not significantly degrade the shear strength of the GFRP laminates with different moisture contents.

- Based on the coupled hygro-mechanical FE analysis method, an inverse parameter identification approach to short-beam shear tests was developed and employed to determine the environment-dependent interlaminar shear modulus of GFRP laminates. This method was proven to be effective to determine the interlaminar shear modulus of FRP materials.

- Compared with the unconditioned dry specimen, the interlaminar shear modulus of the moisture-saturated specimen tested at 20 °C and 40 °C decreased by 33.3% and 42.9%, respectively. One moisture absorption–desorption process induced a 29.2% loss of interlaminar shear modulus for specimens tested at 20 °C, and a 19% loss for specimens tested at 40 °C.

- Predictive equations for moisture-dependent shear strength and the modulus of GFRP laminates were obtained in this research. These predictive equations can be used as input parameters for a coupled hygro-mechanical FE model, and contribute to the design code of FRP structures as far as the long-term performance is concerned.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Knippers, J.; Pelke, E.; Gabler, M.; Berger, D. Bridges with Glass Fibre-Reinforced Polymer Decks: The Road Bridge in Friedberg, Germany. Struct. Eng. Int. 2010, 20, 400–404. [Google Scholar] [CrossRef]

- Luke, S.; Canning, L.; Collins, S.; Knudsen, E.; Brown, P.; Taljsten, B.; Olofsson, I. Advanced composite bridge decking system—Project ASSET. Struct. Eng. Int. 2002, 12, 76–79. [Google Scholar] [CrossRef]

- Alampalli, S.; Kunin, J. Rehabilitation and field testing of an FRP bridge deck on a truss bridge. Compos. Struct. 2002, 57, 373–375. [Google Scholar] [CrossRef]

- Schollmayer, M. Through-Thickness Performance of Adhesive Connections between FRP Bridge Decks and Steel Main Girders; Ecole Polytechnique Federale de Lausanne: Lausanne, Switzerland, 2009. [Google Scholar]

- Gurtler, H.W. Composite Action of FRP Bridge Decks Adhesively Bonded to Steel Main Girders Lausanne; Ecole Polytechnique Federale de Lausanne: Lausanne, Switzerland, 2004. [Google Scholar]

- Keller, T.; Bai, Y.; Vallee, T. Long-term performance of a glass fiber-reinforced polymer truss bridge. J. Compos. Constr. 2007, 11, 99–108. [Google Scholar] [CrossRef]

- Hollaway, L.C. A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties. Constr. Build. Mater. 2010, 24, 2419–2445. [Google Scholar] [CrossRef]

- Awad, Z.K.; Aravinthanm, T.; Zhuge, Y.; Gonzalez, F. A review of optimization techniques used in the design of fibre composite structures for civil engineering applications. Mater. Des. 2012, 33, 534–544. [Google Scholar]

- Shao, Y.X.; Kouadi, S. Durability of fiberglass composite sheet piles in water. J. Compos. Constr. 2002, 6, 280–287. [Google Scholar] [CrossRef]

- Bank, L.C.; Gentry, T.R.; Barkatt, A. Accelerated Test Methods to Determine the Long-Term Behavior of Frp Composite Structures–Environmental-Effects. J. Reinf. Plast. Compos. 1995, 14, 559–587. [Google Scholar] [CrossRef]

- Nogueira, P.; Ramirez, C.; Torres, A.; Abad, M.J.; Cano, J.; Lopez, J.; Barral, L. Effect of water sorption on the structure and mechanical properties of an epoxy resin system. J. Appl. Polym. Sci. 2001, 80, 71–80. [Google Scholar]

- Earl, J.S.; Shenoi, R.A. Hygrothermal ageing effects on FRP laminate and structural foam materials. Compos. Part A Appl. Sci. Manuf. 2004, 35, 1237–1247. [Google Scholar] [CrossRef]

- Robert, M.; Roy, R.; Benmokrane, B. Environmental Effects on Glass Fiber Reinforced Polypropylene Thermoplastic Composite Laminate for Structural Applications. Polym. Compos. 2010, 31, 604–611. [Google Scholar] [CrossRef]

- Karbhari, V.M. E-glass/vinylester composites in aqueous environments: Effects on short-beam shear strength. J. Compos. Constr. 2004, 8, 148–156. [Google Scholar] [CrossRef]

- Daly, H.B.; Brahim, H.B.; Hfaied, N.; Harchay, M.; Boukhili, R. Investigation of water absorption in pultruded composites containing fillers and low profile additives. Polym. Compos. 2007, 28, 355–364. [Google Scholar] [CrossRef]

- Karbhari, V.M.; Xian, G.J. Hygrothermal effects on high VF pultruded unidirectional carbon/epoxy composites: Moisture uptake. Compos. Part B Eng. 2009, 40, 41–49. [Google Scholar] [CrossRef]

- Yilmaz, T.; Sinmazcelik, T. Effects of hydrothermal aging on glass–fiber/polyetherimide (PEI) composites. J. Mater. Sci. 2010, 45, 399–404. [Google Scholar] [CrossRef]

- Jiang, X.; Kolstein, H.; Bijlaard, F.S.K. Moisture diffusion and hygrothermal aging in pultruded fibre reinforced polymer composites of bridge decks. Mater. Des. 2012, 37, 304–312. [Google Scholar] [CrossRef]

- Shi, S.; Gu, L.; Liang, J.; Fang, G.; Gong, C.; Dai, C. A mesomechanical model for predicting the degradation in stiffness of FRP composites subjected to combined thermal and mechanical loading. Mater. Des. 2016, 89, 1079–1085. [Google Scholar] [CrossRef]

- Springer, G.S. Enivormental Effects on Composite Materials, Vol.1; Technomic Pubnishing Company: Lancaster, PA, USA, 1981. [Google Scholar]

- Springer, G.S. Enivormental Effects on Composite Materials, Vol.2; Technomic Pubnishing Company: Lancaster, PA, USA, 1984. [Google Scholar]

- Springer, G.S. Enivormental Effects on Composite Materials, Vol.3; Technomic Pubnishing Company: Lancaster, PA, USA, 1987. [Google Scholar]

- Loh, W.K.; Crocombe, A.D.; Wahab, M.M.A.; Ashcroft, I.A. Modelling anomalous moisture uptake, swelling and thermal characteristics of a rubber toughened epoxy adhesive. Int. J. Adhes. Adhes. 2005, 25, 1–12. [Google Scholar] [CrossRef]

- Haque, A.; Mahmood, S.; Walker, L.; Jeelani, S. Moisture and Temperature Induced Degradation in Tensile Properties of Kevlar Graphite Epoxy Hybrid Composites. J. Reinf. Plast. Compos. 1991, 10, 132–145. [Google Scholar] [CrossRef]

- Akay, M.; Mun, S.K.A.; Stanley, A. Influence of moisture on the thermal and mechanical properties of autoclaved and oven-cured Kevlar-49/epoxy laminates. Compos. Sci. Technol. 1997, 57, 565–571. [Google Scholar] [CrossRef]

- Eslami, S.; Honarbakhsh-Raouf, A.; Eslami, S. Effects of moisture absorption on degradation of E-glass fiber reinforced Vinyl Ester composite pipes and modelling of transient moisture diffusion using finite element analysis. Corros. Sci. 2015, 90, 168–175. [Google Scholar] [CrossRef]

- Staab, G.H. Laminar Composites; Butterworth-Heinemann: Oxford, UK, 1999. [Google Scholar]

- Chan, A.; Chiu, W.K.; Liu, X.L. Determining the elastic interlaminar shear modulus of composite laminates. Compos. Struct. 2007, 80, 396–408. [Google Scholar] [CrossRef]

- ASTM D2344/2344M-00. Standard Test Methods for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates; ASTM International: West Conshohocken, PA, USA, 2000. [Google Scholar]

- Jiang, X.; Kolstein, H.; Bijlaard, F.; Qiang, X.H. Effects of hygrothermal aging on glass-fibre reinforced polymer laminates and adhesive of FRP composite bridge: Moisture diffusion characteristics. Compos. Part A Appl. Sci. Manuf. 2014, 57, 49–58. [Google Scholar] [CrossRef]

- Jiang, X.; Song, J.; Qiang, X.; Kolstein, H.; Bijlaard, F. Moisture Absorption/Desorption Effects on Flexural Property of Glass-Fiber-Reinforced Polyester Laminates: Three-Point Bending Test and Coupled Hygro-Mechanical Finite Element Analysis. Polymers 2016, 8, 290. [Google Scholar] [CrossRef]

- ASTM D790-10. Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

| Product Name | Total Weight (g/m2) | Weight Uniformity (g/m2) | ||||

|---|---|---|---|---|---|---|

| Yarn Roving | Knit Yarn | |||||

| 0° (Warp) | +45° | 90° (Weft) | −45° | |||

| EQX 1200 | 1193 | 283 | 300 | 300 | 300 | 10 |

| Property | Tensile (ISO 527-4) | Compression (ISO 8515) | Flexural (ISO 14.125) | |||

|---|---|---|---|---|---|---|

| Mean Value | Warp | Weft | Warp | Weft | Warp | Weft |

| Strength | 331 MPa | 314 MPa | 220 MPa | 200 MPa | 473 MPa | 433 MPa |

| Modulus | 18 GPa | 17 GPa | 14 GPa | 14 GPa | 13 GPa | 11 GPa |

| Specimen Identification | Test | Mt/M∞ | Test Temperature | After Desorption | Number of Specimens | |

|---|---|---|---|---|---|---|

| Set-1 | S-0%-20 °C | shear | 0 | 20 °C | no | 5 |

| S-0%-40 °C | shear | 0 | 40 °C | no | 5 | |

| Set-2 | S-30%-20 °C | shear | 30% | 20 °C | no | 5 |

| S-30%-40 °C | shear | 30% | 40 °C | no | 5 | |

| Set-3 | S-50%-20 °C | shear | 50% | 20 °C | no | 5 |

| S-50%-40 °C | shear | 50% | 40 °C | no | 5 | |

| Set-4 | S-100%-20 °C | shear | 100% | 20 °C | no | 5 |

| S-100%-40 °C | shear | 100% | 40 °C | no | 5 | |

| Set-5 | S-50%-20 °C-D | shear | 50% | 20 °C | yes | 5 |

| S-50%-40 °C-D | shear | 50% | 40 °C | yes | 5 | |

| Set-6 | S-30%-20 °C-D | shear | 30% | 20 °C | yes | 5 |

| S-30%-40 °C-D | shear | 30% | 40 °C | yes | 5 | |

| Set-7 | S-0%-20 °C-D | shear | 0 | 20 °C | yes | 5 |

| S-0%-40 °C-D | shear | 0 | 40 °C | yes | 5 | |

| Specimen Identification | Shear Strength * (MPa) | Standard Deviation (MPa) |

|---|---|---|

| S-0%-20 °C | 32 | 2.74 |

| S-0%-40 °C | 31 | 1.34 |

| S-30%-20 °C | 26 | 1.70 |

| S-30%-40 °C | 25 | 1.89 |

| S-50%-20 °C | 19 | 0.59 |

| S-50%-40 °C | 16 | 2.10 |

| S-100%-20 °C | 15 | 0.24 |

| S-100%-40 °C | 14 | 0.41 |

| S-50%-20 °C-D | 15 | 1.08 |

| S-50%-40 °C-D | 13 | 0.41 |

| S-30%-20 °C-D | 16 | 0.76 |

| S-30%-40 °C-D | 15 | 0.21 |

| S-0%-20 °C-D | 21 | 0.35 |

| S-0%-40 °C-D | 19 | 0.36 |

| Property | FRP Laminates |

|---|---|

| E33 (MPa) | 11,000 |

| ν12 | 0.33 |

| ν23 | 0.3 |

| ν13 | 0.18 |

| G12 (MPa) | 6986 |

| Specimen | 1 | 2 | 3 | 4 | 5 | Mean Value | FEM | Error (100%) | |

|---|---|---|---|---|---|---|---|---|---|

| Identification | |||||||||

| S-0%-20 °C | 4582 | 4323 | 3973 | 4337 | 4534 | 4350 | 4286 | 1.47 | |

| S-30%-20 °C | 3535 | 3692 | 3682 | 4318 | 3878 | 3821 | 4027 | 5.39 | |

| S-50%-20 °C | 3659 | 3981 | 4062 | 3840 | 3684 | 3845 | 3896 | 1.32 | |

| S-100%-20 °C | 3185 | 3163 | 3223 | 3556 | 2355 | 3096 | 3333 | 7.64 | |

| S-0%-20 °C-D | 3295 | 3374 | 3696 | 3154 | 3919 | 3488 | 3571 | 2.39 | |

| S-30%-20 °C-D | 3530 | 3426 | 3175 | 3178 | 3212 | 3304 | 3529 | 6.80 | |

| S-50%-20 °C-D | 3632 | 2865 | 3405 | 2506 | 3517 | 3185 | 3448 | 8.26 | |

| S-0%-40 °C | 3864 | 4162 | 3692 | 3919 | 4129 | 3953 | 3797 | 3.95 | |

| S-30%-40 °C | 3938 | 4320 | 3824 | 4287 | 3753 | 4024 | 3488 | 8.36 | |

| S-50%-40 °C | 4044 | 3069 | 3518 | 2286 | 3187 | 3221 | 3409 | 5.84 | |

| S-100%-40 °C | 2897 | 2896 | 2588 | 3073 | 2694 | 2830 | 2778 | 1.82 | |

| S-0%-40 °C-D | 2831 | 2661 | 2583 | 2653 | 2758 | 2697 | 2970 | 2.70 | |

| S-30%-40 °C-D | 2664 | 2916 | 2902 | 2898 | 2587 | 2793 | 3125 | 8.29 | |

| S-50%-40 °C-D | 2831 | 2661 | 2583 | 2653 | 2758 | 2697 | 2970 | 6.41 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, X.; Luo, C.; Qiang, X.; Zhang, Q.; Kolstein, H.; Bijlaard, F. Coupled Hygro-Mechanical Finite Element Method on Determination of the Interlaminar Shear Modulus of Glass Fiber-Reinforced Polymer Laminates in Bridge Decks under Hygrothermal Aging Effects. Polymers 2018, 10, 845. https://doi.org/10.3390/polym10080845

Jiang X, Luo C, Qiang X, Zhang Q, Kolstein H, Bijlaard F. Coupled Hygro-Mechanical Finite Element Method on Determination of the Interlaminar Shear Modulus of Glass Fiber-Reinforced Polymer Laminates in Bridge Decks under Hygrothermal Aging Effects. Polymers. 2018; 10(8):845. https://doi.org/10.3390/polym10080845

Chicago/Turabian StyleJiang, Xu, Chengwei Luo, Xuhong Qiang, Qilin Zhang, Henk Kolstein, and Frans Bijlaard. 2018. "Coupled Hygro-Mechanical Finite Element Method on Determination of the Interlaminar Shear Modulus of Glass Fiber-Reinforced Polymer Laminates in Bridge Decks under Hygrothermal Aging Effects" Polymers 10, no. 8: 845. https://doi.org/10.3390/polym10080845

APA StyleJiang, X., Luo, C., Qiang, X., Zhang, Q., Kolstein, H., & Bijlaard, F. (2018). Coupled Hygro-Mechanical Finite Element Method on Determination of the Interlaminar Shear Modulus of Glass Fiber-Reinforced Polymer Laminates in Bridge Decks under Hygrothermal Aging Effects. Polymers, 10(8), 845. https://doi.org/10.3390/polym10080845