1. Introduction

Selective laser sintering of polymers (SLS) is a powder- and laser-based additive manufacturing technique. Due to its thermal stability, build accuracy and mechanical properties, selective laser sintering of plastics shows an excellent capability to manufacture serial components [

1,

2]. The lack of fundamental process understanding in selective laser sintering leads to process interruptions and to defective parts, which hampers the breakthrough of selective laser sintering in many industrial sectors. Experimental analysis of the beam-powder interaction in combination with modeling could fundamentally enhance the understanding of SLS processing conditions [

3].

During SLS, a CO

laser selectively melts the thermoplastic powder layer by layer. Exposed to laser irradiation, the plastic material is transformed from an entropy elastic state to a viscous state. In contrast to selective laser melting of metals and according to the model for quasi-isothermal laser sintering, the molten thermoplastic materials remain in the viscous state during the whole laser sintering process. The temperature-dependent viscosity and surface tension determine the viscous flow of the thermoplastic melt. The actual temperature and thus the viscosity are influenced by the absorption behavior of the powder mainly. The resulting material and mechanical properties are dependent on the laser energy input which is dominated by the interaction of the beam with the powder bed [

4,

5]. While thermal modeling of the process is conducted with simplified absorption models [

6,

7], a mesoscopic model at the powder scale is still missing. Therefore, in this work, a ray tracing absorption model for thermoplastic powders is developed and validated with theoretical and experimental data.

2. Absorption Model

The basic idea of the absorption model is to trace the path of photons (ray), emitted by a light source (e.g., a laser) by considering the reflection and refraction at the interface of particles and the atmosphere, while absorbing the energy according to the Beer–Lambert law (Equation (

1)) along its path in dense media. The media, e.g., within a powder particle, are assumed to be linear. The radiation intensity distribution

I in a medium for a single wavelength is given by:

where

x is the path,

is the attenuation coefficient for a unique wavelength in a given medium and

is the initial intensity. To calculate the path of light, a ray is cast at the coordinates of its source

with the propagation vector

normalized to unit length and the energy

. The propagation is discretized into equal steps

n of length

, and at each position

, the medium is sampled and the energy absorbed

by the medium calculated.

At each step, the remaining Energy

of the beam needs to be updated.

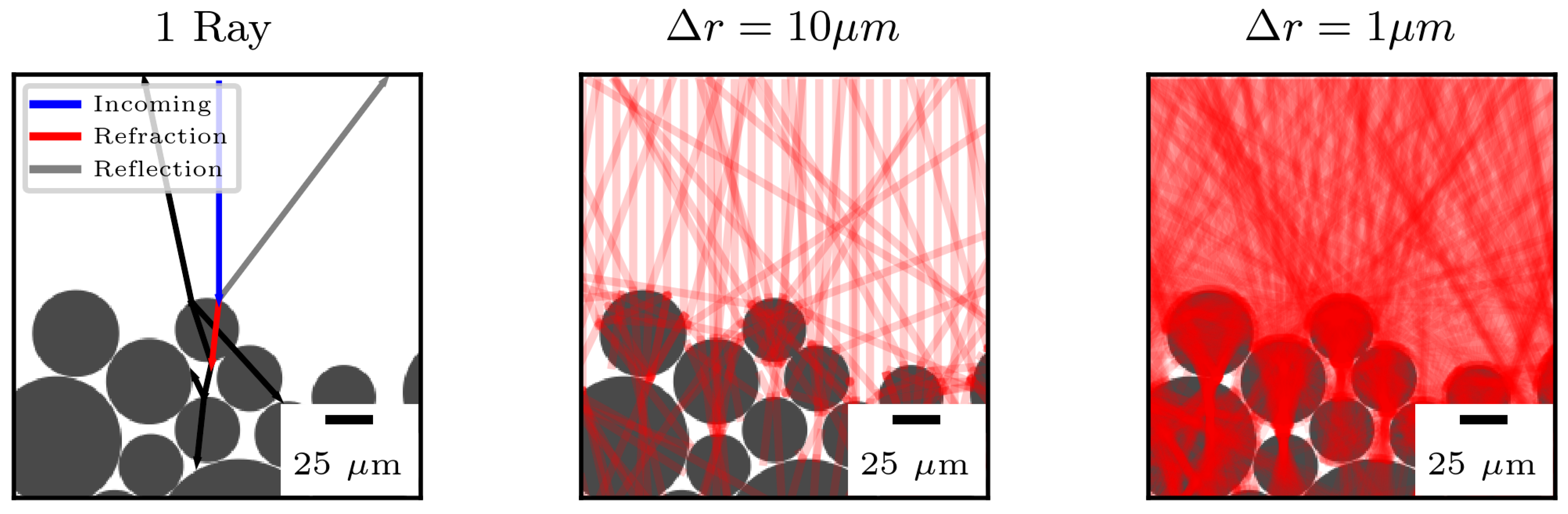

The ray propagates until it encounters a change in media. At that point, the initial ray is terminated, and two new rays are cast (

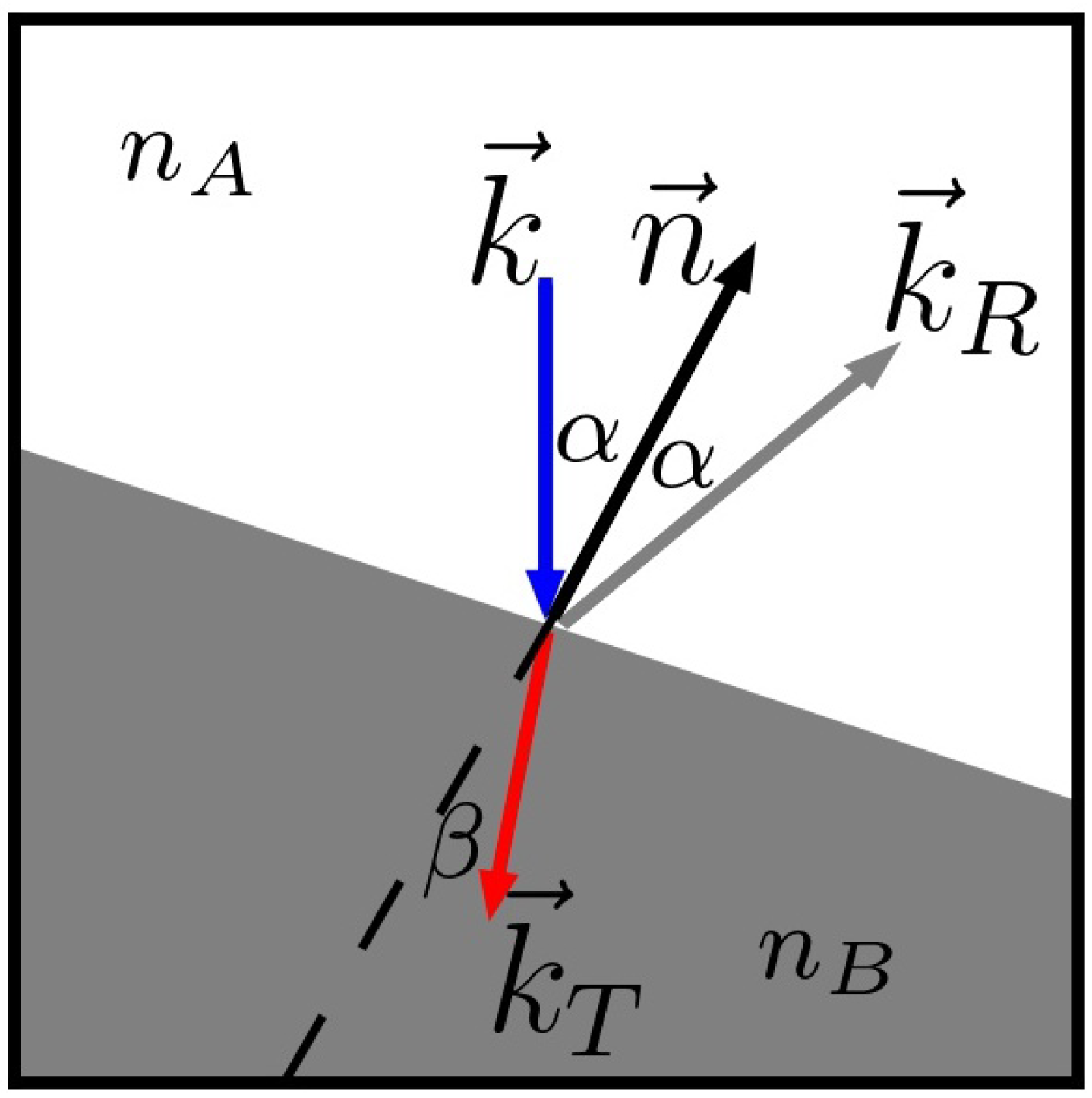

Figure 1), accounting for reflection and refraction at the interface of two different media.

The reflection angle

has the same magnitude as the angle of the incoming ray with respect to the surface normal

.

For the refraction angle

, Snell’s law [

8] can be applied:

with

being the refractive index of the medium

A. The direction of the reflected

and refracted

ray can be easily calculated by multiplying the normal vector by the rotation matrix using the corresponding angle. The remaining energy of the incoming ray

is divided between the two new rays. By using the Fresnel equations for unpolarized light and non-magnetic media, the energy portion for the reflected ray

can be calculated as:

The energy for the transmitted ray

is given by:

By taking into account the starting point, the direction vector and the energy, new rays are cast and propagated analogously to the initial ray.

3. Implementation

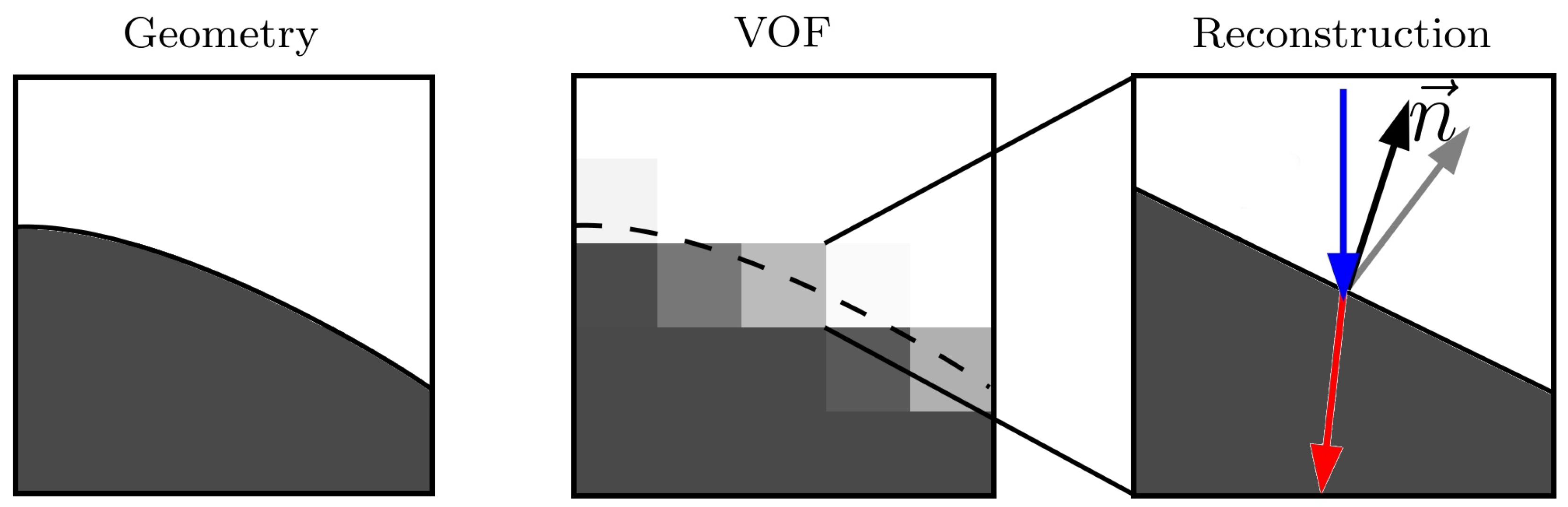

The absorption model described in the previous section can be applied to any simulation method that provides the necessary geometrical information. However, this work will focus on the implementation within the volume of fluid method (VOF) in 2D. It is straight forward to extend the scheme to three dimensions. The VOF in combination with the lattice Boltzmann method has been proven to be very effective when it comes to simulating complex geometries like a powder bed in additive manufacturing [

9,

10,

11]. To represent a given geometry, the space in the simulation domain is discretized into cells. According to its occupation level by that geometry, each cell gets a volume fraction

between zero and one (

Figure 2).

In general, the information of the exact shape of the geometry is lost after the initialization, but the big advantage is that the surface can be locally reconstructed up to certain accuracy; therefore, the algorithm is ideal for parallel computing. The absorption model requires the surface normal

to calculate

and

. One way to estimate the normal vector within one cell at its center

is to sum over the displacements vectors

of the neighboring cells weighted by their inverse volume fraction [

12].

where

and

are the unit vector in Cartesian coordinates. A linear reconstruction of the surface within the cell can be calculated with a template sphere method [

12]. Due to the simplicity and to save computational time, the surface in this work is defined when a ray propagates from a cell with

to a cell with

and vice versa.

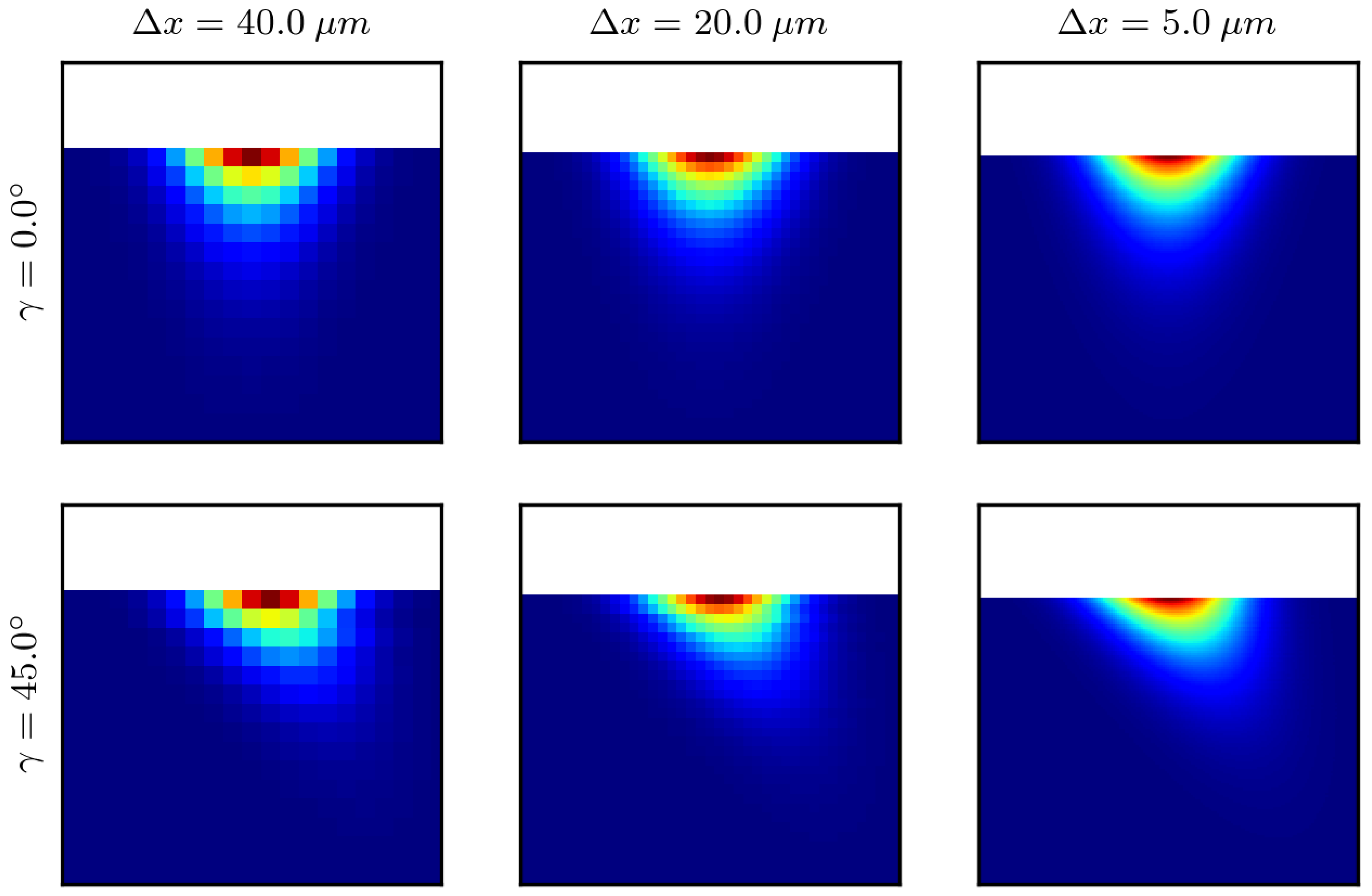

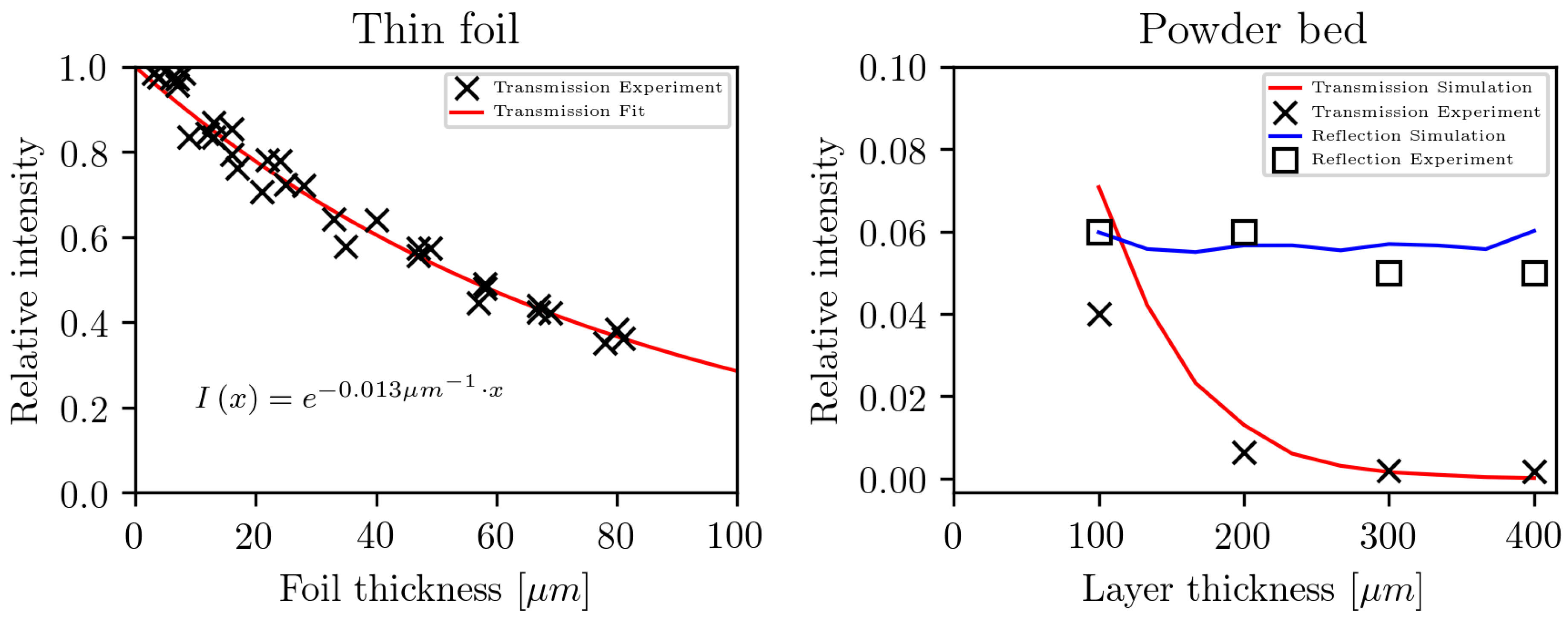

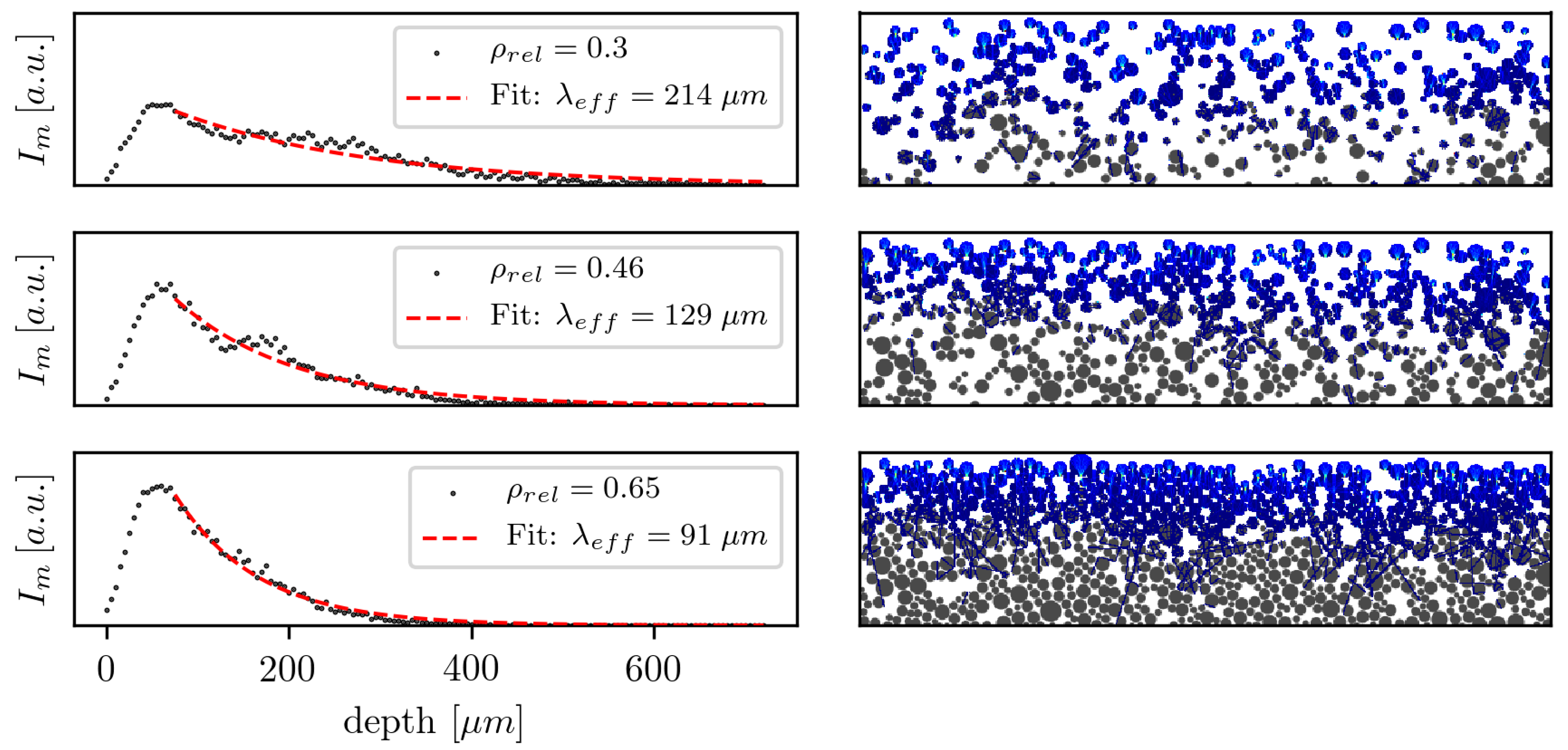

5. Penetration Depth in a Powder Bed

A uniform radiation source is chosen to study the absorption characteristics in a powder bed. The relative density

and the refractive index of the medium are varied. The penetration depth

, which is defined as the inverse of the attenuation coefficient, is set to

m. The powder diameter distribution density

q is given by fitting a log-normal distribution:

to the normalized data given by Drummer et al. [

16], with a median particle size of

m and the parameters

and

. The correlation with the median particle size is given by:

The dimensionless particle diameter

is normalized to the

m scale. The powder bed is generated by randomly sampling a diameter between

m and

m. The diameter is accepted with the probability

and placed into the simulation domain by randomly initializing the particle at the top of the domain and minimizing its potential energy. The algorithm is repeated until the desired fill level is reached. Finally, powder particles are randomly removed to adjust the relative density. Three resulting powder beds with the their intensity distributions are shown in

Figure 8. Commercial PA12 powder (type PA2200, EOS GmbH) has a bulk density of

or a relative density of

. The relative tapped density of this material is

. For the considered relative densities in

Figure 8, values of commercial powders were chosen. Additionally the mean intensity

along the width is plotted over the powder bed depth for three relative densities with

. Unlike the plain surface setup, where the maximum of the absorbed radiation is at the interface, the peak intensity is within the powder bed. This is due to the surface morphology of a powder bed with approximated spherical particles. Commercially-available powders have particles that are not exactly spherical. However, they have a low aspect ratio. The rise from zero to the given relative density of the powder bed needs at least one particle diameter. In the presented examples, this length is between

m and

m, which correlates well with the mean particle size.

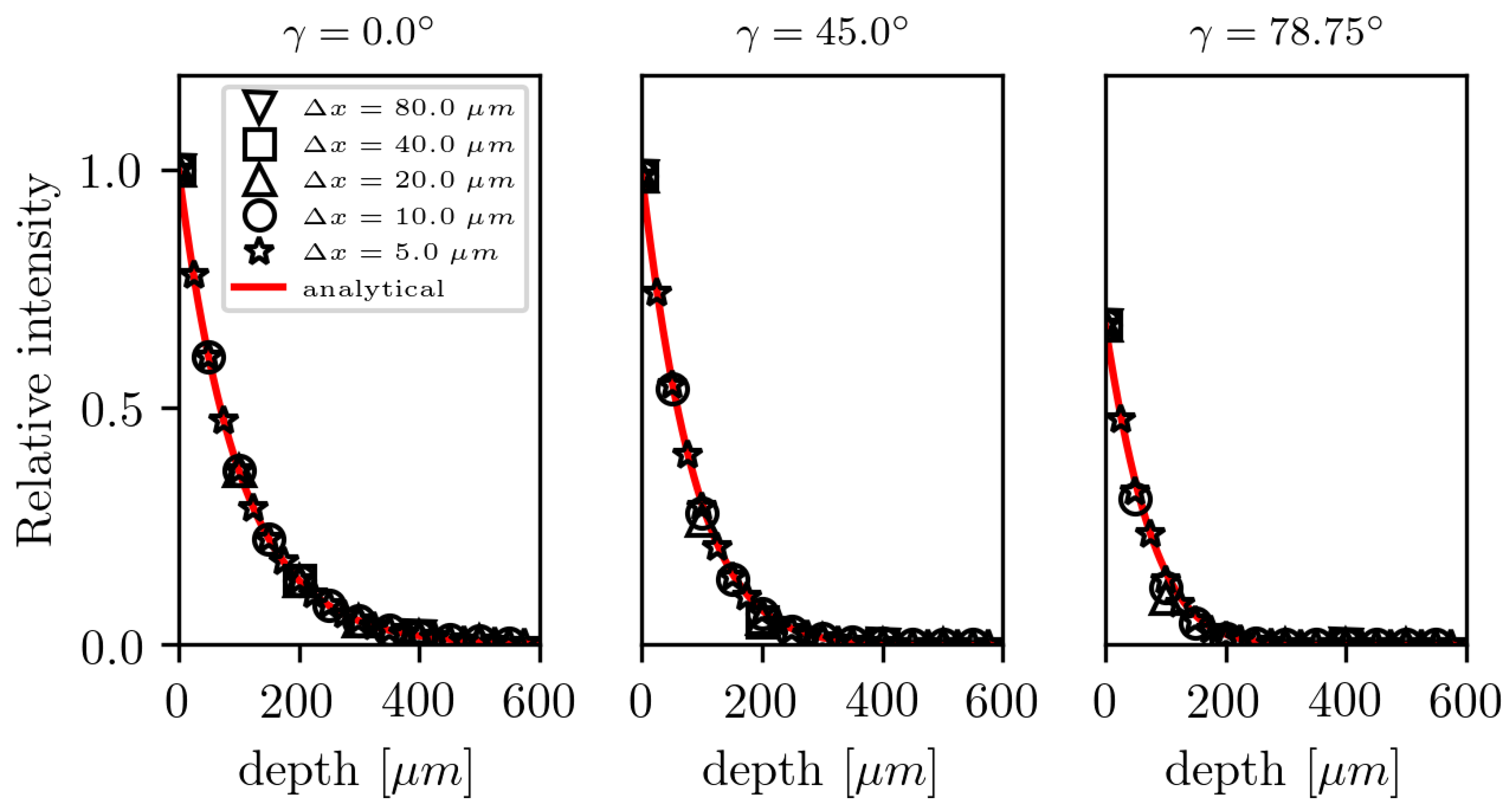

The effective penetration depth

is calculated by fitting Beer–Lambert law (Equation (

1)) onto the tail of

after the peak. The correlation between

and

for three different refractive indices is shown in

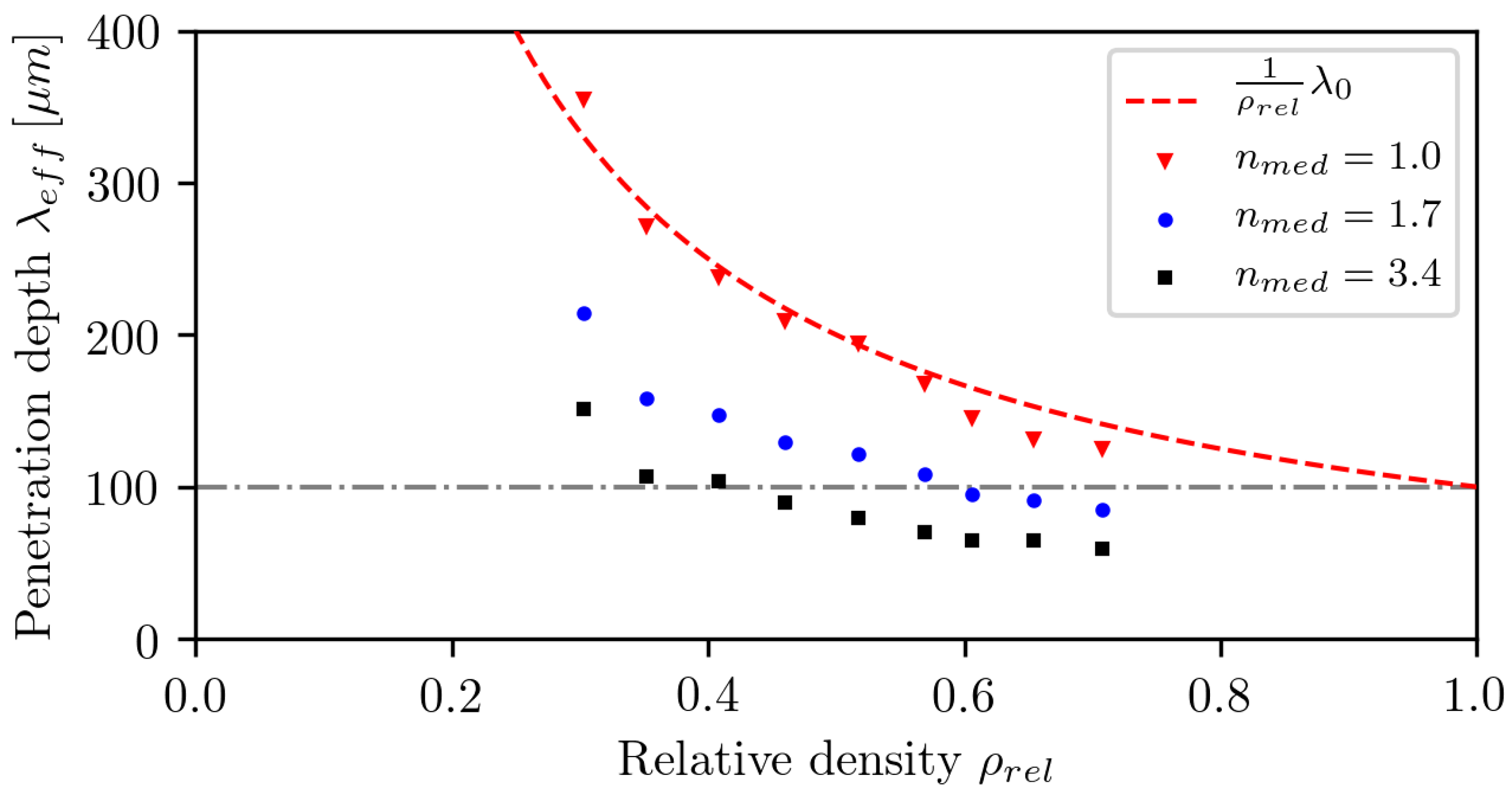

Figure 9.

For

, the effective absorption length is indirectly proportional to the relative density, which is plausible since the rays are not refracted or reflected and therefore propagate along a straight line. On their path, the energy of the ray is only absorbed within the particles, and the fraction of the area covered by dense media is given by

. Therefore, the effective absorption length in this simple case can be calculated by:

For

, the rays are refracted and reflected at the interface of particles and the atmosphere. First, the length of the path to reach the same depth is increased by refraction; therefore, more energy is absorbed. Second, the propagation vector of a portion of the reflected rays points towards the surface of the powder bed, and thereby, a net radiation transport is established, increasing the energy fraction absorbed near the surface. These two effects can considerably decrease the effective absorption length. It is shown that this can even decrease the effective penetration depth below the penetration depth in bulk material. It is especially relevant for powders, e.g., PA12, where the penetration depth is larger than the mean particle size

, because a significant fraction of the total energy is transmitted beyond the first particle layer, and therefore, more interfaces are crossed. A smaller effective absorption length results in a higher energy density at the powder bed surface and, therefore, in higher peak temperatures during sintering, which can lead to degradation of the polymer. Possible implications need to be considered if using finer particle distributions or increasing the relative powder bed density and thereby increasing the interface density. Furthermore, these effects need to be considered when modeling the process and simplifying the powder to a continuum, since Equation (

20) is not sufficient to calculate the penetration depth for

.

6. Conclusions

An absorption model for the interaction of a light source with a single wavelength (e.g., a laser) in complex geometries, such as a polymeric powder bed, is presented. The model is compared with the analytical solution for a plain surface. Furthermore, the attenuation coefficient for polyamide 12 was measured, and the results were used to simulate the absorptance, reflectance and transmittance in a stochastic powder bed, comparing it with experimental data. Overall, a good agreement was found. Additionally, it was shown that the effective penetration depth can be lower than the penetration depth in bulk material for polymer powders, due to refraction and reflection at the interfaces of particles and the atmosphere. This phenomena increases the energy density absorbed at the surface of the powder bed and can increase the peak temperatures in the top layers. It needs to be considered when modeling the process. Furthermore, it could limit the processability of fine powder distributions at high powder bed densities, due to the increase of peak temperatures.