Nitrogen-Containing Fabric Adsorbents Prepared by Radiation Grafting for Removal of Chromium from Wastewater

Abstract

:1. Introduction

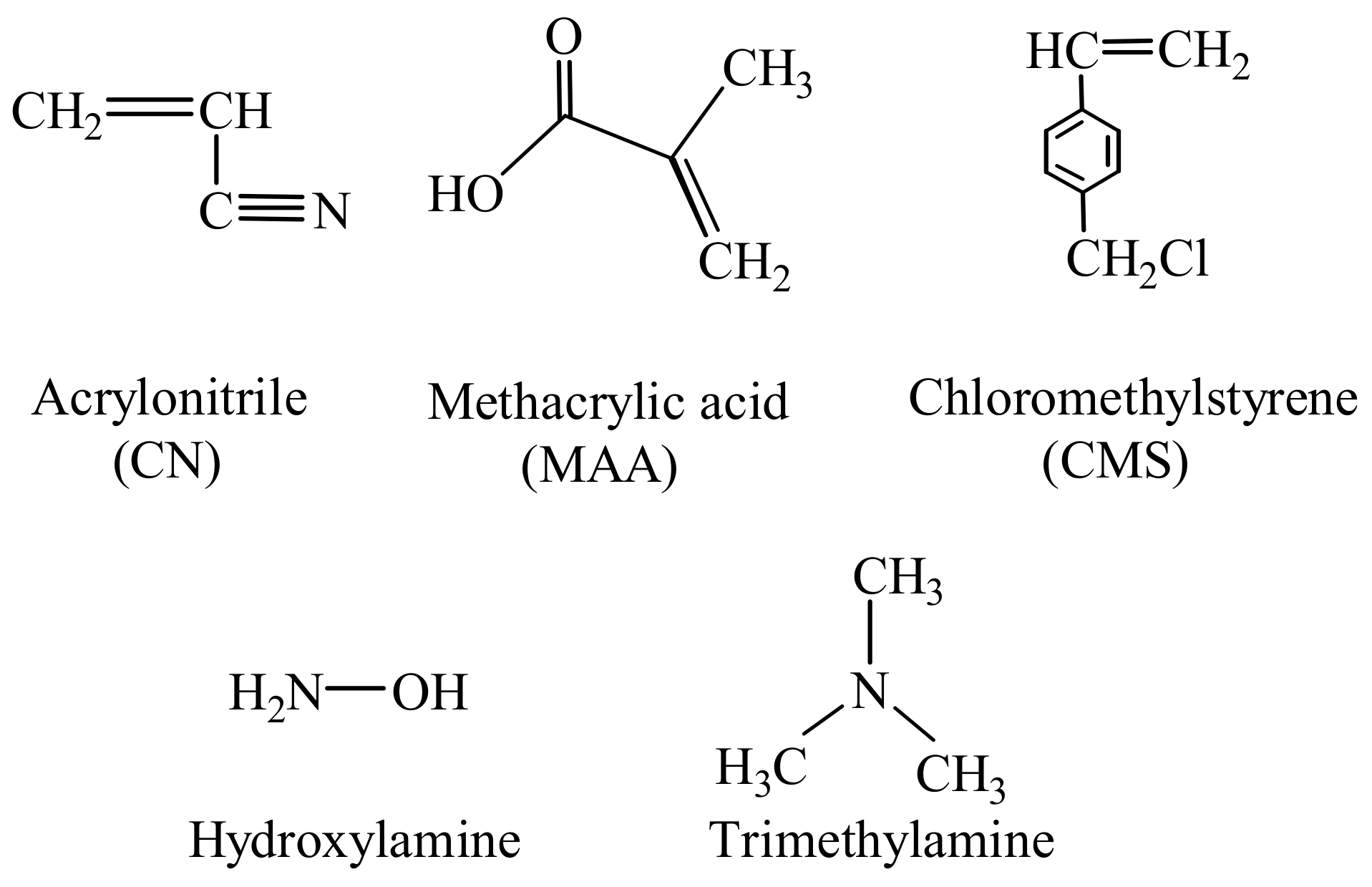

2. Experimental

2.1. Materials

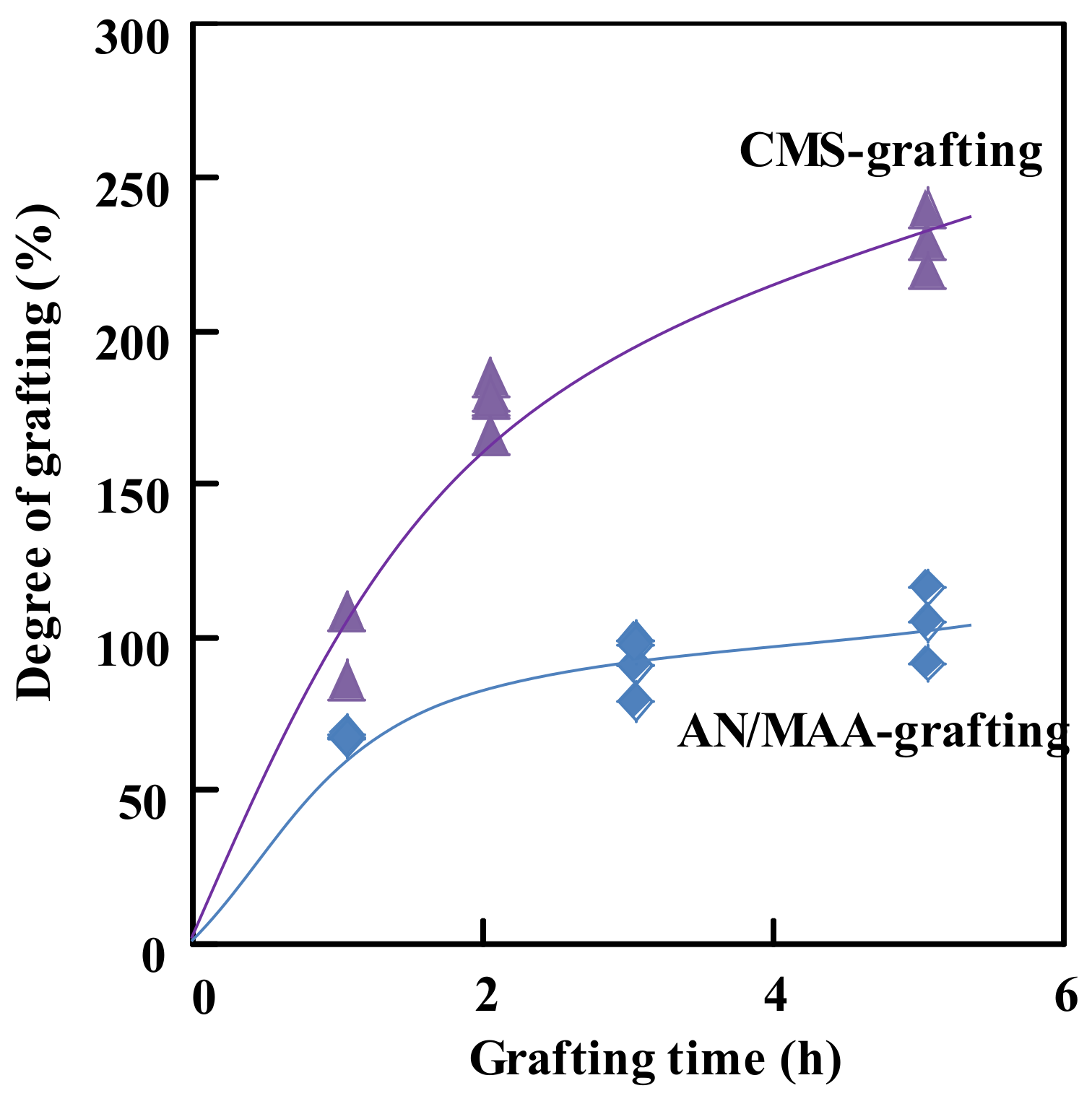

2.2. Radiation Grafting

2.3. Functionalization

2.4. Fourier Transform Infrared (FTIR) and Thermogravimetry/Differential Thermal Analysis (TG/DTA) Measurements

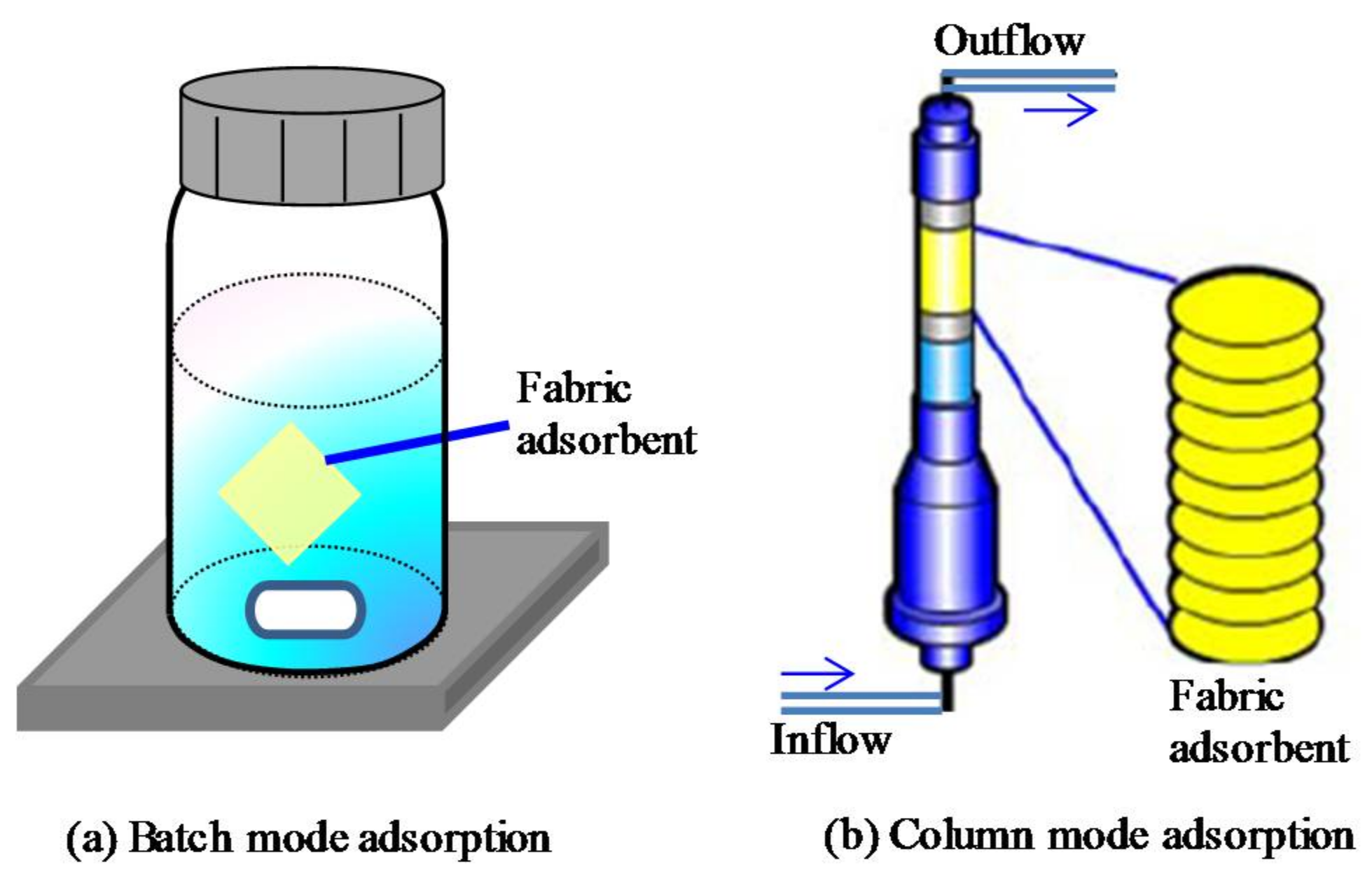

2.5. Batch and Column Mode Adsorptions

3. Results and Discussion

3.1. Preparation of the Fabric Adsorbents

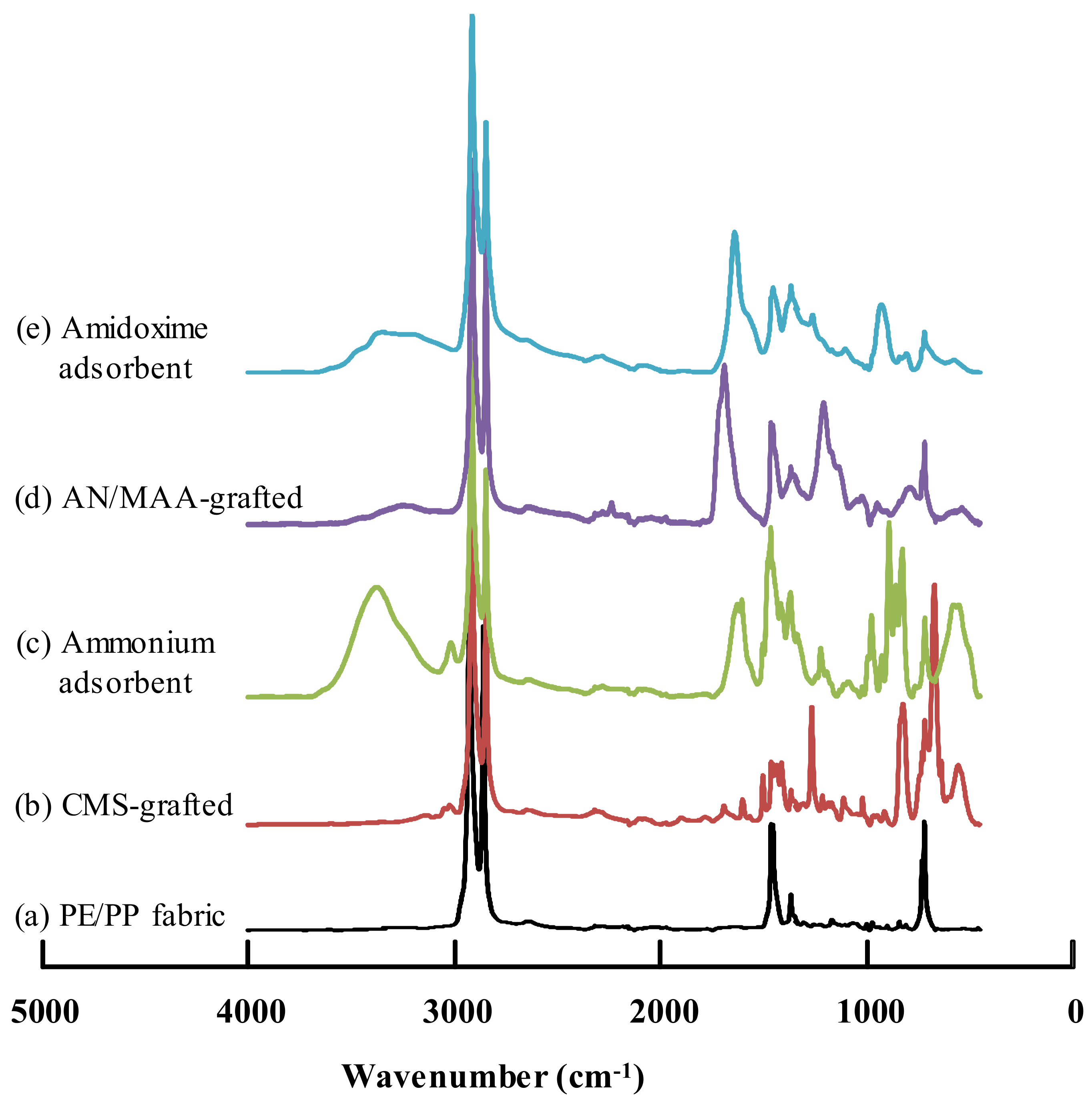

3.2. Characterization of Fabric Adsorbents by FTIR/ATR and TG/DTA Analysis

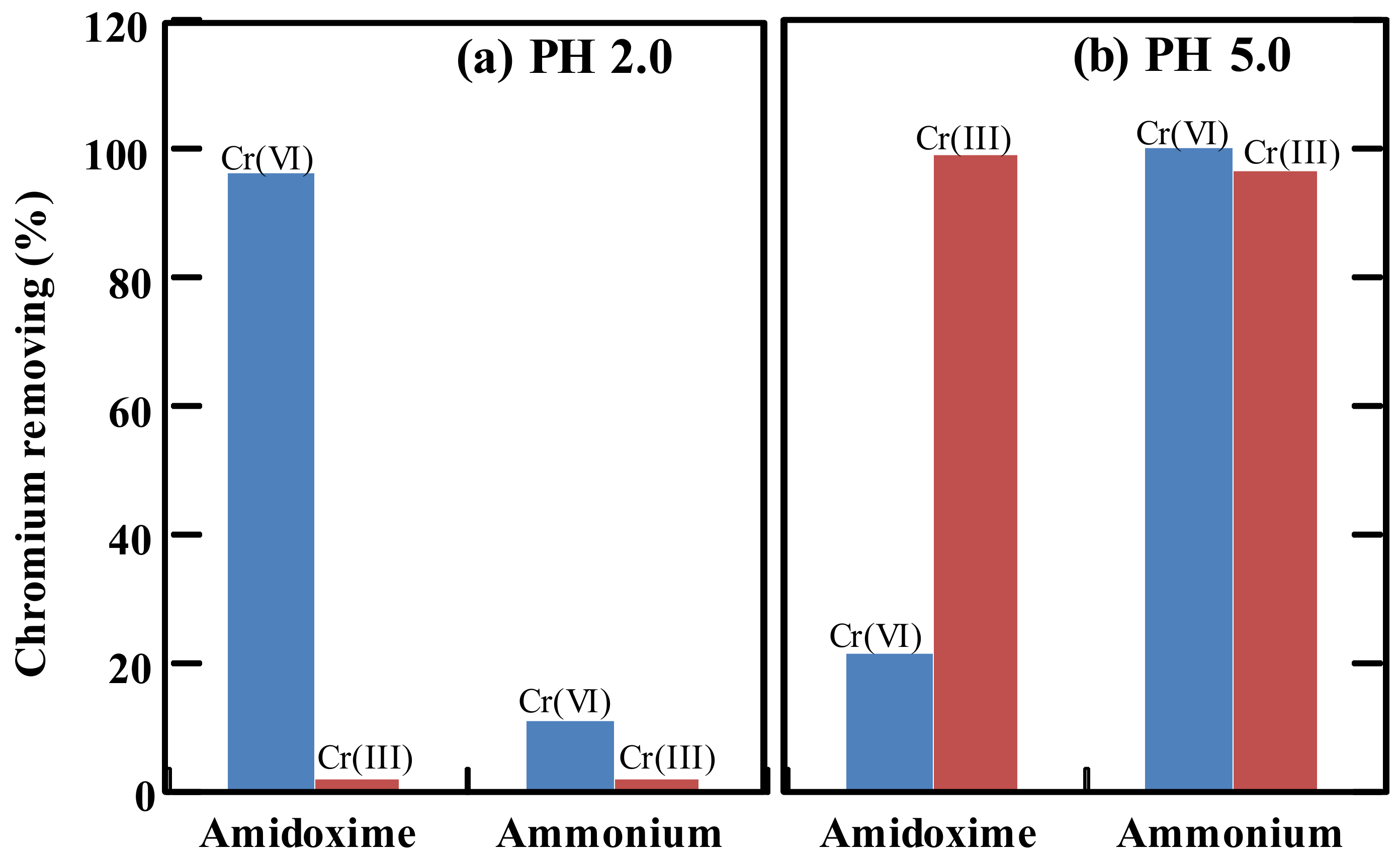

3.3. Batch Mode Adsorption

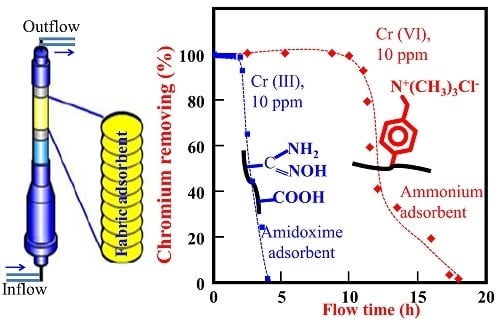

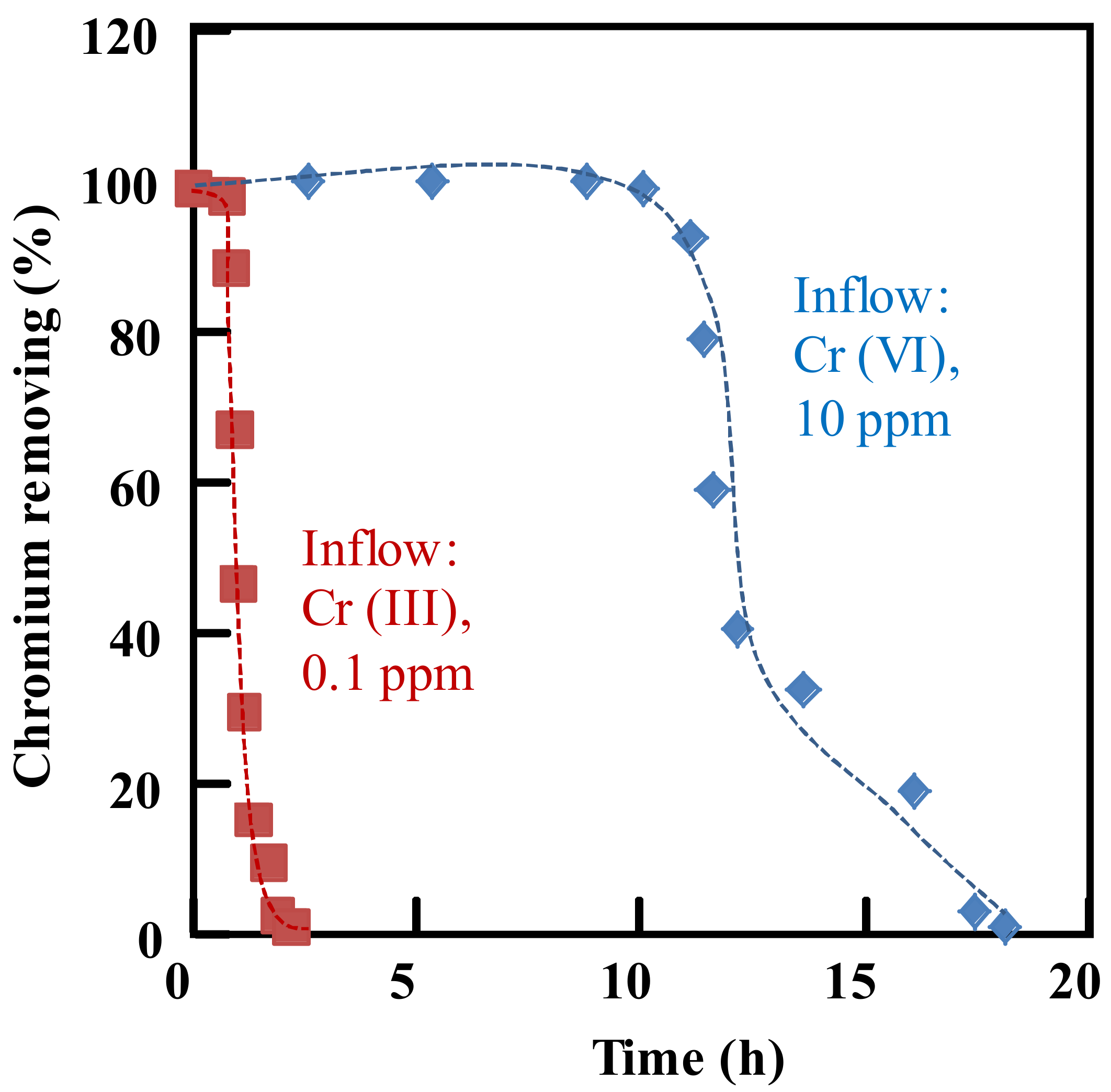

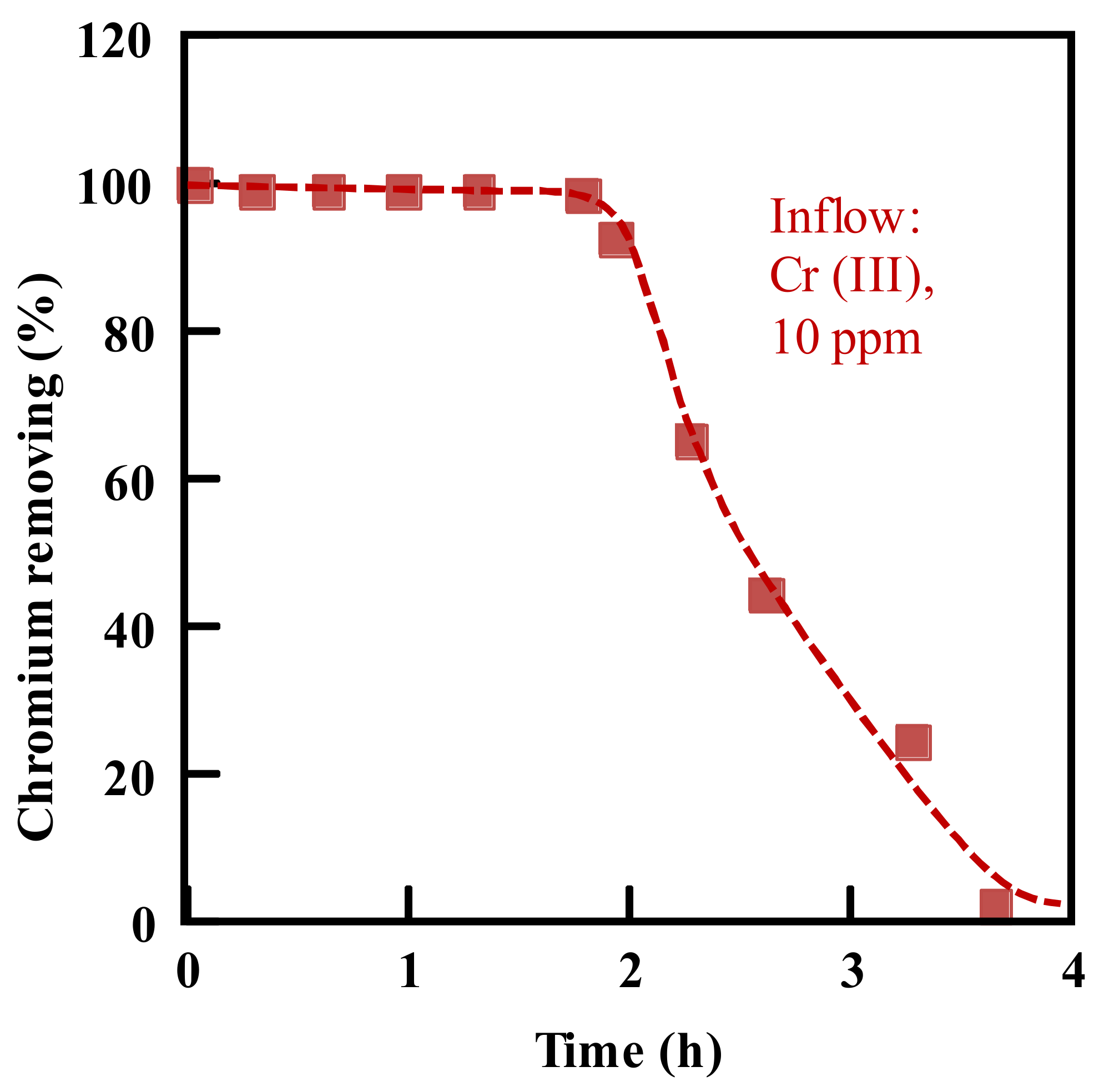

3.4. Column Mode Adsorption

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Costa, M.; Klein, C.B. Toxicity and carcinogenicity of chromium compounds in humans. Crit. Rev. Toxicol. 2006, 36, 155–163. [Google Scholar] [CrossRef] [PubMed]

- Golbaz, S.; Jafari, A.J.; Rafiee, M.; Kalantary, R.R. Separate and simultaneous removal of phenol, chromium, and cyanide from aqueous solution by coagulation/precipitation: Mechanisms and theory. Chem. Eng. J. 2014, 253, 251–257. [Google Scholar] [CrossRef]

- Martín-Domínguez, A.; Rivera-Huerta, M.D.L.; Pérez-Castrejón, S.; Garrido-Hoyos, S.E.; Villegas-Mendoza, I.E.; Gelover-Santiago, S.L.; Drogui, P.; Buelna, G. Chromium removal from drinking water by redox-assisted coagulation: Chemical versus electrocoagulation. Sep. Purif. Technol. 2018, 200, 266–272. [Google Scholar] [CrossRef]

- Duan, W.; Chen, G.; Chen, C.; Sanghvi, R.; Iddya, A.; Walker, S.; Liu, H.; Ronen, A.; Jassby, D. Electrochemical removal of hexavalent chromium using electrically conducting carbon nanotube/polymer composite ultrafiltration membranes. J. Membr. Sci. 2017, 531, 160–171. [Google Scholar] [CrossRef]

- Dharnaik, A.S.; Ghosh, P.K. Hexavalent chromium [Cr(VI)] removal by the electrochemical ion-exchange process. Environ. Technol. 2014, 35, 2272–2279. [Google Scholar] [CrossRef] [PubMed]

- Rengaraj, S.; Yeon, K.H.; Moon, S.H. Removal of chromium from water and wastewater by ion exchange resins. J. Hazard. Mater. 2001, 87, 273–287. [Google Scholar] [CrossRef]

- Dehghani, M.H.; Sanaei, D.; Ali, I.; Bhatnagar, A. Removal of chromium (VI) from aqueous solution using treated waste newspaper as a low-cost adsorbent: Kinetic modeling and isotherm studies. J. Mol. Liq. 2016, 215, 671–679. [Google Scholar] [CrossRef]

- Habiba, U.; Siddique, T.A.; Joo, T.C.; Salleh, A.; Ang, B.C.; Afifi, A.M. Synthesis of chitosan/polyvinyl alcohol/zeolite composite for removal of methyl orange, Congo red and chromium (VI) by flocculation/adsorption. Carbohydr. Polym. 2017, 157, 1568–1576. [Google Scholar] [CrossRef] [PubMed]

- Fu, F.; Wang, Q. Removal of heavy metal ions from wastewaters: A review. J. Environ. Manag. 2011, 92, 407–418. [Google Scholar] [CrossRef] [PubMed]

- Khezami, L.; Capart, R. Removal of chromium (VI) from aqueous solution by activated carbons: Kinetic and equilibrium studies. J. Hazard. Mater. 2005, 123, 223–231. [Google Scholar] [CrossRef] [PubMed]

- Gupta, V.K.; Agarwal, S.; Saleh, T.A. Chromium removal by combining the magnetic properties of iron oxide with adsorption properties of carbon nanotubes. Water Res. 2011, 45, 2207–2212. [Google Scholar] [CrossRef] [PubMed]

- Garg, U.K.; Kaur, M.P.; Garg, V.K.; Sud, D. Removal of hexavalent chromium from aqueous solution by agricultural waste biomass. J. Hazard. Mater. 2007, 140, 60–68. [Google Scholar] [CrossRef] [PubMed]

- Gu, H.; Rapole, S.B.; Sharma, J.; Huang, Y.; Cao, D.; Colorado, H.A.; Luo, Z.; Haldolaarachchige, N.; Yong, D.; Walters, B.; et al. Magnetic polyaniline nanocomposites toward toxic hexavalent chromium removal. RSC Adv. 2012, 2, 11007–11018. [Google Scholar] [CrossRef]

- Kampalanonwat, P.; Supaphol, P. Preparation and adsorption behavior of aminated electrospun polyacrylonitrile nanofiber mats for heavy metal ion removal. ACS Appl. Mater. Int. 2010, 2, 3619–3627. [Google Scholar] [CrossRef] [PubMed]

- Qiu, B.; Xu, C.; Sun, D.; Wei, H.; Zhang, X.; Guo, J.; Wei, S. Polyaniline coating on carbon fiber fabrics for improved hexavalent chromium removal. RSC Adv. 2014, 4, 29855–29865. [Google Scholar] [CrossRef]

- Mayer-Gall, T.; Opwis, K.; Gutmann, J.S. Polyvinylamine modified polyester fibers–innovative textiles for the removal of chromate from contaminated groundwater. J. Mater. Chem. A 2015, 3, 386–394. [Google Scholar] [CrossRef]

- Wang, J.; Pan, K.; Giannelis, E.; Bao, B. Polyacrylonitrile/polyaniline core/shell nanofiber mat for removal of hexavalent chromium from aqueous solution: Mechanism and applications. RSC Adv. 2013, 3, 8978–8987. [Google Scholar] [CrossRef]

- Barsbay, M.; Kavaklı, P.A.; Güven, O. Removal of phosphate using copper-loaded polymeric ligand exchanger prepared by radiation grafting of polypropylene/polyethylene (PP/PE) nonwoven fabric. Radiat. Phys. Chem. 2010, 79, 227–232. [Google Scholar] [CrossRef]

- Nasef, M.M.; Güven, O. Radiation-grafted copolymers for separation and purification purposes: Status, challenges and future directions. Prog. Polym. Sci. 2012, 37, 1597–1656. [Google Scholar] [CrossRef]

- Goel, N.K.; Kumar, V.; Misra, N.; Varshney, L. Cellulose based cationic adsorbent fabricated via radiation grafting process for treatment of dyes waste water. Carbohydr. Polym. 2015, 132, 444–451. [Google Scholar] [CrossRef] [PubMed]

- Verma, S.K.; Kaur, I. Gamma-induced polymerization and grafting of a novel phosphorous-, nitrogen-, and sulfur-containing monomer on cotton fabric to impart flame retardancy. J. Appl. Polym. Sci. 2012, 125, 1506–1512. [Google Scholar] [CrossRef]

- Li, C.; Zhang, Y.; Peng, J.; Wu, H.; Li, J.; Zhai, M. Adsorption of Cr(VI) using cellulose microsphere-based adsorbent prepared by radiation-induced grafting. Radiat. Phys. Chem. 2012, 81, 967–970. [Google Scholar] [CrossRef]

- Dargaville, T.R.; George, G.A.; Hill, D.J.; Whittaker, A.K. High energy radiation grafting of fluoropolymers. Prog. Polym. Sci. 2003, 28, 1355–1376. [Google Scholar] [CrossRef]

- Chen, J.; Asano, M.; Maekawa, Y.; Yoshida, M. Chemically stable hybrid polymer electrolyte membranes prepared by radiation grafting, sulfonation, and silane-crosslinking techniques. J. Polym. Sci. A Polym. Chem. 2008, 46, 5559–5567. [Google Scholar] [CrossRef]

- Chen, J.; Asano, M.; Yamaki, T.; Yoshida, M. Preparation of sulfonated crosslinked PTFE-graft-poly(alkyl vinyl ether) membranes for polymer electrolyte membrane fuel cells by radiation processing. J. Membr. Sci. 2005, 256, 38–45. [Google Scholar] [CrossRef]

- Chen, J.; Asano, M.; Yamaki, T.; Yoshida, M. Preparation and characterization of chemically stable polymer electrolyte membranes by radiation-induced graft copolymerization of four monomers into ETFE films. J. Membr. Sci. 2006, 269, 194–204. [Google Scholar] [CrossRef]

- Chen, J.; Septiani, U.; Asano, M.; Maekawa, Y.; Kubota, H.; Yoshida, M. Comparative study on the preparation and properties of radiation-grafted polymer electrolyte membranes based on fluoropolymer films. J. Appl. Polym. Sci. 2007, 103, 1966–1972. [Google Scholar] [CrossRef]

- Chen, J.; Maekawa, Y.; Asano, M.; Yoshida, M. Double crosslinked polyetheretherketone-based polymer electrolyte membranes prepared by radiation and thermal crosslinking techniques. Polymer 2007, 48, 6002–6009. [Google Scholar] [CrossRef]

- Saito, T.; Brown, S.; Chatterjee, S.; Kim, J.; Tsouris, C.; Mayes, R.T.; Kuo, L.; Oyola, Y.; Hanke, C.; Dai, S. Uranium recovery from seawater: Development of fiber adsorbents prepared via atom-transfer radical polymerization. J. Mater. Chem. A 2014, 2, 14674–14681. [Google Scholar] [CrossRef]

- Liu, X.; Liu, H.; Ma, H.; Cao, C.; Yu, M.; Wang, Z.; Deng, B.; Wang, M.; Li, J. Adsorption of the uranyl ions on an amidoxime-based polyethylene nonwoven fabric prepared by preirradiation-induced emulsion graft polymerization. Ind. Eng. Chem. Res. 2012, 51, 15089–15095. [Google Scholar] [CrossRef]

- Biniak, S.; Pakuła, M.; Szymański, G.S.; Światkowski, A. Effect of activated carbon surface oxygen-and/or nitrogen-containing groups on adsorption of copper (II) ions from aqueous solution. Langmuir 1999, 15, 6117–6122. [Google Scholar] [CrossRef]

- Li, Q.; Qian, Y.; Cui, H.; Zhang, Q.; Tang, R.; Zhai, J. Preparation of poly(aniline-1,8-diaminonaphthalene) and its application as adsorbent for selective removal of Cr(VI) ions. Chem. Eng. J. 2011, 173, 715–721. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, X.; He, X.; Xiao, M.; Zhang, W.; Lu, C. A super biosorbent from dendrimer poly(amidoamine)-grafted cellulose nanofibril aerogels for effective removal of Cr(VI). J. Mater. Chem. A 2015, 3, 14703–14711. [Google Scholar] [CrossRef]

- Huang, S.H.; Chen, D.H. Rapid removal of heavy metal cations and anions from aqueous solutions by an amino-functionalized magnetic nano-adsorbent. J. Hazard. Mater. 2009, 163, 174–179. [Google Scholar] [CrossRef] [PubMed]

- Fel, E.; Khrouz, L.; Massardier, V.; Cassagnau, P.; Bonneviot, L. Comparative study of gamma-irradiated PP and PE polyolefins part 2: Properties of PP/PE blends obtained by reactive processing with radicals obtained by high shear or gamma-irradiation. Polymer 2016, 82, 217–227. [Google Scholar] [CrossRef]

- Kawai, T.; Saito, K.; Sugita, K.; Kawakami, T.; Kanno, J.; Katakai, A.; Seko, N.; Sugo, T. Preparation of hydrophilic amidoxime fibers by cografting acrylonitrile and methacrylic acid from an optimized monomer composition. Radiat. Phys. Chem. 2000, 59, 405–411. [Google Scholar] [CrossRef]

- Ueki, Y.; Mohamed, N.H.; Seko, N.; Tamada, M. Rapid biodiesel fuel production using novel fibrous catalyst synthesized by radiation-induced graft polymerization. Int. J. Org. Chem. 2011, 1, 20. [Google Scholar] [CrossRef]

- Varcoe, J.R.; Slade, R.C.; Lam How Yee, E.; Poynton, S.D.; Driscoll, D.J.; Apperley, D.C. Poly(ethylene-co-tetrafluoroethylene)-derived radiation-grafted anion-exchange membrane with properties specifically tailored for application in metal-cation-free alkaline polymer electrolyte fuel cells. Chem. Mater. 2007, 19, 2686–2693. [Google Scholar] [CrossRef]

- Kawai, T.; Saito, K.; Sugita, K.; Katakai, A.; Seko, N.; Sugo, T.; Kanno, J.; Kawakami, T. Comparison of amidoxime adsorbents prepared by cografting methacrylic acid and 2-hydroxyethyl methacrylate with acrylonitrile onto polyethylene. Ind. Eng. Chem. Res. 2000, 39, 2910–2915. [Google Scholar] [CrossRef]

- Chen, J.; Seko, N. Effects of RAFT Agent on the Chloromethylstyrene Polymerizations in a Simultaneous Radiation Grafting System. Polymers 2017, 9, 307. [Google Scholar] [CrossRef]

- Kavaklı, P.A.; Seko, N.; Tamada, M.; Güven, O. Radiation-induced graft polymerization of glycidyl methacrylate onto PE/PP nonwoven fabric and its modification toward enhanced amidoximation. J. Appl. Polym. Sci. 2007, 105, 1551–1558. [Google Scholar] [CrossRef]

- Vandiver, M.A.; Caire, B.R.; Pandey, T.P.; Li, Y.; Seifert, S.; Kusoglu, A.; Knauss, D.; Herring, A.; Liberatore, M.W. Effect of hydration on the mechanical properties and ion conduction in a polyethylene-b-poly(vinylbenzyl trimethylammonium) anion exchange membrane. J. Membr. Sci. 2016, 497, 67–76. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hayashi, N.; Chen, J.; Seko, N. Nitrogen-Containing Fabric Adsorbents Prepared by Radiation Grafting for Removal of Chromium from Wastewater. Polymers 2018, 10, 744. https://doi.org/10.3390/polym10070744

Hayashi N, Chen J, Seko N. Nitrogen-Containing Fabric Adsorbents Prepared by Radiation Grafting for Removal of Chromium from Wastewater. Polymers. 2018; 10(7):744. https://doi.org/10.3390/polym10070744

Chicago/Turabian StyleHayashi, Natsuki, Jinhua Chen, and Noriaki Seko. 2018. "Nitrogen-Containing Fabric Adsorbents Prepared by Radiation Grafting for Removal of Chromium from Wastewater" Polymers 10, no. 7: 744. https://doi.org/10.3390/polym10070744

APA StyleHayashi, N., Chen, J., & Seko, N. (2018). Nitrogen-Containing Fabric Adsorbents Prepared by Radiation Grafting for Removal of Chromium from Wastewater. Polymers, 10(7), 744. https://doi.org/10.3390/polym10070744