Special Resins for Stereolithography: In Situ Generation of Silver Nanoparticles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

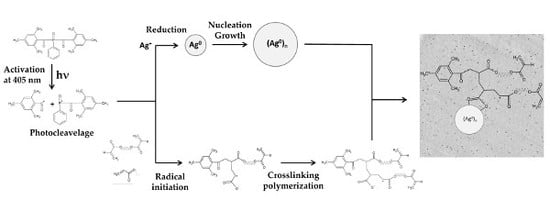

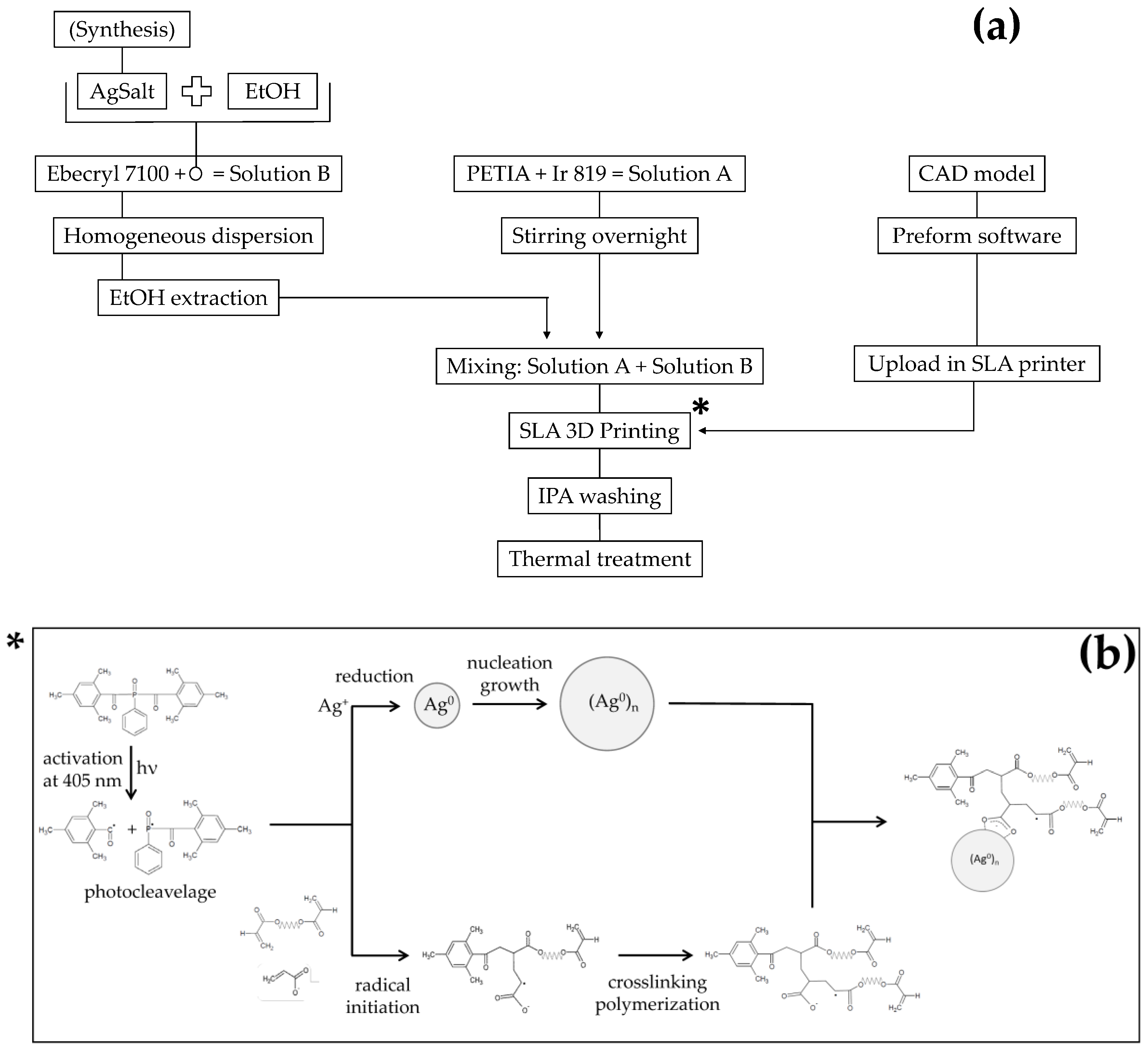

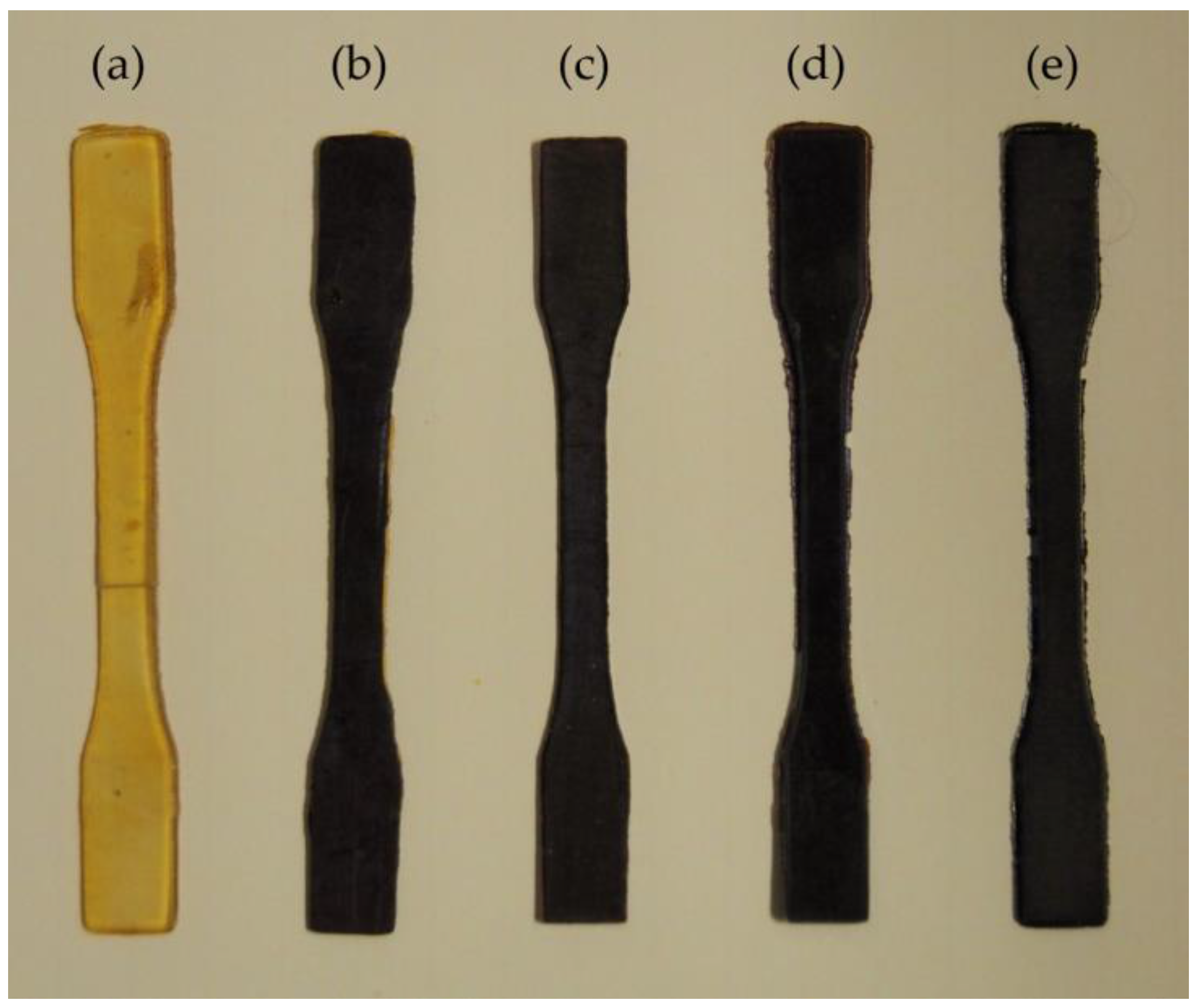

2.2. Samples Preparation

2.3. Samples Characterization

3. Results

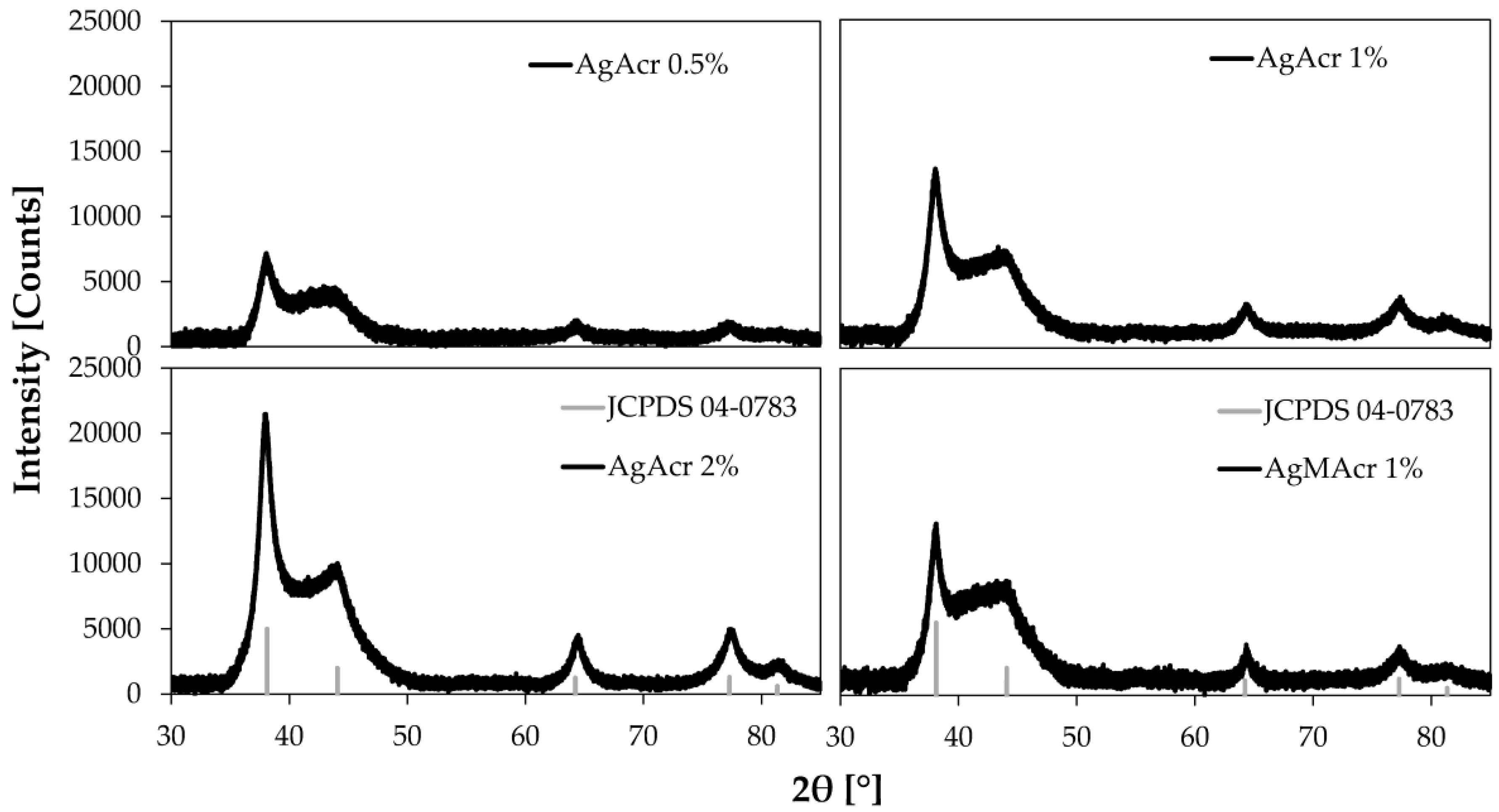

3.1. XRD and TEM Analysis

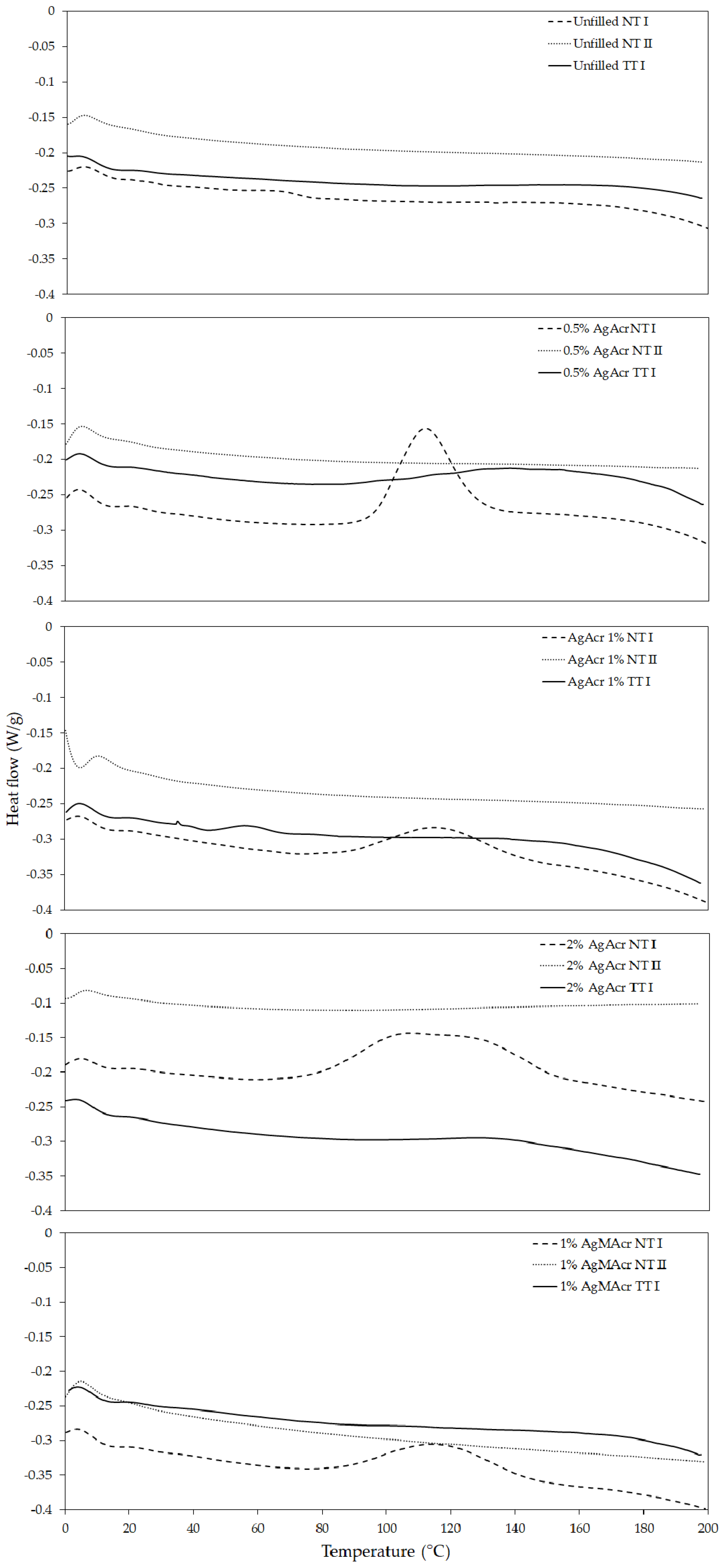

3.2. DSC Analysis

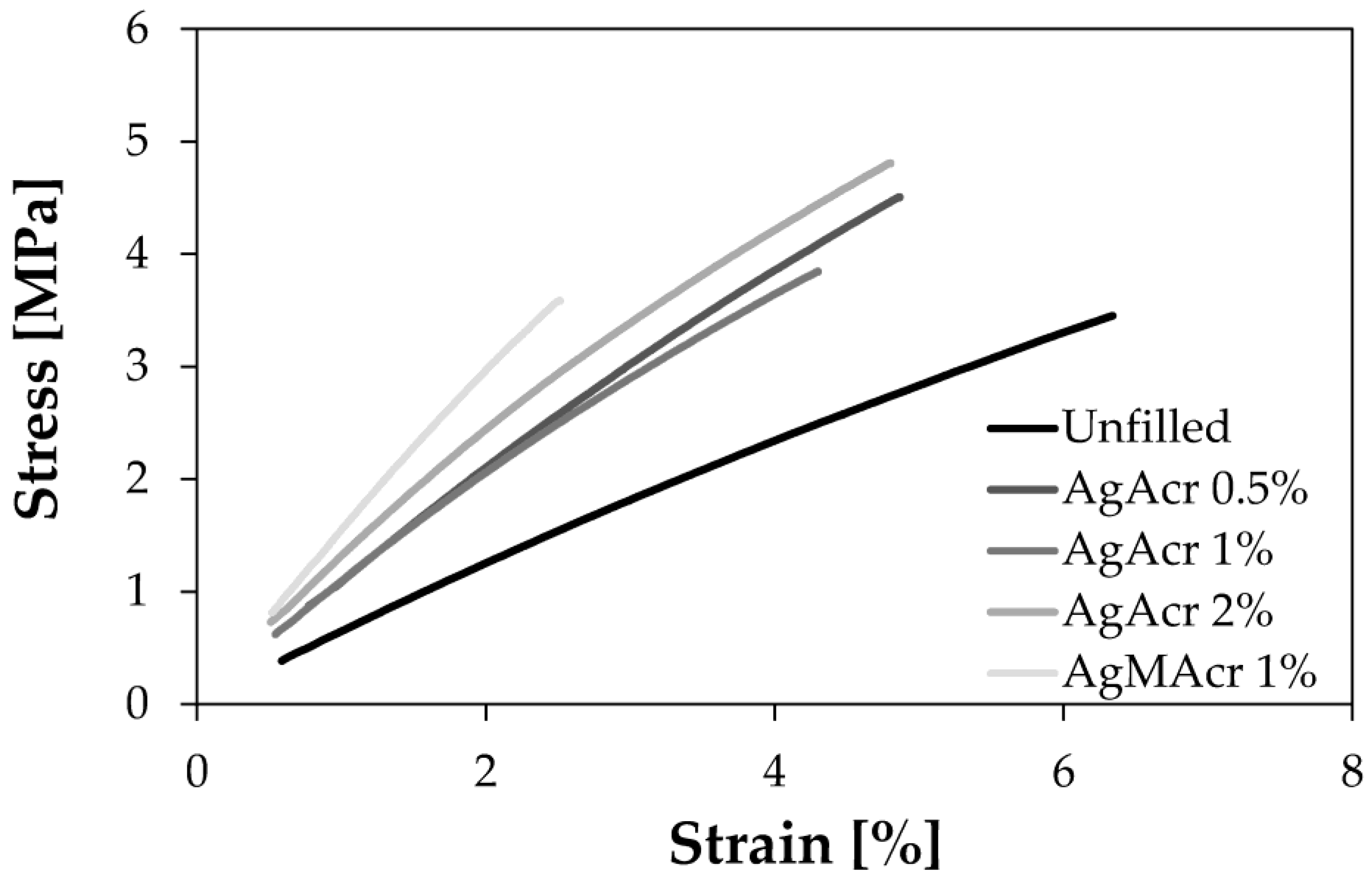

3.3. Tensile Properties

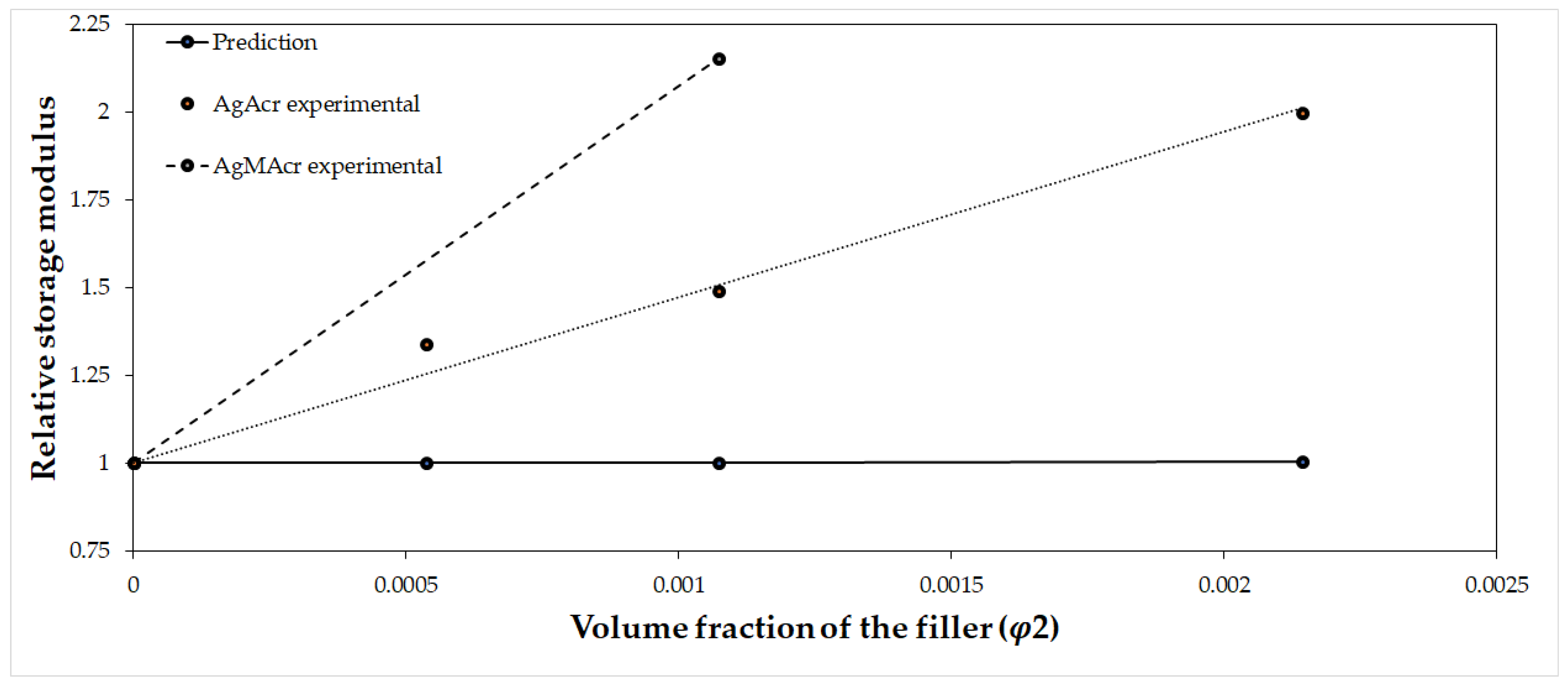

3.4. Dynamic-Mechanical Thermal Properties

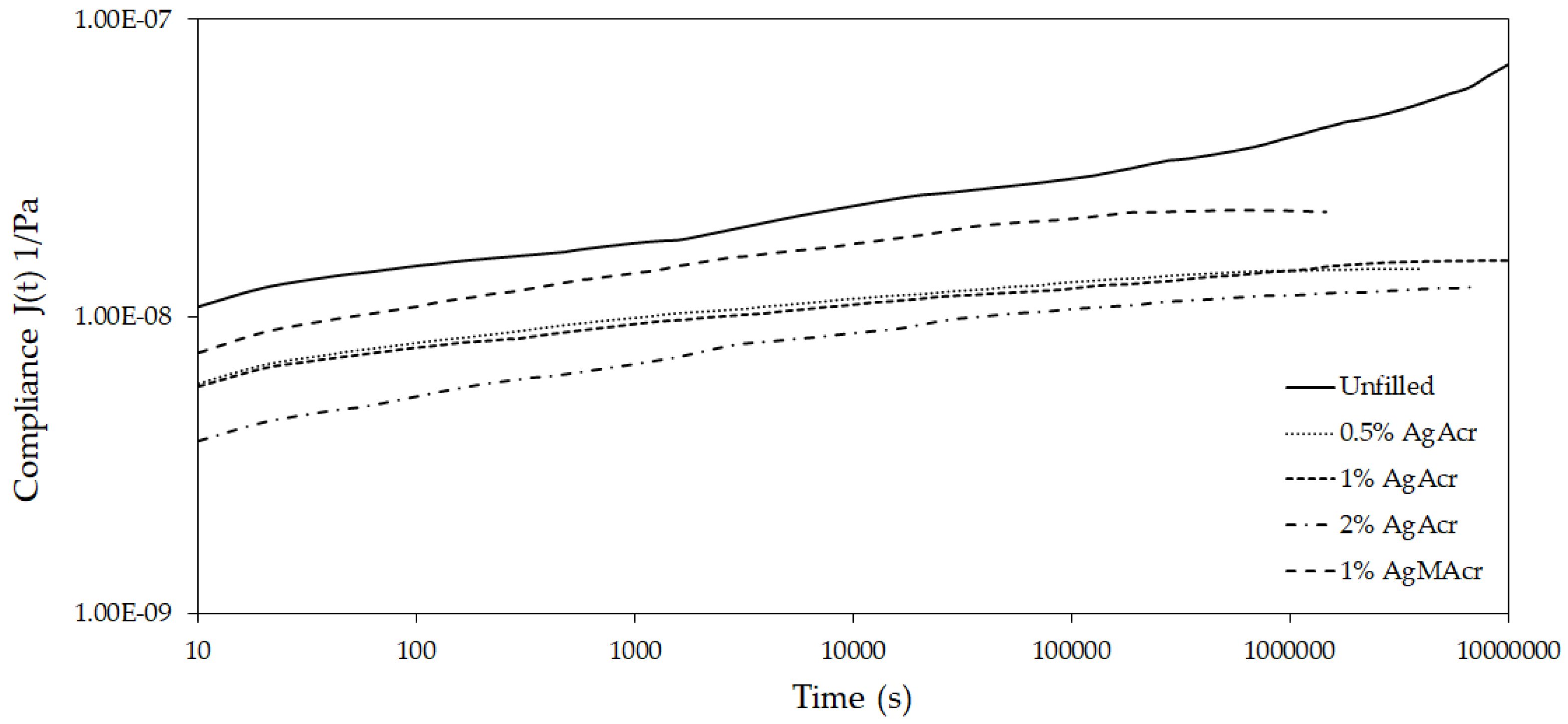

3.5. Creep Properties

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Schniederjans, D.G. Adoption of 3D-printing technologies in manufacturing: A survey analysis. Int. J. Prod. Econ. 2017, 183, 287–298. [Google Scholar] [CrossRef]

- Balletti, C.; Ballarin, M.; Guerra, F. 3D printing: State of the art and future perspectives. J. Cult. Herit. 2017, 26, 172–182. [Google Scholar] [CrossRef]

- Lee, J.-Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2010; pp. 1–473. [Google Scholar]

- Gurr, M.; Hofmann, D.; Ehm, M.; Thomann, Y.; Kubler, R.; Mülhaupt, R. Acrylic Nanocomposite Resins for Use in Stereolithography and Structural Light Modulation Based Rapid Prototyping and Rapid Manufacturing Technologies. Adv. Funct. Mater. 2008, 18, 2390–2397. [Google Scholar] [CrossRef]

- Czyzewski, J.; Burzyński, P.; Gaweł, K.; Meisner, J. Rapid prototyping of electrically conductive components using 3D printing technology. J. Mater. Process. Technol. 2009, 209, 5281–5285. [Google Scholar] [CrossRef]

- Yugang, D.; Yuan, Z.; Yiping, T.; Dichen, L. Nano-TiO2-modified photosensitive resin for RP. Rapid Prototyp. J. 2011, 17, 247–252. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. B 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Manapat, J.Z.; Chen, Q.; Ye, P.; Advincula, R.C. 3D printing of polymer nanocomposites via stereolithography. Macromol. Mater. Eng. 2017, 302, 1–13. [Google Scholar] [CrossRef]

- Fadeel, B. Clear and present danger? Engineered nanoparticles and the immune system. Swiss Med. Wkly. 2012, 142, w13609. [Google Scholar] [CrossRef] [PubMed]

- Farahani, R.D.; Dub, M.; Therriault, D. Three-Dimensional Printing of Multifunctional Nanocomposites: Manufacturing Techniques and Applications. Adv. Mater. 2016, 28, 5794–5821. [Google Scholar] [CrossRef] [PubMed]

- Vishwakarma, V.; Samal, S.; Manoharan, N. Safety and risk associated with nanoparticles-a review. J. Miner. Mater. Charact. Eng. 2010, 9, 455–459. [Google Scholar] [CrossRef]

- Esposito Corcione, C.; Striani, R.; Montagna, F.; Cannoletta, D. Organically modified montmorillonite polymer nanocomposites for stereolithography building process. Polym. Adv. Technol. 2015, 26, 92–98. [Google Scholar] [CrossRef]

- Kumar, S.; Hofmann, M.; Steinmann, B.; Foster, E.J.; Weder, C. Reinforcement of stereolithographic resins for rapid prototyping with cellulose nanocrystals. Appl. Mater. Interfaces 2012, 4, 5399–5407. [Google Scholar] [CrossRef] [PubMed]

- Sandoval, J.H.; Soto, K.F.; Murr, L.E.; Wicker, R.B. Nanotailoring photocrosslinkable epoxy resins with multi-walled carbon nanotubes for stereolithography layered manufacturing. J. Mater. Sci. 2007, 42, 156–165. [Google Scholar] [CrossRef]

- Lin, D.; Jin, S.; Zhang, F.; Wang, C.; Wang, Y.; Zhou, C.; Cheng, G.J. 3D stereolithography printing of graphene oxide reinforced complex architectures. Nanotechnology 2015, 26, 434003. [Google Scholar] [CrossRef] [PubMed]

- Sandoval, J.H.; Wicker, R.B. Functionalizing stereolithography resins: Effects of dispersed multi-walled carbon nanotubes on physical properties. Rapid Prototyp. J. 2006, 12, 292–303. [Google Scholar] [CrossRef]

- Martin, J.J.; Fiore, B.E.; Erb, R.M. Designing bioinspired composite reinforcement architectures via 3D magnetic printing. Nat. Commun. 2015, 6, 8641. [Google Scholar] [CrossRef] [PubMed]

- Melenka, G.W.; Cheung, B.K.O.; Schofield, J.S.; Dawson, M.R.; Carey, J.P. Evaluation and prediction of the tensile properties of continuous fiber-reinforced 3D printed structures. Compos. Struct. 2016, 153, 866–875. [Google Scholar] [CrossRef]

- Spackman, C.C.; Frank, C.R.; Picha, K.C.; Samuel, J. 3D printing of fiber-reinforced soft composites: Process study and material characterization. J. Manuf. Process. 2016, 23, 296–305. [Google Scholar] [CrossRef]

- Fantino, E.; Chiappone, A.; Roppolo, I.; Manfredi, D.; Bongiovanni, R.; Pirri, C.F. 3D Printing of Conductive Complex Structures with in Situ Generation of Silver Nanoparticles. Adv. Mater. 2016, 28, 3712–3717. [Google Scholar] [CrossRef] [PubMed]

- Cooperstein, I.; Layani, M.; Magdassi, S. 3D printing of porous structures by UV-curable O/W emulsion for fabrication of conductive objects. J. Mater. Chem. C 2015, 3, 2040–2044. [Google Scholar] [CrossRef]

- Ronca, A.; Ambrosio, L.; Grijpma, D.W. Preparation of designed poly(d,l-lactide)/nanosized hydroxyapatite composite structures by stereolithography. Acta Biomater. 2013, 9, 5989–5996. [Google Scholar] [CrossRef] [PubMed]

- Yuanyuan, Z.; Houmin, L.; Xi, Y.; Tao, Z.; Kaiqiang, Z.; Wei, S.Z.L.; Sun, H. Additive Manufacturing of Carbon Nanotube-Photopolymer Composite Radar Absorbing Materials. Polym. Compos. 2016. [Google Scholar] [CrossRef]

- Kim, K.; Zhu, W.; Qu, X.; Aaronson, C.; McCall, W.R.; Chen, S.C.; Sirbuly, D.J. 3D optical printing of piezoelectric nanoparticle—Polymer composite materials. ACS Nano 2014, 8, 9799–9806. [Google Scholar] [CrossRef] [PubMed]

- Zaier, M.; Vidal, L.; Hajjar-Garreau, S.; Balan, L. Generating highly reflective and conductive metal layers through a light-assisted synthesis and assembling of silver nanoparticles in a polymer matrix. Sci. Rep. 2017, 7, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Soto-Quintero, A.; Romo-Uribe, Á.; Bermúdez-Morales, V.H.; Quijada-Garrido, I.; Guarrotxena, N. 3D-hydrogel based polymeric nanoreactors for silver nano-antimicrobial composites generation. Nanomaterials 2017, 7, 209. [Google Scholar] [CrossRef] [PubMed]

- Matsuhisa, N.; Inoue, D.; Zalar, P.; Jin, H.; Matsuba, Y.; Itoh, A.; Yokota, T.; Hashizume, D.; Someya, T. Printable elastic conductors by in situ formation of silver nanoparticles from silver flakes. Nat. Mater. 2017, 16, 834–840. [Google Scholar] [CrossRef] [PubMed]

- Weng, Z.; Zhou, Y.; Lin, W.; Senthil, T.; Wu, L. Structure-property relationship of nano enhanced stereolithography resin for desktop SLA 3D printer. Compos. A 2016, 88, 234–242. [Google Scholar] [CrossRef]

- He, M.; Zhao, Y.; Wang, B.; Xi, Q.; Zhou, J.; Liang, Z. 3D Printing Fabrication of Amorphous Thermoelectric Materials with Ultralow Thermal Conductivity. Small 2015, 11, 5889–5894. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Li, Y.; Liu, S. Rapid prototyping of continuous carbon fiber reinforced polylactic acid composites by 3D printing. J. Mater. Process. Technol. 2016, 238, 218–225. [Google Scholar] [CrossRef]

- Sciancalepore, C.; Moroni, F.; Messori, M.; Bondioli, F. Acrylate-based silver nanocomposite by simultaneous polymerization–reduction approach via 3D stereolithography. Compos. Commun. 2017, 6, 11–16. [Google Scholar] [CrossRef]

- Wulandari, P.; Nagahiro, T.; Michioka, K.; Tamada, K.; Ishibashi, K.; Kimura, Y.; Niwano, M. Coordination of Carboxylate on Metal Nanoparticles Characterized by Fourier Transform Infrared Spectroscopy. Chem. Lett. 2008, 37, 888–889. [Google Scholar] [CrossRef]

- Nishimura, S.; Mott, D.; Takagaki, A.; Maenosono, S.; Ebitani, K. Role of base in the formation of silver nanoparticles synthesized using sodium acrylate as a dual reducing and encapsulating agent. Phys. Chem. Chem. Phys. 2011, 13, 9335–9343. [Google Scholar] [CrossRef] [PubMed]

- Prabhu, S.; Poulose, E.K. Silver nanoparticles: Mechanism of antimicrobial action, synthesis, medical applications, and toxicity effects. Int. Nano Lett. 2012, 2, 32–41. [Google Scholar] [CrossRef]

- Ferry, J.D. Viscoelastic Properties of Polymers, 7th ed.; Wiley: New York, NY, USA, 1980; ISBN 978-0471048947. [Google Scholar]

- Nielsen, L.E.; Landel, R.F. Mechanical Properties of Polymers and Composites, 2nd ed.; Marcel Dekker Inc.: New York, NY, USA, 1994; ISBN 9780824789640. [Google Scholar]

- Fantino, E.; Chiappone, A.; Calignano, F.; Fontana, M.; Pirri, F.; Roppolo, I. In situ thermal generation of silver nanoparticles in 3D printed polymeric structures. Materials 2016, 9, 589. [Google Scholar] [CrossRef] [PubMed]

- Shao-Yun, F.; Xi-Qiao, F.; Bernd, L.; Yiu-Wing, M. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate-polymer composites. Compos. B 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Morselli, D.; Bondioli, F.; Sangermano, M.; Messori, M. Photo-cured epoxy networks reinforced with TiO2 in-situ generated by means of non-hydrolytic sol-gel process. Polymer 2012, 53, 283–290. [Google Scholar] [CrossRef]

- Sciancalepore, C.; Bondioli, F.; Messori, M. Non-hydrolytic sol-gel synthesis and reactive suspension method: An innovative approach to obtain magnetite-epoxy based nanocomposite materials. J. Sol-Gel Sci. Technol. 2017, 81, 69–83. [Google Scholar] [CrossRef]

- Barrera, G.; Sciancalepore, C.; Messori, M.; Allia, P.; Tiberto, P.; Bondioli, F. Magnetite-epoxy nanocomposites obtained by the reactive suspension method: Microstructural, thermo-mechanical and magnetic properties. Eur. Polym. J. 2017, 94, 354–365. [Google Scholar] [CrossRef]

| Sample | Et (MPa) | σM (MPa) | εB (%) |

|---|---|---|---|

| Unfilled | 68 ± 2 | 3.4 ± 0.3 | 6.1 ± 0.7 |

| AgAcr 0.5% | 111 ± 3 | 4.3 ± 0.4 | 4.8 ± 0.6 |

| AgAcr 1% | 113 ± 8 | 4.0 ± 0.4 | 4.0 ± 0.1 |

| AgAcr 2% | 142 ± 8 | 5.0 ± 0.8 | 4.7 ± 0.9 |

| AgMAcr 1% | 153 ± 5 | 3.4 ± 0.3 | 2.4 ± 0.2 |

| Sample | TgDMTA (°C) | E′ at 60 °C (MPa) |

|---|---|---|

| Unfilled | 0.7 | 65 |

| AgAcr 0.5% | 4.9 | 87 |

| AgAcr 1% | 5.1 | 97 |

| AgAcr 2% | 11.8 | 130 |

| AgMAcr 1% | 10.5 | 140 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taormina, G.; Sciancalepore, C.; Bondioli, F.; Messori, M. Special Resins for Stereolithography: In Situ Generation of Silver Nanoparticles. Polymers 2018, 10, 212. https://doi.org/10.3390/polym10020212

Taormina G, Sciancalepore C, Bondioli F, Messori M. Special Resins for Stereolithography: In Situ Generation of Silver Nanoparticles. Polymers. 2018; 10(2):212. https://doi.org/10.3390/polym10020212

Chicago/Turabian StyleTaormina, Gabriele, Corrado Sciancalepore, Federica Bondioli, and Massimo Messori. 2018. "Special Resins for Stereolithography: In Situ Generation of Silver Nanoparticles" Polymers 10, no. 2: 212. https://doi.org/10.3390/polym10020212

APA StyleTaormina, G., Sciancalepore, C., Bondioli, F., & Messori, M. (2018). Special Resins for Stereolithography: In Situ Generation of Silver Nanoparticles. Polymers, 10(2), 212. https://doi.org/10.3390/polym10020212