Study on Foaming Quality and Impact Property of Foamed Polypropylene Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Modified Materials

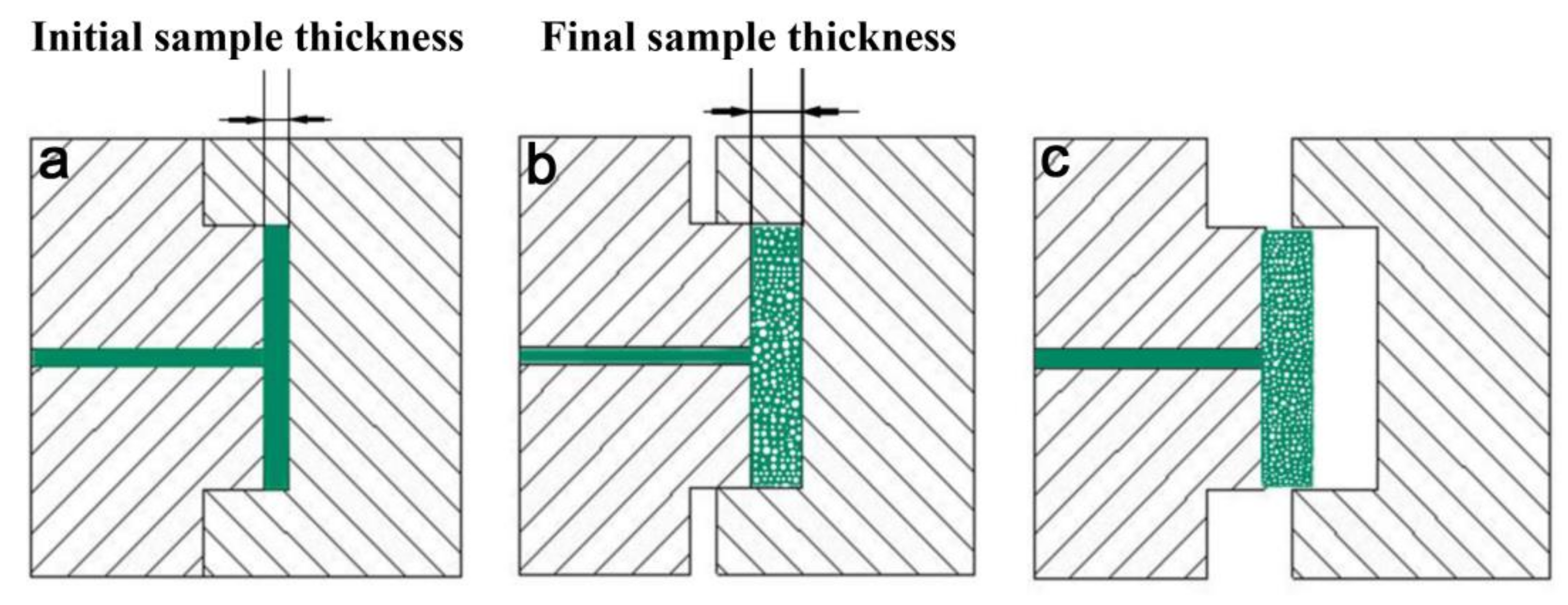

2.3. Preparation of Foamed Sample

2.4. Characterization

2.4.1. Dispersion Characterization of Elastomers

2.4.2. Characterization of Cell Structure

2.4.3. Thermal Analysis

2.4.4. Rheological Properties

2.4.5. Mechanical Properties

2.4.6. Dynamic Mechanical Analysis (DMA)

3. Results and Discussion

3.1. Dispersion of Elastomers in PP Materials

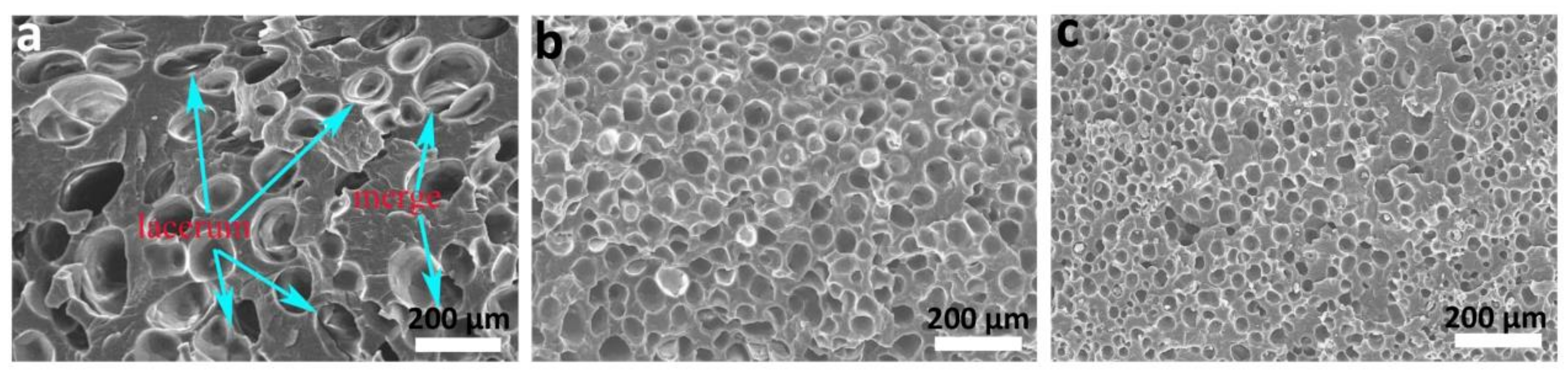

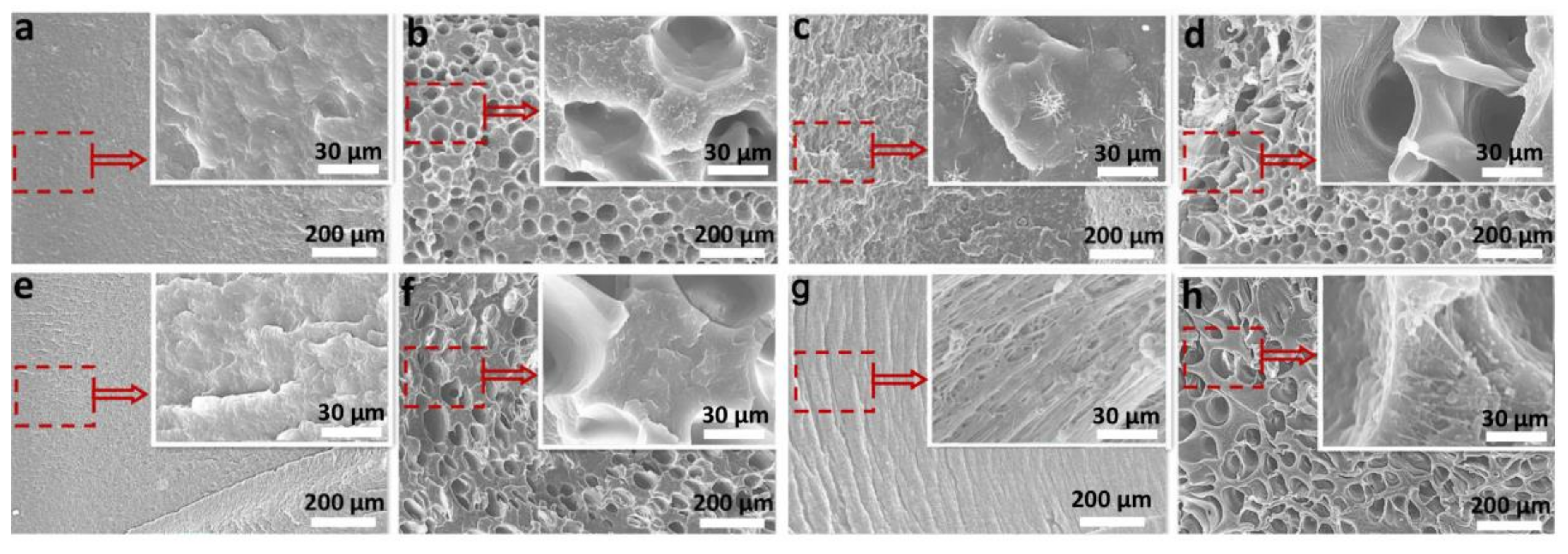

3.2. Influence of Elastomers on Foaming Quality of Foamed PP Composites

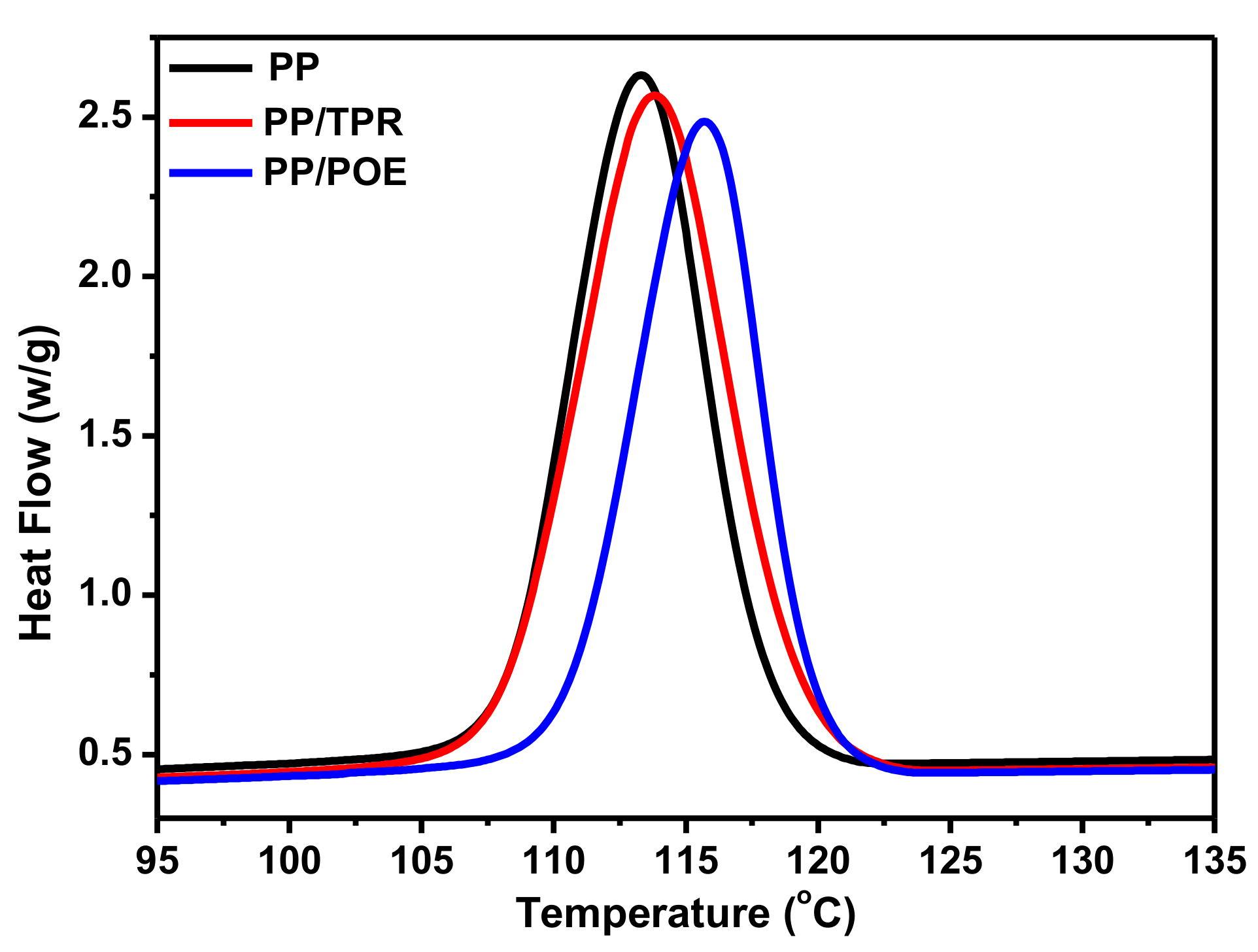

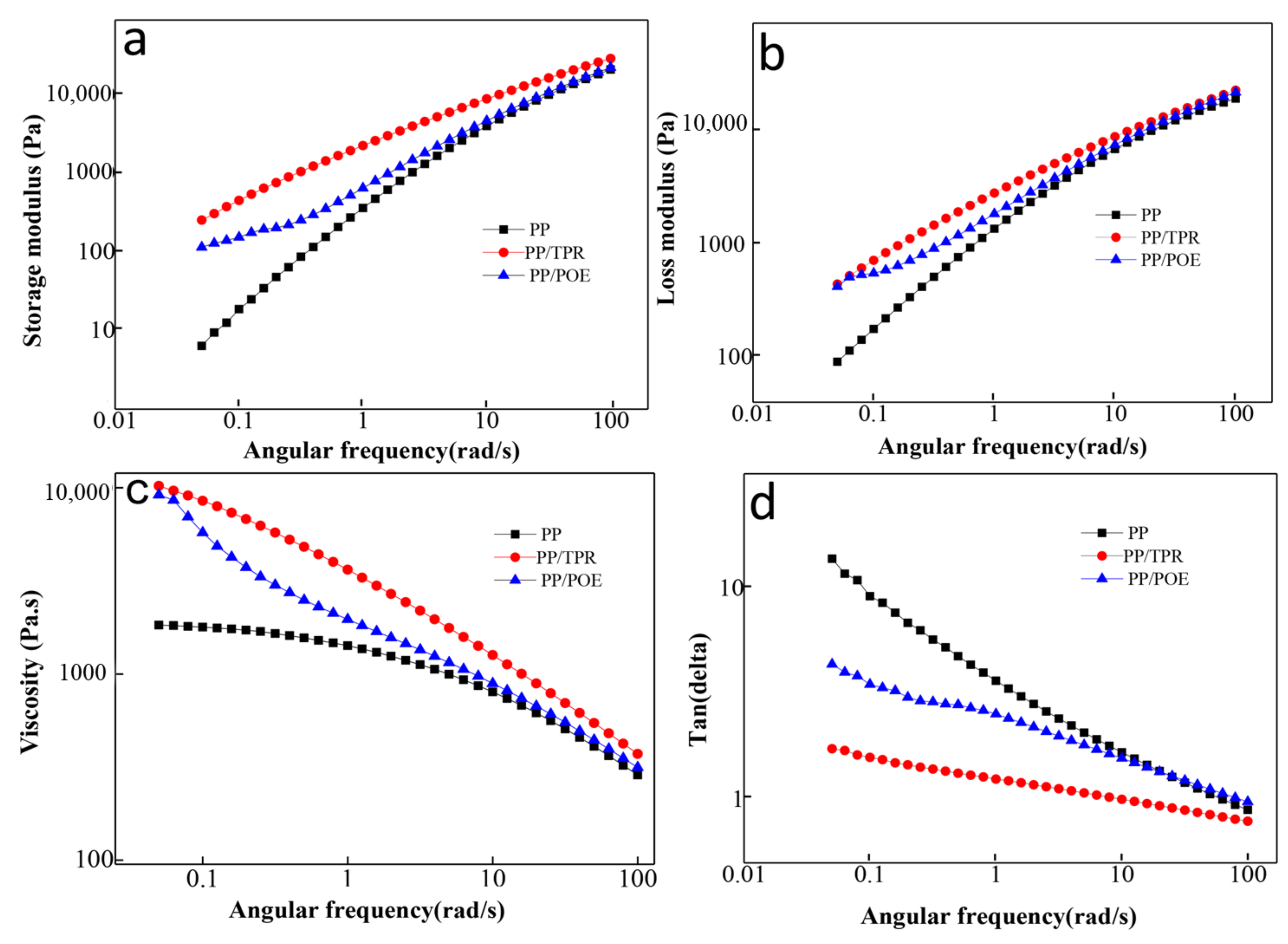

3.3. Effect of Elastomers on Crystallization and Rheological Behaviors of the PP Composites

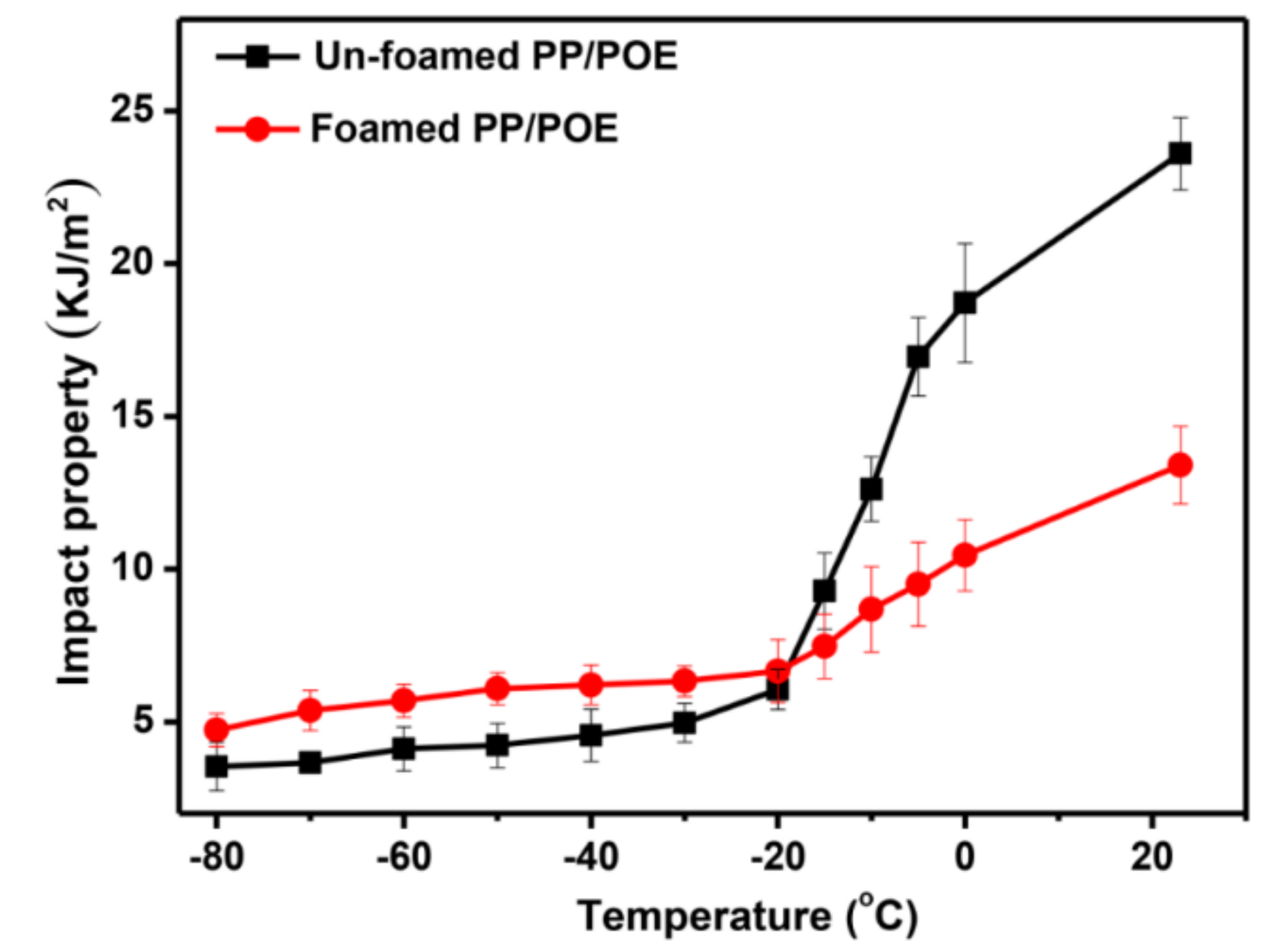

3.4. Influence of Elastomers on the Impact Properties of PP Composites

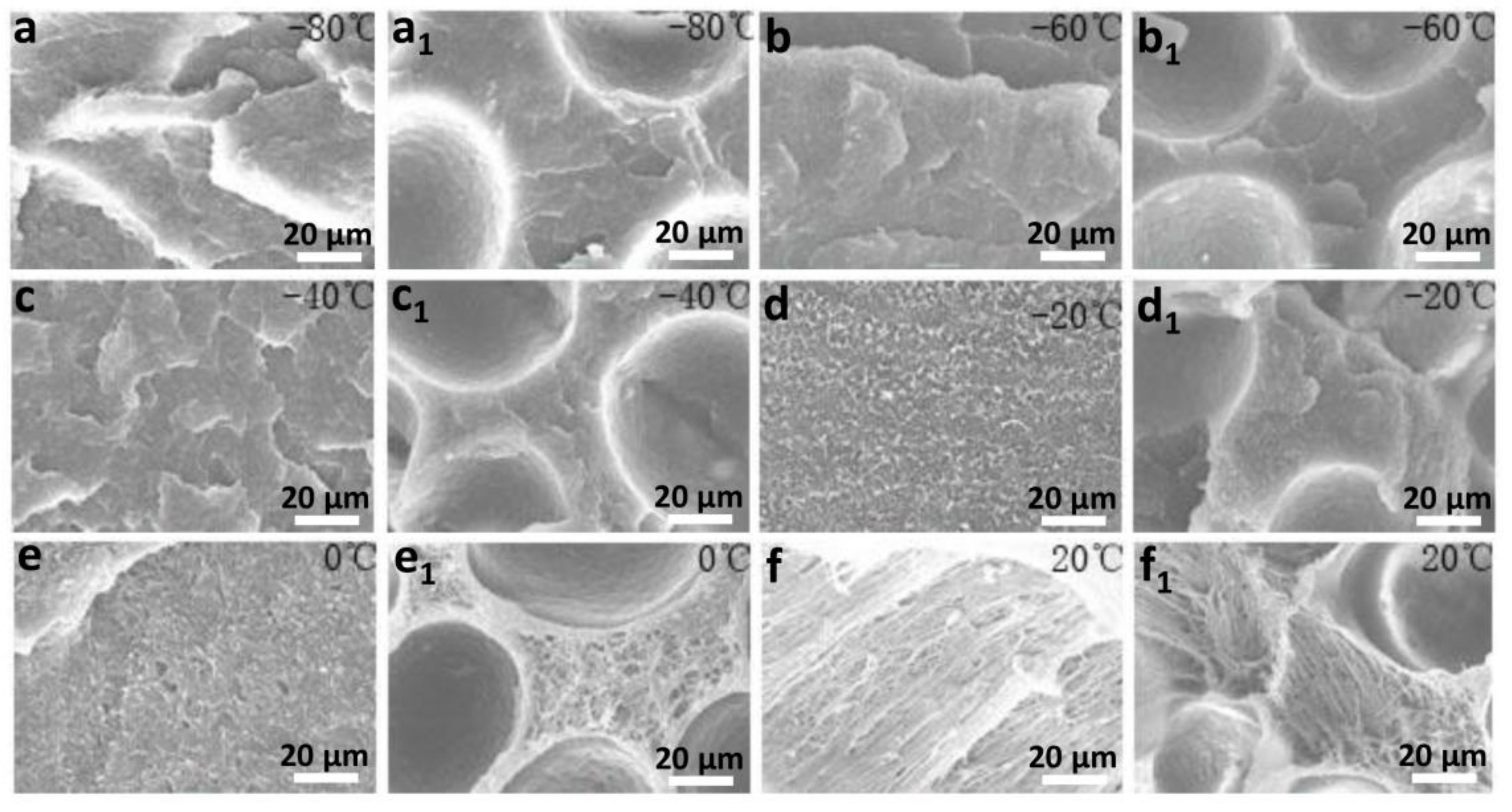

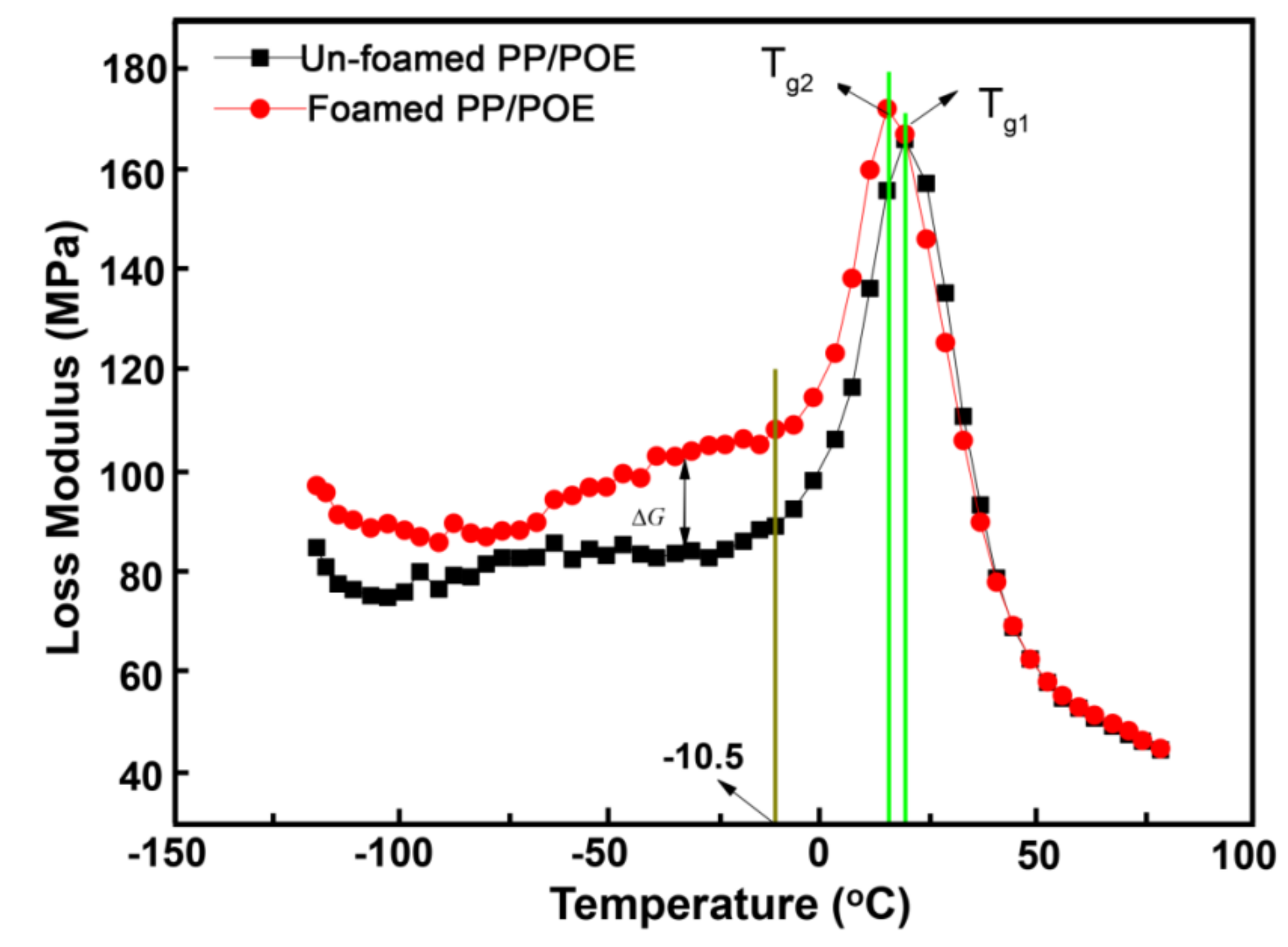

3.5. Effect of Cells on the Low-Temperature Toughness of PP Composites

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Alvarez-Lainez, M.; Rodriguez-Perez, M.A.; Saja, J.A. Acoustic absorption cofficient of open-cell polyolefin-based foams. Mater. Lett. 2014, 121, 26–30. [Google Scholar] [CrossRef]

- Lopez-Gil, A.; Saiz-Arroyo, C.; Tirado, J.; Rodriguez-Perez, M.A. Production of non-crosslinked thermoplastic foams with a controlled density and a wide range of cellular structures. J. Appl. Polym. Sci. 2015, 132, 42324–42334. [Google Scholar] [CrossRef]

- Wang, X.; Pan, Y.; Shen, C.; Liu, C.; Liu, X. Facile thermally impacted water-Induced phase separation approach for the fabrication of skin-free thermoplastic polyurethane foam and its recyclable counterpart for oil–water separation. Macromol. Rapid Commun. 2018, 39, 1800635–1800641. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zhang, J.; Yang, X.; Zhang, C.; Gong, W.; Yu, J. Flexural properties of epoxy syntactic foams reinforced by fiberglass mesh and/or short glass fiber. Mater. Des. 2014, 55, 929–936. [Google Scholar] [CrossRef]

- Ventura, H.; Sorrentino, L.; Laguna-Gutierrez, E.; Rodriguez-Perez, M.A.; Ardanuy, M. Gas dissolution foaming as a novel approach for the production of lightweight biocomposites of PHB/natural fibre fabrics. Polymers 2018, 10, 249. [Google Scholar] [CrossRef]

- Denay, A.G.; Castagnet, S.; Roy, A.; Alise, G.; Thenard, N. Compression behavior of glass-fiber-reinforced and pure polyurethane foams at negative temperatures down to cryogenic ones. J. Cell. Plast. 2013, 49, 209–222. [Google Scholar] [CrossRef]

- Notario, B.; Pinto, J.; Rodriguez-Perez, M.A. Towards a new generation of polymeric foams: PMMA nanocellular foams with enhanced physical properties. Polymer 2015, 63, 116–126. [Google Scholar] [CrossRef]

- Antenucci, A.; Guarino, S.; Tagliaferri, V.; Ucciardello, N. Improvement of the mechanical and thermal characteristics of open cell aluminum foams by the electrode position of Cu. Mater. Des. 2014, 59, 124–129. [Google Scholar] [CrossRef]

- Antunes, M.; Velasco, J.I. Multifunctional polymer foams with carbon nano-particles. Prog. Polym. Sci. 2014, 39, 486–509. [Google Scholar] [CrossRef]

- Solorzano, E.; Laguna-Gutierrez, E.; Perez-Tamarit, S.; Kaestner, A.; Rodriguez-Perez, M.A. Polymer foam evolution characterized by time-resolved neutron radiography. Colloid Surface A 2015, 473, 46–54. [Google Scholar] [CrossRef]

- Wang, X.; Yin, X.; Zhang, C.; Gong, W.; He, L. Dynamic mechanical properties, crystallization behaviors, and low temperature performance of polypropylene random copolymer composites. J. Appl. Polym. Sci. 2016, 133, 1377–1386. [Google Scholar] [CrossRef]

- Kuboki, T.; Lee, Y.H.; Park, C.B.; Sain, M. Mechanical properties and foaming behavior of cellulose fiber reinforced high-density polyethylene composites. Polym. Eng. Sci. 2009, 49, 2179–2188. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, X.; Liu, X.; Lv, C.; Wang, Y.; Zheng, G.; Liu, H.; Liu, C.; Guo, Z.; Shen, C. Porous polyethylene bundles with enhanced hydrophobicity and pumping oil-recovery ability via skin-peeling. ACS Sustain. Chem. Eng. 2018, 6, 12580–12585. [Google Scholar] [CrossRef]

- Wang, X.; Pan, Y.; Qin, Y.; Voigt, M.; Liu, X.; Zheng, G.; Chen, Q.; Schubert, D.W.; Liu, C.; Shen, C. Creep and recovery behavior of injection-molded isotactic polypropylene with controllable skin-core structure. Polym. Test. 2018. [Google Scholar] [CrossRef]

- Jiang, J.; Liu, X.; Lian, M.; Pan, Y.; Chen, Q.; Liu, H.; Zheng, G.; Guo, Z.; Schubert, D.W.; Shen, C.; et al. Self-reinforcing and toughening isotactic polypropylene via melt sequential injection molding. Polym. Test. 2018. [Google Scholar] [CrossRef]

- Pan, Y.; Guo, X.; Zheng, G.; Liu, C.; Chen, Q.; Shen, C.; Liu, X. Shear-induced skin-core structure of molten isotactic polypropylene and the formation of β-crystal. Macromol. Mater. Eng. 2018, 303, 1800083–1800090. [Google Scholar] [CrossRef]

- Rizvi, A.; Tabatabaei, A.; Barzegari, M.R.; Mahmood, S.H.; Park, C.B. In situ fibrillation of CO2-philic polymers: Sustainable route to polymer foams in a continuous process. Polymer 2013, 54, 4645–4652. [Google Scholar] [CrossRef]

- Keramati, M.; Ghasemi, I.; Karrabi, M.; Azizi, H. Microcellular foaming of PP/EPDM/organoclaynanocomposites: The effect of the distribution of nanoclay on foam morphology. Polym. J. 2012, 44, 433–438. [Google Scholar] [CrossRef]

- Kuboki, T. Mechanical properties and foaming behavior of injection molded cellulose fiber reinforced polypropylene composite foams. J. Cell. Plast. 2014, 50, 129–143. [Google Scholar] [CrossRef]

- Xi, Z.; Sha, X.; Liu, T.; Zhang, L. Microcellular injection molding of polypropylene and glass fiber composites with supercritical nitrogen. J. Cell. Plast. 2014, 50, 489–505. [Google Scholar] [CrossRef]

- Gong, W.; Gao, J.; Jiang, M.; He, L.; Yu, J.; Zhu, J. Influence of cell structure parameters on the mechanical properties of microcellular polypropylene materials. J. Appl. Polym. Sci. 2011, 122, 2907–2914. [Google Scholar] [CrossRef]

- Forest, C.; Chaumont, P.; Cassagnau, P.; Swoboda, B.; Sonntag, P. Polymer nano-foam for insulating applications prepared from CO2 foaming. Prog. Polym. Sci. 2015, 41, 122–145. [Google Scholar] [CrossRef]

- He, Y. The Study of High Toughness Polyolefin Microcellular Foaming Structural Materials; Guizhou University: Guiyang, China, 2016; pp. 17–47. [Google Scholar]

- Wang, L.; Yang, X.; Jiang, T.; Zhang, C.; He, L. Cell morphology, bubbles migration, and flexural properties of non-uniform epoxy foams using chemical foaming agent. J. Appl. Polym. Sci. 2014, 131, 41175–41184. [Google Scholar] [CrossRef]

- Zhou, Y.H.; Gong, W.; He, L. Application of a novel organic nucleating agent: Cucurbit[6]uril to improve polypropylene injection foaming behavior and their physical properties. J. Appl. Polym. Sci. 2017, 135, 24538–24546. [Google Scholar] [CrossRef]

- Pan, Y.; Liu, X.; Kaschta, J.; Liu, C.; Schubert, D.W. Reversal phenomena of molten immiscible polymer blends during creep-recovery in shear. J. Rheol. 2018, 61, 759–767. [Google Scholar] [CrossRef]

- Pan, Y.; Liu, X.; Kaschta, J.; Hao, X.; Liu, C.; Schubert, D.W. Viscoelastic and electrical behavior of poly(methyl methacrylate)/carbon black composites prior to and after annealing. Polymer 2017, 113, 34–38. [Google Scholar] [CrossRef]

- Karimi, M.; Heuchel, M.; Weigel, T.; Schossig, M.; Hofmann, D.; Lendlein, A. Formation and size distribution of pores in poly(ε-caprolactone) foams prepared by pressure quenching using supercritical CO2. J. Supercrit. Fluid. 2012, 61, 175–190. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, L.; Xiao, X.; Gong, W.; He, L. Preparation of a novel inorganic-organic nucleating agent and its effect on the foaming behavior of polypropylene. J. Inorg. Organomet. Polym. 2017, 27, 1538–1545. [Google Scholar] [CrossRef]

- Wang, A.; Guo, Y.; Park, C.B.; Zhou, N.Q. A polymer visualization system with accurate heating and cooling control and high-speed imagine. Int. J. Mol. Sci. 2015, 16, 9196–9216. [Google Scholar] [CrossRef]

- Yang, C.; Wang, M.; Zhang, M.; Li, X.; Wang, H.; Xing, Z.; Ye, L.; Wu, G. Supercritical CO2 foaming of radiation cross-linked isotactic polypropylene in the presence of TAIC. Polymers 2016, 21, 1660. [Google Scholar] [CrossRef]

| Sample | Cell Density (N0) (× 106 cells·cm−3) | Cell Diameter () (μm) | Cell Dispersion (Sd) (μm) |

|---|---|---|---|

| PP | 2.62 | 55.36 | 20.5 |

| PP/TPR | 7.54 | 31.21 | 12.3 |

| PP/POE | 12.5 | 25.42 | 8.1 |

| Sample | Initial Crystallization Temperature (°C) | Crystalline Peak Temperature (°C) | Crystallinity (Xc) % |

|---|---|---|---|

| PP | 106.6 | 113.3 | 43.1 |

| PP/TPR | 107.2 | 113.8 | 36.1 |

| PP/POE | 109.3 | 115.7 | 32.3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, W.; Fu, H.; Zhang, C.; Ban, D.; Yin, X.; He, Y.; He, L.; Pei, X. Study on Foaming Quality and Impact Property of Foamed Polypropylene Composites. Polymers 2018, 10, 1375. https://doi.org/10.3390/polym10121375

Gong W, Fu H, Zhang C, Ban D, Yin X, He Y, He L, Pei X. Study on Foaming Quality and Impact Property of Foamed Polypropylene Composites. Polymers. 2018; 10(12):1375. https://doi.org/10.3390/polym10121375

Chicago/Turabian StyleGong, Wei, Hai Fu, Chun Zhang, Daming Ban, Xiaogang Yin, Yue He, Li He, and Xianglin Pei. 2018. "Study on Foaming Quality and Impact Property of Foamed Polypropylene Composites" Polymers 10, no. 12: 1375. https://doi.org/10.3390/polym10121375

APA StyleGong, W., Fu, H., Zhang, C., Ban, D., Yin, X., He, Y., He, L., & Pei, X. (2018). Study on Foaming Quality and Impact Property of Foamed Polypropylene Composites. Polymers, 10(12), 1375. https://doi.org/10.3390/polym10121375