Effects of Graphene Oxide on the Structure and Properties of Regenerated Wool Keratin Films

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation and Modification of Regenerated Keratin Film

2.2.1. Preparation of Wool Keratin Solution

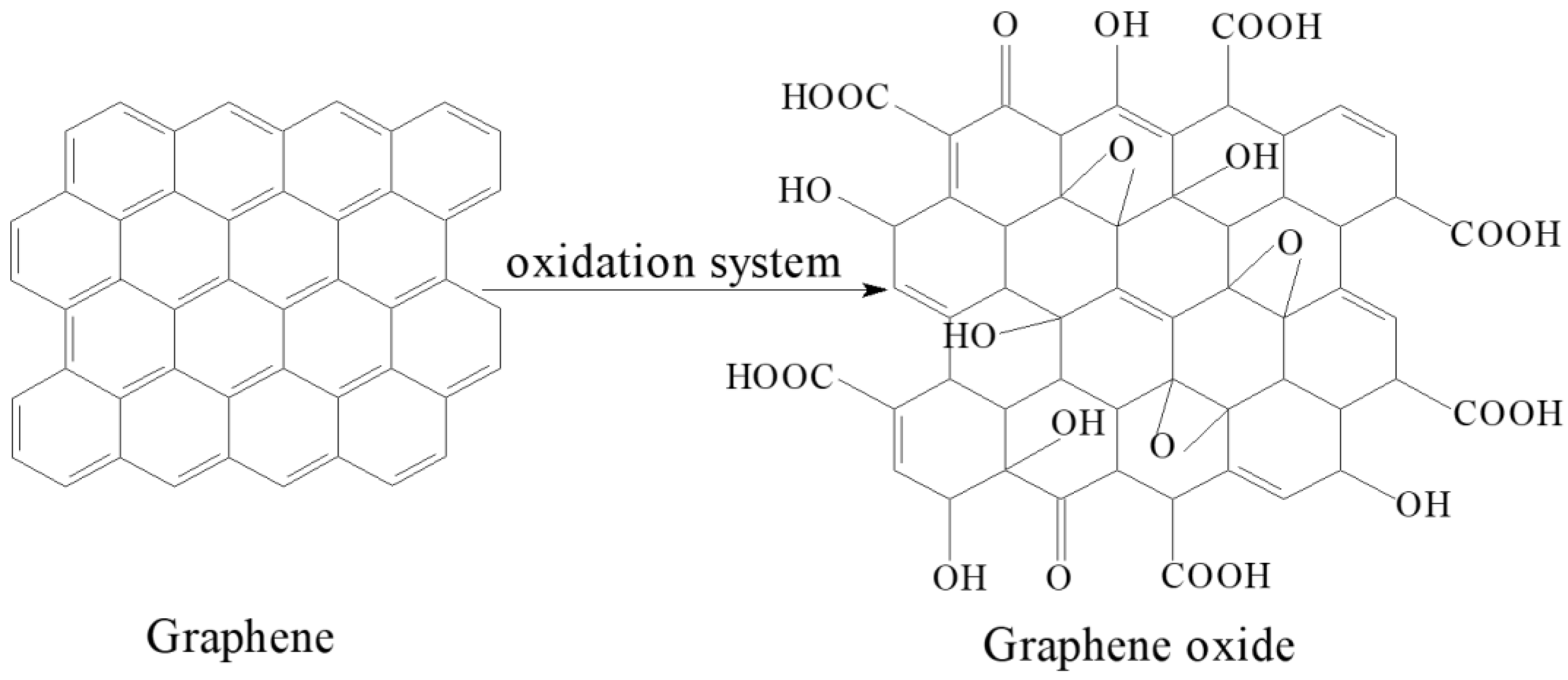

2.2.2. Modification of Regenerated Keratin with Graphene Oxide

2.2.3. Preparation of Regenerated Keratin Films

2.3. Measurements

2.3.1. Sodium Dodecyl Sulfate-Polyacrylamide Gel Electrophoresis Analysis (SDS-PAGE)

2.3.2. Scanning Electron Microscopy (SEM)

2.3.3. Fourier Transform Infrared Spectroscopy (FT-IR)

2.3.4. Raman Spectra

2.3.5. X-ray Diffraction (XRD)

2.3.6. Thermal Performance Analysis

2.3.7. Tensile Strength Test

3. Results and Discussion

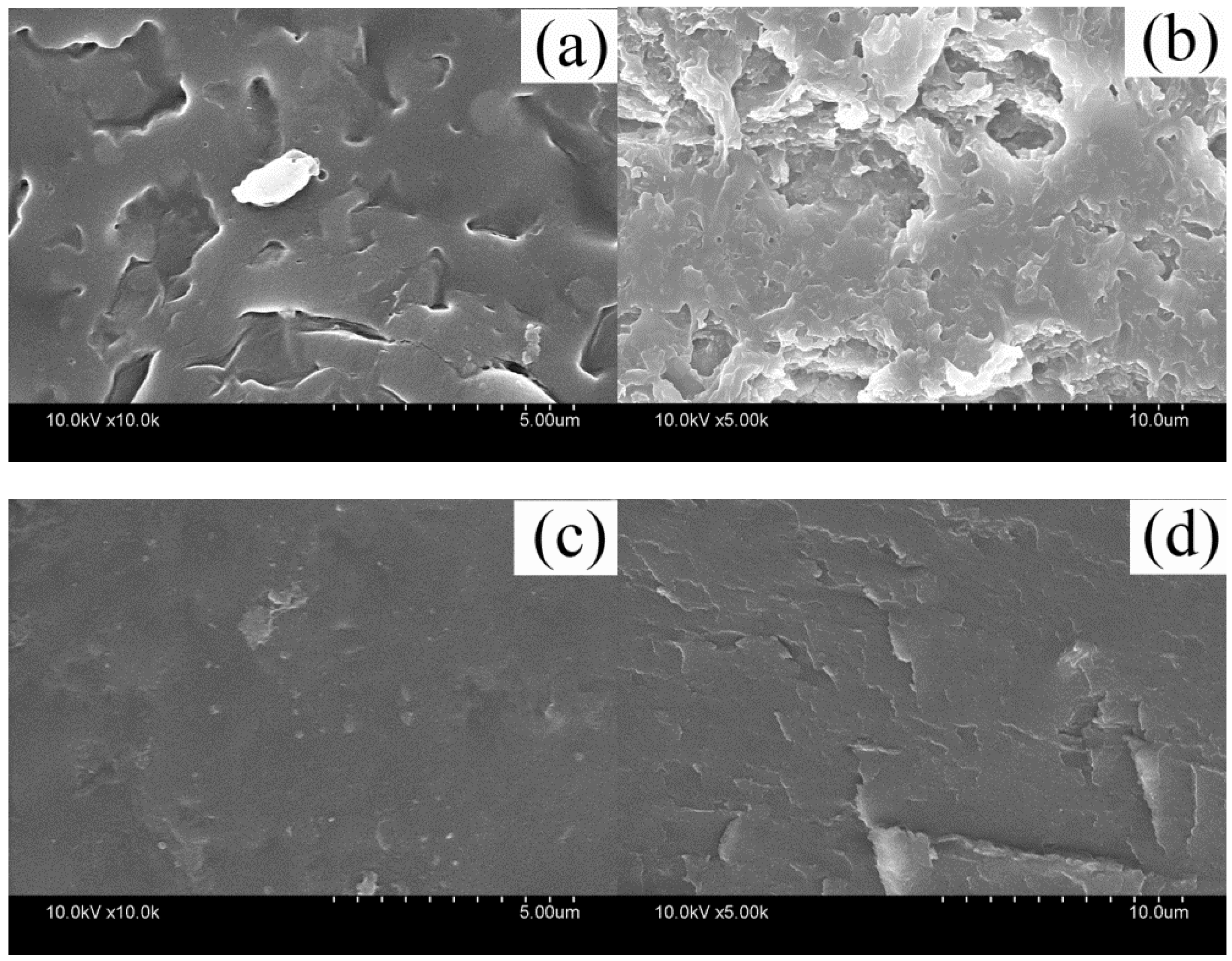

3.1. Electron Microscope Characterization of Keratin Films

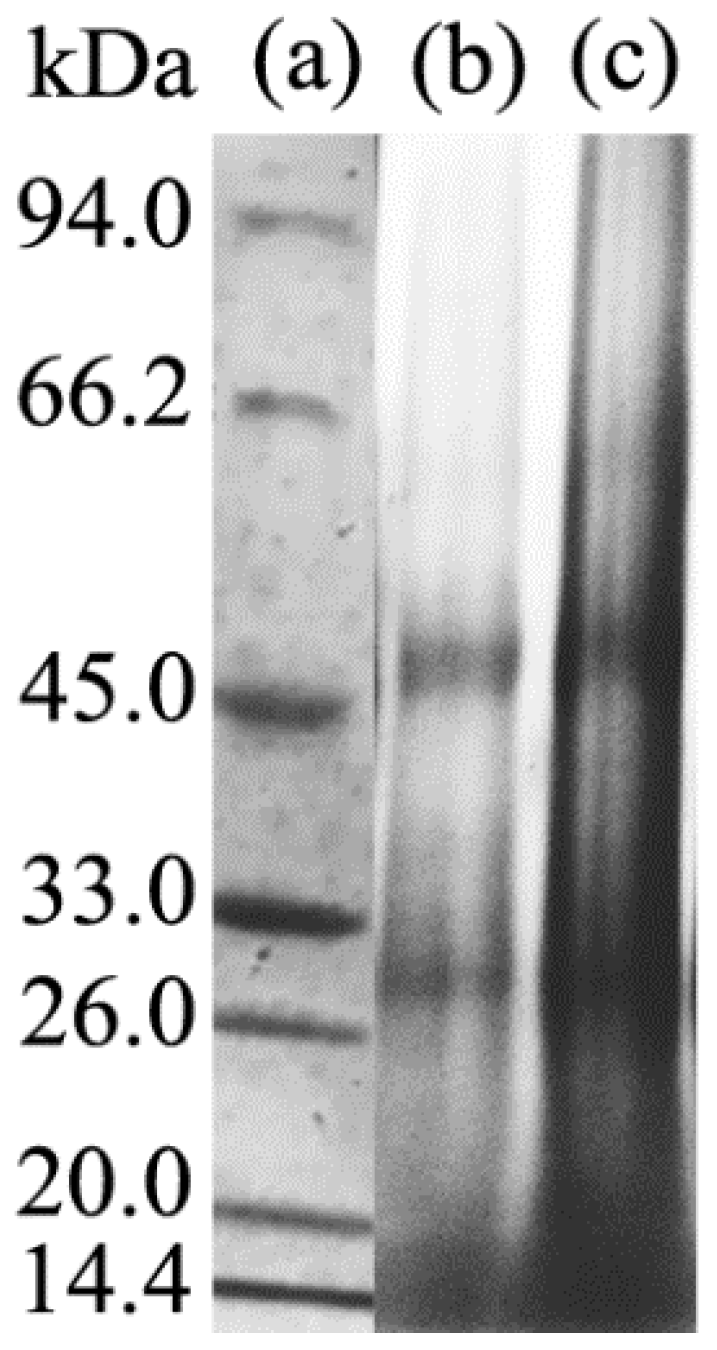

3.2. Keratin Films’ Molecular Weight Test

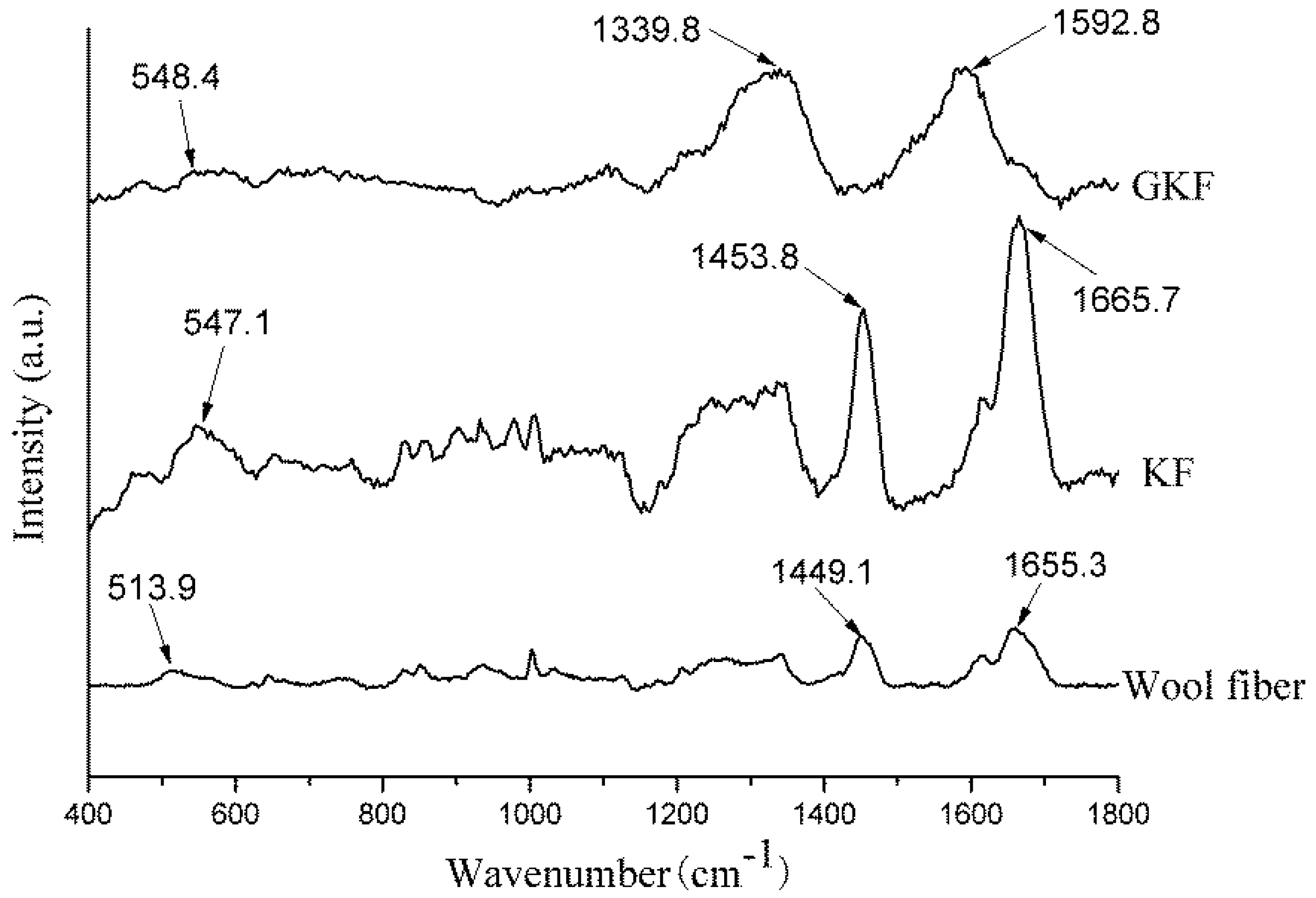

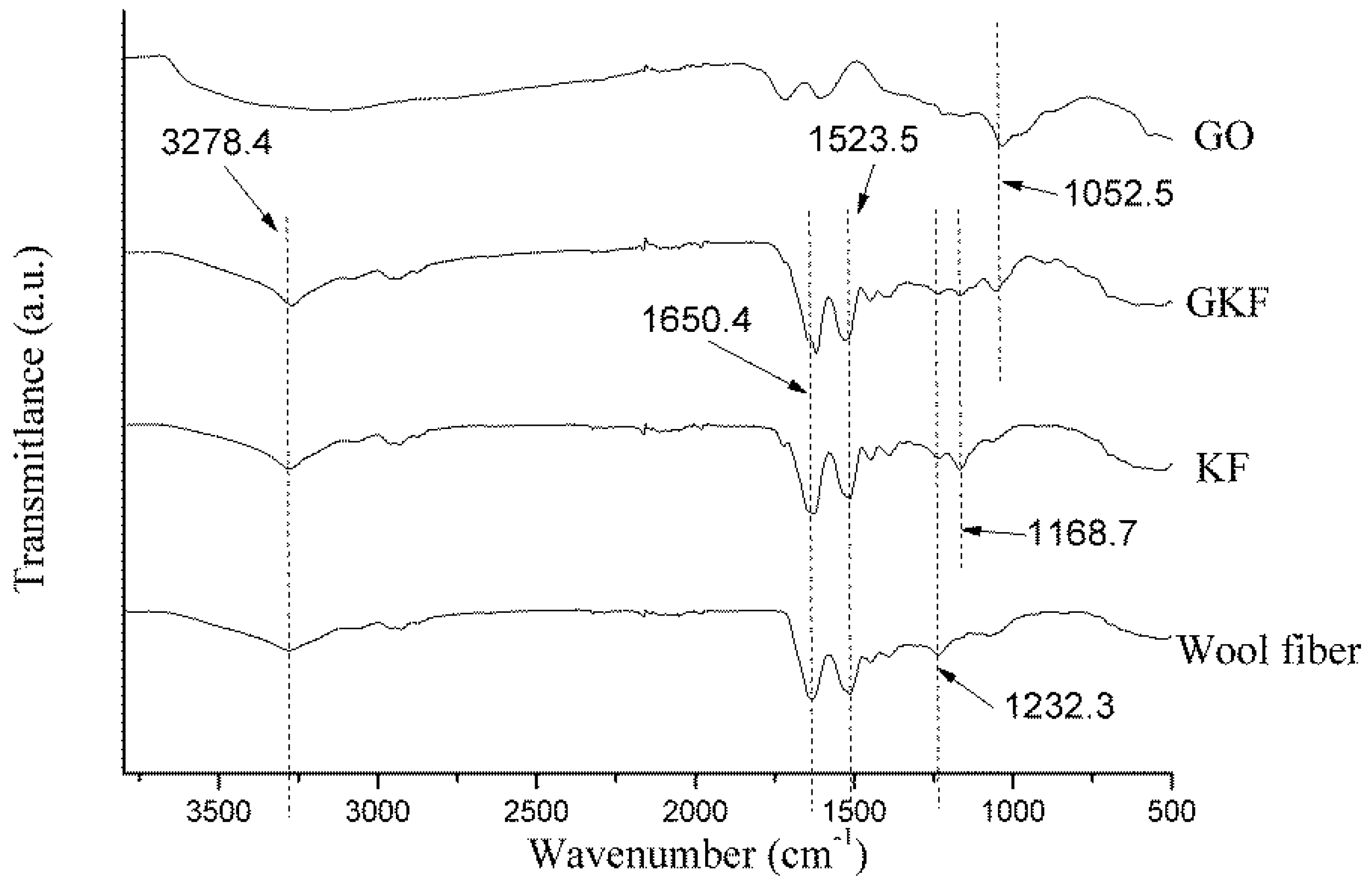

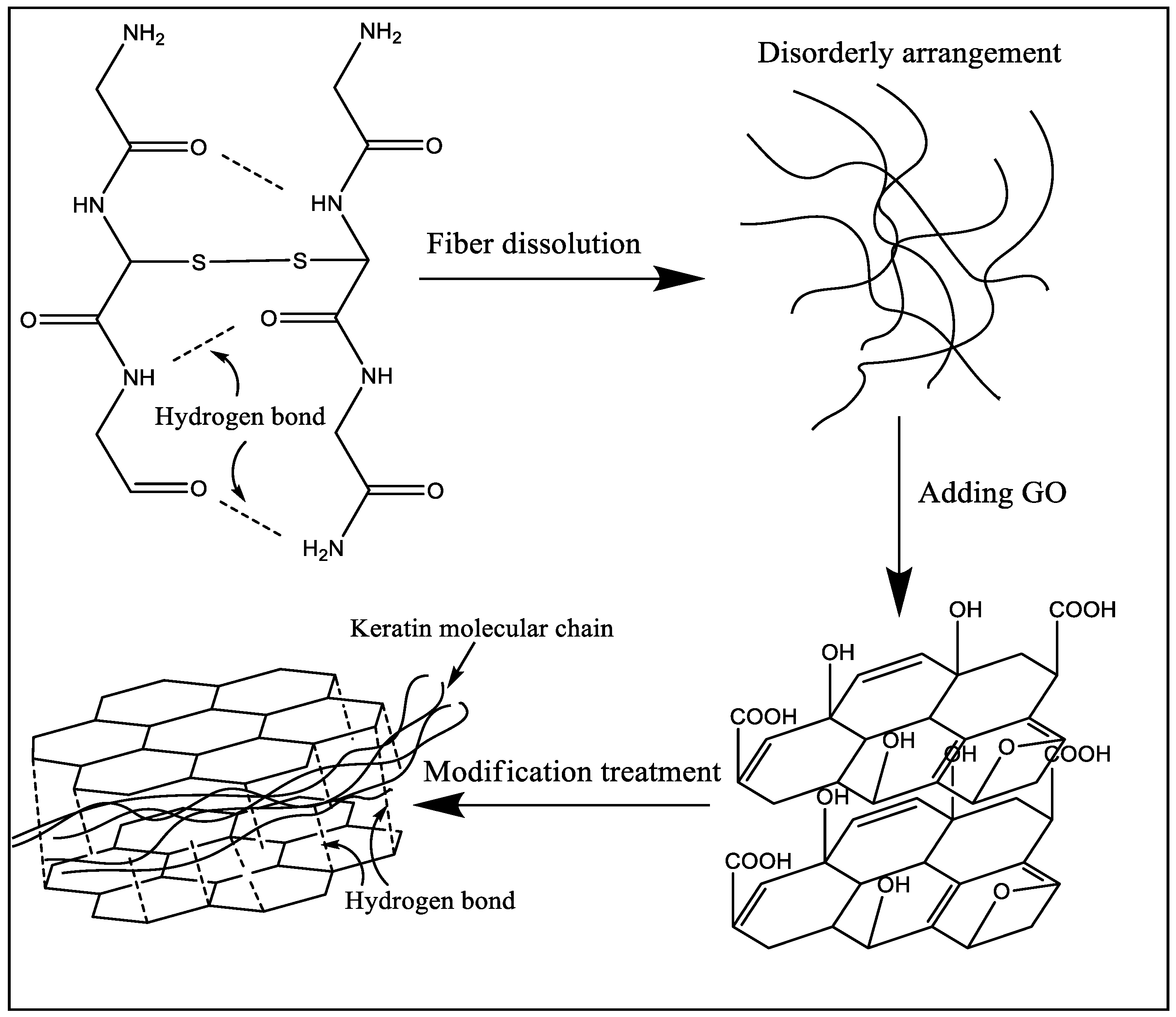

3.3. Chemical Structure Change of Keratin

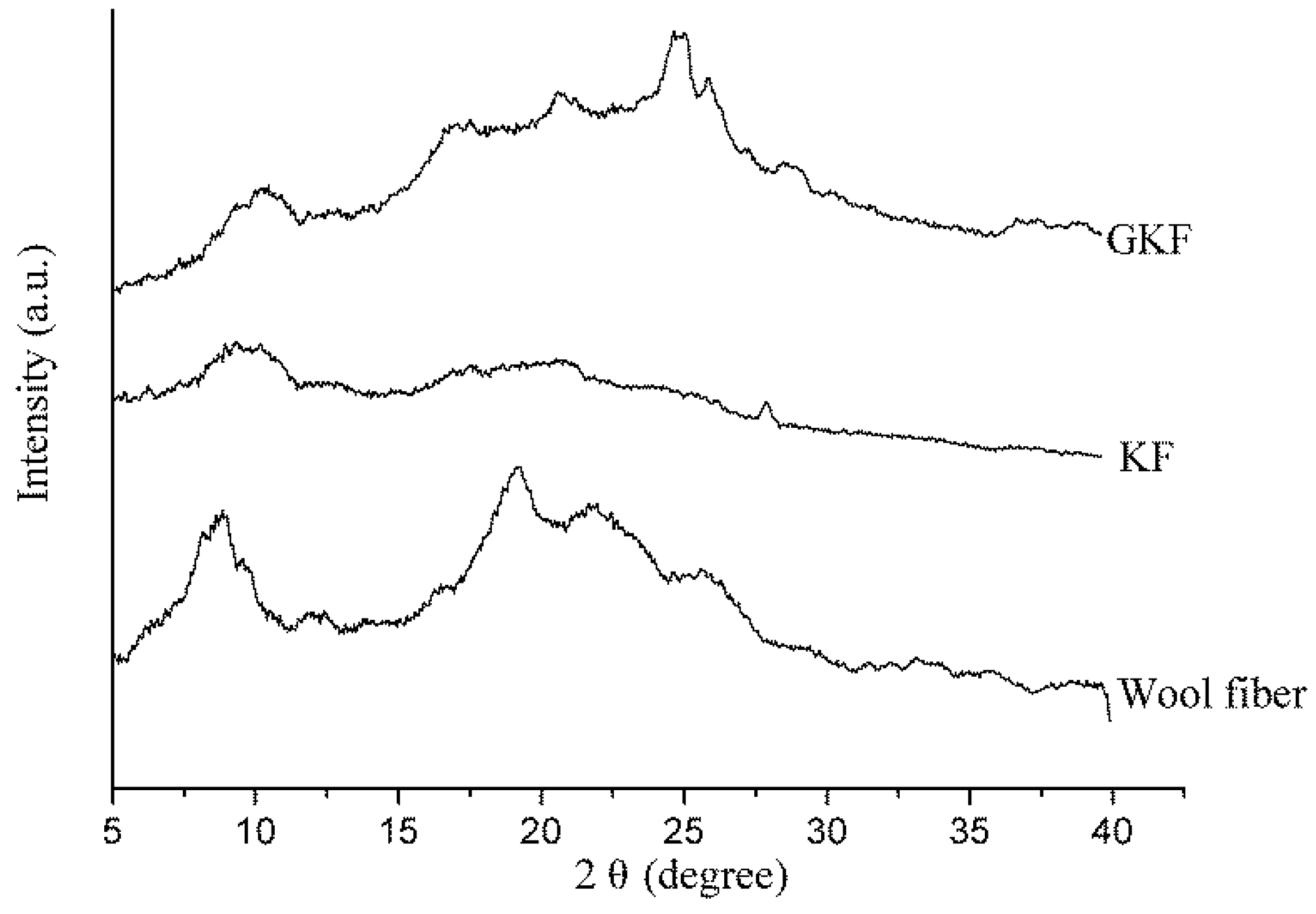

3.4. Effect of Graphene Oxide on the Crystal Structure of Regenerated Keratin

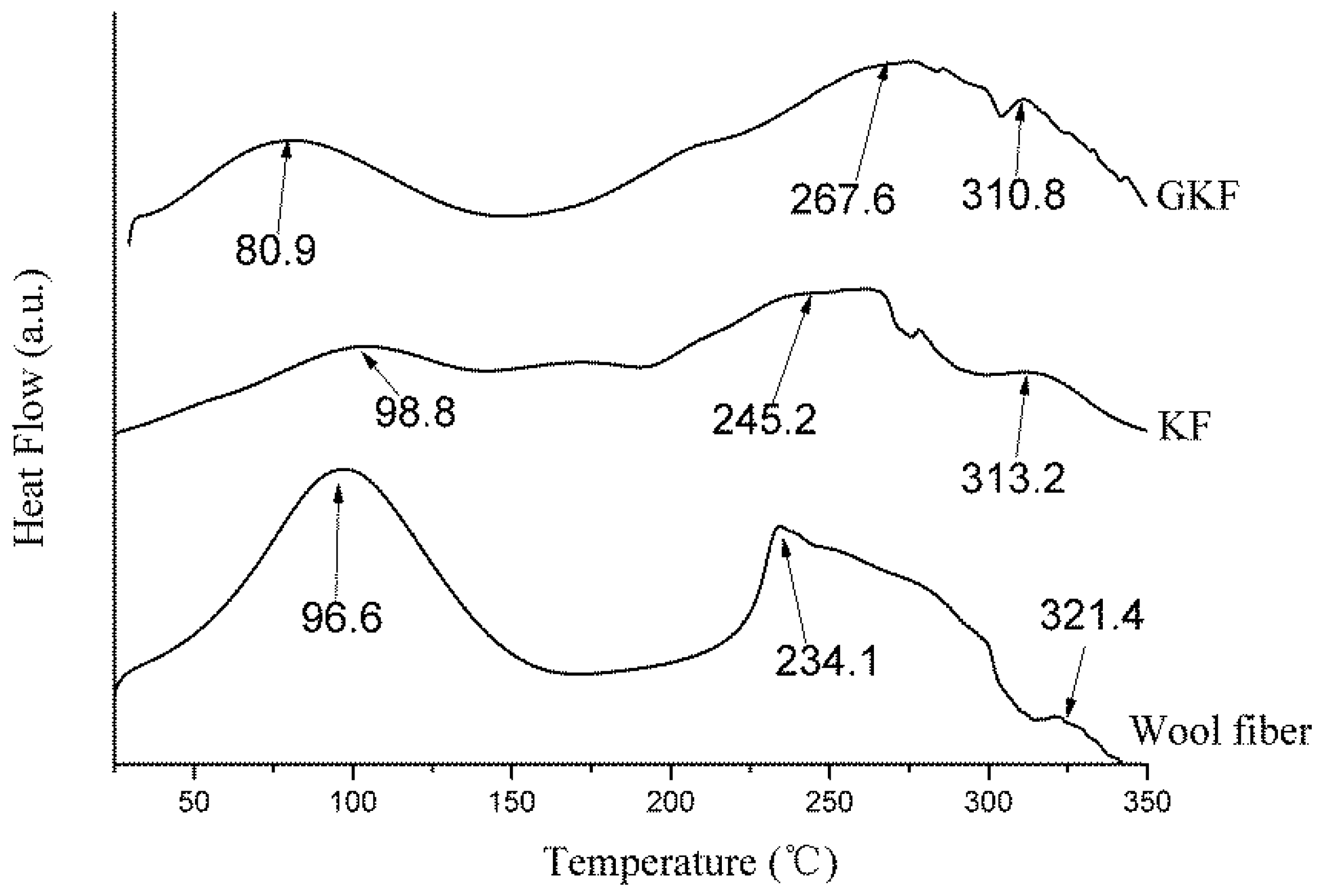

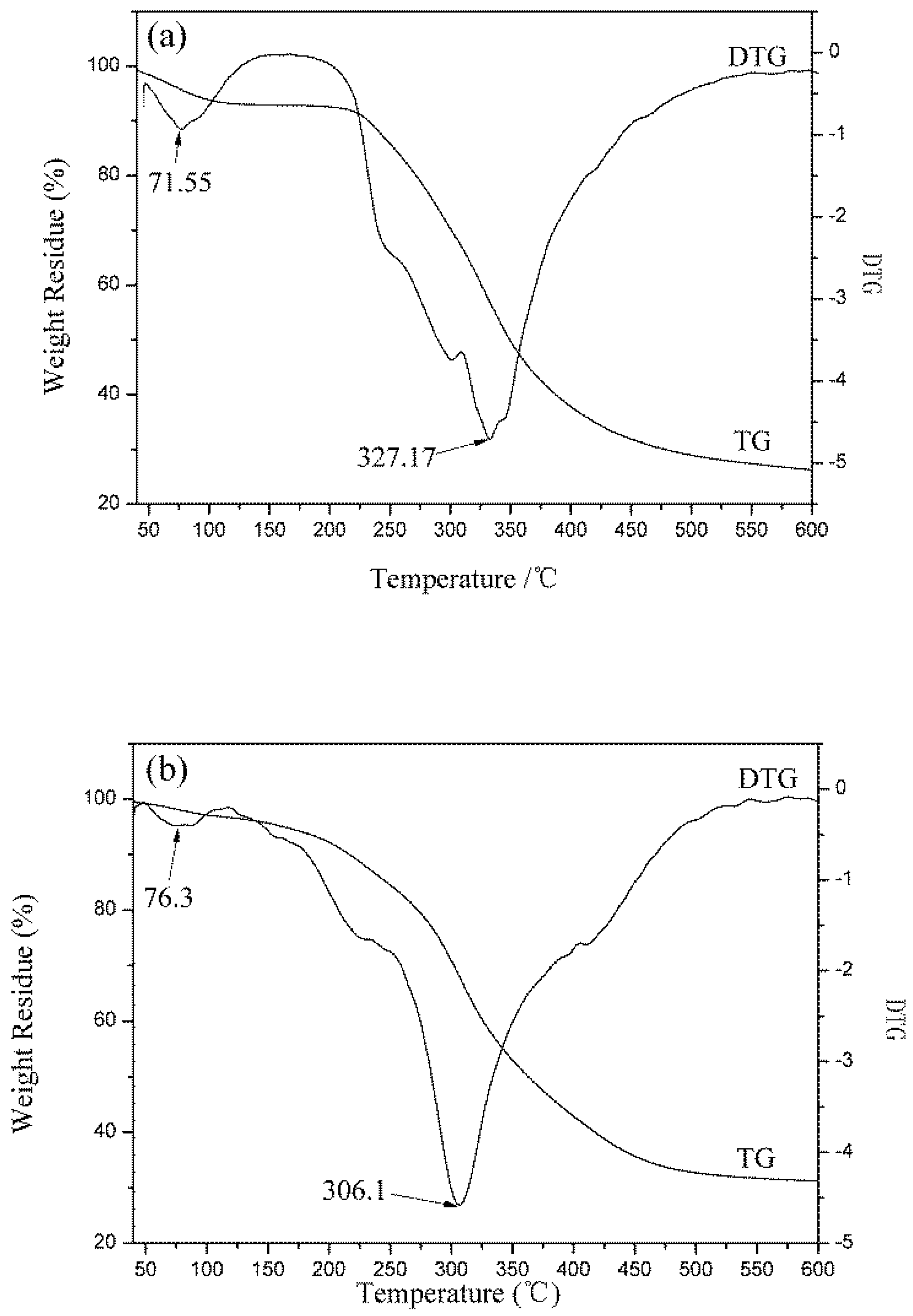

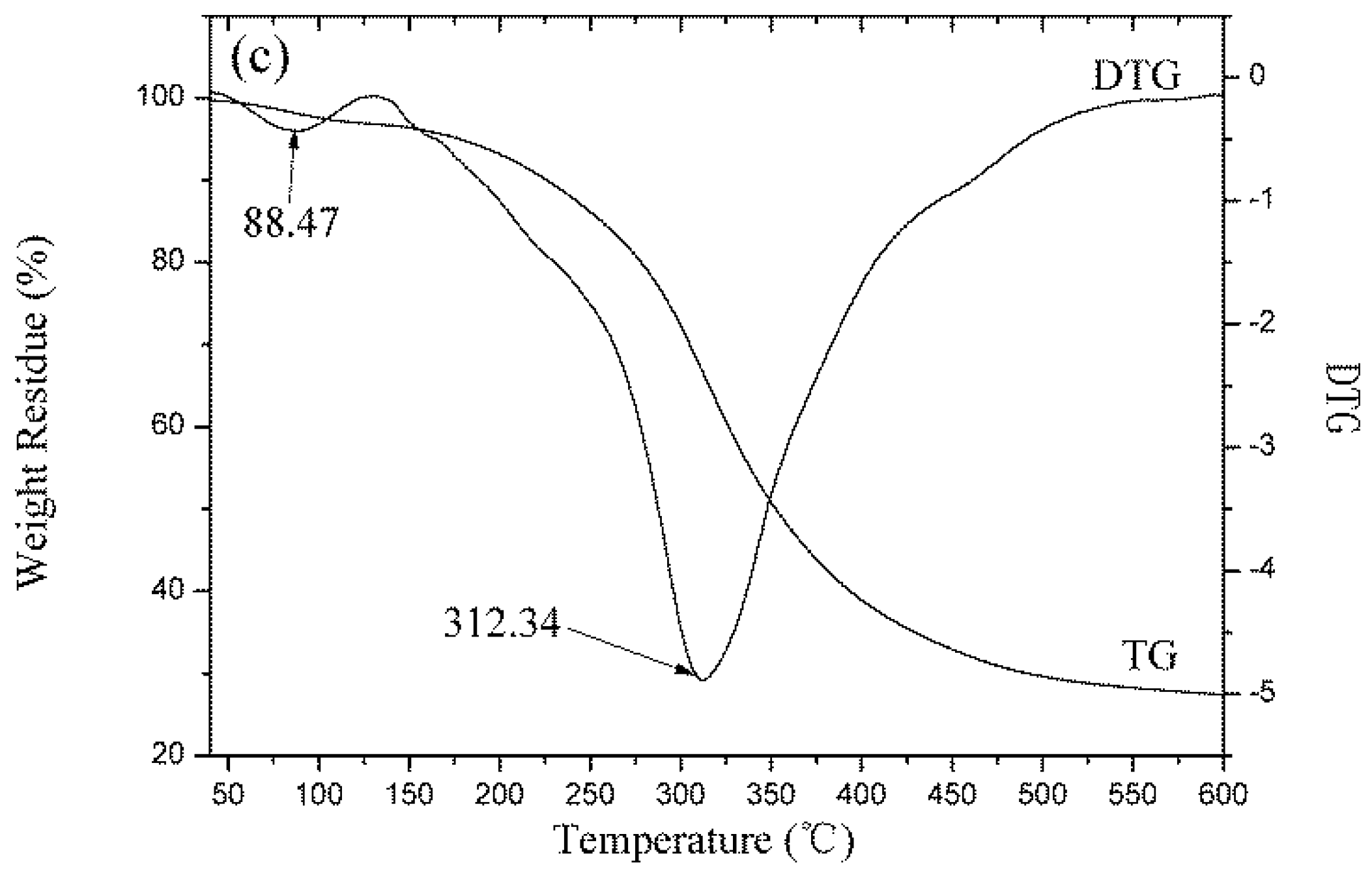

3.5. Thermal Performance Analysis

3.6. Mechanical Properties of Regenerated Keratin Films

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Zheng, J.; Liang, L.I.; Liu, R.; Zhang, D. Preparation of wool keratin and its modification to polyester fabrics. J. Text. Res. 2018, 03, 92–97. [Google Scholar]

- Wu, P.P.; Dai, X.; Chen, K.; Li, R.; Xing, Y. Fabrication of regenerated wool keratin/polycaprolactone nanofiber membranes for cell culture. Int. J. Biol. Macromol. 2018, 114, 1168–1173. [Google Scholar] [CrossRef] [PubMed]

- Idris, A.; Vijayaraghavan, R.; Rana, U.; Patti, A.F.; Macfarlane, D.R. Dissolution and regeneration of wool keratin in ionic liquids. Green Chem. 2014, 16, 2857–2864. [Google Scholar] [CrossRef]

- Tonin, C.; Aluigi, A.; Vineis, C.; Varesano, A.; Montarsolo, A.; Ferrero, F. Thermal and structural characterization of poly(ethylene-oxide)/keratin blend films. J. Therm. Anal. Calorim. 2007, 89, 601–608. [Google Scholar] [CrossRef]

- Hill, P.; Brantley, H.; Dyke, M.V. Some properties of keratin biomaterials: Kerateines. Biomaterials 2010, 31, 585–593. [Google Scholar] [CrossRef] [PubMed]

- Atri, H.; Bidram, E.; Dunstan, D.E. Reconstituted Keratin Biomaterial with Enhanced Ductility. Materials 2015, 8, 7472–7485. [Google Scholar] [CrossRef] [PubMed]

- Tran, C.D.; Mututuvari, T.M. Cellulose, Chitosan and Keratin Composite Materials: Facile and Recyclable Synthesis, Conformation and Properties. ACS Sustain. Chem. Eng. 2016, 4, 1850–1862. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Shan, G.; Cao, P.; He, J.; Lin, Z.; Huang, Y. Mechanical and biological properties of oxidized horn keratin. Mater. Sci. Eng. C 2015, 47, 123–134. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.B.; Xing, Y.; Yu, W.; Liu, H. Wool keratin and silk sericin composite films reinforced by molecular network reconstruction. J. Mater. Sci. 2018, 53, 5418–5428. [Google Scholar] [CrossRef]

- Fraser, R.D.B.; Parry, D.A.D. Trichocyte Keratin-Associated Proteins (KAPs). Adv. Exp. Med. Biol. 2018, 1054, 71–86. [Google Scholar] [PubMed]

- Zhang, Y.C.; Huang, W.; Hayashi, C.; Gatesy, J.; Mckittrick, J. Microstructure and mechanical properties of different keratinous horns. J. R. Soc. Interface 2018, 15, 20180093. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.; Panthi, G.; Liu, Y.; Kim, J.; Chae, S.H.; Lee, C. Keratin/poly (vinyl alcohol) blended nanofibers with high optical transmittance. Polymer 2015, 58, 146–152. [Google Scholar] [CrossRef]

- Wang, J.; Hao, S.; Luo, T.; Zhou, T.; Yang, X.; Wang, B. Keratose/poly (vinyl alcohol) blended nanofibers: Fabrication and biocompatibility assessment. Mater. Sci. Eng. C 2017, 72, 212–219. [Google Scholar] [CrossRef] [PubMed]

- Tu, H.; Yu, W.; Duan, L. Structural studies and macro-performances of hydroxyapatite-reinforced keratin thin films for biological applications. J. Mater. Sci. 2016, 51, 1–16. [Google Scholar] [CrossRef]

- Aluigi, A.; Zoccola, M.; Vineis, C.; Tonin, C.; Ferrero, F.; Canetti, M. Study on the structure and properties of wool keratin regenerated from formic acid. Int. J. Biol. Macromol. 2007, 41, 266–273. [Google Scholar] [CrossRef] [PubMed]

- Ramos, M.L.P.; González, J.A.; Fabian, L.; Pérez, C.J.; Villanueva, M.E.; Copello, G.J. Sustainable and smart keratin hydrogel with pH-sensitive swelling and enhanced mechanical properties. Mater. Sci. Eng. C Mater. Biol. Appl. 2017, 78, 619–626. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Ma, Z.; Yang, Y. Dissolution and regeneration of wool via controlled disintegration and disentanglement of highly crosslinked keratin. J. Mater. Sci. 2014, 49, 7513–7521. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and graphene oxide: Synthesis, properties, and applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef] [PubMed]

- Strankowski, M.; Korzeniewski, P.; Strankowska, J.; Thomas, S. Morphology, Mechanical and Thermal Properties of Thermoplastic Polyurethane Containing Reduced Graphene Oxide and Graphene Nanoplatelets. Materials 2018, 11, 82. [Google Scholar] [CrossRef] [PubMed]

- Dreyer, D.R.; Park, S.; Bielawski, C.W.; Ruoff, R.S. The chemistry of graphene oxide. Chem. Soc. Rev. 2009, 39, 228–240. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Feng, H.B.; Li, J.H. Graphene oxide: Preparation, functionalization, and electrochemical applications. Chem. Rev. 2012, 112, 6027–6053. [Google Scholar] [CrossRef] [PubMed]

- Park, M.; Pant, B.; Choi, J.; Yong, W.P.; Lee, C.; Shin, H.K. Facile preparation of self-assembled wool-based graphene hydrogels by electron beam irradiation. Carbon Lett. 2014, 15, 136–141. [Google Scholar] [CrossRef]

- Esparza, Y.; Ullah, A.; Wu, J. Preparation and characterization of graphite oxide nano-reinforced biocomposites from chicken feather keratin. J. Chem. Technol. Biotechnol. 2017. [Google Scholar] [CrossRef]

- Xu, Z.; Gao, C. In situPolymerization Approach to Graphene-Reinforced Nylon-6 Composites. Macromolecules 2010, 43, 6716–6723. [Google Scholar] [CrossRef]

- Jones, D.C.; Carr, C.M.; Cooke, W.D.; Lewis, D.M. Investigating the photo-oxidation of wool using FT-Raman and FT-IR spectroscopies. Text. Res. J. 1998, 68, 739–748. [Google Scholar] [CrossRef]

- Kuzuhara, A. Analysis of structural changes in bleached keratin fibers (black and white human hair) using Raman spectroscopy. Biopolymers 2010, 81, 506–514. [Google Scholar] [CrossRef] [PubMed]

- Kuzuhara, A. Internal structural changes in keratin fibres resulting from combined hair waving and stress relaxation treatments: A Raman spectroscopic investigation. Int. J. Cosmet. Sci. 2016, 38, 201–209. [Google Scholar] [CrossRef] [PubMed]

- Amieva, J.C.; Fuentes-Ramirez, R.; Martinez-Hernandez, A.L.; Millan-Chiu, B.; Lopez-Marin, L.M.; Castaño, V.M. Graphene oxide and reduced graphene oxide modification with polypeptide chains from chicken feather keratin. J. Alloys Compd. 2015, 643, 137–143. [Google Scholar] [CrossRef]

- Zheng, S.; Nie, Y.; Zhang, S.; Zhang, X.; Wang, L. Highly efficient dissolution of wool keratin by dimethylphosphate ionic liquids. ACS Sustain. Chem. Eng. 2015, 3, 2925–2932. [Google Scholar] [CrossRef]

- Fan, J.; Lei, T.D.; Li, J.; Zhai, P.Y.; Wang, Y.H.; Cao, F.Y. High protein content keratin/poly (ethylene oxide) nanofibers crosslinked in oxygen atmosphere and its cell culture. Mater. Des. 2016, 104, 60–67. [Google Scholar] [CrossRef]

- Li, R.; Wang, D. Preparation of regenerated wool keratin films from wool keratin–ionic liquid solutions. J. Appl. Polym. Sci. 2012, 127, 2648–2653. [Google Scholar] [CrossRef]

- Shavandi, A.; Carne, A.; Bekhit, A.A.; Bekhit, E.D. An improved method for solubilisation of wool keratin using peracetic acid. J. Environ. Chem. Eng. 2017, 5, 1977–1984. [Google Scholar] [CrossRef]

- Bendit, E.G. A Quantitative X-Ray Diffraction Study of the Alpha-Beta Transformation in Wool Keratin. Text. Res. J. 1960, 30, 547–555. [Google Scholar] [CrossRef]

- Wang, L.; Nie, Y.; Zhang, X.; Zeng, S. Synergistic Effects of Cosolvents on the Dissolution of Wool Keratin Using Ionic Liquids. Chem. Eng. Technol. 2016, 39, 979–986. [Google Scholar] [CrossRef]

- Suzuta, K.; Arai, K. Disulfide Cross-Linked Network Structure of Intermediate Filament and Matrix in Hair and Wool Cortices. Fiber 2015, 71, 237–249. [Google Scholar] [CrossRef]

- Amin, S.; El-Din, B.A.; Alan, C.; Adnan, B.; Sun, Z.; Azam, A. Evaluation of keratin extraction from wool by chemical methods for bio-polymer application. J. Bioact. Compat. Polym. 2016, 4. [Google Scholar] [CrossRef]

- Ntumba, Y.H.; Prochoń, M. The effect of modified keratin on the thermal properties of a cellulosic–elastomeric material. J. Therm. Anal. Calorim. 2016, 125, 1–10. [Google Scholar]

| Wool Fiber | KF | Assignment |

|---|---|---|

| 1655.3 | 1665.7 | Amide I |

| 1613.5 | 1611.9 | Tyrosine |

| 1449.1 | 1453.8 | CH2 bending mode |

| 1338.5 | 1339.9 | Tryptophan |

| 1248.2 | 1248.1 | Amide III |

| 1002.3 | 1002.9 | Phenylalanine |

| 931.1 | 931.9 | C–C stretch |

| 663.2 | 666.8 | C–S stretch |

| 513.9 | 547.1 | S–S |

| Samples | Amide A | C–H | Amide I | Amide II | Amide III | S–O | C–O |

|---|---|---|---|---|---|---|---|

| wool fibers | 3278.4 | 2947.2 | 1650.4 | 1523.5 | 1232.3 | ||

| KF | 3271.2 | 2943.3 | 1627.6 | 1524.4 | 1238.5 | 1168.7 | |

| GKF | 3268.8 | 2945.2 | 1620.4 | 1524.9 | 1234.7 | 1169.1 | 1052.5 |

| GO | 1045.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Yao, J.; Niu, J.; Liu, J.; Wang, L.; Feng, M.; Sun, Y. Effects of Graphene Oxide on the Structure and Properties of Regenerated Wool Keratin Films. Polymers 2018, 10, 1318. https://doi.org/10.3390/polym10121318

Li B, Yao J, Niu J, Liu J, Wang L, Feng M, Sun Y. Effects of Graphene Oxide on the Structure and Properties of Regenerated Wool Keratin Films. Polymers. 2018; 10(12):1318. https://doi.org/10.3390/polym10121318

Chicago/Turabian StyleLi, Bo, Jinbo Yao, Jiarong Niu, Jianyong Liu, Le Wang, Mao Feng, and Yanli Sun. 2018. "Effects of Graphene Oxide on the Structure and Properties of Regenerated Wool Keratin Films" Polymers 10, no. 12: 1318. https://doi.org/10.3390/polym10121318

APA StyleLi, B., Yao, J., Niu, J., Liu, J., Wang, L., Feng, M., & Sun, Y. (2018). Effects of Graphene Oxide on the Structure and Properties of Regenerated Wool Keratin Films. Polymers, 10(12), 1318. https://doi.org/10.3390/polym10121318