Effect of Compatibilizer on the Interface Bonding of Graphene Oxide/Polypropylene Composite Fibers

Abstract

:1. Introduction

2. Experiment

2.1. Materials

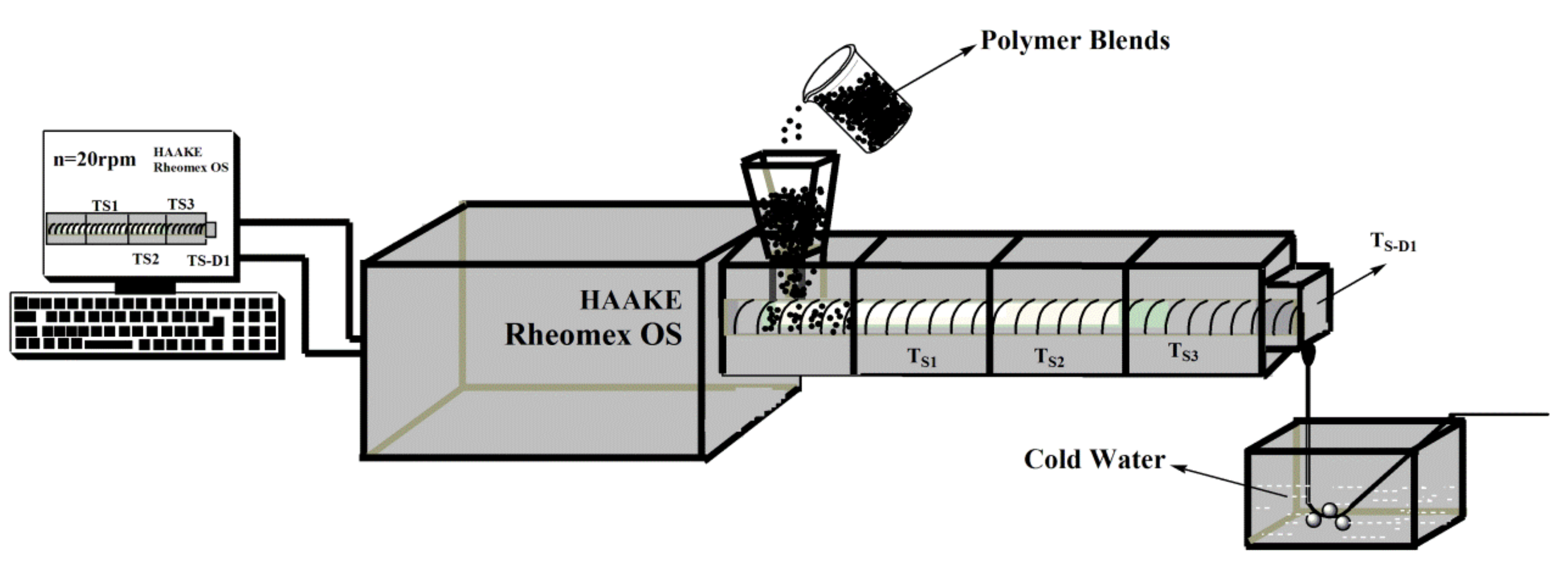

2.2. Preparation of Composite Fiber

2.3. Characterization

3. Results and Analysis

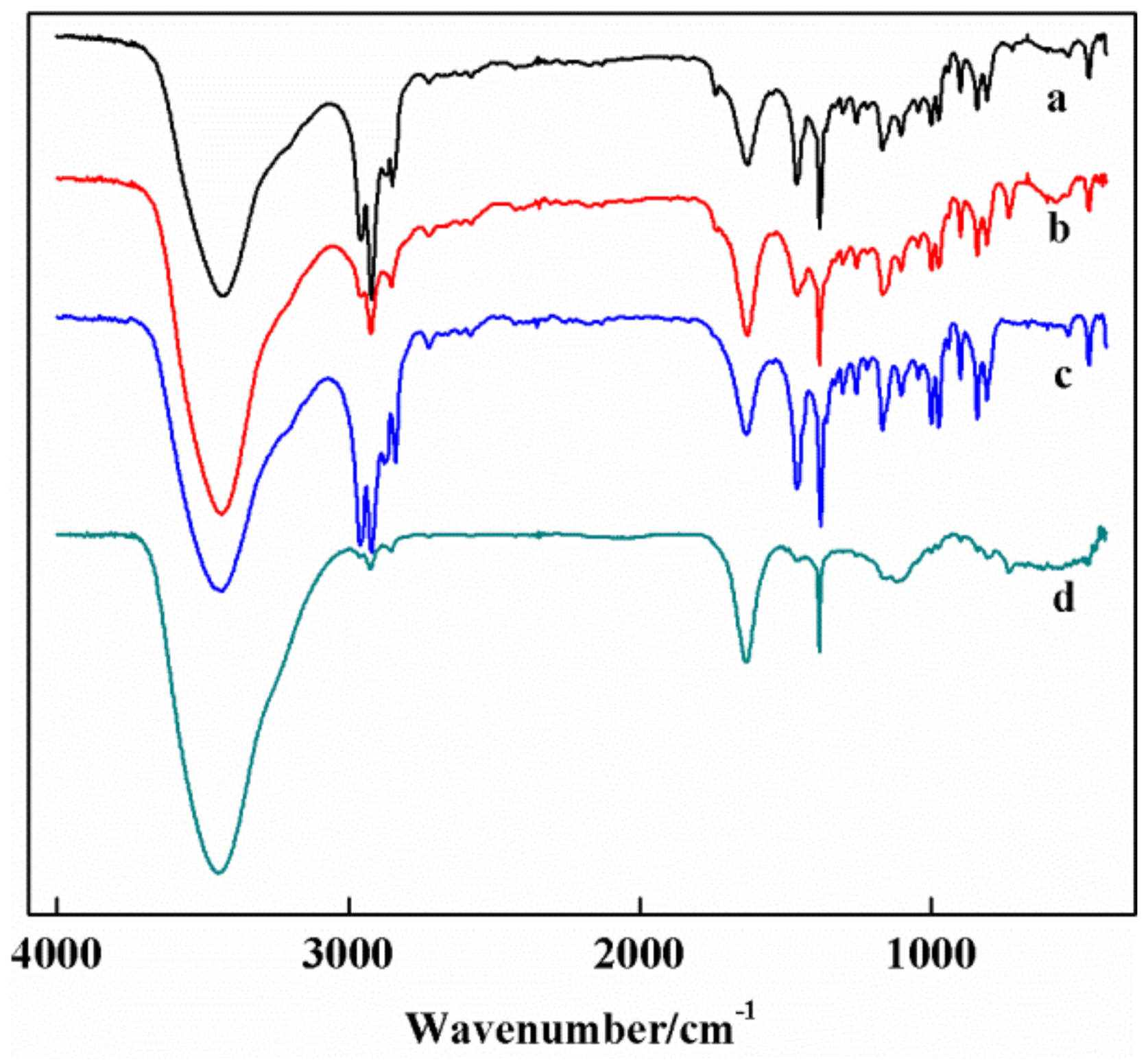

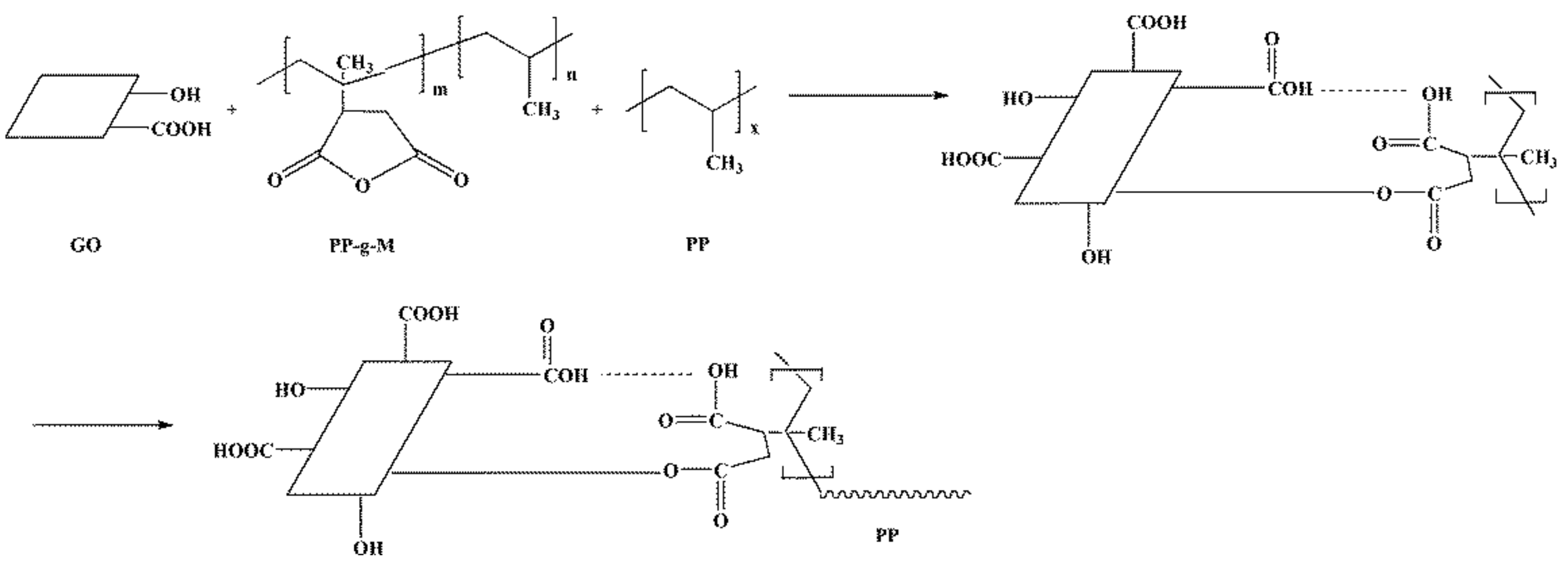

3.1. FT-IR Analysis of Composite Fibers

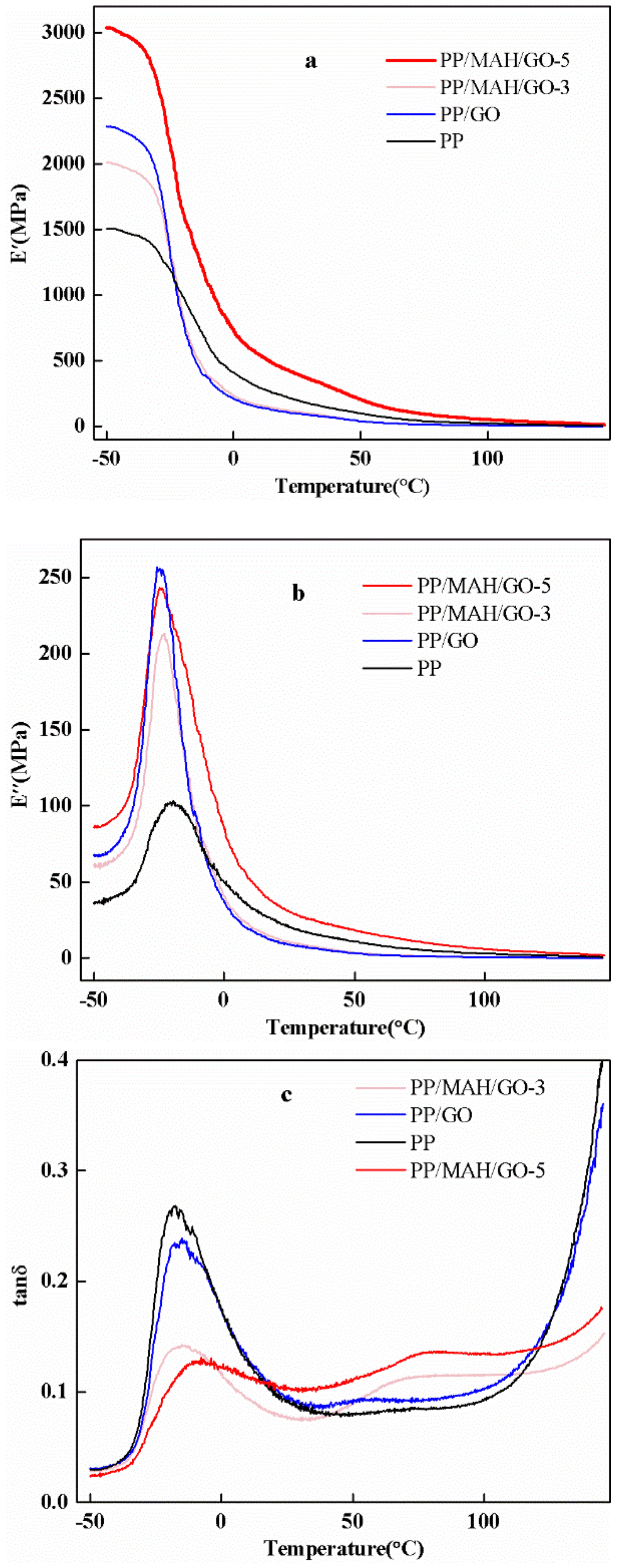

3.2. Dynamic Mechanical Properties of Composite Fibers

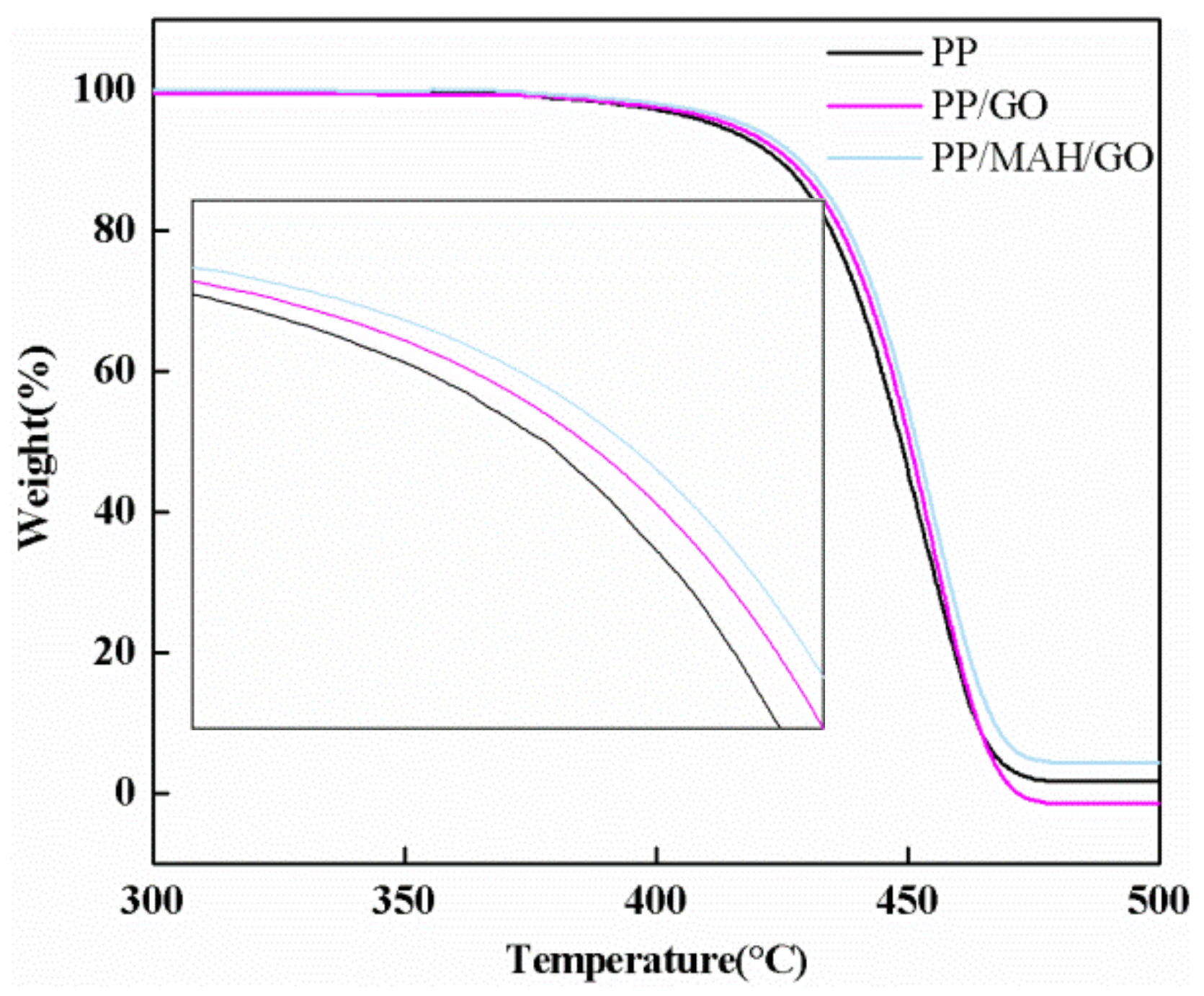

3.3. TGA of Composite Fibers

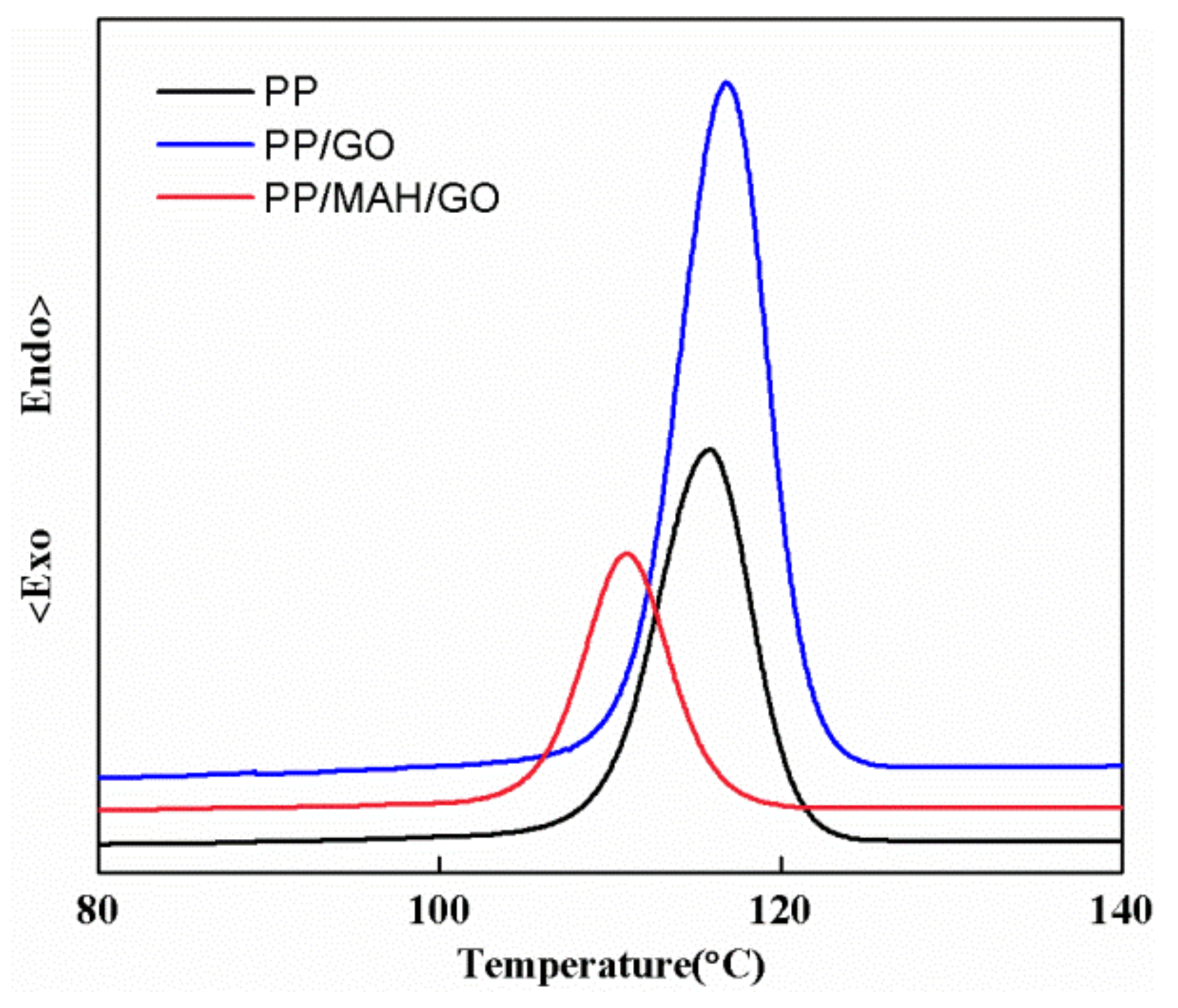

3.4. Thermal Transition Behavior Analysis of Composite Fibers

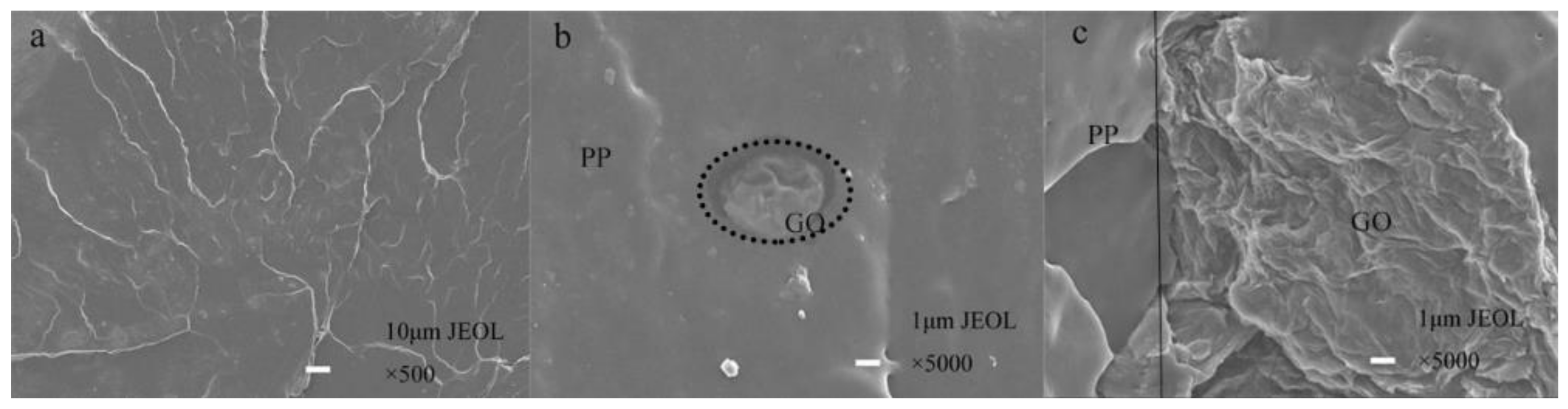

3.5. SEM of Composite Fibers

4. Conclusions and Prospects

Author Contributions

Funding

Conflicts of Interest

References

- Lee, T.W.; Jeong, Y.G. Enhanced electrical conductivity, mechanical modulus, and thermal stability of immiscible polylactide/polypropylene blends by the selective localization of multi-walled carbon nanotubes. Compos. Sci. Technol. 2014, 103, 78–84. [Google Scholar] [CrossRef]

- Luo, W.; Zhang, B.; Zou, H.; Liang, M.; Chen, Y. Enhanced interfacial adhesion between polypropylene and carbon fiber by graphene oxide/polyethyleneimine coating. J. Ind. Eng. Chem. 2017, 51, 129–139. [Google Scholar] [CrossRef]

- Stragliotto, M.F.; Strumia, M.C.; Gomez, C.G.; Romero, M. Optimization of an UV-Induced Graft Polymerization of Acrylic Acid on Polypropylene Films Using CdS as a Light Sensor. Ind. Eng. Chem. Res. 2018, 57, 1188–1196. [Google Scholar] [CrossRef]

- Chagas, G.R.; Weibel, D.E. UV-induced switchable wettability between superhydrophobic and superhydrophilic polypropylene surfaces with an improvement of adhesion properties. Polym. Bull. 2017, 74, 1965–1978. [Google Scholar] [CrossRef]

- Sanbhal, N.; Mao, Y.; Sun, G.; Xu, R.F.; Zhang, Q.; Wang, L. Surface modification of polypropylene mesh devices with cyclodextrin via cold plasma for hernia repair: Characterization and antibacterial properties. Appl. Surf. Sci. 2018, 439, 749–759. [Google Scholar] [CrossRef]

- Honarvar, Z.; Farhoodi, M.; Khani, M.R.; Mohammadi, A.; Shokri, B.; Ferdowsi, R.; Shojaee-Aliabadi, S. Application of cold plasma to develop carboxymethyl cellulose-coated polypropylene films containing essential oil. Carbohydr. Polym. 2017, 176, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Mao, Q.; Wyatt, T.P.; Chien, A.; Chen, J.; Yao, D. Melt spinning of high-strength fiber from low-molecular-weight polypropylene. Polym. Eng. Sci. 2016, 56, 233–239. [Google Scholar] [CrossRef]

- Vogel, R.; Gedan-Smolka, M.; Häussler, L. Evaluation of the crystallization of polypropylene at melt spinning conditions using the green chemical orotic acid as nucleating agent. Adv. Res. Text. Eng. 2018, 3, 1023. [Google Scholar]

- Banerjee, S.S.; Janke, A.; Gohs, U.; Heinrich, G. Electron-induced reactive processing of polyamide 6/polypropylene blends: Morphology and properties. Eur. Polym. J. 2017, 98, 295–301. [Google Scholar] [CrossRef]

- Ezat, G.S.; Kelly, A.L.; Mitchell, S.C.; Youseffi, M.; Coates, P.D. Effect of maleic anhydride grafted polypropylene compatibilizer on the morphology and properties of polypropylene/multiwalled carbon nanotube composite. Polym. Compos. 2012, 33, 1376–1386. [Google Scholar] [CrossRef]

- Szentes, A.; Varga, C.; Horvath, G.; Bartha, L.; Kónya, Z.; Haspel, H.; Szél, J.; Kukovecz, Á. Electrical resistivity and thermal properties of compatibilized multi-walled carbon nanotube/polypropylene composites. Express Polym. Lett. 2012, 6, 494–502. [Google Scholar] [CrossRef]

- Li, P.L.; Ma, S.S.; Li, J.G.; Zhang, D.Y. Analysis of Dynamic Response Master Curve of Carbon Black Modified Asphalt Mixture. J. Zhengzhou Univ. 2018, 39, 12–17. [Google Scholar]

- Zhou, C.; Liu, T.; Liu, J.; Lu, X.; Shi, Y.; Zhou, S.; Xin, Z. Polybenzoxazine/organoclay composite coatings with intercalated structure: Relationship between solubility parameters and corrosion protection performance. Prog. Org. Coat. 2018, 115, 188–194. [Google Scholar] [CrossRef]

- Yao, X.; Gao, X.; Jiang, J.; Xu, C.; Deng, C.; Wang, J. Comparison of carbon nanotubes and graphene oxide coated carbon fiber for improving the interfacial properties of carbon fiber/epoxy composites. Compos. Part B 2018, 132, 170–177. [Google Scholar] [CrossRef]

- Zhan, Y.; Wan, X.; He, S.; Yang, Q.; He, Y. Design of durable and efficient poly(arylene ether nitrile)/bioinspired polydopamine coated graphene oxide nanofibrous composite membrane for anionic dyes separation. Chem. Eng. J. 2018, 333, 132–145. [Google Scholar] [CrossRef]

- Teng, X.; Wen, L.; Lv, Y.; Tang, W.; Zhao, X.; Chen, C. Effects of potassium titanate whisker and glass fiber on tribological and mechanical properties of PTFE/PEEK blend. High Perform. Polym. 2017, 30, 752–764. [Google Scholar] [CrossRef]

- Su, W.; Kumar, N.; Krayev, A.; Chaigneau, M. In situ topographical chemical and electrical imaging of carboxyl graphene oxide at the nanoscale. Nat. Commun. 2018, 9, 2891. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Zhang, H.; Cheng, X.-L. Highly stable two-dimensional graphene oxide: Electronic properties of its periodic structure and optical properties of its nanostructures. Chin. Phys. B 2018, 27, 027301. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Oraon, R.; De Adhikari, A.; Nayak, G.C. A thermomechanical study on selective dispersion and different loading of graphene oxide in polypropylene/polycarbonate blends. J. Appl. Polym. Sci. 2017, 134, 45062. [Google Scholar] [CrossRef]

- Joseph, B.O.; James, R.; Sinha, R.S. Thermal, mechanical, and rheological properties of graphite- and graphene oxide-filled biodegradable polylactide/poly(ε-caprolactone) blend composites. J. Appl. Polym. Sci. 2017, 134, 45373. [Google Scholar]

- Wang, X.; Gao, Y.; Li, X.; Xu, Y.; Jiang, J.; Hou, J.; Li, Q.; Turng, L.-S. Selective localization of graphene oxide in electrospun polylactic acid/poly(ε-caprolactone) blended nanofibers. Polym. Test. 2017, 59, 396–403. [Google Scholar] [CrossRef]

- Chen, J.; Chen, X.; Meng, F.; Li, D.; Tian, X.; Wang, Z.; Zhou, Z. Super-high thermal conductivity of polyamide-6/graphene-graphene oxide composites through in situ polymerization. High Perform. Polym. 2017, 29, 585–594. [Google Scholar] [CrossRef]

- Meng, F.; Huang, F.; Guo, Y.; Chen, J.; Chen, X.; Hui, D.; He, P.; Zhou, X.; Zhou, Z. In situ, intercalation polymerization approach to polyamide-6/graphite nanoflakes for enhanced thermal conductivity. Compos. Part B 2017, 117, 165–173. [Google Scholar] [CrossRef]

| Sample Name | E′(MPa) | E″(MPa) | Tg (°C) | |

|---|---|---|---|---|

| PP | 2913 | 253 | 0.296 | −17.91 |

| PP/GO | 2188 | 241 | 0.235 | −16.56 |

| PP/MAH/GO-0.3 | 1923 | 212 | 0.14 | −16.15 |

| PP/MAH/GO-0.5 | 1439 | 99.8 | 0.12 | −10.61 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miao, M.; Wei, C.; Wang, Y.; Qian, Y. Effect of Compatibilizer on the Interface Bonding of Graphene Oxide/Polypropylene Composite Fibers. Polymers 2018, 10, 1283. https://doi.org/10.3390/polym10111283

Miao M, Wei C, Wang Y, Qian Y. Effect of Compatibilizer on the Interface Bonding of Graphene Oxide/Polypropylene Composite Fibers. Polymers. 2018; 10(11):1283. https://doi.org/10.3390/polym10111283

Chicago/Turabian StyleMiao, Miao, Chunyan Wei, Ying Wang, and Yongfang Qian. 2018. "Effect of Compatibilizer on the Interface Bonding of Graphene Oxide/Polypropylene Composite Fibers" Polymers 10, no. 11: 1283. https://doi.org/10.3390/polym10111283

APA StyleMiao, M., Wei, C., Wang, Y., & Qian, Y. (2018). Effect of Compatibilizer on the Interface Bonding of Graphene Oxide/Polypropylene Composite Fibers. Polymers, 10(11), 1283. https://doi.org/10.3390/polym10111283