Effect of Cotton Cationization Using Copolymer Nanospheres on Ink-Jet Printing of Different Fabrics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

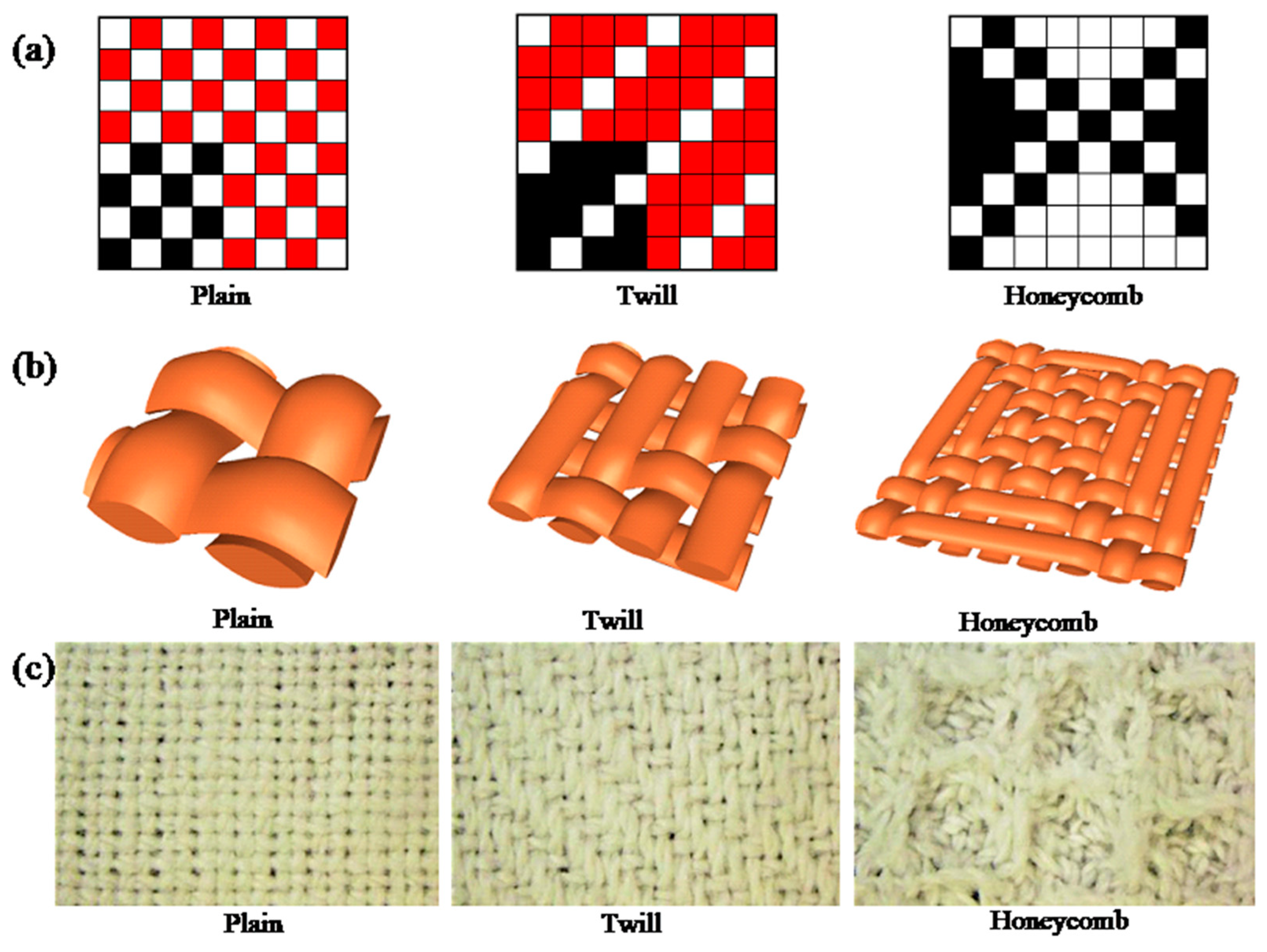

2.1.1. Textile Material

2.1.2. Chemical and Reagents

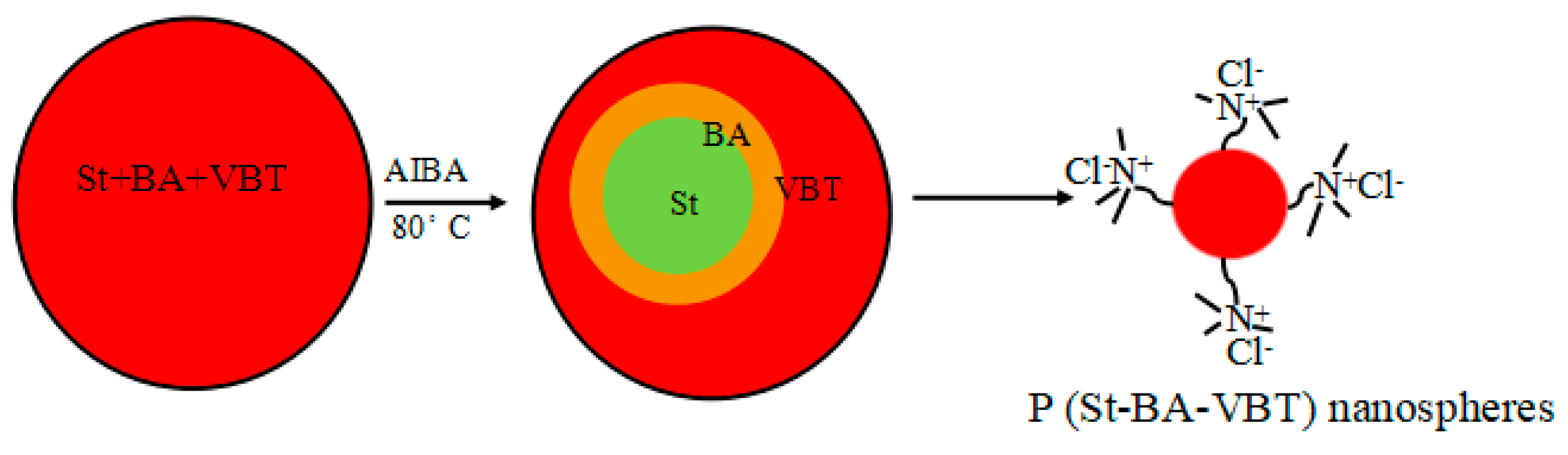

2.2. Preparation of Cationic P(St-BA-VBT) Nanospheres

2.3. Cationization Modification of Cotton Fabrics

2.4. Ink-jet Printing of Cotton Fabrics

2.5. Measurements

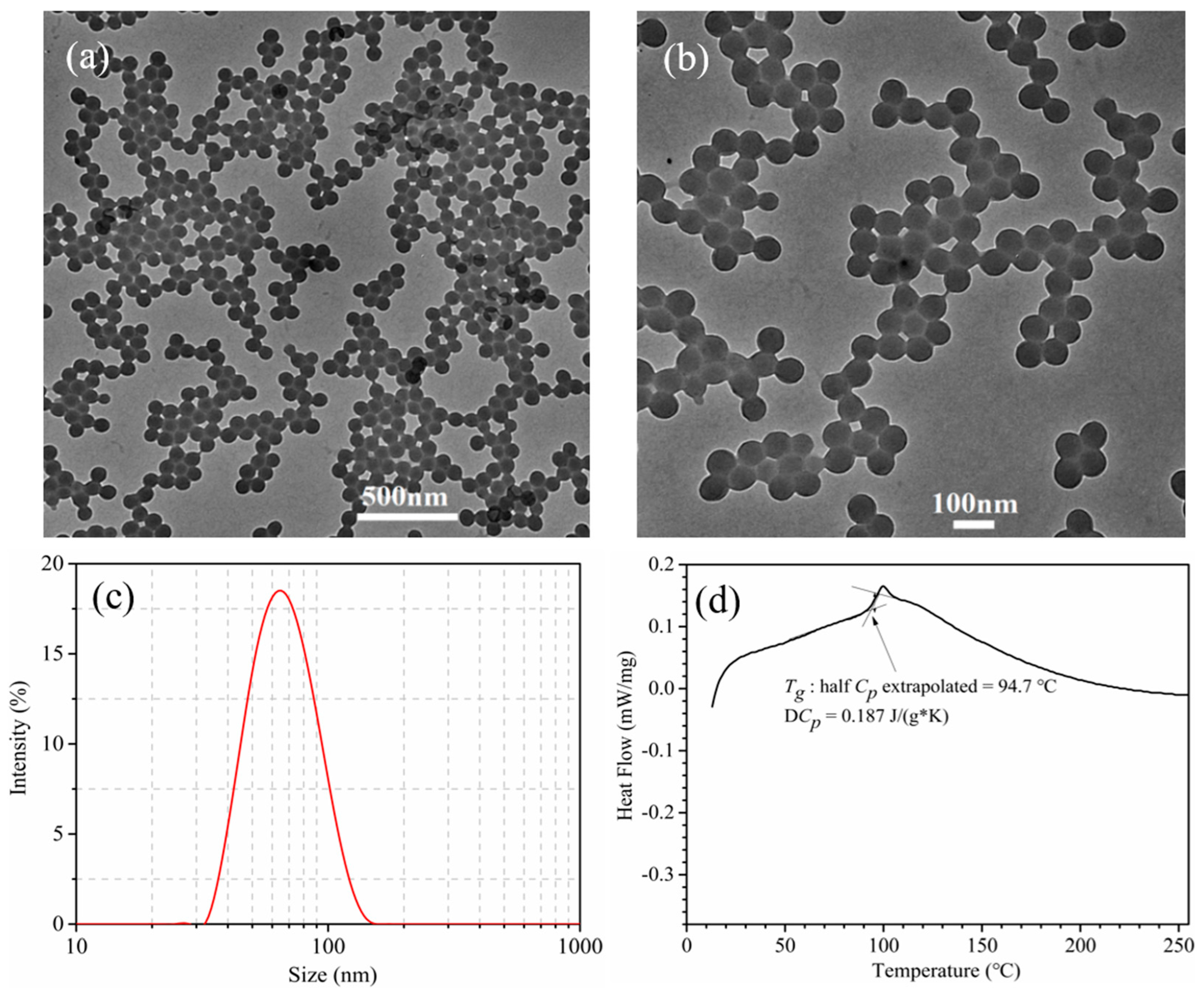

2.5.1. Transmission Electron Microscopy (TEM) Analysis

2.5.2. Sizes and Zeta Potential of the Nanospheres

2.5.3. Differential Scanning Calorimetry (DSC) Analysis

2.5.4. Colorimetric Data and Outline Sharpness of Ink-jet Printed Fabrics

2.5.5. Rubbing and Washing Fastness

2.5.6. Scanning Electron Microscopy (SEM) Analysis

2.5.7. X-ray Photoelectron Spectroscopy (XPS) Analysis

2.5.8. Fourier Transform Infrared (FTIR) Analysis

2.5.9. Tensile Breaking Strength

3. Results and Discussion

3.1. Properties of Cationic P(St-BA-VBT) Nanospheres

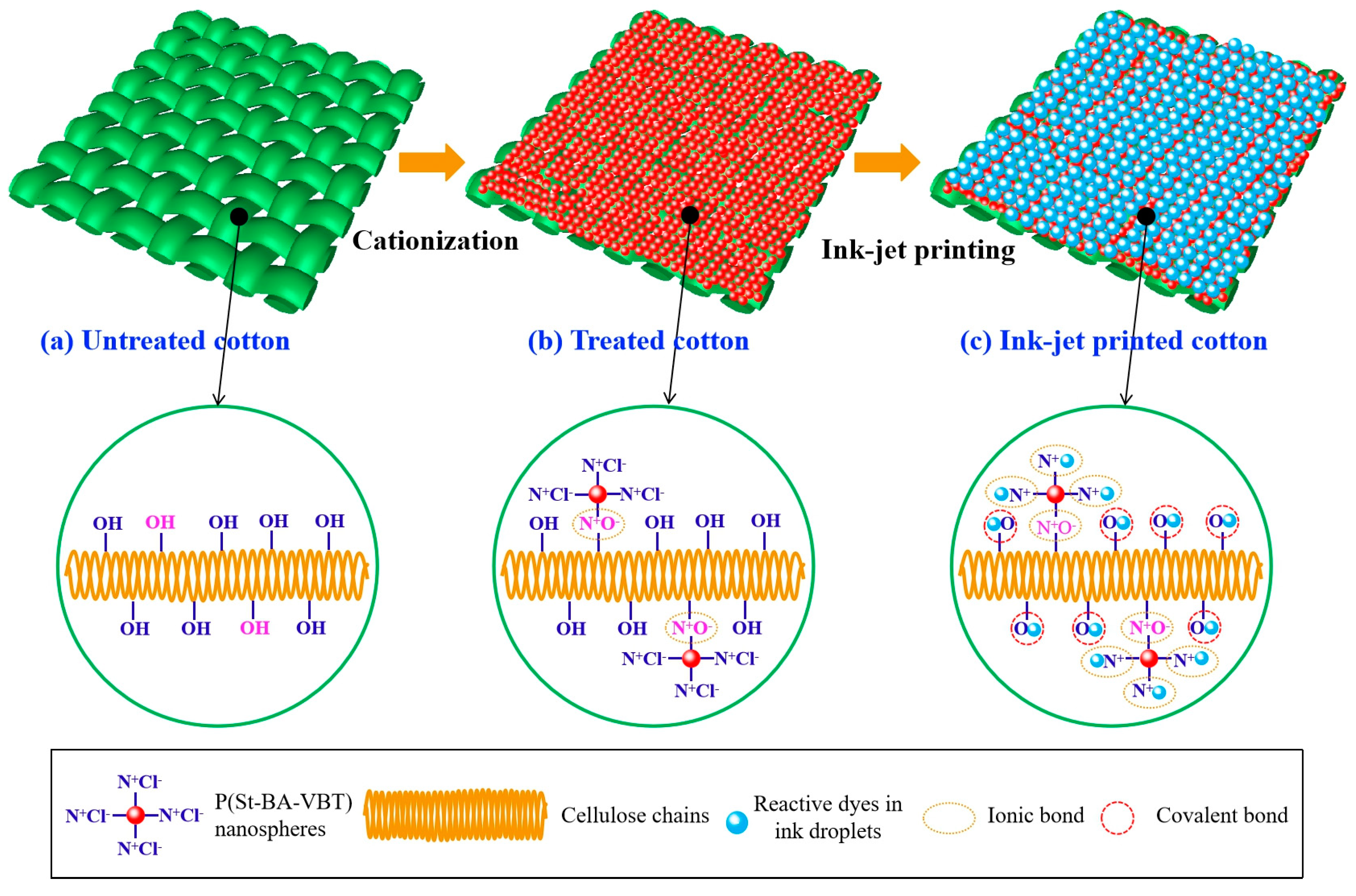

3.2. Influence of Cationic Nanospheres on K/S Value and Outline Sharpness of Ink-jet Printed Cotton Fabric

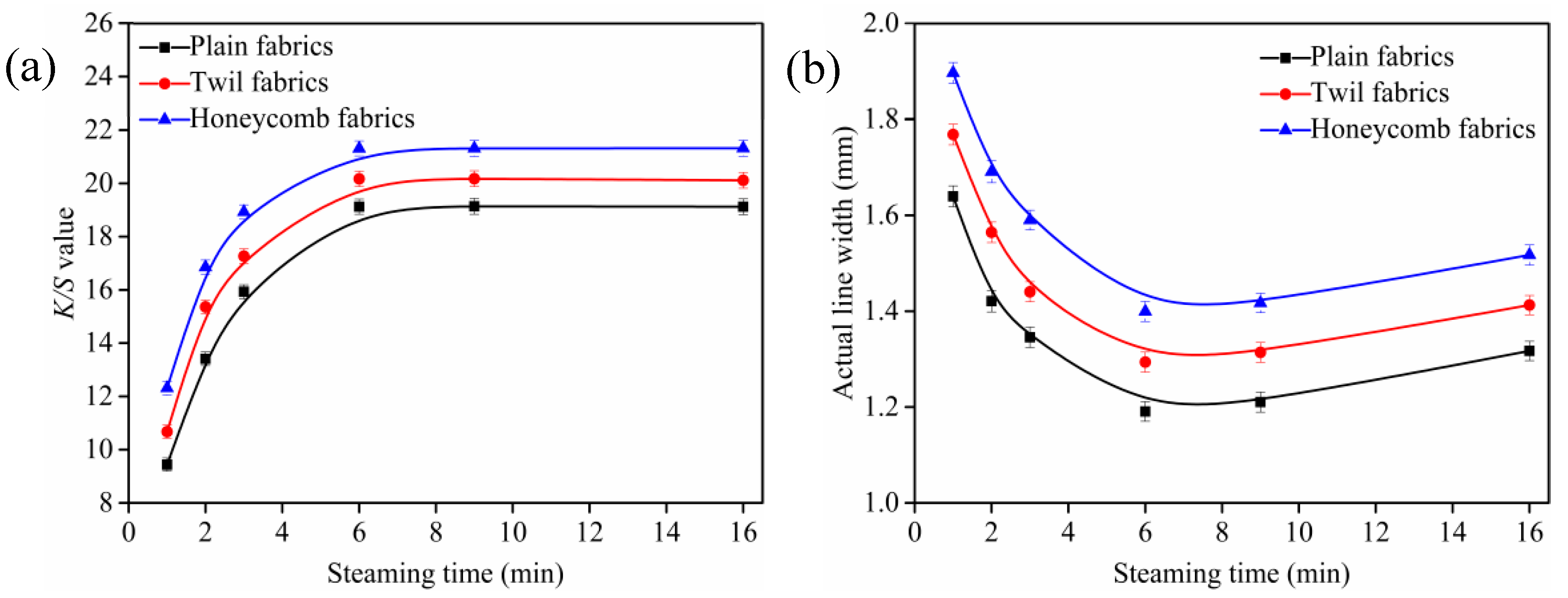

3.3. Influence of Steaming Time on K/S Value and Outline Sharpness of Ink-Jet Printed Cotton Fabric

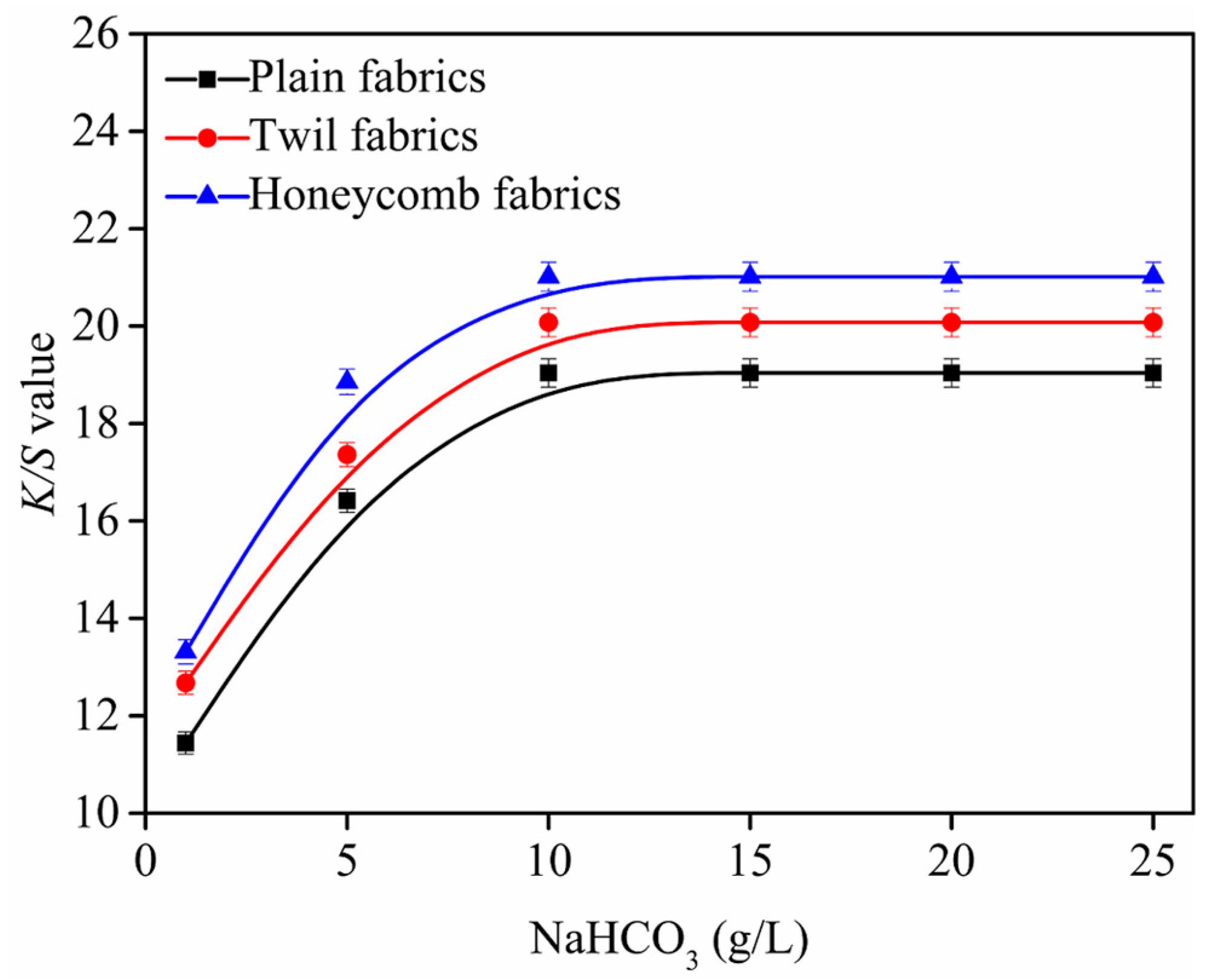

3.4. Influence of NaHCO3 Amounts on K/S Value of Ink-jet Printed Cotton Fabric

3.5. Color Characteristic and Color Fastness of Cotton Fabrics

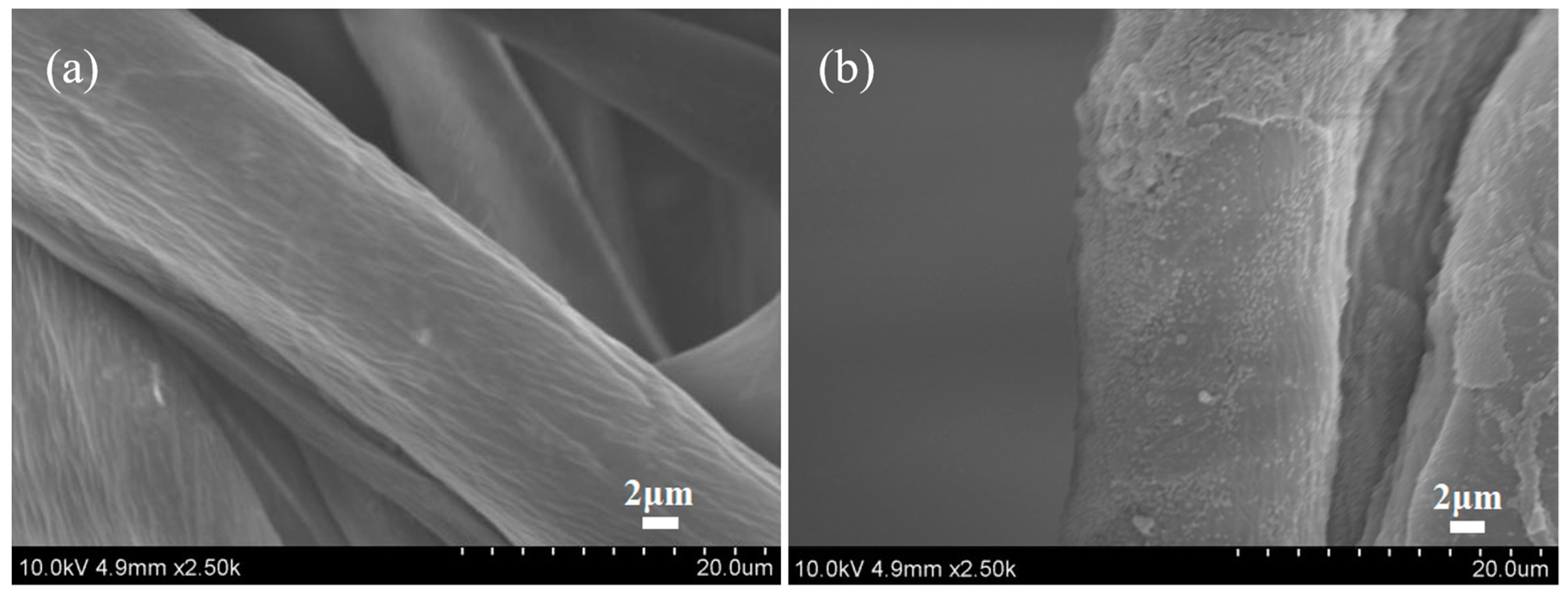

3.6. SEM Analysis of Cotton Fabrics

3.7. XPS Analysis of Cotton Fabrics

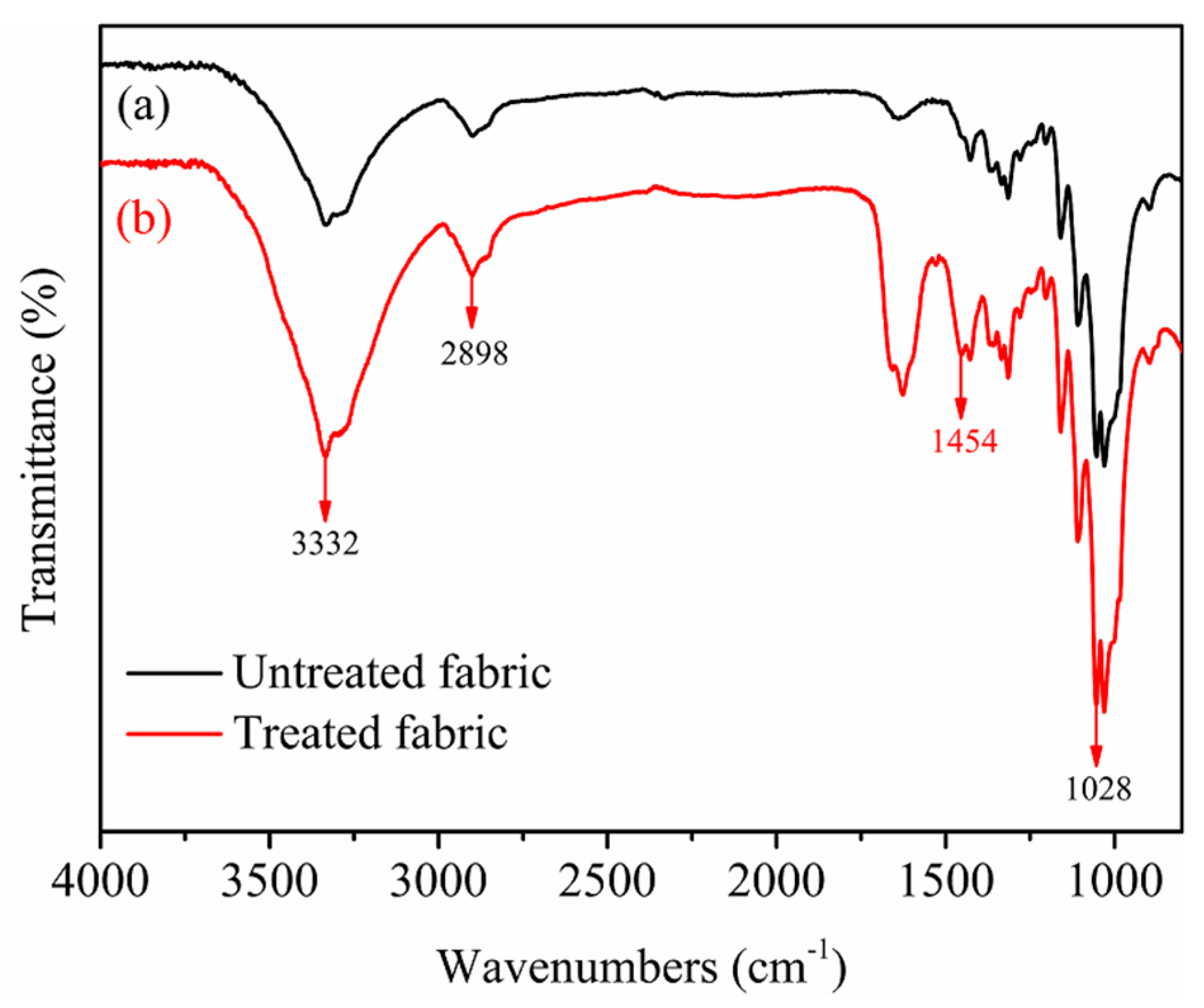

3.8. FTIR Analysis of Cotton Fabrics

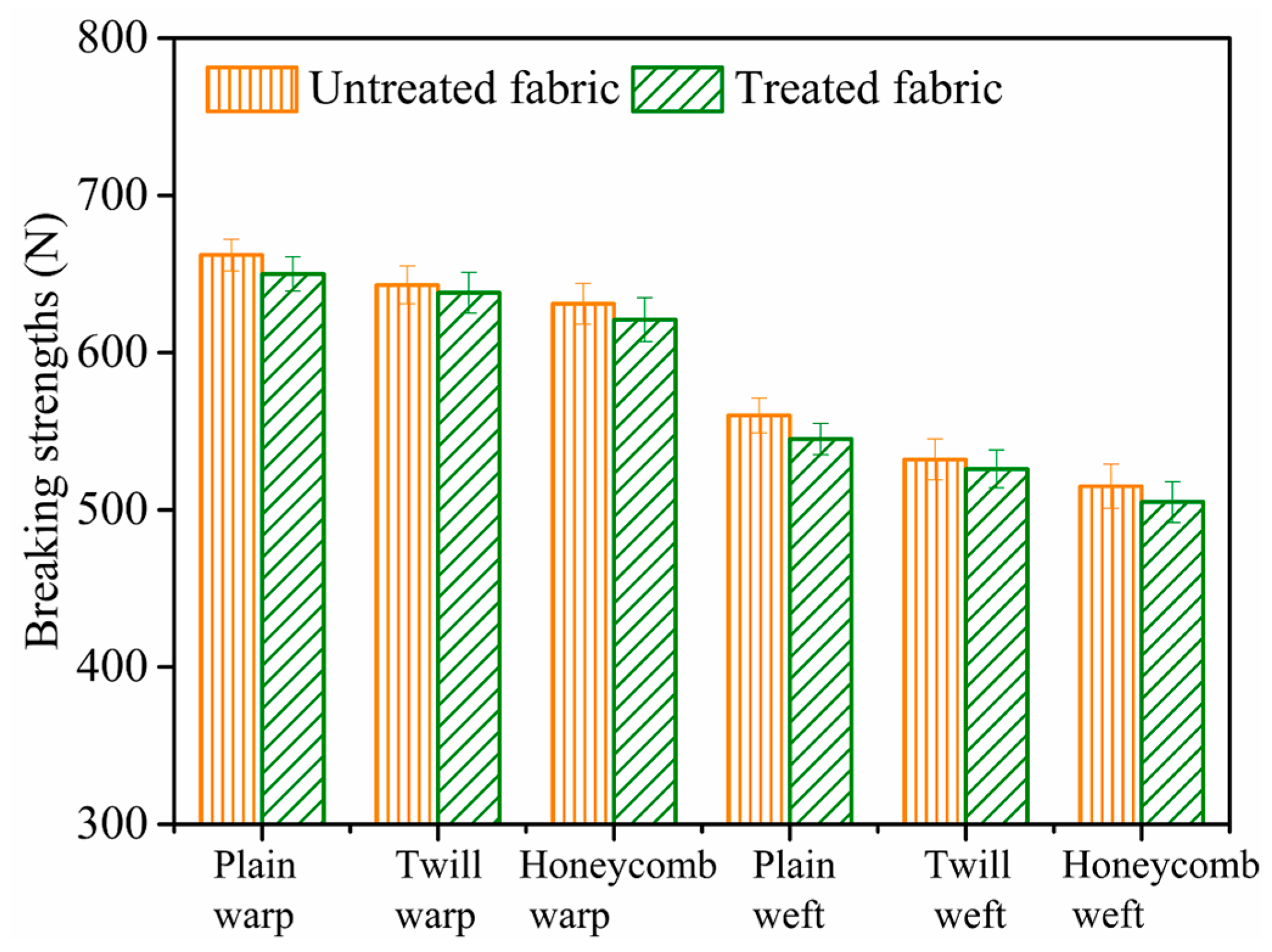

3.9. Tensile Breaking Strength of Cotton Fabrics

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Memon, H.; Khoso, N.A.; Memon, S.; Wang, N.N.; Zhu, C.Y. Formulation of eco-friendly inks for ink-jet printing of polyester and cotton blended fabric. Key. Eng. Mater. 2016, 671, 109–114. [Google Scholar] [CrossRef]

- Park, Y.; Koo, K. The eco-friendly surface modification of textiles for deep digital textile printing by in-line atmospheric non-thermal plasma treatment. Fiber Polym. 2014, 15, 1701–1707. [Google Scholar] [CrossRef]

- Rekaby, M.; Salem, A.A.; Nassar, S.H. Eco-friendly printing of natural fabrics using natural dyes from alkanet and rhubarb. J. Text. Inst. 2009, 100, 486–495. [Google Scholar] [CrossRef]

- Ibrahim, N.A.; Fahmy, H.M.; Awad, M.; El Badawy, L.E. Influence of selective chemical pretreatments on eco-friendly pigment printing of polyester/cellulosic blends. Polym-Plast. Technol. 2005, 44, 133–150. [Google Scholar] [CrossRef]

- Pransilp, P.; Pruettiphap, M.; Bhanthumnavin, W.; Paosawatyanyong, B.; Kiatkamjornwong, S. Surface modification of cotton fabrics by gas plasmas for color strength and adhesion by inkjet ink printing. Appl. Surf. Sci. 2016, 364, 208–220. [Google Scholar] [CrossRef]

- Soleimani-Gorgani, A.; Najafi, F.; Karami, Z. Modification of cotton fabric with a dendrimer to improve ink-jet printing process. Carbohydr. Polym. 2015, 131, 168–176. [Google Scholar] [CrossRef] [PubMed]

- Kan, C.W.; Yuen, C.W.M.; Tsoi, W.Y. Using atmospheric pressure plasma for enhancing the deposition of printing paste on cotton fabric for digital ink-jet printing. Cellulose 2011, 18, 827–839. [Google Scholar] [CrossRef]

- Kaimouz, A.W.; Wardman, R.H.; Christie, R.M. The inkjet printing process for lyocell and cotton fibres. part 1: the significance of pre-treatment chemicals and their relationship with colour strength, absorbed dye fixation and ink penetration. Dyes Pigm. 2010, 84, 79–87. [Google Scholar] [CrossRef]

- Fang, K.; Zhang, C. Surface physical–morphological and chemical changes leading to performance enhancement of atmospheric pressure plasma treated polyester fabrics for inkjet printing. Appl. Surf. Sci. 2009, 255, 7561–7567. [Google Scholar] [CrossRef]

- Zhang, C.; Fang, K. Aging of surface properties of polyester fabrics treated with atmospheric pressure plasma for inkjet printing. Surf. Eng. 2008, 28, 306–310. [Google Scholar] [CrossRef]

- Fang, K.; Wang, S.; Wang, C.; Tian, A. Inkjet printing effects of pigment inks on silk fabrics surface-modified with O2 plasma. J. Appl. Polym. Sci. 2008, 107, 2949–2955. [Google Scholar] [CrossRef]

- Zhang, C.; Fang, K. Surface modification of polyester fabrics for inkjet printing with atmospheric-pressure air/Ar plasma. Surf. Coat. Technol. 2009, 203, 2058–2063. [Google Scholar] [CrossRef]

- Hashem, M.; Hauser, P.; Smith, B. Reaction efficiency for cellulose cationization using 3-chloro-2-hydroxypropyl trimethyl ammonium chloride. Text. Res. J. 2003, 73, 1017–1023. [Google Scholar] [CrossRef]

- Farrell, M.J.; Ormond, R.B.; Gabler, W.J. Quantitative analysis of trimethyl amine in cotton fabrics cationized with 3-chloro-2-hydroxypropyltrimethylam-monium chloride. Cellulose 2015, 22, 3435–3439. [Google Scholar] [CrossRef]

- Fang, K.; Shu, D.; Liu, X.; Cai, Y.; An, F.; Zhang, X. Reactive pad-steam dyeing of cotton fabric modified with cationic P(St-BA-VBT) nanospheres. Polymers 2018, 10, 564. [Google Scholar] [CrossRef]

- Shu, D.; Fang, K.; Liu, X.; Cai, Y.; Zhang, X.; Zhang, J. Cleaner coloration of cotton fabric dyed with reactive dyes using a pad-batch-steam dyeing process. J. Clean. Prod. 2018, 196, 935–942. [Google Scholar] [CrossRef]

- Fang, K.; Zhao, H.; Li, J.; Chen, W.; Cai, Y.; Hao, L. Salt-free dyeing of cotton fabrics modified with cationic copolymer nanospheres using an acid dye. Fibers Polym. 2017, 18, 400–406. [Google Scholar] [CrossRef]

- Fang, K.; Song, T.; Zhang, K.; Chen, W.; Cai, Y.; Hao, L. Fixation of cationic P (st-BA-AA-GMA) emulsion on pigment particles in dyeing of cotton fabrics. J. Appl. Polym. Sci. 2017, 134, 44987–44996. [Google Scholar] [CrossRef]

- Liu, X.; Li, C.; Fang, K.; Shu, D.; Guo, Z. Coloration of apocynum venetum/cotton blends with an acid dye through combined pretreatment using cationic nanoparticles. Color. Technol. 2017, 133, 293–299. [Google Scholar] [CrossRef]

- Liu, X.; Li, C.; Fang, K.; Shu, D. A novel approach for Apocynum venetum/cotton blended fabrics modification by cationic polymer nanoparticles. Chin. Chem. Lett. 2017, 28, 955–959. [Google Scholar] [CrossRef]

- Wang, W.; Cai, Z.; Yu, J. Cationic modification and dyeing behavior of jute/cotton blended fabric. J. Text. Res. 2011, 32, 74–79. [Google Scholar]

- Guo, Z.; Liu, X.; Fang, K.; Cai, Y. Preparation of reactive dye/polymer composite copolymer microspheres. J. Text. Res. 2017, 38, 80–84. [Google Scholar]

- Gong, J.; Ren, Y.; Fu, R.; Li, Z.; Zhang, J. pH-mediated antibacterial dyeing of cotton with prodigiosins nanomicelles produced by microbial fermentation. Polymers 2017, 9, 468. [Google Scholar] [CrossRef]

- Avinc, O.; Gedik, A.; Gedik, G.; Yavas, A. Natural dye extraction from waste barks of turkish red pine (pinus;brutia ten.) timber and eco-friendly natural dyeing of various textile fibers. Fibers Polym. 2013, 14, 866–873. [Google Scholar] [CrossRef]

- Baliarsingh, S.; Panda, A.K.; Jena, J.; Das, T.; Das, N.B. Exploring sustainable technique on natural dye extraction from native plants for textile: identification of colourants, colourimetric analysis of dyed yarns and their antimicrobial evaluation. J. Clean. Prod. 2012, 37, 257–264. [Google Scholar] [CrossRef]

- Fang, K.; Liu, Y.; Hao, L.; Cai, Y.; Zhang, J.; Zhang, L. Cationic styrene-butyl acrylate-quaternary ammonium copolymer nanospheres for surface modification of cotton fibers. Fibers Polym. 2015, 16, 982–990. [Google Scholar] [CrossRef]

- Liu, X.; He, D.; Fang, K. Adsorption of P(St-co-DMHB-co-BA)n+·Brn− nanoscale particles onto cotton fiber surfaces: a study by conductometric titration. Fibers Polym. 2015, 16, 1237–1242. [Google Scholar] [CrossRef]

- Fang, K.; Xia, X.; Cai, Y.; Hao, L.; Zhang, J.; Zhao, Y. Blue core–shell nanospheres prepared by dyeing poly(styrene-co-methacrylic acid) dispersions. Color. Technol. 2016, 131, 458–463. [Google Scholar] [CrossRef]

- Ashraf, U. Effect of cotton fiber and yarn characteristics on color variation in woven fabric dyed with vat dyes. J. Text. Inst. 2014, 105, 1287–1292. [Google Scholar] [CrossRef]

- Farooq, S.; Yousufani, S.A. Effect of inter yarn fabric porosity on dye uptake of reactive dyed cotton woven Fabric. Mehran. Univ. Res. J. Eng. Technol. 2015, 34, 265–272. [Google Scholar]

- Bae, J.H.; Hong, K.H.; Lamar, T.M. Effect of texture on color variation in inkjet-printed woven textiles. Color. Res. Appl. 2015, 40, 297–303. [Google Scholar] [CrossRef]

- Çay, A.; Atav, R.; Duran, K. Effects of warp-weft density variation and fabric porosity of the cotton fabrics on their colour in reactive dyeing. Fibres. Text. East. Eur. 2007, 15, 91–94. [Google Scholar]

- Khatun, M. Effect of Yarn Count on the dyeing performance of reactive dye in exhaust method. Int. J. Text. Sci. 2013, 2, 92–104. [Google Scholar]

- Romdhani, Z.; Baffoun, A.; Hamdaoui, M.; Roudesli, S. Experimental study and mathematical model to follow the spreading diameter on coated woven cotton fabric. Fibers Polym. 2017, 18, 2454–2461. [Google Scholar] [CrossRef]

- Liu, Z.; Fang, K.; Gao, H.; Liu, X.; Zhang, J. Effect of cotton fabric pretreatment on drop spreading and colour performance of reactive dye inks. Color. Technol. 2016, 132, 407–413. [Google Scholar] [CrossRef]

- Wang, L.; Hu, C.; Yan, K. Cleaner production of inkjet printed cotton fabrics using a urea-free ecosteam process. J. Clean. Prod. 2017, 143, 1–6. [Google Scholar] [CrossRef]

- Liu, D.; Hao, L.; Fang, K. Adsorption of cationic copolymer nanospheres onto cotton fibers investigated by a facile nephelometry. Colloid. Surf. A 2014, 452, 82–88. [Google Scholar] [CrossRef]

- Abdali, H.; Ajji, A. Preparation of electrospun nanocomposite nanofibers of polyaniline/poly(methyl methacrylate) with amino-functionalized graphene. Polymers 2017, 9, 453. [Google Scholar] [CrossRef]

- Wang, L.; Hu, C.; Yan, K. A one-step inkjet printing technology with reactive dye ink and cationic compound ink for cotton fabrics. Carbohydr. Polym. 2018, 197, 490–496. [Google Scholar] [CrossRef] [PubMed]

- Bulut, M.O.; Akar, E. Ecological dyeing with some plant pulps on woolen yarn and cationized cotton fabric. J. Clean. Prod. 2012, 32, 1–9. [Google Scholar] [CrossRef]

- Ben, T.M.; Haddar, W.; Meksi, N.; Guesmi, A.; Mhenni, M.F. Improving dyeability of modified cotton fabrics by the natural aqueous extract from red cabbage using ultrasonic energy. Carbohydr. Polym. 2016, 154, 287–295. [Google Scholar]

| Fabrics | Warp Roughness (μm) | Weft Roughness (μm) | Thickness (mm) | Porosity (%) |

|---|---|---|---|---|

| Plain | 2.8 | 5.2 | 0.6 | 84.5 |

| Twill | 3.5 | 6.2 | 0.8 | 85.5 |

| Honeycomb | 5.7 | 8.4 | 1.7 | 86.6 |

| Cotton Fabric | Weave | Color Characteristic Values | |||||

|---|---|---|---|---|---|---|---|

| K/S | L* | a* | b* | C* | h° | ||

| Untreated | Plain | 16.6 | 56.9 | −32.7 | −29.8 | 44.2 | 222.4 |

| Twill | 17.9 | 55.9 | −33.3 | −31.9 | 46.1 | 223.8 | |

| Honeycomb | 18.8 | 55.4 | −34.1 | −32.3 | 47.0 | 223.4 | |

| Treated | Plain | 20.2 | 54.5 | −33.5 | −32.3 | 46.5 | 223.9 |

| Twill | 21.4 | 53.4 | −34.3 | −33.3 | 47.8 | 224.1 | |

| Honeycomb | 22.8 | 52.6 | −34.1 | −33.4 | 47.7 | 224.4 | |

| Cotton Fabric | Weave | Rubbing Fastness | Washing Fastness | |||

|---|---|---|---|---|---|---|

| Dry | Wet | SW | CC | SC | ||

| Untreated | Plain | 4–5 | 3 | 4–5 | 4–5 | 4–5 |

| Twill | 4–5 | 3–4 | 5 | 5 | 5 | |

| Honeycomb | 4–5 | 4 | 5 | 5 | 5 | |

| Treated | Plain | 4–5 | 3–4 | 4–5 | 4–5 | 4–5 |

| Twill | 4–5 | 3–4 | 5 | 5 | 5 | |

| Honeycomb | 4–5 | 4 | 5 | 5 | 5 | |

| Cotton Fabric | Binding Energy (eV) | Atomic Concentration (%) | Atomic Ratio O/C | ||||

|---|---|---|---|---|---|---|---|

| C1s | O1s | N1s | C1s | O1s | N1s | ||

| Untreated | 286 | 533 | 400 | 67.01 | 32.99 | - | 0.49 |

| Treated | 68.02 | 28.91 | 3.07 | 0.43 | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Fang, K.; Liu, X.; Cai, Y.; An, F. Effect of Cotton Cationization Using Copolymer Nanospheres on Ink-Jet Printing of Different Fabrics. Polymers 2018, 10, 1219. https://doi.org/10.3390/polym10111219

Yang H, Fang K, Liu X, Cai Y, An F. Effect of Cotton Cationization Using Copolymer Nanospheres on Ink-Jet Printing of Different Fabrics. Polymers. 2018; 10(11):1219. https://doi.org/10.3390/polym10111219

Chicago/Turabian StyleYang, Haizhen, Kuanjun Fang, Xiuming Liu, Yuqing Cai, and Fangfang An. 2018. "Effect of Cotton Cationization Using Copolymer Nanospheres on Ink-Jet Printing of Different Fabrics" Polymers 10, no. 11: 1219. https://doi.org/10.3390/polym10111219

APA StyleYang, H., Fang, K., Liu, X., Cai, Y., & An, F. (2018). Effect of Cotton Cationization Using Copolymer Nanospheres on Ink-Jet Printing of Different Fabrics. Polymers, 10(11), 1219. https://doi.org/10.3390/polym10111219