Improved Processability and the Processing-Structure-Properties Relationship of Ultra-High Molecular Weight Polyethylene via Supercritical Nitrogen and Carbon Dioxide in Injection Molding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Methods

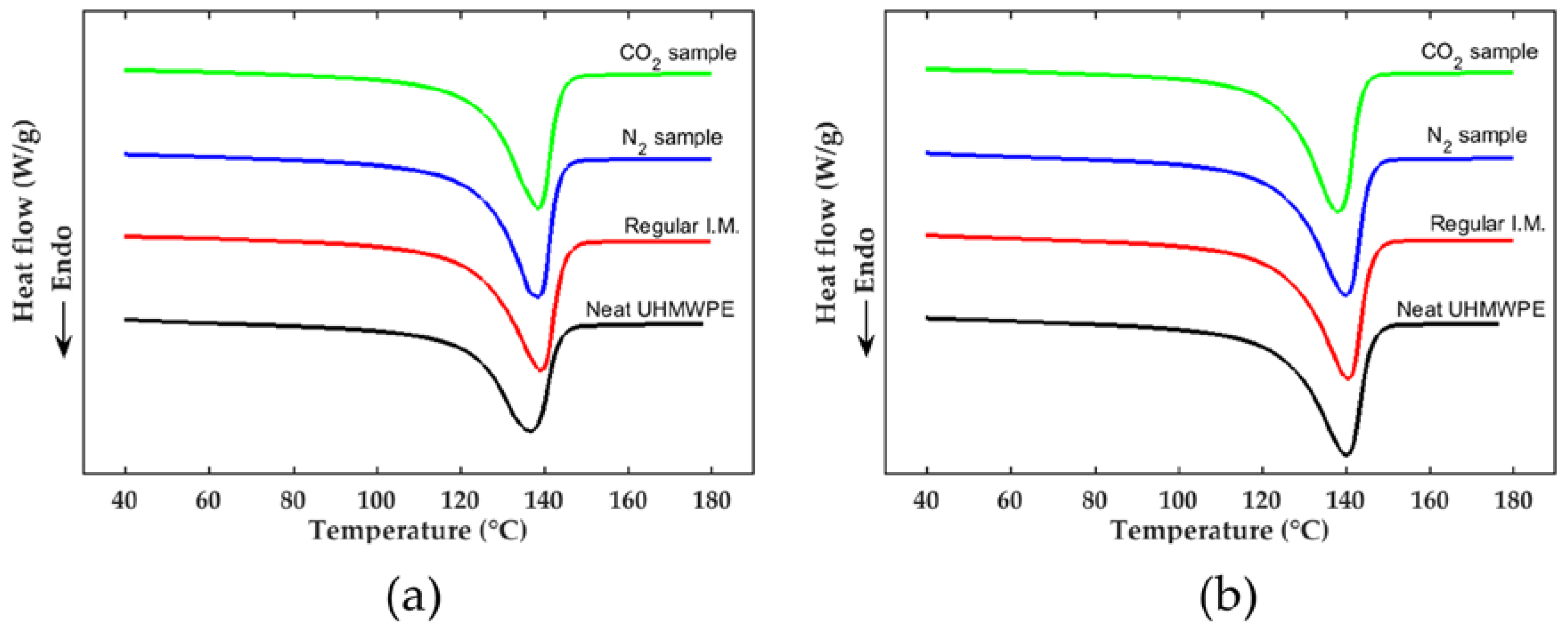

2.2. Differential Scanning Calorimetry

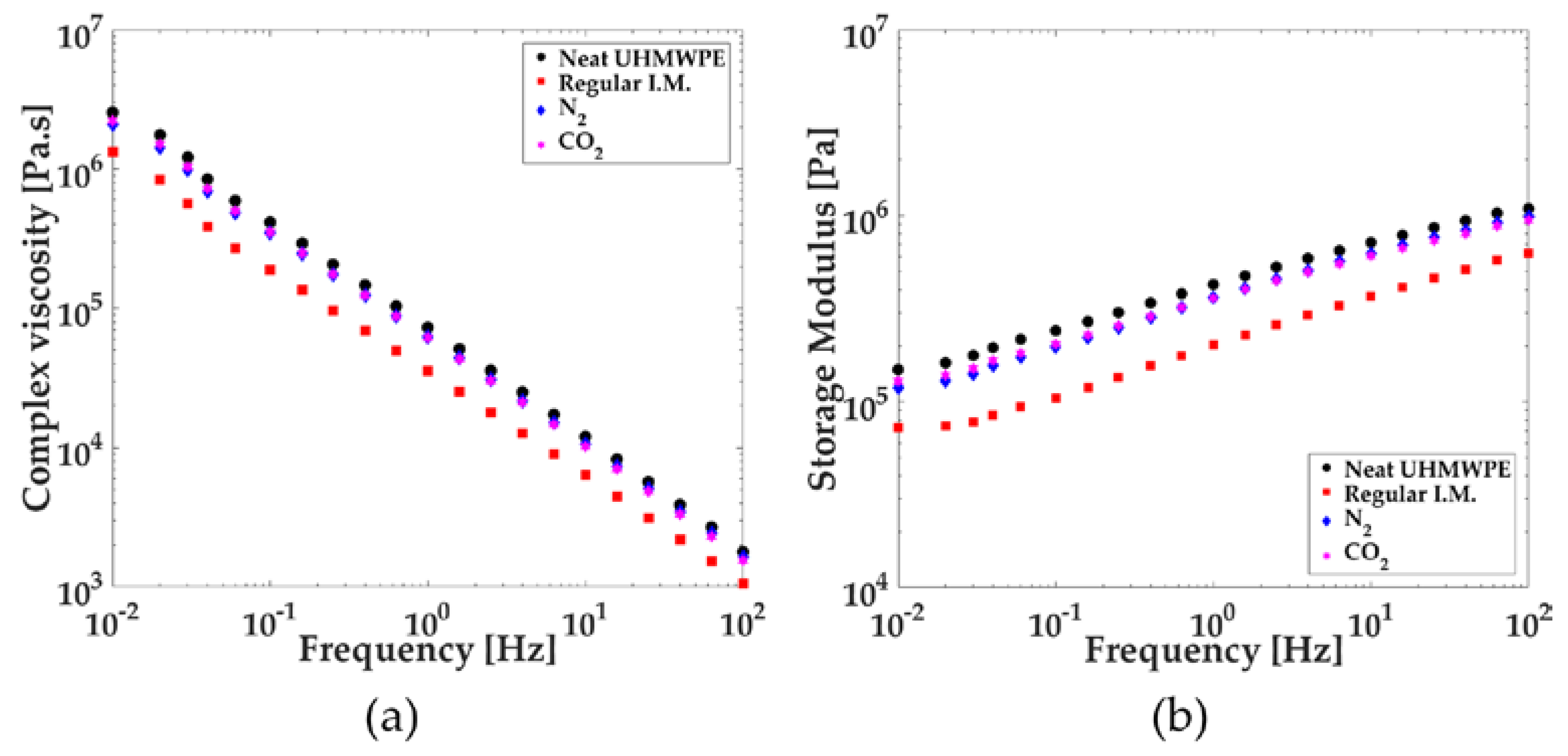

2.3. Rheology

2.4. Micro-Computed Tomography (μCT)

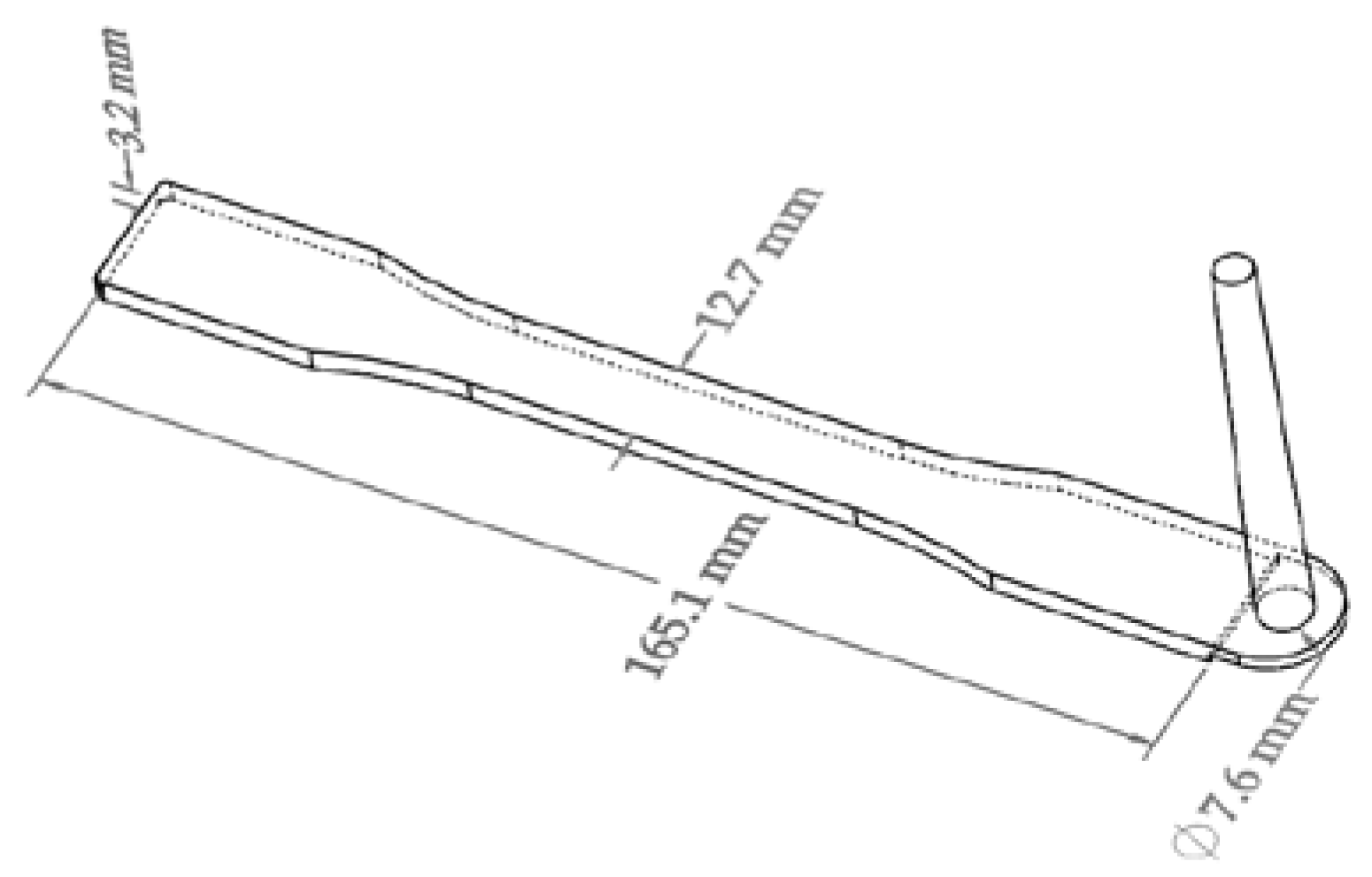

2.5. Tensile Tests

2.6. Tensile Bar Images and Injection Pressure Measurements

3. Results and Discussion

3.1. Differential Scanning Calorimetry

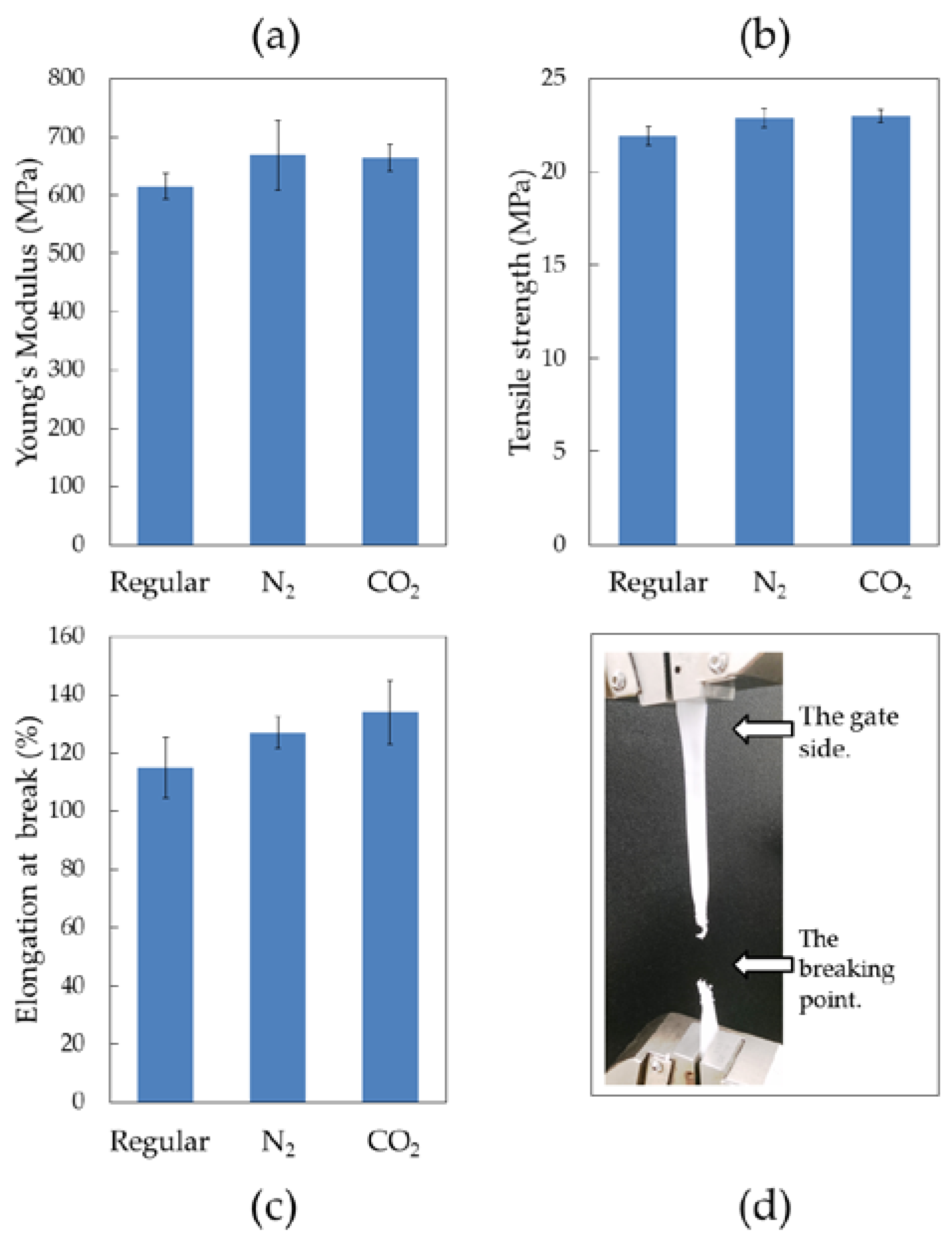

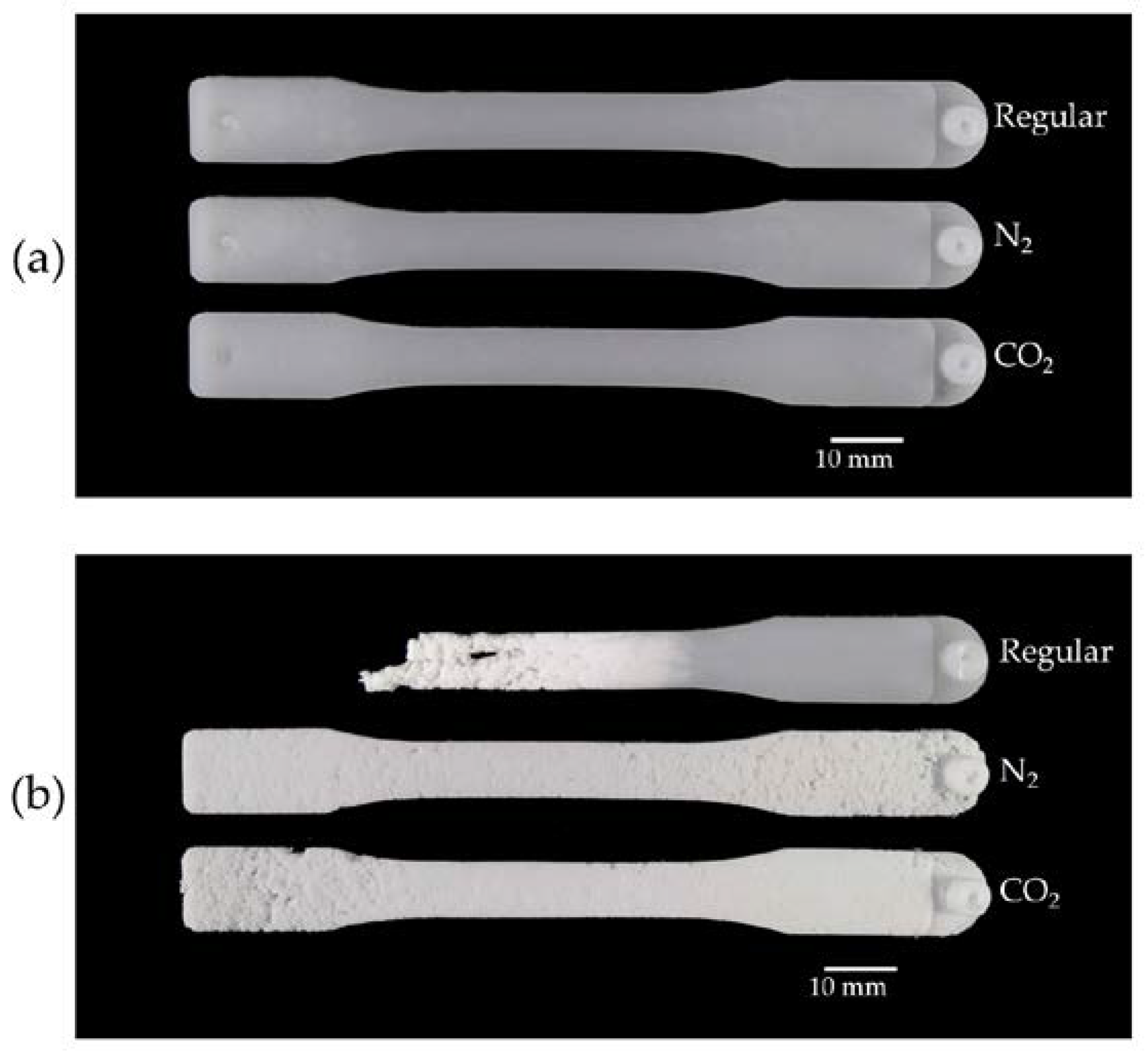

3.2. Mechanical Properties

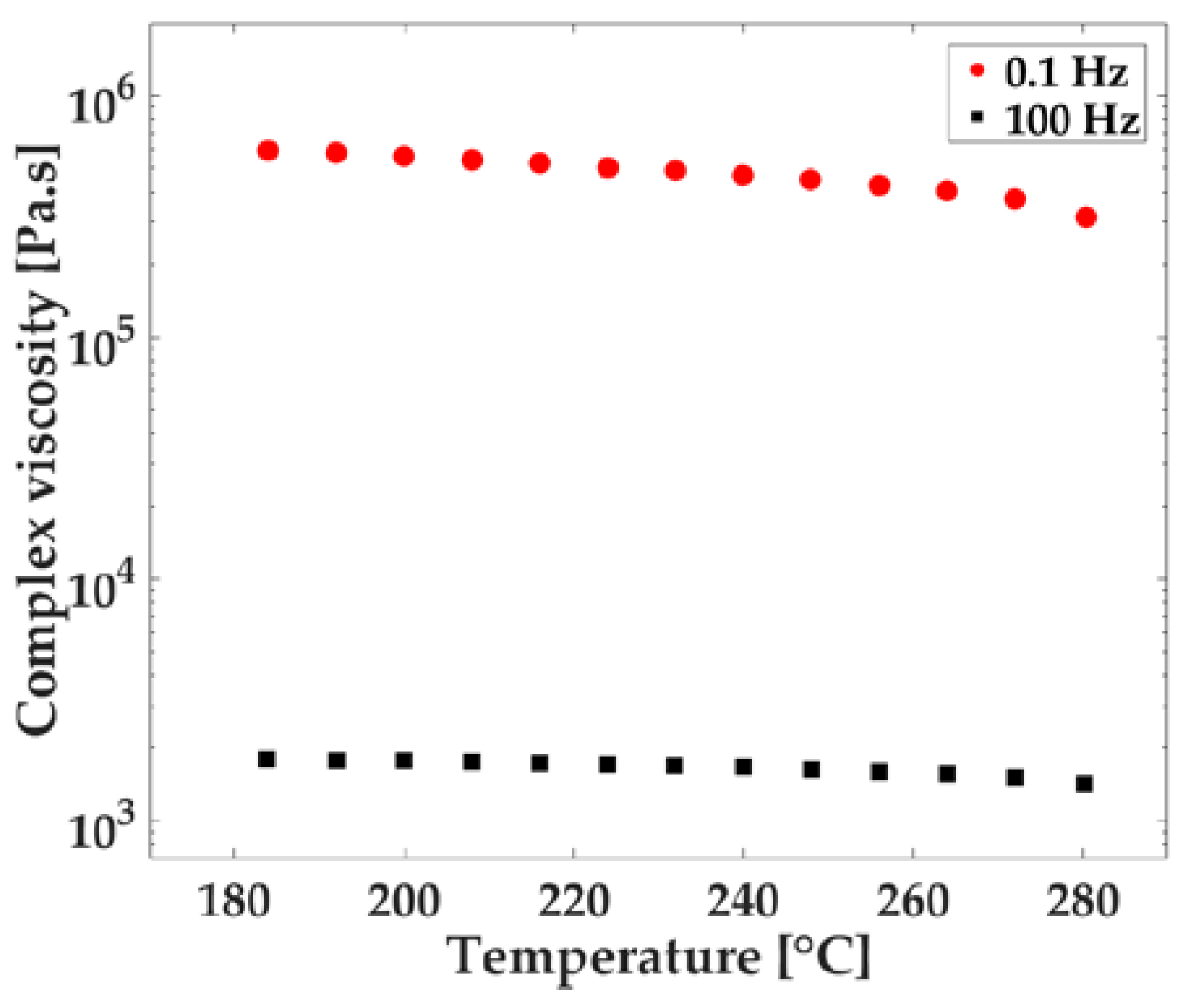

3.3. Rheology

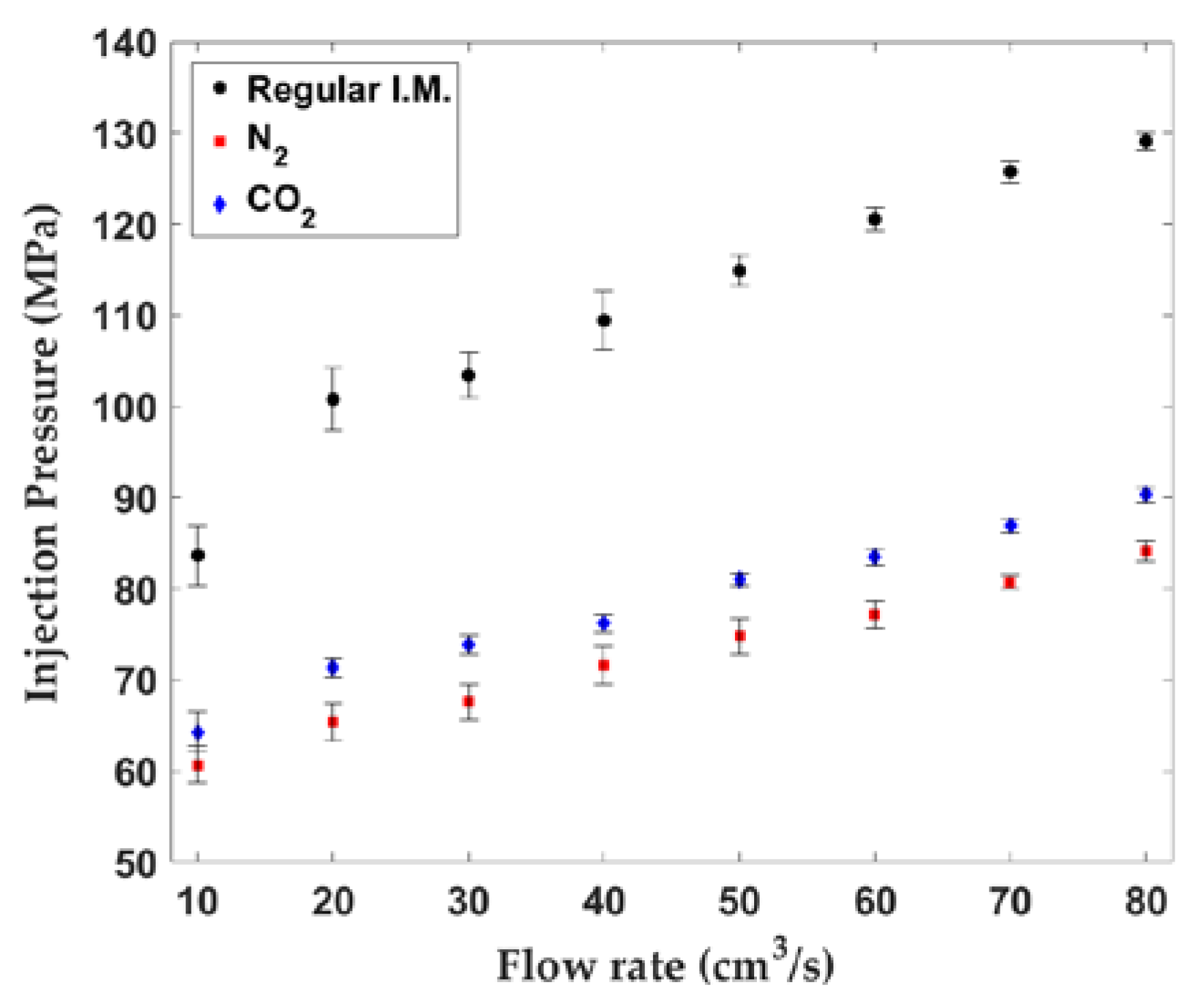

3.4. Tensile Bar Images and Injection Pressure Measurements

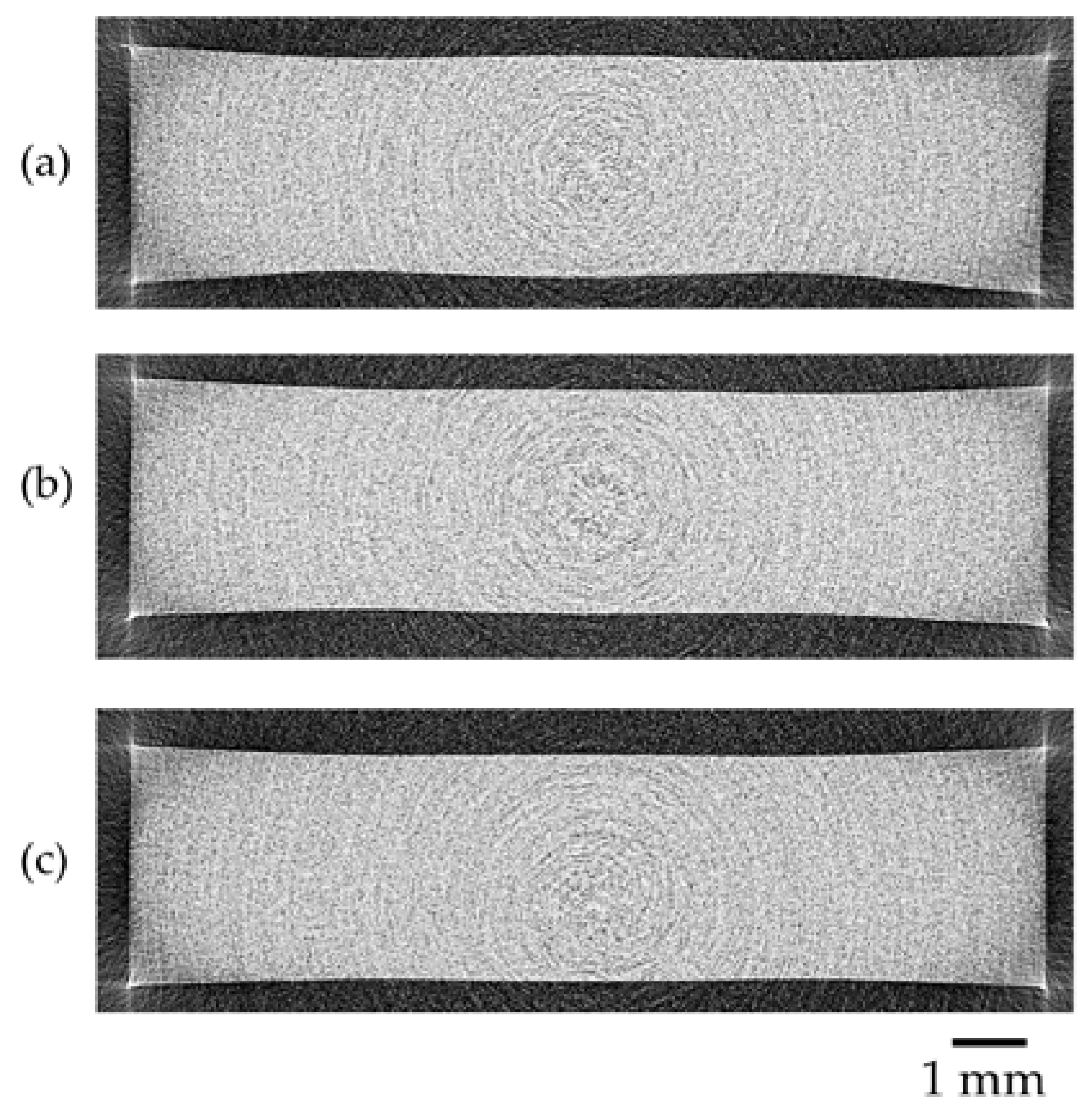

3.5. Micro-Computed Tomography (μCT)

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Peacock, A.J. Handbook of Polyethylene: Structures, Properties and Applications; Marcel Dekker: New York, NY, USA, 2000; ISBN 0471166286. [Google Scholar]

- Edidin, A.A.; Kurtz, S.M. Influence of mechanical behavior on the wear of 4 clinically relevant polymeric biomaterials in a hip simulator. J. Arthroplast. 2000, 15, 321–331. [Google Scholar] [CrossRef]

- Osswald, T.A.; Baur, E.; Brinkmann, S.; Oberbach, K.; Schmachtenberg, E. International Plastics Handbook; Hanser: München, Germany, 2006; ISBN 9781569903995. [Google Scholar]

- Kurtz, S.M. The UHMWPE Biomaterials Handbook: Ultra-High Molecular Weight Polyethylene in Total Joint Replacement and Medical Devices, 2nd ed.; Academic Press: Burlington, MA, USA, 2009; Volume 2, ISBN 978-0-12-374721-1. [Google Scholar]

- McKellop, H.; Shen, F.; Lu, B.; Campbell, P.; Salovey, R. Development of an extremely wear-resistant ultra high molecular weight polythylene for total hip replacements. J. Orthop. Res. 1999, 17, 157–167. [Google Scholar] [CrossRef] [PubMed]

- Schaller, R.; Feldman, K.; Smith, P.; Tervoort, T.A. High-Performance Polyethylene Fibers “Al Dente”: Improved Gel-Spinning of Ultrahigh Molecular Weight Polyethylene Using Vegetable Oils. Macromolecules 2015, 48, 8877–8884. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Fouad, H.; Elleithy, R. Impact of some environmental conditions on the tensile, creep-recovery, relaxation, melting and crystallinity behaviour of UHMWPE-GUR 410-medical grade. Mater. Des. 2009, 30, 4112–4119. [Google Scholar] [CrossRef]

- Xu, M.M.; Huang, G.Y.; Feng, S.S.; McShane, G.J.; Stronge, W.J. Static and dynamic properties of semi-crystalline polyethylene. Polymers 2016, 8, 77. [Google Scholar] [CrossRef]

- Heim, H.-P. Specialized Injection Molding Techniques, 1st ed.; William Andrew: Oxford, UK, 2015; ISBN 9780323371216. [Google Scholar]

- Osswald, T.A.; Turng, L.-S.; Gramann, P.J. Injection Molding Handbook, 2nd ed.; Hanser: München, Germany, 2008; ISBN 9781569904206. [Google Scholar]

- Bryce, B.D.M. Plastic Injection Molding Manufacturing Process Fundamentals; Society of Manufacturing Engineers: Dearborn, MI, USA, 1996; Volume I, ISBN 0872634728. [Google Scholar]

- Kuo, H.C.; Jeng, M.C. The influence of injection molding and injection compression molding on ultra-high molecular weight polyethylene polymer microfabrication. Int. Polym. Process. 2011, 26, 508–516. [Google Scholar] [CrossRef]

- Kuo, H.-C.; Jeng, M.-C. The influence of injection molding on tribological characteristics of ultra-high molecular weight polyethylene under dry sliding. Wear 2010, 268, 803–810. [Google Scholar] [CrossRef]

- Kuo, H.-C.; Jeng, M.-C. Effects of part geometry and injection molding conditions on the tensile properties of ultra-high molecular weight polyethylene polymer. Mater. Des. 2010, 31, 884–893. [Google Scholar] [CrossRef]

- Okamoto, K.T. Microcellular Processing; Hanser: München, Germany, 2003; ISBN 1569903441. [Google Scholar]

- Xu, J. Microcellular Injection Molding; Wiley: Hoboken, NJ, USA, 2010; ISBN 9781118057872. [Google Scholar]

- Kikic, I. Polymer-supercritical fluid interactions. J. Supercrit. Fluids 2009, 47, 458–465. [Google Scholar] [CrossRef]

- Hernández-Ortiz, J.C.; Van Steenberge, P.H.M.; Reyniers, M.F.; Marin, G.B.; D’hooge, D.R.; Duchateau, J.N.E.; Remerie, K.; Toloza, C.; Vaz, A.L.; Schreurs, F. Modeling the reaction event history and microstructure of individual macrospecies in postpolymerization modification. AIChE J. 2017, 63, 4944–4961. [Google Scholar] [CrossRef]

- Vrentas, J.S.; Duda, J.L. Diffusion in Polymer-Solvent Systems. I. Reexamination of the Free-Volume Theory. J. Polym. Sci. Polym. Phys. Ed. 1977, 15, 403–416. [Google Scholar] [CrossRef]

- D’Hooge, D.R.; Van Steenberge, P.H.M.; Reyniers, M.F.; Marin, G.B. The strength of multi-scale modeling to unveil the complexity of radical polymerization. Prog. Polym. Sci. 2016, 58, 59–89. [Google Scholar] [CrossRef]

- Nalawade, S.P.; Picchioni, F.; Janssen, L.P.B.M. Supercritical carbon dioxide as a green solvent for processing polymer melts: Processing aspects and applications. Prog. Polym. Sci. 2006, 31, 19–43. [Google Scholar] [CrossRef]

- Sun, X.; Turng, L.S. Novel injection molding foaming approaches using gas-laden pellets with N2, CO2, and N2 + CO2 as the blowing agents. Polym. Eng. Sci. 2014, 54, 899–913. [Google Scholar] [CrossRef]

- Tomasko, D.L.; Burley, A.; Feng, L.; Yeh, S.-K.; Miyazono, K.; Nirmal-Kumar, S.; Kusaka, I.; Koelling, K. Development of CO2 for polymer foam applications. J. Supercrit. Fluids 2009, 47, 493–499. [Google Scholar] [CrossRef]

- Wingert, M.J.; Shen, J.; Davis, P.M.; Lee, L.J.; Tomasko, D.L.; Koelling, K.W. Rheological Studies of Polymers under High Pressure Carbon Dioxide. In Proceedings of the Society of Plastics Engineers Annual Technical Conference (ANTEC), Boston, MA, USA, 1–5 May 2005; pp. 1143–1147. [Google Scholar]

- Garcia-Leiner, M.; Song, J.; Lesser, A.J. Drawing of ultrahigh molecular weight polyethylene fibers in the presence of supercritical carbon dioxide. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 1375–1383. [Google Scholar] [CrossRef]

- Kiran, E. Supercritical fluids and polymers—The year in review—2014. J. Supercrit. Fluids 2016, 110, 126–153. [Google Scholar] [CrossRef]

- Ellingham, T.; Duddleston, L.; Turng, L.-S. Sub-critical gas-assisted processing using CO2 foaming to enhance the exfoliation of graphene in polypropylene + graphene nanocomposites. Polymer 2017, 117, 132–139. [Google Scholar] [CrossRef]

- Wilding, M.D.; Baird, D.G.; Eberle, A.P.R. Melt Processability and Foam Suppression of High Molecular Weight Polyethylenes Plasticized with Supercritical Carbon Dioxide. Int. Polym. Process. 2008, 23, 228–237. [Google Scholar] [CrossRef]

- Hsu, C.-L.; Turng, L.-S.; Osswald, T.A.; Rudolph, N.; Dougherty, E.; Gorton, P. Effects of Pressure and Supercritical Fluid on Melt Viscosity of LDPE in Conventional and Microcellular Injection Molding. Int. Polym. Process. 2012, 27, 18–24. [Google Scholar] [CrossRef]

- Sun, X.; Kharbas, H.; Peng, J.; Turng, L.S. A novel method of producing lightweight microcellular injection molded parts with improved ductility and toughness. Polymer 2015, 56, 102–110. [Google Scholar] [CrossRef]

- Kharbas, H.A. Developments in Microcellular Injection Molding Technology; University of Wisconsin—Madison: Madison, WI, USA, 2003. [Google Scholar]

- Turng, L.-S.; Kharbas, H. Development of a Hybrid Solid-Microcellular Co-injection Molding Process. Int. Polym. Process. 2004, 19, 77–86. [Google Scholar] [CrossRef]

- Kharbas, H.; Ellingham, T.; Turng, L.-S. Use of core retraction to achieve low density foams in microcellular injection molded polypropylene parts. In Proceedings of the Technical Conference & Exhibition, Indianapolis, IN, USA, 23–25 May 2016; pp. 1285–1290. [Google Scholar]

- Gong, S.; Yuan, M.; Chandra, A.; Kharbas, H.; Osorio, A.; Turng, L.S. Microcellular Injection Molding. Int. Polym. Process. 2005, 20, 202–214. [Google Scholar] [CrossRef]

- Shaayegan, V.; Wang, G.; Park, C.B. Effect of foam processing parameters on bubble nucleation and growth dynamics in high-pressure foam injection molding. Chem. Eng. Sci. 2016, 155, 27–37. [Google Scholar] [CrossRef]

- Shaayegan, V.; Wang, C.; Costa, F.; Han, S.; Park, C.B. Effect of the melt compressibility and the pressure drop rate on the cell-nucleation behavior in foam injection molding with mold opening. Eur. Polym. J. 2017, 92, 314–325. [Google Scholar] [CrossRef]

- Liang, J.Z.; Ness, J.N. The calculation of cooling time in injection moulding. J. Mater. Process. Technol. 1996, 57, 62–64. [Google Scholar] [CrossRef]

- Wunderlich, B.; Cormier, C.M. Heat of fusion of polyethylene. J. Polym. Sci. Part A Polym. Phys. 1967, 5, 987–988. [Google Scholar] [CrossRef]

- Osswald, T.A.; Rudolph, N. Polymer Rheology: Fundamentals and Applications; Hanser: Munich, Germany, 2015; ISBN 978-1-56990-517-3. [Google Scholar]

- Pang, W.; Ni, Z.; Chen, G.; Huang, G.; Huang, H.; Zhao, Y. Mechanical and thermal properties of graphene oxide/ultrahigh molecular weight polyethylene nanocomposites. RSC Adv. 2015, 5, 63063–63072. [Google Scholar] [CrossRef]

- Ergoz, E.; Fatou, J.G.; Mandelkern, L. Molecular Weight Dependence of the Crystallization Kinetics of Linear Polyethylene. I. Experimental Results. Macromolecules 1972, 5, 147–157. [Google Scholar] [CrossRef]

- Yasuniwa, M.; Tsubakihara, S.; Nakafuku, C. Molecular Weight Effect on the High Pressure Crystallization of Polyethylene. Polym. J. 1988, 20, 1075–1082. [Google Scholar] [CrossRef]

- Kubáut, J.; Månson, J.-A.; Rigdahl, M. Influence of mold design on the mechanical properties of high-pressure injection—molded polyethylene. Polym. Eng. Sci. 1983, 23, 877–882. [Google Scholar] [CrossRef]

- Kalay, G.; Sousa, R.A.; Reis, R.L.; Cunha, A.M.; Bevis, M.J. The enhancement of the mechanical properties of a high-density polyethylene. J. Appl. Polym. Sci. 1999, 73, 2473–2483. [Google Scholar] [CrossRef]

- Osswald, T.A.; Menges, G. Material Science of Polymers for Engineers; Hanser: München, Germany, 2012; ISBN 9781569905142. [Google Scholar]

- Sauceau, M.; Fages, J.; Common, A.; Nikitine, C.; Rodier, E. New challenges in polymer foaming: A review of extrusion processes assisted by supercritical carbon dioxide. Prog. Polym. Sci. 2011, 36, 749–766. [Google Scholar] [CrossRef]

- Beaumont, J.P. Runner and Gating Design Handbook: Tools for Successful Injection Molding; Hanser: München, Germany, 2004; ISBN 9783446226722. [Google Scholar]

- Joseph, P.M.; Spital, R.D. The exponential edge-gradient effect in X-ray computed tomography. Phys. Med. Biol. 1981, 26, 473–487. [Google Scholar] [CrossRef] [PubMed]

| Sample Name | SCF | Critical Points [15] | Loading % by Weight |

|---|---|---|---|

| Regular | N/A | N/A | 0 |

| CO2 sample | CO2 | 31 °C, 7.37 MPa | 1.5 |

| N2 sample | N2 | −147 °C, 3.40 MPa | 1.5 |

| Processing Parameters | Units | Value |

|---|---|---|

| Injection speed | cm3/s | 80 |

| Injection vol. | cm3 | 17.2 |

| Cooling time | s | 25 |

| Back pressure | MPa | Regular: 0.5 N2: 5 CO2: 8 |

| Packing pressure | MPa | 110 |

| Packing time | s | 7 |

| Nozzle temperature | °C | 260 |

| Mold temperature | °C | 80 |

| Sample | Tm (°C) | ∆Hs | % Crystallinity |

|---|---|---|---|

| Neat | 136.9 ± 0.1 | 142.4 ± 1.9 | 49.2 ± 0.7 |

| Regular | 139.5 ± 0.4 | 158.2 ± 3.2 | 54.7 ± 1.1 |

| N2 sample | 138.7 ± 1.0 | 161.1 ± 2.7 | 55.7 ± 0.8 |

| CO2 sample | 138.6 ± 0.7 | 159.6 ± 2.2 | 55.1 ± 0.9 |

| Sample | Tm (°C) | ∆Hs | % Crystallinity |

|---|---|---|---|

| Neat | 139.8 ± 0.6 | 166.7 ± 0.7 | 57.6 ± 0.2 |

| Regular | 140.3 ± 0.9 | 167.7 ± 2.7 | 58.0 ± 0.8 |

| N2 sample | 140.2 ± 0.8 | 169.8 ± 1.5 | 58.7 ± 0.5 |

| CO2 sample | 139.7 ± 1.2 | 167.6 ± 1.9 | 57.9 ± 0.6 |

| Samples | Young’s Modulus (MPa) | Elongation at Break (%) | Tensile Strength (MPa) | Toughness (J/m3) |

|---|---|---|---|---|

| Regular | 615.2 ± 21.4 | 115 ± 10 | 21.9 ± 0.5 | 64.4 ± 7.1 |

| N2 samples | 669.6 ± 59.9 | 127 ± 5 | 22.9 ± 0.5 | 73.2 ± 4.0 |

| CO2 samples | 664.0 ± 22.7 | 134 ± 11 | 23.0 ± 0.3 | 77.8 ± 8.4 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yilmaz, G.; Ellingham, T.; Turng, L.-S. Improved Processability and the Processing-Structure-Properties Relationship of Ultra-High Molecular Weight Polyethylene via Supercritical Nitrogen and Carbon Dioxide in Injection Molding. Polymers 2018, 10, 36. https://doi.org/10.3390/polym10010036

Yilmaz G, Ellingham T, Turng L-S. Improved Processability and the Processing-Structure-Properties Relationship of Ultra-High Molecular Weight Polyethylene via Supercritical Nitrogen and Carbon Dioxide in Injection Molding. Polymers. 2018; 10(1):36. https://doi.org/10.3390/polym10010036

Chicago/Turabian StyleYilmaz, Galip, Thomas Ellingham, and Lih-Sheng Turng. 2018. "Improved Processability and the Processing-Structure-Properties Relationship of Ultra-High Molecular Weight Polyethylene via Supercritical Nitrogen and Carbon Dioxide in Injection Molding" Polymers 10, no. 1: 36. https://doi.org/10.3390/polym10010036

APA StyleYilmaz, G., Ellingham, T., & Turng, L.-S. (2018). Improved Processability and the Processing-Structure-Properties Relationship of Ultra-High Molecular Weight Polyethylene via Supercritical Nitrogen and Carbon Dioxide in Injection Molding. Polymers, 10(1), 36. https://doi.org/10.3390/polym10010036