Silica Modified by Alcohol Polyoxyethylene Ether and Silane Coupling Agent Together to Achieve High Performance Rubber Composites Using the Latex Compounding Method

Abstract

:1. Introduction

2. Experimental Materials and Methods

2.1. Materials

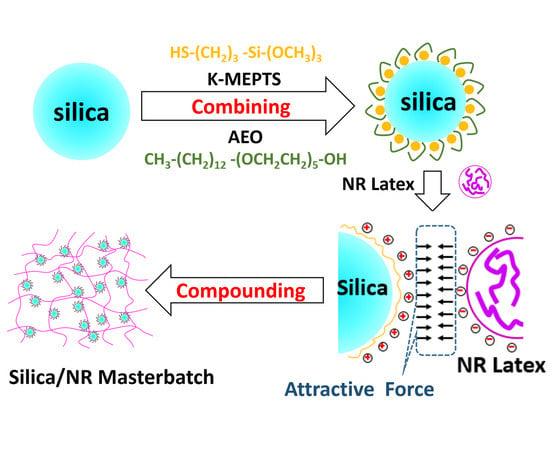

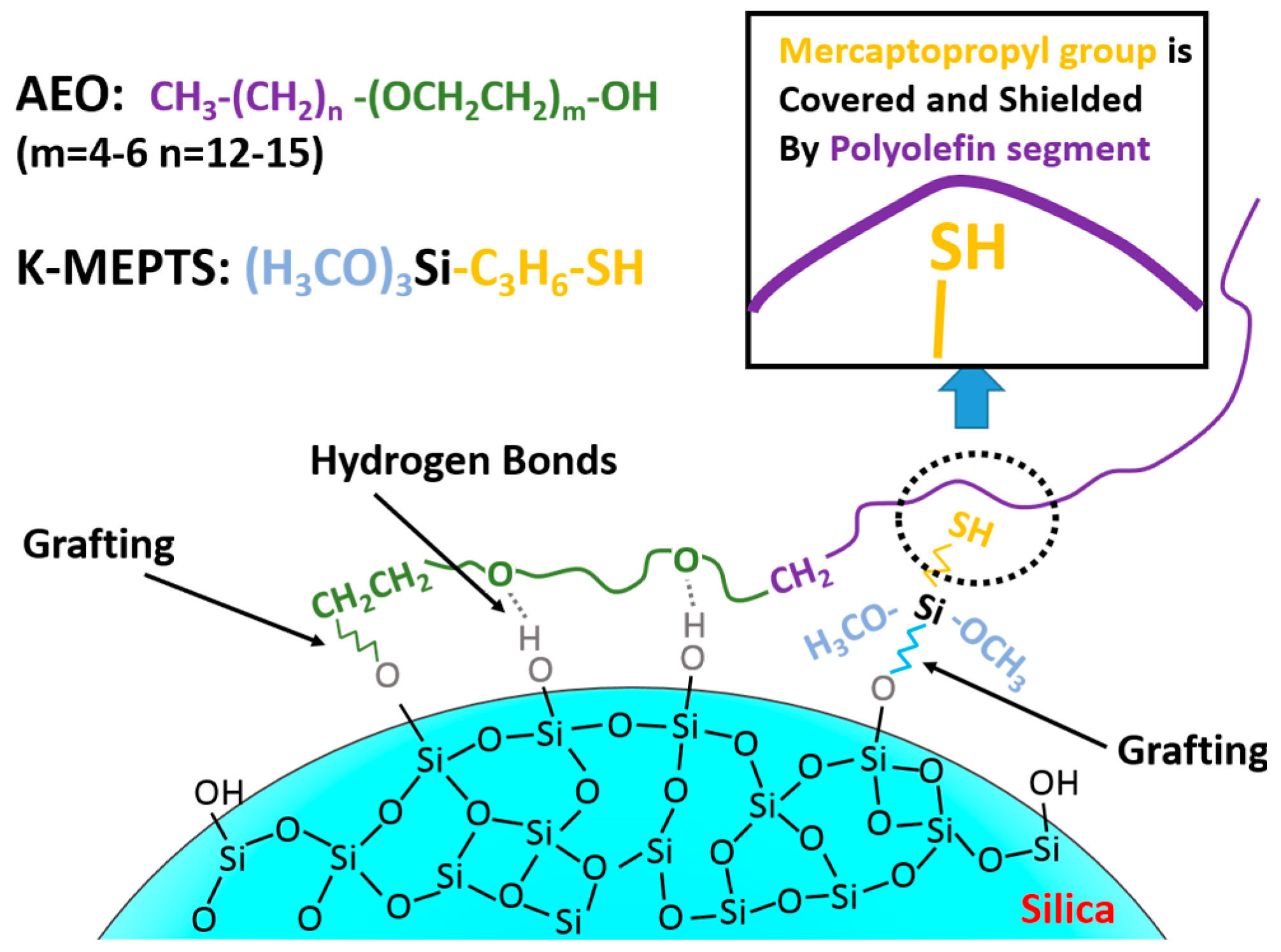

2.2. Preparation of Modified Silica

2.3. Preparation of Master Batches

2.4. Preparation of Silica/NR Composites

2.5. Characterizations

3. Results and Discussion

3.1. Characterization of Silica Modified by AEO and K-MEPTS

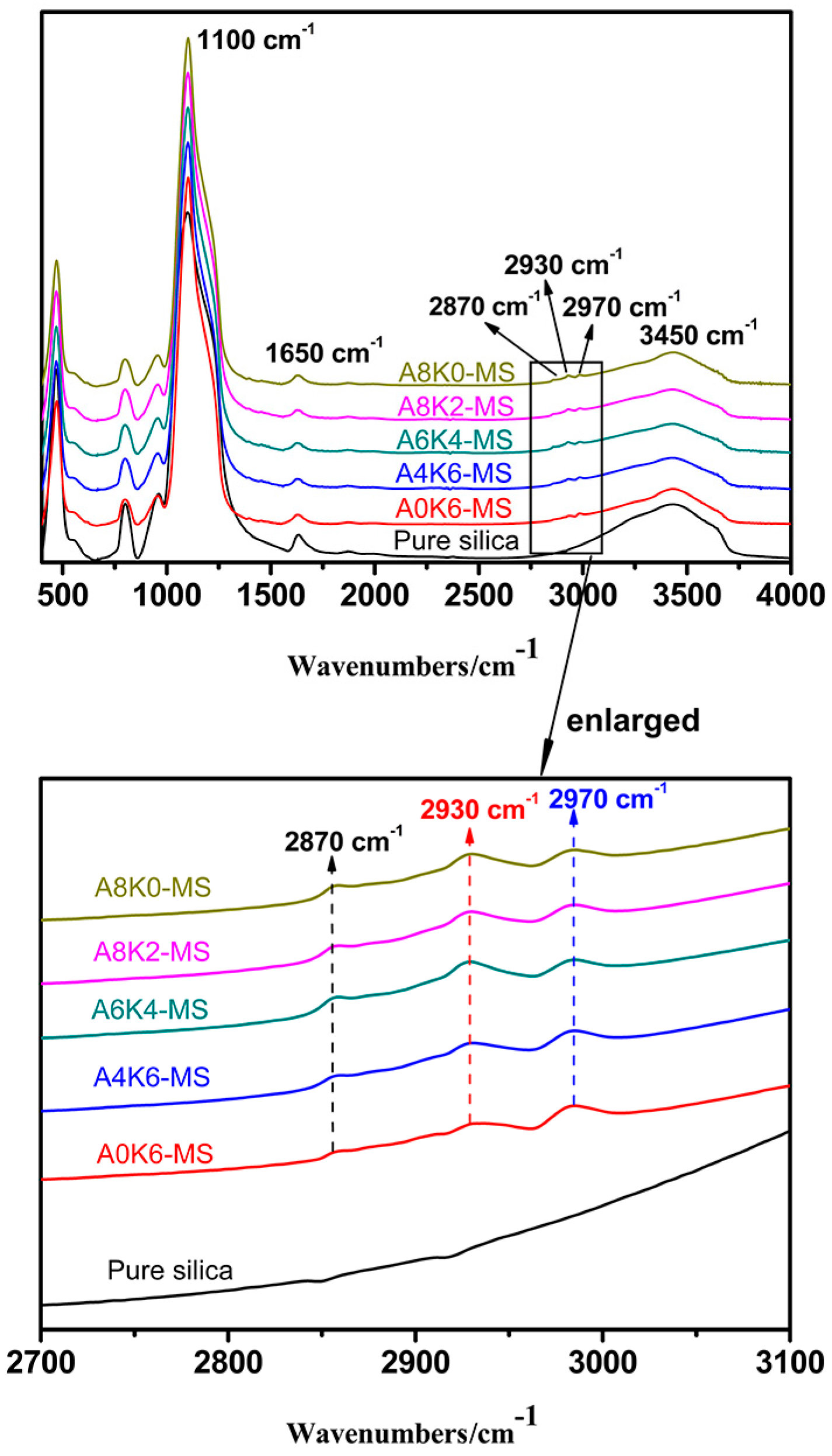

3.1.1. FT-IR of Pure and Modified Silica

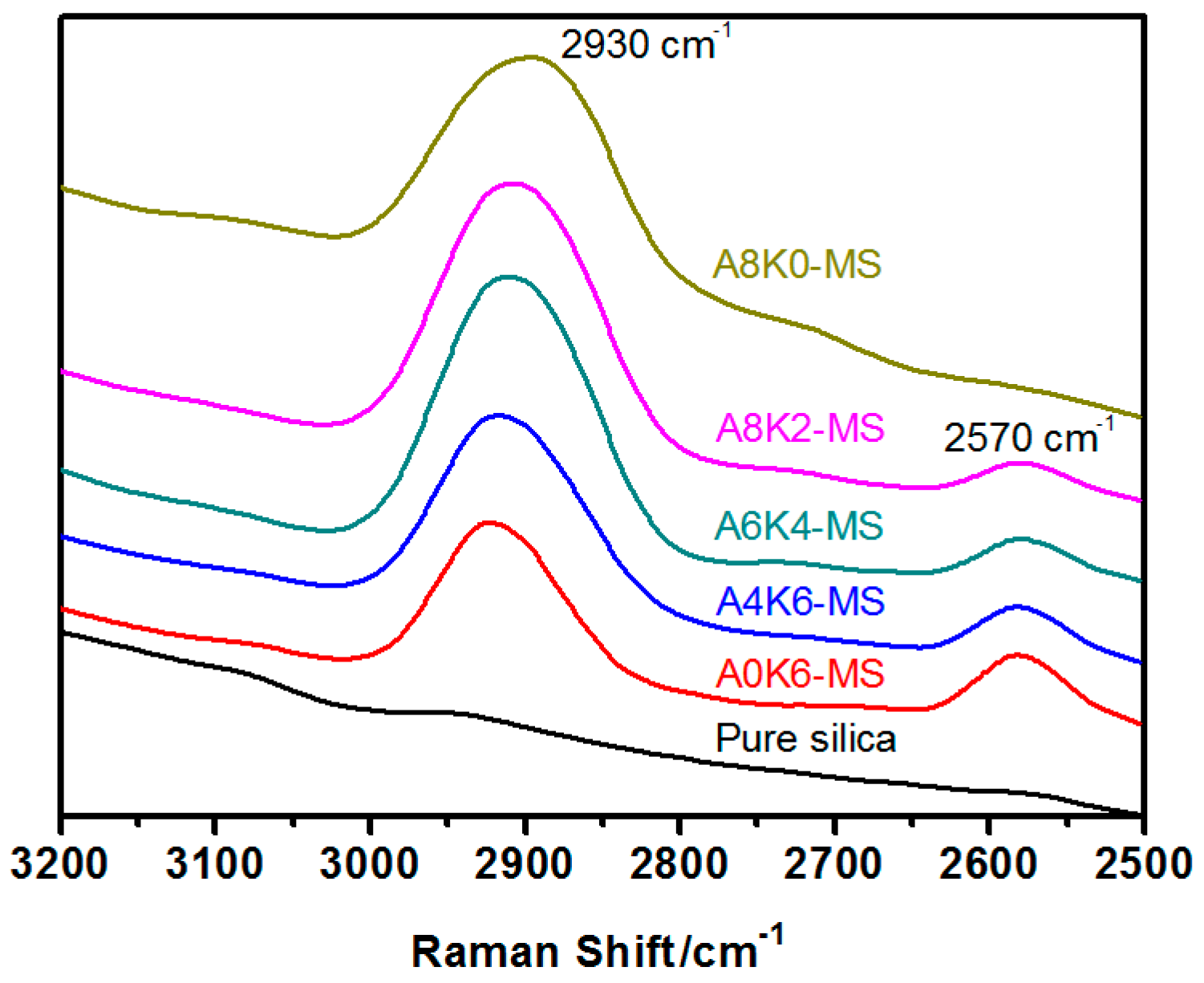

3.1.2. Raman Spectroscopy of Pure and Modified Silica

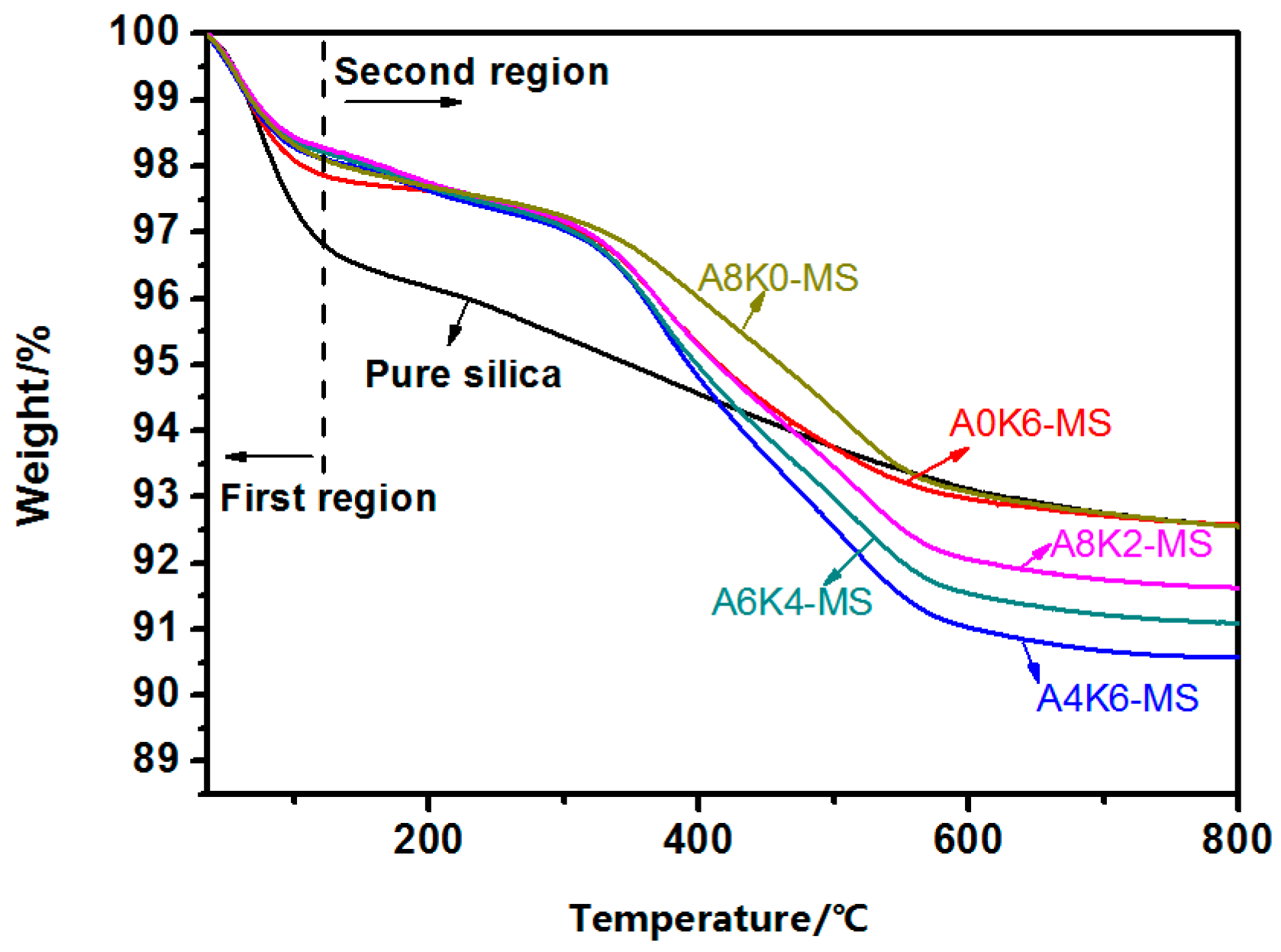

3.1.3. TGA Curves of Pure and Modified Silica

3.2. Characterization of Silica/NR Master Batches Prepared with Pure and Modified Silica

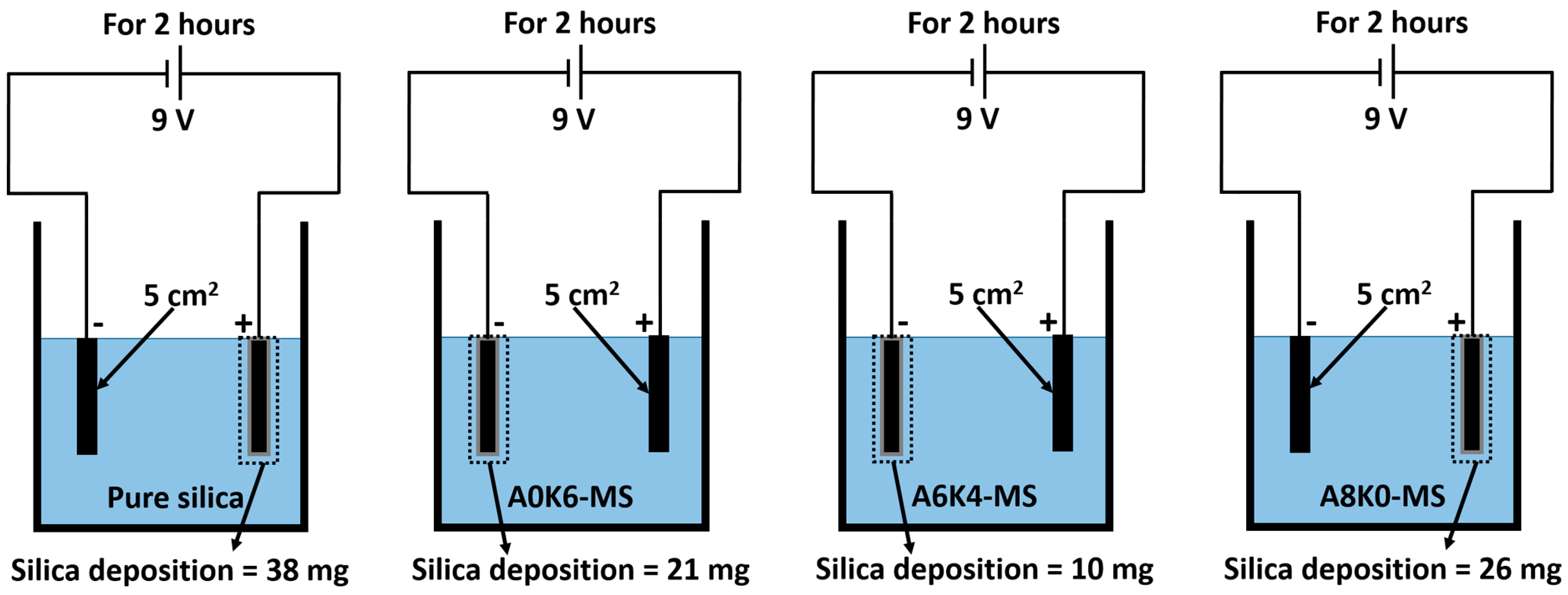

3.2.1. Co-Coagulation of Silica/NR Mixture in Preparing the Master Batches

3.2.2. Actual Amount of Silica in Silica/NR Master Batches

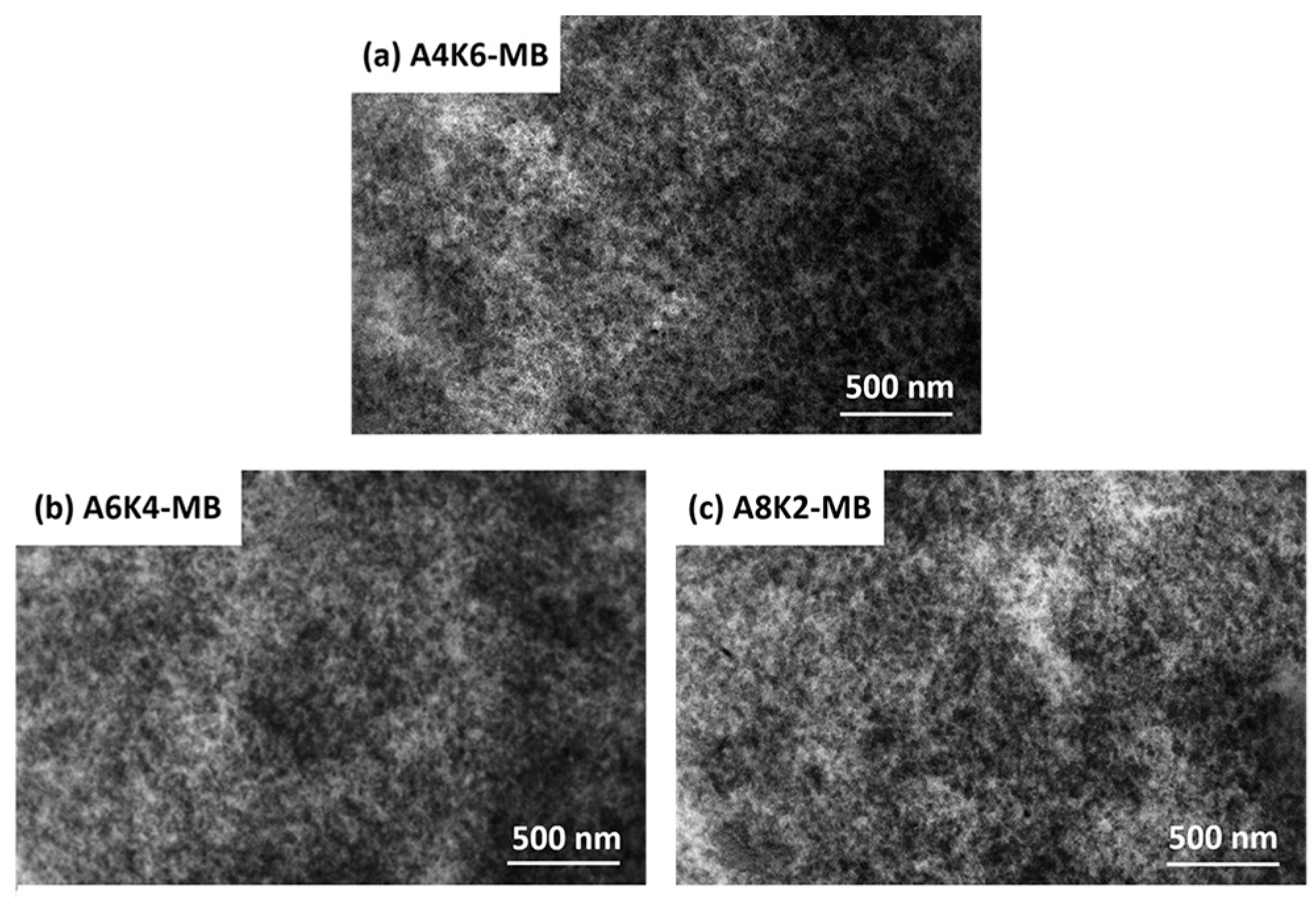

3.2.3. Micromorphology of the Silica/NR Master Batches Observed by TEM

3.3. Characterization of the Preparation Process of Silica/NR Composites

3.4. Characterization of Silica Dispersion in Silica/NR Composites

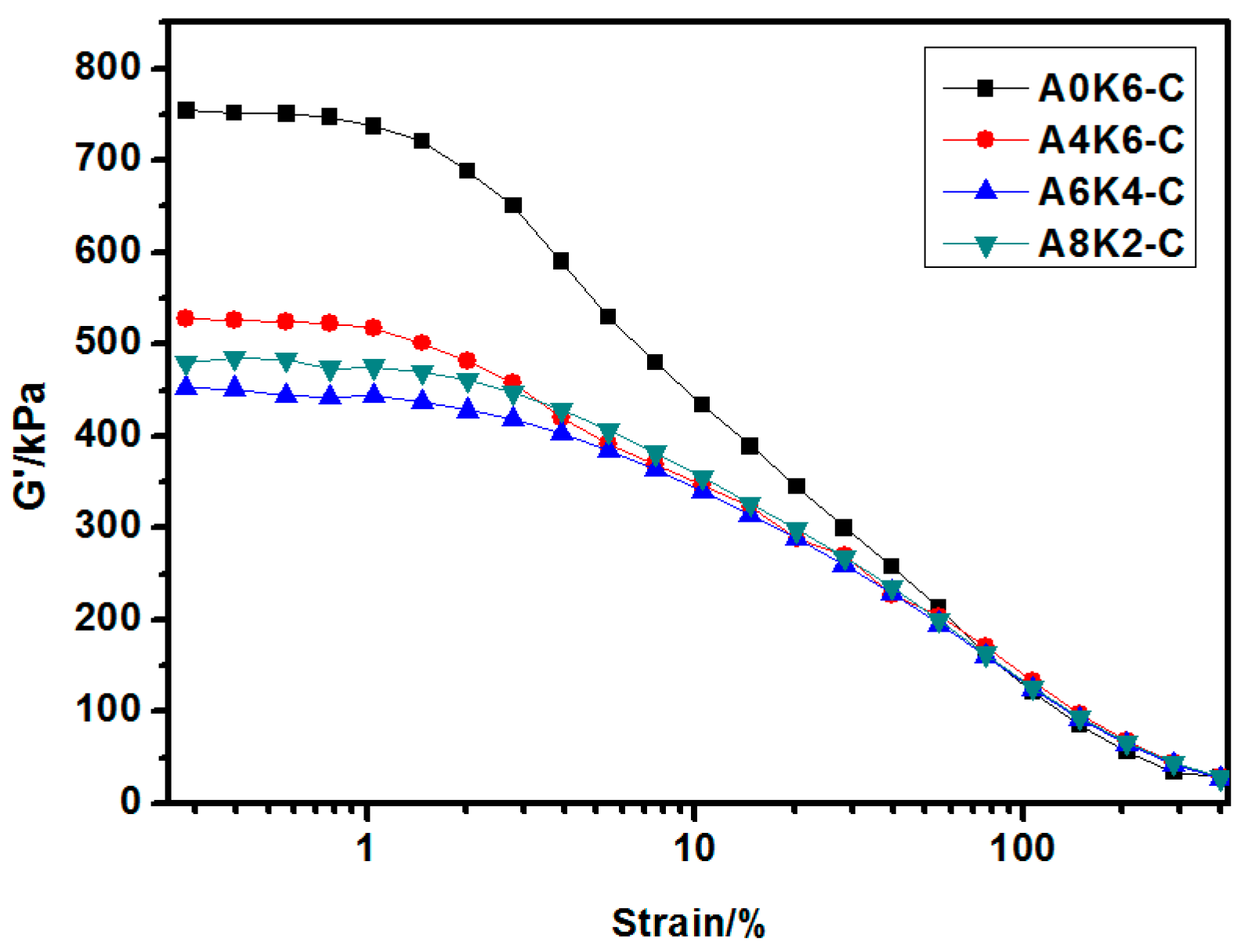

3.4.1. Payne Effect of Silica/NR Compounds Investigated by RPA

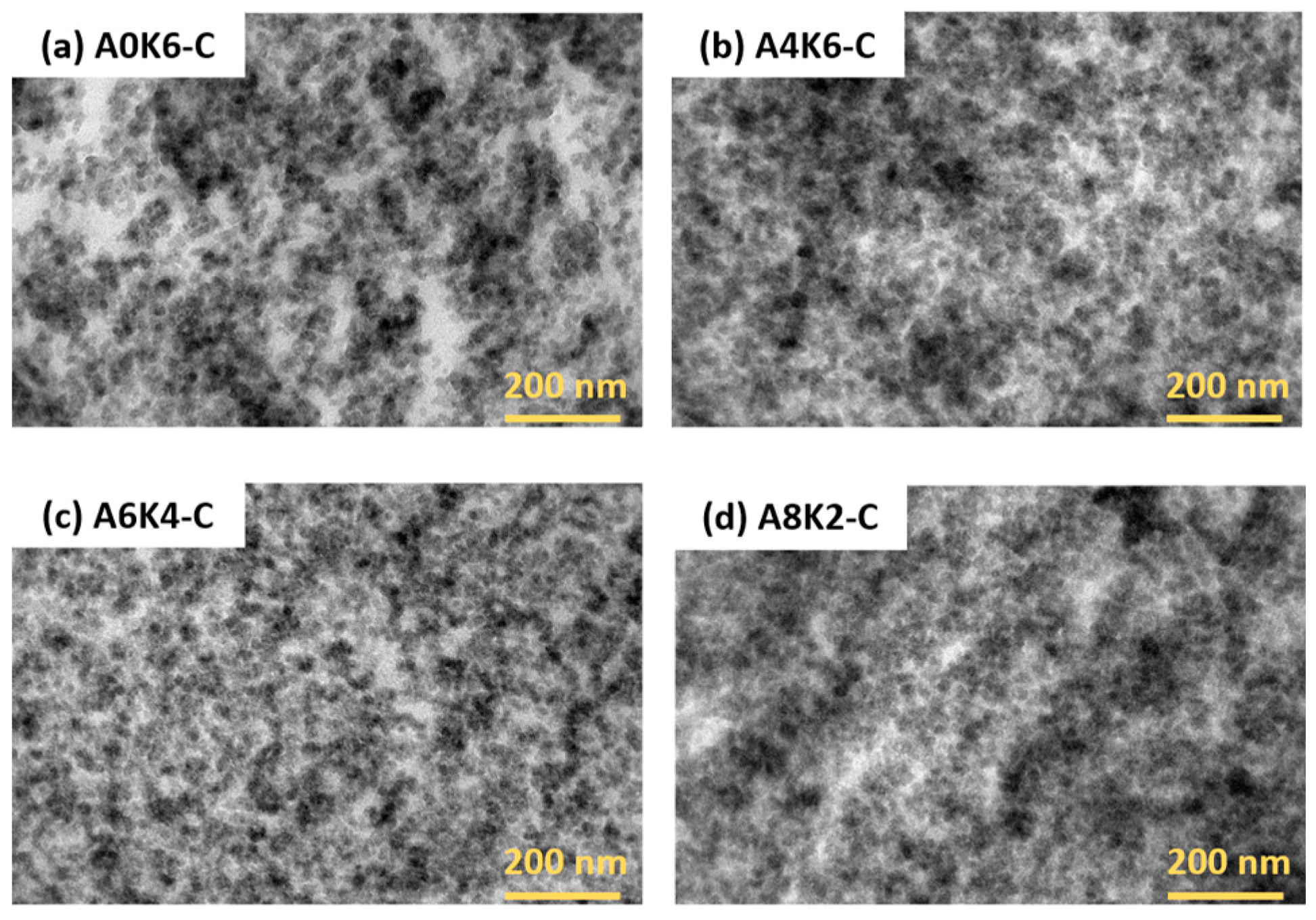

3.4.2. Micromorphology of the Silica/NR Composites Observed by TEM

3.5. Characterization of Silica/NR Composites

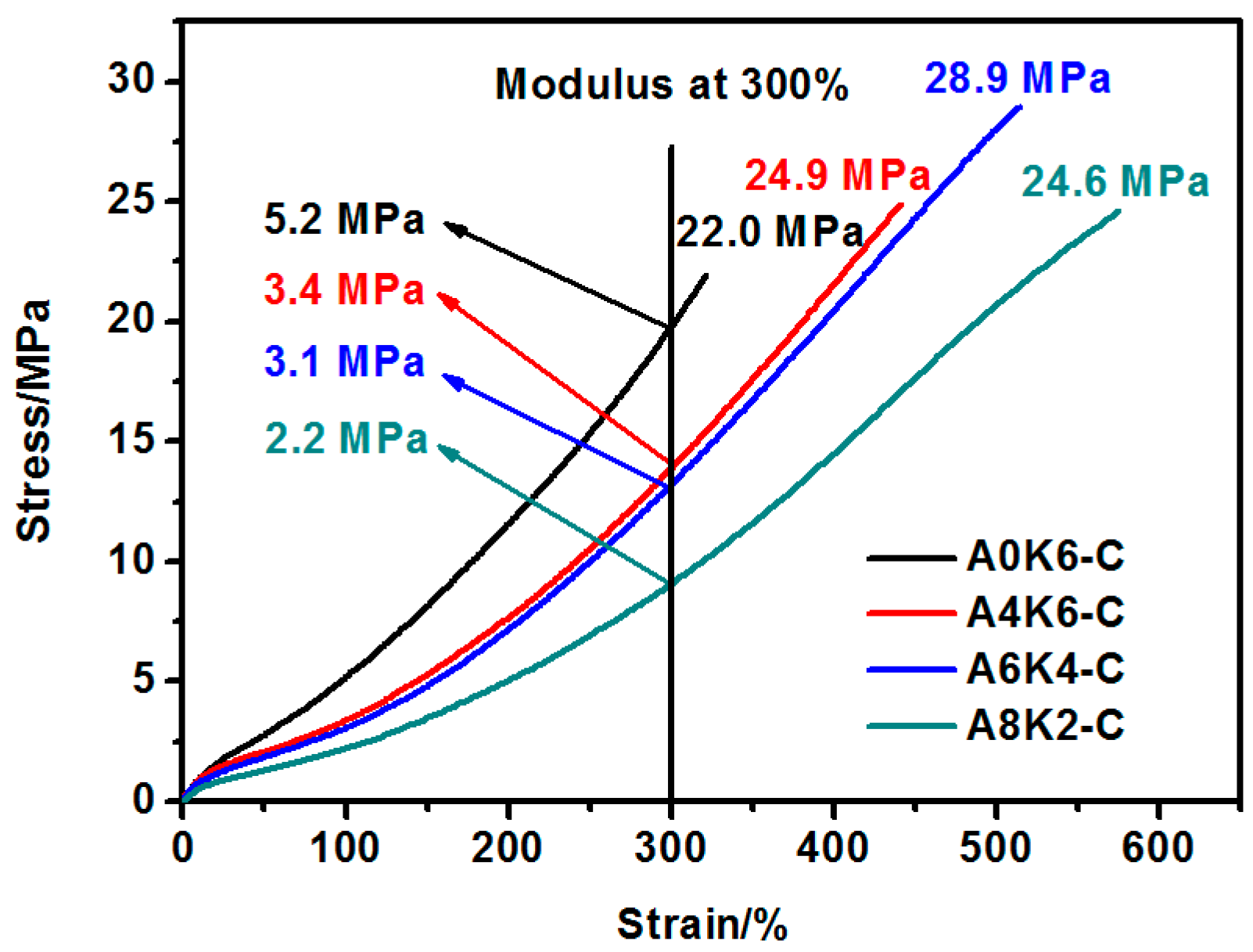

3.5.1. Mechanical Performances of Silica/NR Composites

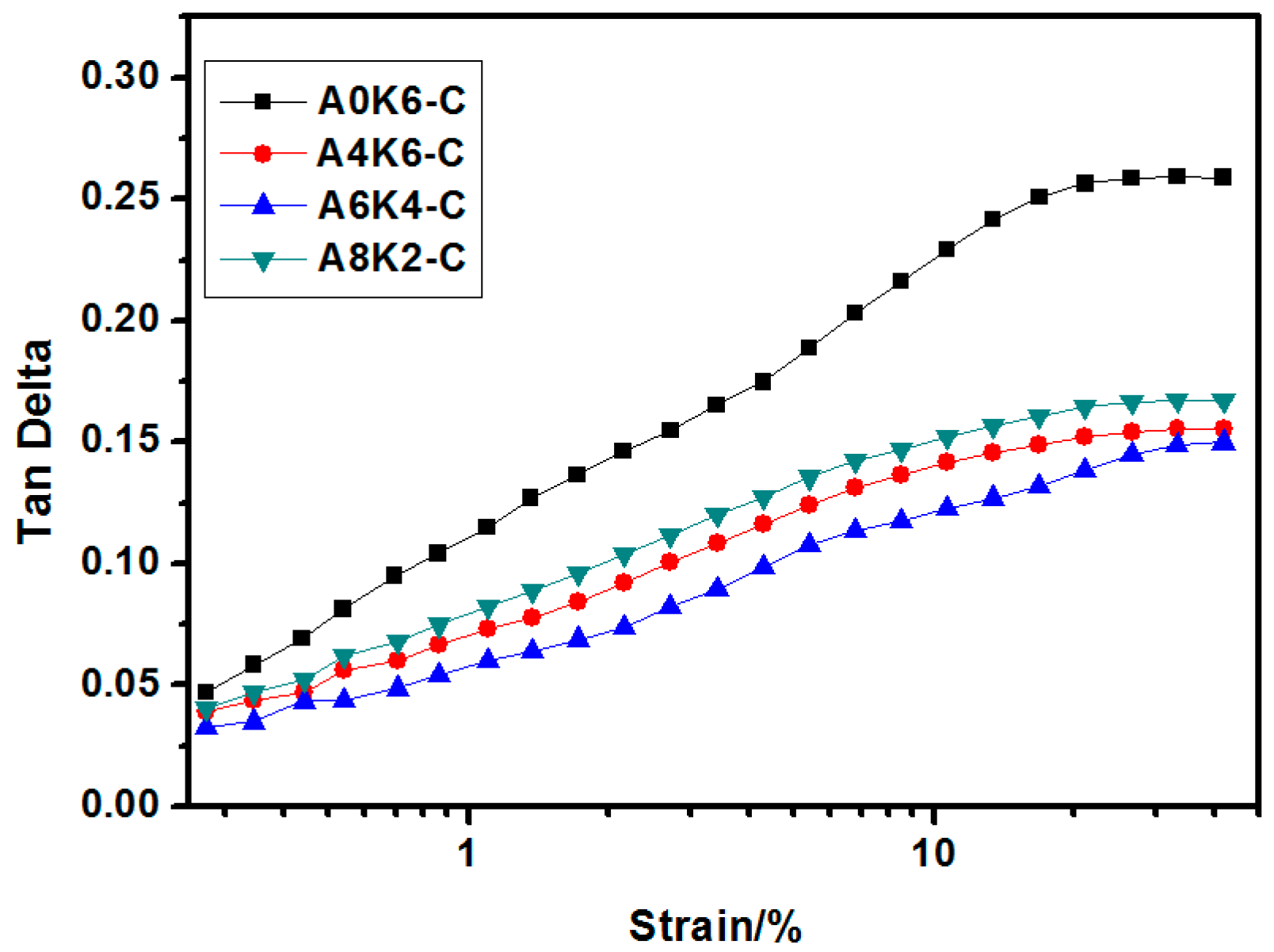

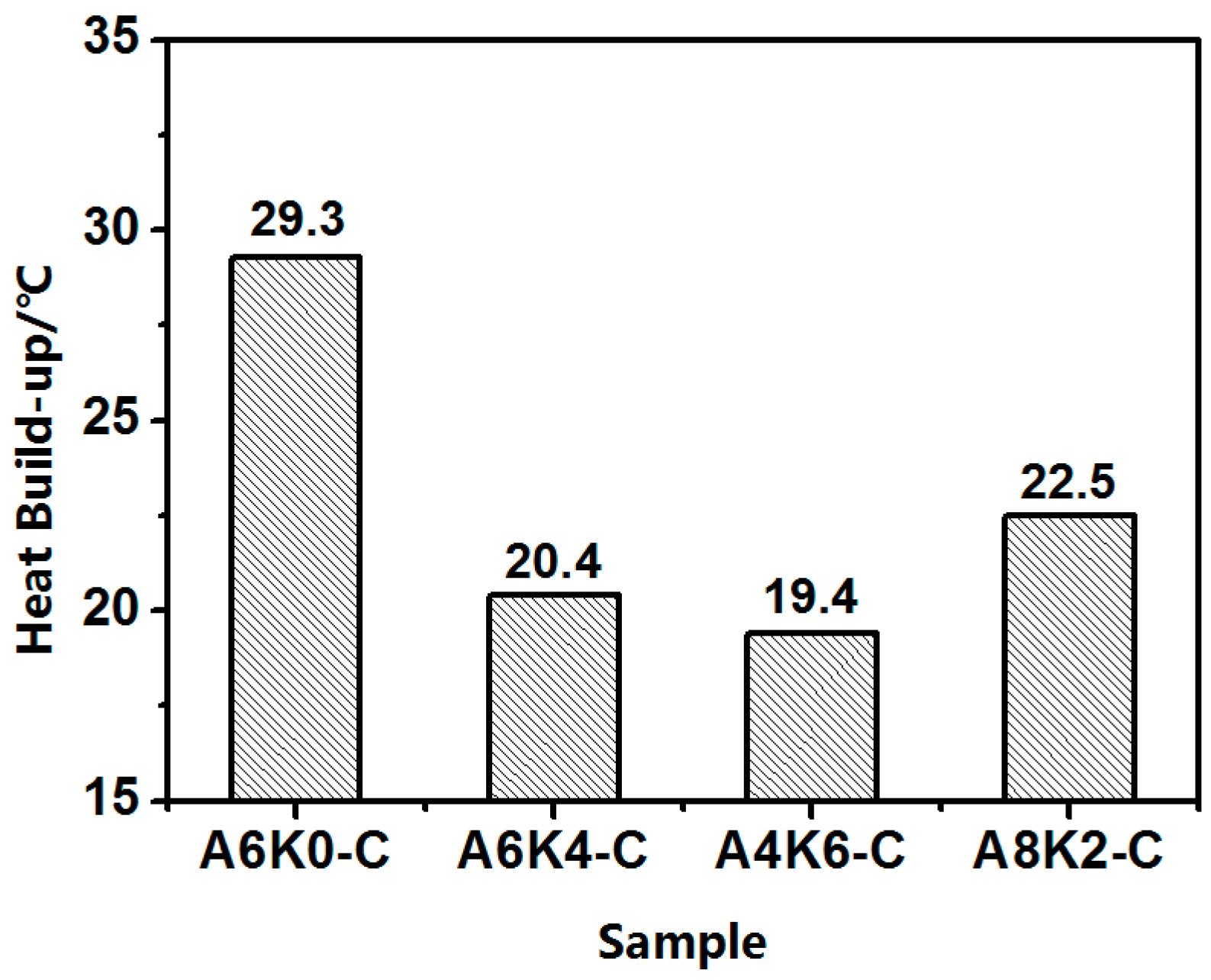

3.5.2. Dynamic Performances of Silica/NR Composites

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Miloskovska, E.; Nies, E.; Hristova-Bogaerds, D.; van Duin, M.; de With, G. Influence of reaction parameters on the structure of in situ rubber/silica compounds synthesized via sol-gel reaction. J. Polym. Sci. B 2014, 52, 967–978. [Google Scholar] [CrossRef]

- Dong, B.; Liu, C.; Wu, Y.P. Fracture and fatigue of silica/carbon black/natural rubber composites. Polym. Test 2014, 38, 40–45. [Google Scholar] [CrossRef]

- Saeed, F.; Ansarifar, A.; Ellis, R.J.; Haile-Meskel, Y.; Irfan, M.S. Two advanced styrene-butadiene/polybutadiene rubber blends filled with a silanized silica nanofiller for potential use in passenger car tire tread compound. J. Appl. Polym. Sci. 2012, 123, 1518–1529. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, S.H.; Zhang, X.Y.; Li, X.L.; Bai, Y. Preparation, structure, and properties of solution-polymerized styrene-butadiene rubber with functionalized end-groups and its silica-filled composites. Polymer 2014, 55, 1964–1976. [Google Scholar] [CrossRef]

- Hilonga, A.; Kim, J.K.; Sarawade, P.B.; Quang, D.V.; Shao, G.N.; Elineema, G.; Kim, H.T. Synthesis of mesoporous silica with superior properties suitable for green tire. J. Ind. Eng. Chem. 2012, 18, 1841–1844. [Google Scholar] [CrossRef]

- Lin, Y.; Liu, S.Q.; Peng, J.; Liu, L. The filler-rubber interface and reinforcement in styrene butadiene rubber composites with graphene/silica hybrids: A quantitative correlation with the constrained region. Compos. A 2016, 86, 19–30. [Google Scholar] [CrossRef]

- Toyonaga, M.; Chammingkwan, P.; Terano, M.; Taniike, T. Well-defined polypropylene/polypropylene-grafted silica nanocomposites: Roles of number and molecular weight of grafted chains on mechanistic reinforcement. Polymers 2016, 8, 300. [Google Scholar] [CrossRef]

- Sarkawi, S.S.; Dierkes, W.K.; Noordermeer, J.W.M. Elucidation of filler-to-filler and filler-to-rubber interactions in silica-reinforced natural rubber by tem network visualization. Eur. Polym. J. 2014, 54, 118–127. [Google Scholar] [CrossRef]

- Krysztafkiewicz, A.; Binkowski, S.; Jesionowski, T. Adsorption of dyes on a silica surface. Appl. Surf. Sci. 2002, 199, 31–39. [Google Scholar] [CrossRef]

- Iacono, M.; Heise, A. Stable poly(methacrylic acid) brush decorated silica nano-particles by arget atrp for bioconjugation. Polymers 2015, 7, 1427–1443. [Google Scholar] [CrossRef]

- Suzuki, N.; Ito, M.; Ono, S. Effects of rubber/filler interactions on the structural development and mechanical properties of nbr/silica composites. J. Appl. Polym. Sci. 2005, 95, 74–81. [Google Scholar] [CrossRef]

- Ramier, J.; Chazeau, L.; Gauthier, C.; Guy, L.; Bouchereau, M.N. Grafting of silica during the processing of silica-filled sbr: Comparison between length and content of the silane. J. Polym. Sci. B 2006, 44, 143–152. [Google Scholar] [CrossRef]

- Zhang, J.L.; Guo, Z.C.; Zhi, X.; Tang, H.Q. Surface modification of ultrafine precipitated silica with 3-methacryloxypropyltrimethoxysilane in carbonization process. Colloids Surf. A 2013, 418, 174–179. [Google Scholar] [CrossRef]

- Kim, J.H.J.; You, Y.J.; Jeong, Y.J.; Choi, J.H. Stable failure-inducing micro-silica aqua epoxy bonding material for floating concrete module connection. Polymers 2015, 7, 2389–2409. [Google Scholar] [CrossRef]

- Zhang, X.X.; Wen, H.; Wu, Y.J. Computational thermomechanical properties of silica-epoxy nanocomposites by molecular dynamic simulation. Polymers 2017, 9. [Google Scholar] [CrossRef]

- Ridaoui, H.; Donnet, J.B.; Balard, H.; Kellou, H.; Hamdi, B.; Barthel, H.; Gottschalk-Gaudig, T.; Legrand, A.P. Silane modified fumed silicas and their behaviours in water: Influence of grafting ratio and temperature. Colloids Surf. A 2008, 330, 80–85. [Google Scholar] [CrossRef]

- Kunioka, M.; Taguchi, K.; Ninomiya, F.; Nakajima, M.; Saito, A.; Araki, S. Biobased contents of natural rubber model compound and its separated constituents. Polymers 2014, 6, 423–442. [Google Scholar] [CrossRef]

- Wadeesirisak, K.; Castano, S.; Berthelot, K.; Vaysse, L.; Bonfils, F.; Peruch, F.; Rattanaporn, K.; Liengprayoon, S.; Lecomte, S.; Bottier, C. Rubber particle proteins ref1 and srpp1 interact differently with native lipids extracted from hevea brasiliensis latex. Biochim. Biophys. Acta 2017, 1859, 201–210. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, S.; Daik, R.; Abdullah, I. Functionalization of liquid natural rubber via oxidative degradation of natural rubber. Polymers 2014, 6, 2928–2941. [Google Scholar] [CrossRef]

- Tangpasuthadol, V.; Intasiri, A.; Nuntivanich, D.; Niyompanich, N.; Kiatkamjornwong, S. Silica-reinforced natural rubber prepared by the sol-gel process of ethoxysilanes in rubber latex. J. Appl. Polym. Sci. 2008, 109, 424–433. [Google Scholar] [CrossRef]

- Prasertsri, S.; Rattanasom, N. Mechanical and damping properties of silica/natural rubber composites prepared from latex system. Polym. Test. 2011, 30, 515–526. [Google Scholar] [CrossRef]

- Gui, Y.; Zheng, J.; Ye, X.; Han, D.; Xi, M.; Zhang, L. Preparation and performance of silica/sbr masterbatches with high silica loading by latex compounding method. Compos. B 2016, 85, 130–139. [Google Scholar] [CrossRef]

- Watanabe, M.; Tamaii, T. Acrylic polymer/silica organic-inorganic hybrid emulsions for coating materials: Role of the silane coupling agent. J. Polym. Sci. A 2006, 44, 4736–4742. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, S.; Qiao, X.; Li, X.; Wu, L. Synthesis of sio2/poly(styrene-co-butyl acrylate) nanocomposite microspheres via miniemulsion polymerization. J. Polym. Sci. A 2006, 44, 3202–3209. [Google Scholar] [CrossRef]

- Li, Y.; Han, B.; Wen, S.; Lu, Y.; Yang, H.; Zhang, L.; Liu, L. Effect of the temperature on surface modification of silica and properties of modified silica filled rubber composites. Compos. A 2014, 62, 52–59. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. A 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Li, Y.; Han, B.; Liu, L.; Zhang, F.; Zhang, L.; Wen, S.; Lu, Y.; Yang, H.; Shen, J. Surface modification of silica by two-step method and properties of solution styrene butadiene rubber (ssbr) nanocomposites filled with modified silica. Compos. Sci. Technol. 2013, 88, 69–75. [Google Scholar] [CrossRef]

- Ostad-Movahed, S.; Yasin, K.A.; Ansarifar, A.; Song, M.; Hameed, S. Comparing effects of silanized silica nanofiller on the crosslinking and mechanical properties of natural rubber and synthetic polyisoprene. J. Appl. Polym. Sci. 2008, 109, 869–881. [Google Scholar] [CrossRef]

- Ansarifar, A.; Wang, L.; Ellis, R.J.; Haile-Meskel, Y. Using a silanized silica nanofiller to reduce excessive amount of rubber curatives in styrene-butadiene rubber. J. Appl. Polym. Sci. 2011, 119, 922–928. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, J.; Shen, J.; Cao, D.; Zhang, L. Molecular dynamics simulation of the rupture mechanism in nanorod filled polymer nanocomposites. Phys. Chem. Chem. Phys. 2014, 16, 18483–18492. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Zhao, F.; Yuan, Y.; Shi, X.; Zhao, S. Network evolution based on general-purpose diene rubbers/sulfur/tbbs system during vulcanization (i). Polymer 2010, 51, 257–263. [Google Scholar] [CrossRef]

- Akbari, A.; Yegani, R.; Pourabbas, B. Synthesis of poly(ethylene glycol) (peg) grafted silica nanoparticles with a minimum adhesion of proteins via one-pot one-step method. Colloids Surf. A 2015, 484, 206–215. [Google Scholar] [CrossRef]

- Cheng, Q.L.; Pavlinek, V.; He, Y.; Lengalova, A.; Li, C.Z.; Saha, P. Structural and electrorheological properties of mesoporous silica modified with triethanolamine. Colloids Surf. A 2008, 318, 169–174. [Google Scholar] [CrossRef]

- Ma, X.K.; Lee, N.H.; Oh, H.J.; Kim, J.W.; Rhee, C.K.; Park, K.S.; Kim, S.J. Surface modification and characterization of highly dispersed silica nanoparticles by a cationic surfactant. Colloids Surf. A 2010, 358, 172–176. [Google Scholar] [CrossRef]

- Wang, W.; Li, J.; Yang, X.; Li, P.; Guo, C.; Li, Q. Synthesis and properties of a branched short-alkyl polyoxyethylene ether alcohol sulfate surfactant. J. Mol. Liq. 2015, 212, 597–604. [Google Scholar] [CrossRef]

- Debnath, N.; Mitra, S.; Das, S.; Goswami, A. Synthesis of surface functionalized silica nanoparticles and their use as entomotoxic nanocides. Powder Technol. 2012, 221, 252–256. [Google Scholar] [CrossRef]

- Montenegro, L.M.P.; Griep, J.B.; Tavares, F.C.; de Oliveira, D.H.; Bianchini, D.; Jacob, R.G. Synthesis and characterization of imine-modified silicas obtained by the reaction of essential oil of eucalyptus citriodora, 3-aminopropyltriethoxysilane and tetraethylorthosilicate. Vib. Spectrosc. 2013, 68, 272–278. [Google Scholar] [CrossRef]

- Yoshida, T.; Tanabe, T.; Hirano, M.; Muto, S. Ft-ir study on the effect of oh content on the damage process in silica glasses irradiated by hydrogen. Nucl. Instrum. Methods Phys. Res. 2004, 218, 202–208. [Google Scholar] [CrossRef]

- Peng, Z.; Kong, L.; Li, S.; Chen, Y.; Huang, M. Self-assembled natural rubber/silica nanocomposites: Its preparation and characterization. Compos. Sci. Technol. 2007, 67, 3130–3139. [Google Scholar] [CrossRef]

- Sajjayanukul, T.; Saeoui, P.; Sirisinha, C. Experimental analysis of viscoelastic properties in carbon black-filled natural rubber compounds. J. Appl. Polym. Sci. 2005, 97, 2197–2203. [Google Scholar] [CrossRef]

- Boonstra, B.B. Mixing of carbon black and polymer: Interaction and reinforcement. J. Appl. Polym. Sci. 1967, 11, 389–406. [Google Scholar] [CrossRef]

| Material | A0K6-MS | A4K6-MS | A6K4-MS | A8K2-MS | A8K0-MS |

|---|---|---|---|---|---|

| Silica (dry weight)/g | 100 | 100 | 100 | 100 | 100 |

| 3-mercaptopropyltriethoxysilane (K-MEPTS)/g | 6 | 6 | 4 | 2 | 0 |

| polyoxyethylene ether (AEO)/g | 0 | 4 | 6 | 8 | 8 |

| Material | Amount (phr a) | Comment |

|---|---|---|

| Master batches | 155 | Filler and matrix |

| Stearic acid | 2.0 | Activator |

| Zinc oxide | 5.0 | Activator |

| N-1,3-dimethylbutyl-N′-phenyl-p-phenylenediamine | 2.0 | Antioxidant |

| N-Cyclohexyl-2-beozothiazole sulfenamide | 2.0 | Accelerator |

| 1,3-Diphenylguanidine | 1.0 | Accelerator |

| Sulfur | 2.0 | Curing agent |

| Sample | Pure silica | A0K6-MS | A4K6-MS | A6K4-MS | A8K2-MS | A8K0-MS |

|---|---|---|---|---|---|---|

| RI | 0.318 | 0.211 | 0.189 | 0.184 | 0.178 | 0.196 |

| Sample | Weight loss in the first region (35–120 °C)/% | Weight loss in the second region (120–800 °C)/% |

|---|---|---|

| Pure silica | 3.16 | 4.27 |

| A0K6-MS | 2.13 | 5.31 |

| A4K6-MS | 1.88 | 7.54 |

| A6K4-MS | 1.78 | 7.13 |

| A8K2-MS | 1.71 | 6.66 |

| A8K0-MS | 1.90 | 5.55 |

| Samples | Weight residual/% | Theoretical amount of silica in masterbatches/phr | Actual amount of silica in masterbatches/phr |

|---|---|---|---|

| Pure NR | 1.32 | - | - |

| Pure silica | 92.57 | - | - |

| KH-590 | 9.13 | - | - |

| AEO | 3.27 | ||

| A0K6-MB | 26.32 | 50 | 38.33 |

| A4K6-MB | 30.76 | 50 | 49.55 |

| A6K4-MB | 30.83 | 50 | 49.83 |

| A8K2-MB | 30.65 | 50 | 49.46 |

| A8K0-MB | 23.71 | 50 | 33.31 |

| A0K0-MB | 22.89 | 50 | 30.96 |

| Samples | T10/min | T90/min | ΔM/dNm |

|---|---|---|---|

| A0K6-C | 0.65 | 3.03 | 30.39 |

| A4K6-C | 2.05 | 5.28 | 28.72 |

| A6K4-C | 3.25 | 5.87 | 26.89 |

| A8K2-C | 3.72 | 7.33 | 24.95 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, J.; Ye, X.; Han, D.; Zhao, S.; Wu, X.; Wu, Y.; Dong, D.; Wang, Y.; Zhang, L. Silica Modified by Alcohol Polyoxyethylene Ether and Silane Coupling Agent Together to Achieve High Performance Rubber Composites Using the Latex Compounding Method. Polymers 2018, 10, 1. https://doi.org/10.3390/polym10010001

Zheng J, Ye X, Han D, Zhao S, Wu X, Wu Y, Dong D, Wang Y, Zhang L. Silica Modified by Alcohol Polyoxyethylene Ether and Silane Coupling Agent Together to Achieve High Performance Rubber Composites Using the Latex Compounding Method. Polymers. 2018; 10(1):1. https://doi.org/10.3390/polym10010001

Chicago/Turabian StyleZheng, Junchi, Xin Ye, Dongli Han, Suhe Zhao, Xiaohui Wu, Youping Wu, Dong Dong, Yiqing Wang, and Liqun Zhang. 2018. "Silica Modified by Alcohol Polyoxyethylene Ether and Silane Coupling Agent Together to Achieve High Performance Rubber Composites Using the Latex Compounding Method" Polymers 10, no. 1: 1. https://doi.org/10.3390/polym10010001

APA StyleZheng, J., Ye, X., Han, D., Zhao, S., Wu, X., Wu, Y., Dong, D., Wang, Y., & Zhang, L. (2018). Silica Modified by Alcohol Polyoxyethylene Ether and Silane Coupling Agent Together to Achieve High Performance Rubber Composites Using the Latex Compounding Method. Polymers, 10(1), 1. https://doi.org/10.3390/polym10010001