Sensing Characteristics of Side-Polished Fiber Based on the Alterations in Helical Structure of Thermo-Sensitive Cholesteric Liquid Crystals

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Design

2.2. Preparation of CLCs

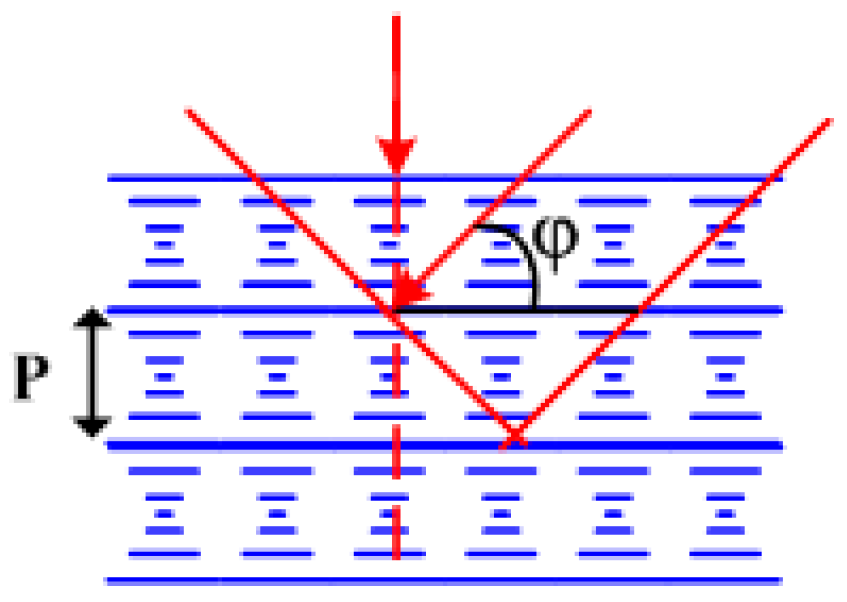

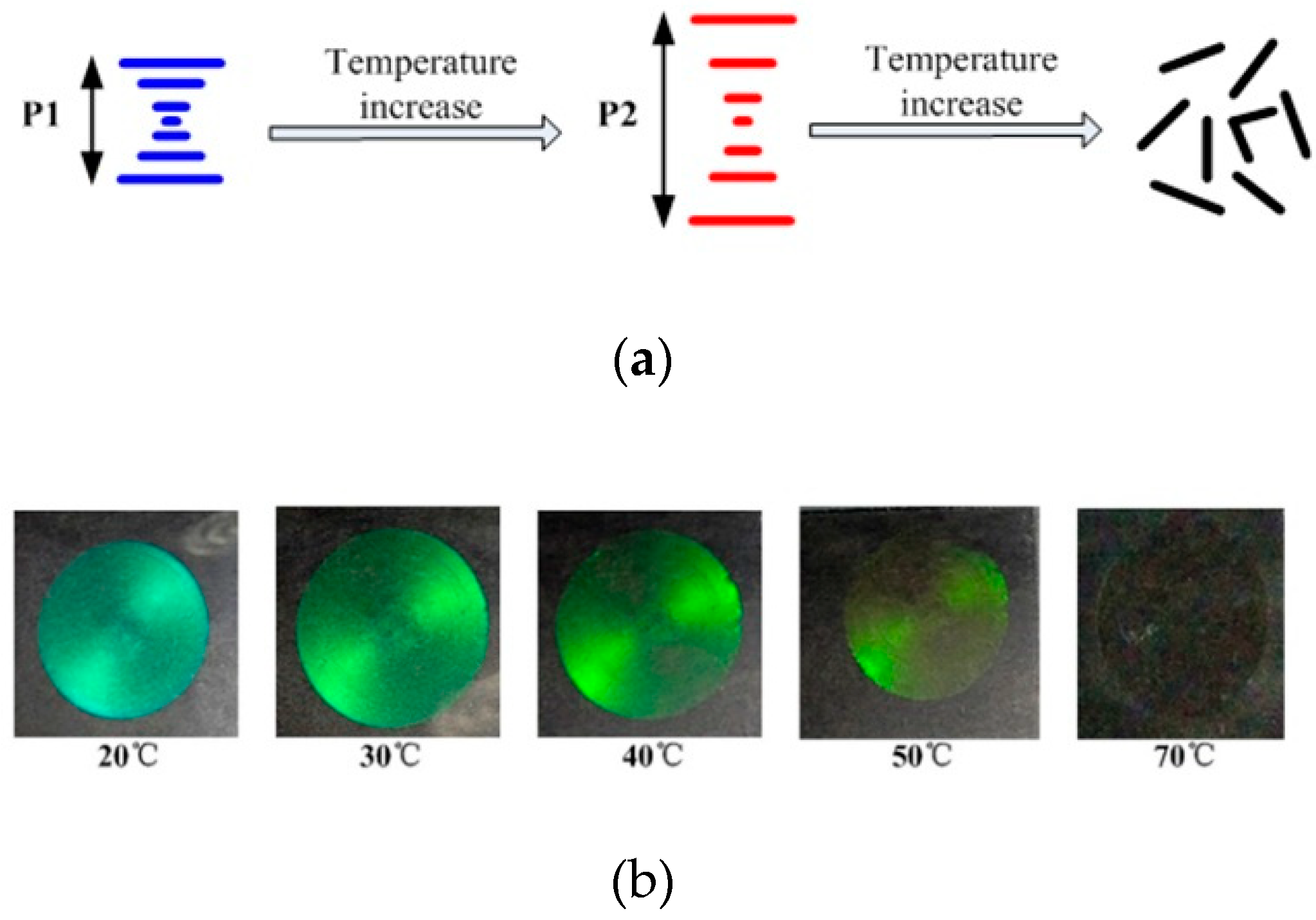

2.3. Thermosensitivity of CLCs

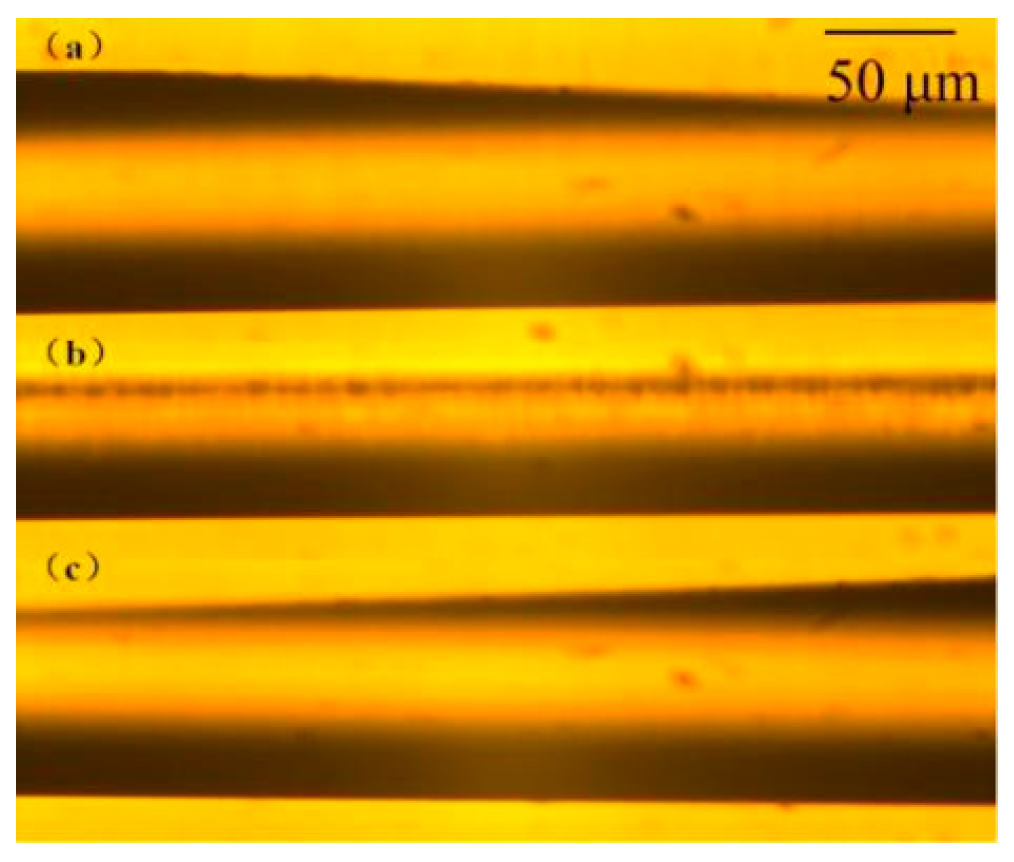

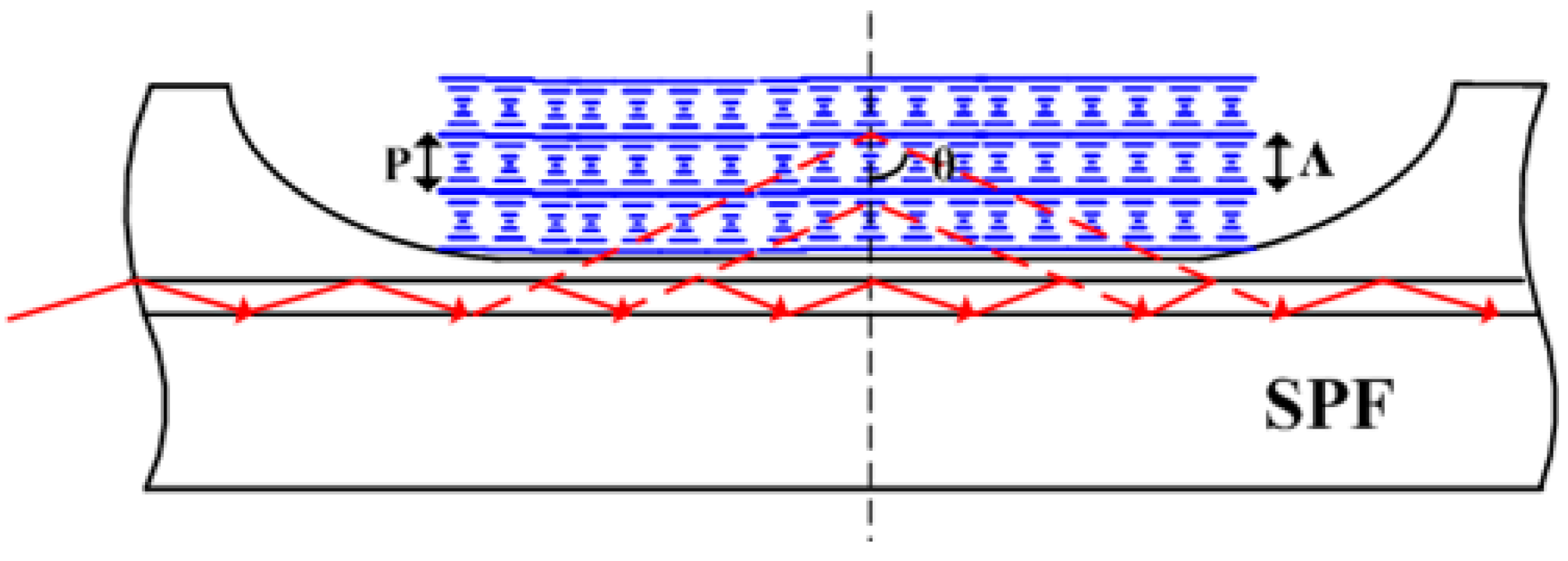

2.4. Preparation of SPFs

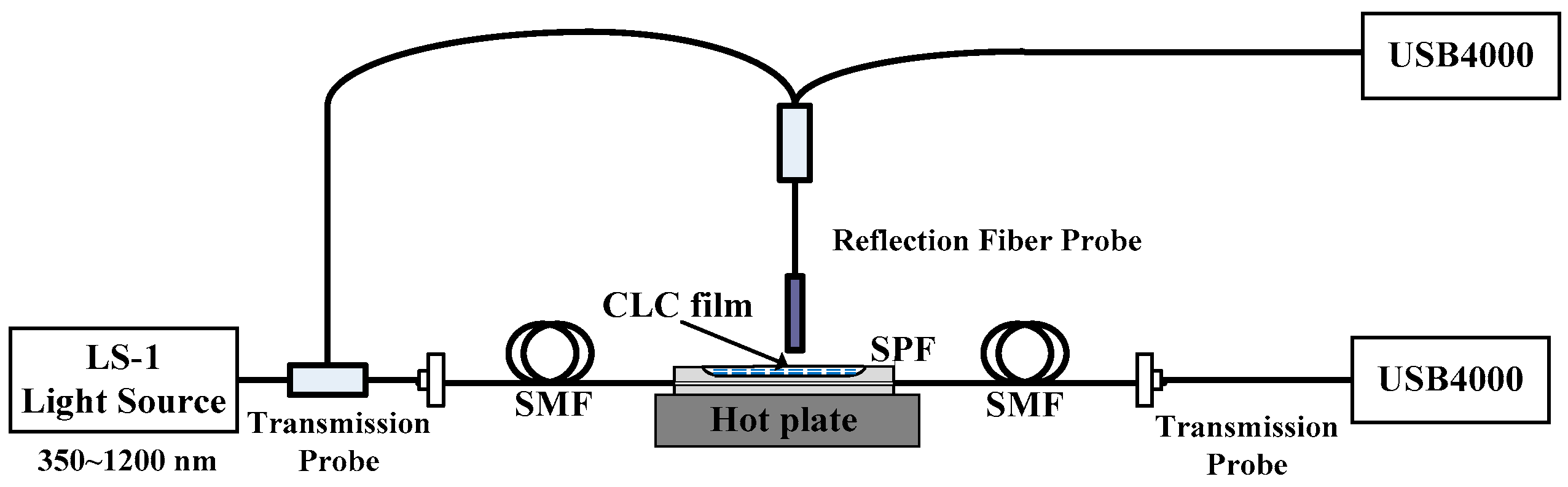

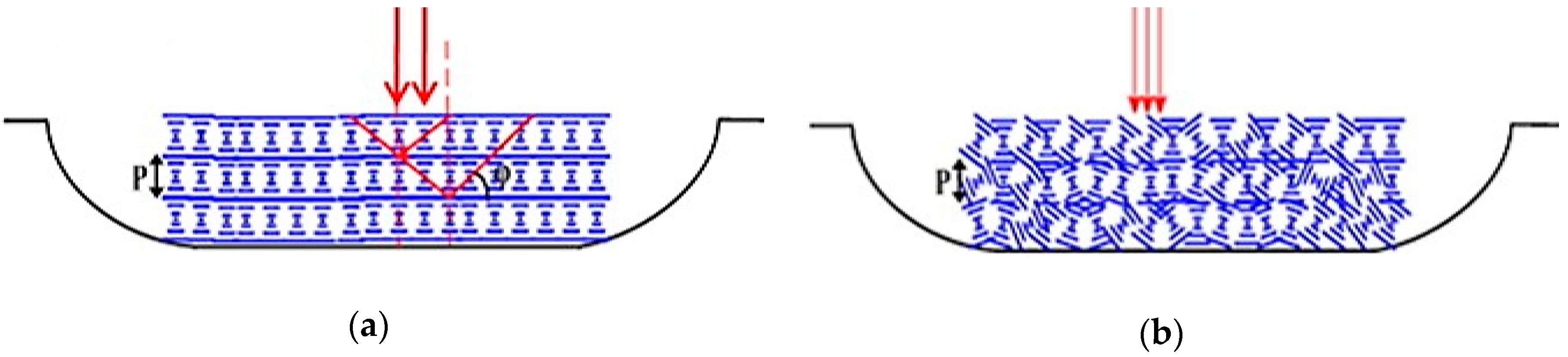

2.5. Reflection Spectrum Measurement of CLCs

2.6. Transmission Spectrum Measurement of SPFs

2.7. Experimental Device

3. Results and Discussion

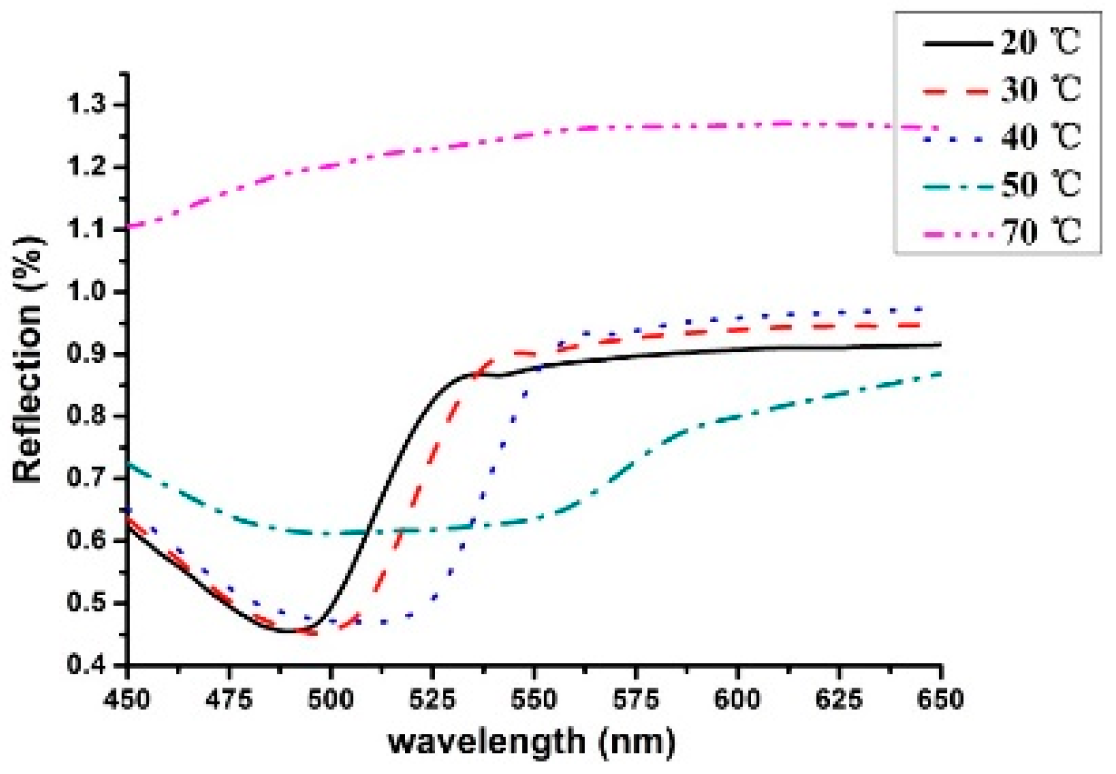

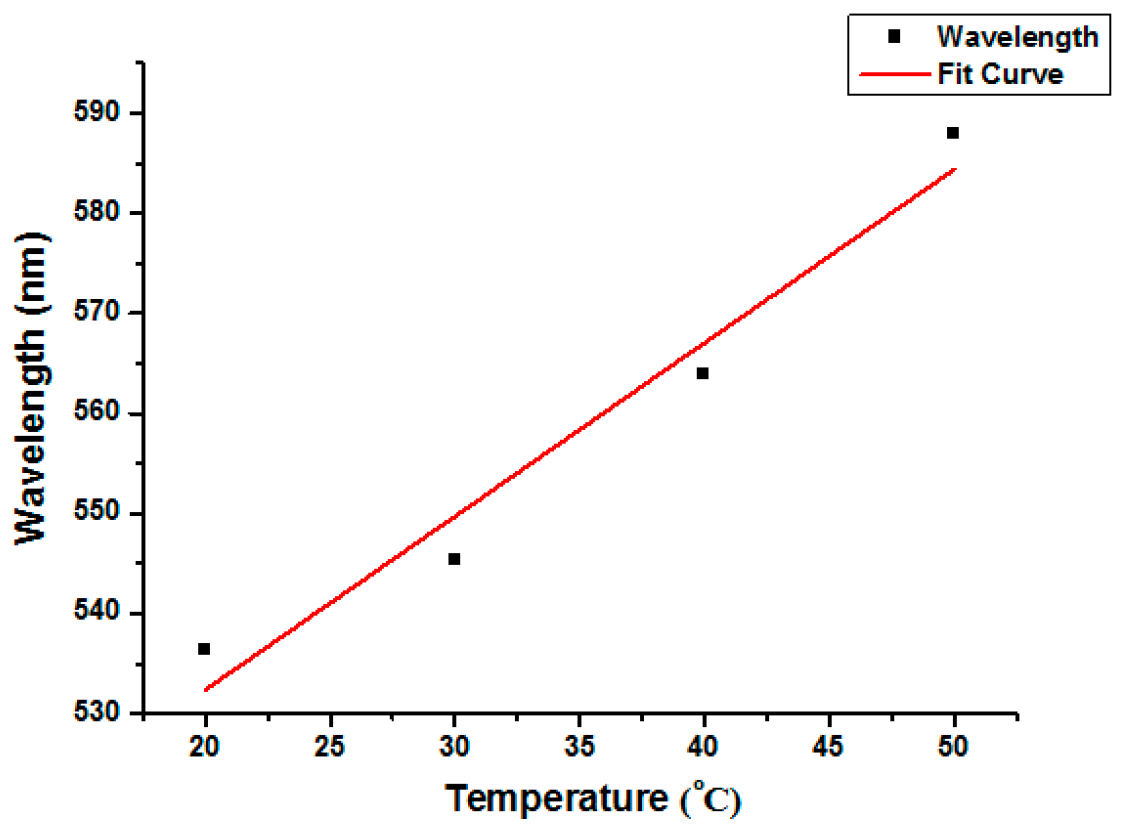

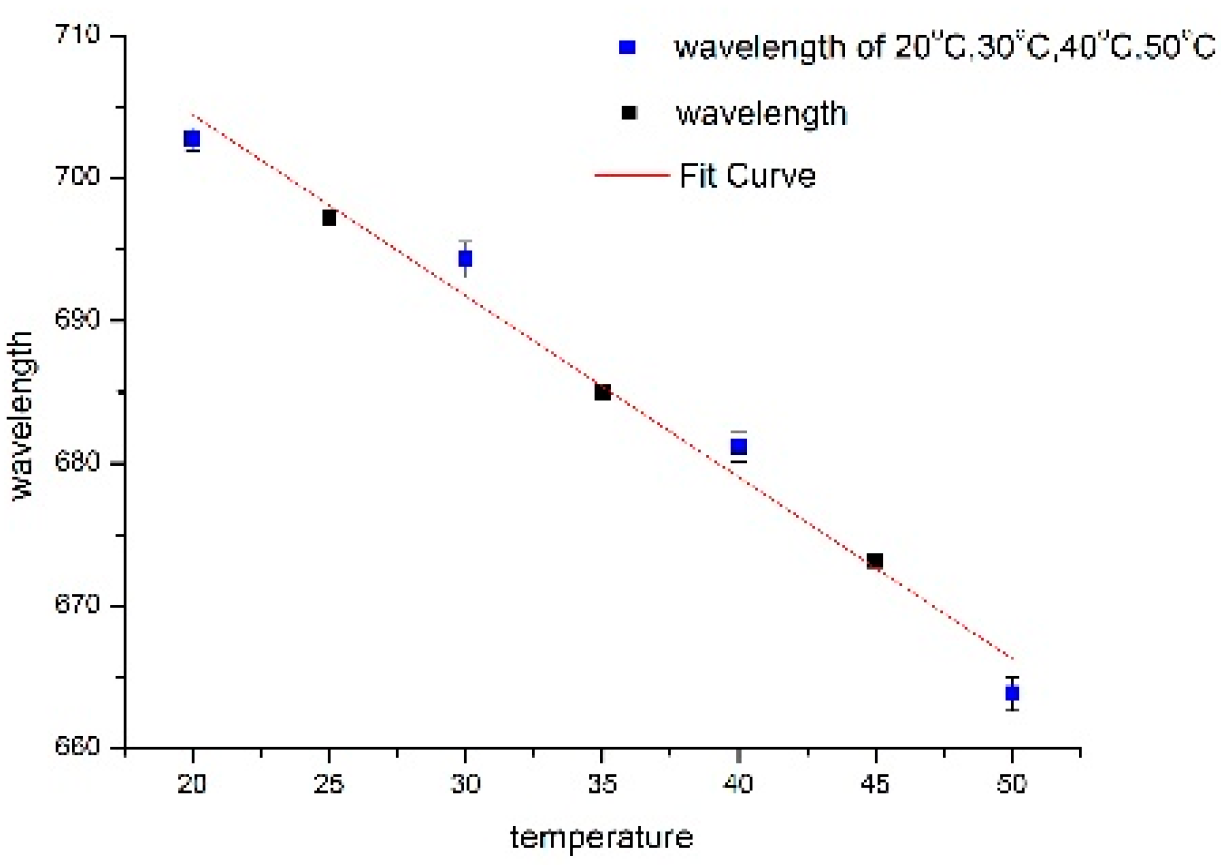

3.1. Reflection Spectra of CLCs in Response to Environmental Temperature Changes

3.2. Transmission Spectra of SPFs in Response to the Structural Changes of CLCs

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Woliński, T.R.; Bock, W.J. Cholesteric liquid crystal sensing of high hydrostatic pressure utilizing optical fibers. Mol. Cryst. Liq. Cryst. 1991, 199, 7–17. [Google Scholar] [CrossRef]

- Shibaev, P.V.; Schlesier, C. Distant mechanical sensors based on cholesteric liquid crystals. Appl. Phys. Lett. 2012, 101, 193503. [Google Scholar] [CrossRef]

- Moreira, M.F.; Carvalho, I.C.S.; Cao, W.; Bailey, C.; Taheri, B.; Palffy-Muhoray, P. Cholesteric liquid-crystal laser as an optic fiber-based temperature sensor. Appl. Phys. Lett. 2004, 85, 2691–2693. [Google Scholar] [CrossRef]

- Mitov, M. Cholesteric Liquid Crystals with a Broad Light Reflection Band. Adv. Mater. 2012, 24, 6260–6276. [Google Scholar] [CrossRef]

- Hennig, G.; Brittenham, G.M.; Sroka, R.; Kniebühler, G.; Vogeser, M.; Stepp, H. Bandwidth-variable tunable optical filter unit for illμmination and spectral imaging systems using thin-film optical band-pass filters. Rev. Sci. Instrum. 2013, 84, 043113. [Google Scholar] [CrossRef]

- Hikmet, R.A.M.; Kemperman, H. Electrically switchable mirrors and optical components made from liquid-crystal gels. Nature 1998, 392, 476–479. [Google Scholar] [CrossRef]

- Woltman, S.J.; Jay, G.D.; Crawford, G.P. Liquid-crystal materials find a new order in biomedical applications. Nat. Mater. 2007, 6, 929–938. [Google Scholar] [CrossRef]

- Hsiao, Y.C.; Sung, Y.C.; Lee, M.J.; Lee, W. Highly sensitive color-indicating and quantitative biosensor based on cholesteric liquid crystal. Biomed. Opt. Express 2015, 6, 5033–5038. [Google Scholar] [CrossRef]

- Popov, N.; Honaker, L.W.; Popova, M.; Usol’tseva, N.; Mann, E.K.; Jákli, A.; Popov, P. Thermotropic Liquid Crystal-Assisted Chemical and Biological Sensors. Materials 2017, 11, 20. [Google Scholar] [CrossRef]

- Brake, J.M.; Mezera, A.D.; Abbott, N.L. Active control of the anchoring of 4’-pentyl-4-cyanobiphenyl (5CB) at an aqueous-liquid crystal interface by using a redox-active ferrocenyl surfactant. Langmuir 2003, 19, 8629–8637. [Google Scholar] [CrossRef]

- McCamley, M.K.; Ravnik, M.; Artenstein, A.W.; Opal, S.M.; Žumer, S.; Crawford, G.P. Detection of alignment changes at the open surface of a confined nematic liquid crystal sensor. J. Appl. Phys. 2009, 105, 123504. [Google Scholar] [CrossRef]

- Huang, H.; Zhai, J.; Ren, B. Fiber-Optic Evanescent Wave Biosensor and Its Application. ACTA Opi. Sin. 2003, 23, 451–454. [Google Scholar]

- Deng, L.; Feng, Y.; Wei, L. The Research of Fiber Optic Evanescent Wave Biosensor. ACTA Photonica Sin. 2005, 34, 1688–1692. [Google Scholar]

- Lin, H.Y.; Tsai, W.H.; Tsao, Y.C.; Sheu, B.C. Side-polished multimode fiber biosensor based on surface plasmon resonance with halogen light. Appl. Opt. 2007, 46, 800–806. [Google Scholar] [CrossRef]

- Chen, Z.; Li, F.; Zhong, J. Side polished fiber and application. In Proceedings of the 12th Fiber Communication and 13th Integrated Optics Conference, Jinan University, Guangzhou, China, 2005; pp. 407–412. [Google Scholar]

- Chen, Z.; Cui, F.; Zeng, Y. Theoretical analysis on optical propagation characteristics of side-polished fibers. Acta Photonica Sin. 2008, 37, 918–923. [Google Scholar]

- Chen, Z.; Qin, J.; Pan, H.; Zhang, J.; Xiao, Y.; Yu, J. All-fiber integrated optical power monitor-controller. Chin. J. Lasers 2010, 37, 1047–1052. [Google Scholar] [CrossRef]

- Hsiao, V.K.S.; Li, Z.; Chen, Z.; Peng, P.C.; Tang, J. Optically controllable side-polished fiber attenuator with photoresponsive liquid crystal overlay. Opt. Express 2009, 17, 19988–19995. [Google Scholar] [CrossRef]

- Fu, W.H.; Hsiao, V.K.S.; Tang, J.Y.; Wu, M.H.; Chen, Z. All fiber-optic sensing of light using side-polished fiber overlaid with photoresponsive liquid crystals. Sens. Actuators B Chem. 2011, 156, 423–427. [Google Scholar] [CrossRef]

- Yu, J.; Li, X.; Du, Y.; Zhang, J.; Chen, Z. Study of photorefractive properties of liquid crystal hybrid thin film by side polished fiber sensor. In Proceedings of the Third Asia Pacific Optical Sensors Conference, Sydney, Australia, 31 January–3 February 2012; p. 835122. [Google Scholar]

- Yu, J.; Li, H.; Hsiao, V.K.; Liu, W.; Tang, J.; Zhai, Y.; Du, Y.; Zhang, J.; Xiao, Y.; Chen, Z. A fiber-optic violet sensor by using the surface grating formed by a photosensitive hybrid liquid crystal film on side-polished fiber. Meas. Sci. Technol. 2013, 24, 094019. [Google Scholar] [CrossRef]

- Tang, J.; Fang, J.; Liang, Y.; Zhang, B.; Luo, Y.; Liu, X.; Li, Z.; Cai, X.; Xian, J.; Lin, H.; et al. All-fiber-optic VOC gas sensor based on side-polished fiber wavelength selectively coupled with cholesteric liquid crystal film. Sens. Actuators B Chem. 2018, 273, 1816–1826. [Google Scholar] [CrossRef]

- Han, Y.; Chen, Z.; Cao, D.; Yu, J.; Li, H.; He, X.; Zhang, J.; Luo, Y.; Lu, H.; Tang, J.; et al. Side-polished fiber as a sensor for the determination of nematic liquid crystal orientation. Sens. Actuators B Chem. 2014, 196, 663–669. [Google Scholar] [CrossRef]

- Stewart, G.T. Liquid Crystals in Biological Systems. Mol. Cryst. Liq. Cryst. 1966, 1, 563–580. [Google Scholar] [CrossRef]

- Elser, W.; Ennulat, R.D. Selective Reflection of Cholesteric Liquid Crystals. Adv. Liq. Cryst. 1976, 2, 73–172. [Google Scholar]

- Zhou, Y.; Huang, Y.; Ge, Z.; Chen, L.-P.; Hong, Q.; Wu, T.X.; Wu, S.-T. Enhanced photonic band edge laser emission in a cholesteric liquid crystal resonator. Phys. Rev. E 2006, 74, 061705. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, Y.; Jiang, Y.; Guo, W. Sensing Characteristics of Side-Polished Fiber Based on the Alterations in Helical Structure of Thermo-Sensitive Cholesteric Liquid Crystals. Crystals 2019, 9, 465. https://doi.org/10.3390/cryst9090465

Han Y, Jiang Y, Guo W. Sensing Characteristics of Side-Polished Fiber Based on the Alterations in Helical Structure of Thermo-Sensitive Cholesteric Liquid Crystals. Crystals. 2019; 9(9):465. https://doi.org/10.3390/cryst9090465

Chicago/Turabian StyleHan, Yuqi, Yan Jiang, and Wei Guo. 2019. "Sensing Characteristics of Side-Polished Fiber Based on the Alterations in Helical Structure of Thermo-Sensitive Cholesteric Liquid Crystals" Crystals 9, no. 9: 465. https://doi.org/10.3390/cryst9090465

APA StyleHan, Y., Jiang, Y., & Guo, W. (2019). Sensing Characteristics of Side-Polished Fiber Based on the Alterations in Helical Structure of Thermo-Sensitive Cholesteric Liquid Crystals. Crystals, 9(9), 465. https://doi.org/10.3390/cryst9090465