Simulation-Based Development of a New Cylindrical-Cavity Microwave-Plasma Reactor for Diamond-Film Synthesis

Abstract

1. Introduction

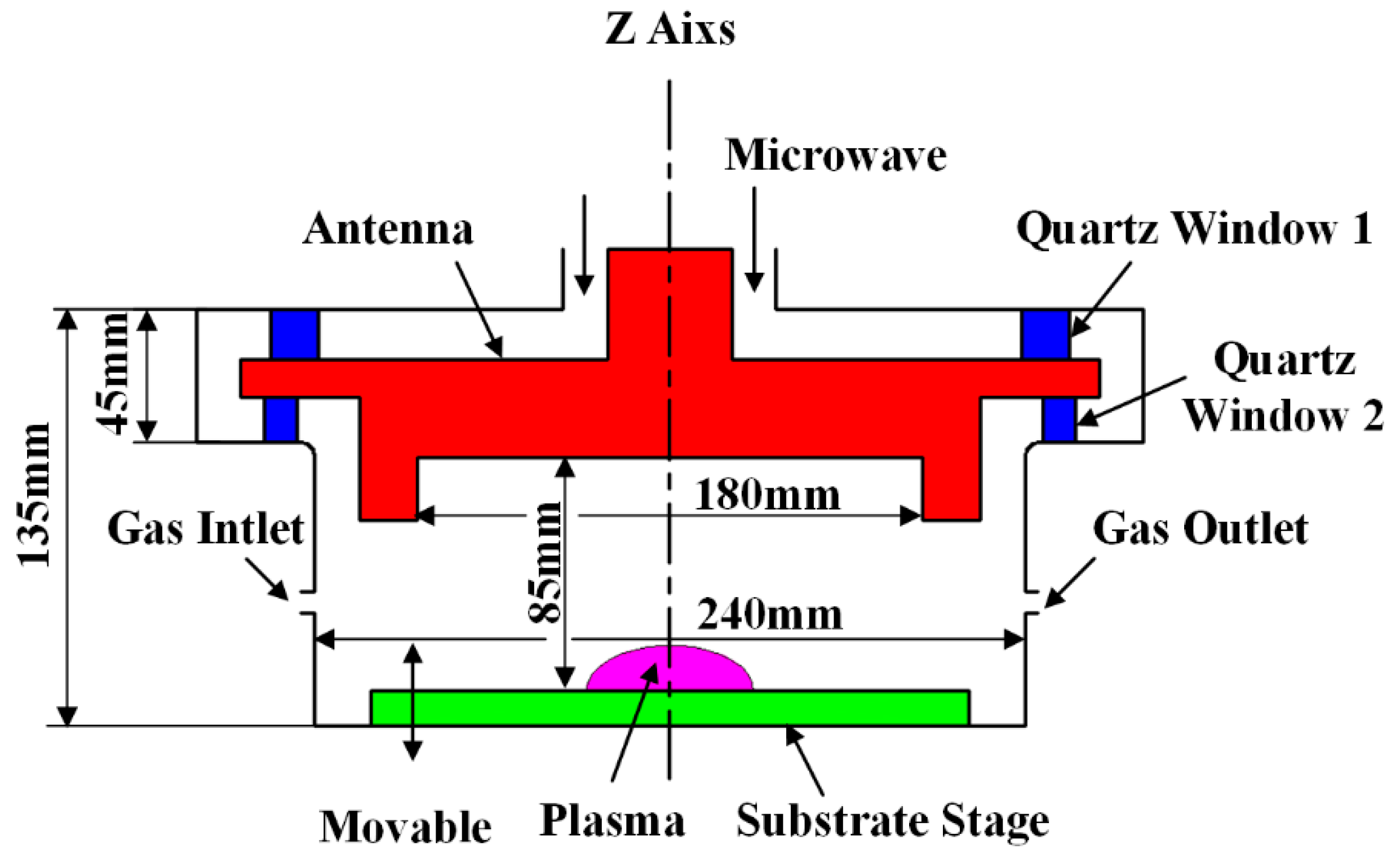

2. New Reactor Design

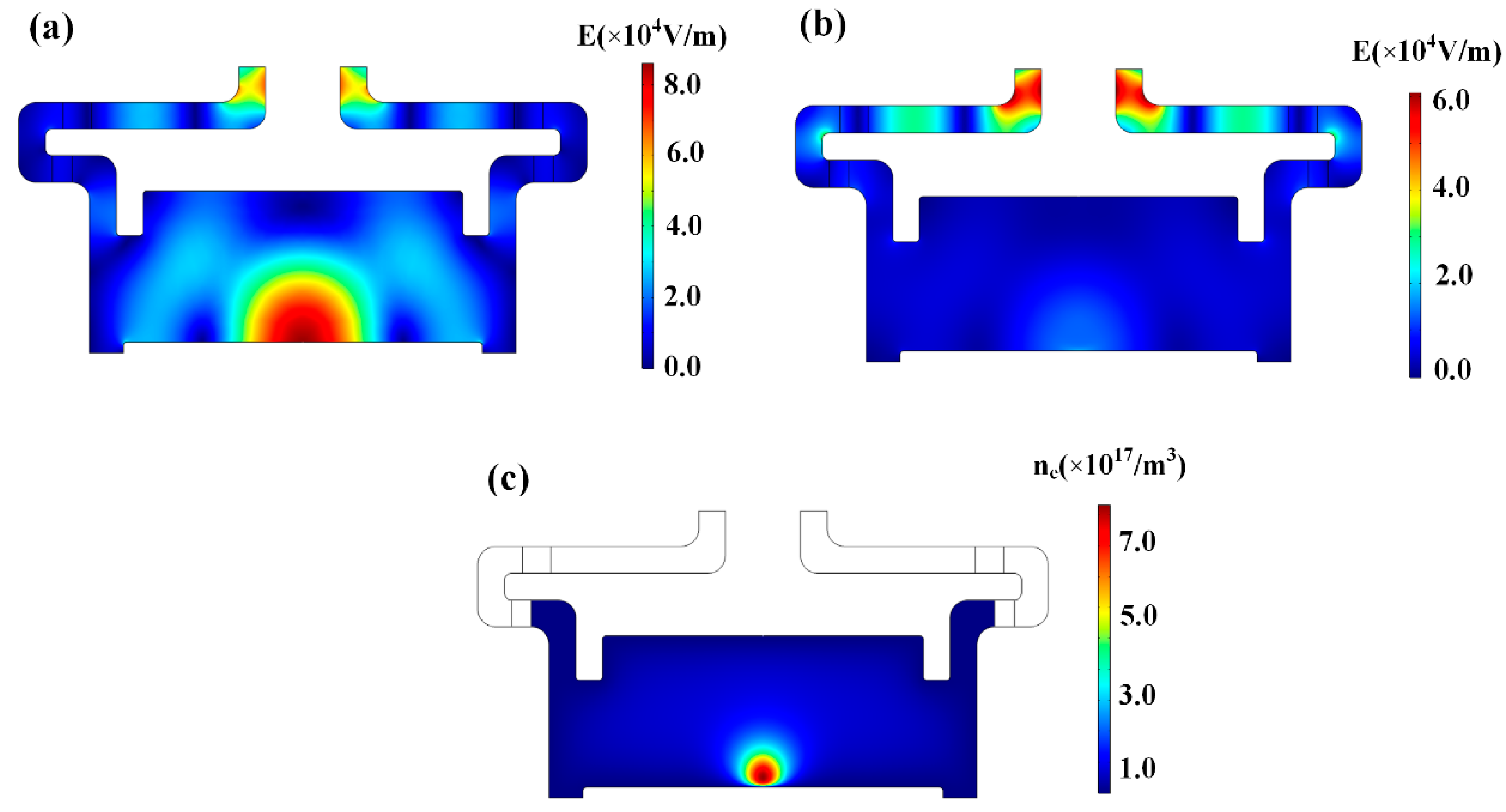

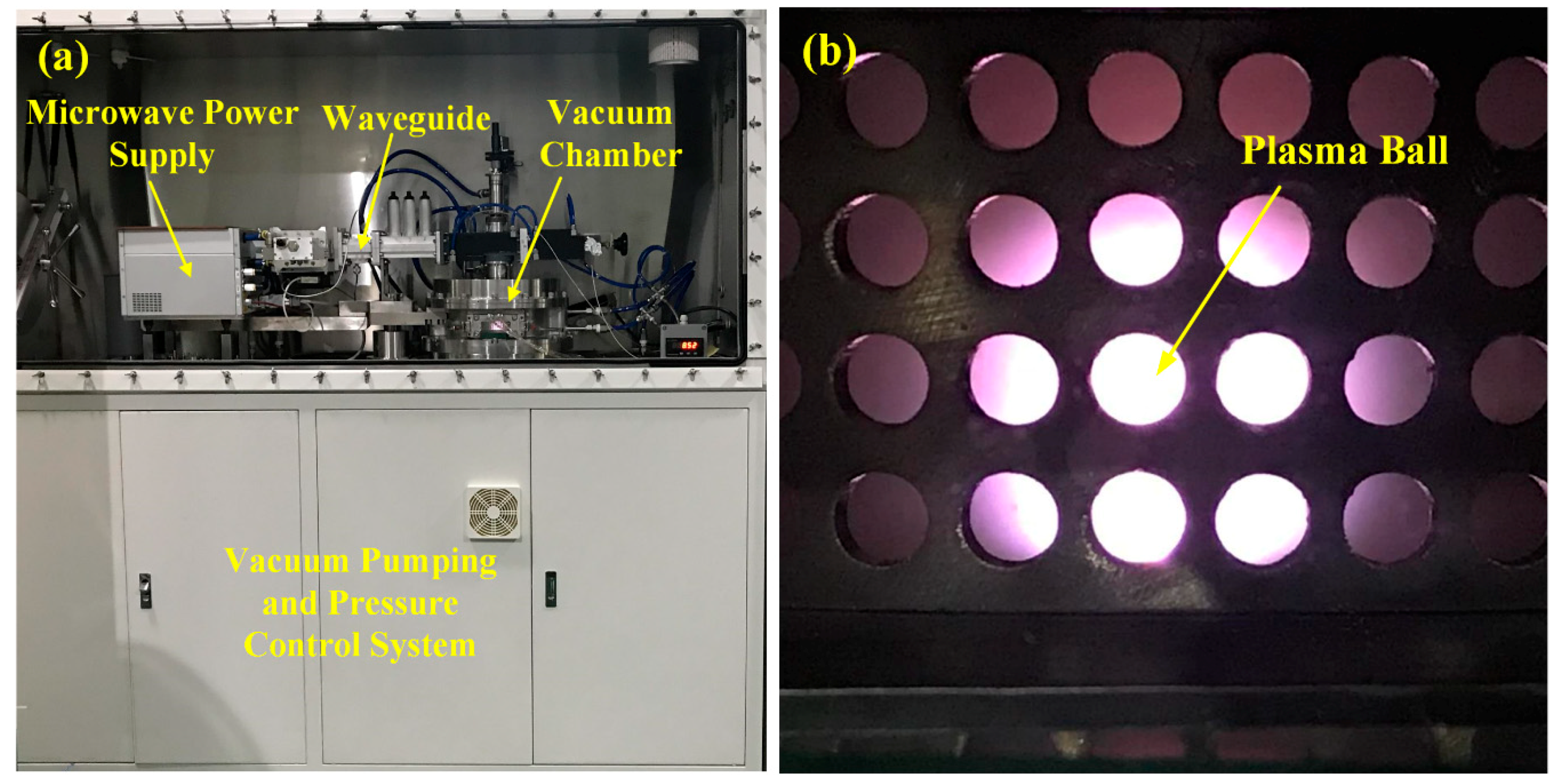

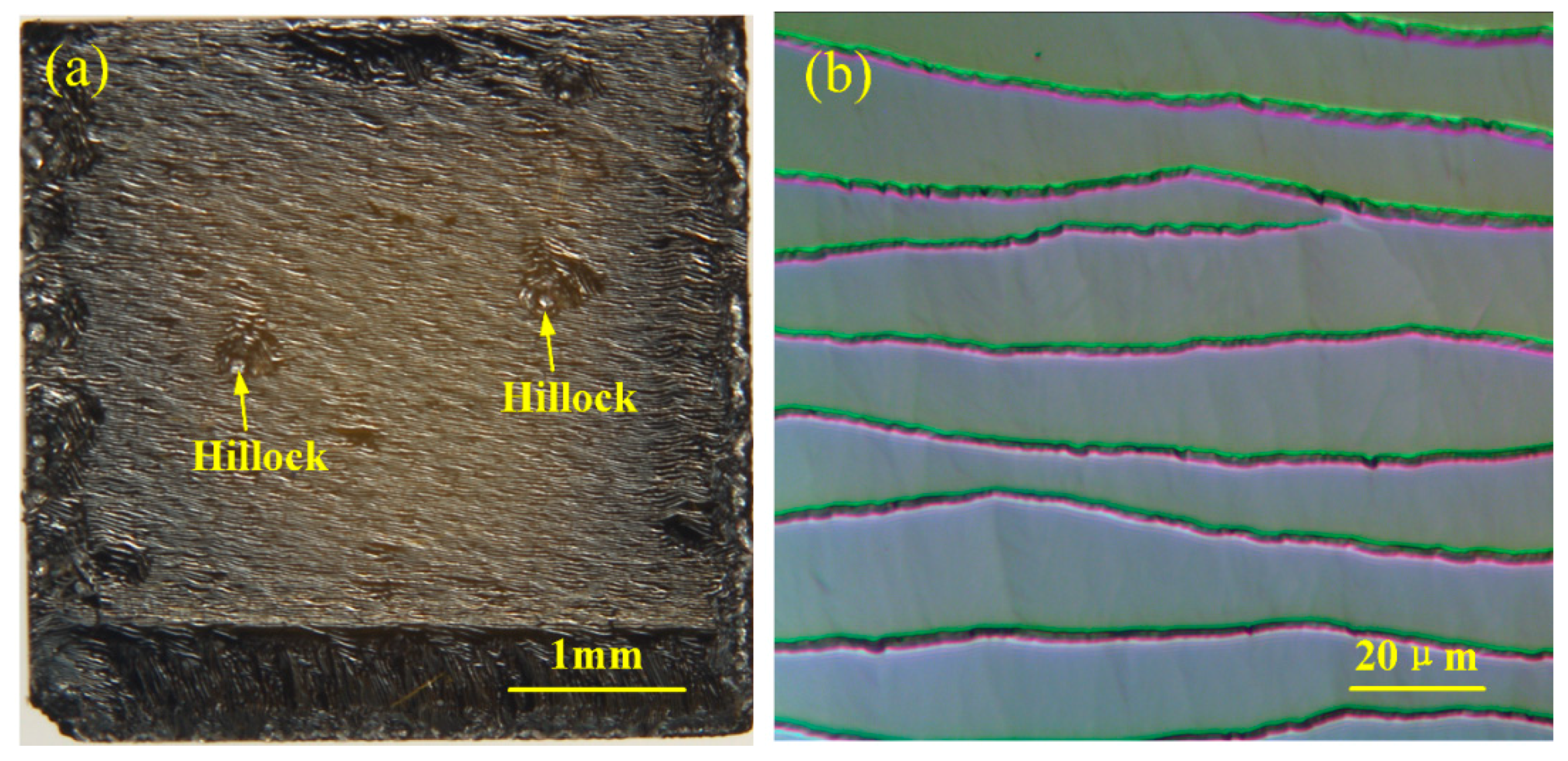

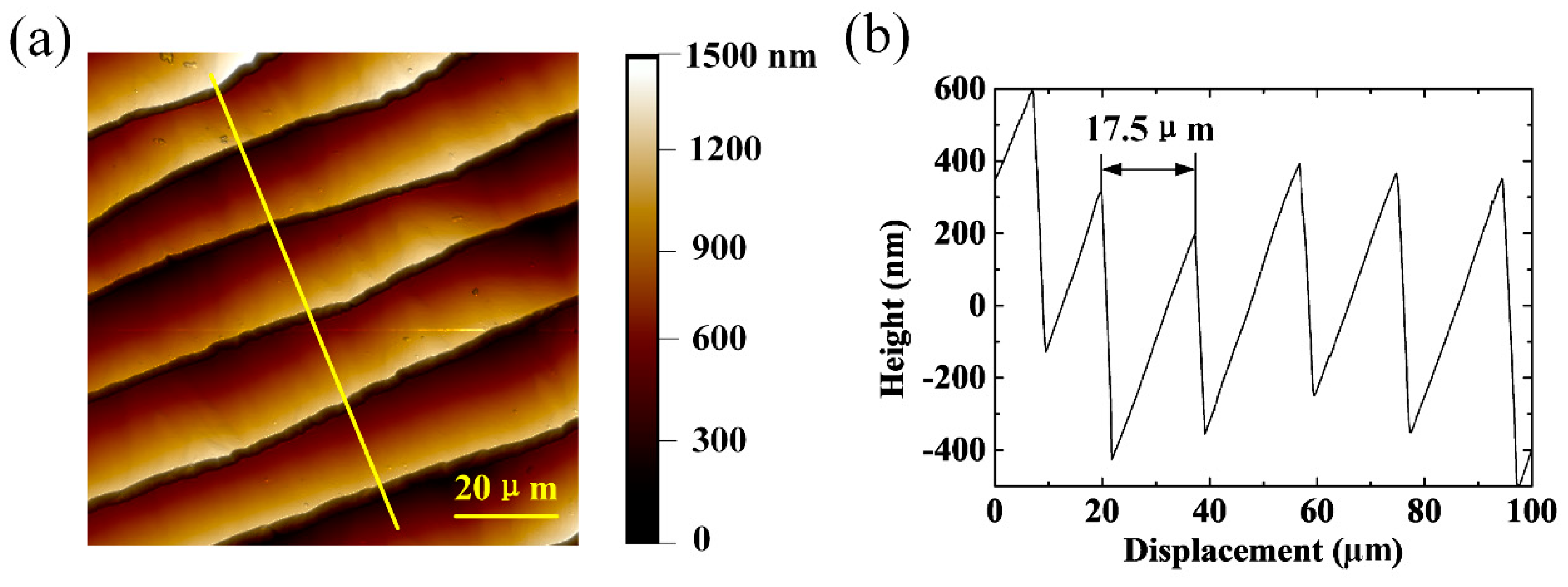

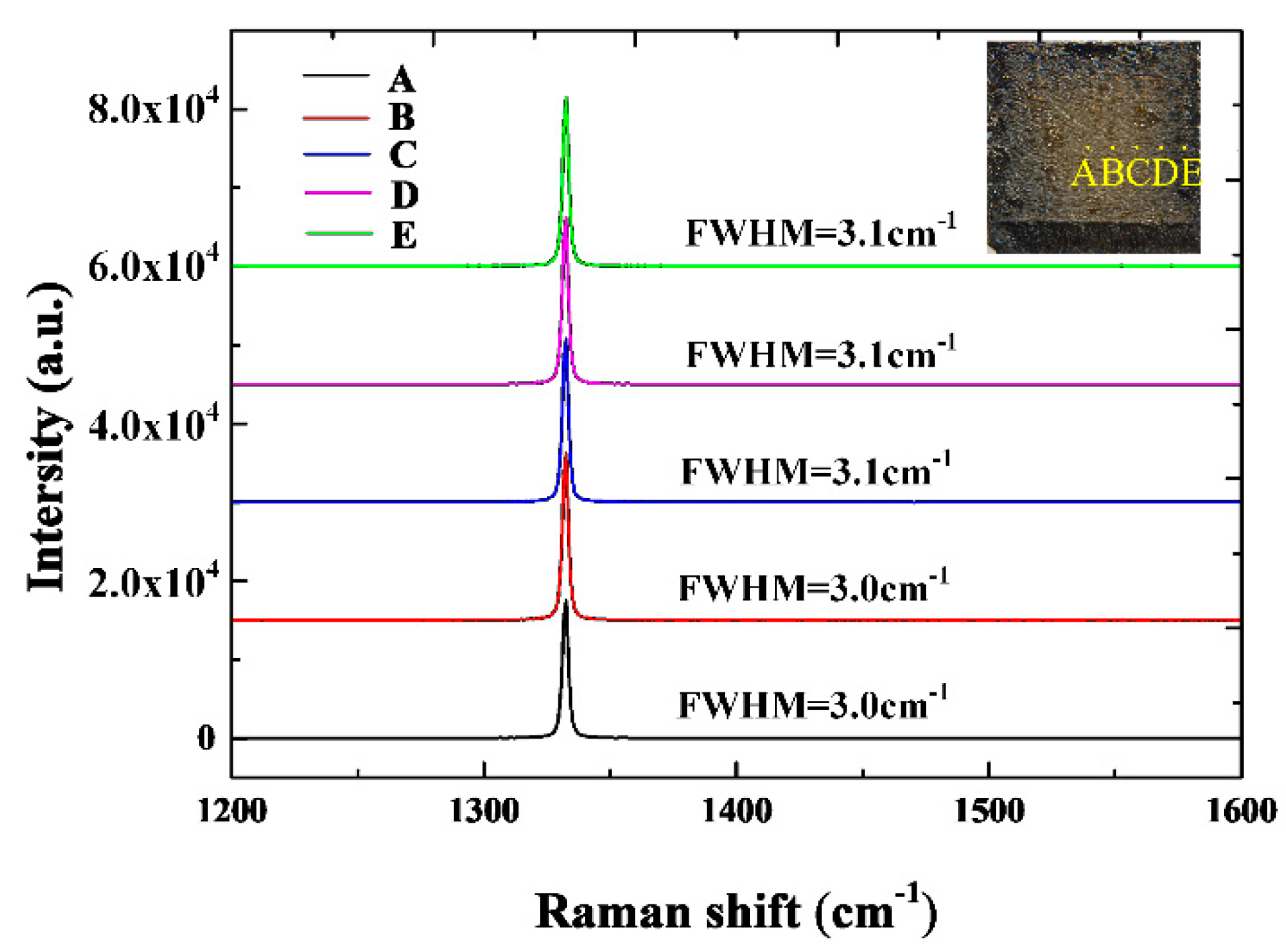

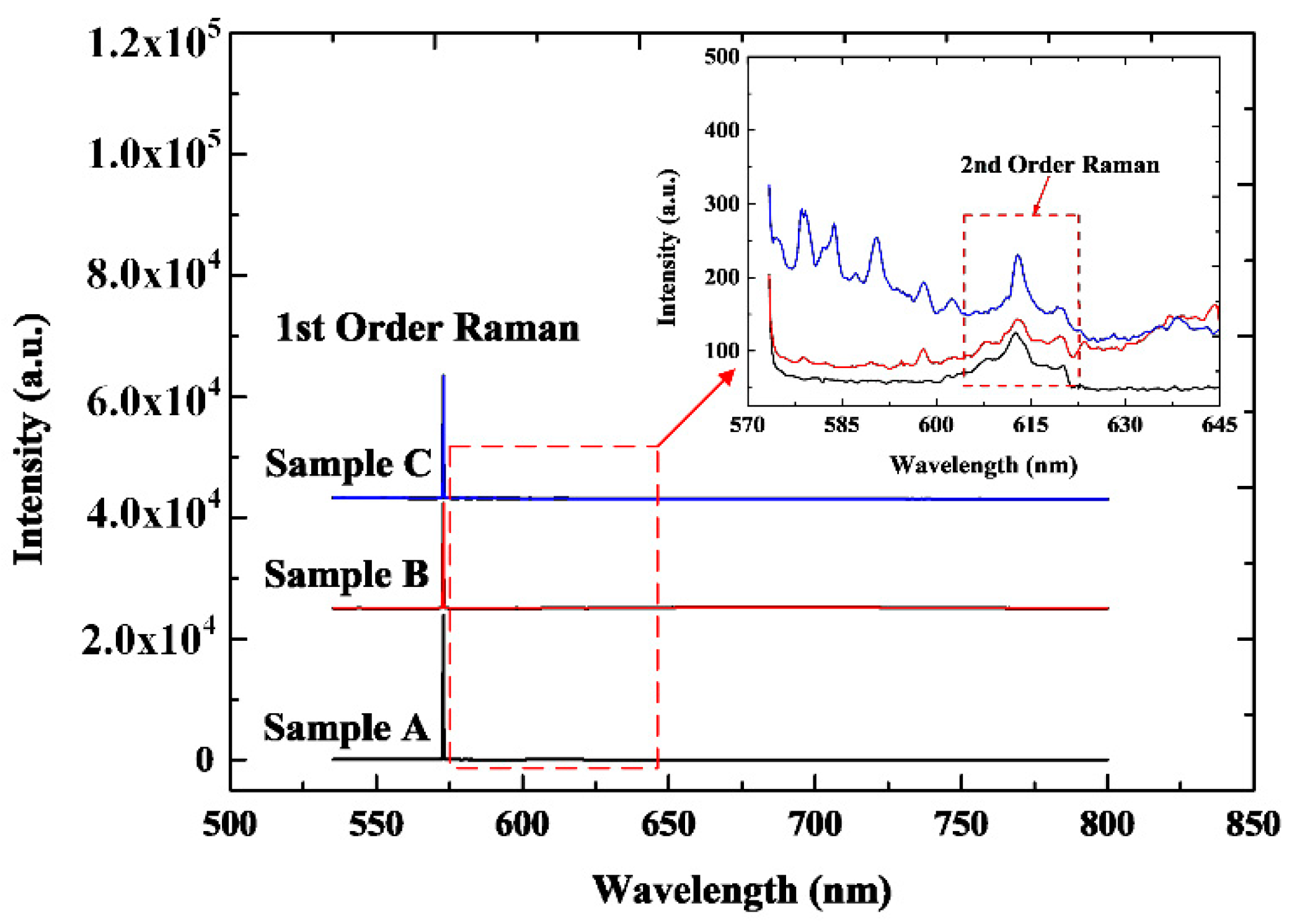

3. Numerical Simulation

4. Reactor Performance

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| MP | microwave plasma |

| CVD | chemical-vapor deposition |

| AFM | atomic force microscope |

| PL | photoluminescence |

| XRD | X-ray diffraction |

| HPHT | high-pressure high-temperature |

| DC | direct current |

| TE | transverse electric |

| TM | transverse magnetic |

| PC | personal computer |

| FWHM | full width at half maximum |

| RMS | root mean square |

References

- Wort, C.J.H.; Balmer, R.S. Diamond as an electronic material. Mater. Today 2008, 11, 22–28. [Google Scholar] [CrossRef]

- Evgeny, E.A.; Roman, A.K.; Vadim, S.S.; Andrew, A.K.; Alexander, V.K.; Viktor, G.R. Morphology of diamond layers grown on different facets of single crystal diamond substrates by a microwave plasma CVD in CH4-H2-N2 gas mixtures. Crystals 2017, 7, 166. [Google Scholar]

- Olsen, R.H.; Dewes, R.C.; Aspinwall, D.K. Machining of electrically conductive CVD diamond tool blanks using EDM. J. Mater. Process. Tech. 2004, 149, 627–632. [Google Scholar] [CrossRef]

- Balmer, R.S.; Brandon, J.R.; Clewes, S.L.; Dhillon, H.K.; Dodson, J.M.; Friel, I.; Inglis, P.N.; Madgwick, T.D.; Markham, M.L.; Mollart, T.P.; et al. Chemical vapour deposition synthetic diamond: materials, technology and applications. J. Phys. Condens. Matter. 2009, 21, 364221. [Google Scholar] [CrossRef] [PubMed]

- Mokuno, Y.; Chayahara, A.; Soda, Y.; Yamada, H.; Horino, Y.; Fujimori, N. High rate homoepitaxial growth of diamond by microwave plasma CVD with nitrogen addition. Diam. Relat. Mater. 2006, 15, 455–459. [Google Scholar] [CrossRef]

- Railkar, T.A.; Kang, W.P.; Windischmann, H.; Malshe, A.P.; Naseem, H.A.; Davidson, J.L.; Brown, W.D. A critical review of chemical vapor-deposited (CVD) diamond for electronic applications. Crit. Rev. Solid State 2000, 25, 163–277. [Google Scholar] [CrossRef]

- Liu, J.; Hei, L.F.; Song, J.H.; Li, C.M.; Tang, W.Z.; Chen, G.C.; Lu, F.X. High-rate homoepitaxial growth of CVD single-crystal diamond by dc arc plasma jet at blow-down (open cycle) mode. Diam. Relat. Mater. 2014, 46, 42–51. [Google Scholar] [CrossRef]

- Hei, L.F.; Liu, J.; Li, C.M.; Song, J.H.; Tang, W.Z.; Lu, F.X. Fabrication and characterizations of large homoepitaxial single-crystal diamond grown by DC arc plasma jet CVD. Diam. Relat. Mater. 2012, 30, 77–84. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, X.C.; Shen, B.; Shen, F.H.; Zhang, Z.M. The effect of deposition parameters on the morphology of micron diamond powders synthesized by HFCVD method. J. Cryst. Growth 2013, 372, 49–56. [Google Scholar] [CrossRef]

- Fuentes-Fernandez, E.M.A.; Alcantar-Peña, J.J.; Lee, G.; Boulom, A.; Phan, H.; Smith, B.; Nguyen, T.; Sahoo, S.; Ruiz-Zepeda, F.; Arellano-Jimenez, M.J.; et al. Synthesis and characterization of microcrystalline diamond to ultrananocrystalline diamond films via Hot Filament Chemical Vapor Deposition for scaling to large area applications. Thin Solid Films 2016, 603, 62–68. [Google Scholar] [CrossRef]

- Anuj Soni; Choudhary, R.K.; Polymeris, G.S.; Mishra, D.R.; Mishra, P.; Kulkarni, M.S. TL and OSL studies on undoped diamond films grown by hot filament chemical vapor deposition. J. Lumin. 2016, 177, 184–189. [Google Scholar]

- Hideaki, Y.; Akiyoshi, C.; Yoshiaki, M.; Shikata, S. Simulation with an improved plasma model utilized to design a new structure of microwave plasma discharge for chemical vapor deposition of diamond crystals. Diam. Relat. Mater. 2008, 17, 494–497. [Google Scholar]

- Silva, F.; Bonnin, X.; Scharpf, J.; Pasquarelli, A. Microwave analysis of PACVD diamond deposition reactor based on electric modelling. Diam. Relat. Mater. 2010, 19, 397–403. [Google Scholar] [CrossRef]

- Gu, Y.J.; Lu, J.; Grotjohn, T.; Schuelke, T.; Asmussen, J. Microwave plasma reactor design for high pressure and high power density diamond synthesis. Diam. Relat. Mater. 2012, 24, 210–214. [Google Scholar] [CrossRef]

- Silva, F.; Hassouni, K.; Bonin, X.; Gicquel, A. Microwave engineering of plasma-asisted CVD reactors for diamond deposition. J. Phys. Condens. Matter 2009, 21, 364202. [Google Scholar] [CrossRef] [PubMed]

- Kamo, M.; Sato, Y.; Matsumoto, S.; Setaka, N. Diamond synthesis from gas phase in microwave plasma. J. Cryst. Growth 1983, 62, 642–644. [Google Scholar] [CrossRef]

- Baudrillart, B.; Nave, A.S.C.; Hamann, S.; Bénédic, F.; Lombardi, G.; van Helden, J.H.; Röpcke, J.; Achard, J. Growth processes of nanocrystalline diamond films in microwave cavity and distributed co-axial mode transformer array systems: A comparative study. Diam. Relat. Mater. 2017, 71, 53–62. [Google Scholar] [CrossRef]

- Hemawan, K.W.; Grotjohn, T.A.; Reinhard, D.K.; Asmussen, J. Improved microwave plasma cavity reactor for diamond synthesis at high pressure and high power density. Diam. Relat. Mater. 2010, 19, 1446–1452. [Google Scholar] [CrossRef]

- Li, Y.F.; An, X.M.; Liu, X.C.; Jiang, L.; Zhang, P.W.; Guo, H.; Sun, Z.L.; Zhao, H.Z.; Tang, W.Z. A 915 MHz/75 kW cylindrical cavity type microwave plasma chemical vapor deposition reactor with a ladder-shaped circumferential co-axial mode transformer developed for growing large area diamond films. Diam. Relat. Mater. 2017, 78, 67–72. [Google Scholar] [CrossRef]

- Li, Y.F.; Su, J.J.; Liu, Y.Q.; Ding, M.H.; Wang, G.; Tang, W.Z. A circumferential antenna ellipsoidal cavity type MPCVD reactor developed for diamond film deposition. Diam. Relat. Mater. 2015, 51, 24–29. [Google Scholar] [CrossRef]

- Pleuler, E.; Wild, C.; Füner, M.; Koidl, P. The CAP-reactor, a novel microwave CVD system for diamond deposition. Diam. Relat. Mater. 2002, 11, 467–471. [Google Scholar] [CrossRef]

- Füner, M.; Wild, C.; Koidl, P. Simulation and development of optimized microwave plasma reactors for diamond deposition. Surf. Coat. Tech. 1999, 116–119, 853–862. [Google Scholar] [CrossRef]

- Su, J.J.; Li, Y.F.; Li, X.L.; Yao, P.L.; Liu, Y.Q.; Ding, M.H.; Tang, W.Z. A novel microwave plasma reactor with a unique structure for chemical vapor deposition of diamond films. Diam. Relat. Mater. 2014, 42, 28–32. [Google Scholar] [CrossRef]

- Shivkumar, G.; Tholeti, S.S.; Alrefae, M.A.; Fisher, T.S.; Alexeenko, A.A. Analysis of hydrogen plasma in a microwave plasma chemical vapor deposition reactor. J. Appl. Phys. 2016, 119, 113301. [Google Scholar] [CrossRef]

- Hideaki, Y.; Akiyoshi, C.; Yoshiaki, M. Simplified description of microwave plasma discharge for chemical vapor deposition of diamond. J. Appl. Phys. 2007, 101, 063302. [Google Scholar]

- Mahoney, E.J.D.; Truscott, B.S.; Mushtaq, S.; Ashfold, M.N.R.; Mankelevich, Y.A. Spatially resolved optical emission and modeling studies of microwave-activated hydrogen plasmas operating under conditions relevant for diamond chemical vapor deposition. J. Phys. Chem. A 2018, 122, 8286–8300. [Google Scholar] [CrossRef] [PubMed]

- Achard, J.; Silva, F.; Tallaire, A.; Bonnin, X.; Lombardi, G.; Hassouni, K.; Gicquel, A. High quality MPACVD diamond single crystal growth: high microwave power density regime. J. Phys. D: Appl. Phys. 2007, 40, 6175–6188. [Google Scholar] [CrossRef]

- Yamada, H. Numerical simulations to study growth of single-crystal diamond by using microwave plasma chemical vapor deposition with reactive (H, C, N) species. Jpn. J. Appl. Phys. 2012, 51, 090105. [Google Scholar] [CrossRef]

- Wu, G.; Chen, M.H.; Liao, J. The influence of recess depth and crystallographic orientation of seed sides on homoepitaxial growth of CVD single crystal diamonds. Diam. Relat. Mater. 2016, 65, 144–151. [Google Scholar] [CrossRef]

- Shu, G.Y.; Dai, B.; Ralchenko, V.G.; Khomich, A.A.; Ashkinazi, E.E.; Bolshakov, A.P.; Bokova-Sirosh, S.N.; Liu, K.; Zhao, J.S.; Han, J.C.; et al. Epitaxial growth of mosaic diamond: Mapping of stress and defects in crystal junction with a confocal Raman spectroscopy. J. Cryst. Growth 2017, 463, 19–26. [Google Scholar] [CrossRef]

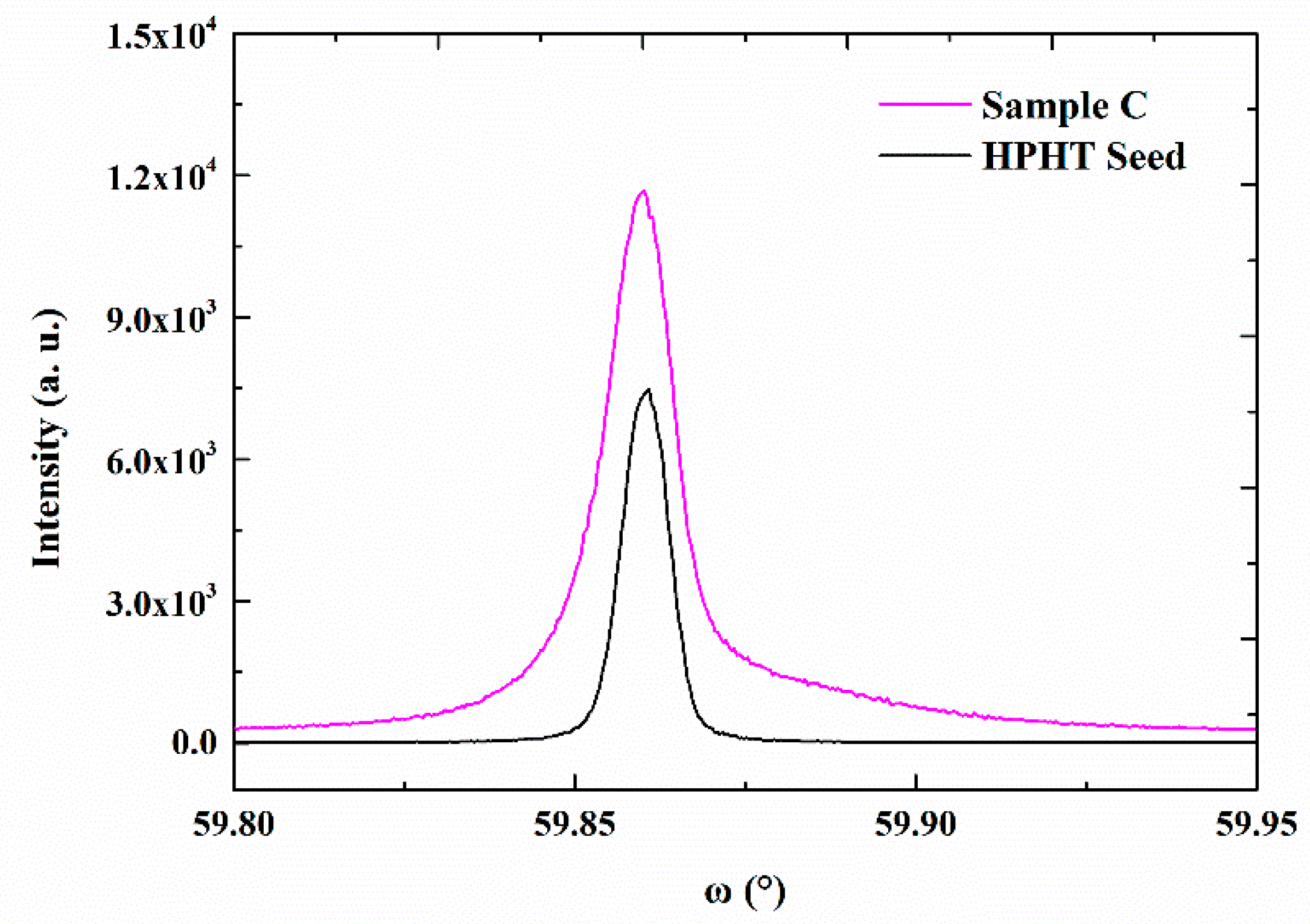

| Sample | Power (kW) | CH4/H2 (%) | Pressure (mbar) | Temperature (°C) | Deposition Rate (μm/h) | Raman FWHM (cm−1) | XRD FWHM (arcsec) |

|---|---|---|---|---|---|---|---|

| A | 3 | 1.5 | 155 | 985~1025 | 5.6 | 3.2 | 35 |

| B | 2.5 | 145 | 975~1015 | 5.4 | 3.5 | 39 | |

| C | 3.5 | 130 | 925~955 | 6.6 | 3.1 | 43 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Wu, G.; Liu, S.; Gan, Z.; Yang, B.; Pan, J. Simulation-Based Development of a New Cylindrical-Cavity Microwave-Plasma Reactor for Diamond-Film Synthesis. Crystals 2019, 9, 320. https://doi.org/10.3390/cryst9060320

Wang Q, Wu G, Liu S, Gan Z, Yang B, Pan J. Simulation-Based Development of a New Cylindrical-Cavity Microwave-Plasma Reactor for Diamond-Film Synthesis. Crystals. 2019; 9(6):320. https://doi.org/10.3390/cryst9060320

Chicago/Turabian StyleWang, Qijun, Gai Wu, Sheng Liu, Zhiyin Gan, Bo Yang, and Junheng Pan. 2019. "Simulation-Based Development of a New Cylindrical-Cavity Microwave-Plasma Reactor for Diamond-Film Synthesis" Crystals 9, no. 6: 320. https://doi.org/10.3390/cryst9060320

APA StyleWang, Q., Wu, G., Liu, S., Gan, Z., Yang, B., & Pan, J. (2019). Simulation-Based Development of a New Cylindrical-Cavity Microwave-Plasma Reactor for Diamond-Film Synthesis. Crystals, 9(6), 320. https://doi.org/10.3390/cryst9060320