Morphological and Crystallographic Characteristics of α Structure in a Low-Carbon Iron–Nickel Alloy

Abstract

:1. Introduction

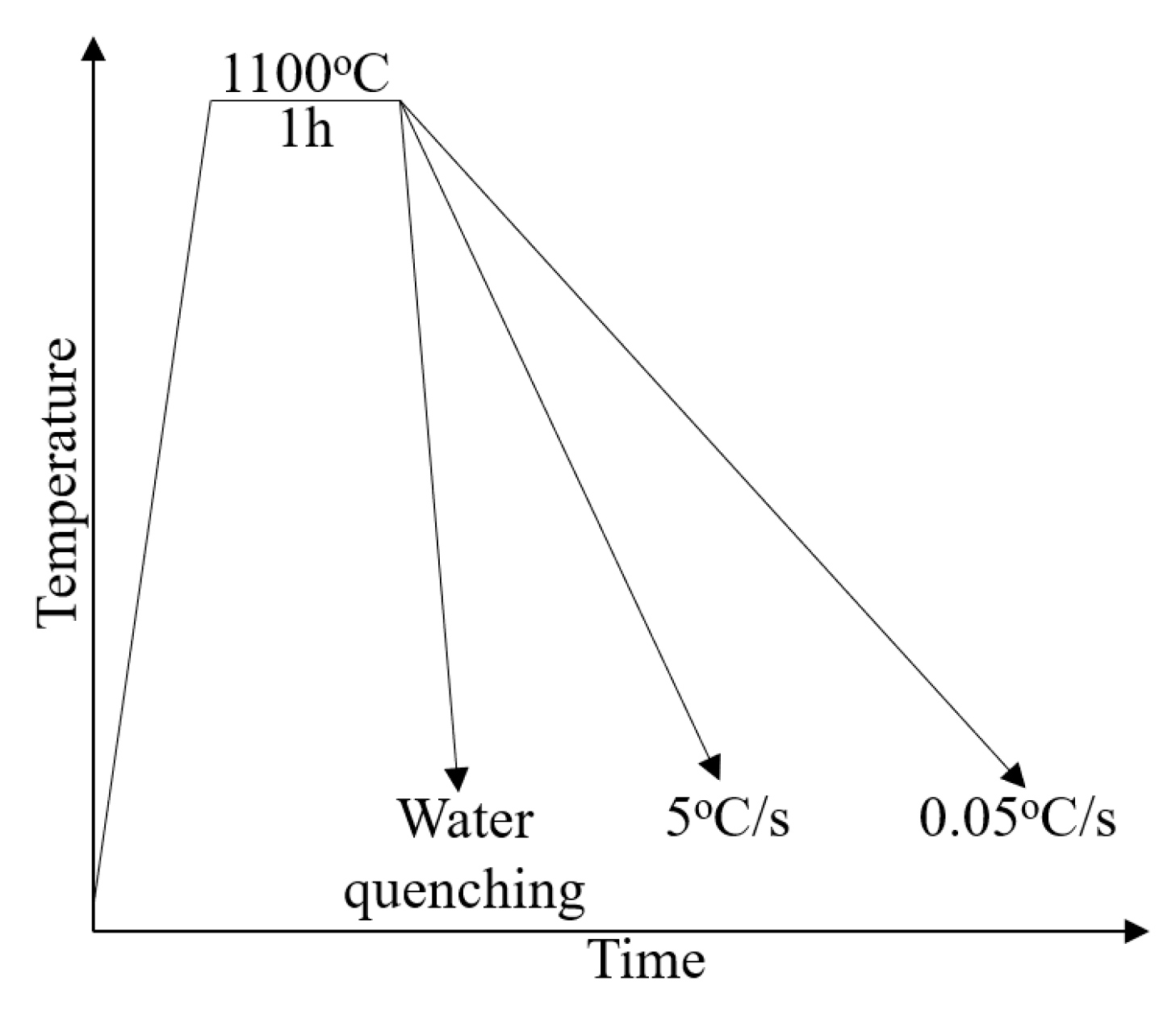

2. Materials and Methods

3. Results

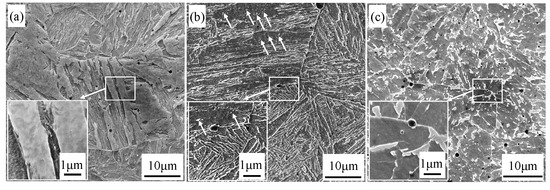

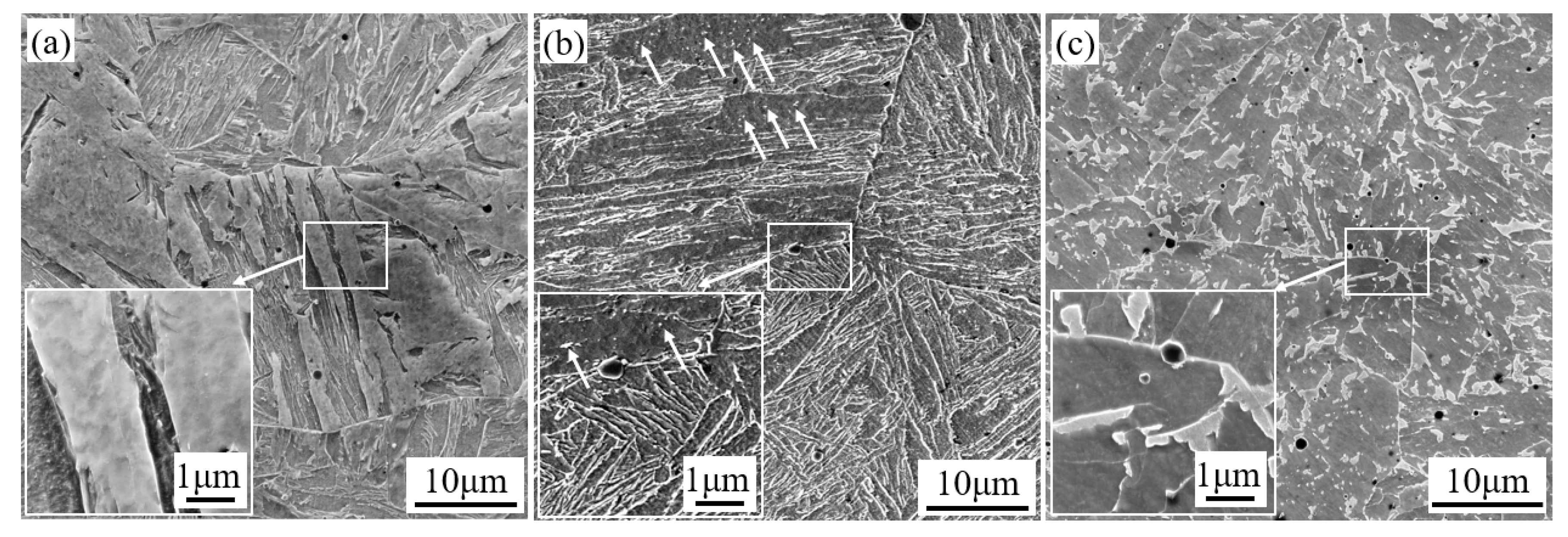

3.1. Morphologic Features

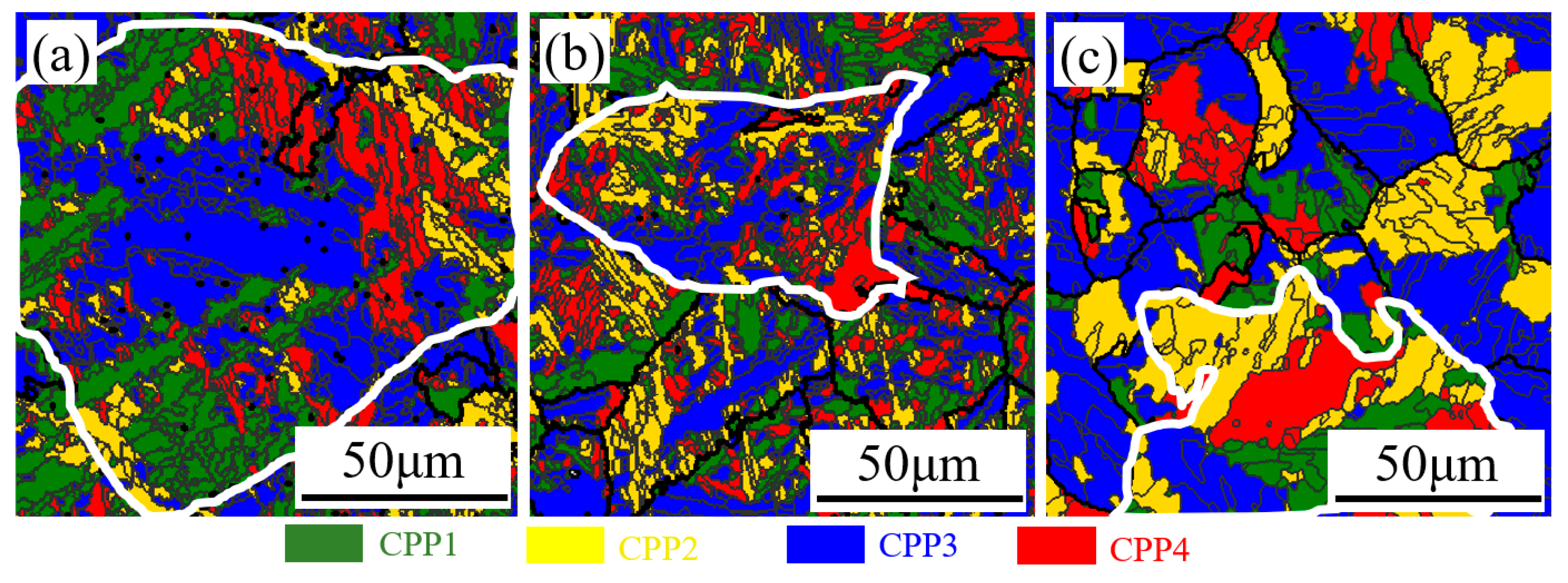

3.2. Crystallographic Features

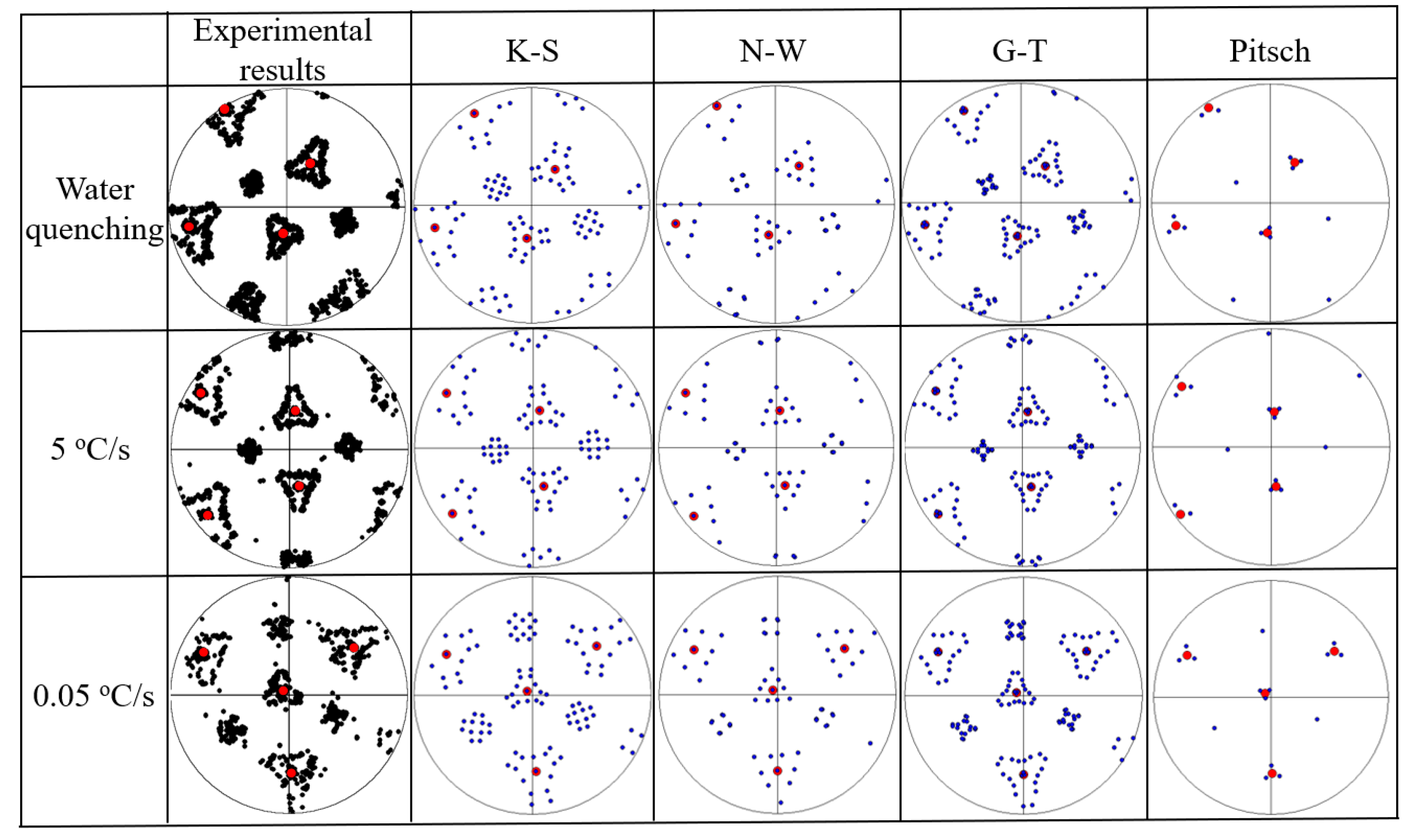

3.3. Orientation Relationships

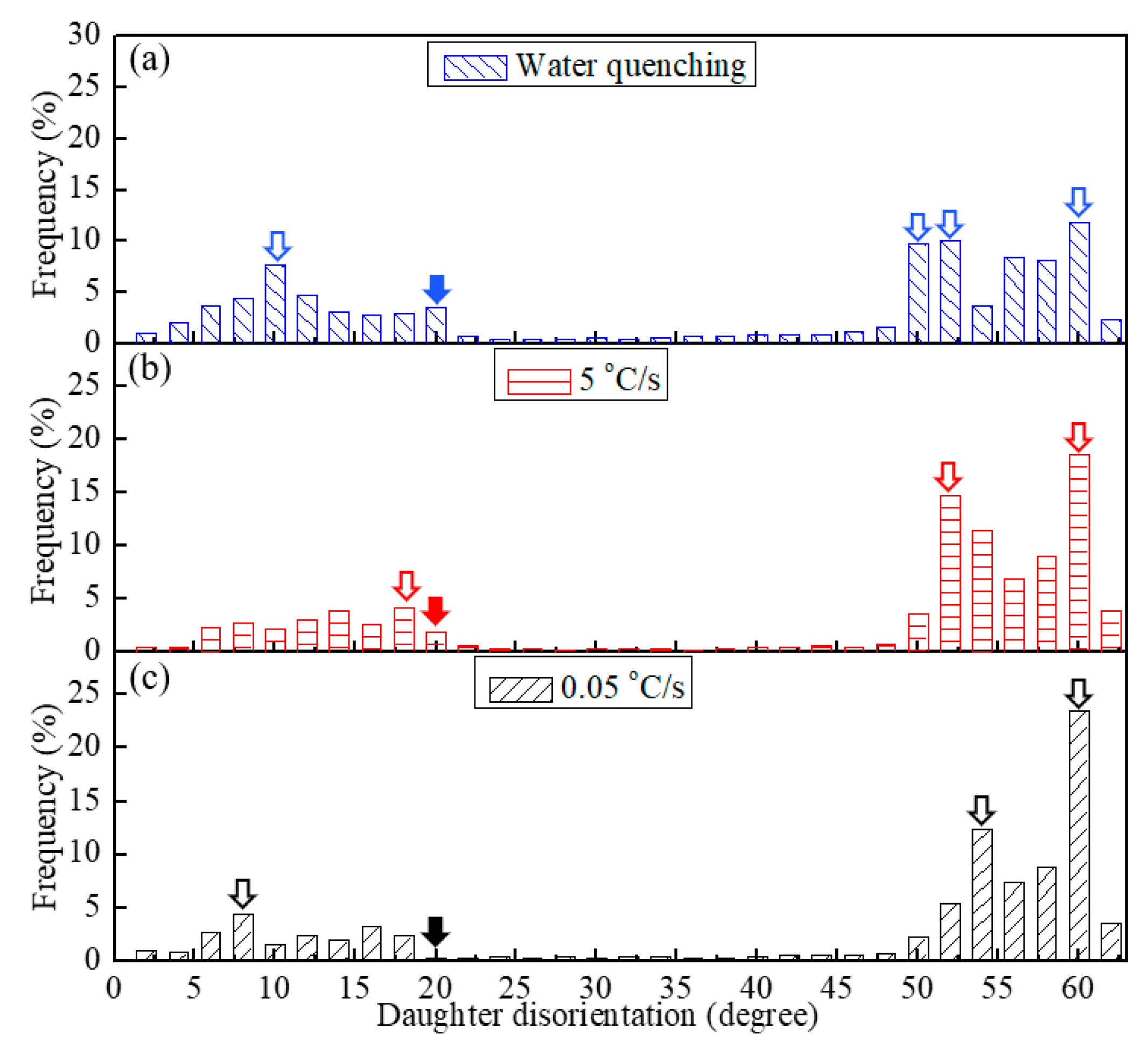

3.4. Boundary Disorienttaion Features

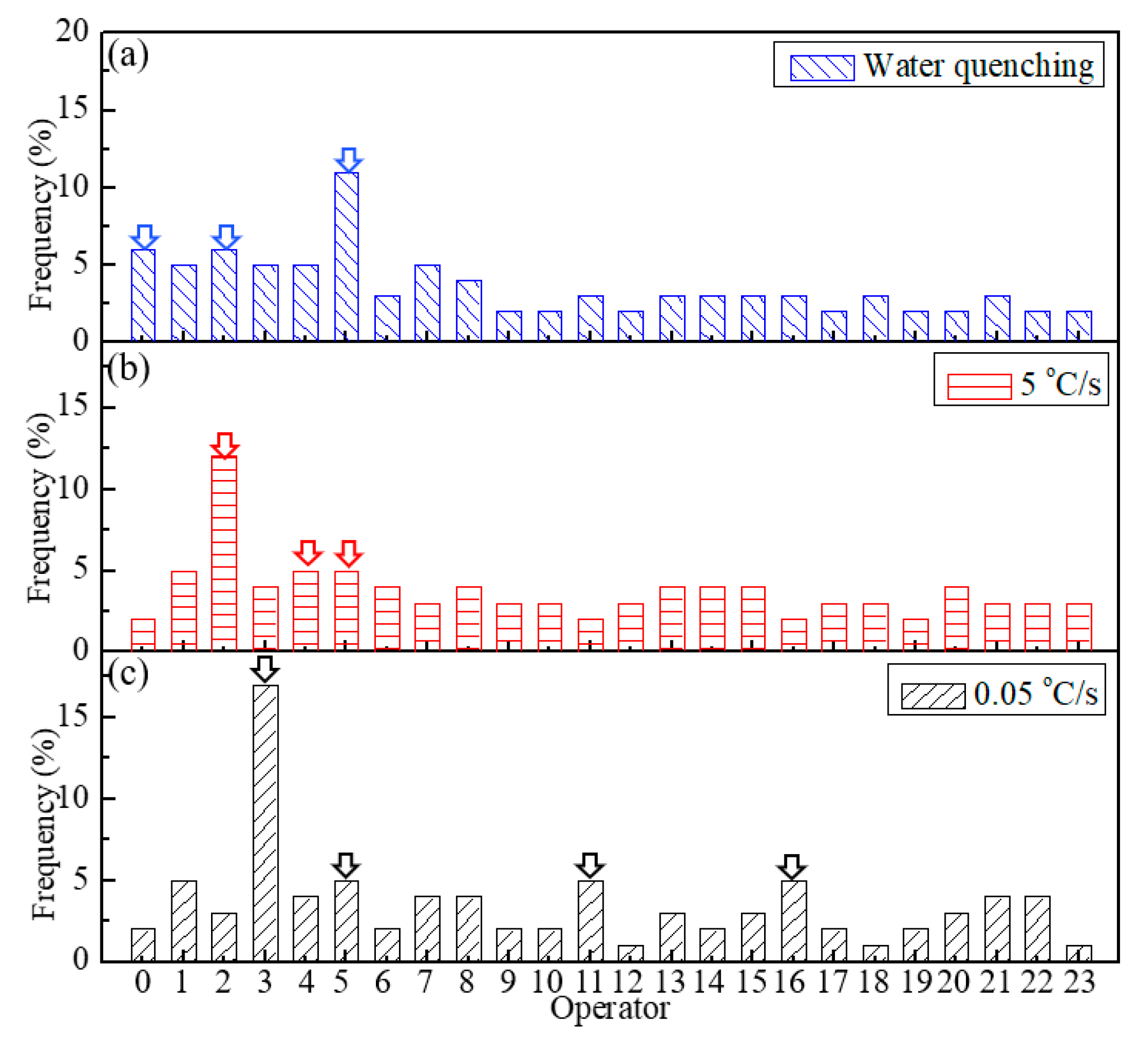

3.5. Operator Distribution Tendency

4. Discussion

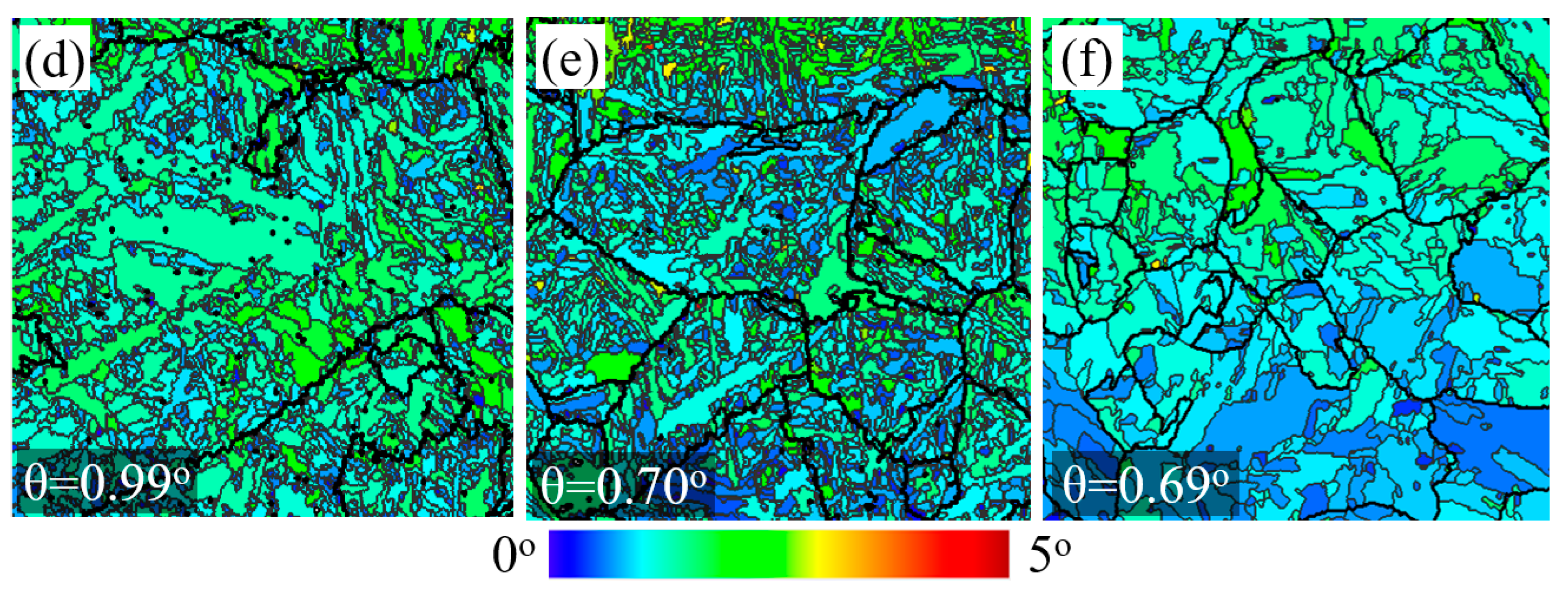

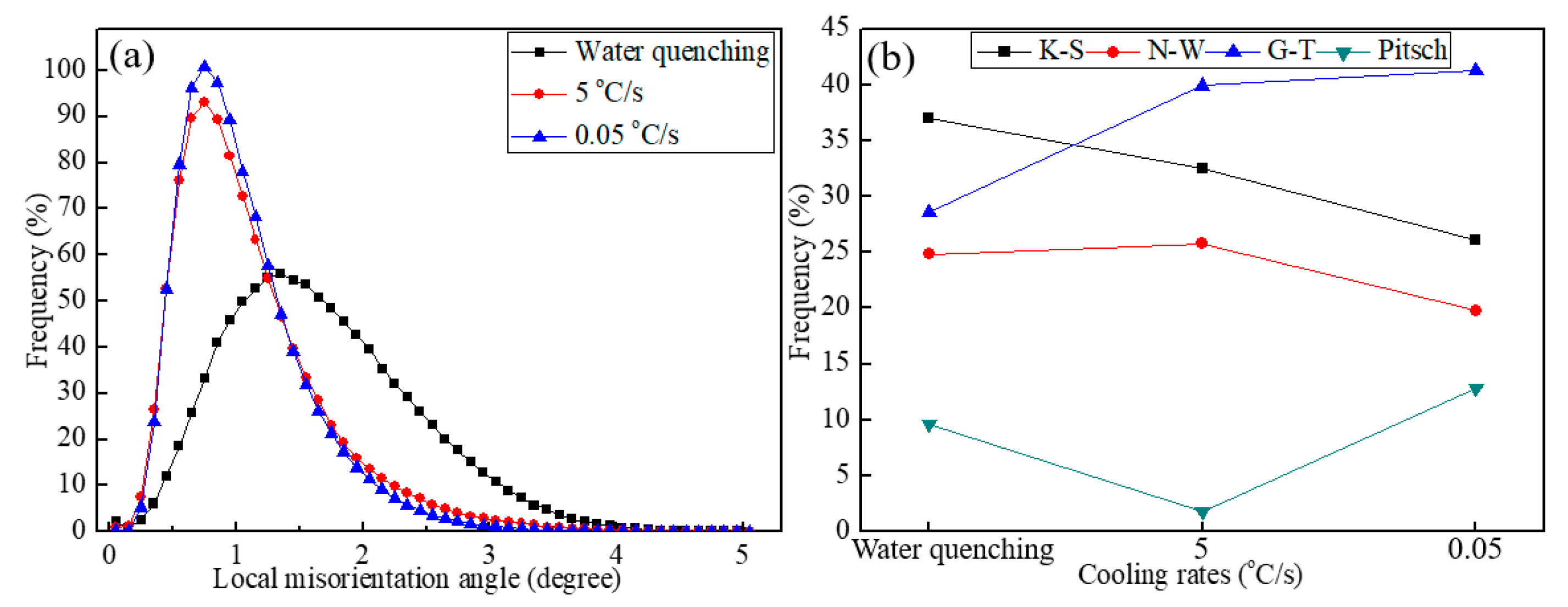

4.1. Determination of Strain Distribution and Dislocation Density

4.2. Determination of Orientation Relationships

4.3. Determination of Boundary Features and Variant Groupings

5. Conclusions

- Both the martensite obtained by water quenching and the bainite obtained at 5 °C/s had lamellar morphologies. Granular bainite is a type of ferrite matrix, on which long stripes of martensite-austenite constituents are dispersed randomly along the grain boundaries or inside the grains.

- The dislocation densities in lath bainite and granular bainite were lower than in lath martensite.

- The K-S OR was the most frequent OR in as-quenched martensite, while G-T OR was predominant in both lath bainite and granular bainite

- More CPP packets were generated at higher cooling rates (LM), while Bain packets were predominant at low cooling rates (LM and GB).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Offerman, S.E.; van Dijk, N.H.; Sietsma, J.; Grigull, S.; Lauridsen, E.M.; Margulies, L.; Poulsen, H.F.; Rekveldt, M.T.; van der Zwaag, S. Grain nucleation and growth during phase transformations. Science 2002, 298, 1003–1005. [Google Scholar] [CrossRef] [PubMed]

- Morris, J. Stronger, tougher steels. Science 2008, 320, 1022–1023. [Google Scholar] [CrossRef] [PubMed]

- Wen, C.F.; Wang, Z.D.; Deng, X.T. Effect of heat input on the microstructure and mechanical properties of low alloy ultra-high strength structural steel welded joint. Steel Res. Int. 2018, 89, 1700500. [Google Scholar] [CrossRef]

- Mao, G.J.; Cao, R.; Cayron, C.; Logé, R.; Guo, X.L.; Jiang, Y.; Chen, J.H. Microstructural evolution and mechanical property development with nickel addition in low-carbon weld butt joints. J. Mater. Process. Technol. 2018, 262, 638–649. [Google Scholar] [CrossRef]

- Navarro-López, A.; Hidalgo, J.; Sietsma, J.; Santofimia, M.J. Characterization of bainitic/martensitic structures formed in isothermal treatments below the Ms temperature. Mater. Character. 2017, 128, 248–256. [Google Scholar] [CrossRef]

- Beladi, H.; Tari, V.; Timokhina, I.B.; Cizek, P.; Rohrer, G.S.; Rollett, A.D.; Hodgson, P.D. On the crystallographic characteristics of nanobainitic steel. Acta Mater. 2017, 127, 426–437. [Google Scholar] [CrossRef]

- Mao, G.J.; Cao, R.; Guo, X.L.; Jiang, Y.; Chen, J.H. In situ observation of kinetic processes of lath bainite nucleation and growth by laser scanning confocal microscope in reheated weld metals. Metall. Mater. Trans. A 2017, 48, 5783–5798. [Google Scholar] [CrossRef]

- Heung, N.H.; Suh, D.W. A model for transformation plasticity during bainite transformation of steel under external stress. Acta Mater. 2003, 51, 4907–4917. [Google Scholar]

- Cayron, C. One-step theory of fcc-bcc martensitic transformation. Acta Crystallogr. A 2013, 69, 498–509. [Google Scholar] [CrossRef]

- Inoue, T.; Matsuda, S.; Okamura, Y.; Aoki, K. The fracture of a low carbon tempered martensite. Trans. Jpn. Inst. Met. 1970, 11, 36–43. [Google Scholar] [CrossRef]

- Bouyne, E.; Flower, H.M.; Lindley, T.C.; Pineau, A. Use of EBSD technique to examine microstructure and cracking in a bainitic steel. Scr. Mater. 1998, 39, 295–300. [Google Scholar] [CrossRef]

- Morito, S.; Huang, X.; Furuhara, T.; Maki, T.; Hansen, N. The morphology and crystallography of lath martensite in alloy steels. Acta Mater. 2006, 54, 5323–5331. [Google Scholar] [CrossRef]

- Lambert-Perladea, A.; Gourgues, A.F.; Pineau, A. Austenite to bainite transformation in heat-affected zone of a high strength low alloy steel. Acta Mater. 2004, 52, 2337–2348. [Google Scholar] [CrossRef]

- Takayamaa, N.; Miyamoto, G.; Furuhara, T. Effects of transformation temperature on variant pairing of bainitic ferrite in low carbon steel. Acta Mater. 2012, 60, 2387–2396. [Google Scholar] [CrossRef]

- Cayron, C. ARPGE: A computer program to automatically reconstruct the parent grains from electron backscatter diffraction data. J. Appl. Crystallogr. 2007, 40, 1183–1188. [Google Scholar] [CrossRef] [PubMed]

- Josefsson, B.; Andren, H.O. Microstructure of granular bainite. J. Phy. Coll. 1988, 49, 293–298. [Google Scholar] [CrossRef]

- Hatherly, M.; Humphreys, F.J. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: New York, NY, USA, 2004. [Google Scholar]

- Miyamoto, G.; Iwata, N.; Takayama, N.; Furuhara, T. Variant selection of lath martensite and bainite transformation in low carbon steel by ausforming. J. Alloy. Compd. 2013, 577, S528–S532. [Google Scholar] [CrossRef]

- Bowles, J.S.; MacKenzie, J.K. The crystallography of martensite transformations I. Acta Metall. 1954, 2, 129–137. [Google Scholar] [CrossRef]

- MacKenzie, J.K.; Bowles, J.S. The crystallography of martensite transformations II. Acta Metall. 1954, 2, 138–147. [Google Scholar] [CrossRef]

- Bowles, J.S.; Kennon, N.F. Crystallographic aspects of the bainite transformation. J. Aust. Inst. Met. 1960, 5, 106–113. [Google Scholar]

- Srinivasan, G.R.; Wayman, C.M. The crystallography of the bainite transformation I. Acta Metall. 1968, 16, 621–636. [Google Scholar] [CrossRef]

- Swallow, E.; Bhadeshia, H.K.D.H. High resolution observations of displacements caused by bainitic transformation. Mater. Sci. Technol. 1996, 12, 121–125. [Google Scholar] [CrossRef]

- Mao, G.J.; Cayron, C.; Cao, R.; Loge, R.; Chen, J.H. The relationship between low-temperature toughness and secondary crack in low-carbon bainitic weld metals. Mater. Character. 2018, 145, 516–526. [Google Scholar] [CrossRef]

- Maki, T.; Wayman, C.M. Substructure of ausformed martensite in Fe-Ni and Fe-Ni-C alloys. Metall. Trans. A 1976, 7, 1511–1518. [Google Scholar] [CrossRef]

- Bate, P.; Hutchinson, B. Effect of elastic interactions between displacive transformations on textures in steels. Acta Mater. 2000, 48, 3183–3192. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Bainite in Steels, 2nd ed.; Institute of Materials: London, UK, 2001. [Google Scholar]

- Kaneshita, T.; Miyamoto, G.; Furuhara, T. Variant selection in grain boundary nucleation of bainite in Fe-2Mn-C alloys. Acta Mater. 2017, 127, 368–378. [Google Scholar] [CrossRef]

- He, S.H.; He, B.B.; Zhu, K.Y.; Huang, M.X. Evolution of dislocation density in bainitic steel: Modeling and experiments. Acta Mater. 2018, 149, 46–56. [Google Scholar] [CrossRef]

- Cornide, J.; Miyamoto, G.; Caballero, F.G.; Furuhara, T.; Miller, M.K.; Garcia-Mateo, C. Distribution of dislocations in nanostructured bainite. Solid State Phenom. 2011, 172–714, 117–122. [Google Scholar] [CrossRef]

- Christian, J. Simple geometry and crystallography applied to ferrous bainites. Metall. Trans. A 1990, 21, 799–803. [Google Scholar] [CrossRef]

- Cayron, C. EBSD imaging of orientation relationships and variant groupings in different martensitic alloys and Widmanstatten iron meteorites. Mater. Character. 2014, 94, 93–110. [Google Scholar] [CrossRef]

- Kelly, P.M.; Jostsons, A.; Blake, R.G. The orientation relationship between lath martensite and austenite in low carbon, low alloy steels. Acta Metall. Mater. 1990, 38, 1075–1081. [Google Scholar] [CrossRef]

- Greninger, A.B.; Troiano, A.R. The mechanism of martensite formation. Met. Trans. 1949, 185, 590–598. [Google Scholar] [CrossRef]

- Zhang, M.X.; Kelly, P.M. Accurate orientation relationship between ferrite and austenite in low carbon martensite and granular bainite. Scr. Mater. 2002, 47, 749–755. [Google Scholar] [CrossRef]

- Morito, S.; Tanaka, H.; Konishi, R. The morphology and crystallography of lath martensite in Fe-C alloys. Acta Mater. 2003, 51, 1789–1799. [Google Scholar] [CrossRef]

- Furuhara, T.; Kawata, H.; Morito, S.; Maki, T. Crystallography of upper bainite in Fe–Ni–C alloys. Mater. Sci. Eng. A 2006, 431, 228–236. [Google Scholar] [CrossRef]

- Abbasi, M.; Nelson, T.W.; Sorensen, C.D. Analysis of variant selection in friction-stir-processed high-strength low-alloy steels. J. Appl. Crystallogr. 2013, 46, 716–725. [Google Scholar] [CrossRef]

| Orientation Relationship | Parallelism | Minimum Angle/Axis |

|---|---|---|

| Kurdjumov-Sachs (K-S) | {111}fcc//{110}bcc <110>fcc//<111>bcc | 42.85°/<0.968 0.178 0.178> |

| Nishiyama–Wassermann (N-W) | {111}fcc //{110}bcc <112> fcc //<110> bcc | 45.98°/<0.976 0.083 0.201> |

| Greninger-Troiano (G-T) | {110}fcc //{111}bcc <123> fcc //<133> bcc | 44.23°/<0.973 0.189 0.133> |

| Pitsch | {100 fcc //{110}bcc <110> fcc //<111> bcc | 45.98°/<0.08 0.2 0.98> |

| Name | Operators Inside the Packets |

|---|---|

| CPP packets | {O0, O1, O2, O4, O5, O7} |

| CPD packets | {O0, O2, O3, O8} |

| Bain packets | {O0, O3, O5, O11, O16, O18, O20, O22} |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, G.; Cayron, C.; Mao, X.; Cao, R.; Logé, R.; Chen, J. Morphological and Crystallographic Characteristics of α Structure in a Low-Carbon Iron–Nickel Alloy. Crystals 2018, 8, 468. https://doi.org/10.3390/cryst8120468

Mao G, Cayron C, Mao X, Cao R, Logé R, Chen J. Morphological and Crystallographic Characteristics of α Structure in a Low-Carbon Iron–Nickel Alloy. Crystals. 2018; 8(12):468. https://doi.org/10.3390/cryst8120468

Chicago/Turabian StyleMao, Gaojun, Cyril Cayron, Xiuli Mao, Rui Cao, Roland Logé, and Jianhong Chen. 2018. "Morphological and Crystallographic Characteristics of α Structure in a Low-Carbon Iron–Nickel Alloy" Crystals 8, no. 12: 468. https://doi.org/10.3390/cryst8120468

APA StyleMao, G., Cayron, C., Mao, X., Cao, R., Logé, R., & Chen, J. (2018). Morphological and Crystallographic Characteristics of α Structure in a Low-Carbon Iron–Nickel Alloy. Crystals, 8(12), 468. https://doi.org/10.3390/cryst8120468